Panasonic MINAS A4P User Manual

Instruction Manual

AC Servo Motor and Driver

MINAS A4P Series

•Thank you for buying and using Panasonic AC Servo Motor and Driver, MINAS A4P Series.

•Read through this Instruction Manual for proper use, especially read "Precautions for Safety" ( P.8 to 11) without fail for safety purpose.

•Keep this Manual at an easily accessible place so as to be referred anytime as necessary.

DV0P4490

Content

[Before Using the Products]

page

Safety Precautions .................................................................... |

8 |

Maintenance and Inspection................................................... |

12 |

Introduction.............................................................................. |

14 |

Outline .......................................................................................................................................................... |

14 |

On Opening the Package ............................................................................................................................. |

14 |

Check of the Driver Model ............................................................................................................................ |

14 |

Check of the Motor Model ............................................................................................................................ |

15 |

Check of the Combination of the Driver and the Motor ................................................................................ |

16 |

Parts Description ..................................................................... |

18 |

Driver ............................................................................................................................................................ |

18 |

Motor............................................................................................................................................................. |

20 |

Console......................................................................................................................................................... |

21 |

Installation................................................................................ |

22 |

Driver ............................................................................................................................................................ |

22 |

Motor............................................................................................................................................................. |

24 |

Console......................................................................................................................................................... |

26 |

[Preparation] |

page |

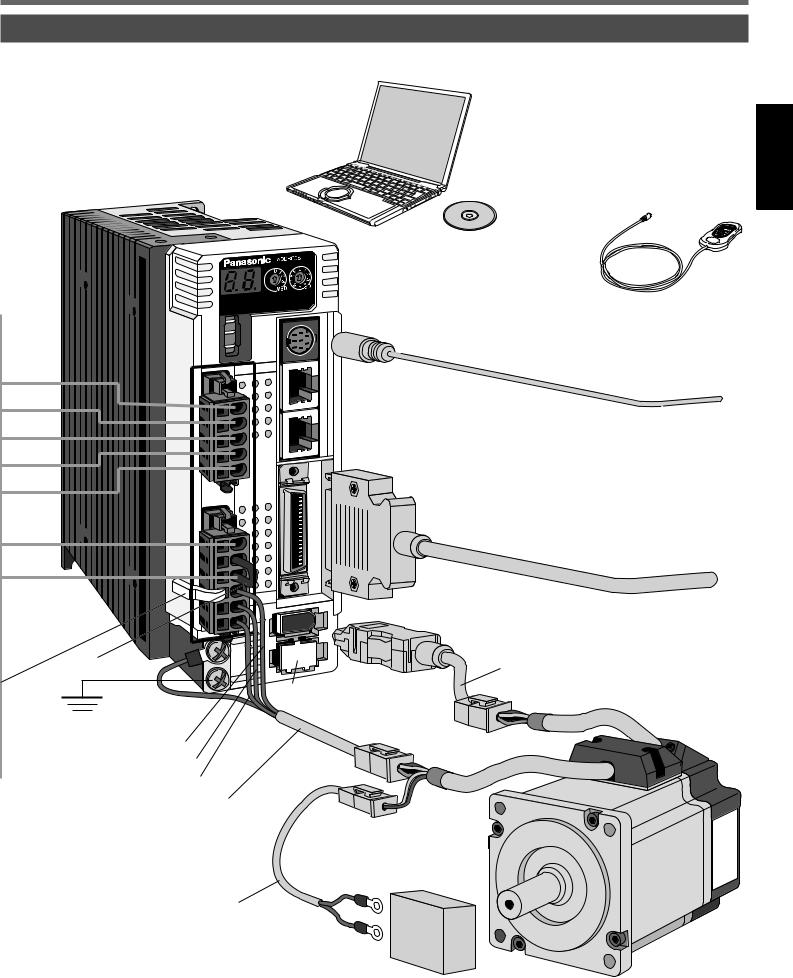

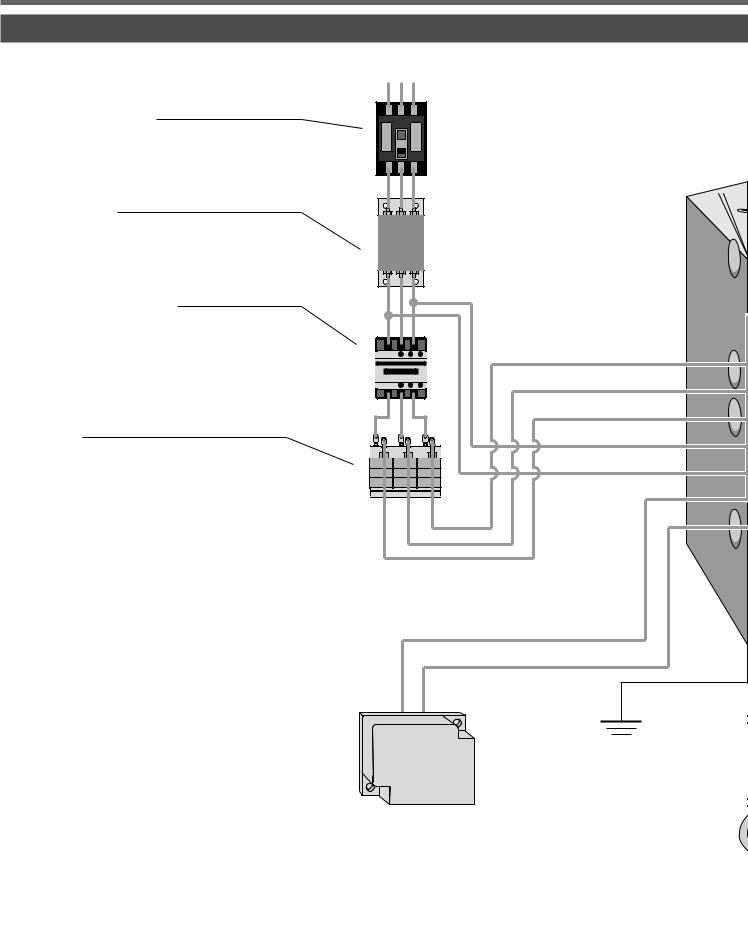

System Configuration and Wiring .......................................... |

28 |

Overall Wiring (Connecting Example of C-frame, 3-phase)......................................................................... |

28 |

Overall Wiring (Connecting Example of E-frame) ........................................................................................ |

30 |

Driver and List of Applicable Peripheral Equipments ................................................................................... |

32 |

Wiring of the Main Circuit (A to D-frame) ..................................................................................................... |

34 |

Wiring of the Main Circuit (E and F-frame)................................................................................................... |

35 |

Wiring to the Connector, CN X6 (Connection to Encoder) ........................................................................... |

38 |

Wiring to the Connector, CN X3 and 4 |

|

Wiring to the Connector, CN X7 (Connection to External Scale) ................................................................. |

40 |

Wiring to the Connector, CN X5 (Connection to Host Controller) ................................................................ |

41 |

Wiring for Connector CN X5 ......................................................................................................................... |

42 |

Interface Circuit ............................................................................................................................................ |

43 |

List of Signal for Connector CN X5 .............................................................................................................. |

44 |

Setup with the Front Panel...................................................... |

48 |

Composition of Touch Panel and Display..................................................................................................... |

48 |

Initial Status of the Front Panel Display (7-Segment LED) .......................................................................... |

48 |

Output Signals (Analog) and Their Functions .............................................................................................. |

49 |

Built-in Holding Brake ............................................................. |

50 |

Dynamic Brake......................................................................... |

52 |

[Setting] |

page |

Parameter Setup ...................................................................... |

56 |

Outline of Parameter .................................................................................................................................... |

56 |

How to Set .................................................................................................................................................... |

56 |

How to Connect ............................................................................................................................................ |

56 |

Composition of Parameters .......................................................................................................................... |

57 |

2

List of Servo Parameter ................................................................................................................................ |

58 |

List of 16-bit Positioning Parameters ........................................................................................................... |

73 |

List of 32-bit Positioning Parameters ........................................................................................................... |

77 |

List of Step Parameters ................................................................................................................................ |

77 |

Setup of Torque Limit.................................................................................................................................... |

78 |

How to Use the Console.......................................................... |

80 |

Setup with the Console ................................................................................................................................ |

80 |

Initial Status of the Console Display (7 Segment LED)................................................................................ |

80 |

Mode Change ............................................................................................................................................... |

81 |

Monitor Mode................................................................................................................................................ |

82 |

Teaching Mode ............................................................................................................................................. |

87 |

Parameter setup mode ................................................................................................................................. |

91 |

EEPROM Writing Mode ................................................................................................................................ |

96 |

Auto-Gain Tuning Mode ............................................................................................................................... |

97 |

Auxiliary Function Mode ............................................................................................................................... |

98 |

Copying Function (Console Only) .............................................................................................................. |

101 |

Outline of Setup Support Software, "PANATERM®" ........... |

103 |

Using BeforeProducts the

Preparation

Setting

Outline of PANATERM® .............................................................................................................................. |

103 |

How to Connect .......................................................................................................................................... |

103 |

[Operation Setting] |

page |

Overview of Operation Setting.............................................. |

106 |

Step Operation ....................................................................... |

107 |

Step Operation ........................................................................................................................................... |

107 |

Example of Incremental Operation Setting ................................................................................................ |

108 |

Example of Absolute Operation Setting ..................................................................................................... |

109 |

Example of Rotary Axis Operation Setting ................................................................................................. |

110 |

Example of Dwell Timer Operation Setting ................................................................................................ |

111 |

Jog Operation ........................................................................ |

112 |

Jog Operation ............................................................................................................................................. |

112 |

Homing ................................................................................... |

114 |

Homing Operation ...................................................................................................................................... |

114 |

Home Sensor + Z Phase (based on the front end) .................................................................................... |

116 |

Home Sensor (based on the front end) ...................................................................................................... |

117 |

Home sensor + Z phase (based on the rear end) ...................................................................................... |

118 |

Limit Sensor + Z phase .............................................................................................................................. |

120 |

Limit Sensor................................................................................................................................................ |

121 |

Z Phase Homing ......................................................................................................................................... |

122 |

Bumping Homing ........................................................................................................................................ |

122 |

Data Set ...................................................................................................................................................... |

123 |

Homing Offset Operation ............................................................................................................................ |

124 |

Emergency Stop Operation/Deceleration-and-Stop Operation ..... |

125 |

Temporary Stop Operation.................................................... |

126 |

Block Operation ..................................................................... |

127 |

Overview of Block Operation ...................................................................................................................... |

127 |

Continuous Block Operation....................................................................................................................... |

127 |

Combined Block Operation ........................................................................................................................ |

128 |

Sequential Operation............................................................. |

130 |

S-shaped Acceleration/Deceleration Function .................... |

131 |

OperationSetting

Adjustment

Whenin Trouble

Supplement

3

Timing Chart .......................................................................... |

132 |

Operation Timing after Power-ON .............................................................................................................. |

132 |

When an Error (Alarm) Has Occurred (at Servo-ON Command) .............................................................. |

133 |

When an Alarm Has Been Cleared (at Servo-ON Command) ................................................................... |

134 |

Servo-ON/OFF Action While the Motor Is at Stall (Servo-Lock) ................................................................ |

135 |

Servo-ON/OFF Action While the Motor Is in Motion .................................................................................. |

135 |

Absolute System ................................................................... |

136 |

Overview of Absolute System..................................................................................................................... |

136 |

Configuration of Absolute System .............................................................................................................. |

136 |

Battery (for Backup) Installation ................................................................................................................. |

136 |

Setup (Initialization) of Absolute Encoder .................................................................................................. |

136 |

Outline of Full-Closed Control .............................................. |

140 |

What Is Full-Closed Control ? .................................................................................................................... |

140 |

[Adjustment] |

page |

Gain Adjustment .................................................................... |

142 |

Real-Time Auto-Gain Tuning Mode....................................... |

144 |

Adaptive Filter............................................................................................................................................. |

147 |

Normal Mode Auto-Gain Tuning ........................................... |

148 |

Release of Automatic Gain Adjusting Function .................. |

151 |

Manual Gain Tuning (Basic) .................................................. |

152 |

Adjustment in Position Control Mode ......................................................................................................... |

153 |

Adjustment in Full-Closed Control Mode.................................................................................................... |

154 |

Gain Switching Function............................................................................................................................. |

155 |

Suppression of Machine Resonance ......................................................................................................... |

158 |

Manual Gain Tuning (Application) ........................................ |

160 |

Instantaneous Speed Observer.................................................................................................................. |

160 |

Damping Control......................................................................................................................................... |

161 |

[When in Trouble]

page

When in Trouble..................................................................... |

164 |

What to Check ? ......................................................................................................................................... |

164 |

Protective Function (What is Error Code ?) ............................................................................................... |

164 |

Protective Function (Detail of Error Code) ................................................................................................. |

165 |

Troubleshooting .................................................................... |

172 |

Motor Does Not Run / Motor Stops During an Operation .......................................................................... |

172 |

Point Deviates / Positioning Accuracy is Poor ........................................................................................... |

173 |

Home position Slips .................................................................................................................................... |

173 |

Abnormal Motor Noise or Vibration ............................................................................................................ |

173 |

Overshoot/Undershoot / Overheating of the Motor (Motor Burn-Out)........................................................ |

174 |

Parameter Returns to Previous Setup ....................................................................................................... |

174 |

Display of "Communication port or driver cannot be detected" Appears on the Screen While Using the |

|

PANATERM®. .............................................................................................................................................. |

174 |

4

[Supplement] |

page |

Conformity to EC Directives and UL Standards .................. |

176 |

Options ................................................................................... |

180 |

Recommended components................................................. |

191 |

Dimensions (Driver)............................................................... |

192 |

Dimensions (Motor) ............................................................... |

195 |

Permissible Load at Output Shaft ........................................ |

210 |

Motor Characteristics (S-T Characteristics) ........................ |

211 |

Motor with Gear Reducer ...................................................... |

217 |

Dimensions/Motor with Gear Reducer ................................. |

218 |

Permissible Load at Output Shaft/Motor with Gear Reducer ........ |

220 |

Characteristics of Motor with Gear Reducer ....................... |

221 |

Block Diagram of Driver ....................................................... |

222 |

Block Diagram by Control Mode........................................... |

224 |

Specifications (Driver)........................................................... |

226 |

Default Parameters (for all the models of A4P Series) .... |

228 |

Using BeforeProducts the

Preparation

Setting

Setting |

Operation |

Adjustment

Whenin Trouble

Supplement

5

6

[Before Using the Products]

|

page |

Safety Precautions .................................................... |

8 |

Maintenance and Inspection .................................. |

12 |

Introduction ............................................................. |

14 |

Outline ......................................................................................... |

14 |

On Opening the Package ............................................................ |

14 |

Check of the Driver Model........................................................... |

14 |

Check of the Motor Model ........................................................... |

15 |

Check of the Combination of the Driver and the Motor ............... |

16 |

Parts Description .................................................... |

18 |

Driver ........................................................................................... |

18 |

Motor ........................................................................................... |

20 |

Console ....................................................................................... |

21 |

Installation ............................................................... |

22 |

Driver ........................................................................................... |

22 |

Motor ........................................................................................... |

24 |

Console ....................................................................................... |

26 |

7

Safety Precautions Observe the Following Instructions Without Fail

Observe the following precautions in order to avoid damages on the machinery and injuries to the operators and other personnel during the operation.

• In this document, the following symbols are used to indicate the level of damages or injuries which might be incurred by the misoperation ignoring the precautions.

DANGER |

Indicates |

a |

potentially |

hazardous |

situation |

which, |

if |

not |

avoided, will result in death or serious injury. |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

CAUTION |

Indicates |

a |

potentially |

hazardous |

situation |

which, |

if |

not |

avoided, will result in minor injury or property damage. |

|

|||||||

|

|

|

|

|

|

|

|

|

• The following symbols represent "MUST NOT" or "MUST" operations which you have to observe. (Note that there are other symbols as well.)

Represents "MUST NOT" operation which is inhibited.

Represents "MUST" operation which has to be executed.

DANGER

DANGER

Do not subject the Product to water, corrosive or flammable gases, and combustibles.

Failure to observe this instruction could result in fire.

Do not put your hands in the servo driver.

Failure to observe this instruction could result in burn and electrical shocks.

Do not drive the motor with external power.

Failure to observe this instruction could result in fire.

Do not subject the cables to excessive force, heavy object, or pinching force, nor damage the cables.

Failure to observe this instruction could result in electrical shocks, damages and breakdowns.

Do not touch the rotating portion of the motor while it is running.

Rotating portion

Failure to observe this instruction could result in injuries.

Do not touch the motor, servo driver and external regenerative resistor of the driver, since they become very hot.

Failure to observe this instruction could result in burns.

8

[Before Using the Products]

DANGER

DANGER

Do not place combustibles near by the motor, driver and regenerative resistor.

Failure to observe this instruction could result in fire.

Do not place the console close to a heating unit such as a heater or a large wire wound resistor.

Failure to observe this instruction could result in fire and breakdowns.

Using Before Products the

Ground the earth terminal of the motor and driver without fail.

Failure to observe this instruction could result in electrical shocks.

Install an overcurrent protection, earth leakage breaker, over-tem- perature protection and emergency stop apparatus without fail.

Install an emergency stop circuit externally so that you can stop the operation and shut off the power immediately.

|

Failure to observe this instruction could |

|

result in injuries, electrical shocks, fire, |

|

breakdowns and damages. |

Install and mount the Product and machinery securely to prevent any possible fire or accidents incurred by earthquake.

Failure to observe this instruction could result in electrical shocks, injuries and fire.

Turn off the power and wait for a longer time than the specified time, before transporting, wiring and inspecting the driver.

Failure to observe this instruction could result in electrical shocks.

Turn off the power and make it sure that there is no risk of electrical shocks before transporting, wiring and inspecting the motor.

Check and confirm the safety of the operation after the earthquake.

Failure to observe this instruction could result in electrical shocks, injuries and fire.

Mount the motor, driver and regenerative resistor on incombustible material such as metal.

Failure to observe this instruction could result in fire.

Wiring has to be carried out by the qualified and authorized specialist.

Failure to observe this instruction could result in electrical shocks.

Make the correct phase sequence of the motor and correct wiring of the encoder.

Failure to observe this instruction could result in injuries breakdowns and damages.

9

Safety Precautions Observe the Following Instructions Without Fail

CAUTION

CAUTION

Do not hold the motor cable or motor shaft during the transportation.

Failure to observe this instruction could result in injuries.

Never run or stop the motor with the electro-magnetic contactor installed in the main power side.

Failure to observe this instruction could result in breakdowns.

Do not give strong impact shock to

the motor shaft.

Failure to observe this  instruction could result

instruction could result

in breakdowns.

Do not approach to the machine since it may suddenly restart after the power resumption. Design the machine to secure the safety for the operator even at a sudden restart.

Failure to observe this instruction could result in injuries.

Do not use the built-in brake as a "Braking" to stop the moving load.

Failure to observe this instruction could result in injuries and breakdowns.

Do not modify, disassemble nor repair the Product.

Failure to observe this instruction could result in fire, electrical shocks and injuries.

Do not block the heat dissipating holes or put the foreign particles into them.

Failure to observe this instruction could result in electrical shocks and fire.

Do not step on the Product nor place the heavy object on them.

Failure to observe this instruction could result in electrical shocks, injuries, breakdowns and damages.

Do not turn on and off the main power of the driver repeatedly.

Failure to observe this instruction could result in breakdowns.

Do not make an extreme gain adjustment or change of the drive. Do not keep the machine running/operating unstably.

Failure to observe this instruction could result in injuries.

Do not give strong impact shock to the Product.

Failure to observe this instruction could result in breakdowns.

Do not pull the cables with excessive force.

Failure to observe this instruction could result in breakdowns.

10

[Before Using the Products]

CAUTION

CAUTION

Use the motor and the driver in |

Make a wiring correctly and |

||

the specified combination. |

securely. |

|

|

Failure to |

observe this |

Failure to |

observe this |

instruction |

could result in |

instruction |

could result in |

fire. |

|

fire and electrical shocks. |

|

Using Before Products the

Use the eye bolt of the motor for transportation of the motor only, and never use this for transportation of the machine.

Failure to observe this instruction could result in injuries and breakdowns.

Make an appropriate mounting of the Product matching to its wight and output rating.

Failure to observe this instruction could result in injuries and breakdowns.

Keep the ambient temperature below the permissible temperature for the motor and driver.

Failure to observe this instruction could result in breakdowns.

Connect the brake control relay to the relay which is to shut off at emergency stop in series.

Failure to observe this instruction could result in injuries and breakdowns.

When you dispose the batteries, observe any applicable regulations or laws after insulating them with tape.

Observe the specified mounting method and direction.

Failure to observe this instruction could result in breakdowns.

Observe the specified voltage.

Failure to observe this instruction could result in electrical shocks, injuries and fire.

Execute the trial run without connecting the motor to the machine system and fix the motor. After checking the operation, connect to the machine system again.

Failure to observe this instruction could result in injuries.

When any error occurs, remove the cause and release the error after securing the safety, then restart.

Failure to observe this instruction could result in injuries.

This Product shall be treated as Industrial Waste when you dispose.

11

Maintenance and Inspection

• Routine maintenance and inspection of the driver and motor are essential for the proper and safe operation.

Notes on Maintenance and Inspection

1)Turn on and turn off should be done by operators or inspectors themselves.

2)Internal circuit of the driver is kept charged with high voltage for a while even after power-off. Turn off the power and allow 15 minutes or longer after LED display of the front panel has gone off, before performing maintenance and inspection.

3)Disconnect all of the connection to the driver when performing megger test (Insulation resistance measurement) to the driver, otherwise it could result in breakdown of the driver.

Inspection Items and Cycles

General and normal running condition

Ambient conditions : 30˚C (annual average), load factor of 80% or lower, operating hours of 20 hours or less per day.

Perform the daily and periodical inspection as per the items below.

Type |

Cycles |

Items to be inspected |

|

|

|

|

|

|

|

• Ambient temperature, humidity, speck, dust or foreign object |

|

|

|

• Abnormal vibration and noise |

|

|

|

• Main circuit voltage |

|

|

|

• Odor |

|

Daily |

Daily |

• Lint or other particles at air holes |

|

inspection |

• Cleanness at front portion of the driver and connecter |

||

|

|||

|

|

• Damage of the cables |

|

|

|

• Loose connection or misalignment between the motor and |

|

|

|

machine or equipment |

|

|

|

• Pinching of foreign object at the load |

|

|

|

|

|

|

|

• Loose tightening |

|

Periodical |

|

||

• Trace of overheat |

|||

Annual |

|||

inspection |

|||

|

• Damage of the terminals |

||

|

|

||

|

|

|

<Note> Inspection cycle may change when the running conditions of the above change.

12

[Before Using the Products]

Guideline for Parts Replacement

Use the table below for a reference. Parts replacement cycle varies depending on the actual operating conditions. Defective parts should be replaced or repaired when any error have occurred.

Using Before Products the

|

Disassembling for inspection and repair should be carried |

Prohibited |

out only by authorized dealers or service company. |

|

|

|

|

Product |

Component |

|

|

|

Standard replacement |

|

Note |

|

||

|

|

|

cycles (hour) |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Smoothing capacitor |

|

|

|

Approx. 5 years |

|

|

|

|

|

|

Cooling fan |

|

|

|

|

2 to 3 years |

|

|

|

|

|

|

|

|

(10,000 to 30,000 hours) |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

|

Aluminum electrolytic |

|

|

|

|

|

|

|

||

|

|

|

Approx. 5 years |

|

|

|

|

|||

capacitor (on PCB) |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

||

Driver |

|

|

|

|

|

Approx. 100,000 times |

|

|

|

|

|

Rush current |

|

|

|

|

|

|

|

||

|

|

|

|

(depending on working |

|

|

|

|

||

|

preventive relay |

|

|

|

|

|

|

|||

|

|

|

condition) |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Approx. 20,000 times |

These |

hours |

or cycles |

are |

|

|

|

|

|

|

||||||

Rush current preventive |

|

(depending on working |

reference. |

|

|

|||||

|

resistor |

|

|

|

|

|

|

|||

|

|

|

|

condition) |

When |

you experience |

any |

|||

|

|

|

|

|

|

|||||

Bearing |

|

|

|

|

3 to 5 years |

error, replacement is required |

||||

|

|

|

|

|||||||

|

|

|

(20,000 to 30,000 hours) |

even |

before |

this standard |

||||

|

|

|

|

|

|

|||||

|

Oil seal |

|

|

|

|

5000 hours |

replacement cycle. |

|

||

|

Encoder |

|

|

|

|

3 to 5 years |

|

|

|

|

|

|

|

|

(20,000 to 30,000 hours) |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

Motor |

|

|

|

|

Life time varies depending |

|

|

|

|

|

|

|

|

|

|

on working conditions. |

|

|

|

|

|

|

Battery |

|

|

|

Refer to the instruction |

|

|

|

|

|

|

for absolute encoder |

|

|

manual attached to the |

|

|

|

|

||

|

|

|

|

|

battery for absolute |

|

|

|

|

|

|

|

|

|

|

encoder. |

|

|

|

|

|

Motor with |

Gear reducer |

|

|

|

|

10,000 hours |

|

|

|

|

gear reducer |

|

|

|

|

|

|

|

|

||

13

Introduction

Outline

MINAS-A4P Series is a servo motor and driver of I/O command type. A4P Series is based on the highperformance servo driver MINAS-A4 Series, which achieved response frequency of 1kHz, real-time autogain tuning function and damping control, and contains the NC function which can perform positioning more easily.

A maximum of 60 setting points can be set for (1) moving distance, (2) maximum rotation speed in a moving section, (3) acceleration time and (4) deceleration time in each moving section and positioning can be performed by an external contact input. Moreover, in combination with a motor equipped with a 17-bit absolute encoder, positioning can be performed at an absolute position and a homing operation is not required. A4P Series have also improved the user-friendliness by offering some optional components, e.g., a console which enables you to monitor the rotation speed display, set up parameters, perform teaching (setup of target position) and copy parameters, and a waveform graphic display to show a operating waveform and the communication software “PANATERM®” available for frequency measurement to measure machine resonance point.

Read this document with care and exploit the versatile functions of A4P Series to full extent.

Cautions

1)Any part or whole of this document shall not be reproduced without written permission from us.

2)Contents of this document are subject to change without notice.

On Opening the Product Package

•Make sure that the model is what you have ordered.

•Check if the product is damaged or not during transportation.

•Check if the instruction manual is attached or not.

•Check if the power connector and motor connecters (CN X1 and CN X2 connectors) are attached or not (A to D-frame).

Contact to a dealer if you find any failures.

Check of the Driver Model

Contents of Name Plate

Model number |

|

|

AC SERVO |

|

Model No. MADDT1205P Serial No.P05110001Z |

||||

|

||||

Rated input/output voltage |

Phase |

INPUT |

OUTPUT |

|

1ø |

3ø |

|||

|

Voltage |

200-240V |

69V |

|

|

F.L.C |

1.3A |

1.2A |

|

Rated input/output current |

Freq. |

50/60Hz |

0~333.3Hz |

|

Power |

|

100W |

||

Rated output of applicable motor |

|

|

|

|

Model Designation

Serial Number

e.g.) : P0511 0001Z

Lot number Month of production

Year of production (Lower 2 digits of AD year)

M A D D T 1 2 0 5 P

|

1 to 4 |

|

|

|

Frame-size symbol |

|

|

|

|

|

|

|

||

|

|

|

|

|

Symbol |

Frame |

|

||

MADD A4-series, A-frame |

||||

|

|

|

||

MBDD A4-series, B-frame |

||||

|

|

|

||

MCDD A4-series, C-frame |

||||

|

|

|

||

MDDD A4-series, D-frame |

||||

|

|

|

||

MEDD A4-series, E-frame |

||||

MFDD |

A4-series, F-frame |

|

||

|

|

|

|

5 to 6 |

7 |

||

|

|

|

|

|

|

|

|

Max. current rating of power device

Symbol Current rating

T1 10A

T2 15A

T3 30A

T5 50A

T7 70A

TA 100A

TB 150A

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Special specifications |

||||

|

8 to 9 |

|

10 |

11, 12 |

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(letters and numbers) |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Interface specification |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

I/O command type |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Current detector rating |

|

|||||

Power supply |

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

Current |

|

Current |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Symbol |

|

|

Specifications |

|

|

Symbol |

rating |

|

Symbol |

rating |

||||||||||

|

1 |

|

Single phase, 100V |

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

05 |

5A |

|

30 |

30A |

|||||||||||

|

2 |

|

Single phase, 200V |

|

|

|

|

|||||||||||||

|

|

|

|

|

07 |

7.5A |

|

40 |

40A |

|||||||||||

|

3 |

|

3-phase, 200V |

|

|

|

|

|||||||||||||

|

|

|

|

|

10 |

10A |

|

64 |

64A |

|||||||||||

|

|

|

|

Single/3-phase, |

|

|

|

|

||||||||||||

5 |

|

|

|

|

15 |

15A |

|

90 |

90A |

|||||||||||

|

200V |

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

20 |

20A |

|

A2 |

120A |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

14

[Before Using the Products]

Check of the Motor Model

Contents of Name Plate

Model |

|

|

|

|

|

|

|

CONT. TORQUE 0.64 Nm |

|

|

|

|

|

AC SERVO MOTOR |

RATING |

S1 |

|||

Rated input voltage/current |

|

|

|

MODELNo. MSMD5AZS1S |

INS. CLASS |

B (TÜV) A (UL) |

|||

|

|

|

|||||||

|

|

|

INPUT 3ØAC |

92 |

|

V |

IP65 |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

1.6 |

|

A |

CONNECTION |

|

|

|

|

|

RATED OUTPUT 0.2 |

|

kW |

SER No. |

05110001 |

|

|

|

|

|

RATED FREQ. |

200 |

|

Hz |

|

|

Rated output |

|

|

|

RATED REV. |

3000 |

r/min |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rated rotational speed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Serial Number

e.g.) : 0511 0001

Lot number Month of production

Year of production (Lower 2 digits of AD year)

Model Designation

Using Before Products the

M S M D 5 A Z S 1 S

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 to 4 |

|

|

5 to 6 |

7 |

8 |

9 |

10 |

|

11 to 12 |

|

Special specifications |

|

||||||||||||||||

|

|

|

|

|

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(letters and numbers) |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Motor structure |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Symbol |

|

|

Type |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Design order |

|

|||||||||

MAMA Ultra low inertia |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1: Standard |

|

|||||||||||

|

(100W to 750W) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Low inertia |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

MQMA (100W to 400W) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Voltage specifications |

|

||||||||||||||

|

Low inertia |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

MSMD (50W to 750W) |

|

Motor rated output |

|

|

|

|

|

|

Symbol |

|

|

Specifications |

|

|

||||||||||||||||||

|

Low inertia |

|

Symbol |

|

Output |

Symbol |

Output |

|

|

1 |

100 V |

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

MSMA (1.0kW to 5.0kW) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

5A |

|

50W |

|

15 |

1.5kW |

|

|

2 |

200 V |

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

MDMA Middle inertia |

01 |

|

100W |

|

20 |

2.0kW |

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

100/200 common |

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

(1.0kW to 5.0kW) |

02 |

|

200W |

|

25 |

2.5kW |

|

|

Z |

(50W only) |

|

|

|||||||||||||||||||

High inertia |

|

|

|

|||||||||||||||||||||||||||||

04 |

|

400W |

|

30 |

3.0kW |

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

MHMA (500W to 5.0kW) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

05 |

|

500W |

|

40 |

4.0kW |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

Middle inertia |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

MFMA |

08 |

|

750W |

|

45 |

4.5kW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

(400W to 4.5kW) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

09 |

|

900W |

50 |

5.0kW |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

Middle inertia |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

MGMA |

10 |

|

1.0kW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

(900W to 4.5kW) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

Rotary encoder specifications |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

Symbol |

|

|

|

|

|

|

|

|

|

|

|

Specifications |

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

Format |

|

|

|

Pulse count |

Resolution |

Wire count |

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

P |

|

Incremental |

|

|

|

2500P/r |

|

10,000 |

5-wire |

|

|

|

||||||||||||||||

|

|

|

|

S |

Absolute/Incremental common |

|

17bit |

|

131,072 |

7-wire |

|

|

|

|||||||||||||||||||

Motor structure

MSMD, MQMA

Symbol |

Shaft |

Holding brake |

Oil seal |

|

Round Key way Without With |

*1 |

|||

|

||||

|

Without With |

|||

A |

|

|

||

B |

|

|

||

S  *2

*2

T  *2

*2

*1 The product with oil seal is a special order product. *2 Key way with center tap.

Products are standard stock items or build to order items. For details, inquire of the dealer.

MAMA

|

Symbol |

Shaft |

Holding brake |

Oil seal |

|||

|

Round |

Key way |

Without |

With |

Without |

With |

|

|

A |

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

E |

|

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MSMA, MDMA, MFMA, MGMA, MHMA |

|

||||||

|

Symbol |

Shaft |

Holding brake |

Oil seal |

|||

|

Round |

Key way |

Without |

With |

Without |

With |

|

|

C |

|

|

|

|

|

|

|

D |

|

|

|

|

|

|

|

G |

|

|

|

|

|

|

|

H |

|

|

|

|

|

|

15

Introduction

Check of the Combination of the Driver and the Motor

This drive is designed to be used in a combination with the motor which are specified by us.

Check the series name of the motor, rated output torque, voltage specifications and encoder specifications.

Incremental Specifications, 2500P/r

<Remarks> Do not use in other combinations than those listed below.

Power |

|

|

Applicable motor |

|

Applicable driver |

|||

|

Motor |

Rated |

|

Rated |

|

|

||

supply |

|

Model |

Model |

Frame |

||||

|

series |

rotational speed |

output |

|||||

|

|

|

|

|

||||

Single phase, |

|

MAMA |

|

MAMA012P1* |

100W |

MADDT1207P |

A-frame |

|

200V |

|

|

MAMA022P1* |

200W |

MBDDT2210P |

B-frame |

||

|

Ultra low |

|||||||

|

|

5000r/min |

|

|

|

|

||

3-phase, |

|

MAMA042P1* |

400W |

MCDDT3520P |

C-frame |

|||

|

inertia |

|

||||||

200V |

|

|

MAMA082P1* |

750W |

MDDDT5540P |

D-frame |

||

|

|

|||||||

Single phase, |

|

|

|

MQMA011P1* |

100W |

MADDT1107P |

A-frame |

|

|

|

|

MQMA021P1* |

200W |

MBDDT2110P |

B-frame |

||

100V |

|

|||||||

|

MAMA |

|

|

|

|

|

||

|

|

MQMA041P1* |

400W |

MCDDT3120P |

C-frame |

|||

|

|

Low |

3000r/min |

|||||

|

MQMA012P1* |

100W |

MADDT1205P |

A-frame |

||||

Single phase, |

|

inertia |

|

|||||

|

|

MQMA022P1* |

200W |

MADDT1207P |

A-frame |

|||

200V |

|

|

||||||

|

|

|

MQMA042P1* |

400W |

MBDDT2210P |

B-frame |

||

|

|

|||||||

|

|

|

|

MSMD5AZP1* |

50W |

MADDT1105P |

A-frame |

|

Single phase, |

|

|

|

MSMD011P1* |

100W |

MADDT1107P |

||

|

|

|||||||

100V |

|

|

|

MSMD021P1* |

200W |

MBDDT2110P |

||

|

B-frame |

|||||||

|

|

MSMD |

|

MSMD041P1* |

400W |

MCDDT3120P |

C-frame |

|

|

|

Low |

3000r/min |

MSMD5AZP1* |

50W |

MADDT1205P |

|

|

Single phase, |

|

inertia |

|

MSMD012P1* |

100W |

A-frame |

||

|

|

|||||||

200V |

|

|

|

MSMD022P1* |

200W |

|

||

|

MADDT1207P |

|||||||

|

|

|

|

MSMD042P1* |

400W |

MBDDT2210P |

B-frame |

|

Single/3-phase, |

|

|

|

MSMD082P1* |

750W |

MCDDT3520P |

C-frame |

|

|

|

|

MSMA102P1* |

1.0kW |

|

|

||

200V |

|

MDDDT5540P |

D-frame |

|||||

|

|

|

MSMA152P1* |

1.5kW |

||||

|

|

|

|

|||||

|

|

MSMA |

|

|

|

|||

|

|

|

MSMA202P1* |

2.0kW |

||||

|

Low |

3000r/min |

MEDDT7364P |

E-frame |

||||

3-phase, |

|

MSMA302P1* |

3.0kW |

MFDDTA390P |

||||

|

inertia |

|

|

|||||

200V |

|

MSMA402P1* |

4.0kW |

|

||||

|

|

|

MFDDTB3A2P |

F-frame |

||||

|

|

MSMA502P1* |

5.0kW |

|

||||

|

|

|

|

|||||

Single/3-phase, |

|

MDMA102P1* |

1.0kW |

|

||||

|

|

|

MDDDT3530P |

D-frame |

||||

200V |

|

MDMA152P1* |

1.5kW |

MDDDT5540P |

||||

|

MDMA |

|

|

|||||

|

|

MDMA202P1* |

2.0kW |

MEDDT7364P |

||||

|

Middle |

2000r/min |

E-frame |

|||||

3-phase, |

|

MDMA302P1* |

3.0kW |

MFDDTA390P |

|

|||

|

inertia |

|

||||||

200V |

|

MDMA402P1* |

4.0kW |

|

F-frame |

|||

|

|

|

MFDDTB3A2P |

|||||

|

|

MDMA502P1* |

5.0kW |

|

||||

|

|

|

|

|||||

|

|

|

MHMA052P1* |

500W |

C-frame |

|||

Single/3-phase, |

|

|

MCDDT3520P |

|||||

|

MHMA102P1* |

1.0kW |

|

|||||

200V |

|

|

MDDDT3530P |

D-frame |

||||

MHMA |

MHMA152P1* |

1.5kW |

||||||

|

|

|

MDDDT5540P |

|

||||

|

|

High |

MHMA202P1* |

2.0kW |

MEDDT7364P |

E-frame |

||

|

2000r/min |

|||||||

3-phase, |

|

inertia |

|

MHMA302P1* |

3.0kW |

MFDDTA390P |

|

|

200V |

|

|

|

MHMA402P1* |

4.0kW |

MFDDTB3A2P |

F-frame |

|

|

|

|

|

MHMA502P1* |

5.0kW |

|

||

|

|

|||||||

Single/3-phase, |

|

|

|

MFMA042P1* |

400W |

C-frame |

||

|

MCDDT3520P |

|||||||

|

|

MFMA |

|

|

|

|

|

|

200V |

|

2000r/min |

MFMA152P1* |

1.5kW |

MDDDT5540P |

D-frame |

||

|

Middle |

|||||||

3-phase, |

|

MFMA252P1* |

2.5kW |

MEDDT7364P |

E-frame |

|||

|

inertia |

|

||||||

200V |

|

MFMA452P1* |

4.5kW |

MFDDTB3A2P |

F-frame |

|||

|

|

|

||||||

Single/3-phase, 200V |

|

MGMA092P1* |

900W |

MDDDT5540P |

D-frame |

|||

|

MGMA |

|

||||||

|

|

MGMA202P1* |

2.0kW |

MFDDTA390P |

|

|||

|

Middle |

1000r/min |

||||||

3-phase, 200V |

|

MGMA302P1* |

3.0kW |

MFDDTB3A2P |

F-frame |

|||

|

inertia |

|

||||||

|

|

|

MGMA452P1* |

4.5kW |

|

|||

|

|

|

|

|

|

|||

<Note>

Suffix of " * " in the applicable motor model represents the motor structure.

16

[Before Using the Products]

Absolute/Incremental Specifications, 17-bit

<Remarks> Do not use in other combinations than those listed below.

Power |

|

|

Applicable motor |

|

Applicable driver |

|||

|

Motor |

Rated |

|

Rated |

|

|

||

supply |

|

Model |

Model |

Frame |

||||

|

series |

rotational speed |

output |

|||||

|

|

|

|

|

||||

Single phase, |

|

MAMA |

|

MAMA012S1* |

100W |

MADDT1207P |

A-frame |

|

200V |

|

|

MAMA022S1* |

200W |

MBDDT2210P |

B-frame |

||

|

Ultra low |

|||||||

|

|

5000r/min |

|

|

|

|

||

3-phase, |

|

MAMA042S1* |

400W |

MCDDT3520P |

C-frame |

|||

|

inertia |

|

||||||

200V |

|

|

MAMA082S1* |

750W |

MDDDT5540P |

D-frame |

||

|

|

|||||||

Single phase, |

|

|

|

MQMA011S1* |

100W |

MADDT1107P |

A-frame |

|

|

|

|

MQMA021S1* |

200W |

MBDDT2110P |

B-frame |

||

100V |

|

|||||||

|

MAMA |

|

|

|

|

|

||

|

|

MQMA041S1* |

400W |

MCDDT3120P |

C-frame |

|||

|

|

Low |

3000r/min |

|||||

|

MQMA012S1* |

100W |

MADDT1205P |

A-frame |

||||

Single phase, |

|

inertia |

|

|||||

|

|

MQMA022S1* |

200W |

MADDT1207P |

A-frame |

|||

200V |

|

|

||||||

|

|

|

MQMA042S1* |

400W |

MBDDT2210P |

B-frame |

||

|

|

|||||||

|

|

|

|

MSMD5AZS1* |

50W |

MADDT1105P |

A-frame |

|

Single phase, |

|

|

|

MSMD011S1* |

100W |

MADDT1107P |

||

|

|

|||||||

100V |

|

|

|

MSMD021S1* |

200W |

MBDDT2110P |

||

|

B-frame |

|||||||

|

|

MSMD |

|

MSMD041S1* |

400W |

MCDDT3120P |

C-frame |

|

|

|

Low |

3000r/min |

MSMD5AZS1* |

50W |

MADDT1205P |

|

|

Single phase, |

|

inertia |

|

MSMD012S1* |

100W |

A-frame |

||

|

|

|||||||

200V |

|

|

|

MSMD022S1* |

200W |

|

||

|

MADDT1207P |

|||||||

|

|

|

|

MSMD042S1* |

400W |

MBDDT2210P |

B-frame |

|

Single/3-phase, |

|

|

|

MSMD082S1* |

750W |

MCDDT3520P |

C-frame |

|

|

|

|

MSMA102S1* |

1.0kW |

|

|

||

200V |

|

MDDDT5540P |

D-frame |

|||||

|

|

|

MSMA152S1* |

1.5kW |

||||

|

|

|

|

|||||

|

|

MSMA |

|

|

|

|||

|

|

|

MSMA202S1* |

2.0kW |

||||

|

Low |

3000r/min |

MEDDT7364P |

E-frame |

||||

3-phase, |

|

MSMA302S1* |

3.0kW |

MFDDTA390P |

||||

|

inertia |

|

|

|||||

200V |

|

MSMA402S1* |

4.0kW |

|

||||

|

|

|

MFDDTB3A2P |

F-frame |

||||

|

|

MSMA502S1* |

5.0kW |

|

||||

|

|

|

|

|||||

Single/3-phase, |

|

MDMA102S1* |

1.0kW |

|

||||

|

|

|

MDDDT3530P |

D-frame |

||||

200V |

|

MDMA152S1* |

1.5kW |

MDDDT5540P |

||||

|

MDMA |

|

|

|||||

|

|

MDMA202S1* |

2.0kW |

MEDDT7364P |

||||

|

Middle |

2000r/min |

E-frame |

|||||

3-phase, |

|

MDMA302S1* |

3.0kW |

MFDDTA390P |

|

|||

|

inertia |

|

||||||

200V |

|

MDMA402S1* |

4.0kW |

|

F-frame |

|||

|

|

|

MFDDTB3A2P |

|||||

|

|

MDMA502S1* |

5.0kW |

|

||||

|

|

|

|

|||||

|

|

|

MHMA052S1* |

500W |

C-frame |

|||

Single/3-phase, |

|

|

MCDDT3520P |

|||||

|

MHMA102S1* |

1.0kW |

|

|||||

200V |

|

|

MDDDT3530P |

D-frame |

||||

MHMA |

MHMA152S1* |

1.5kW |

||||||

|

|

|

MDDDT5540P |

|

||||

|

|

High |

MHMA202S1* |

2.0kW |

MEDDT7364P |

E-frame |

||

|

2000r/min |

|||||||

3-phase, |

|

inertia |

|

MHMA302S1* |

3.0kW |

MFDDTA390P |

|

|

200V |

|

|

|

MHMA402S1* |

4.0kW |

MFDDTB3A2P |

F-frame |

|

|

|

|

|

MHMA502S1* |

5.0kW |

|

||

|

|

|||||||

Single/3-phase, |

|

|

|

MFMA042S1* |

400W |

C-frame |

||

|

MCDDT3520P |

|||||||

|

|

MFMA |

|

|

|

|

|

|

200V |

|

2000r/min |

MFMA152S1* |

1.5kW |

MDDDT5540P |

D-frame |

||

|

Middle |

|||||||

3-phase, |

|

MFMA252S1* |

2.5kW |

MEDDT7364P |

E-frame |

|||

|

inertia |

|

||||||

200V |

|

MFMA452S1* |

4.5kW |

MFDDTB3A2P |

F-frame |

|||

|

|

|

||||||

Single/3-phase, 200V |

|

MGMA092S1* |

900W |

MDDDT5540P |

D-frame |

|||

|

MGMA |

|

||||||

|

|

MGMA202S1* |

2.0kW |

MFDDTA390P |

|

|||

|

Middle |

1000r/min |

||||||

3-phase, 200V |

|

MGMA302S1* |

3.0kW |

MFDDTB3A2P |

F-frame |

|||

|

inertia |

|

||||||

|

|

|

MGMA452S1* |

4.5kW |

|

|||

|

|

|

|

|

|

|||

<Notes>

1)Suffix of " * " in the applicable motor model represents the motor structure.

2)Default of the driver is set for the incremental encoder specifications. When you use in absolute, make the following operations.

a)Install a battery for absolute encoder. (refer to P.190, "Options" of Supplement.)

b)Switch the parameter SV.Pr0B (Absolute encoder setup) from "1 (default)" to "0".

3)No wiring for back up battery is required when you use the absolute 17-bit encoder in incremental.

Using Before Products the

17

Parts Description

Driver

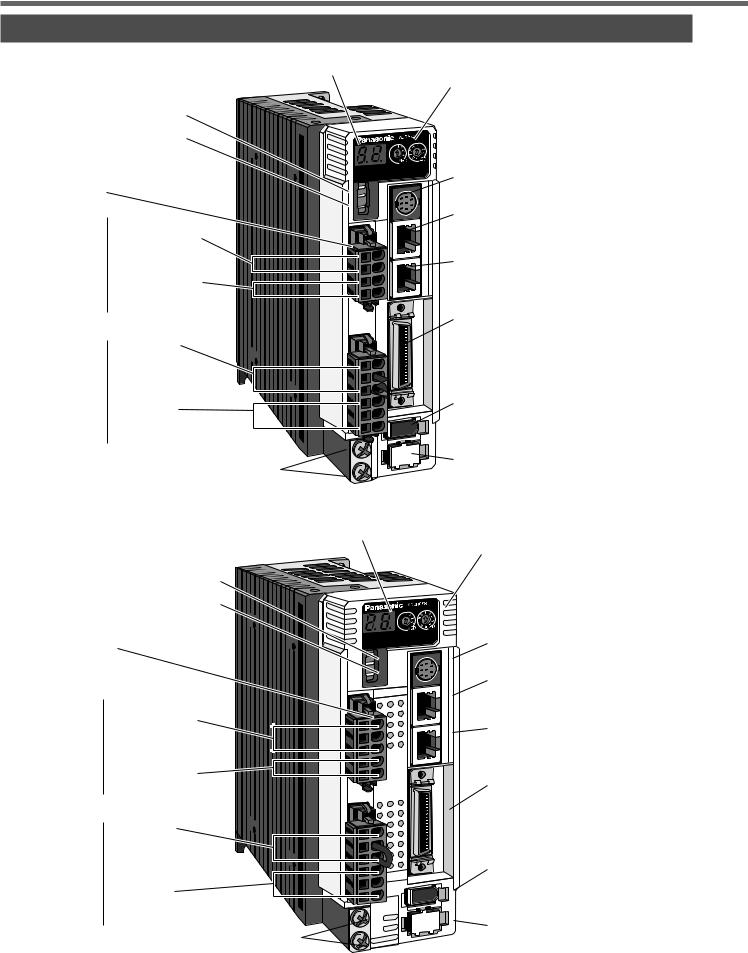

• A and B-frame |

Display LED (2-digit) |

ID address setup |

|

||

|

|

rotary switch (MSD, LSD) |

Velocity monitor check pin (SP) |

|

|

Torque monitor check pin (IM) |

|

|

Check pin (G : GND) |

|

|

Connector |

|

|

|

|

Main power |

|

|

|

Connector, CN X1 |

|

input terminals |

for power input |

|

(L1,L2) |

connection |

|

Control power |

04JFAT-SAXGF |

|

|

(JST) |

|

input terminals |

|

(L1C, L2C) |

|

|

|

|

|

|

Terminals |

|

|

|

Connector, CN X2 |

|

for external |

for motor |

|

regenerative resistor |

connection |

|

(RB1,RB2,RB3) |

06JFAT-SAXGF |

|

Terminals |

(JST) |

|

for motor connection |

|

|

(U,V,W) |

|

|

Screws for earth (x2) |

SP |

|

|

IM |

X4 |

|

G |

||

|

||

|

X3A |

|

|

X3B |

X5

X6

X6

X7

Communication connector, CN X4

Connector, CN X4A

(For manufacturers' use only: Not for individual use)

Connector, CN X4B

(For manufacturers' use only: Not for individual use)

Connector, CN X5 for host connection

Connector, CN X6 for encoder connection

Connector, CN X7

for external scale connection

e.g.) : MADDT1207P (Single phase, 200V, 200W : A-frame)

• C and D-frame

Velocity monitor check pin (SP)

Torque monitor check pin (IM)

Check pin (G : GND)

Connector

|

|

Main power |

Connector, CN X1 |

|

input terminals |

for power input |

|

(L1,L2) |

connection |

|

Control power |

04JFAT-SAXGF |

|

|

(JST) |

|

input terminals |

|

(L1C, L2C) |

|

|

|

|

|

|

Terminals |

|

|

|

Connector, CN X2 |

|

for external |

for motor |

|

regenerative resistor |

connection |

|

(RB1,RB2,RB3) |

06JFAT-SAXGF |

|

Terminals |

(JST) |

|

for motor connection |

|

|

(U,V,W) |

|

|

Screws for earth (x2) |

Display LED (2-digit) |

ID address setup |

|

rotary switch (MSD, LSD) |

SP |

|

|

IM |

X4 |

|

G |

||

|

||

|

X3A |

|

|

X3B |

X5

X6

X6

Communication connector, CN X4

Connector, CN X4A

(For manufacturers' use only: Not for individual use)

Connector, CN X4B

(For manufacturers' use only: Not for individual use)

Connector, CN X5 for host connection

Connector, CN X6 for encoder connection

X7 |

Connector, CN X7 |

|

for external scale connection |

e.g.) : MCDDT3520P (Single/3-phase, 200V, 750W : C-frame)

<Note>

X1 and X2 are attached in A to D-frame driver.

18

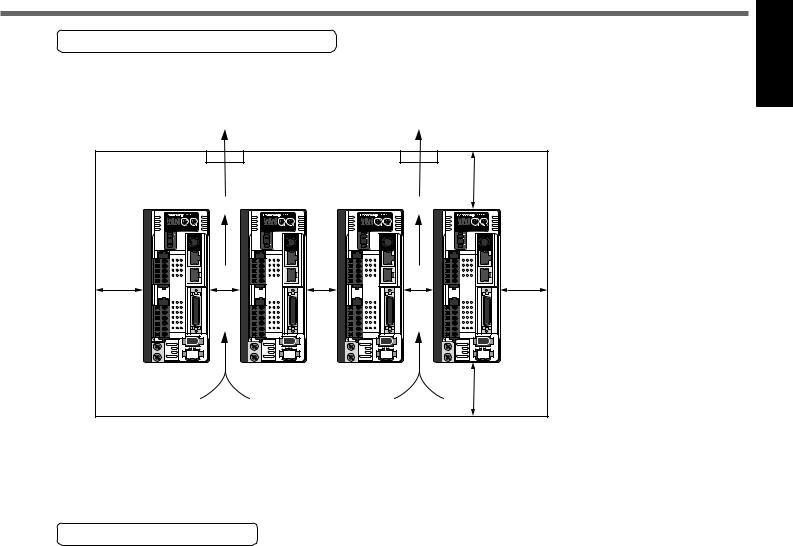

• E and F-frame

Check pin (G : GND)

Main power input terminals (L1,L2,L3)

Control power input terminals (r, t)

Terminals for external regenerative resistor

(P, B1, B2)

Terminals for motor connection (U,V,W)

[Before Using the Products]

Velocity monitor check pin (SP)

Torque monitor check pin (IM)

Display LED (2-digit)

ID address setup rotary switch (MSD, LSD)

SP |

|

IM |

X4 |

G |

|

|