Panasonic mva18fbas6hbcp, mva24fbas6hbcp, mva30fbas6hbcp, mva36fbas6hbcp, mva42fbas6hbcp Operation Manual

...

MVA Series Air Handling Unit

Installation, Operation and Maintenance

Manual

MVA Series units are direct drive vertical and multi-position Air Handlers delivering nominal cooling capacities of 1.5 to 5 tons. Units may be specified with hot water or electric heating coils to meet space cooling loads or heating loads or both. Two styles of unit orientation are available for maximum flexibility.

How to Use this Manual:

This manual gives instructions regarding installation, operation and maintenance for the MVA Series air handling units.

Use these instructions in conjunction with other appropriate instructions, including but not limited to those instructions supplied with the outdoor unit. Installation must comply with all applicable local codes.

SAFETY WARNING:

Installer should pay particular attention to the following words:

NOTE–intended to clarify or make installation easier.

CAUTION–given to prevent equipment damage.

WARNING–to alert installer that personal injury and/or equipment damage may result if installation procedure is not properly followed.

GENERAL

Installation and maintenance are to be performed only by qualified personnel who are familiar with local codes and regulations and are experienced with HVAC equipment of this type.

WARNING: Sharp edges, coil surfaces and rotating fans are a potential injury hazard – avoid contact.

WARNING: Hazardous voltage – Disconnect and Lock Out all incoming power sources before servicing or installing unit. ELECTRIC SHOCK CAN CAUSE DEATH.

WARNING: This equipment may be installed well above finished floor—Use extreme caution when working at heights.

UNPACKING-CHECK FOR DAMAGE!

Immediately inspect each unit for damage upon receipt.

Inspect units for external and concealed damage immediately.

File any damage claims in accordance with the Freight Damage Policy and Terms and Conditions.

Do not repair damaged units without written authorization.

Protect stored units from damage.

035-000039-001 |

Page 1 of 32 |

MVA IOM 1.3 9-10-2014 |

THIS PAGE INTENTIONALLY LEFT BLANK

035-000039-001 |

Page 2 of 32 |

MVA IOM 1.3 9-10-2014 |

MVA Series Air Handling Unit

Installation, Operation and Maintenance

Manual

/ŶƐƚĂůůĂƟŽŶ͕^ƚĂƌƚ-Up and Service

/ŶƐƚƌƵĐƟŽŶƐ

Topic |

Page |

SAFETY CONSIDERATIONS |

1, 5 |

PRODUCT NOMENCLATURE |

6-7 |

UNPACKING |

8 |

|

|

INSTALLATION |

8 |

Pre-installation |

8 |

Rigging |

8 |

Unpackaging |

8 |

Service Clearances |

8,11 |

Return Air & Unit Orientation |

9 |

Vertical to Horizontal Conversion (EEV) |

10 |

Unit Suspension or Floor Mount |

8,12,13 |

Condensate Drain |

12 |

Ductwork |

12 |

Refrigerant Piping |

14 |

Electric Heater Accessory |

14-15 |

Electrical |

16-21 |

START-UP |

22-23 |

Fan Airflow Step-Up |

23-24 |

Airflow Data |

23-24 |

SERVICE |

25-28 |

Fan & Fan Motor |

25-26 |

Filters |

27 |

Access Panels |

27 |

Coil & Drain Pan Service |

28 |

ELECTRICAL RATINGS |

29 |

DIMENSIONS |

30 |

Startup Report |

31 |

035-000039-001 |

Page 3 of 32 |

MVA IOM 1.3 9-10-2014 |

THIS PAGE INTENTIONALLY LEFT BLANK

035-000039-001 |

Page 4 of 32 |

MVA IOM 1.3 9-10-2014 |

DANGER

NEVER enter an enclosed fan cabinet or reach into a unit while the fan is running.

LOCK OPEN AND TAG the fan motor power disconnect switch before working on a fan. Take fuses with you and note removal on tag. Electric shock can cause personal injury or death.

LOCK OPEN AND TAG the electric heat coil power disconnect switch before working on or near heaters.

Failure to follow these warnings could lead to personal injury or death.

WARNING

CHECK the assembly and component weights to be sure that the rigging equipment can handle them safely.

Note also, the centers of gravity and any specific rigging instructions.

CHECK for adequate ventilation so that fumes will not migrate through ductwork to occupied spaces when welding or cutting inside air-handling unit cabinet or plenum.

WHEN STEAM CLEANING COILS be sure that the area is clear of personnel.

DO NOT attempt to handle access covers and removable panels on outdoor units when winds are strong or gusting until you have sufficient help to control them. Make sure panels are properly secured while repairs are being made to a unit.

DO NOT remove access panel fasteners or open access doors until fan is completely stopped. Pressure developed by a moving fan can cause excessive force against the panel which can injure personnel.

DO NOT work on dampers until their operators are disconnected.

BE SURE that fans are properly grounded before working on them.

Failure to follow these warnings could result in personal injury or equipment damage.

035-000039-001 |

Page 5 of 32 |

MVA IOM 1.3 9-10-2014 |

PRODUCT NOMENCLATURE

Unit Type/Size |

Description |

||

|

|

||

Code |

Selection |

||

|

|||

|

|

|

|

01, 02 |

MV |

Direct Drive Multiposition air handling unit |

|

|

|

||

Generation/Series |

Description |

||

|

|

||

Code |

Selection |

||

|

|||

|

|

|

|

03 |

A |

Revision Level |

|

|

|

||

Unit Type/Size |

Description |

||

|

|

|

|

Code |

Selection |

NOM Capacity |

|

|

|

|

|

|

18 |

18,000 Btu/hr |

|

|

24 |

24,000 Btu/hr |

|

|

30 |

30,000 Btu/hr |

|

04, 05 |

36 |

36,000 Btu/hr |

|

|

42 |

42,000 Btu/hr |

|

|

48 |

48,000 Btu/hr |

|

|

60 |

60,000 Btu/hr |

|

|

|

||

Primary Coil Type |

Description |

||

|

|

||

Code |

Selection |

||

|

|||

|

|

|

|

06 |

F |

4 ROW DX with electronic expansion valve, R-410a |

|

|

|

||

Heating Coil |

Description |

||

|

|

||

Code |

Selection |

||

|

|||

|

|

|

|

07 |

B |

Electric Heat Ready (ready to accept field installed EH Accessory kit, ordered |

|

separately) |

|||

|

|

||

|

|

|

|

|

|

||

|

|

|

|

Future Use |

Description |

||

|

|

|

|

Code |

Selection |

|

|

|

|

|

|

08 |

A |

Future Use |

|

|

|

||

Unit Grade |

Description |

||

|

|

|

|

Code |

Selection |

|

|

|

|

|

|

09 |

S |

Standard |

|

035-000039-001 |

Page 6 of 32 |

MVA IOM 1.3 9-10-2014 |

PRODUCT NOMENCLATURE—CONT’D

Unit Voltage |

Description |

|

|

|

|

|

|

Code |

Selection |

|

|

|

|

|

|

10 |

6 |

208/230/1/60 ECM-VE (customer change transformer tap for 208V) |

|

|

|

|

|

Controls |

Description |

|

|

|

|

|

|

Code |

Selection |

|

|

|

|

|

|

11 |

H |

Internal Use |

|

|

|

||

Return Air Cabinet Options |

|

||

|

|

||

Ordering Number |

Description |

|

|

|

|

|

|

Code |

Selection |

Unit Orientation |

Return Location |

|

|

|

|

12 |

B |

Vertical (Fro nt RH Co nd |

Bottom Return |

Drain Cnx) o r Ho rizo ntal |

|||

|

|

Right |

|

|

|

|

|

|

|

|

|

Drain Pan |

Description |

|

|

|

|

|

|

Code |

Selection |

drain pan and cabinet insulation type |

|

|

|

|

|

13 |

C |

Fiberglass, Universal Drainpan - Galvanized |

|

|

|

|

|

Tracking |

Description |

|

|

|

|

|

|

Code |

Selection |

|

|

|

|

|

|

14 |

P |

Internal Use |

|

Accessory Electric Heater Kits

P/N |

Description |

Unit Size |

Power |

kW* |

012-000458-001 |

FC EH-HEATER MVA-3-1-240 3KW |

MVA18-60 |

240/1/60 |

3 |

012-000458-002 |

FC EH-HEATER MVA-5-1-240 5KW |

MVA18-60 |

240/1/60 |

5 |

012-000458-003 |

FC EH-HEATER MVA-6-1-240 6KW |

MVA18-60 |

240/1/60 |

6 |

012-000458-004 |

FC EH-HEATER MVA-8-1-240 8KW |

MVA18-60 |

240/1/60 |

8 |

012-000458-005 |

FC EH-HEATER MVA-9.5-1-240 9.5KW |

MVA18-60 |

240/1/60 |

9.5 |

*Note: If unit power is 208V/1ph/60Hz, then the kW is reduced to 75% of the table value.

Accessory Filter Kits

P/N |

Description |

||

473-550115-001 |

2" FILTER RACK MERV 8 |

- MVA18/24 |

|

473-550115-002 |

2" FILTER RACK MERV 8 |

- MVA30/36 |

|

473-550115-003 |

2" FILTER RACK MERV 8 |

- MVA42/48 |

|

473-550115-004 |

2" FILTER RACK MERV 8 |

- MVA60 |

|

473-550116-001 |

4" FILTER RACK MERV 13 |

- MVA18/24 |

|

473-550116-002 |

4" FILTER RACK MERV 13 |

- MVA30/36 |

|

473-550116-003 |

4" FILTER RACK MERV 13 |

- MVA42/48 |

|

473-550116-004 |

4" FILTER RACK MERV 13 |

- MVA60 |

|

035-000039-001 |

Page 7 of 32 |

MVA IOM 1.3 9-10-2014 |

INSTALLATION

Pre-installation

1.Check items received against packing list.

2.Do not stack unit components or accessories during storage. Stacking can cause damage or deformation.

3.If unit is to be stored for more than 2 weeks prior to installation, observe the following precautions:

a.Choose a dry storage site that is reasonably level and sturdy to prevent undue stress or permanent damage to the unit structure or components. Do not store unit on vibrating surface. Damage to stationary bearings can occur. Set unit off ground if in heavy rain area.

b.Remove all fasteners and other small parts from jobsite to minimize theft. Tag and store parts in a safe place until needed.

c.Cover entire unit with a tarp or plastic coverall. Extend cover under unit if stored on ground. Secure cover with adequate tie-downs or store indoors. Be sure all coil connections have protective shipping caps.

d.Monthly — Remove tarp from unit, enter fan section through access door or through fan inlet, and rotate fan and motor slowly by hand to redistribute the bearing grease and to prevent bearing

corrosion.

Rigging — Do not remove shipping skids or protective covering until unit is ready for final placement. Use slings and spreader bars as applicable to lift unit. Do not lift unit by coil connections or headers.

Do not remove protective caps from coil piping connections until ready to connect piping.

Unpackaging

1.Remove all packaging and any foreign material from unit.

2.Check blower wheel for free rotation.

3.Check copper lines, coil etc. for internal or hidden damage.

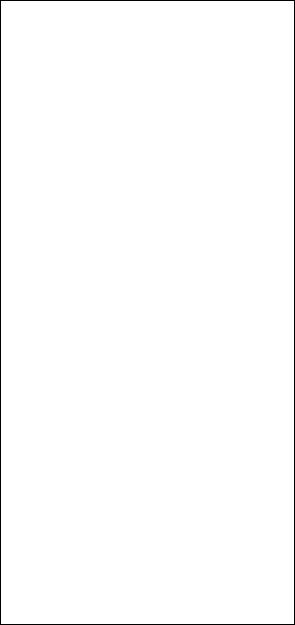

Return Air and Unit Orientation

Units may be positioned in several configurations depending on the return air configuration selected—see Figure 1.

NOTE: Right and left return units are not recommended for horizontal installation.

Service Clearance

The fan coil is completely serviceable from the front. Units are approved for 0” (zero

WARNING-AUXILIARY DRAIN PAN

RECOMMMENDED:

This product has an auxiliary condensate drain which should be piped to a condensate overflow sensor or safe drain location or both to protect the equipment and property from damage in the case of condensate overflow.

In addition, the International Mechanical Code (IMC) section 307.2.3 requires the use of auxiliary drain pans. Many municipalities have adopted this code.

This practice represents the standard for professional installation whether or not this code has been adopted in a specific municipality or territory. As such, water damages that would have been prevented had an auxiliary pan been deployed will not be considered for compensation. This position is taken regardless of whether the source of the moisture was specified as a potential failure mode in the applicable building code or not. A freeze burst, cracked drain pan, failed weld, or corrosion induced leak are some of the potential failure modes that are mitigated when an auxiliary pan is properly installed. Professional installers recognize the value of protecting customer assets against foreseeable events. Customers who choose to avoid the cost of common protective measures waive their right to seek damages when those foreseeable events occur. If the product is located above a living space or where damage may result from condensate overflow, install a watertight pan of corrosion-resistant metal beneath the unit to catch over-flow which may result from clogged drains or from other reasons. Provide proper drain piping for this auxiliary pan. Consult local codes for additional precautions before installation.

inches) of clearance. This allows substantial freedom in the positioning of the unit to best serve the requirements of the structure.

Unit Support

Floor mounting: Unit may be mounted on a housekeeping pad, floor, platform or plenum. Provide a suitable isolation pad to minimize sound transmission to the structure. CAU-

TION! Make sure to allow enough elevation to permit construction of the condensate trap. Also allow enough elevation and clearance for opening the filter door (removes to the front). See Service Clearances.

035-000039-001 |

Page 8 of 32 |

MVA IOM 1.3 9-10-2014 |

INSTALLATION

NOTE:

Electronic Expansion Valve (EEV) must be oriented vertically, and is shipped for vertical cabinet orientation.

For horizontal cabinet orientation, follow procedure to rotate the EEV assembly. Refer to Figure 2.

WARNING

FOR HORIZONTAL CABINET ORIENTATION, EEV MUST BE ROTATED TO VERTICAL POSITION! Failure to reorient the EEV can result in improper unit operation or equipment damage or dangerous condition.

Figure 1

Return Configurations and

Unit Orientations

035-000039-001 |

Page 9 of 32 |

MVA IOM 1.3 9-10-2014 |

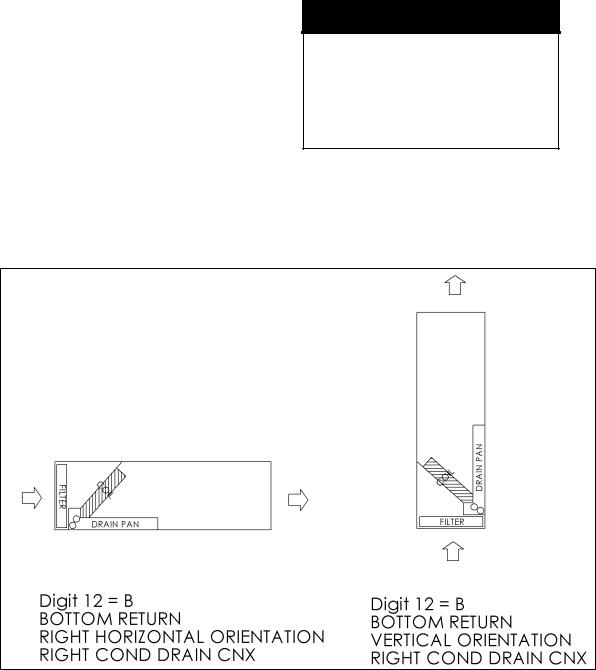

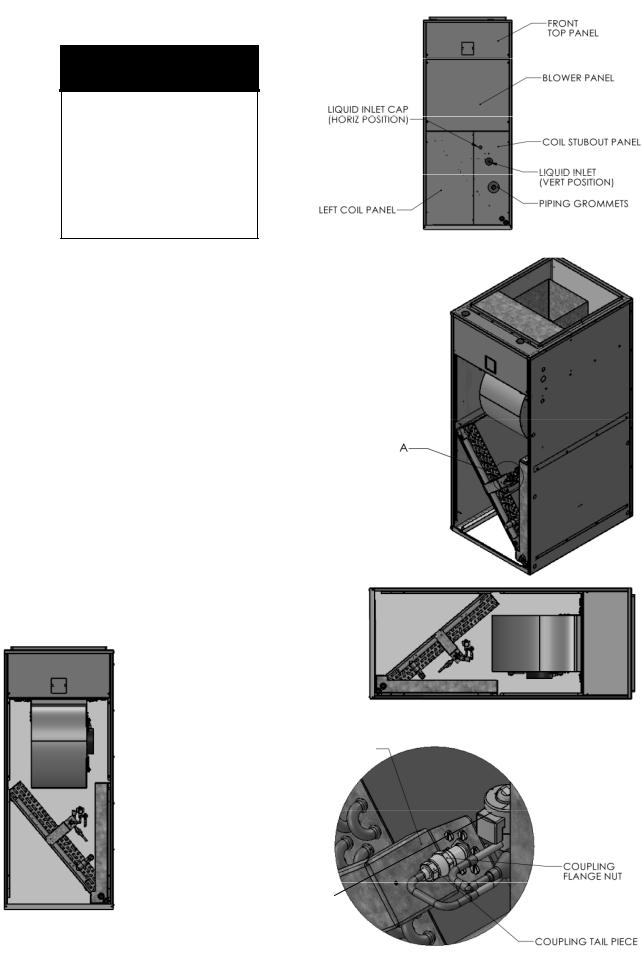

INSTALLATION—VERTICAL TO HORIZONTAL CONVERSION—EEV ROTATION

WARNING

FOR HORIZONTAL CABINET ORIENTATION, EEV MUST BE ROTATED TO VERTICAL POSITION! Failure to reorient the EEV in VERTICAL position can result in improper unit operation or equipment damage or dangerous condition.

Figure 2a-

Vertical

Orientation

CONVERSION PROCEDURE:

1.UNIT IS SHIPPED WITH NITROGEN CHARGE. IF UNIT HAS ALREADY BEEN

CHARGED WITH REFRIGERANT, REMOVE REFRIGERANT CHARGE PER LOCAL CODES BEFORE PERFORMING CONVERSION PROCEDURE.

2.REMOVE PIPING PLUGS AND SAVE FOR LATER USE. NITROGEN WILL DISCHARGE FROM COIL.

3.REMOVE PIPING GROMMETS; REMOVE LIQUID INLET CAP FOR HORIZONTAL POSITION.

4.REMOVE BLOWER PANEL, LEFT AND RIGHT COIL PANELS

5.SECURE EEV BRACKET WITH WRENCH AND TURN COUPLING FLANGE NUT COUNTER CLOCKWISE WITH 3/4" WRENCH TO LOOSEN AND DISCONNECT COUPLING. THE COUPLING TAIL NUT SHOULD BE ALLOWED TO TURN FREELY.

6.REPOSITION EXPANSION VALVE ASSEMBLY AS SHOWN IN FIGURE 2d. ENSURE EXPANSION VALVE IS VERTICAL WITHIN +/- 15 DEG WITH UNIT INSTALLED IN HORIZONTAL POSITION

7.REATTACH COUPLING AND TIGHTEN TO 10-12 FT LBS WHILE SECURING EEV BRACKET WITH WRENCH.

8.AS AN ALTERNATIVE TO STEP 5 COUPLING MAY BE TIGHTENED UNTIL NO THREADS ARE SHOWING AND COUPLING IS BOTTOMED OUT. THEN TURN AN ADDITIONAL 60 DEG (OR ONE HEX FLAT) TO TIGHTEN.

9.REINSTALL FRONT PANELS, GROMMETS, AND PIPING PLUGS.

Figure 2b-

Vertical

Orientation

EEV IN VERTICAL

ORIENTATION

Figure 2c-Vertical

Orientation, Panels

Removed

Figure 2d-Horizontal

Orientation

Detail A-

EEV Detail

035-000039-001 |

Page 10 of 32 |

MVA IOM 1.3 9-10-2014 |

Loading...

Loading...