SHARP R305HD Service Manual

R-305HD

SERVICE MANUAL

SERVICE MANUAL

S5406R305HPD/

MICROWAVE OVEN

MODEL R-305HD

In the interest of user-safety the oven should be restored to its original condition and only parts identical to those specified should be used.

WARNING TO SERVICE PERSONNEL: Microwave ovens contain circuitry capable of producing very high voltage and current, contact with following parts may result in a severe, possibly fatal, electrical shock. (High Voltage Capacitor, High Voltage Power Transformer, Magnetron, High Voltage Rectifier Assembly, High Voltage Harness etc..)

This is a supplemental Service Manual for Model R-305HD. This mode is quite similar to base models R-305HK/R-305HW. Use this supplemental manual together with the Base Model Service Manual (Refer No. is S2304R305HPW/) for complete operation, service information, etc..

TABLE OF CONTENTS |

|

|

Page |

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SERVICING TO |

|

AVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY ................... |

INSIDE FRONT COVER |

BEFORE SERVICING ...................................................................................................... |

INSIDE FRONT COVER |

OVEN SCHEMATIC ............................................................................................................................................... |

1 |

TEST PROCEDURE .............................................................................................................................................. |

2 |

PARTS LIST .......................................................................................................................................................... |

3 |

PACKING AND ACCESSORIES ........................................................................................................................... |

5 |

SHARP CORPORATION

This document has been published to be used for after sales service only.

The contents are subject to change without notice.

R-305HD

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SERVICING TO AVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY

(a)Do not operate or allow the oven to be operated with the door open.

(b)Make the following safety checks on all ovens to be serviced before activating the magnetron or other microwave source, and make repairs as necessary: (1) interlock operation, (2) proper door closing, (3) seal and sealing surfaces (arcing, wear, and other damage), (4) damage to or loosening of hinges and latches, (5) evidence of dropping or abuse.

(c)Before turning on microwave power for any service test or inspection within the microwave generating compartments, check the magnetron, wave guide or transmission line, and cavity for proper alignment, integrity, and connections.

(d)Any defective or misadjusted components in the interlock, monitor, door seal, and microwave generation and transmission systems shall be repaired, replaced, or adjusted by procedures described in this manual before the oven is released to the owner.

(e)A microwave leakage check to verify compliance with the Federal Performance Standard should be performed on each oven prior to release to the owner.

BEFORE SERVICING

Before servicing an operative unit, perform a microwave emission check as per the Microwave Measurement Procedure outlined in this service manual.

If microwave emissions level is in excess of the specified limit, contact SHARP ELECTRONICS CORPORATION immediately @1-800-237-4277.

If the unit operates with the door open, service person should 1) tell the user not to operate the oven and 2) contact SHARP ELECTRONICS CORPORATION and Food and Drug Administration's Center for Devices and Radiological Health immediately.

Service personnel should inform SHARP ELECTRONICS CORPORATION of any certified unit found with emissions in excess of 4mW/cm2. The owner of the unit should be instructed not to use the unit until the oven has been brought into compliance.

R-305HD

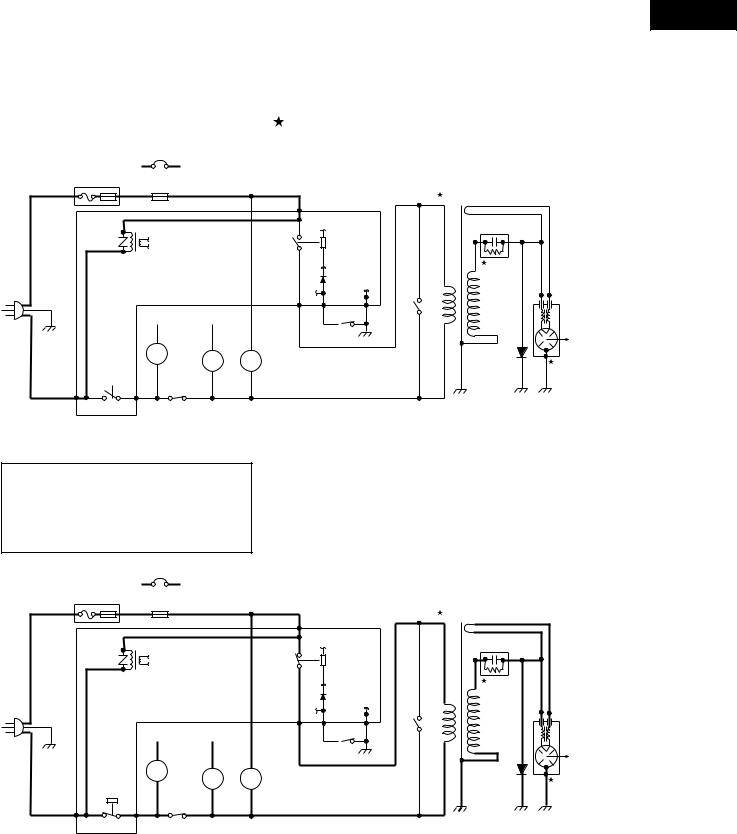

|

SCHEMATIC |

|

NOTE: CONDITION OF OVEN |

|

|

1. |

DOOR CLOSED |

NOTE: " " indicates components with potential above 250V. |

2. |

CLOCK APPEARS ON DISPLAY |

|

|

|

|

|

THERMAL CUT-OUT |

|

|

|

145ßC (OVEN) |

|

|

|

OR |

|

|

C/T FUSE |

TEMPERATURE |

|

|

|

FUSE 150ßC (OVEN) |

|

|

|

N.O. |

|

|

|

|

|

PRIMARY |

|

|

|

INTERLOCK |

|

|

|

RELAY (RY2) |

|

CONTROL UNIT |

|

|

GRN |

COM. |

B2 |

B1 |

|

|

|

120V AC

60 Hz DOOR

60 Hz DOOR

SENSING

SWITCH

|

|

OL |

OVEN |

|

|

|

|

|

LAMP |

TTM |

FM |

||

|

|

|

|

|||

OVEN LAMP |

|

|

|

|

||

RELAY (RY1) |

SECONDARY |

TURN- |

FAN |

|||

|

|

|

INTERLOCK |

|

TABLE |

MOTOR |

|

|

|

|

MOTOR |

||

|

|

|

SWITCH |

|

|

|

|

|

|

|

|

|

|

POWER

TRANSFORMER

CAPACITOR 0.94 F

AC 2200V

SWITCH

MONITOR

RECTIFIER

RECTIFIER

MAGNETRON

N.O. |

COM. |

Figure O-1. Oven Schematic-Off Condition

SCHEMATIC

NOTE: CONDITION OF OVEN

1.DOOR CLOSED

2.COOKING TIME PROGRAMMED

3.VARIABLE COOKING CONTROL "P-HI" (100%)

4."START" PAD TOUCHED

|

THERMAL CUT-OUT |

|

|

|

145ßC (OVEN) |

|

|

|

OR |

|

|

C/T FUSE |

TEMPERATURE |

|

|

|

FUSE 150ßC (OVEN) |

|

|

|

N.O. |

|

|

|

|

|

PRIMARY |

|

|

|

INTERLOCK |

|

|

|

RELAY (RY2) |

|

CONTROL UNIT |

|

|

GRN |

COM. |

B2 |

B1 |

|

|

|

120V AC

60 Hz DOOR

60 Hz DOOR

SENSING

SWITCH

|

OL |

OVEN |

|

|

|

|

LAMP |

TTM |

FM |

||

|

|

|

|||

|

OVEN LAMP |

|

|

|

|

|

RELAY (RY1) |

SECONDARY |

TURN- |

FAN |

|

|

|

TABLE |

|||

|

|

INTERLOCK |

|

MOTOR |

|

|

|

|

MOTOR |

||

|

|

SWITCH |

|

|

|

|

|

|

|

|

|

N.O. |

COM. |

|

|

|

|

|

|

|

|

|

|

POWER

TRANSFORMER

CAPACITOR 0.94 F

AC 2200V MONITOR SWITCH

RECTIFIER

RECTIFIER

MAGNETRON

Figure O-2. Oven Schematic-Cooking Condition

1

Loading...

Loading...