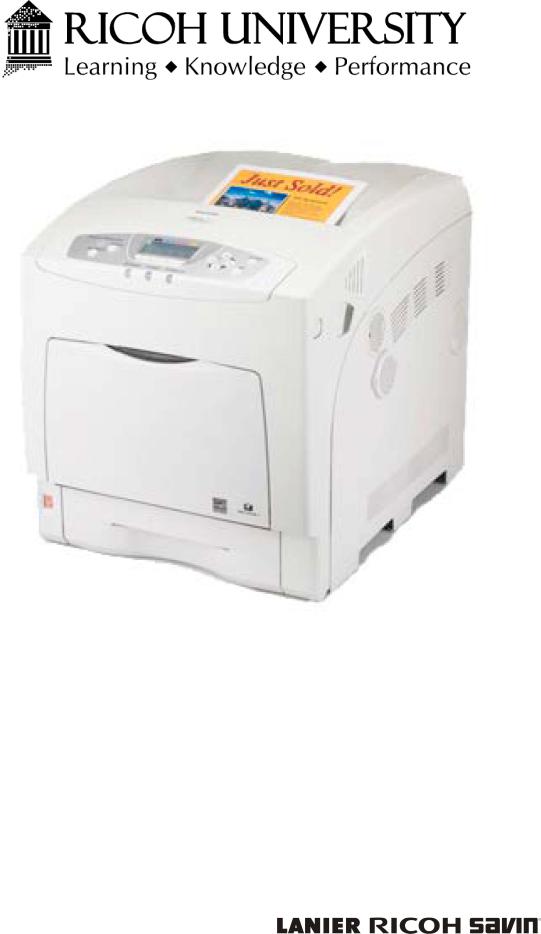

Ricoh SP-C420DN Service manual

CÓPIA NÃO CONTROLADA

G190 SERVICE MANUAL

003603MIU

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

G190 MANUAL SERVICE

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

G190

SERVICE MANUAL

003603MIU

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

It is the reader's responsibility when discussing the information contained within this document to maintain a level of confidentiality that is in the best interest of Ricoh Americas Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY FASHION AND DISTRIBUTED WITHOUT THE PRIOR PERMISSION OF RICOH AMERICAS CORPORATION.

All product names, domain names or product illustrations, including desktop images, used in this document are trademarks, registered trademarks or the property of their respective companies.

They are used throughout this book in an informational or editorial fashion only and for the benefit of such companies. No such use, or the use of any trade name, or web site is intended to convey endorsement or other affiliation with Ricoh products.

© 2008 RICOH Americas Corporation. All rights reserved.

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

WARNING

The Service Manual contains information regarding service techniques, procedures, processes and spare parts of office equipment distributed by Ricoh Americas Corporation. Users of this manual should be either service trained or certified by successfully completing a Ricoh Technical Training Program.

Untrained and uncertified users utilizing information contained in this service manual to repair or modify Ricoh equipment risk personal injury, damage to property or loss of warranty protection.

Ricoh Americas Corporation

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

LEGEND

PRODUCT |

|

COMPANY |

|

|

CODE |

GESTETNER |

LANIER |

RICOH |

SAVIN |

G190 |

SP C420DN |

LP331cn |

SP C420DN |

CLP131DN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DOCUMENTATION HISTORY

REV. NO. |

DATE |

COMMENTS |

* |

04/2008 |

Original Printing |

|

|

|

|

|

|

|

|

|

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

G190

TABLE OF CONTENTS

INSTALLATION

1. INSTALLATION PROCEDURE ............................................... |

1-1 |

|

1.1 INSTALLATION REQUIREMENTS....................................................... |

1-1 |

|

|

1.1.1 ENVIRONMENT .......................................................................... |

1-1 |

|

1.1.2 MACHINE LEVEL ........................................................................ |

1-1 |

|

1.1.3 MACHINE SPACE REQUIREMENTS ......................................... |

1-2 |

|

1.1.4 POWER REQUIREMENTS.......................................................... |

1-2 |

1.2 OPTIONAL UNIT COMBINATIONS ...................................................... |

1-3 |

|

|

1.2.1 MACHINE OPTIONS ................................................................... |

1-3 |

|

1.2.2 CONTROLLER OPTIONS ........................................................... |

1-3 |

PRINTER INSTALLATION.......................................................................... |

1-4 |

|

|

1.2.3 INSTALLATION PROCEDURE.................................................... |

1-4 |

|

Unpacking ....................................................................................... |

1-4 |

|

Installing the toner ......................................................................... |

1-11 |

|

Loading Paper ............................................................................... |

1-13 |

|

Turning Power on .......................................................................... |

1-15 |

|

Selecting the Panel Display Language.......................................... |

1-16 |

|

Printing the Test Page................................................................... |

1-16 |

|

Settings Relevant to the Service Contract..................................... |

1-16 |

|

1.2.4 METER CLICK CHARGE........................................................... |

1-17 |

|

1.2.5 MOVING THE MACHINE........................................................... |

1-19 |

|

1.2.6 TRANSPORTING THE MACHINE............................................. |

1-19 |

1.3 OPTIONS INSTALLATION ................................................................. |

1-20 |

|

|

1.3.1 PAPER FEED UNIT................................................................... |

1-20 |

|

1.3.2 TRAY HEATER.......................................................................... |

1-20 |

1.4 CONTROLLER OPTIONS .................................................................. |

1-22 |

|

|

1.4.1 OVERVIEW................................................................................ |

1-22 |

|

I/F Card Slots ................................................................................ |

1-22 |

|

SD Card Slots................................................................................ |

1-22 |

G190 |

i |

SM |

|

CÓPIA NÃO CONTROLADA |

|

CÓPIA NÃO CONTROLADA

1.4.2 SD CARD APPLI MOVE ............................................................ |

1-22 |

Overview ....................................................................................... |

1-22 |

Move Exec..................................................................................... |

1-23 |

Undo Exec..................................................................................... |

1-24 |

Storing the SD Card ...................................................................... |

1-25 |

PREVENTIVE MAINTENANCE

2. PREVENTIVE MAINTENANCE ............................................... |

2-1 |

2.1 USER REPLACEABLE ITEMS ............................................................. |

2-1 |

2.2 SERVICE MAINTENANCE ................................................................... |

2-2 |

2.2.1 RECOMMENDED CLEANING PROCEDURE ............................. |

2-2 |

REPLACEMENT AND ADJUSTMENT

3. REPLACEMENT AND ADJUSTMENT .................................... |

3-1 |

3.1 BEFORE YOU START.......................................................................... |

3-1 |

3.2 SPECIAL TOOLS AND LUBRICANTS.................................................. |

3-2 |

3.2.1 TOOLS......................................................................................... |

3-2 |

3.3 ELECTRICAL COMPONENTS ............................................................. |

3-3 |

3.3.1 ELECTRICAL BOARD UNIT........................................................ |

3-3 |

3.3.2 IOB (INPUT/OUTPUT BOARD) ................................................... |

3-6 |

3.3.3 CONTROLLER BOARD............................................................... |

3-6 |

3.3.4 INSTALLING THE NEW NVRAM................................................. |

3-8 |

3.3.5 PSU (POWER SUPPLY UNIT) BOARD....................................... |

3-8 |

3.3.6 HIGH VOLTAGE POWER SUPPLY BOARD 1............................ |

3-9 |

3.3.7 EGB (ENGINE BOARD) AND HIGH VOLTAGE POWER SUPPLY |

|

BOARD 2 ............................................................................................ |

3-10 |

3.3.8 LCD PANEL ............................................................................... |

3-11 |

3.3.9 NVRAM REPLACEMENT PROCEDURE .................................. |

3-11 |

NVRAM on the EGB (Engine Board)............................................. |

3-11 |

NVRAM on the Controller.............................................................. |

3-12 |

NVRAMs on the EGB and Controller............................................. |

3-13 |

SM |

ii |

G190 |

|

CÓPIA NÃO CONTROLADA |

|

|

CÓPIA NÃO CONTROLADA |

|

3.4 LASER OPTICS.................................................................................. |

3-14 |

|

|

3.4.1 CAUTION DECAL LOCATIONS ................................................ |

3-14 |

|

3.4.2 LD UNIT..................................................................................... |

3-14 |

|

Replacement ................................................................................. |

3-14 |

|

Color Registration Adjustment....................................................... |

3-15 |

|

3.4.3 LDB............................................................................................ |

3-18 |

|

3.4.4 POLYGON MIRROR MOTOR ................................................... |

3-18 |

|

3.4.5 LASER SYNCHRONIZING DETECTOR BOARDS ................... |

3-19 |

|

3.4.6 LDU SHUTTER MOTOR UNIT AND SENSOR.......................... |

3-20 |

3.5 PAPER FEED ..................................................................................... |

3-21 |

|

|

3.5.1 PAPER FEED ROLLER............................................................. |

3-21 |

|

3.5.2 PAPER FRICTION PAD............................................................. |

3-22 |

|

3.5.3 BY-PASS PAPER SIZE SENSOR ............................................. |

3-22 |

|

3.5.4 BY-PASS FEED ROLLER, FRICTION PAD .............................. |

3-23 |

|

Reassembling the by-pass friction pad.......................................... |

3-24 |

|

3.5.5 REGISTRATION SENSOR ........................................................ |

3-25 |

|

3.5.6 PAPER VOLUME SENSOR, END SENSOR AND PAPER WIDTH |

|

|

SENSOR............................................................................................. |

3-25 |

|

3.5.7 PAPER SIZE SENSOR AND TEMPERATURE/ HUMIDITY |

|

|

SENSOR............................................................................................. |

3-28 |

|

3.5.8 PAPER FEED MOTOR.............................................................. |

3-28 |

|

3.5.9 PAPER REGISTRATION CLUTCH, PAPER FEED CLUTCH AND |

|

|

BY-PASS CLUTCH ............................................................................. |

3-29 |

3.6 DEVELOPMENT................................................................................. |

3-31 |

|

|

3.6.1 COLOR DEVELOPMENT MOTOR, COLOR OPC MOTOR AND |

|

|

BLACK OPC/DEVELOPMENT MOTOR ............................................. |

3-31 |

|

3.6.2 DEVELOPMENT CLUTCH ........................................................ |

3-32 |

|

3.6.3 TRANSFER BELT CONTACT MOTOR ..................................... |

3-32 |

|

3.6.4 TONER SUPPLY MOTOR......................................................... |

3-33 |

|

3.6.5 TRANSFER ROLLER CONTACT MOTOR................................ |

3-33 |

|

3.6.6 ID SENSORS............................................................................. |

3-35 |

3.7 DRIVE ................................................................................................. |

3-36 |

|

|

3.7.1 DRIVE UNIT............................................................................... |

3-36 |

3.8 DUPLEX.............................................................................................. |

3-38 |

|

|

3.8.1 DUPLEX JAM SENSOR ............................................................ |

3-38 |

|

3.8.2 INVERTER SENSOR................................................................. |

3-39 |

G190 |

iii |

SM |

|

CÓPIA NÃO CONTROLADA |

|

CÓPIA NÃO CONTROLADA

3.8.3 DUPLEX MOTOR AND INVERTER MOTOR ............................ |

3-40 |

3.9 FUSING .............................................................................................. |

3-41 |

3.9.1 FUSING UNIT ............................................................................ |

3-41 |

3.9.2 THERMISTOR AND THERMOSTAT ......................................... |

3-41 |

3.9.3 FUSING LAMP........................................................................... |

3-44 |

3.9.4 FUSING EXIT SENSOR AND PAPER EXIT SENSOR.............. |

3-44 |

3.9.5 FUSING REGISTRATION SENSOR ......................................... |

3-45 |

3.9.6 FAN DIRECTION ....................................................................... |

3-45 |

3.10 ADJUSTMENTS............................................................................ |

3-46 |

3.10.1 GAMMA ADJUSTMENT....................................................... |

3-46 |

Summary....................................................................................... |

3-46 |

Adjustment Procedure................................................................... |

3-48 |

TROUBLESHOOTING

4. TROUBLESHOOTING ............................................................. |

4-1 |

4.1 PROCESS CONTROL RESULTS......................................................... |

4-1 |

4.2 SERVICE CALL CONDITIONS............................................................. |

4-3 |

4.2.1 SUMMARY................................................................................... |

4-3 |

4.2.2 SC CODE DESCRIPTIONS......................................................... |

4-4 |

Engine SC ....................................................................................... |

4-4 |

Controller Error.............................................................................. |

4-25 |

4.3 TROUBLESHOOTING GUIDE............................................................ |

4-43 |

4.3.1 BLANK PRINT ........................................................................... |

4-43 |

4.3.2 ALL-BLACK PRINT.................................................................... |

4-44 |

4.3.3 MISSING CMY COLOR ............................................................. |

4-45 |

4.3.4 LIGHT PRINT............................................................................. |

4-46 |

4.3.5 REPEATED SPOTS OR LINES ON PRINTS ............................ |

4-47 |

4.3.6 DARK VERTICAL LINE ON PRINTS ......................................... |

4-47 |

4.3.7 WHITE HORIZONTAL LINES OR BANDS ................................ |

4-48 |

4.3.8 MISSING PARTS OF IMAGES .................................................. |

4-49 |

4.3.9 DIRTY BACKGROUND.............................................................. |

4-49 |

4.3.10 PARTIAL CMY COLOR DOTS............................................. |

4-49 |

4.3.11 DARK IRREGULAR STREAKS ON PRINTS ....................... |

4-50 |

4.3.12 CMY COLOR IRREGULAR STREAKS ................................ |

4-50 |

4.3.13 GHOSTING .......................................................................... |

4-50 |

SM |

iv |

G190 |

|

CÓPIA NÃO CONTROLADA |

|

CÓPIA NÃO CONTROLADA

4.3.14 UNFUSED OR PARTIALLY FUSED PRINTS ...................... |

4-51 |

|

4.3.15 |

IMAGE SKEW ...................................................................... |

4-51 |

4.3.16 |

BACKGROUND STAIN ........................................................ |

4-52 |

4.3.17 NO PRINTING ON PAPER EDGE ....................................... |

4-52 |

|

4.3.18 IMAGE NOT CENTERED WHEN IT SHOULD BE............... |

4-53 |

|

4.4 ELECTRICAL COMPONENT DEFECTS ............................................ |

4-54 |

|

4.4.1 SENSORS ................................................................................. |

4-54 |

|

4.5 BLOWN FUSE CONDITIONS............................................................. |

4-59 |

|

4.5.1 POWER SUPPLY UNIT............................................................. |

4-59 |

|

4.5.2 IOB............................................................................................. |

4-59 |

|

4.6 LEDS................................................................................................... |

|

4-60 |

SERVICE TABLES

5. SERVICE TABLES................................................................... |

5-1 |

5.1 SERVICE PROGRAM MODE ............................................................... |

5-1 |

5.1.1 SERVICE MODE OPERATION ................................................... |

5-1 |

Entering the Service Mode .............................................................. |

5-1 |

Accessing the Required Program.................................................... |

5-2 |

Inputting a Value or Setting for a Service Program ......................... |

5-2 |

Exiting Service Mode....................................................................... |

5-2 |

5.1.2 REMARKS ................................................................................... |

5-3 |

Display on the Control Panel Screen............................................... |

5-3 |

5.1.3 BIT SWITCH PROGRAMMING ................................................... |

5-6 |

5.2 SERVICE MODE TABLE ...................................................................... |

5-7 |

5.2.1 CONTROLLER SERVICE MODE ................................................ |

5-7 |

5.2.2 ENGINE SERVICE MODE......................................................... |

5-14 |

SP1-XXX (Feed)............................................................................ |

5-14 |

SP2-XXX (Drum) ........................................................................... |

5-38 |

SP3-XXX (Process)..................................................................... |

5-111 |

SP5-XXX (Mode)......................................................................... |

5-136 |

SP7-XXX (Data Log) ................................................................... |

5-179 |

SP8-XXX (Data Log 2) ................................................................ |

5-207 |

SP9-XXX ..................................................................................... |

5-224 |

5.2.3 INPUT CHECK TABLE ............................................................ |

5-231 |

5.2.4 OUTPUT CHECK TABLE ........................................................ |

5-237 |

G190 |

v |

SM |

|

CÓPIA NÃO CONTROLADA |

|

CÓPIA NÃO CONTROLADA

5.3 FIRMWARE UPDATE ....................................................................... |

5-240 |

5.3.1 TYPE OF FIRMWARE ............................................................. |

5-240 |

5.3.2 BEFORE YOU BEGIN ............................................................. |

5-241 |

5.3.3 UPDATING FIRMWARE.......................................................... |

5-241 |

File Arrangement......................................................................... |

5-241 |

Update Procedure ....................................................................... |

5-242 |

Error Handling ............................................................................. |

5-243 |

Power Failure .............................................................................. |

5-243 |

5.3.4 NVRAM DATA UPLOAD/DOWNLOAD.................................... |

5-245 |

Uploading NVRAM Data.............................................................. |

5-245 |

Downloading NVRAM Data ......................................................... |

5-246 |

5.3.5 ADDRESS BOOK UPLOAD/DOWNLOAD............................... |

5-247 |

Download .................................................................................... |

5-247 |

Upload......................................................................................... |

5-247 |

5.3.6 HANDLING FIRMWARE UPDATE ERRORS .......................... |

5-249 |

Error Message Table................................................................... |

5-249 |

5.4 CONTROLLER SELF-DIAGNOSTICS.............................................. |

5-251 |

5.4.1 OVERVIEW.............................................................................. |

5-251 |

5.5 USING THE DEBUG LOG ................................................................ |

5-252 |

5.5.1 SWITCHING ON AND SETTING UP SAVE DEBUG LOG ...... |

5-252 |

5.5.2 RETRIEVING THE DEBUG LOG FROM THE HDD ................ |

5-256 |

5.5.3 DEBUG LOG CODES.............................................................. |

5-257 |

SP5857-015 Copy SD Card-to-SD Card: Any Desired Key......... |

5-257 |

SP5857-016 Create a File on HDD to Store a Log...................... |

5-257 |

SP5857-017 Create a File on SD Card to Store a Log................ |

5-257 |

5.6 DIP SWITCHES ................................................................................ |

5-258 |

5.6.1 CONTROLLER BOARD........................................................... |

5-258 |

DETAILED DESCRIPTIONS

6. DETAILED DESCRIPTIONS.................................................... |

6-1 |

6.1 OVERVIEW........................................................................................... |

6-1 |

6.1.1 COMPONENT LAYOUT .............................................................. |

6-1 |

6.1.2 PAPER PATH .............................................................................. |

6-2 |

6.1.3 DRIVE LAYOUT........................................................................... |

6-3 |

6.1.4 BOARD STRUCTURE ................................................................. |

6-4 |

SM |

vi |

G190 |

|

CÓPIA NÃO CONTROLADA |

|

|

CÓPIA NÃO CONTROLADA |

|

|

6.1.5 PRINTING PROCESS ................................................................. |

6-6 |

6.2 PROCESS CONTROL .......................................................................... |

6-8 |

|

|

6.2.1 OVERVIEW.................................................................................. |

6-8 |

|

6.2.2 POTENTIAL CONTROL............................................................... |

6-8 |

|

Overview ......................................................................................... |

6-8 |

|

Process Control Self-check ............................................................. |

6-9 |

|

Process Control Self-Check Procedure......................................... |

6-10 |

|

6.2.3 TONER SUPPLY CONTROL..................................................... |

6-12 |

|

Toner Supply Control Modes......................................................... |

6-12 |

|

Low Image Coverage .................................................................... |

6-12 |

|

6.2.4 TONER NEAR END/TONER END DETECTION ....................... |

6-13 |

|

Introduction.................................................................................... |

6-13 |

|

Toner Near End Detection............................................................. |

6-14 |

|

Toner End Detection ..................................................................... |

6-14 |

|

Toner End Recovery ..................................................................... |

6-14 |

|

6.2.5 DEVELOPER INITIALIZATION.................................................. |

6-15 |

6.3 PAPER FEED ..................................................................................... |

6-16 |

|

|

6.3.1 OVERVIEW................................................................................ |

6-16 |

|

6.3.2 PAPER FEED DRIVE ................................................................ |

6-17 |

|

6.3.3 PAPER TRAY ............................................................................ |

6-18 |

|

Paper Lift....................................................................................... |

6-18 |

|

Paper Size Detection..................................................................... |

6-19 |

|

Paper Near End/End Detection ..................................................... |

6-20 |

|

6.3.4 BY-PASS TRAY FEED AND SIZE DETECTION ....................... |

6-21 |

|

Paper Feed Mechanism ................................................................ |

6-21 |

|

Paper Size Detection Mechanism ................................................. |

6-21 |

|

6.3.5 DUPLEX..................................................................................... |

6-22 |

|

Drive.............................................................................................. |

6-23 |

|

Interleaving.................................................................................... |

6-24 |

6.4 LASER EXPOSURE ........................................................................... |

6-26 |

|

|

6.4.1 OVERVIEW................................................................................ |

6-26 |

|

6.4.2 OPTICAL PATH ......................................................................... |

6-27 |

|

6.4.3 LASER SYNCHRONIZING DETECTOR.................................... |

6-28 |

|

Overview ....................................................................................... |

6-28 |

|

Main Scan Start Detection............................................................. |

6-28 |

|

6.4.4 LD SAFETY SWITCH ................................................................ |

6-29 |

G190 |

vii |

SM |

|

CÓPIA NÃO CONTROLADA |

|

|

CÓPIA NÃO CONTROLADA |

|

|

6.4.5 AUTOMATIC LINE POSITION ADJUSTMENT.......................... |

6-30 |

|

Overview ....................................................................................... |

6-30 |

|

Summary of Each Adjustment ....................................................... |

6-30 |

|

Adjustment Conditions .................................................................. |

6-31 |

|

Main Scan Skew Adjustment......................................................... |

6-34 |

|

LDU Shutter................................................................................... |

6-34 |

6.5 PHOTOCONDUCTOR UNIT............................................................... |

6-35 |

|

|

6.5.1 OVERVIEW................................................................................ |

6-35 |

|

6.5.2 DRIVE AND DRIVE GEAR POSITION SENSOR ...................... |

6-36 |

|

Mechanism .................................................................................... |

6-36 |

|

Initialization Process and SC Codes ............................................. |

6-36 |

|

6.5.3 DRUM CHARGE AND QUENCHING ........................................ |

6-38 |

|

6.5.4 DRUM CLEANING..................................................................... |

6-39 |

|

6.5.5 WASTE TONER COLLECTION................................................. |

6-40 |

|

6.5.6 WASTE TONER BOTTLE FULL DETECTION AND SET |

|

|

DETECTION ....................................................................................... |

6-41 |

|

6.5.7 PCU DETECTION (DEVELOPMENT UNIT DETECTION) ........ |

6-42 |

|

Unit Set Detection Pins ................................................................. |

6-42 |

|

New Unit Detection........................................................................ |

6-42 |

|

Error Message............................................................................... |

6-42 |

6.6 DEVELOPMENT................................................................................. |

6-43 |

|

|

6.6.1 OVERVIEW................................................................................ |

6-43 |

|

6.6.2 DRIVE........................................................................................ |

6-44 |

|

6.6.3 DEVELOPER MIXING ............................................................... |

6-44 |

|

6.6.4 DEVELOPMENT BIAS............................................................... |

6-45 |

|

6.6.5 TONER SUPPLY MECHANISM ................................................ |

6-46 |

|

Overview ....................................................................................... |

6-46 |

6.7 IMAGE TRANSFER ............................................................................ |

6-47 |

|

|

6.7.1 OVERVIEW................................................................................ |

6-47 |

|

6.7.2 TRANSFER UNIT DETECTION AND NEW UNIT DETECTION6-48 |

|

|

6.7.3 DRIVE AND TRANSFER BELT ROLLER VOLTAGE ................ |

6-49 |

|

Transfer belt contact...................................................................... |

6-50 |

|

Transfer Belt Cleaning................................................................... |

6-51 |

|

6.7.4 TRANSFER ROLLER UNIT ....................................................... |

6-52 |

|

Discharge ...................................................................................... |

6-53 |

|

Transfer Roller Contact ................................................................. |

6-54 |

SM |

viii |

G190 |

|

CÓPIA NÃO CONTROLADA |

|

CÓPIA NÃO CONTROLADA

6.8 FUSING .............................................................................................. |

6-55 |

6.8.1 OVERVIEW................................................................................ |

6-55 |

6.8.2 FUSING TEMPERATURE CONTROL....................................... |

6-56 |

Overall Procedure ......................................................................... |

6-56 |

Fusing Roller Idling........................................................................ |

6-56 |

Idling Ready Temperature before First Print Job: [A] .................... |

6-57 |

Machine Ready Temperature: [B].................................................. |

6-57 |

Print ready temperature: [C] .......................................................... |

6-57 |

Target Printing Temperature: [D]................................................... |

6-57 |

First Print Temperature: [G]........................................................... |

6-57 |

Corrections for Small Paper Sizes (less than A5).......................... |

6-58 |

Overheat Protection ...................................................................... |

6-58 |

6.8.3 DRIVE........................................................................................ |

6-59 |

6.9 CONTROLLER.................................................................................... |

6-60 |

SPECIFICATIONS

7. SPECIFICATIONS.................................................................... |

7-1 |

7.1 SPECIFICATIONS ................................................................................ |

7-1 |

7.1.1 GENERAL SPECIFICATIONS ..................................................... |

7-1 |

7.1.2 SUPPORTED PAPER SIZES ...................................................... |

7-5 |

7.1.3 SOFTWARE ACCESSORIES...................................................... |

7-7 |

Printer Drivers ................................................................................. |

7-7 |

Utility Software ................................................................................ |

7-8 |

7.1.4 MACHINE CONFIGURATION ..................................................... |

7-9 |

G190 |

ix |

SM |

|

CÓPIA NÃO CONTROLADA |

|

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

INSTALLATION

PREVENTIVE MAINTENANCE

REPLACEMENT AND ADJUSTMENT

TROUBLESHOOTING

SERVICE TABLES

DETAILED DESCRIPTIONS

SPECIFICATIONS

APPENDIX

TAB |

POSITION 1 |

|

|

|

|

TAB |

POSITION 2 |

|

|

|

|

TAB |

POSITION 3 |

|

|

|

|

TAB |

POSITION 4 |

|

|

|

|

TAB |

POSITION 5 |

|

|

|

|

TAB |

POSITION 6 |

|

|

|

|

TAB |

POSITION 7 |

|

|

|

|

TAB |

POSITION 8 |

|

|

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Read This First

Safety Notices

Important Safety Notices

Prevention of Physical Injury

1.Before disassembling or assembling parts of the printer and peripherals, make sure that the printer power cord is unplugged.

2.The wall outlet should be near the printer and easily accessible.

3.If any adjustment or operation check has to be made with exterior covers off or open while the main switch is turned on, keep hands away from electrified or mechanically driven components.

4.The printer drives some of its components when it completes the warm-up period. Be careful to keep hands away from the mechanical and electrical components as the printer starts operation.

5.The inside and the metal parts of the fusing unit become extremely hot while the printer is operating. Be careful to avoid touching those components with your bare hands.

Health Safety Conditions

Toner and developer are non-toxic, but if you get either of them in your eyes by accident, it may cause temporary eye discomfort. Immediately wash eyes with plenty of water. If unsuccessful, get medical attention.

Observance of Electrical Safety Standards

The printer and its peripherals must be serviced by a customer service representative who has completed the training course on those models.

Lithium Batteries

Incorrect replacement of lithium battery(s) on the EGB and controller board may pose risk of explosion. Replace only with the same type or with an equivalent type recommended by the manufacturer. Discard used batteries in accordance with the manufacturer’s instructions.

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Safety and Ecological Notes for Disposal

1.Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly when exposed to an open flame.

2.Dispose of used toner, the maintenance unit which includes developer or the organic photoconductor in accordance with local regulations. (These are non-toxic supplies.)

3.Dispose of replaced parts in accordance with local regulations.

4.When keeping used lithium batteries in order to dispose of them later, do not put more than 100 batteries per sealed box. Storing larger numbers or not sealing them apart may lead to chemical reactions and heat build-up.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of laser-based optical units in the field. The optical housing unit can only be repaired in a factory or at a location with the requisite equipment. The laser subsystem is replaceable in the field by a qualified Customer Engineer. The laser chassis is not repairable in the field. Customer engineers are therefore directed to return all chassis and laser subsystems to the factory or service depot when replacement of the optical subsystem is required.

Use of controls, or adjustment, or performance of procedures other than those specified in this manual may result in hazardous radiation exposure.

Turn off the main switch before attempting any of the procedures in the Laser Optics Housing Unit section. Laser beams can seriously damage your eyes.

CAUTION MARKING:

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Symbols, Abbreviations, and Trademarks

Symbols and Abbreviations

This manual uses the symbols and abbreviations shown below.

Symbol |

Meaning |

|

|

|

Refer to section number |

|

|

|

Clip ring |

|

|

|

Screw |

|

|

|

Connector |

|

|

= |

Clamp |

|

|

|

E-ling |

|

|

SEF |

Short Edge Feed |

|

|

LEF |

Long Edge Feed |

|

|

Trademarks

Microsoft®, Windows®, and MS-DOS® are registered trademarks of Microsoft Corporation in the United States and /or other countries.

PostScript® is a registered trademark of Adobe Systems, Incorporated. PCL® is a registered trademark of Hewlett-Packard Company. Ethernet® is a registered trademark of Xerox Corporation.

PowerPC® is a registered trademark of International Business Machines Corporation. Other product names used herein are for identification purposes only and may be trademarks of their respective companies. We disclaim any and all rights involved with those marks.

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

INSTALLATION

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Installation Requirements

1. INSTALLATION PROCEDURE

1.1 INSTALLATION REQUIREMENTS

1.1.1 ENVIRONMENT

Installation

1.Temperature Range: 10°C to 32°C (50°F to 89.6°F)

2.Humidity Range: 15% to 80% RH

3.Ambient Illumination: Less than 1500 lux (do not expose to direct sunlight)

4.Ventilation: 3 times/hr/person or more

5.Do not let the machine get exposed to the following:

1)Cool air from an air conditioner

2)Heat from a heater

6.Do not install the machine in areas that are exposed to corrosive gas.

7.Install the machine at locations lower than 2,500 m (8,200 ft.) above sea level.

8.Install the machine on a strong, level base. (Inclination on any side must be no more than 5 mm.)

9.Do not install the machine in areas that get strong vibrations.

1.1.2 MACHINE LEVEL

Front to back: Within 5 mm (0.2")

Right to left: Within 5 mm (0.2")

G190 |

1-1 |

SM |

|

CÓPIA NÃO CONTROLADA |

|

CÓPIA NÃO CONTROLADA

Installation Requirements

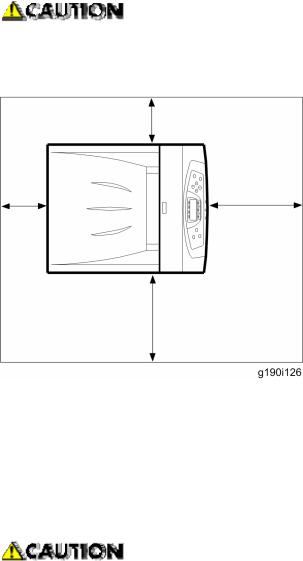

1.1.3 MACHINE SPACE REQUIREMENTS

This machine, which uses high voltage power sources, can generate ozone gas. High ozone density is harmful to human health. Therefore, the machine must be installed in a well-ventilated room.

Left side: Over 50cm (19.7”)

Rear: |

Over 10cm (4”) |

Right side: Over 10cm (4”)

Front: Over 70cm (27.6”)

Put the machine near the power source with the clearance.

1.1.4 POWER REQUIREMENTS

Insert the plug firmly in the outlet.

Do not use an outlet extension plug or cord.

Ground the machine.

1.Input voltage level:

2.120 V, 60 Hz: More than 11 A

3.220 V to 240 V, 50 Hz/60 Hz: More than 6 A

4.Permissible voltage fluctuation: ±10 %

5.Do not put things on the power cord.

SM |

1-2 |

G190 |

|

CÓPIA NÃO CONTROLADA |

|

Loading...

Loading...