Taylor C803 Parts List

Models C801, C801R, F802, P802, C803, C803R, C804

Wendy's Grills

Operating Instructions

072493-M

5/22/09 (Original Publication)

(Updated 6/5/12)

C801/C801R/F802/P802/C803/C803R/C804 Table of Contents

Table of Contents

Section 1 To the Installer 1............................................

Installer Safety 1........................................................

Electrical Connections 1.................................................

Installation 2...........................................................

Setup and Checkout Instructions 3........................................

Ventilation and Clearance 3..............................................

Grease Disposal Container 3.............................................

Section 2 To the Operator 4...........................................

Section 3 Safety 5....................................................

Section 4 Operator Parts Identification 7...............................

C801 7................................................................

C801 Reverse 8........................................................

F802 Front Unit 9.......................................................

P802 Pick Up Window Unit 10.............................................

C803 11................................................................

C803 Reverse 12........................................................

C804 13................................................................

Accessories - Supplied By T aylor Company 14..............................

Accessories Not Supplied By Taylor Company -

Obtain From Wendy's Small Wares Vendors 15..............................

Section 5 Important: To the Operator 16.................................

C801 16................................................................

C801 Reverse 17........................................................

F802 Front Unit 18.......................................................

P802 Pick Up Window Unit 19.............................................

Table of Contents C801/C801R/F802/P802/C803/C803R/C804

Table of Contents - Page 2

C803 20................................................................

C803 Reverse 21........................................................

C804 22................................................................

Section 6 Operating Procedures 26.....................................

Morning Procedures 26...................................................

Operating Procedures 31.................................................

Cook to Order Mode 33...................................................

Nightly Cleaning Procedures 34............................................

Section 7 Troubleshooting Guide 36....................................

Section 8 Warranty Explanation 40......................................

Parts 40................................................................

Labor 40................................................................

Section 9 Parts List 41.................................................

Wiring Diagrams 56......................................................

Note: Continuing research results in steady improvements; therefore, information

in this manual is subject to change without notice.

Note: Only instructions originating from the factory or its authorized translation

representative(s) are considered to be the original set of instructions.

E May, 2009 Taylor (Original Publication)

(Updated June, 2012)

072493-M

The word Taylor and the Crown design

are registered trademarks in the United States

of America and certain other countries.

Taylor Company

750 N. Blackhawk Blvd.

Rockton, IL 61072

1

C801/C801R/F802/P802/C803/C803R/C804 To the Installer

Section 1 To the Installer

The following are general installation instructions.

For complete installation details, please see the

check out card.

Installer Safety

In all areas of the world, equipment should

be installed in accordance with existing local codes.

Please contact your local authorities if you have any

questions.

Care should be taken to ensure that all basic safety

practices are followed during the installation and

servicing activities related to the installation and

service of Taylor equipment.

S Only Taylor authorized service personnel

should perform installation and repairs on

the equipment.

S Authorized service personnel should consult

OSHA Standard 29CFRI910.147 or the

applicable code of the local area for the

industry standards on lockout/tagout

procedures before beginning any installation

or repairs.

S Authorized service personnel must ensure

that the proper PPE is available and worn

when required during installation and

service.

S Authorized service personnel must remove

all metal jewelry, rings, and watches before

working on electrical equipment.

The main power supply(s) to the equipment

must be disconnected prior to performing any

repairs. Failure to follow this instruction may result in

personal injury or death from electrical shock or

hazardous moving parts as well as poor

performance or damage to the equipment.

Note:Allrepairsmustbeperformedbyan

authorized Taylor Service Technician.

This unit has many sharp edges that can

cause severe injuries.

Electrical Connections

Electrical connections to the grill must be provided

and arranged by Wendy's, with their preferred

licensed electrician. This must be completed

immediately following grill installation and prior to the

grill Start Up and Checkout by the local Taylor

representative.

Check the data plate on the grill for voltage, cycle,

phase and electrical specifications. The power

connections are located behind the access cover of

the control box under the front staging side of the

grill.

In the United States, this equipment is intended to

be installed in accordance with the National

Electrical Code (NEC), ANSI/NFPA 70-1987. The

purpose of the NEC code is the practical

safeguarding of persons and property from hazards

arising from the use of electricity. This code contains

provisions considered necessary for safety.

Compliance therewith and proper maintenance will

result in an installation essentially free from hazard!

In all other areas of the world, equipment should be

installed in accordance with the existing local codes.

Please contact your local authorities.

The Proper Wire Size and Branch Circuit

Overcurrent Device shall be selected according to

the data label information and in accordance with

CEC Part I 2006, Section 14-100(e)(i). Incoming

power must be connected to the line side of the

power contactor.

FOLLOW YOUR LOCAL ELECTRICAL CODES!

2

C801/C801R/F802/P802/C803/C803R/C804To the Installer

CAUTION: THIS EQUIPMENT MUST BE

PROPERLY GROUNDED! FAILURE TO DO SO

CAN RESULT IN SEVERE PERSONAL INJURY

FROM ELECTRICAL SHOCK!

This unit is provided with an equipotential

grounding lug that is to be properly attached to the

rear of the frame by the authorized installer. The

installation location is marked by the equipotential

bonding symbol (5021 of IEC 60417-1) on both the

removable panel and the equipments frame.

S Stationary appliances which are not

equipped with a power cord and a plug or

another device to disconnect the appliance

from the power source must have an all-pole

disconnecting device with a contact gap of

at least 3mm installed in the external

installation.

S Appliances that are permanently connected

to fixed wiring and for which leakage

currents may exceed 10 mA, particularly

when disconnected or not used for long

periods, or during initial installation, shall

have protective devices such as a GFI, to

protect against the leakage of current,

installed by the authorized personnel to the

local codes.

S Supply cords used with this unit shall be

oil-resistant, sheathed flexible cable not

lighter than ordinary polychloroprene or

other equivalent synthetic

elastomer-sheathed cord (Code designation

60245 IEC 57) installed with the proper cord

anchorage to relieve conductors from strain,

including twisting, at the terminals and

protect the insulation of the conductors from

abrasion.

Installation

These machines are designed for indoor use

only.

The C801 grill and the C801 Reverse grill must be

lifted and positioned in place with the aid of a lift

device. They are suspended between the adjacent

sandwich counter and the meat well.

The F802,C803, C803 Reverse, and C804 grills are

mounted on carts. They are wheeled into position in

the store.

The P802 grill is installed into the sandwich counter.

The items to be installed / connected by the

distributor include:

S Node board modules

S Lane dividers

S Miscellaneous accessory brackets

DO NOT installthemachineinanarea

where a water jet could be used to clean or rinse the

machine. Failure to follow this instruction may result

in serious electrical shock.

This grill must be installed on a level

surface. Failure to comply may result in personal

injury or equipment damage.

3

C801/C801R/F802/P802/C803/C803R/C804 To the Installer

Setup and Checkout Instructions

Step 1

Install the panels, starting with the bottom. Install the

panels under the node board modules, the lane

dividers (staging side) and the accessory brackets.

Step 2

Install the node board modules.

Step 3

Tighten all screws.

Step 4

Once the electrical connections are completed,

install the box cover and turn the grill on.

Step 5

Wait for 45 minutes for the grill to reach stable

temperatures before proceeding to the next step.

The grill will indicate it is ready to cook in

approximately 15 - 20 minutes.

CAUTION: The grill will be hot. Wear

proper protective equipment to avoid severe burns

from high temperatures.

Step 6

Check the platen lift mechanism and adjust, if

needed (not applicable to P802). (See Lift/Latch

Instructions in the Service Manual.)

Step 7

Install the back panel.

Step 8

The platen should be lowered onto the lower plate

and the gap settings should be properly calibrated.

To close the platen, touch and hold the red button

corresponding to the desired platen. A cook cycle

will not start and the display will read “Standby”.

Release the button after the platen has closed. (See

Platen Gapping Procedures in the Service

Manual.)

Step 9

Once the gaps are set, install the cook side back

splash, lane divider, and the release sheets.

Step 10

Cook one run of product on each platen to check the

product appearance and the finished product

temperature. (Internal temperature must be above

175°F / 79°C.)

Step 11

Check the “cook to order” and back up staging.

Step 12

Fill out the checkout card and the work order /

invoice.

Ventilation and Clearance

To ensure proper operation of this appliance, it must

be installed so that the products of combustion are

efficiently removed.

After set up, do not store anything on top of

the grill. Failure to follow this instruction may result

in a fire hazard.

Grease Disposal Container

In order to comply with NSF Standard 4

requirements, an appropriate grease disposal

container must be provided. This container is

supplied by the KES, not the Taylor Company.

4

C801/C801R/F802/P802/C803/C803R/C804To the Operator

Section 2 To the Operator

The grill you have purchased has been carefully

engineered and manufactured to provide

dependable operation.

This grill, when properly operated and maintained,

will produce a consistent quality product. Like all

mechanical products, they require cleaning and

maintenance. A minimum amount of care and

attention is necessary if the operating procedures in

this manual are followed closely.

This Operator's Manual should be read before

operating or performing any maintenance on your

equipment.

It is strongly recommended that all personnel

responsible for the equipment's operation and

cleaning, review these procedures for proper training

and assurance that no misunderstandings exist.

In the event that you require technical assistance,

please call 877-222-7010 for authorized service.

Note: Warranty is valid only if the parts are

authorized Taylor parts, purchased from an

authorized Taylor Distributor, and the required

service work is provided by an authorized Taylor

service technician. Taylor reserves the right to deny

warranty claims on equipment or parts if

non-approved parts or refrigerant were installed in

the machine, system modifications were performed

beyond factory recommendations, or it is determined

that the failure was caused by neglect or abuse.

Note: Constant research results in steady

improvements; therefore, information in this

manual is subject to change without notice.

If the crossed out wheeled bin symbol is

affixed to this product, it signifies that this product is

compliant with the EU Directive as well as other

similar legislation in effect after August 13, 2005.

Therefore, it must be collected separately after its

use is completed, and cannot be disposed as

unsorted municipal waste.

The user is responsible for returning the product to

the appropriate collection facility, as specified by

your local code.

For additional information regarding applicable local

laws, please contact the municipal facility and/or

local distributor.

5

C801/C801R/F802/P802/C803/C803R/C804 Safety

120605

Section 3 Safety

We at Taylor Company are deeply concerned about

the safety of the operator when he or she comes in

contact with the grill and its parts. Taylor has gone

to extreme efforts to design and manufacture built-in

safety features to protect both you and the service

technician. As an example, warning labels have

been attached to the grill to further point out safety

precautions to the operator.

Please call 877-222-7010 for authorized service.

To Operate Safely:

DO NOT operate the grill without reading

this operator's manual. This manual should be kept

in a safe place for future reference.

Per IEC 60335-1 and its part 2 standards,

“This appliance is to be used only by trained

personnel. It is not intended for use by children or

people with reduced physical, sensory, or mental

capabilities, or lack of experience and knowledge,

unless given supervision or instruction concerning

the use of the appliance by a person responsible for

their safety.”

Failure to follow the instructions below may

result in severe injury or death from electrocution:

S DO NOT operate the grill unless it is

properly grounded.

S DO NOT attempt any repairs unless the

power supply to the grill has been

disconnected (must be performed by an

authorized service technician).

S DO NOT operate the grill unless all service

panels are restrained with screws.

S Stationary appliances which are not

equipped with a power cord and a plug or

other device to disconnect the appliance

from the power source must have an all-pole

disconnecting device with a contact gap of

at least 3 mm installed in the external

installation.

S Appliances that are permanently connected

to fixed wiring and for which leakage

currents may exceed 10 mA, particularly

when disconnected or not used for long

periods, or during initial installation, shall

have protective devices such as a GFI, to

protect against the leakage of current,

installed by the authorized personnel to the

local codes.

S Supply cords used with this unit shall be

oil-resistant, sheathed flexible cable not

lighter than ordinary polychloroprene or

other equivalent synthetic

elastomer-sheathed cord, (Code designation

60245 IEC 57), installed with the proper

cord anchorage to relieve conductors from

strain, including twisting, at the terminals

and protect the insulation of the conductors

from abrasion.

IMPORTANT: DO NOT use a water jet or

spray excessive water on or anywhere near the

grill. Failure to follow this instruction may result in

serious electrical shock and cause permanent

electrical and mechanical damage to internal parts.

Failure to follow this instruction may result in:

S serious electrical shock

S burns from hot steam

S liquid collecting inside the grill and

destroying electrical components.

6

C801/C801R/F802/P802/C803/C803R/C804Safety

DO NOT use cold water or ice to cool the

upper cook surface, the lower cook surface, or the

staging grill plate. Failure to follow this instruction

may result in:

S serious electrical shock

S burns from hot steam

S liquid collecting inside the grill and

destroying electrical components.

Failure to follow the instructions below may

result in severe burns from high temperatures:

S DO NOT prepare or remove product without

proper equipment.

S DO NOT allow untrained personnel to

operate this grill.

S USE EXTREME CAUTION when cleaning

the grill.

Appropriate grill clearance must be

maintained from all combustible materials. Failure to

comply could result in a fire hazard.

Take caution to protect eyes, lungs, and all

parts of the body from potential harm when using

any chemical cleaner. Failure to follow this

instruction may result in a chemical burn.

DO NOT use any abrasives or cleaners

other than approved food service cleaners and

degreasers. Failure to comply may cause illness to

the consumer and may also damage grill surfaces.

This grill must be installed on a level

surface. Failure to comply may result in personal

injury or equipment damage.

NOISE LEVEL: Airborne noise emission does not

exceed 70 dB(A) when measured at a distance of

1.0 meter from the surface of the machine and at a

height of 1.6 meters from the floor.

7

C801/C801R/F802/P802/C803/C803R/C804 Operator Parts Identification

Section 4 Operator Parts Identification

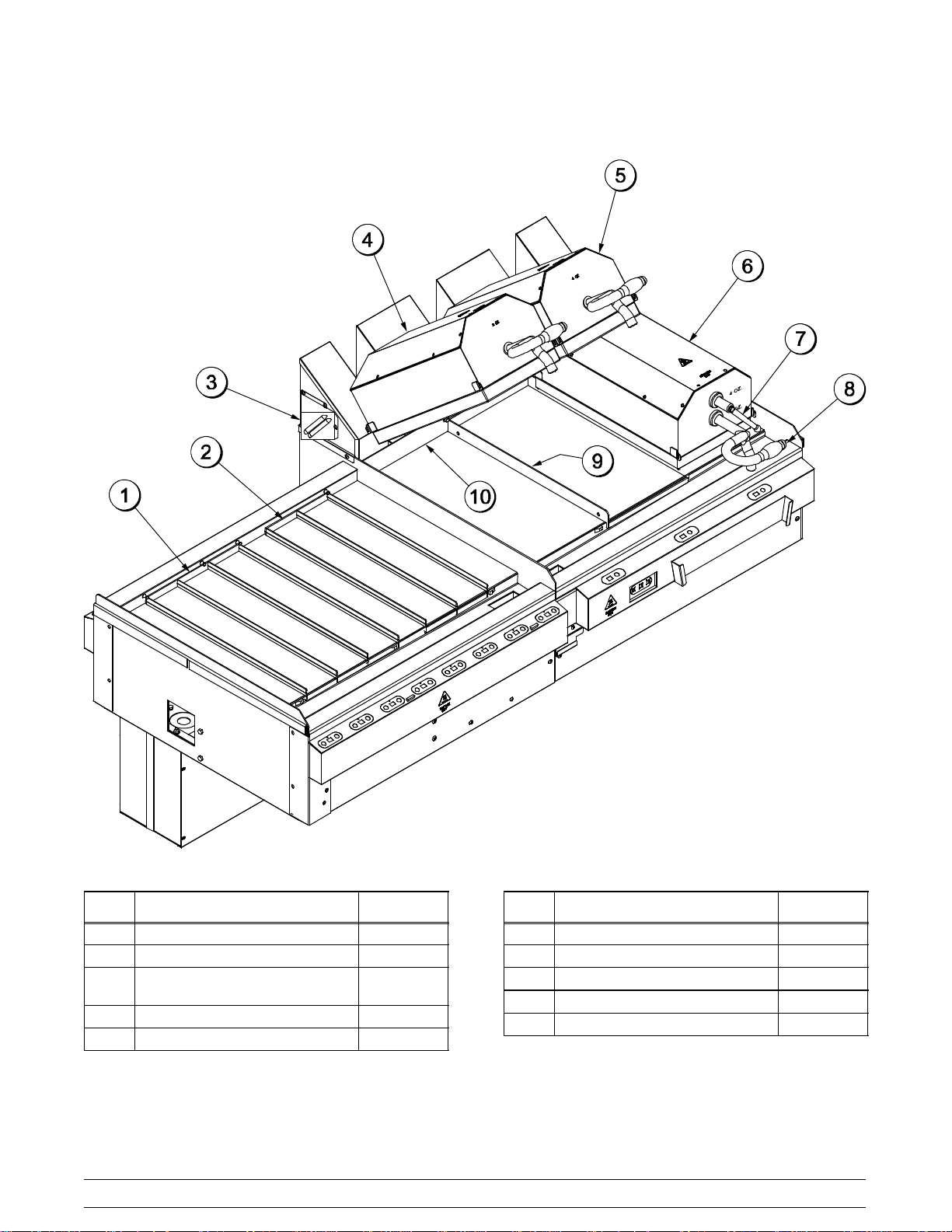

C801

Figure 1

ITEM DESCRIPTION PART NO.

1 HANDLE-ADJUST-PLATEN 070647

2 PLATEN A.-ADJUSTABLE X71825-23

3 HANDLE-LIFT-PLATEN 072711

4 PLATEN A.-4OZ X71824-23

5 PLATEN A.-2OZ X71823-23

ITEM DESCRIPTION PART NO.

6 PANEL A.-SPLASH SHLD W/SP X70783

7 DIVIDER A.-2 LANE 070847

8 DIVIDER A.-3 LANE *STAGE 070848

9 SHIELD-BACKSPLASH 070765

10 DIVIDER A.-COOK 070851

8

C801/C801R/F802/P802/C803/C803R/C804Operator Parts Identification

C801 Reverse

Figure 2

ITEM DESCRIPTION PART NO.

1 DIVIDER A.-3 LANE *STAGE 070848

2 DIVIDER A.-*2 LANE*STAGE 070847

3 PANEL A.-SPLASH SHIELD

W/SPEAKER

X72247

4 PLATEN A.-*C801*2 OZ SERV X71823-23

5 PLATEN A.-*C801* 4 OZ X71824-23

ITEM DESCRIPTION PART NO.

6 PLATEN A.-ADJUSTABLE SERV X71825-23

7 HANDLE-ADJUST-PLATEN 070647

8 HANDLE-LIFT-PLATEN 072711

9 DIVIDER A.-COOK 070851

10 SHIELD-BACKSPLASH 070765

9

C801/C801R/F802/P802/C803/C803R/C804 Operator Parts Identification

F802 Front Unit

Figure 3

ITEM DESCRIPTION PART NO.

1 DIVIDER A.-2 LANE 070847

2 HANDLE-LIFT-PLATEN 072711

3 HANDLE-ADJUST-PLATEN 070647

4 PLATEN A.-SERVICEADJ LEFT X72669-23

ITEM DESCRIPTION PART NO.

5 PLATEN A.-SERVICEADJ X71825-23

6 SHIELD-BACKSPLASH 071732

7 DIVIDER A.-COOK 070851

10

C801/C801R/F802/P802/C803/C803R/C804Operator Parts Identification

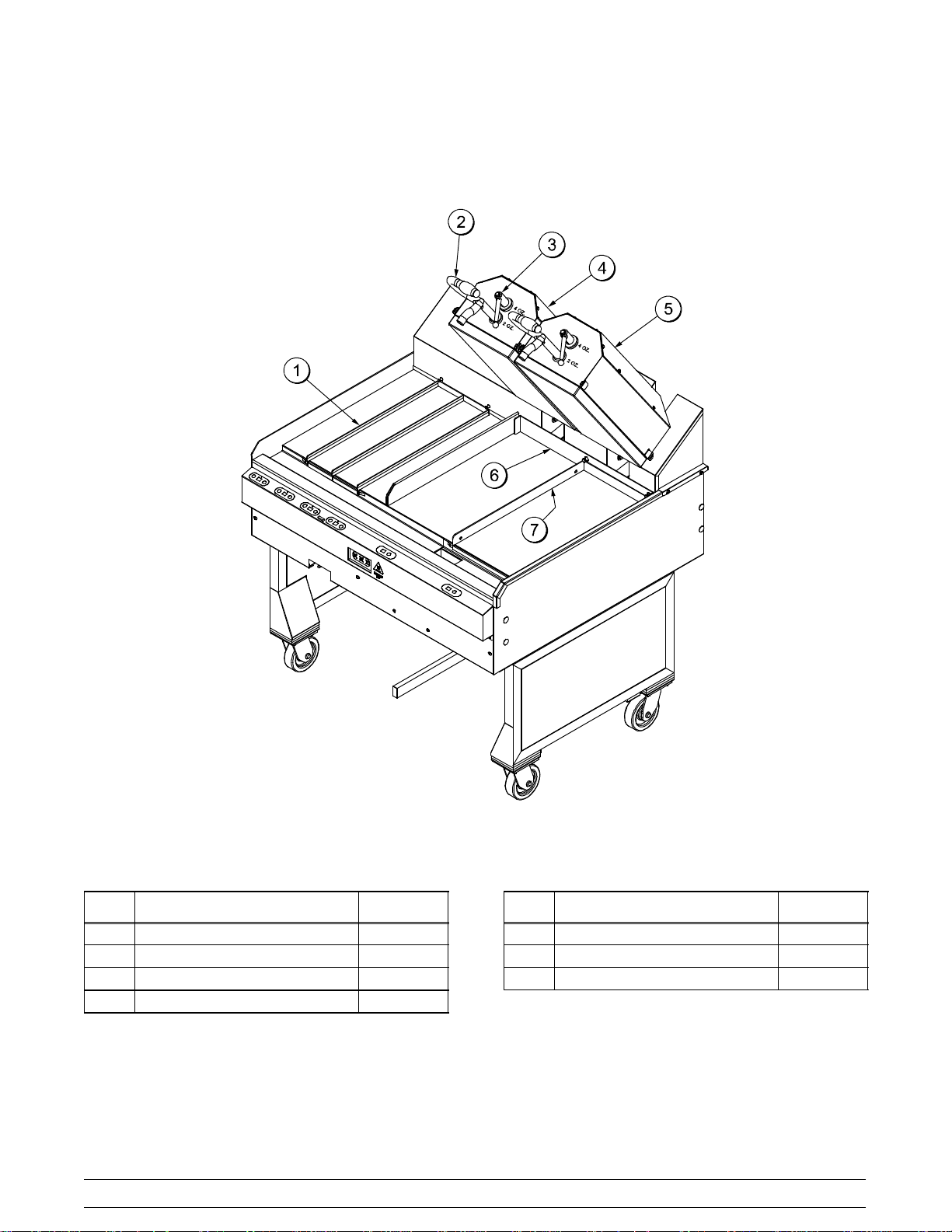

P802 Pick Up Window Unit

Figure 4

ITEM DESCRIPTION PART NO.

1 DIVIDER A.-*2 LANE 070847

11

C801/C801R/F802/P802/C803/C803R/C804 Operator Parts Identification

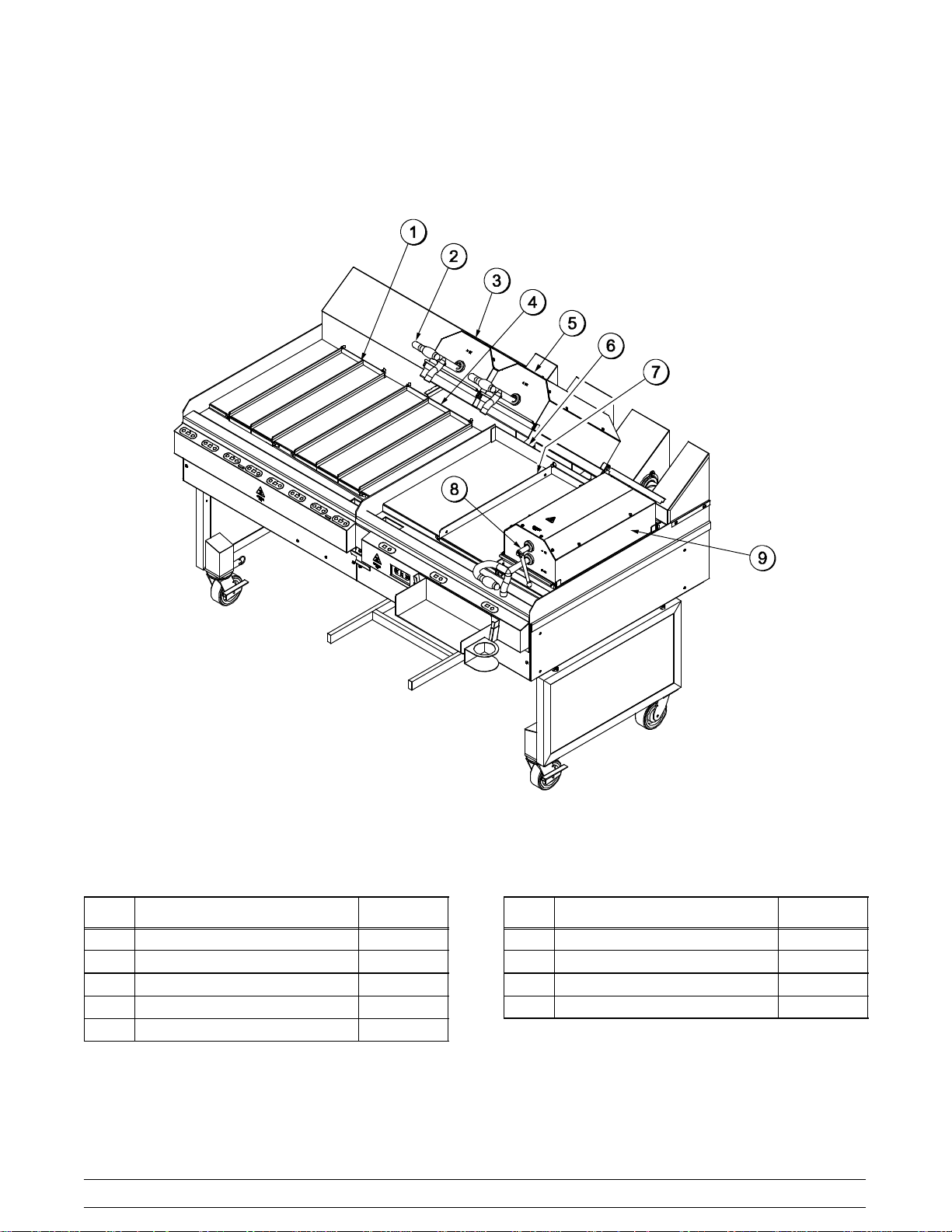

C803

Figure 5

ITEM DESCRIPTION PART NO.

1 HANDLE-LIFT-PLATEN 072711

2 HANDLE-ADJUST-PLATEN 070647

3 PLATEN A.-ADJUSTABLE SERV X71825-23

4 PLATEN A.-*C801*4 OZ SERV X71824-23

5 PLATEN A.-*C801*2 OZ SERV X71823-23

ITEM DESCRIPTION PART NO.

6 SHIELD-BACKSPLASH 070765

7 DIVIDER A.-COOK 070851

8 DIVIDER A.-2 LANE STAGE 070847

9 DIVIDER A.-3 LANE STAGE 070848

12

C801/C801R/F802/P802/C803/C803R/C804Operator Parts Identification

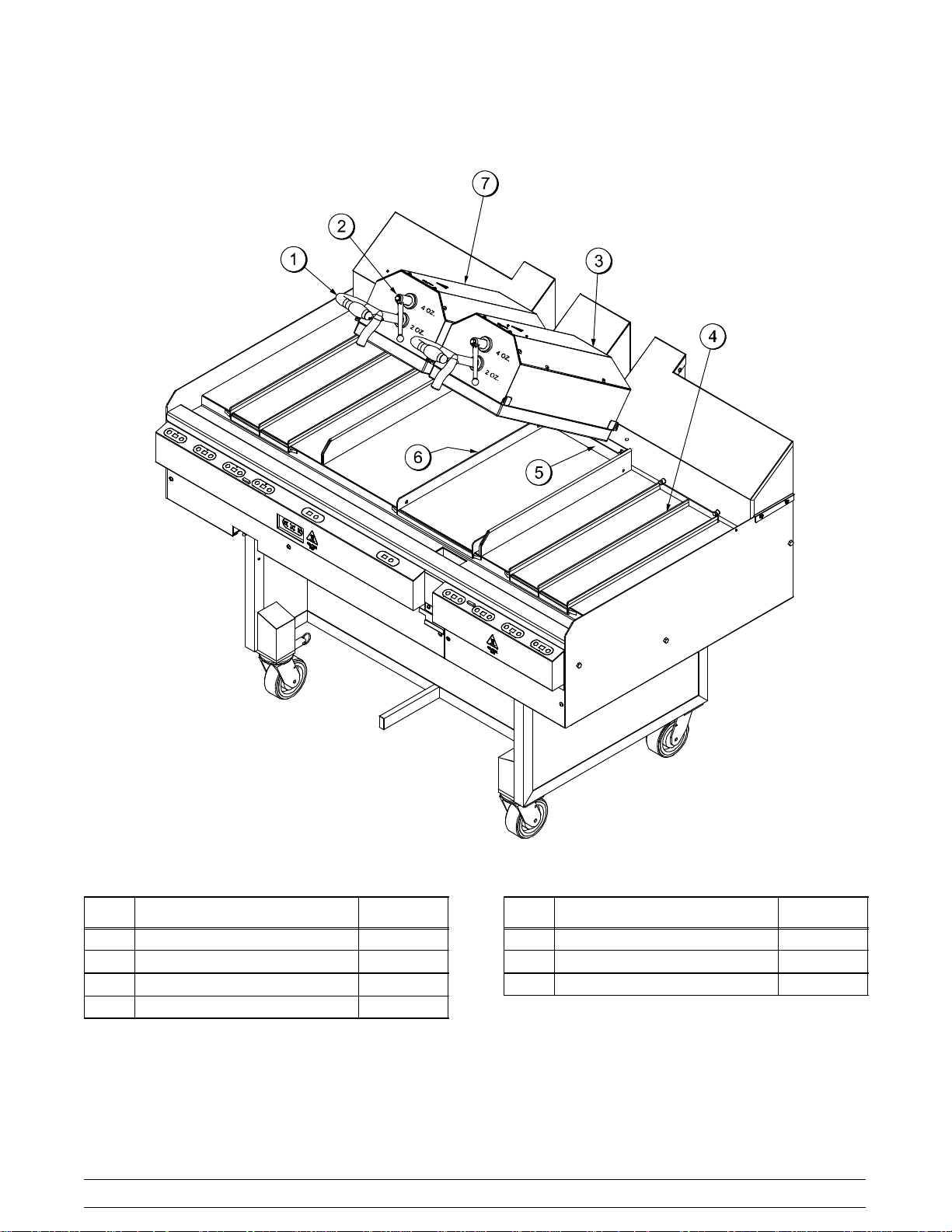

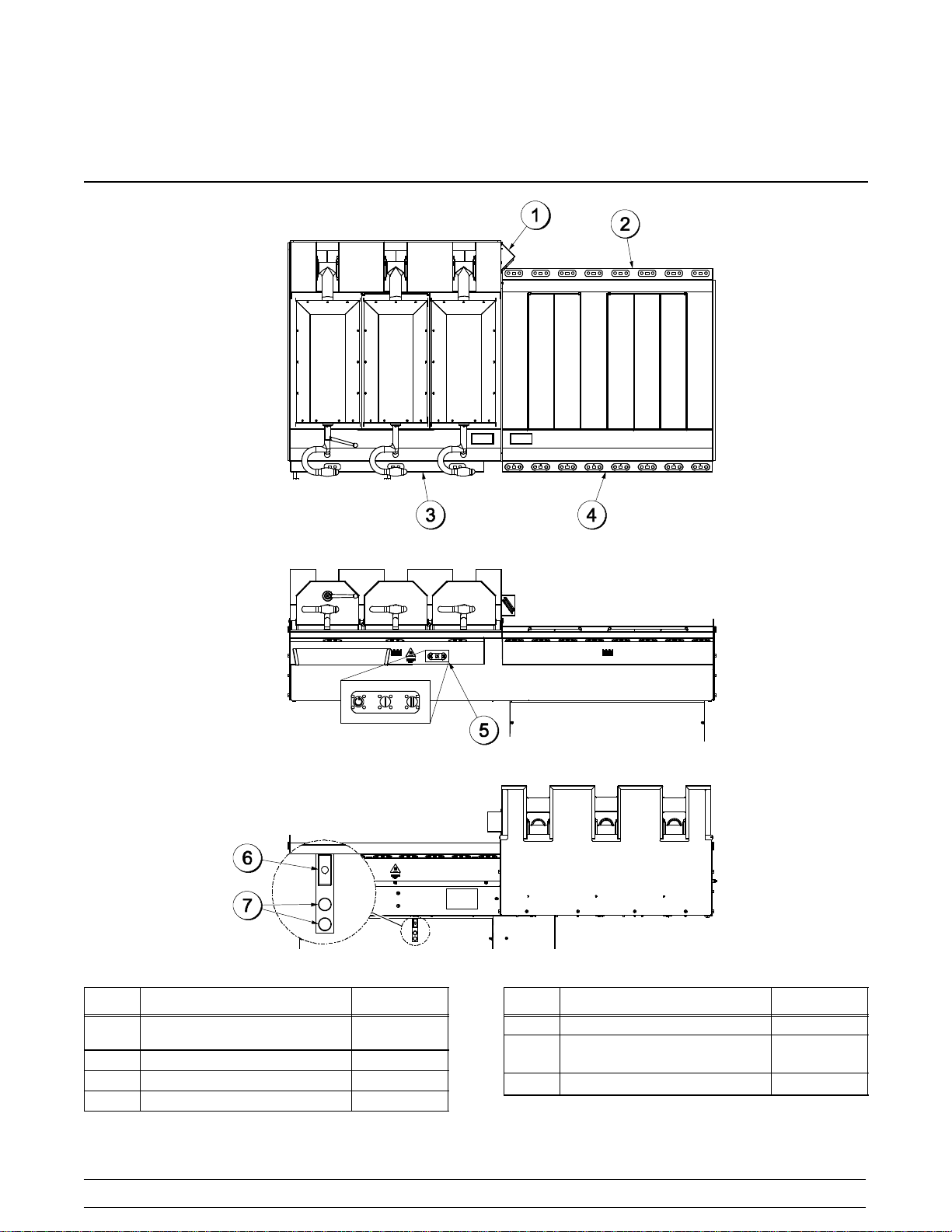

C803 Reverse

Figure 6

ITEM DESCRIPTION PART NO.

1 DIVIDER A.-2 LANE 070847

2 HANDLE-LIFT-PLATEN 072711

3 PLATEN A.-2 OZ X71823-23

4 DIVIDER A.-3 LANE STAGE 070848

5 PLATEN A.-4 OZ X71824-23

ITEM DESCRIPTION PART NO.

6 SHIELD-BACKSPLASH 070765

7 DIVIDER A.-COOK 070851

8 HANDLE-ADJUST-PLATEN 070647

9 PLATEN A.-ADJUSTABLE X71825-23

13

C801/C801R/F802/P802/C803/C803R/C804 Operator Parts Identification

C804

Figure 7

ITEM DESCRIPTION PART NO.

1 HANDLE-LIFT-PLATEN 072711

2 HANDLE-ADJUST-PLATEN 070647

3 PLATEN A.-SERVICE ADJ X71825-23

4 DIVIDER A.-2 LANE 070847

ITEM DESCRIPTION PART NO.

5 SHIELD-BACK SPLASH 071732

6 DIVIDER A.-COOK 070851

7 PLATEN A.-SERVICE ADJ LEFT X72669-23

14

C801/C801R/F802/P802/C803/C803R/C804Operator Parts Identification

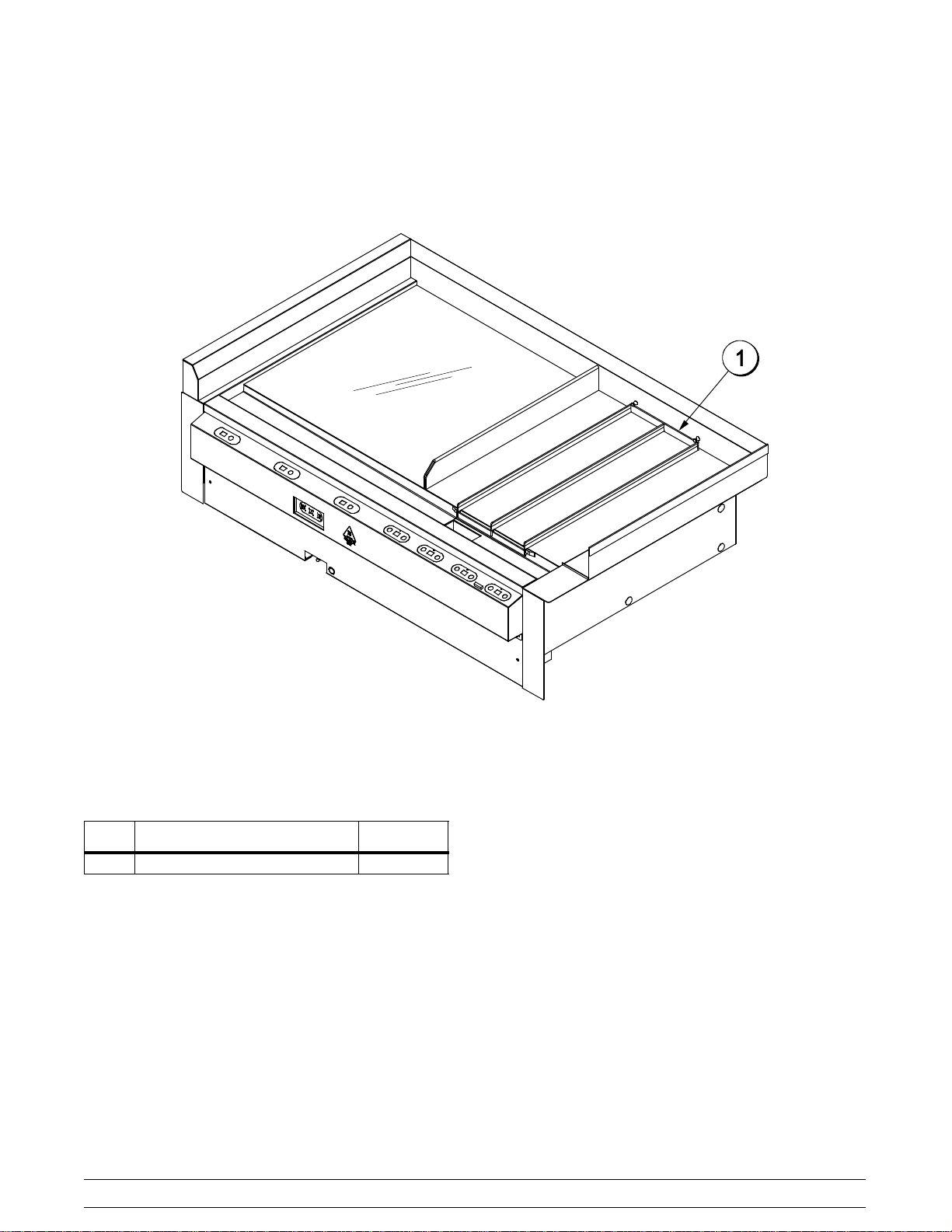

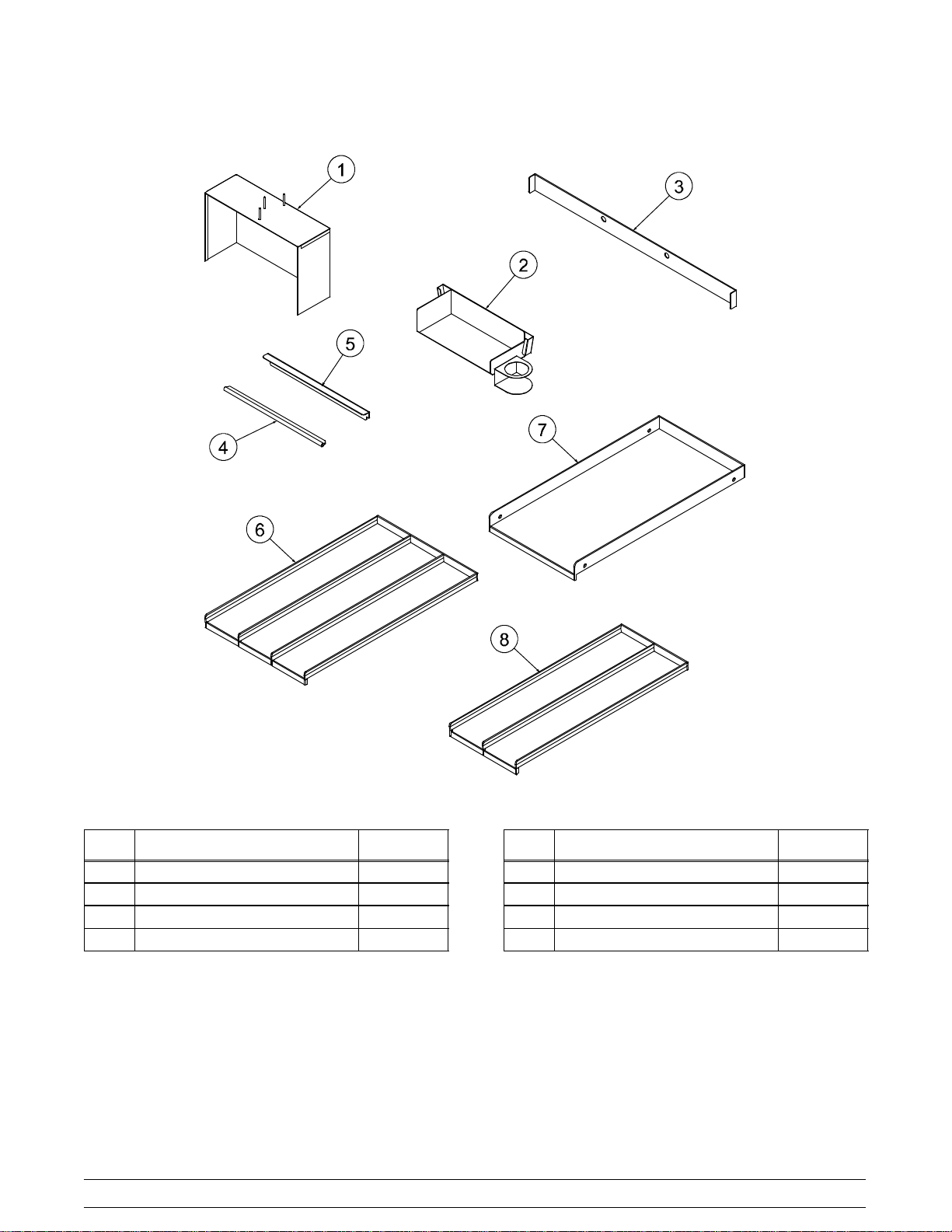

Accessories - Supplied By Taylor Company

Figure 8

ITEM DESCRIPTION PART NO.

1 SHIELDA.-LOCATING BUCKET X71284

2 SHELF A.-MEAT LOADING X70944

3 SHIELD-BACKSPLASH 070765

4 CLIP-RELEASE SHEET 070709

ITEM DESCRIPTION PART NO.

5 BRACKET-RELEASESHEET 070707

6 DIVIDER A.-3 LANE *STAGE 070848

7 DIVIDER A. *COOK 070851

8 DIVIDER A. *2 LANE 070847

15

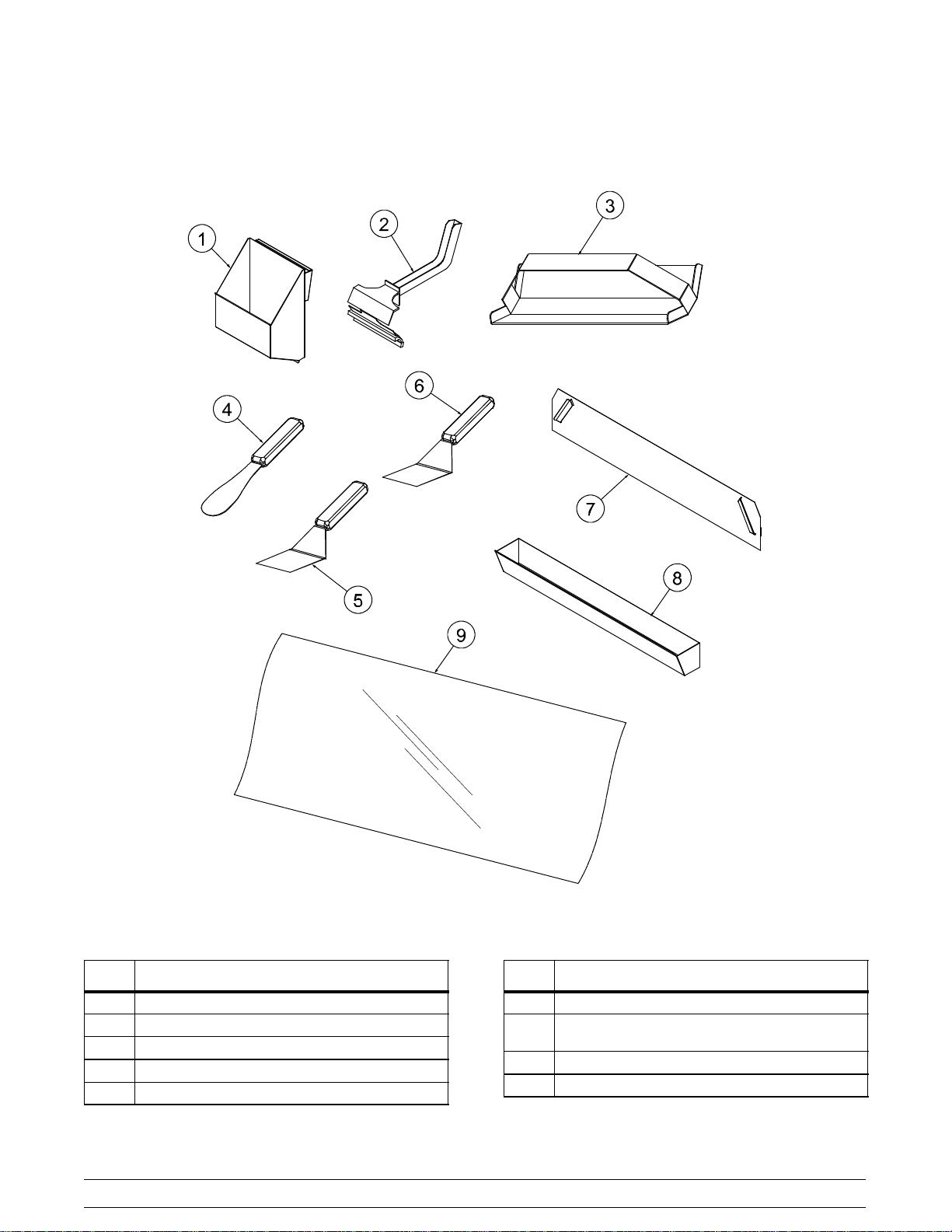

C801/C801R/F802/P802/C803/C803R/C804 Operator Parts Identification

Accessories Not Supplied By Taylor Company -

Obtain From Wendy's Small Wares Vendors

Figure 9

ITEM DESCRIPTION

1 HOLDER-SQUEEGEE

2 HANDLE-SQUEEZE

3 TOOL-TRANSFER

4 SPATULA-REDHANDLE-SERRATED

5 SPATULA-REDHANDLE-SERVING

ITEM DESCRIPTION

6 SPATULA-WHITE HANDLE-SERVING

7 HOLDER-WHITE HANDLED SERVING

SPATULA

8 TROUGH

9 SHEET-RELEASE

16

C801/C801R/F802/P802/C803/C803R/C804Important: To the Operator

Section 5 Important: To the Operator

C801

Figure 10

ITEM DESCRIPTION PART NO.

1 PANEL A.-SPLASH SHIELD

W/SPEAKER

X70783

2 KIT A.-NODE-REAR W/HARN X72136

3 KIT A.-NODE-COOK W/HARN X72134

4 KIT A.-NODE-FRONT W/HARN X72135

ITEM DESCRIPTION PART NO.

5 CONTROL-C801 NODE I/O 071242-SER

6 CONTROL-RESET SWITCH

10A/230

070717

7 LIGHT-RED 230V 070880-27

17

C801/C801R/F802/P802/C803/C803R/C804 Important: To the Operator

C801 Reverse

Figure 11

ITEM DESCRIPTION PART NO.

1 KIT A.-NODE REAR C801

W/HARN

X72136

2 PANEL A.-SPLASH SHIELD

W/SPEAKER

X72247

3 CONTROL-RESET SWITCH

10A/250

070717

4 LIGHT-RED 230V 070880-27

ITEM DESCRIPTION PART NO.

5 NODE A.-COMPLETE C801R

COOK

X72254

6 NODE A.-COMPLETE C801R

STG F

X72243

7 CONTROL C801 MODEI/O 071242-SER

Loading...

Loading...