Ricoh SP5200DN, SP5210D Service manual

M020/M021

SERVICE MANUAL

It is the reader's responsibility when discussing the information contained

within this document to maintain a level of confidentiality that is in the best

interest of Ricoh Americas Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

F ASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH AMERICAS CORPORATION.

All product names, domain names or product illustrations, including

desktop images, used in this document are trademarks, registered

trademarks or the property of their respective companies.

They are used throughout this book in an informational or editorial fashion

only and for the benefit of such companies. No such use, or the use of

any trade name, or web site is intended to convey endorsement or other

affiliation with Ricoh products.

© 2011 RICOH Americas Corporation. All rights reserved.

WARNING

The Service Manual contains information

regarding service techniques, procedures,

processes and spare parts of office equipment

distributed by Ricoh Americas Corporation.

Users of this manual should be either service

trained or certified by successfully completing a

Ricoh Technical Training Program.

Untrained and uncertified users utilizing

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property or loss of warranty

protection.

Ricoh Americas Corporation

LEGEND

PRODUCT

COMPANY

CODE

M020

M021

LANIER RICOH SAVIN

SP5200DN Aficio SP 5200DN SP5200DN

SP5210DN Aficio SP 5210DN SP5210DN

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

*

11/2011 Original Printing

M020/M021

TABLE OF CONTENTS

1. PRODUCT INFORMATION .......................................................... 1-1

1.1SPECIFICATIONS ..................................................................................... 1-1

1.2MACHINE CONFIGURATION ................................................................... 1-2

1.2.1 SYSTEM COMPONENTS ................................................................ 1-2

Main ..................................................................................................... 1-2

Options ................................................................................................. 1-2

Internal options ..................................................................................... 1-4

1.3OVERVIEW ................................................................................................ 1-5

1.3.1 MECHANICAL COMPONENT LAYOUT ........................................... 1-5

1.3.2 PAPER PATH ................................................................................... 1-7

2. INSTALLATION ............................................................................ 2-1

2.1MACHINE INSTALLATION ........................................................................ 2-1

2.2INSTALLATION REQUIREMENTS ............................................................ 2-2

2.2.1 ENVIRONMENT ............................................................................... 2-2

2.2.2 MACHINE LEVEL ............................................................................. 2-2

2.2.3 MINIMUM OPERATIONAL SPACE REQUIREMENTS .................... 2-3

2.2.4 POWER SUPPLY ............................................................................. 2-3

2.3CONTROLLER OPTIONS ......................................................................... 2-4

2.3.1 OVERVIEW ...................................................................................... 2-4

I/F Card Slots ....................................................................................... 2-4

SD Card Slots ...................................................................................... 2-4

SDRAM slot .......................................................................................... 2-4

Hard disk connector ............................................................................. 2-4

2.3.2 INSTALLING THE SD MEMORY CARD OPTIONS.......................... 2-5

Installation ............................................................................................ 2-5

2.3.3 SD CARD APPLICATION MOVE ..................................................... 2-7

Overview .............................................................................................. 2-7

Move Exec ........................................................................................... 2-8

Undo Exec ............................................................................................ 2-8

2.3.4 IEEE 802.11 A/G (WIRELESS LAN) ................................................. 2-9

Installation Procedure .......................................................................... 2-9

SM i M020/M021

UP Mode Settings for Wireless LAN .................................................. 2-10

SP Mode and UP Mode Settings for IEEE 802.11 a/g Wireless LAN . 2-12

2.3.5 IEEE 1284 INTERFACE BOARD .................................................... 2-13

2.3.6 GIGABIT ETHERNET ..................................................................... 2-15

2.3.7 MEMORY UNIT TYPE G 256MB / I 512MB (ONLY FOR M020) .... 2-17

2.3.8 HARD DISK DRIVE TYPE 2670 (ONLY FOR M020)...................... 2-19

2.3.9 CHECK ALL CONNECTIONS ........................................................ 2-21

2.3.10 IC CARD READER (EXTERNAL OPTIONS) ATTACHING

LOCATION ............................................................................................... 2-21

2.4PAPER FEED UNIT TK1120 (M386) ....................................................... 2-22

2.4.1 ACCESSORY CHECK .................................................................... 2-22

2.4.2 INSTALLATION PROCEDURE ...................................................... 2-22

2.4.3 WHEN STACKING FOUR OPTIONAL PAPER FEED UNITS ........ 2-25

Fixing the units together ..................................................................... 2-26

2.5PAPER FEED UNIT TK1130 (M389) ....................................................... 2-27

2.5.1 ACCESSORY CHECK .................................................................... 2-27

2.5.2 INSTALLATION PROCEDURE ...................................................... 2-27

2.5.3 WHEN STACKING FOUR OPTIONAL PAPER FEED UNITS ........ 2-30

Fixing the units together ..................................................................... 2-31

3. PREVENTIVE MAINTENANCE .................................................... 3-1

3.1MAINTENANCE TABLES .......................................................................... 3-1

3.1.1 USER MAINTENANCE ..................................................................... 3-1

3.1.2 SERVICE MAINTENANCE ............................................................... 3-1

3.2PM PARTS SETTINGS .............................................................................. 3-2

3.2.1 BEFORE REMOVING THE OLD PM PARTS ................................... 3-2

3.2.2 AFTER INSTALLING THE NEW PM PARTS ................................... 3-2

3.2.3 OPERATION CHECK ....................................................................... 3-2

4. REPLACEMENT AND ADJUSTMENT ........................................ 4-1

4.1GENERAL PRECAUTIONS ....................................................................... 4-1

4.1.1 PRECAUTIONS ON DISASSEMBLY ............................................... 4-1

4.1.2 RELEASING PLASTIC LATCHES .................................................... 4-2

4.1.3 AFTER SERVICING THE MACHINE ................................................ 4-2

4.2COVERS .................................................................................................... 4-3

4.2.1 RIGHT COVER ................................................................................. 4-3

4.2.2 LEFT COVER ................................................................................... 4-5

4.2.3 UPPER COVER ................................................................................ 4-6

4.2.4 FRONT COVER ................................................................................ 4-7

M020/M021 ii SM

4.2.5 REAR COVER .................................................................................. 4-9

4.2.6 OPERATION PANEL ...................................................................... 4-10

4.3LASER UNIT ............................................................................................ 4-11

4.3.1 CAUTION DECAL LOCATIONS ..................................................... 4-11

4.3.2 LASER UNIT ................................................................................... 4-12

4.3.3 POLYGON MIRROR MOTOR ........................................................ 4-14

4.3.4 LASER SYNCHRONIZATION DETECTOR .................................... 4-15

4.4TRANSFER ROLLER .............................................................................. 4-16

4.5FUSING ................................................................................................... 4-17

4.5.1 FUSING UNIT ................................................................................. 4-17

4.5.2 HOT ROLLER AND PRESSURE ROLLER SECTIONS ................. 4-18

4.5.3 FUSING LAMP ............................................................................... 4-19

4.5.4 HOT ROLLER ................................................................................. 4-20

4.5.5 FUSING THERMISTOR .................................................................. 4-21

4.5.6 THERMOSTATS ............................................................................. 4-21

4.5.7 PRESSURE ROLLER ..................................................................... 4-22

4.5.8 FUSING CLEANING ROLLER ........................................................ 4-23

4.6PAPER FEED .......................................................................................... 4-24

4.6.1 PAPER FEED ROLLER .................................................................. 4-24

4.6.2 FRICTION PAD .............................................................................. 4-24

4.6.3 PAPER END SENSOR ................................................................... 4-27

4.6.4 REMAINING PAPER SENSORS 1 AND 2 ..................................... 4-29

4.6.5 REGISTRATION SENSOR ............................................................. 4-31

4.7BY-PASS TRAY ....................................................................................... 4-32

4.7.1 BY-PASS TRAY UNIT .................................................................... 4-32

4.7.2 BY-PASS FEED ROLLER .............................................................. 4-33

4.7.3 BY-PASS FRICTION PAD .............................................................. 4-34

4.7.4 BY-PASS PAPER SENSOR ........................................................... 4-35

4.8DUPLEX .................................................................................................. 4-36

4.8.1 DUPLEX UNIT ................................................................................ 4-36

4.8.2 DUPLEX ENTRANCE SENSOR ..................................................... 4-37

4.8.3 DUPLEX RELAY SENSOR ............................................................. 4-38

4.9PAPER EXIT ............................................................................................ 4-40

4.9.1 PAPER OVERFLOW SENSOR ...................................................... 4-40

4.9.2 PAPER EXIT SENSOR ................................................................... 4-41

4.10 ELECTRICAL COMPONENTS .......................................................... 4-43

4.10.1 CONTROLLER BOARD ............................................................. 4-43

4.10.2 CONTROLLER BOX ................................................................... 4-44

SM iii M020/M021

4.10.3 PSU AND PSU COVER .............................................................. 4-45

4.10.4 ENGINE BOARD ........................................................................ 4-47

When installing a new engine board .................................................. 4-48

4.10.5 ENGINE BOARD BRACKET ...................................................... 4-49

4.10.6 ENGINE BOARD WITH BRACKET ............................................ 4-50

4.10.7 RFID (RADIO FREQUENCY ID) ................................................. 4-51

4.10.8 HVPS (HIGH VOLTAGE POWER SUPPLY) .............................. 4-52

4.10.9 OPERATION PANEL UNIT ......................................................... 4-52

Keyboard Unit .................................................................................... 4-52

Operation panel controller and LCD unit ............................................ 4-54

4.10.10 NVRAM AND EEPROM ............................................................ 4-55

NVRAMs ............................................................................................ 4-55

EEPROM ............................................................................................ 4-56

4.11 SWITCHES ........................................................................................ 4-57

4.11.1 TRAY SET SWITCH AND PAPER SIZE DETECTION SENSOR

BOARD 4-57

4.11.2 REAR-LEFT INTERLOCK SWITCH ........................................... 4-58

4.11.3 REAR-RIGHT INTERLOCK SWITCH ......................................... 4-59

4.11.4 FRONT INTERLOCK SWITCH ................................................... 4-60

4.12 CLUTCHES ........................................................................................ 4-61

4.12.1 OVERVIEW ................................................................................ 4-61

4.12.2 REGISTRATION CLUTCH ......................................................... 4-62

4.12.3 RELAY CLUTCH ........................................................................ 4-62

4.12.4 BY-PASS FEED CLUTCH .......................................................... 4-63

4.12.5 PAPER FEED CLUTCH ............................................................. 4-63

4.13 FANS .................................................................................................. 4-64

4.13.1 OVERVIEW ................................................................................ 4-64

4.13.2 AIO FAN ..................................................................................... 4-65

4.13.3 EXHAUST FAN ........................................................................... 4-65

4.13.4 PSU FAN .................................................................................... 4-66

4.13.5 TRANSFER THERMISTOR ........................................................ 4-66

4.14 OTHER ELECTRICAL COMPONENTS ............................................. 4-67

4.14.1 HDD (OPTION FOR M020) ........................................................ 4-67

4.14.2 DIMM (OPTION FOR M020) ....................................................... 4-68

4.14.3 DUPLEX JUNCTION SOLENOID ............................................... 4-69

4.14.4 TONER END SENSOR .............................................................. 4-70

4.15 DRIVE SECTION ............................................................................... 4-71

4.15.1 OVERVIEW ................................................................................ 4-71

M020/M021 iv SM

4.15.2 MAIN MOTOR GEAR ASSY ....................................................... 4-72

4.15.3 MAIN MOTOR ............................................................................ 4-73

4.15.4 PAPER EXIT MOTOR ................................................................ 4-74

4.15.5 DUPLEX MOTOR ....................................................................... 4-75

5. SYSTEM MAINTENANCE REFERENCE ..................................... 5-1

5.1PRINTER SERVICE MODE ....................................................................... 5-1

5.1.1 SP1-XXX (SERVICE MODE) ............................................................ 5-1

5.2ENGINE SERVICE MODE ....................................................................... 5-10

5.2.1 ENGINE MODE TABLE .................................................................. 5-10

SP1-xxx: Feed .................................................................................... 5-10

SP2-xxx: Drum ................................................................................... 5-16

SP3-xxx: Process ............................................................................... 5-18

SP5-xxx: Mode ................................................................................... 5-19

SP7-xxx: Data Log ............................................................................. 5-77

SP8XXX: Data Log 2 .......................................................................... 5-92

5.3FIRMWARE UPDATE ............................................................................ 5-103

5.3.1 TYPE OF FIRMWARE .................................................................. 5-103

5.3.2 PRECAUTIONS ............................................................................ 5-104

Handling SD Cards .......................................................................... 5-104

Upload/Download ............................................................................. 5-104

Network Connection ......................................................................... 5-104

5.3.3 MACHINE FIRMWARE UPDATE ................................................. 5-105

5.4NVRAM DATA UPLOAD/DOWNLOAD .................................................. 5-107

5.4.1 UPLOADING NVRAM DATA ........................................................ 5-107

5.4.2 DOWNLOADING NVRAM DATA .................................................. 5-108

5.5SD CARD APPLICATION MOVE ........................................................... 5-110

5.5.1 OVERVIEW .................................................................................. 5-110

5.5.2 MOVE EXEC ................................................................................ 5-110

5.5.3 UNDO EXEC ................................................................................ 5-111

5.6MENU MODE ......................................................................................... 5-112

5.7CONTROLLER BOARD DIP SWITCHES .............................................. 5-115

5.8CARD SAVE FUNCTION ....................................................................... 5-116

5.8.1 OVERVIEW .................................................................................. 5-116

Card Save: ....................................................................................... 5-116

5.8.2 PROCEDURE ............................................................................... 5-116

6. TROUBLESHOOTING ................................................................. 6-1

6.1SERVICE CALL CONDITIONS .................................................................. 6-1

SM v M020/M021

6.1.1 SUMMARY ....................................................................................... 6-1

6.1.2 SC CODE DESCRIPTIONS .............................................................. 6-2

6.2ERROR MESSAGES ............................................................................... 6-32

6.2.1 COMMON ERROR MESSAGES .................................................... 6-32

6.3JAM DETECTION .................................................................................... 6-37

6.3.1 PAPER JAM DISPLAY ................................................................... 6-37

6.3.2 PAPER JAM SENSORS ................................................................. 6-37

6.3.3 JAM CODES AND DISPLAY CODES ............................................. 6-38

6.3.4 INITIAL JAM RELATIONS .............................................................. 6-40

6.4GENERAL TROUBLESHOOTING ........................................................... 6-41

6.4.1 IMAGE ADJUSTMENT ................................................................... 6-41

Registration Adjustment ..................................................................... 6-41

Parallelogram Image Adjustment ....................................................... 6-41

6.4.2 SKEW ADJUSTMENT .................................................................... 6-42

6.4.3 STREAKS IN THE SUB SCAN DIRECTION .................................. 6-42

7. ENERGY SAVING ........................................................................ 7-1

7.1ENERGY SAVE ......................................................................................... 7-1

7.1.1 ENERGY SAVER MODES ............................................................... 7-1

Timer Settings ...................................................................................... 7-2

Return to Stand-by Mode ..................................................................... 7-2

Recommendation ................................................................................. 7-2

7.1.2 ENERGY SAVE EFFECTIVENESS .................................................. 7-3

7.2PAPER SAVE ............................................................................................ 7-5

7.2.1 EFFECTIVENESS OF DUPLEX/COMBINE FUNCTION .................. 7-5

1. Duplex .............................................................................................. 7-5

2. Combine mode ................................................................................. 7-5

3. Duplex + Combine ............................................................................ 7-6

How to calculate the paper reduction ratio ........................................... 7-6

M020/M021 vi SM

READ THIS FIRST

Safety, Conventions

Safety

Prevention of Physical Injury

1. Before disassembling or assembling parts of the printer and peripherals, make sure that the

printer power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. Note that some components of the printer and the paper tray unit are supplied with

electrical voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off or open while

the main switch is turned on, keep hands away from electrified or mechanically driven

components.

5. The inside and the metal parts of the fusing unit become extremely hot while the printer is

operating. Be careful to avoid touching those components with your bare hands.

6. To prevent a fire or explosion, keep the machine away from flammable liquids, gases, and

aerosols.

Health Safety Conditions

Toner and developer are non-toxic, but if you get either of them in your eyes by accident, it may

cause temporary eye discomfort. Try to remove with eye drops or flush with water as first aid. If

unsuccessful, get medical attention.

Observance of Electrical Safety Standards

The printer and its peripherals must be installed and maintained by a customer service

representative who has completed the training course on those models.

Safety and Ecological Notes For Disposal

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly when

exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in accordance with local

regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do not put more than

100 batteries per sealed box. Storing larger numbers or not sealing them apart may lead to

chemical reactions and heat build-up.

The controller board in this machine contains a lithium battery.

The danger of explosion exists if a battery of this type is incorrectly replaced. Replace

only with the same or an equivalent type of battery recommended by the manufacturer.

Dispose of batteries in accordance with the manufacturer's instructions and local laws

and regulations.

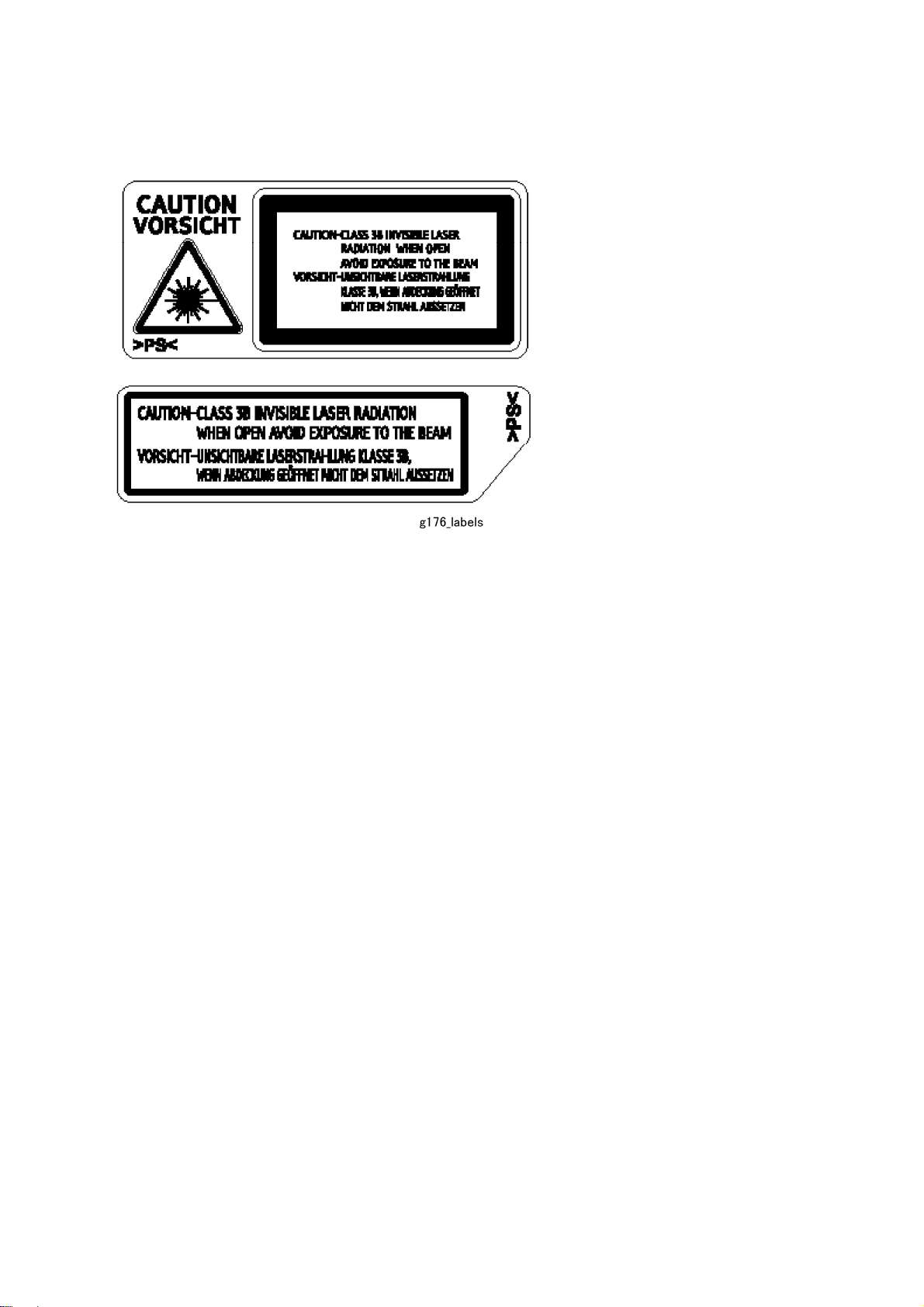

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of laser-based

optical units in the field. The optical housing unit can only be repaired in a factory or at a

location with the requisite equipment. The laser subsystem is replaceable in the field by a

qualified Customer Engineer. The laser chassis is not repairable in the field. Customer

engineers are therefore directed to return all chassis and laser subsystems to the factory or

service depot when replacement of the optical subsystem is required.

Use of controls, or adjustment, or performance of procedures other than those

specified in this manual may result in hazardous radiation exposure.

Turn off the main switch before attempting any of the procedures in the Laser Unit

section. Laser beams can seriously damage your eyes.

Caution Labels

Conventions

Conventions

Symbol What it means

Refer to section number

See Core Tech Manual for details

Screw

Connector

E-ring

C-ring

The following notations are used in text to describe the direction of paper feed: lengthwise and

sideways. The annotations “SEF” and “LEF” denote “Short Edge Feed” and “Long Edge Feed”.

(The arrows indicate the direction of paper feed.)

PRODUCT INFORMATION

REVISION HISTORY

Page Date Added/Updated/New

None

1. PRODUCT INFORMATION

Specifications

1.1 SPECIFICATIONS

See Appendices:

Appendices: Basic Specifications

Appendices: Controller Specifications

Product

Information

SM 1-1 M020/M021

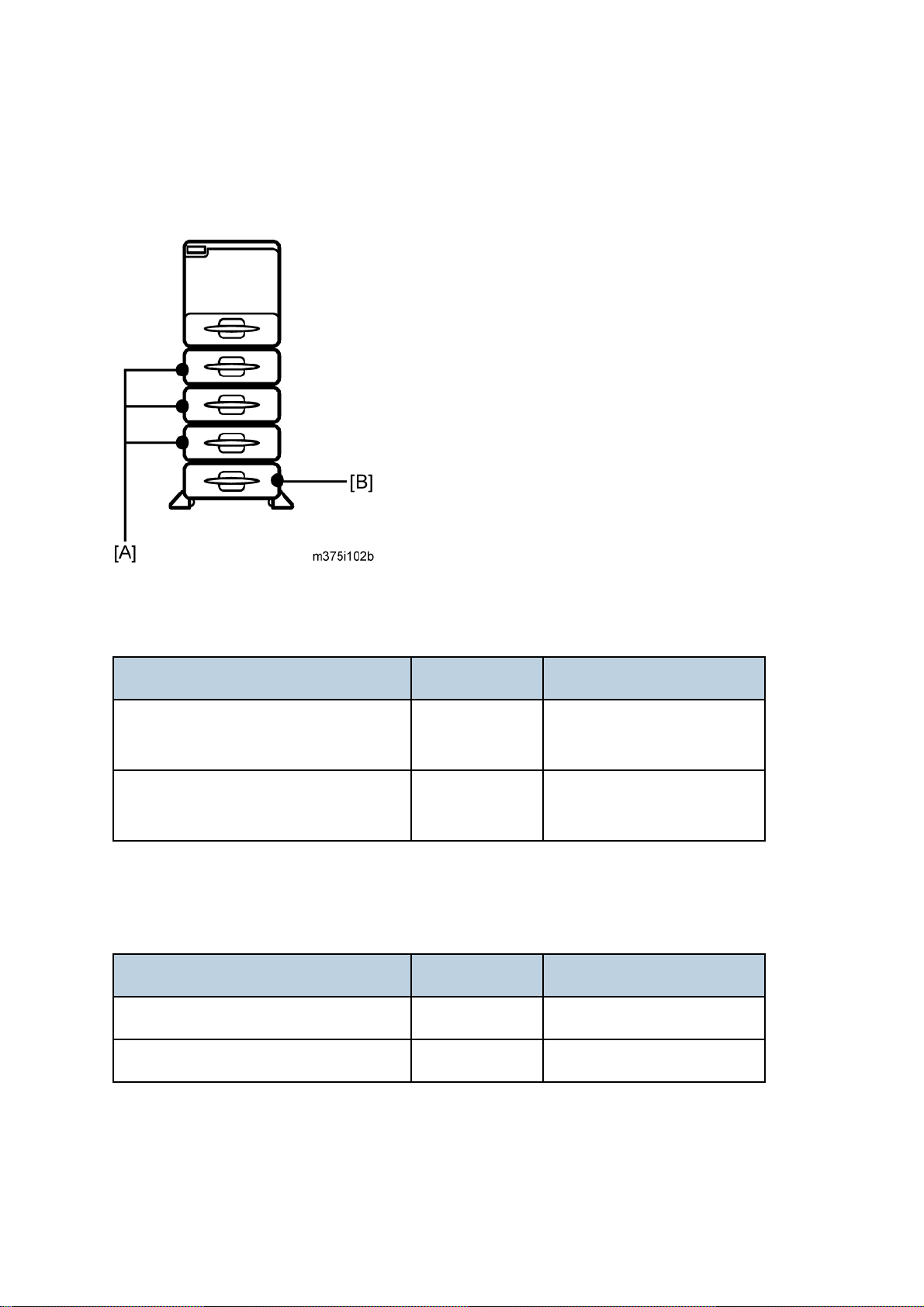

1.2 MACHINE CONFIGURATION

1.2.1 SYSTEM COMPONENTS

Main

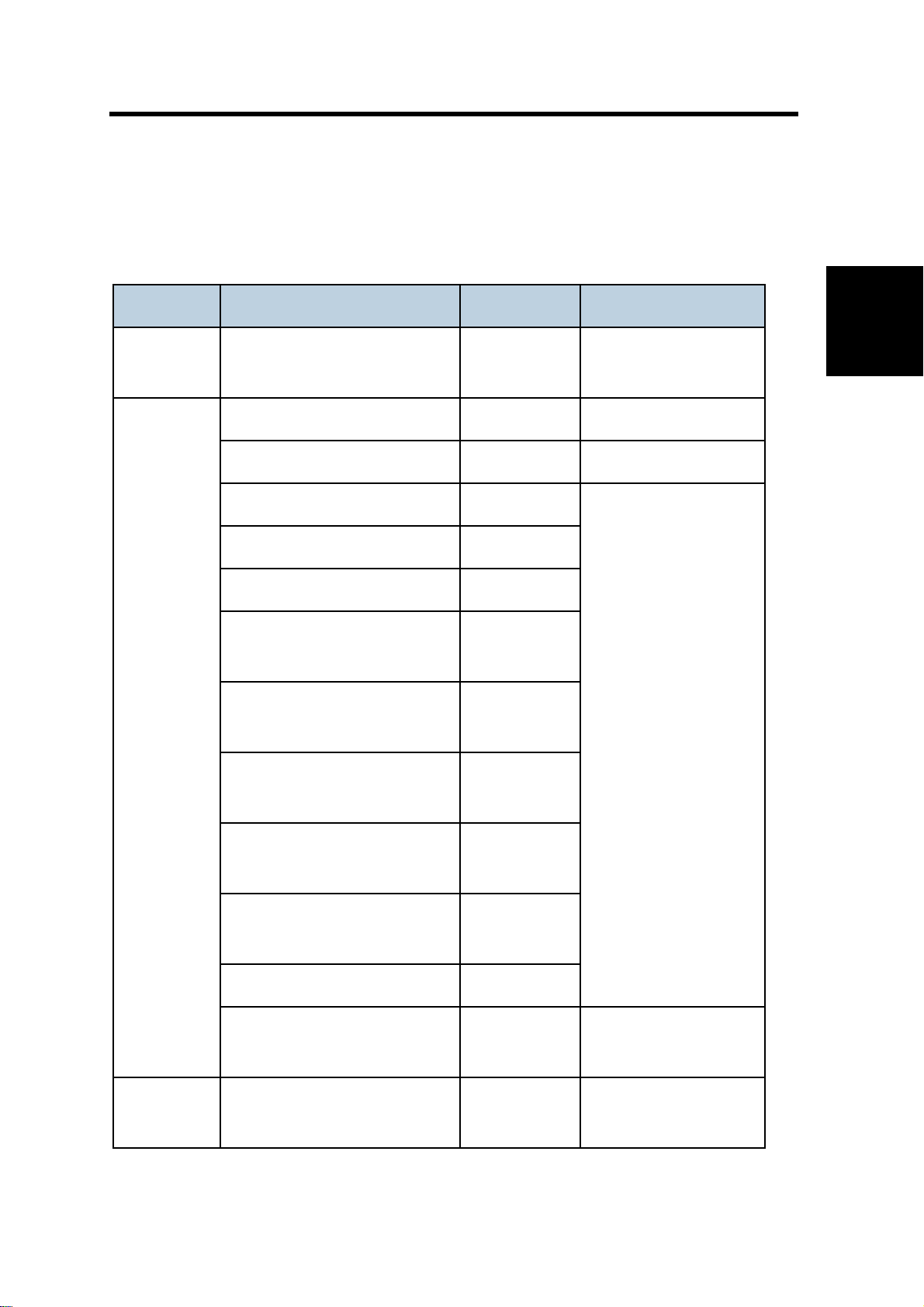

Item Machine code Remarks

Mainframe (45 / 47 ppm) M020

Mainframe (50 / 52 ppm) M021

Options

Item Machine code Remarks

45 ppm (A4 - SEF)

47 ppm (LT - SEF)

50 ppm (A4 - SEF)

52 ppm (LT - SEF)

Paper Feed Unit TK1120 [A] M386 Without casters

Paper Feed Unit TK1130 [B] M389 With casters

M020/M021 1-2 SM

Machine Configuration

Product

Information

SM 1-3 M020/M021

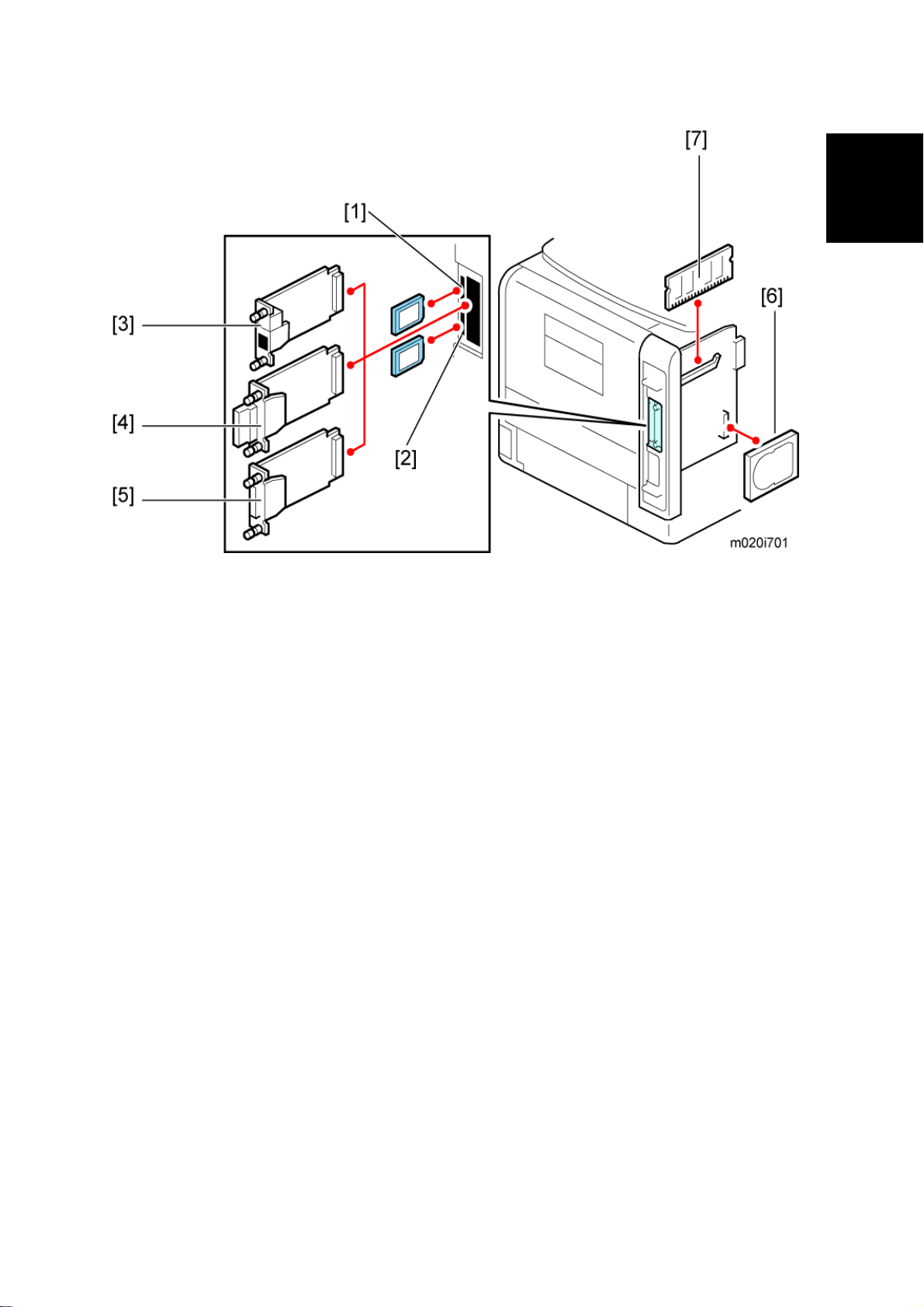

Internal options

Item Machine code Remarks

Memory Unit Type G 256 MB [7] D362 Optional for M020

Memory Unit Type I 512 MB [7] D435 Optional for M020

Hard Disk Drive Type 4310 [6] M394 Optional for M020

IEEE 1284 Interface Board Type A [5] B679

IEEE 802.11a/g interface Unit Type L

[4]

IEEE 802.11a/g Interface Unit Type M

[4]

Gigabit Ethernet Board Type A [3] G874

Gigabit Ethernet Board Type C [3] M397 For NA

SD Card for Netware Printing Type E

[1]

IPDS Unit Type 5200 [1] M388-04 For NA

IPDS Unit Type 5200 [1] M388-05 For EU

SD Card for Fonts Type C [1] M352 For EU

M344 For NA

M344 For EU

M388-03

M020/M021 1-4 SM

1.3 OVERVIEW

Overview

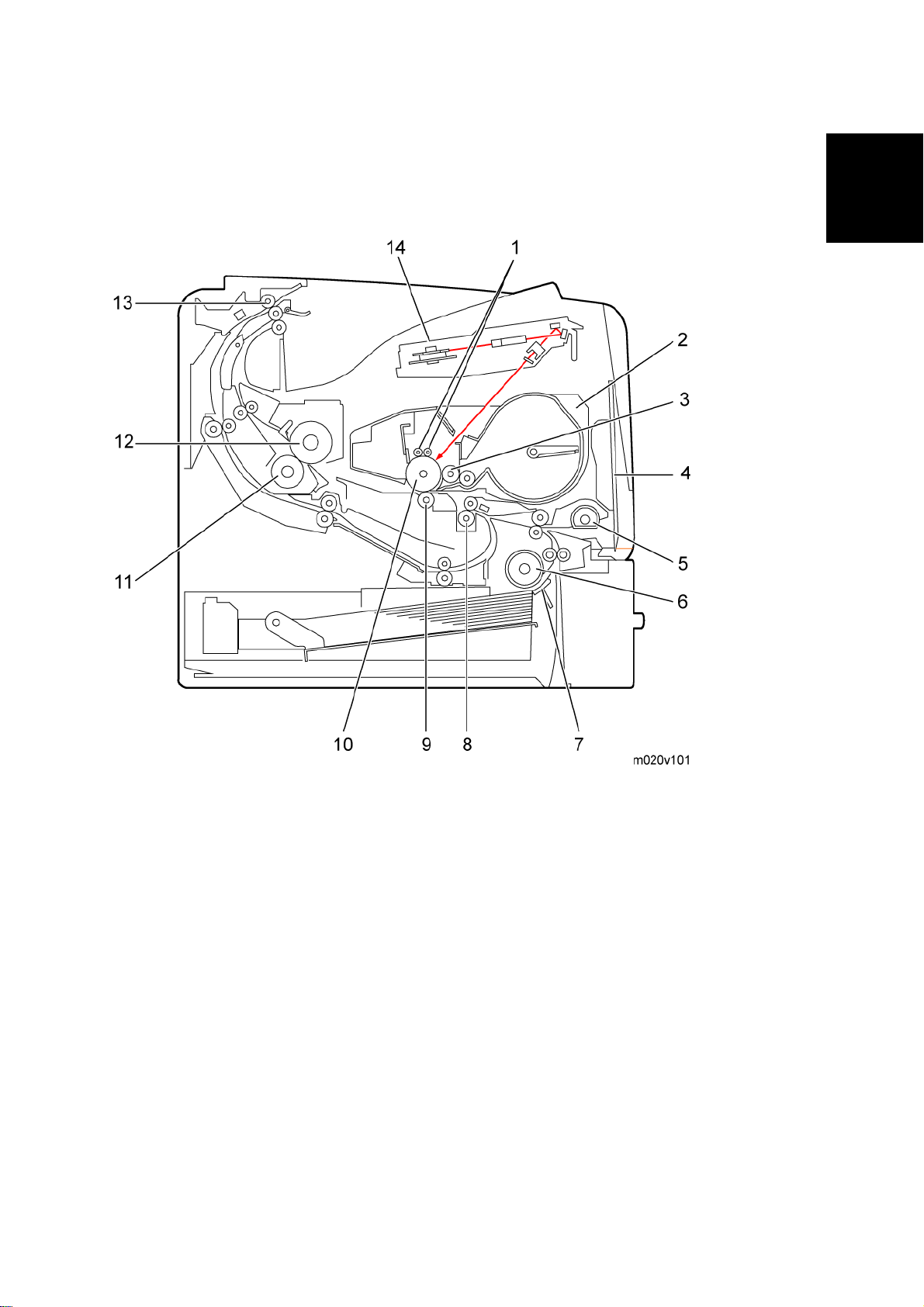

1.3.1 MECHANICAL COMPONENT LAYOUT

Product

Information

1. Charge roller 8. Registration roller

2. Cartridge (AIO-type) 9. Transfer roller

3. Development roller 10. Drum

4. By-pass feed tray 11. Pressure roller

5. By-pass feed roller 12. Hot roller

6. Paper feed roller 13. Paper exit roller

7. Friction pad 14. Laser unit

SM 1-5 M020/M021

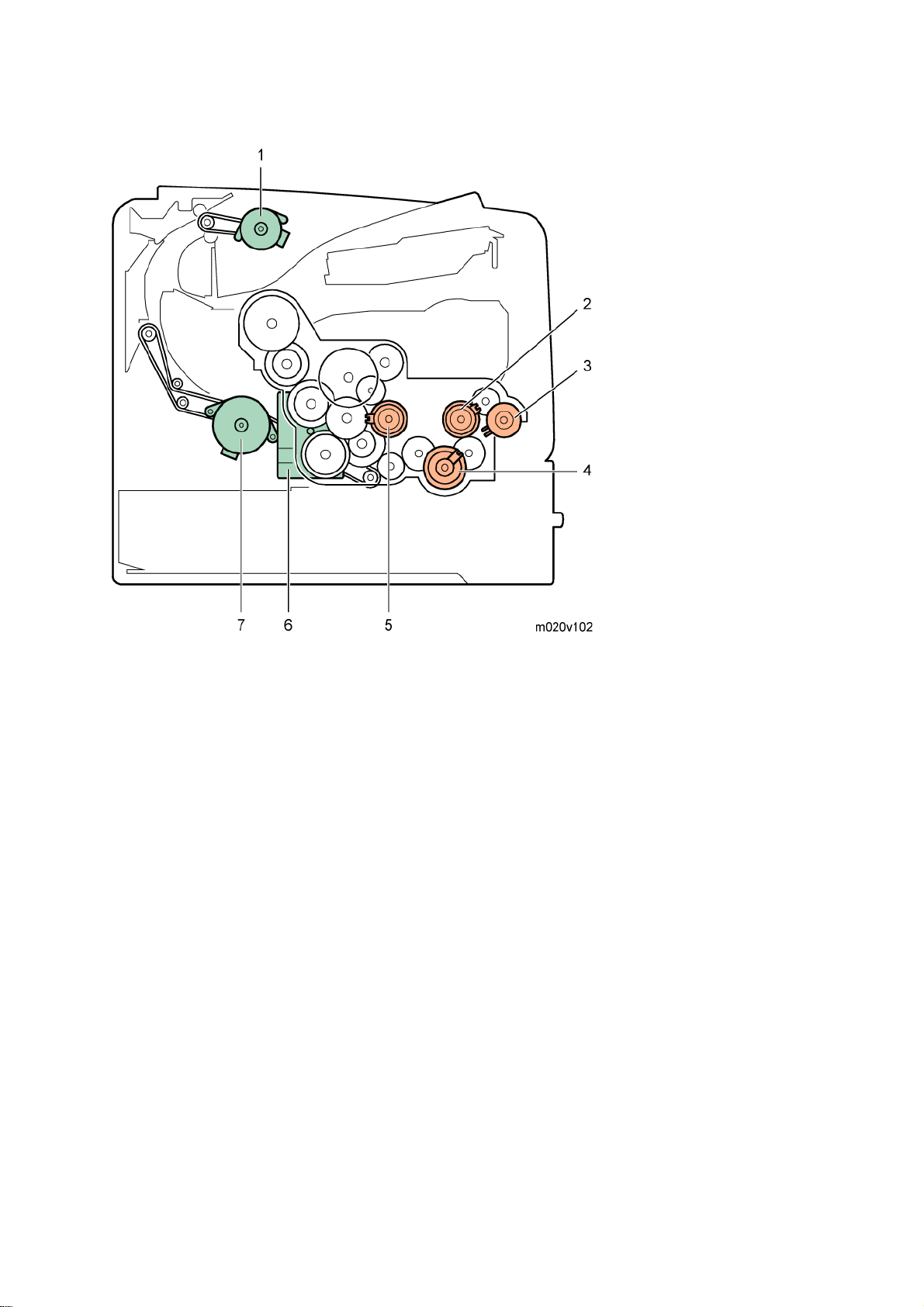

Drive Layout

1. Paper exit motor

2. Relay clutch

3. By-pass feed clutch

4. Paper feed clutch

5. Registration clutch

6. Main motor

7. Duplex motor

M020/M021 1-6 SM

1.3.2 PAPER PATH

Overview

Product

Information

1. Paper feed through duplex unit

2. Paper exit to the paper stack

3. Paper feed from tray 1

4. Paper feed from by-pass tray

5. Paper feed from optional PFU (tray 2)

6. Paper feed from optional PFU (tray 3)

7. Paper feed from optional PFU (tray 4)

8. Paper feed from optional PFU (tray 5)

SM 1-7 M020/M021

INSTALLATION

REVISION HISTORY

Page Date Added/Updated/New

None

2. INSTALLATION

2.1 MACHINE INSTALLATION

Refer to the following sections for installation details for all models.

Category Item Machine code References

Machine Installation

Main unit -

Paper Feed Unit TK1120 M386 p.2-22

Paper Feed Unit TK1130 M389 p.2-27

Memory Unit Type G 256 MB D362

Memory Unit Type I 512 MB D435

Hard Disk Drive Type 4310 M394

IEEE 802.11a/g interface Unit

Type L (NA) *1

IEEE 802.11a/g interface Unit

Options

Type M (EU) *1

IEEE 1284 Interface Board

Type A

M020/

M021

M344

M344

B679

Quick Installation Guide

p.2-4, p.2-5

Installation

Gigabit Ethernet Board Type A

*1

Gigabit Ethernet Board Type C

*1

IPDS Unit Type 5200 D571

SD Card for Netware Printing

Type E

Drivers -

*1: These units cannot be installed at the same time.

SM 2-1 M020/M021

G874

M397

Software Guide,

M388-03

Section 6

Software Guide,

Section 1

Installation Requirements

2.2 INSTALLATION REQUIREMENTS

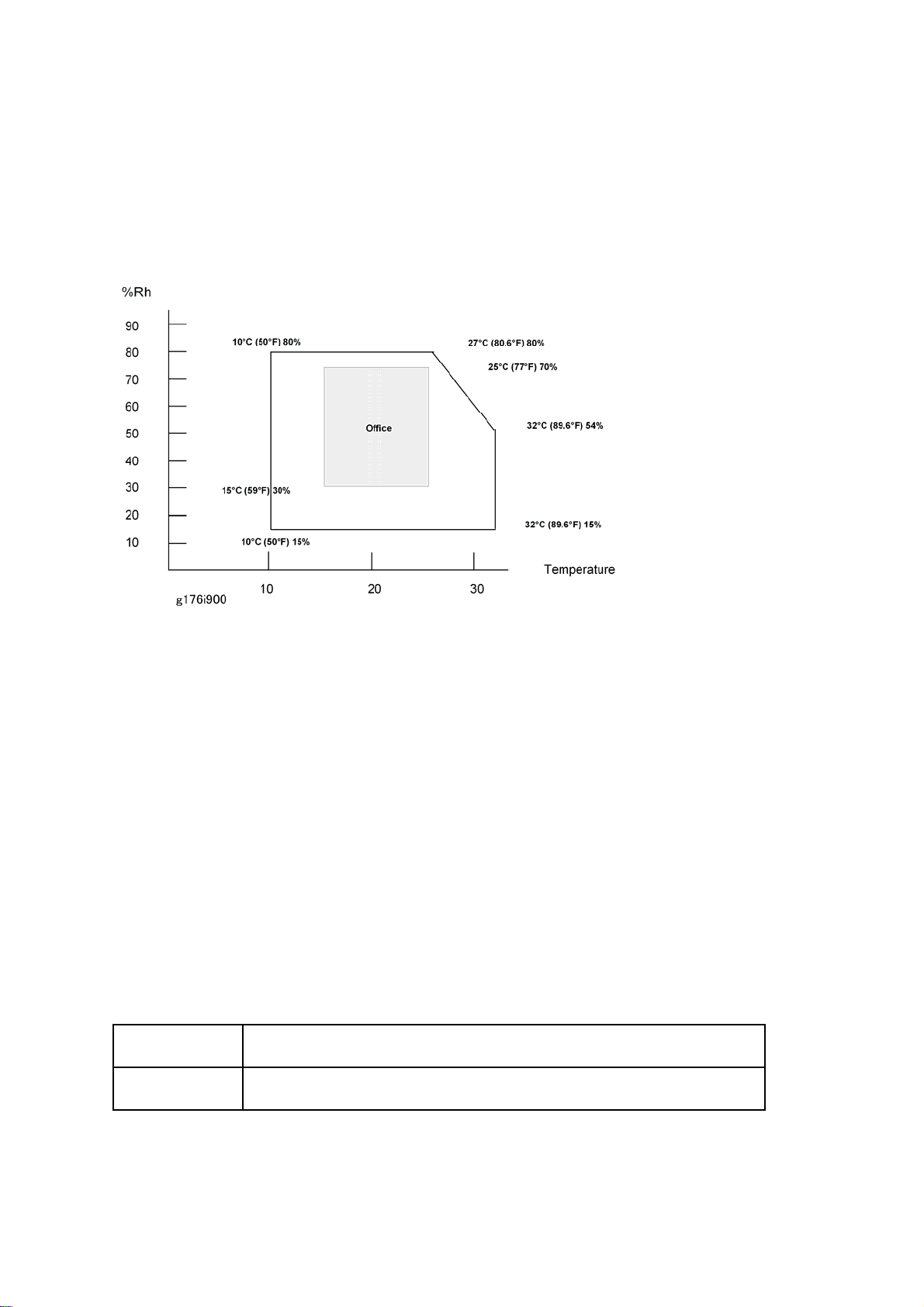

2.2.1 ENVIRONMENT

–Temperature and Humidity Chart–

Temperature Range: 10°C to 32°C (50°F to 89.6°F)

Humidity Range: 15% to 80% RH

Ambient Illumination: Less than 1,500 lux (Do not expose to direct sunlight.)

Ventilation: Room air should turn over at least 3 times/hr/person

3

Ambient Dust: Less than 0.1 mg/m

Do not install the machine where it will be exposed to direct sunlight or to direct airflow

(from a fan, air conditioner, air cleaner, etc.).

Do not install the machine where it will be exposed to corrosive gas.

Install the machine at a location lower than 2,000 m (6,560 ft.) above sea level.

Place the machine on a firm and level base.

Do not install the machine where it may be subjected to strong vibration.

2.2.2 MACHINE LEVEL

Front to back: Within 5 mm (0.2") of level

Right to left: Within 5 mm (0.2") of level

M020/M021 2-2 SM

Installation Requirements

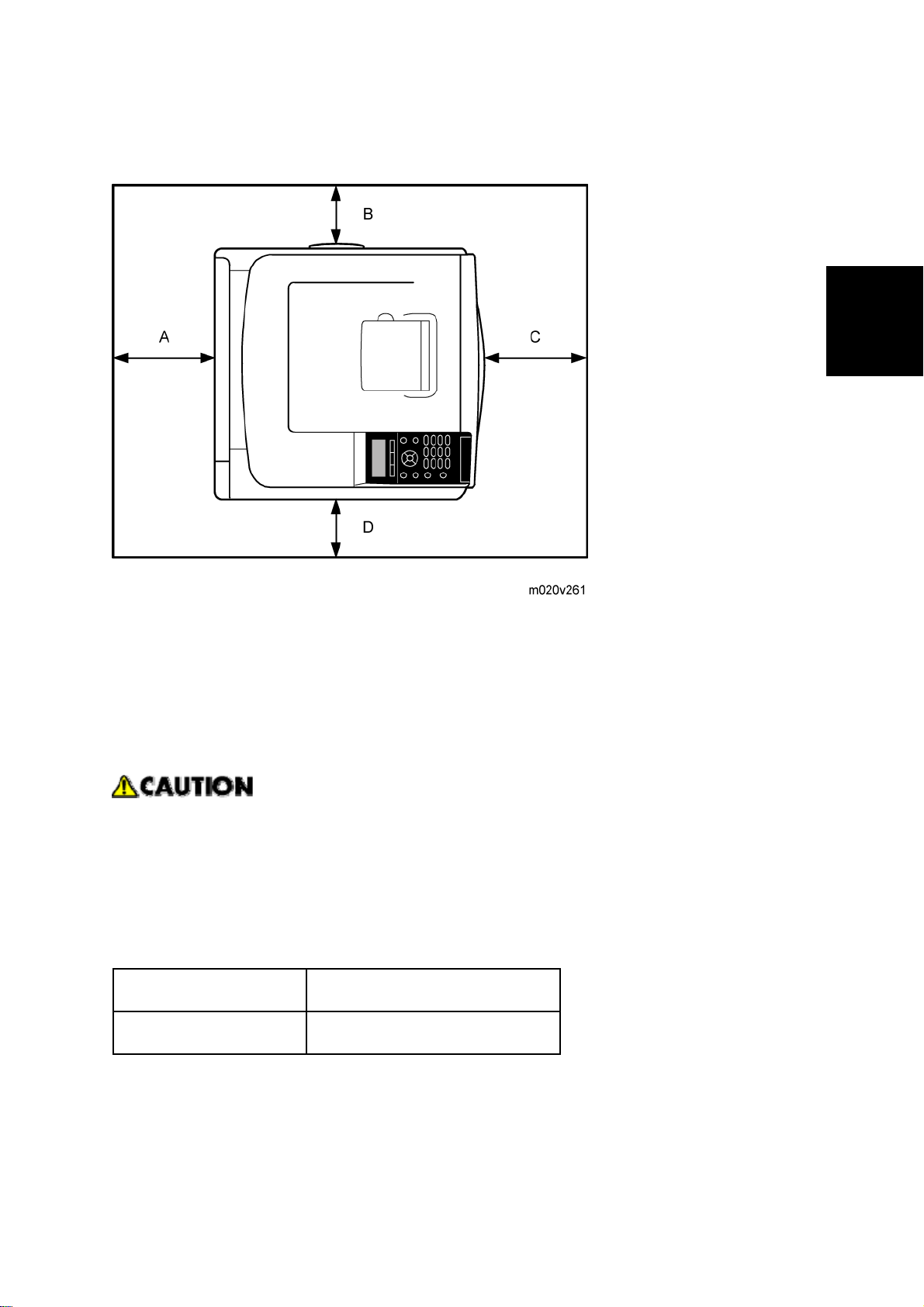

2.2.3 MINIMUM OPERATIONAL SPACE REQUIREMENTS

Place the machine near the power source, providing clearance as shown.

Installation

A: Rear – 200 mm (7.9")

B: Right – 100 mm (4.0")

C: Front – 350 mm (13.8")

D: Left – 100 mm (4.0")

2.2.4 POWER SUPPLY

Make sure that the wall outlet is near the machine and easily accessible. After

completing installation, make sure the plug fits firmly into the outlet.

Avoid multiple connections to the same power outlet.

Be sure to ground the machine.

Input voltage:

North America: 120 – 127 V, 60 Hz, 12 A

Europe/Asia: 220 – 240 V, 50/60 Hz, 8 A

Image quality guaranteed at rated voltage ± 10%.

Operation guaranteed at rated voltage ± 15%.

SM 2-3 M020/M021

Loading...

Loading...