Taylor C602 User Manual

MILKSHAKE AND SOFT-SERVE MACHINES |

SS 3 |

|

Taylor Company

Milkshake and Soft-serve Machine

Model C602

Daily maintenance tasks

SS 3 D1 |

Opening |

|

procedures |

SS 3 D2 |

Closing procedures |

Weekly maintenance tasks

SS 3 W1 Clean and sanitize syrup lines with duckbill valves

SS 3 W2 Clean hot sundae topping water baths

SS 3 W3 Clean and sanitize hot sundae topping pumps

Bi-weekly maintenance tasks

SS 3 B1 14 day brush cleaning

Monthly maintenance tasks

SS 3 M1 |

Calibrate hopper |

|

|

|

temperatures |

SS 3 M2 |

Calibrate draw |

|

|

|

temperatures |

SS 3 |

M3 |

Calibrate hot |

|

|

sundae topping |

|

|

temperatures and |

|

|

volumes |

Quarterly maintenance tasks |

||

SS 3 |

Q1 |

Replace soft-serve |

|

|

mix scraper blades |

SS 3 |

Q2 |

Clean non- |

|

|

aluminum air filter |

SS 3 |

Q3 |

Replace machine |

|

|

components |

Semi-annual maintenance tasks

SS 3 S1 Replace milkshake mix scraper blades

Annual maintenance tasks

SS 3 A1 |

Replace syrup |

|

pump tubes |

SS 3 A2 |

Replace non- |

|

aluminum air filter |

Model C602

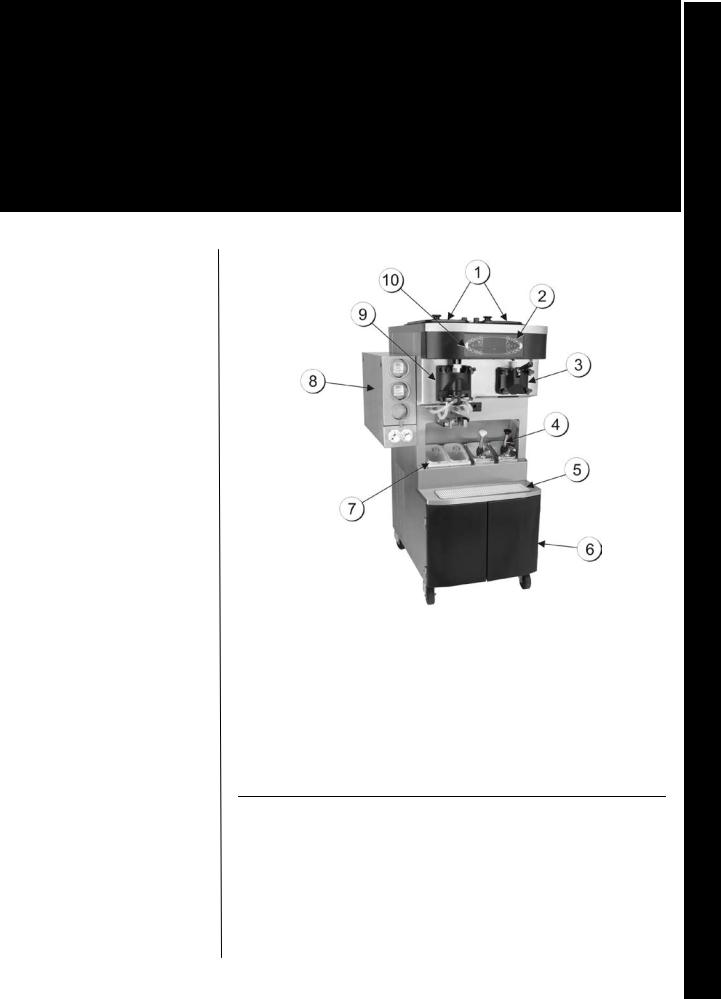

1. |

Hopper Covers |

6. |

Cabinet Doors |

2. |

Keypad-Soft Serve |

7. |

Cold Topping Containers |

3. |

Soft Serve Door Assembly |

8. |

Cup & Cone Dispenser |

4. |

Topping Pump |

9. |

Shake Door Assembly |

5. |

Drip Tray/Splash Shield |

10. |

Keypad-Shake |

Hazards

Hazards

These icons alert you to a possible risk of personal injury.

Equipment alerts

Equipment alerts

Look for this icon to find information about how to avoid damaging the equipment while doing a procedure.

Tips

Tips

Look for this icon to find helpful tips about how to do a procedure.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021

<![endif]>C602 model machine serve-soft and milkshake Company Taylor

<![if ! IE]><![endif]>3 SS

|

Opening Procedures |

|

|

|

Daily |

|

|

|

SS 3 D1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Why |

Prepare Milkshake/Soft-Serve machine for serving |

|

|

|

|

|||||

|

Time required |

product after the heat treatment cycle is completed |

|

|

|

|

|||||

|

5 minutes to prepare |

30 minutes to complete |

|

|

|

|

|||||

|

Time of day |

When store opens in the morning |

24-hour restaurants: during low-volume periods |

||||||||

|

Hazard icons |

|

|

|

|

|

|

|

|

|

|

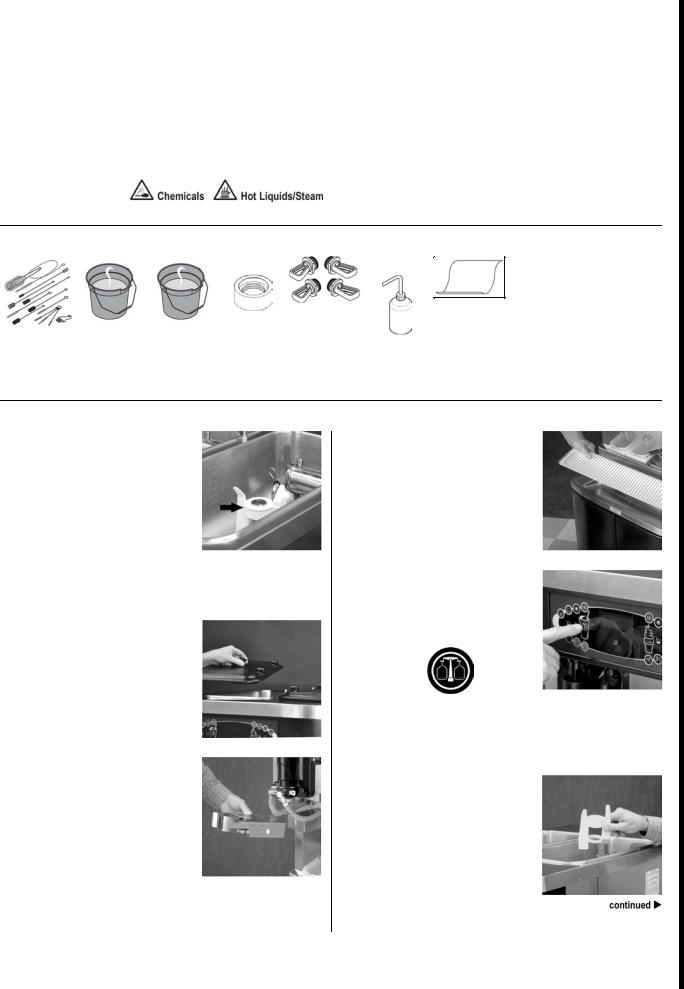

Tools and supplies

Brushes |

Bucket with Kay 5 |

Kay 5 |

Taylor Seal |

Taylor Lube HP |

Clean Sanitized |

|

Sanitizing Solution |

Sanitizing |

Install / |

|

Towels |

|

|

Solution |

Removal Tool |

|

|

Procedure – Set Up

1Fill heated topping wells with clean water.

Remove the topping containers. Fill the heated wells with clean water, up to the fill line located on the bottom of the well.

2Place topping heaters in ON position.

Place the topping heaters in the ON position by touching the topping heater symbols.

Note: Clean and sanitize topping containers, topping pumps, and heated wells weekly. (See PM cards SS01 W2 & W3.)

3Fill topping containers.

Fill the topping containers. Place the caramel and fudge topping containers in the heated wells and the remaining two containers in the unheated wells. Cover the containers.

4Sanitize topping ladles.

Sanitize the topping ladles and place them in the cold topping containers.

5Fill cup dispensers, cup lid holder and cone dispenser.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 1 of 4 |

<![endif]>C602m rvesl mod-softchineand milkshake Company Taylor

<![if ! IE]><![endif]>3 SS Daily

<![if ! IE]><![endif]>D1

Opening Procedures (continued)

Procedure – Shake Side

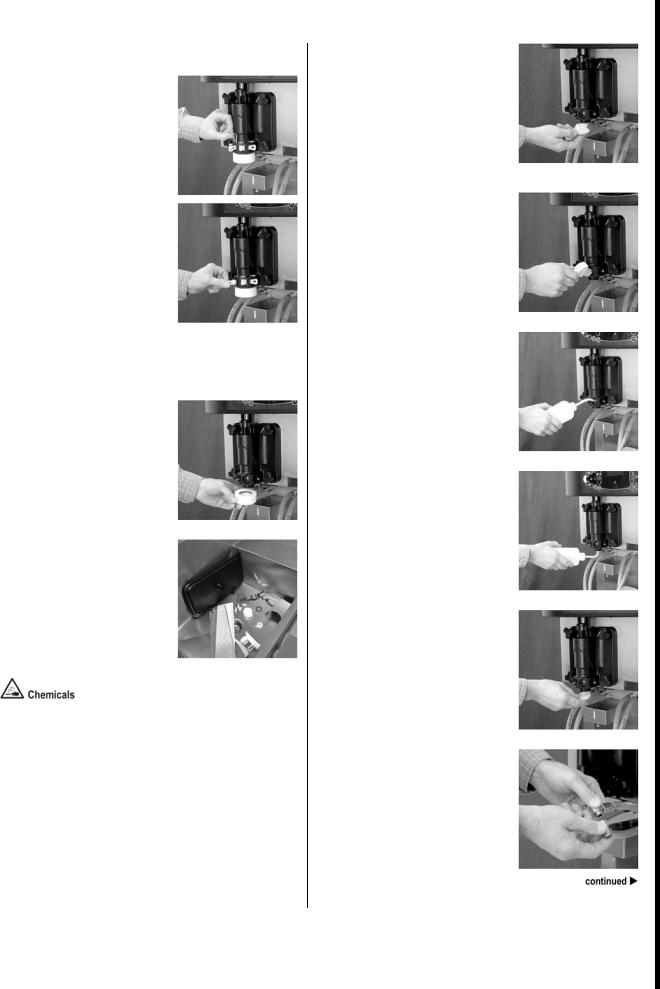

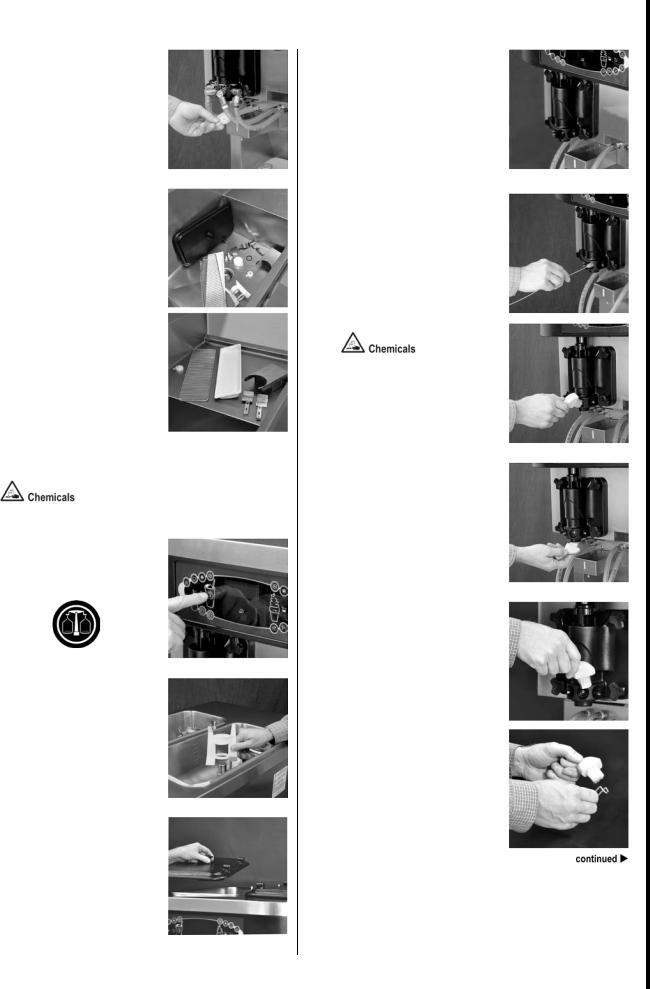

1Remove syrup valve retainers and syrup hole plugs.

Remove the syrup valve retainers and the syrup hole plugs.

Remove the o-rings from the syrup hole plugs.

2Remove draw valve cap.

Remove the draw valve cap and remove the o-ring.

3Sanitize parts.

Prepare a small amount of KAY-5 Sanitizer solution. Sanitize the o-rings, restrictor cap, syrup hole plugs, syrup valve retainers, draw valve cap, shake cup holder, front drip tray, and splash shield in this solution.

Sanitizer Solution

4Sanitize door spout, driven spinner, spinner blade, and syrup line fittings.

Brush clean each item for a total of 60 seconds, repeatedly dipping the brush in sanitizing solution.

5Sanitize syrup port holes.

Place a pail below the door spout.

Brush each syrup port hole 10 to 15 times. Dip the brush in sanitizing solution before brushing each port.

6Flush syrup port holes with sanitizing solution.

Insert tube end of squeeze bottle into each syrup port and squeeze the bottle firmly. Flush each port for 10 seconds.

7Flush door spout with sanitizing solution.

Flush the bottom of the door spout door with sanitizing solution.

8Install syrup valve retainers and restrictor cap on door spout.

9Remove syrup nose fittings.

Remove the syrup nose fitting from each syrup line by turning the syrup nose fitting counter-clockwise.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 2 of 4 |

<![endif]>m rvesC l mod-softchineand milkshake Company Taylor

<![if ! IE]><![endif]>602

<![if ! IE]><![endif]>Daily

<![if ! IE]><![endif]>D1 3 SS

Opening Procedures (continued)

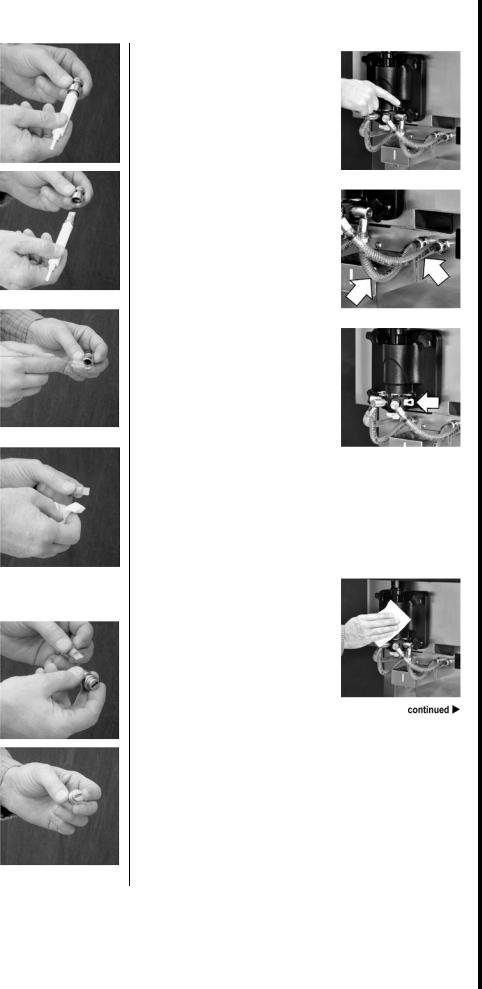

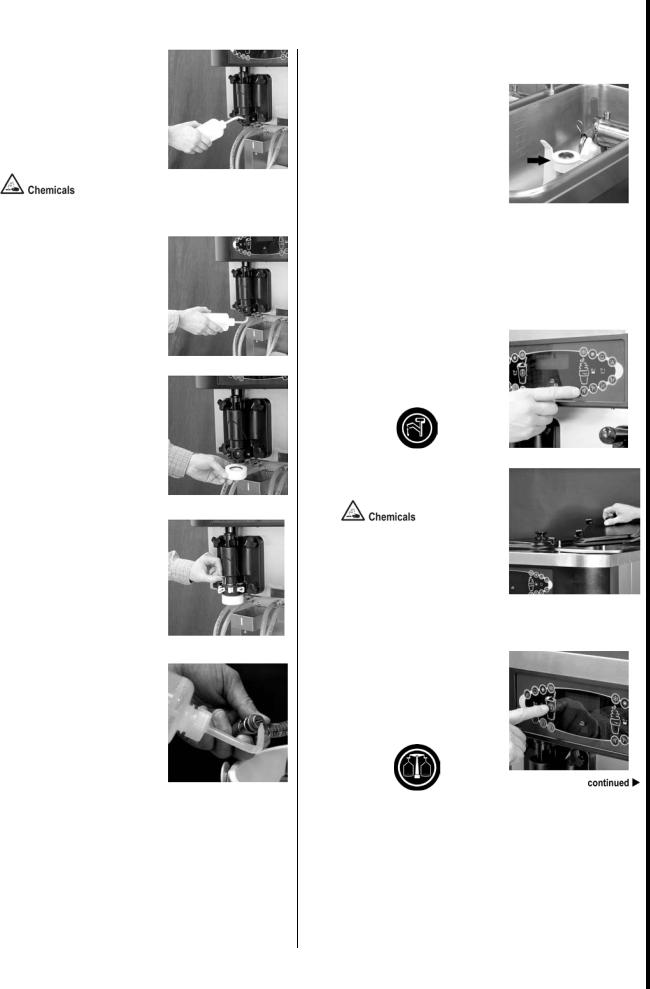

10Remove duckbill valve.

Remove the duckbill valve and the o-ring from each syrup nose fitting, by using the seal removal tool.

11Clean syrup nose fitting.

Using a brush and the sanitizing solution, brush clean the inside of each syrup nose fitting until there is no remaining syrup or mix inside the fitting.

12Sanitize syrup nose fittings and duckbill valve.

Using a clean, sanitized towel, gently wipe any syrup and mix from each duckbill valve.

Use a milkshake cup filled with sanitizing solution to thoroughly rinse the nose fittings and duckbill valve.

13Install duckbill valve into syrup nose fitting and install syrup nose fitting onto syrup line fitting.

Install the duckbill valve into the syrup nose fitting with the flat end aligned with the open slot in the fitting.

Install the syrup nose fitting onto the syrup line fitting. Tighten by hand (clockwise) until snug.

Install and lubricate the o-ring on the syrup nose fitting.

14Install syrup valves.

Raise the syrup valve retainer and install the syrup valve. Push the retainer down to hold the valve in place. Repeat for each syrup valve.

15Check syrup lines for air pockets in the line.

If air pockets are present, prime the syrup lines. (See Operator Manual for priming syrup lines.)

16Install syrup plugs for unused syrup lines.

Install a syrup hole plug into the syrup port in the door whenever a syrup line is not in use. (Example: When the optional flavor shake is not being served.)

Do not install an empty syrup line into the syrup port of an unused syrup line.

Note: The syrup system must be flushed and sanitized weekly.

(See PM card SS01 W1)

17Wipe exterior of machine.

Using a clean, sanitized towel, wipe down the freezer door, front panel, and other areas that have a build up of moisture or food substance.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 3 of 4 |

<![endif]>m rvesC l mod-softchineand milkshake Company Taylor

<![if ! IE]><![endif]>602

<![if ! IE]><![endif]>Daily

<![if ! IE]><![endif]>D1 3 SS

Opening Procedures (continued)

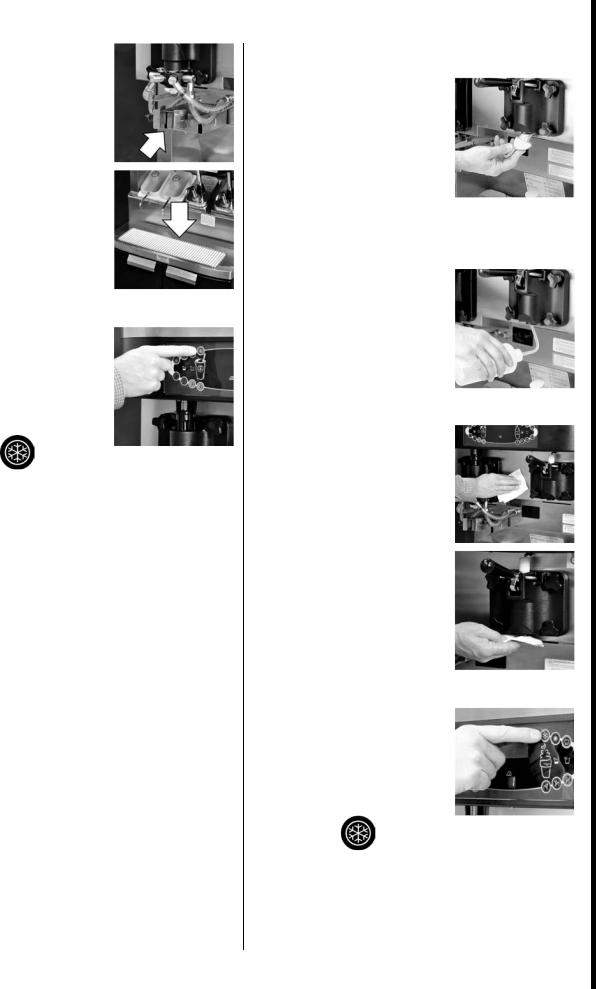

18Install shake cup holder, front drip tray and splash shield.

19Select the AUTO symbol.

When ready to resume normal operation, touch the AUTO symbol. The frozen product should be ready to serve in approximately 10 minutes.

Note: This step should be performed approximately 15 minutes prior to serving product.

Procedure – Soft Serve Side

1Sanitize door spout and bottom of draw valve.

With a pail placed beneath the soft serve door, dip the door spout brush in sanitizing solution. Brush clean the door spout and bottom of the draw valve. Repeatedly dip the brush in sanitizing solution and brush clean each item for 60 seconds.

2Flush door spout and bottom of draw valve with sanitizing solution.

Use the squeeze bottle filled with sanitizing solution to flush the door spout and bottom of the draw valve.

3Wipe exterior of machine.

Using a clean, sanitized towel, wipe down the freezer door, front panel, and other areas that have a build up of moisture or food substance.

4Select the AUTO symbol.

When ready to resume normal operation, touch the AUTO symbol. The frozen product should be ready to serve in approximately 10 minutes.

Note: This step should be performed approximately 15 minutes prior to serving product.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 4 of 4 |

<![endif]>m rvesC l mod-softchineand milkshake Company Taylor

<![if ! IE]><![endif]>602

<![if ! IE]><![endif]>Daily

<![if ! IE]><![endif]>D1 3 SS

|

Closing Procedures |

|

|

|

Daily |

|

|

|

SS 3 D2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Why |

Prepare Milkshake/Soft-Serve machine for the heat treatment cycle |

|

|

|

|

|||||

|

Time required |

30 minutes |

|

|

|

|

|

|

|

|

|

|

Time of day |

At closing |

24-hour restaurants: one hour before heat treatment cycle |

||||||||

begins

Hazard icons

Tools and supplies

Brushes |

SolidSense All |

Kay 5 Sanitizing |

Valve Cap |

Syrup Hole Plugs |

Kay 5 Sanitizing |

Clean Sanitized |

|

Purpose Super |

Solution |

|

|

Solution |

Towels |

|

Concentrate (APSC) |

|

|

|

|

|

|

Solution |

|

|

|

|

|

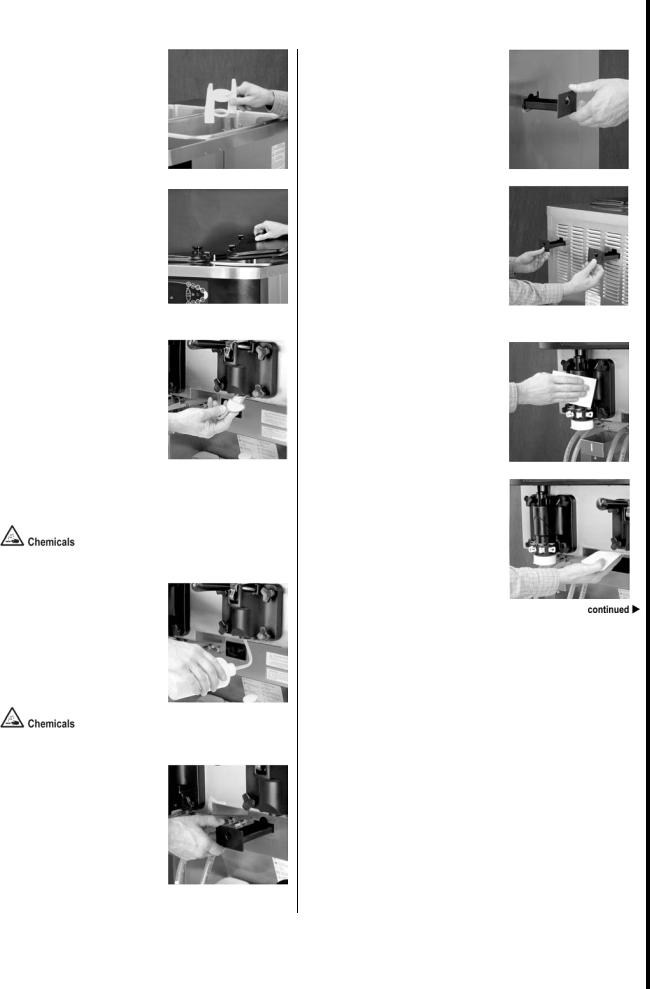

Procedure – Shake Side

1Fill mix hopper.

Fill the hopper with fresh mix, up to the line on the agitator paddle. Do not fill above the agitator paddle.

Important: The level of mix in the hopper must be at the line on the agitator paddle. The mix low light must not be on.

2Remove hopper cover.

3Remove milkshake cup holder.

4Remove drip tray and splash shield.

5Remove agitator paddle.

Select the calibrate symbol to momentarily stop the agitator paddle from turning.

Important: Make sure your hands are clean and sanitized before performing the next steps.

With sanitized hands, remove the agitator paddle from the hopper.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 1 of 5 |

<![endif]>C602m rvesl mod-softchineand milkshake Company Taylor

<![if ! IE]><![endif]>Daily

<![if ! IE]><![endif]>3 SS

<![if ! IE]><![endif]>D2

Closing Procedures (continued)

6Remove restrictor cap.

Remove the restrictor cap from the door spout.

7Clean and sanitize parts.

At the sink, brush clean and sanitize:

Agitator paddle

Hopper cover

Milkshake cup holder

Milkshake restrictor cap

Drip tray

Splash shield

Syrup hole plugs

Spout cap

Spout cap o-ring

Place the restrictor cap, splash shield, drip tray, and milkshake cup holder on a clean, dry surface to air dry overnight or until the heat treatment cycle is complete.

APSC & Sanitizer solution

8Install agitator paddle.

Select the calibrate symbol to momentarily stop the agitator drive motor.

Using sanitized hands, reinstall the agitator paddle on the drive post in the hopper.

9Install hopper cover.

10Remove syrup lines.

Raise the retaining pins and remove the syrup valves.

11Clean syrup port holes.

Place a bucket beneath the door. Brush clean each syrup port hole 10 to 15 times. Dip the brush in cleaning solution before brushing each port.

Brush each item for a total of 60 seconds.

APSC solution

12Clean door spout, bottom of driven spinner, spinner blade and syrup line fittings.

Brush clean each item for a total of 60 seconds, repeatedly dipping the brush in cleaning solution.

13Clean syrup valve retainers and holes.

With sanitized hands, remove the syrup valve retainers. Dip the brush in cleaning solution and brush clean the retainers and the retainer holes. Reinstall the syrup valve retainers.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 2 of 5 |

<![endif]>C602m rvesl mod-softchineand milkshake Company Taylor

<![if ! IE]><![endif]>3 SS Daily

<![if ! IE]><![endif]>D2

Closing Procedures (continued)

14Flush syrup port holes with sanitizing solution.

Insert the tube end of the squeeze bottle filled with sanitizing solution into each syrup port. Squeeze the bottle firmly. Flush each port for 10 seconds.

APSC solution

15Flush door spout with sanitizing solution.

Flush the bottom of the door spout door with sanitizing solution.

16Fill valve cap with sanitizing solution and install.

Fill the insulated valve cap with sanitizing solution and install the cap onto the milkshake door spout.

17Install syrup hole plugs.

Raise the retainer pins. Install a syrup hole plug into each syrup port. Lower the retainer pins to secure the syrup hole plugs.

18Sanitize syrup nose fittings.

Hold the squeeze bottle over a bucket. Squeeze the bottle and thoroughly rinse the slot of each syrup nose fitting.

Wipe the outside of the syrup nose fittings with a clean, sanitized towel.

Note: The syrup system must be flushed and sanitized weekly.

(See PM card SS01 W1.)

Procedure – Soft Serve Side

1Fill mix hopper.

Fill the hopper with fresh mix, up to the line on the agitator paddle. Do not fill the mix hopper above the agitator paddle.

Important: The level of mix in the hopper must be at the line on the agitator paddle. The mix low light must not be on.

2Place topping heaters in OFF position.

Turn the topping heaters OFF by selecting the topping heater symbols.

3Remove, clean, and sanitize hopper cover.

APSC & Sanitizer solution

4Remove, clean, sanitize, and reinstall agitator paddle.

Select the calibrate symbol to momentarily stop the agitator paddle from turning.

Important: Make sure your hands are clean and sanitized before performing the next steps.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 3 of 5 |

<![endif]>C602m rvesl mod-softchineand milkshake Company Taylor

<![if ! IE]><![endif]>3 SS Daily

<![if ! IE]><![endif]>D2

Closing Procedures (continued)

Remove the agitator paddle from the hopper and take it to the sink. Brush clean, sanitize, and reinstall the agitator paddle.

5 Install hopper cover.

6Clean door spout and bottom of draw valve.

Place a bucket beneath the soft-serve door. Dip the door spout brush into cleaning solution and brush clean the door spout and bottom of the draw valve. Repeatedly dip the brush in cleaning solution and brush clean each item for 60 seconds.

APSC solution

7Flush door spout with sanitizing solution.

Use the squeeze bottle filled with sanitizing solution to rinse the bottom of the door spout. Rinse the spout with sanitizing solution for 10 seconds.

Sanitizer solution

8Remove, clean and reinstall drip pans.

Remove the drip pans and take them to the sink. Brush clean, sanitize, and reinstall the drip pans.

Note: Mix in the drip pans indicates there is a leak that needs to be corrected before damage occurs inside the machine.

Examples:

If mix is in the front or side drip pans, inspect/replace the beater drive shaft seals. If mix is in the rear drip pan, inspect/replace the pump drive shaft seals.

9Wipe exterior of machine.

Use a clean, sanitized towel to wipe down the freezer doors, front panels, and any other areas that have a build-up of either moisture or food substance.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 4 of 5 |

<![endif]>C602m rvesl mod-softchineand milkshake Company Taylor

<![if ! IE]><![endif]>3 SS Daily

<![if ! IE]><![endif]>D2

Closing Procedures (continued)

10 Make sure unit is in AUTO.

Note: The machine must be in AUTO (or STANDBY) to start the heat treatment cycle at the programmed time.

DO NOT attempt to draw product or disassemble the machine during the HEAT cycle. The product is hot and under extreme pressure.

When the heat cycle is complete, the control panel will change to the STANDBY mode. The STANDBY symbols will be illuminated.

<![endif]>C602m rvesl mod-softchineand milkshake Company Taylor

<![if ! IE]><![endif]>3 SS Daily

<![if ! IE]><![endif]>D2

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 5 of 5 |

|

Clean and sanitize syrup lines with duckbill |

|

|

|

Weekly |

|

|

|

SS 3 W1 |

|

|

|

valves |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Why |

To break the bacteria cycle |

|

|

|

|

|

|

|

|

|

|

Time required |

5 minutes to prepare |

20 minutes to complete |

|

|

|

|

||||

|

Time of day |

At close |

For 24-hour restaurants: during breakfast menu |

||||||||

|

Hazard icons |

|

|

|

|

|

|

|

|

|

|

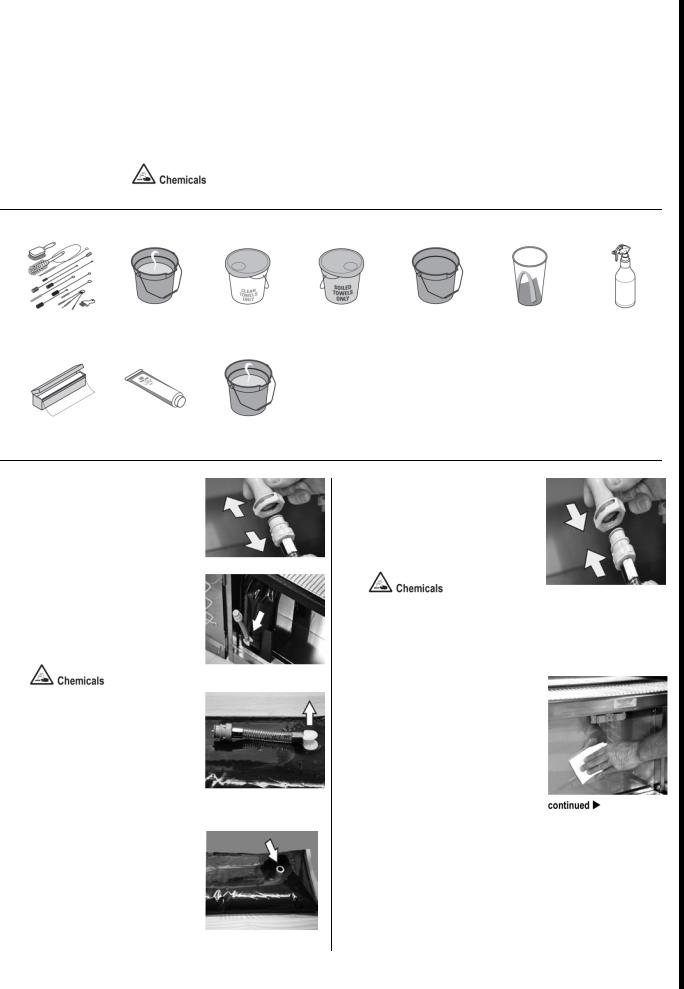

Tools and supplies

Brushes |

Bucket, SolidSense |

Bucket, clean and |

Bucket, soiled towels |

Bucket, plastic |

Cold-drink cup |

Kay-5 Sanitizing |

|

All Purpose Super |

sanitizer-soaked |

|

|

|

solution |

|

Concentrate (APSC) |

towels |

|

|

|

|

Plastic wrap |

Taylor Lube HT |

Kay-5 Sanitizing |

|

|

solution |

Procedure

1Disconnect the QD fitting

Disconnect the QD fitting on the syrup bag.

Remove the syrup bags with the line attached from the cabinet.

Wipe the outside of the feed tubes or the hose connector fittings with a clean, sanitizer-soaked towel.

Sanitizer solution

2Place the syrup bag on a level surface. Remove the syrup bag line from the syrup bag.

4Re-connect the QD

Fitting/Hose from the syrup bag

Place the syrup feed hose in a bucket of APSC solution.

APSC Solution

5Clean inside of cabinet.

Wipe down the inside of the syrup cabinet with a clean, sanitizer-soaked towel. Spray resistant areas with additional sanitizer solution.

3Cover the syrup inlet port with plastic wrap.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 1 of 4 |

<![endif]>C602 model machine serve-soft and milkshake Company Taylor

<![if ! IE]><![endif]>Weekly

<![if ! IE]><![endif]>W1 3 SS

Clean and sanitize syrup lines with duckbill valves (continued)

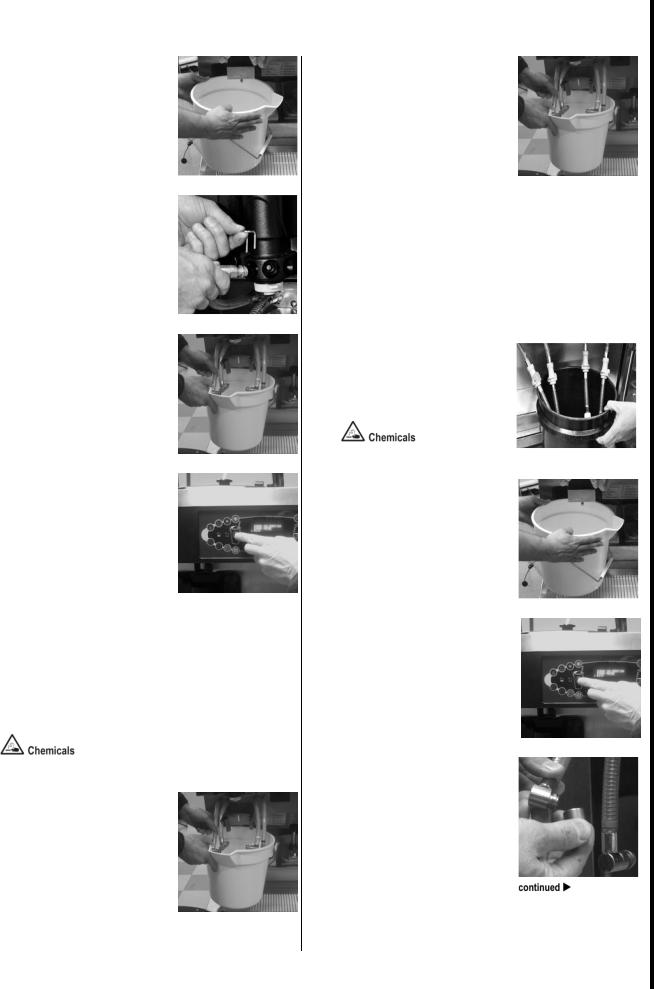

6Place empty bucket under milkshake draw valve.

Place a clean plastic bucket under the milkshake draw valve.

7Remove syrup line from milkshake freezer door.

Disconnect the corresponding syrup line from the milkshake freezer door by raising the syrup valve retainer. Pull the valve straight out.

8Place syrup line and valve in bucket.

Hang the syrup line and valve in the empty bucket.

9Start flow of APSC solution.

Press the Calibration key on the control panel to display the menu options.

Touch the Auto key to move the arrow to “Syrup Prime.”

Touch the Calibration key again to display the syrup prime screen.

Press the Flavor Select key for the correct flavor, to start the flow of APSC through the line.

APSC solution

10Flush syrup line with APSC solution.

Allow the APSC solution to continue to flow into the empty bucket until all the syrup is flushed from the line. When the liquid from the syrup line runs clear, the line is completely flushed.

11Pump all liquid from syrup line.

Remove the syrup feed tube from the bucket of APSC solution and continue to run the pump until APSC solution no longer runs from the syrup line.

Touch the Flavor Select key to stop the flow of APSC solution through the syrup line.

12Rinse with clean, hot water

Repeat steps 7-10 with clean, hot water.

13Place feed tubes in sanitizer solution.

Place the syrup bag connect fittings into a bucket of sanitizer solution.

Sanitizer solution

14Place empty bucket under milkshake draw valve.

Place a clean plastic bucket under the milkshake draw valve.

15Flush syrup line with sanitizer solution.

Repeat steps 7 through 9 using sanitizer solution.

16Remove nose fitting.

Unscrew the nose fitting from the syrup valve in the bucket by turning the cap counterclockwise.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 2 of 4 |

<![endif]>C602 model machine serve-soft and milkshake Company Taylor

<![if ! IE]><![endif]>Weekly

<![if ! IE]><![endif]>W1 3 SS

Clean and sanitize syrup lines with duckbill valves (continued)

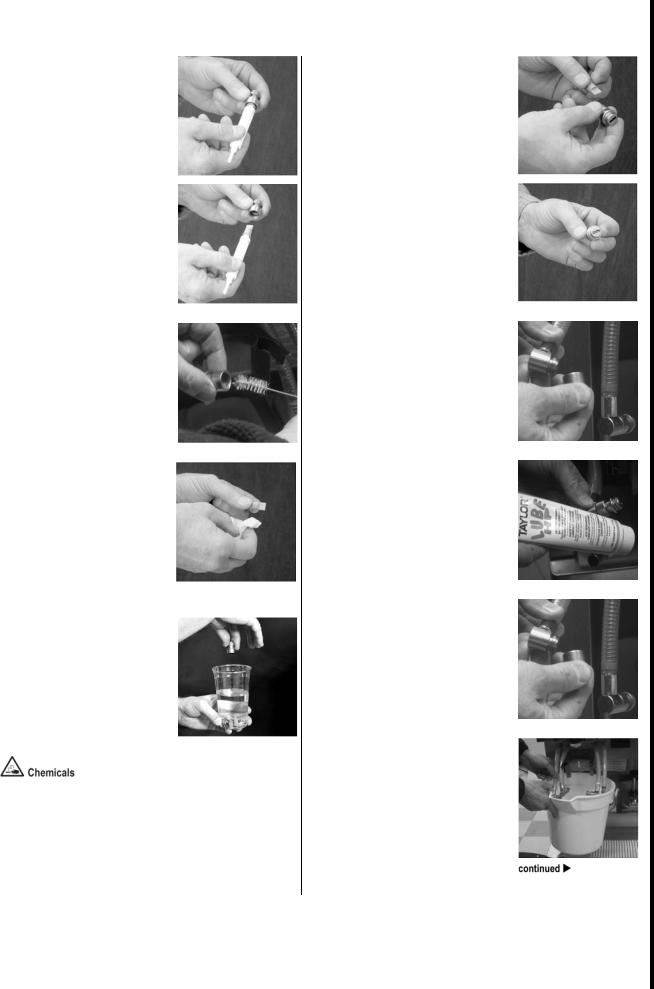

17Remove valve and o-ring.

Remove the duckbill valve and o-ring from each syrup nose fitting, by using the seal removal tool.

18Clean nose and elbow fitting.

Use the white end of the double-ended brush to scrub the inside of the syrup nose fitting and the elbow fitting. Remove any residual particles.

19Clean duckbill valves.

Use a clean, sanitizer-soaked towel to wipe any syrup from the duckbill valves.

20Sanitize syrup valve fittings.

Fill a cup with sanitizer solution. Submerge the syrup valve fittings in the sanitizer solution in the cup. Rotate the cup gently so the fittings are washed thoroughly. Allow to soak for at least one minute.

Sanitizer solution

21Insert duckbill valve.

Install the duckbill valve into one of the nose fittings with the flat end aligned with the open slot in the nose fitting.

Do not lubricate the duckbill valve.

22Connect nose fitting.

Screw the nose fitting onto one of the syrup valve elbows by turning it clockwise. Tighten it by hand until snug.

23Install and lubricate o-ring.

Push one of the o-rings onto the nose fitting and lubricate it with Taylor Lube HP.

24Reassemble remaining valves.

Repeat steps 20 through 22 to reassemble the remaining syrup valves.

25Place clean bucket under milkshake draw valve.

Place a clean plastic bucket under the milkshake draw valve. Position the sanitized valves so they are hanging over the bucket.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 |

Page 3 of 4 |

<![endif]>C602 model machine serve-soft and milkshake Company Taylor

<![if ! IE]><![endif]>Weekly

<![if ! IE]><![endif]>W1 3 SS

Loading...

Loading...