Siemens D410 User Manual

SIMOTION

D410

Commissioning Manual

Valid for SIMOTION D410 DP and D410 PN

08/2008 Edition

Preface

Description |

1 |

|

|

|

|

Commissioning (hardware) |

2 |

|

Configuring SIMOTION |

|

|

3 |

||

D410 |

||

|

|

|

Commissioning (software) |

4 |

|

|

|

|

Maintenance and service |

5 |

|

|

|

|

Diagnostics data |

6 |

|

|

|

|

Standards and approvals |

A |

|

|

|

|

ESD guidelines |

B |

|

|

|

|

Appendix |

C |

|

|

|

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are graded according to the degree of danger.

DANGER

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes in this documentation qualified persons are defined as persons who are authorized to commission, ground and label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

WARNING

WARNING

This device may only be used for the applications described in the catalog or the technical description and only in connection with devices or components from other manufacturers which have been approved or recommended by Siemens. Correct, reliable operation of the product requires proper transport, storage, positioning and assembly as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this publication may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG |

Copyright © Siemens AG 2008. |

Industry Sector |

Technical data subject to change |

Postfach 48 48 |

|

90327 NÜRNBERG |

|

GERMANY |

|

Preface

Contents of the commissioning manual

This manual is part of the SIMOTION D4xx documentation package, Edition 08/2008. This manual describes commissioning of the SIMOTION devices D410 DP and D410 PN.

Information blocks in this manual

The following information blocks describe the purpose and use of the commissioning manual.

●Description

This section provides information pertaining to the SIMOTION system and its integration into the information landscape.

●Commissioning (hardware)

This section describes how to start up the device and what you must take into account.

●Configuring SIMOTION D410

This section describes how to integrate SIMOTION D410 in a project and how to configure the interfaces.

●Commissioning (software)

This section describes how to configure a plant and how to test the drives and axes you configured.

●Maintenance and service

This section describes how to replace a module, how to run updates, and how to modify settings.

●Diagnostics data

This section provides information about diagnostic possibilities and LED states.

●Appendices with factual information for reference (for example, Standards and Approvals, and ESD)

●Index for locating information.

SIMOTION Documentation

An overview of the SIMOTION documentation can be found in a separate list of references.

This documentation is included as electronic documentation with the supplied SIMOTION SCOUT.

D410 |

3 |

Commissioning Manual, 08/2008 Edition |

Preface

The SIMOTION documentation consists of 9 documentation packages containing approximately 80 SIMOTION documents and documents on related systems (e.g. SINAMICS).

The following documentation packages are available for SIMOTION V4.1 SP2:

●SIMOTION Engineering System

●SIMOTION System and Function Descriptions

●SIMOTION Diagnostics

●SIMOTION Programming

●SIMOTION Programming - References

●SIMOTION C

●SIMOTION P350

●SIMOTION D4xx

●SIMOTION Supplementary Documentation

Hotline and Internet addresses

Technical support

If you have any technical questions, please contact our hotline:

|

Europe / Africa |

|

Phone |

+49 |

180 5050 222 (subject to charge) |

Fax |

+49 |

180 5050 223 |

Internet |

http://www.siemens.com/automation/support-request |

|

|

|

|

|

Americas |

|

Phone |

+1 423 262 2522 |

|

Fax |

+1 423 262 2200 |

|

mailto:techsupport.sea@siemens.com |

||

|

|

|

|

Asia / Pacific |

|

Phone |

+86 |

1064 719 990 |

Fax |

+86 |

1064 747 474 |

mailto:adsupport.asia@siemens.com |

||

4 |

D410 |

Commissioning Manual, 08/2008 Edition |

Preface

Note

Country-specific telephone numbers for technical support are provided under the following Internet address:

http://www.siemens.com/automation/service&support

Calls are subject to charge, e.g. 0.14 €/min. on the German landline network. Tariffs of other phone companies may differ.

Questions about this documentation

If you have any questions (suggestions, corrections) regarding this documentation, please fax or e-mail us at:

Fax |

+49 913198 63315 |

mailto:docu.motioncontrol@siemens.com |

Siemens Internet address

The latest information about SIMOTION products, product support, and FAQs can be found on the Internet at:

●General information:

–http://www.siemens.de/simotion (German)

–http://www.siemens.com/simotion (international)

●Product support:

–http://support.automation.siemens.com/WW/view/en/10805436

Additional support

We also offer introductory courses to help you familiarize yourself with SIMOTION.

Please contact your regional training center or our main training center at D-90027 Nuremberg, phone +49 (911) 895 3202.

Information about training courses on offer can be found at: www.sitrain.com

D410 |

5 |

Commissioning Manual, 08/2008 Edition |

Preface

Disposal and recycling

SIMOTION D410 is an environmentally friendly product! It includes the following features:

●In spite of its excellent resistance to fire, the flame-resistant agent in the plastic used for the housing does not contain halogens.

●Identification of plastic materials in accordance with DIN 54840

●Less material used because the unit is smaller and with fewer components thanks to integration in ASICs

SIMOTION D410 can be recycled because it is made with low-polluting materials.

For state-of-the art environmentally friendly recycling and disposal of your old modules, contact your Siemens representative. To locate your representative, visit us online at:

http://www.ad.siemens.com/partner

Further information / FAQs

You can find further information on this manual under the following FAQs: http://support.automation.siemens.com/WW/view/de/27585482

The following resources are also available:

●SIMOTION - Utilities & Applications CD: This CD is supplied together with the SIMOTION SCOUT and, along with FAQs, also contains free utilities (e.g. calculation tools, optimization tools, etc.) and application examples (ready-to-apply solutions such as winder, cross cutter or handling).

●The latest FAQs for SIMOTION can be found at: http://support.automation.siemens.com/WW/view/de/10805436

●SIMOTION SCOUT online help

●Additional documentation: see SIMOTION references

6 |

D410 |

Commissioning Manual, 08/2008 Edition |

Table of contents

|

Preface |

...................................................................................................................................................... |

3 |

1 |

Description............................................................................................................................................... |

11 |

|

|

1.1 .......................................................................................................................... |

System overview |

11 |

|

1.2 .................................................................................................................... |

System components |

14 |

|

1.3 ....................................................................................................... |

SIMOTION D410 DP display |

19 |

|

1.4 ....................................................................................................... |

SIMOTION D410 PN display |

23 |

|

1.5 ............................................................................................................... |

The CompactFlash card |

27 |

|

1.6 ...................................................................................................................................... |

Licensing |

28 |

|

1.7 ........................................................................................................................ |

Safety information |

29 |

2 |

Commissioning ......................................................................................................................(hardware) |

31 |

|

|

2.1 .................................................................................................. |

Prerequisites for commissioning |

31 |

|

2.2 ................................................................................................ |

Inserting the Compact Flash card |

32 |

|

2.3 .................................................................................................... |

Switching on the power supply |

33 |

|

2.4 .............................................................................................................................. |

RESET button |

34 |

|

2.5 .................................................................................................................. |

User memory concept |

35 |

|

2.5.1 ................................................................................................. |

SIMOTION D410 memory model |

35 |

|

2.5.2 .................................................................................................. |

Properties of the user memories |

36 |

|

2.5.3 ..................................................................... |

Operator actions and their impact on user memory |

38 |

3 |

Configuring ..................................................................................................................SIMOTION D410 |

43 |

|

|

3.1 ................................................................................................................. |

Software requirements |

43 |

|

3.2 ..................................................................................... |

Inserting SIMOTION D410 into a project |

43 |

|

3.3 .......................................................... |

Configuring the PROFIBUS DP interface (only D410 DP) |

46 |

|

3.3.1 ........................................................ |

General information about PROFIBUS DP communication |

46 |

|

3.3.2 ............................................................. |

Assignment of the PROFIBUS addresses in HW Config |

47 |

|

3.3.3 .......................................................................... |

Operating SIMOTION D410 on PROFIBUS DP |

48 |

|

3.3.4 ....................................................................................... |

Creating a new PROFIBUS DP subnet |

48 |

|

3.3.5 ............................................................................. |

Setting the DP cycle and system cycle clocks |

49 |

|

3.3.6 .................................................................................................... |

Rules for SIMOTION D410 DP |

50 |

|

3.4 ................................................................................ |

Configuring PROFINET (only for D410 PN) |

52 |

|

3.4.1 ............................................................... |

General information about PROFINET communication |

52 |

|

3.4.2 .......................................................................... |

Operating SIMOTION D410 PN on PROFINET |

53 |

|

3.4.3 ................................................................................. |

Setting the send cycles and system clocks |

56 |

|

3.4.4 .................................................................................................... |

Rules for SIMOTION D410 PN |

58 |

4 |

Commissioning .......................................................................................................................(software) |

61 |

|

|

4.1 ......................................................................................................... |

Overview of commissioning |

61 |

|

4.2 ........................................................................................ |

Configuring the system in offline mode |

62 |

D410 |

|

|

7 |

Commissioning Manual, 08/2008 Edition |

|||

Table of contents

|

4.2.1 |

Overview..................................................................................................................................... |

62 |

|

4.2.2 |

Accessing the drive wizard.......................................................................................................... |

63 |

|

4.2.3 |

Configuring the components....................................................................................................... |

64 |

|

4.2.4 |

Aligning HW Config..................................................................................................................... |

70 |

|

4.2.5 |

Downloading the project to SIMOTION D410............................................................................. |

71 |

|

4.3 |

Configuring the system in online mode....................................................................................... |

73 |

|

4.3.1 |

Overview..................................................................................................................................... |

73 |

|

4.3.2 |

Establishing the online connection.............................................................................................. |

74 |

|

4.3.3 |

Starting automatic configuration ................................................................................................. |

75 |

|

4.3.4 |

Editing SINAMICS components.................................................................................................. |

77 |

|

4.3.5 |

Aligning HW Config..................................................................................................................... |

78 |

|

4.3.6 |

Download the project to SIMOTION D410.................................................................................. |

78 |

|

4.4 |

Creating an axis.......................................................................................................................... |

79 |

|

4.5 |

Integrating additional encoders (optional)................................................................................... |

81 |

|

4.5.1 |

General information..................................................................................................................... |

81 |

|

4.5.2 |

Configure the encoder interface on the drive side...................................................................... |

82 |

|

4.5.3 |

Configuring a second encoder for a TO axis in SIMOTION........................................................ |

83 |

|

4.5.4 |

Configuring external encoders in SIMOTION ............................................................................. |

84 |

|

4.6 |

Using drive-related I/Os by SIMOTION....................................................................................... |

85 |

|

4.6.1 |

Onboard I/Os and terminal modules configuration overview...................................................... |

85 |

|

4.6.2 |

Use of message frame 39x......................................................................................................... |

87 |

|

4.6.3 |

Free message frame configuring with P915/P916 (only TM15/TM17 High Feature) ................. |

91 |

|

4.6.4 |

Configuring free message frames by means of BICO................................................................ |

92 |

|

4.6.5 |

Expanding a message frame...................................................................................................... |

97 |

|

4.6.6 |

Using high-speed outputs for output cams on D410................................................................. |

100 |

|

4.6.7 |

Using probe inputs on D410...................................................................................................... |

101 |

|

4.6.8 |

Outputs of cam outputs and probe inputs on TM15/TM17 High Feature ................................. |

105 |

|

4.7 |

Creating and programming TM41............................................................................................. |

106 |

|

4.7.1 |

Overview................................................................................................................................... |

106 |

|

4.7.2 |

Configuring TM41 at SINAMICS Integrated.............................................................................. |

106 |

|

4.8 |

Creating a DMC20 .................................................................................................................... |

107 |

|

4.8.1 |

DMC20 hub properties.............................................................................................................. |

107 |

|

4.8.2 |

Creating a DRIVE-CLiQ hub..................................................................................................... |

108 |

|

4.9 |

Testing the configured drive using the drive control panel ....................................................... |

109 |

|

4.10 |

Testing the configured axis using the axis control panel.......................................................... |

111 |

|

4.11 |

Downloading and saving user data........................................................................................... |

113 |

|

4.12 |

Deleting data............................................................................................................................. |

114 |

|

4.12.1 |

Overview of data deletion.......................................................................................................... |

114 |

|

4.12.2 |

Resetting the memory of SIMOTION D410 .............................................................................. |

115 |

|

4.12.3 |

Deleting user data from the CompactFlash Card ..................................................................... |

117 |

|

4.12.4 |

Restoring the default settings of SINAMICS Integrated............................................................ |

118 |

|

4.12.5 |

Restoring the default settings of SIMOTION D410................................................................... |

118 |

|

4.13 |

System shutdown...................................................................................................................... |

119 |

5 |

Maintenance and service....................................................................................................................... |

121 |

|

|

5.1 |

Replacing modules.................................................................................................................... |

121 |

|

5.1.1 |

Removing and replacing the SIMOTION D410......................................................................... |

121 |

|

5.1.2 |

Replacing DRIVE-CLiQ components........................................................................................ |

124 |

|

5.2 |

Replacing the fan...................................................................................................................... |

125 |

8 |

D410 |

Commissioning Manual, 08/2008 Edition |

|

|

|

Table of contents |

|

5.3 |

Performing a software and firmware update .............................................................................. |

126 |

|

5.4 |

SIMOTION CompactFlash Card ................................................................................................ |

131 |

|

5.4.1 |

Replacing the CompactFlash Card ............................................................................................ |

131 |

|

5.4.2 |

Writing and deleting data on CompactFlash Cards ................................................................... |

131 |

|

5.4.3 |

Formatting the CompactFlash Card ........................................................................................... |

132 |

|

5.4.4 |

Bootloader on the CompactFlash card ...................................................................................... |

133 |

6 |

Diagnostics data.................................................................................................................................... |

135 |

|

|

6.1 |

Diagnostics by means of LED displays ...................................................................................... |

135 |

|

6.2 |

Extended diagnostic capabilities ................................................................................................ |

138 |

A |

Standards and approvals....................................................................................................................... |

139 |

|

|

A.1 |

General rules .............................................................................................................................. |

139 |

|

A.2 |

Safety of electronic controllers ................................................................................................... |

140 |

|

A.3 |

Electromagnetic Compatibility .................................................................................................... |

142 |

B |

ESD guidelines...................................................................................................................................... |

143 |

|

|

B.1 |

ESD definition ............................................................................................................................ |

143 |

|

B.2 |

Electrostatic charging of individuals ........................................................................................... |

143 |

|

B.3 |

Basic measures for protection against discharge of static electricity ........................................ |

144 |

C |

Appendix |

................................................................................................................................................ |

145 |

|

C.1 |

List of abbreviations ................................................................................................................... |

145 |

|

Index...................................................................................................................................................... |

|

147 |

D410 |

9 |

Commissioning Manual, 08/2008 Edition |

Description |

1 |

1.1System overview

Overview

In SIMOTION D, the SIMOTION functionality is integrated directly in the closed-loop control module of the SINAMICS S120 drive system.

SIMOTION D410 is a module drive system for single axes, which solves demanding drive tasks for a very wide range of industrial applications. SIMOTION D410 supplements D425, D435 and D445, the three power levels for multi-axis connections.

SIMOTION D is an integral part of the Totally Integrated Automation (TIA) concept. TIA features standardized data management, configuration and communication over all products and systems. Thus, an extensive toolbox of automation modules is also available for SIMOTION D410.

Application

Combining a power module with SIMOTION D410 forms a compact single drive for machine and plant engineering.

Applications include:

●Machine concepts with central drive (e.g., pressing, printing and packaging machines, . .

.)

●Modular machine concepts where the machine modules broken down to single axes

●Single drives with high accuracy, stability and concentricity requirements (compared with standard drives) in machine and industrial plant engineering

●Single drives for transport tasks (conveying, raising, lowering)

●Single drives with integrated PLC functionality and expanded motion control functionality such as output cam or cams

●Drives without power recovery (wire drawing, extruding)

●Drive connections with high availability requirements (incoming supply failure may not cause all axes to fail)

Product variants

SIMOTION D410 comes in two variants:

●SIMOTION D410 DP with PROFIBUS DP interface.

●SIMOTION D410 PN with PROFINET interface.

D410 |

11 |

Commissioning Manual, 08/2008 Edition |

Description

1.1 System overview

System integration

SIMOTION provides an optimized system platform for automation and drive solutions where the main focus is on motion control applications and technology tasks.

The SIMOTION system is made up of three components:

●SIMOTION SCOUT Engineering System

●Runtime Software

●Hardware platforms

The innovative SIMOTION concept involves integrating pure automation and motion functions, which have been traditionally isolated in the past.

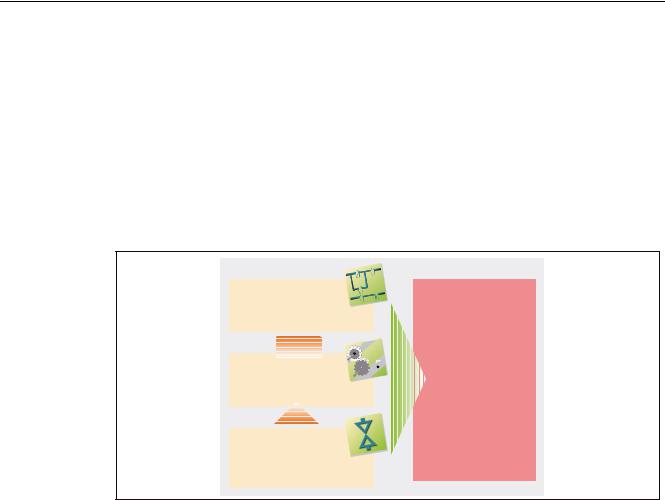

3/& IXQFWLRQDOLW\,(&

0RWLRQ &RQWURO

H J SRVLWLRQLQJ

V\QFKURQRXV RSHUDWLRQ HWF

7HFKQRORJ\

IXQFWLRQV

H J K\GUDXOLFV WHPSHUDWXUH

FRQWURO HWF

7KH V\VWHP DSSURDFK RI

6,027,21

7KH FRPELQLQJ RI PRWLRQ FRQWURO 3/& DQG WHFKQRORJ\ IXQFWLRQV

Figure 1-1 System solution

SIMOTION can be used with all machines with motion control tasks. The focus is on a simple and flexible solution to a wide variety of motion control tasks. In order to achieve this in the best way possible, a new system approach has been introduced:

the fusion of motion control with two other control functions, which are found in most machines: PLC and technology functions.

This approach enables motion control of axes and machines with only one system. The same applies to technology functions, such as pressure control of a hydraulic axis. A seamless switch can be made from position-controlled positioning mode to pressure control.

12 |

D410 |

Commissioning Manual, 08/2008 Edition |

Description 1.1 System overview

Combining the three control functions of motion control, PLC and technology functions has the following benefits:

●Lower engineering expenditure and higher machine performance.

●Interfaces between individual components requiring rapid response are no longer needed.

●Simple, standardized and transparent programming and diagnostics for the complete machine.

D410 |

13 |

Commissioning Manual, 08/2008 Edition |

Description

1.2 System components

1.2System components

Overview

SIMOTION D410 communicates with the components of the automation landscape via the following interfaces:

●PROFIBUS DP (SIMOTION D410 DP only)

●PROFINET (SIMOTION D410 PN only)

●DRIVE-CLiQ (DRIVE Component Link with IQ)

●Power Module Interface (PM-IF)

●SIMOTION D features a SINAMICS Integrated drive element. Communication with the SINAMICS Integrated (node 3) is via PROFIBUS mechanisms (DP integrated).

The most important system components and their functions are listed in the following table.

Table 1-1 |

System components |

|

|

|

|

Components |

|

Function |

SIMOTION D410 |

... is the central motion control module. |

|

|

|

The module contains the programmable SIMOTION Runtime in |

|

|

SIMOTION D410 and the SINAMICS S120 drive software. |

|

|

You can use the integrated rapid digital I/Os as: |

|

|

• Homing inputs |

|

|

• Inputs for measuring inputs |

|

|

• User-addressable process inputs/outputs |

|

|

• Outputs for fast output cams |

|

|

The measuring sockets can output any analog signals. |

|

|

The DRIVE-CLiQ interface permits a fast connection to the SINAMICS drive |

|

|

components. |

System software |

The system software is delivered separately on a CompactFlash card (not |

|

|

|

included in the scope of delivery). |

|

|

Note: An additional license is not required for the real axis technology. |

Power supply (PS) |

... provides the electronic power supply for SIMOTION D410 (e.g., SITOP |

|

|

|

power supply). |

|

|

Note: If the SIMOTION D410 is snapped-on to a PM340 power module, the |

|

|

power module may be used as the sole supply for the SIMOTION D410 in |

|

|

certain cases (e.g., when digital outputs are not used, etc. . .). See the section |

|

|

entitled in the SIMOTION D410 Manual. |

14 |

D410 |

Commissioning Manual, 08/2008 Edition |

Description 1.2 System components

PROFIBUS DP

SIMOTION D410 DP can communicate via PROFIBUS DP interface to the following components:

Table 1-2 |

Components on PROFIBUS DP |

|

|

|

|

Components |

|

Function |

PG/PC programming device |

... configures, sets parameters, programs and tests using the |

|

|

|

SIMOTION SCOUT Engineering System (ES). |

SIMATIC HMI device |

... is used for operator control and monitoring functions. It is not |

|

|

|

absolutely required to run SIMOTION D410. |

Drive units with |

... convert speed setpoints into signals for controlling the motor and |

|

PROFIBUS DP interface |

supply the power required to operate the motors. |

|

(e.g., SINAMICS, |

Can also be operated as an isochronous, equidistant Slave on the |

|

SIMODRIVE 611 universal) |

PROFIBUS DP. |

|

SIMATIC ET 200M |

Modular I/O system for control cabinet installation and high channel |

|

|

|

densities. |

SIMATIC ET 200S |

Finely scalable I/O system for control cabinet installation and |

|

|

|

particularly time-critical applications; including motor starters, safety |

|

|

technology and individual grouping of load groups. |

SIMATIC ET 200pro |

Modular I/O system with IP65/IP67 rating for machine-related |

|

|

|

applications with no control cabinet; with new features such as more |

|

|

compact designs, integrated PROFIsafe safety technology, |

|

|

PROFINET connection and live module replacement. |

SIMATIC ET 200eco |

I/O system with IP65/IP67 rating for machine-related applications |

|

|

|

with no control cabinet, with a flexible and fast connection system in |

|

|

ECOFAST or M12. |

Gateways |

|

• DP/AS Interface Link 20E and DP/AS Interface Link Advanced for |

|

|

the PROFIBUS DP gateway to AS Interface |

|

|

• DP/DP coupler to connect two PROFIBUS DP networks |

Teleservice adapter |

Remote diagnosis |

|

Other controls (e.g., |

|

|

SIMOTION or SIMATIC) |

|

|

Note

Note that only one real axis can be used on a SIMOTION D410.

D410 |

15 |

Commissioning Manual, 08/2008 Edition |

Description

1.2 System components

Note

Please note that not all modules for the I/O systems listed above are enabled for SIMOTION. Moreover, system-related functional differences can come into play when these I/O or I/O systems are used on SIMOTION vs. on SIMATIC. For example, special process-control functions (e.g., HART modules, etc.) are not supported by SIMOTION for the ET 200M distributed I/O system.

A list of all I/O modules that can currently be used with SIMOTION is available under the following link:

http://support.automation.siemens.com/WW/view/de/11886029

In addition to the I/O modules enabled for SIMOTION, all certified standard slaves can, in principle, be connected to SIMOTION if they support the following:

●Cyclic data traffic (DP-V0) and, possibly

●Acyclic data traffic (DP-V1) or

●Isochronous data traffic (DP-V2)

These modules are integrated via the GSD file from the device manufacturer.

Note

Please note that in individual cases further boundary conditions must be fulfilled in order to integrate a standard slave into SIMOTION. For example, "driver modules" in the form of function blocks are required for some modules, which enable integration or make it especially easy.

For modules enabled for SIMOTION (e.g., S7-300 module FM 350-1, etc.), these driver modules are part of the SIMOTION SCOUT Engineering System command library.

16 |

D410 |

Commissioning Manual, 08/2008 Edition |

Description 1.2 System components

PROFINET

SIMOTION D410 PN can communicate via PROFINET interface to the following components:

Table 1-3 |

Components on PROFINET |

|

|

|

|

Components |

|

Function |

The master computer (at |

... communicates with other devices via Ethernet. |

|

company and production |

|

|

management level) |

|

|

PG/PC programming device |

... communicates with the SIMOTION SCOUT Engineering |

|

|

|

Systems (ES), STEP 7 and HMI (Human Machine Interface). |

SIMATIC HMI device |

... is used for operator control and monitoring functions. It is not |

|

|

|

absolutely essential for running SIMOTION D410. |

Drive units with PROFINET |

... convert speed setpoints into signals for controlling the motor |

|

interface (e.g., SINAMICS S120 |

and supply the power required to operate the motors. |

|

with CBE20) |

|

|

SIMATIC ET 200M |

Modular I/O system for control cabinet installation and high |

|

|

|

channel densities. |

SIMATIC ET 200S |

Finely scalable I/O system for control cabinet installation and |

|

|

|

particularly time-critical applications; including motor starters, |

|

|

safety technology and individual grouping of load groups. |

SIMATIC ET 200pro |

Modular I/O system with IP65/IP67 rating for machine-related |

|

|

|

applications with no control cabinet; with new features such as |

|

|

more compact designs, integrated PROFIsafe safety technology, |

|

|

PROFINET connection and live module replacement. |

Gateways |

|

• IE/AS Interface Link PN IO for the PROFINET IO gateway to |

|

|

AS Interface |

|

|

• PN/PN coupler to connect two PROFINET IO networks |

Other controls (e.g., SIMOTION |

|

|

or SIMATIC) |

|

|

Note

Note that only one real axis can be used on a SIMOTION D410.

Note

A list of all I/O modules that can currently be used with SIMOTION is available at the following link:

http://support.automation.siemens.com/WW/view/de/11886029

D410 |

17 |

Commissioning Manual, 08/2008 Edition |

Description

1.2 System components

DRIVE-CLiQ

SIMOTION D410 can communicate via DRIVE-CLiQ interface to the following components:

Table 1-4 |

Components on DRIVE-CLiQ |

|

|

|

|

Components |

|

Function |

SINAMICS S120 AC DRIVE drive |

... convert speed setpoints into signals for controlling the motor |

|

units |

|

and supply the power required to operate the motors. The |

(with CUA31/CUA32) |

AC DRIVE component PM340 is connected via CUA31/CUA32. |

|

|

|

No more than one PM340 can be connected. Chassis power |

|

|

module is connected via DRIVE-CLiQ. |

|

|

Note: Booksize components are not supported! |

TM15 and TM17 High Feature |

The terminal modules TM15 and TM17 High Feature are used to |

|

terminal modules |

implement probe inputs and cam outputs. In addition, terminal |

|

|

|

modules provide drive-related digital inputs and outputs with |

|

|

short signal delay times. |

TM31 terminal module |

... enables terminal expansion via DRIVE-CLiQ (additional |

|

|

|

analog and digital inputs/outputs). |

TM41 terminal module |

... enables terminal expansion (analog and digital inputs/outputs) |

|

|

|

and encoder simulation via DRIVE-CLiQ. The TM41 can be |

|

|

connected to a real axis. It is important to note that exactly one |

|

|

real axis can be configured on the D410. |

TM54F terminal module |

... enables terminal expansion (secure digital inputs/digital |

|

|

|

outputs) for controlling the secure motion monitoring functions of |

|

|

the integrated drive. |

SMx sensor modules |

... enable the acquisition of encoder data from the connected |

|

|

|

motors via DRIVE-CLiQ. |

Motors with DRIVE-CLiQ interface |

... allow simplified commissioning and diagnostics, as the motor |

|

|

|

and encoder type are identified automatically. |

DMC20 |

|

... expands the number of DRIVE-CLiQ nodes |

Note

Note that SIMOTION D410 does not support the CX32 expansion!

18 |

D410 |

Commissioning Manual, 08/2008 Edition |

Description 1.3 SIMOTION D410 DP display

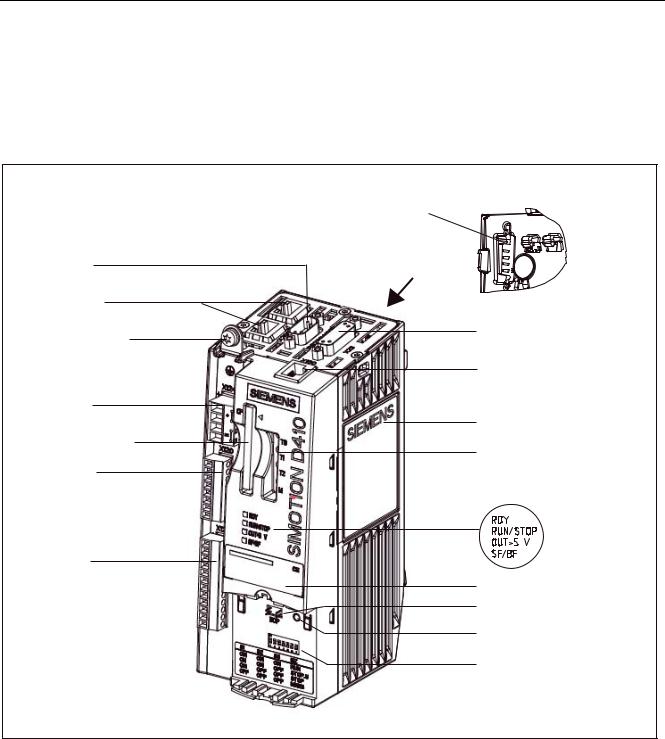

1.3SIMOTION D410 DP display

View

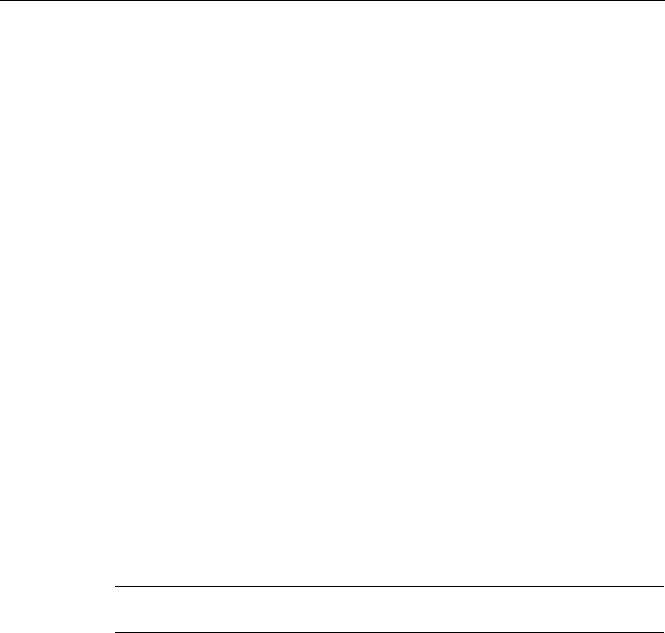

The following figure shows SIMOTION D410 DP with the interfaces and front elements.

; 6HULDO LQWHUIDFH QR IXQFWLRQ

; 352),%86

0 VFUHZ RQ VKLHOG FRQQHFWLRQ

; (OHFWURQLFV SRZHU VXSSO\

&RPSDFW)ODVKbFDUG

; (3 WHUPLQDOV WHPSHUDWXUH VHQVRU FRQQHFWLRQ

; |

|

|

|

|

'LJLWDO LQSXWV RXWSXWV |

||||

6ZLWFK VHWWLQJV RQ WKH PRGH |

||||

VHOHFWRU VZLWFK |

|

|

||

|

|

|

|

|

6 |

6 |

6 |

26 |

|

21 |

21 |

21 |

581 |

|

21 |

21 |

2)) |

6723B8 |

|

21 |

2)) |

2)) |

6723 |

|

2)) |

2)) |

2)) |

05(6 |

|

|

|

|

|

|

3RZHU 0RGXOH ,QWHUIDFH 30 ,)

; (QFRGHU LQWHUIDFH +7/ 77/ 66,

; '5,9( &/L4 LQWHUIDFH

6LGH QDPHSODWH

7 7 7 0 0HDVXULQJ VRFNHWV

/(' GLVSOD\V

7\SH SODWH

%23 LQWHUIDFHQR IXQFWLRQ

5(6(7 EXWWRQ

0RGH VHOHFWRU VZLWFK',3 VZLWFK

Figure 1-2 Location of interfaces and front elements in SIMOTION D410 DP

Note

The label underneath the mode selector lists the switch settings for the operating states of the SIMOTION D410.

D410 |

19 |

Commissioning Manual, 08/2008 Edition |

Description

1.3 SIMOTION D410 DP display

Interfaces

The SIMOTION D410 DP interfaces are described in the following tables.

Table 1-5 |

SIMOTION D410 interfaces |

|

|

|

|

Interface |

|

Description |

Digital inputs/outputs |

12-pin Mini Combicon: |

|

X121 |

|

• 4 digital inputs: for connecting switches or proximity sensors |

|

|

• 4 digital inputs/outputs: for connecting actuators and sensors |

DRIVE-CLiQ interface |

8-pin RJ45plus socket to connect DRIVE-CLiQ nodes |

|

X100 |

|

|

PROFIBUS DP interface |

9-pin SUB-D socket to connect to PROFIBUS DP |

|

X21 |

|

|

Power Module Interface |

8-pin direct connector to connect to a blocksize power module |

|

(PM-IF) |

|

|

Encoder interface (HTL / TTL |

15-pin SUB-D socket for connecting HTL, TTL and SSI encoders. |

|

/ SSI) |

|

|

X23 |

|

|

EP terminals/temperature |

8-pin Mini Combicon for connecting Safety Integrated input terminals |

|

sensor connection |

or for connecting temperature sensing via KTY or PTC |

|

X120 |

|

|

Power supply connection |

4-pin screw terminal connection to connect the 24 V DC load power |

|

X124 |

|

supply |

Measuring sockets |

Sockets to output analog signals |

|

T0, T1, T2 and M |

|

|

20 |

D410 |

Commissioning Manual, 08/2008 Edition |

Description 1.3 SIMOTION D410 DP display

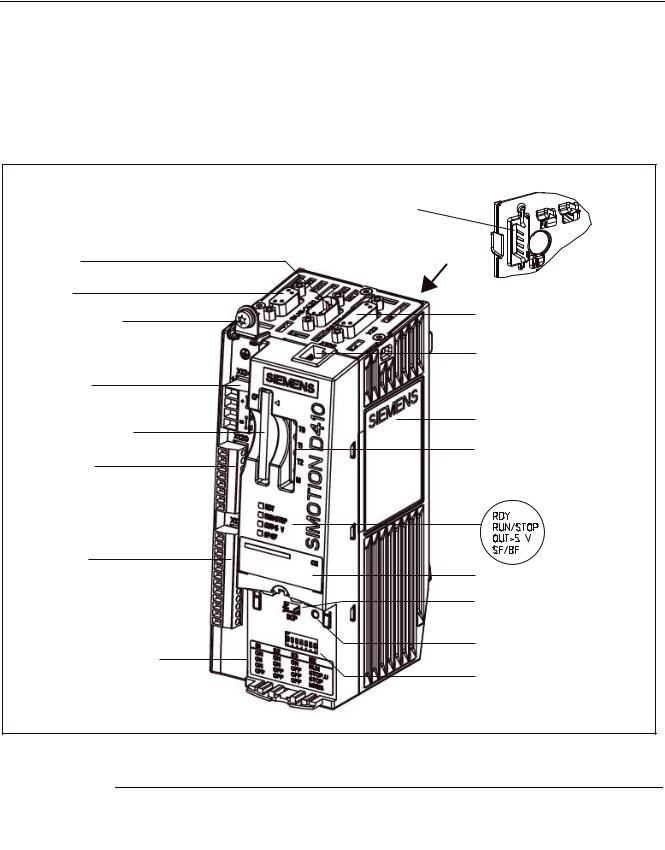

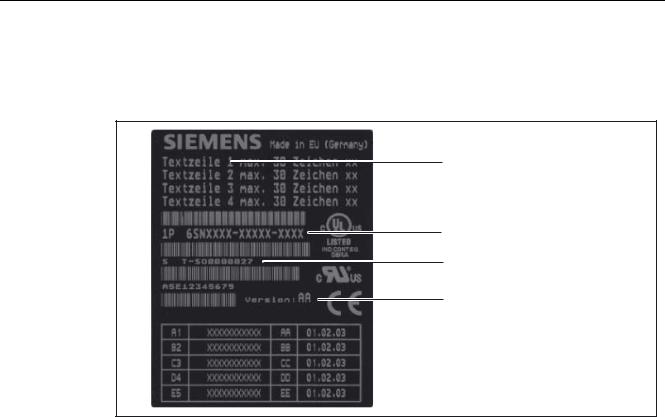

Nameplates

The following figure shows you all the information included on the nameplates located on the side of the unit.

0RGXOH GHVLJQDWLRQ

2UGHU QXPEHU 6HULDO QXPEHU

+: YHUVLRQ

Figure 1-3 SIMOTION D410 nameplate

D410 |

21 |

Commissioning Manual, 08/2008 Edition |

Description

1.3 SIMOTION D410 DP display

The following nameplate includes the SIMOTION D410 DP barcode numbers and is located on the front side of the module.

%DU FRGH 0/)% 1R $8 $$ $$ |

|

3$8$$ $$ |

|

%DU FRGH |

|

6DFK 1U $( |

|

' '3 |

9HUVLRQ |

|

$ |

7\SH GHVLJQDWLRQ |

5HYLVLRQ OHYHO |

3URGXFW QXPEHU |

|

2UGHU QXPEHU 0/)% 1R 6SDFH IRU DSSURYDOV LGHQWLILFDWLRQV

Figure 1-4 SIMOTION D410 DP nameplate (example)

Note

The contents of the individual nameplate fields on the current module may differ from those described in this Manual (e.g., updated product status, space for approvals and identifications, etc.).

22 |

D410 |

Commissioning Manual, 08/2008 Edition |

Description 1.4 SIMOTION D410 PN display

1.4SIMOTION D410 PN display

View

The following figure shows SIMOTION D410 PN with the interfaces and front elements.

; 6HULDO LQWHUIDFH QR IXQFWLRQ

; ; 352),1(7 VRFNHWV

0 VFUHZ RQ VKLHOG FRQQHFWLRQ

; (OHFWURQLFV SRZHU VXSSO\

&RPSDFW)ODVKbFDUG

; (3 WHUPLQDOV WHPSHUDWXUH VHQVRU FRQQHFWLRQ

; 'LJLWDO LQSXWV RXWSXWV

6ZLWFK VHWWLQJV RQ WKH PRGH VHOHFWRU VZLWFK

6 |

6 |

6 |

26 |

|

|

|

|

|

|

21 |

21 |

21 |

581 |

|

|

||||

21 |

21 |

2)) |

6723B8 |

|

21 |

2)) |

2)) |

6723 |

|

2)) |

2)) |

2)) |

05(6 |

|

|

|

|

|

|

3RZHU 0RGXOH ,QWHUIDFH 30 ,)

; (QFRGHU LQWHUIDFH +7/ 77/ 66,

; '5,9( &/L4 LQWHUIDFH

6LGH QDPHSODWH

7 7 7 0 0HDVXULQJ VRFNHWV

/(' GLVSOD\V

7\SH SODWH

%23 LQWHUIDFHQR IXQFWLRQ

5(6(7 EXWWRQ

0RGH VHOHFWRU VZLWFK',3 VZLWFK

Figure 1-5 Location of interfaces and front elements in SIMOTION D410 PN

D410 |

23 |

Commissioning Manual, 08/2008 Edition |

Description

1.4 SIMOTION D410 PN display

Interfaces

The SIMOTION D410 PN interfaces are described in the following tables.

Table 1-6 |

SIMOTION D410 interfaces |

|

|

|

|

Interface |

|

Description |

Digital inputs/outputs |

12-pin Mini Combicon: |

|

X121 |

|

• 4 digital inputs: for connecting switches and proximity sensors |

|

|

• 4 digital inputs/outputs: for connecting actuators and sensors |

DRIVE-CLiQ interface |

8-pin RJ45plus socket to connect DRIVE-CLiQ nodes |

|

X100 |

|

|

PROFINET interface |

8-pin RJ45plus socket to connect to PROFINET |

|

(ports X200 and X201) |

|

|

Power Module Interface |

8-pin direct connector to connect to a blocksize power module |

|

(PM-IF) |

|

|

Encoder interface (HTL / TTL / |

15-pin SUB-D socket for connecting HTL, TTL and SSI encoders. |

|

SSI) |

|

|

X23 |

|

|

EP terminals / temperature |

8-pin Mini Combicon for connecting Safety Integrated input |

|

sensor connection |

terminals or for connecting temperature sensing via KTY or PTC |

|

X120 |

|

|

Power supply connection |

4-pin screw terminal connection to connect the 24 V DC load |

|

X124 |

|

power supply |

Measuring sockets |

Sockets to output analog signals |

|

T0, T1, T2 and M |

|

|

24 |

D410 |

Commissioning Manual, 08/2008 Edition |

Description 1.4 SIMOTION D410 PN display

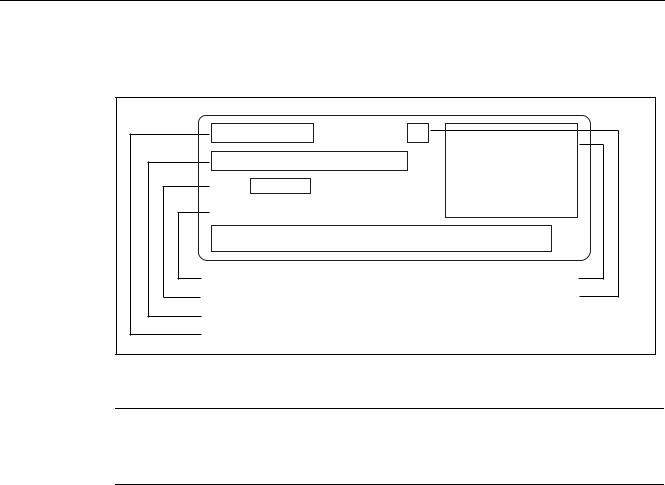

Nameplates

The following figure shows you all the information included on the nameplates located on the side of the unit.

0RGXOH GHVLJQDWLRQ

2UGHU QXPEHU 6HULDO QXPEHU

+: YHUVLRQ

Figure 1-6 SIMOTION D410 nameplate

D410 |

25 |

Commissioning Manual, 08/2008 Edition |

Description

1.4 SIMOTION D410 PN display

The following nameplate includes the MAC address of the PROFINET interface (ports X200 and X201) and is located on the front side of the module.

' 31 |

9HUVLRQ |

$ |

$8 $%$$ $(

; ; ; ; ; ;

%DU FRGH 0$& DGGUHVV

0$& DGGUHVV |

6SDFH IRU DSSURYDOV LGHQWLILFDWLRQV |

3URGXFW QXPEHU |

5HYLVLRQ OHYHO |

2UGHU QXPEHU 0/)% 1R |

|

7\SH GHVLJQDWLRQ |

|

Figure 1-7 SIMOTION PN nameplate (example)

Note

The contents of the individual nameplate fields on the current module may differ from those described in this Manual (e.g., updated product status, space for approvals and identifications, etc.).

26 |

D410 |

Commissioning Manual, 08/2008 Edition |

Description 1.5 The CompactFlash card

1.5The CompactFlash card

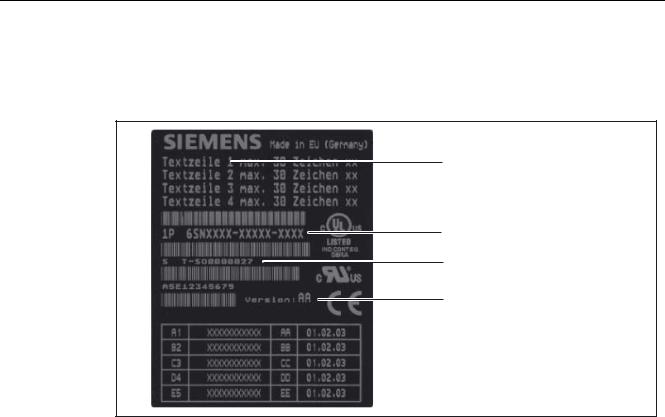

CompactFlash card

The following figure shows you all the information included on the nameplate of the CompactFlash card (CF card).

3RLQWHU WR VKRZ SOXJ LQ GLUHFWLRQ RI WKH &) FDUG

2UGHU QXPEHU

/LVW RI = RSWLRQ OLFHQVHV RQ WKH &) FDUG XSRQ GHOLYHU\

+: VHULHV QXPEHU RI WKH &) FDUG

8QLTXH ,' QXPEHU

'HOLYHU\ QRWH QXPEHU

'HVLJQDWLRQ RI &) FDUG ZLWK = RSWLRQ

3URGXFW DQG YHUVLRQ GHVLJQDWLRQ &DUG FDSDFLW\ %RRWORDGHU YHUVLRQ

3URGXFWLRQ GDWH

%DU FRGH LQFOXGLQJ RUGHU QXPEHU

Figure 1-8 CompactFlash card

Pre-installed runtime licenses

For versions V4.1 SP1 HF6 and higher, pre-installed licenses are printed on the type plate of the CF card as a Z option underneath the order number.

Example with Z option for a combined SIMOTION IT license + 2 TControl licenses: 6AU1400-2PA00-0AA0-Z

Z=J00+T02

A maximum of 7 different Z options are printed on the type plate of the CF card. When there are more than 7 different Z options, the text "Z = see delivery order" is printed on the CF card in place of the Z option.

D410 |

27 |

Commissioning Manual, 08/2008 Edition |

Description

1.6 Licensing

Available Z options / licenses for SIMOTION D CF cards

The following Z options are available for SIMOTION D410:

TControl temperature control:

●Txx – TControl license and number (e.g. T03 = 3 TControl licenses) SIMOTION IT:

●D00 – IT DIAG license

●X00 – OPC XML-DA license

●J00 – Combined license for SIMOTION IT, comprises SIMOTION IT Virtual Machine for Java applications, SIMOTION IT DIAG and SIMOTION IT OPC XML-DA

Safety functions:

●Fxx - License for SINAMICS Safety Integrated Extended Functions (e.g., F01 = 1 license for safety functions)

1.6Licensing

SIMOTION D410 licensing

SIMOTION D410 is a modular drive system for single-axis applications. D410 contains the Motion Control technology functions for exactly one real axis (speed-controlled, positioning, synchronized axis or cam). This means that these technology functions do not require an additional license. It is not possible to increase the number of axes using licenses. Along with the one real axis, further virtual axes can be configured and loaded.

Licenses are required for runtime functions such as SIMOTION IT DIAG. These can be preinstalled on a CompactFlash card (CF card) or ordered separately.

Additional references

For more information about license management, see the SIMOTION SCOUT Configuring Manual. General information about licensing can be found in the Motion Control SIMOTION, SINAMICS S120 catalog and motors for production machines catalog, PM21 2008.

28 |

D410 |

Commissioning Manual, 08/2008 Edition |

Description 1.7 Safety information

1.7Safety information

Observe the following safety information when working with SIMOTION D410 and its components!

CAUTION

CAUTION

The CompactFlash card may only be unplugged and plugged in when SIMOTION D410 is switched off (zero current)!

CAUTION

CAUTION

The 50 mm clearances above and below the components must be observed. The ventilation openings may not be covered by connecting cables.

D410 |

29 |

Commissioning Manual, 08/2008 Edition |

Loading...

Loading...