Omron K3HB-R, K3HB-P, K3HB-C DATASHEET

Cat. No. N136-E1-01B

K3HB-R/-P/-C

Digital Indicators

USER’S MANUAL

Preface

Preface

OMRON products are manufactured for use according to proper procedures by a qualified operator and only for the purposes described in this manual.

This manual describes the functions, performance, and application methods needed for optimum use of the K3HB.

Please observe the following items when using the K3HB.

•This product is designed for use by qualified personnel with a knowledge of electrical systems.

•Read this manual carefully and make sure you understand it well to ensure that you are using the K3HB correctly.

•Keep this manual in a safe location so that it is available for reference when required.

Notice

(1)All rights reserved. No part of this manual may be reprinted or copied without the prior written permission of OMRON.

(2)The specifications and other information contained in this manual are subject to change without notice in order to make improvements.

(3)Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. If you discover any problems with this manual, please notify your nearest OMRON representative, providing them with the catalog number provided on the cover.

I

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying ratings and limitations of use that apply to the products. This information by itself is not sufficient for a complete determination of the suitability of the products in combination with the end product, machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses listed may be suitable for the products.

•Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or uses not described in this manual.

•Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment, amusement machines, vehicles, safety equipment, and installations subject to separate industry or government regulations.

•Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any consequence thereof.

II

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons.

It is our practice to change model numbers when published ratings or features are changed, or when significant construction changes are made. However, some specifications of the products may be changed without any notice. When in doubt, special model numbers may be assigned to fix or establish key specifications for your application on your request. Please consult with your OMRON representative at any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and Limitations of Liability.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

III

Safety Precautions

●Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of the product.

The safety precautions that are provided are extremely important to safety. Always read and heed the information provided in all safety precautions.

The following notation is used.

Indicates a potentially hazardous situation which, if not

WARNING avoided, will result in minor or moderate injury, or may result in serious injury or death. Additionally there may be

significant property damage.

CAUTION

CAUTION

●Symbols

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury or in property damage.

Symbol |

Meaning |

General Caution

Indicates non-specific general cautions, warnings,

and dangers.

Caution

Electrical Shock Caution

Indicates possibility of electric shock under specific conditions.

Prohibition

General Prohibition

Indicates non-specific general prohibitions.

Mandatory

General Caution

Caution

Indicates non-specific general cautions, warnings, and dangers.

IV

●Precautions

WARNING

WARNING

Do not touch the terminals while power is being supplied. Doing so may possibly result in electric shock. Make sure that the terminal cover is installed before using the product.

Always provide protective circuits in the network. Without protective circuits, malfunctions may possibly result in accidents that cause serious injury or significant property damage. Provide double or triple safety measures in external control

circuits, such as emergency stop circuits, interlock circuits, or limit circuits, to ensure safety in the system if an abnormality occurs due to malfunction of the product or another external factor affecting the product's operation.

CAUTION

CAUTION

Do not allow pieces of metal, wire clippings, or fine metallic shavings or filings from installation to enter the product. Doing so may occasionally result in electric shock, fire, or malfunction.

Do not use the product in locations where flammable or explosive gases are present. Doing so may occasionally result in minor or moderate explosion, causing minor or moderate injury, or property damage.

Do not attempt to disassemble, repair, or modify the product. Doing so may occasionally result in minor or moderate injury due to electric shock.

Do not use the equipment for measurements within Measurement Categories II, III, and IV for K3HB-R, K3HB-P, and K3HB-C (according to IEC61010-1). Doing so may occasionally cause unexpected operation, resulting in minor or moderate injury, or damage to the equipment. Use the equipment for measurements only within the Measurement Category for which the product is designed.

Perform correct setting of the product according to the application. Failure to do so may occasionally cause unexpected operation, resulting in minor or moderate injury, or damage to the equipment.

Ensure safety in the event of product failure by taking safety measures, such as installing a separate monitoring system. Product failure may occasionally prevent operation of comparative outputs, resulting in damage to the connected facilities and equipment.

Tighten the screws on the terminal block and the connector locking screws securely using a tightening torque within the following ranges. Loose screws may occasionally cause fire, resulting in minor or moderate injury, or damage to the equipment. Terminal block screws: 0.43 to 0.58 N·m

Connector locking screws: 0.18 to 0.22 N·m

V

CAUTION

CAUTION

Make sure that the product will not be adversely affected if the DeviceNet cycle time is lengthened as a result of changing the program with online editing. Extending the cycle time may cause unexpected operation, occasionally resulting in minor or moderate injury, or damage to the equipment.

Before transferring programs to other nodes or changing I/O memory of other nodes, check the nodes to confirm safety. Changing the program or I/O memory of other nodes may occasionally cause unexpected operation, resulting in minor or moderate injury, or damage to the equipment.

VI

Precautions for Safe Use

(1)Do not use the product in the following locations.

•Locations subject to direct radiant heat from heating equipment

•Locations where the product may come into contact with water or oil

•Locations subject to direct sunlight

•Locations where dust or corrosive gases (in particular, sulfuric or ammonia gas) are present

•Locations subject to extreme temperature changes

•Locations where icing or condensation may occur

•Locations subject to excessive shocks or vibration

(2)Do not use the product in locations subject to temperatures or humidity levels outside the specified ranges or in locations prone to condensation. If the product is installed in a panel, ensure that the temperature around the product (not the temperature around the panel) does not go outside the specified range.

(3)Provide sufficient space around the product for heat dissipation.

(4)Use and store the product within the specified temperature and humidity ranges. If several products are mounted side-by-side or arranged in a vertical line, the heat dissipation will cause the internal temperature of the products to rise, shortening the service life. If necessary, cool the products using a fan or other cooling method.

(5)The service life of the output relays depends on the switching capacity and switching conditions. Consider the actual application conditions and use the product within the rated load and electrical service life. Using the product beyond its service life may result in contact welding or burning.

(6)Install the product horizontally.

(7)Mount to a panel between 1 and 8-mm thick.

(8)Use the specified size of crimp terminals (M3, width: 5.8 mm max.) for wiring. To connect bare wires, use AWG22 (cross section: 0.326 mm2) to AWG14 (cross section: 2.081 mm2) to wire the power supply terminals and AWG28 (cross section: 0.081 mm2) to AWG16 (cross section: 1.309 mm2) for other terminals. (Length of exposed wire: 6 to

8 mm)

(9)In order to prevent inductive noise, wire the lines connected to the product separately from power lines carrying high voltages or currents. Do not wire in parallel with or in the same cable as power lines. Other measures for reducing noise include running lines along separate ducts and using shield lines.

(10)Ensure that the rated voltage is achieved no longer than 2 s after turning the power ON.

(11)Allow the product to operate without load for at least 15 minutes after the power is turned ON.

(12)Do not install the product near devices generating strong high-frequency waves or surges. When using a noise filter, check the voltage and current and install it as close to the product as possible.

(13)Do not use thinner to clean the product. Use commercially available alcohol.

(14)Be sure to confirm the name and polarity for each terminal before wiring the terminal block and connectors.

(15)Use the product within the noted supply voltage and rated load.

VII

(16)Do not connect anything to unused terminals.

(17)Output turns OFF when the mode is changed or settings are initialized. Take this into consideration when setting up the control system.

(18)Install an external switch or circuit breaker that complies with applicable IEC60947-1 and IEC60947-3 requirements and label them clearly so that the operator can quickly turn OFF the power.

(19)Use the specified cables for the communications lines and stay within the specified DeviceNet communications distances. Refer to the User's Manual (Cat. No. N129) for details on communications distance specifications and cables.

(20)Do not pull the DeviceNet communications cables with excessive force or bend them past their natural bending radius.

(21)Do not connect or remove connectors while the DeviceNet power is being supplied. Doing so will cause product failure or malfunction.

(22)Use cables with a heat resistance specification of 70ºC min.

VIII

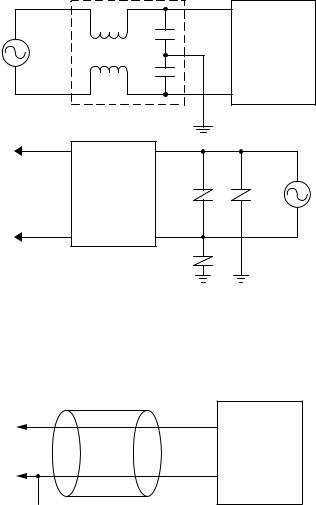

●Noise Countermeasures

Do not install the product near devices generating strong high-frequency waves or surges, such as high-frequency welding and sewing machines.

(1)Mount a surge suppressor or noise filter to peripheral devices generating noise, in particular, motors, transformers, solenoids, and magnet coils.

+

Signal input

-

Line filter

Digital

Indicator

input |

|

supplyPower |

Digital Indicator |

|

Power supply input

Surge suppressor

(2)In order to prevent inductive noise, wire the lines connected to the terminal block separately from power lines carrying high voltages or currents. Do not wire in parallel with or in the same cable as power lines. Other measures for reducing noise include running lines along separate ducts and using shield lines.

Example of Countermeasures for Inductive Noise on Input Lines

+

Digital Indicator

Signal input

-

2 conductors with shield

2 conductors with shield

(3)If a noise filter is used for the power supply, check the voltage and current, and install the noise filter as close to the product as possible.

(4)Reception interference may occur if the product is used close to a radio, television, or wireless.

IX

●Revision History

The revision code of this manual is given at the end of the catalog number at the bottom left of the back cover.

Cat. No. |

|

N136-E1-01B |

|

|

|

|

|

|

|

|

|

|

|

|

Revision code |

|

Date |

|

Pages and changes |

|

|

|

||

01 |

October 2004 |

Original production |

||

|

|

|

||

01A |

March 2005 |

Page 2-4: Changed “B4” to “BCD,” and changed |

||

|

|

|

diagrams. |

|

|

|

|

Page A-4 and A-5: Changed “Meter” to |

|

|

|

|

“Indicator” in tables. |

|

|

|

|

Page A-7: Changed “meter” to “indicator,” and |

|

|

|

|

“B4” to “BCD” in table, and added note. |

|

|

|

|

Page A-17 to A-22: Changed “B4” to “BCD” in |

|

|

|

|

table. |

|

|

|

|

||

01B |

October 2007 |

Page 2-4: Changed figure in upper left corner and |

||

|

|

|

at bottom of page. |

|

|

|

|

Page 2-9: Added table. |

|

|

|

|

Pages 2-10 to 2-12: Changed figures and added |

|

|

|

|

notes. |

|

|

|

|

Page 5-23: Added “prescale value B” and added |

|

|

|

|

note. |

|

|

|

|

Page 5-27: Changed left column of top four rows |

|

|

|

|

of table. |

|

|

|

|

Page 5-28: Changed sentence under first table. |

|

|

|

|

Page 5-71: Changed text in bottom table |

|

|

|

|

(including present values under figures). |

|

|

|

|

Page INDEX-1: Added and corrected index |

|

|

|

|

entries. |

|

|

|

|

|

|

X

About this Manual

About this Manual

Manual Structure

Preface

Provides precautionary information, a manual revision history, an overview of the manual contents, information on using this manual, and other general information.

Section 1 Outline

Provides an overview and describes the features of the product.

Section 2 Preparations

Describes the mounting and wiring required before using the product.

Section 3 Basic Application Methods

Shows typical applications for the product. Also shows wiring and parameter settings which enables the user to understand how to use the product from practical examples.

Section 4 Initial Setup

Describes the initial setup process when using this product.

Section 5 Functions and Operations

Describes the functions and settings methods for more effective use of functions, displays, outputs, and settings for each application.

Section 6 Troubleshooting

Describes how to check and possible countermeasures for errors.

Appendices

Provides specifications and settings lists.

XI

●Settings Data Notation

The letters of the alphabet in settings data are displayed as shown below.

a |

b |

c |

d |

e |

f |

g |

h |

i |

j |

k |

l |

m |

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

K |

L |

M |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n |

o |

p |

q |

r |

s |

t |

u |

v |

w |

x |

y |

z |

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

O |

P |

Q |

R |

S |

T |

U |

V |

W |

X |

Y |

Z |

|

|

|

|

|

|

|

|

|

|

|

|

|

●Applicable Model Notation

The following symbols are used to indicate the applicable models for specific functions.

R

R K3HB-R@@-@@@

K3HB-R@@-@@@

P

P K3HB-P@@-@@@

K3HB-P@@-@@@

C

C K3HB-C@@-@@@

K3HB-C@@-@@@

XII

Contents

CONTENTS

Section 1 Outline

1.1 |

Main Functions and Features of the K3HB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-2 |

1.2 |

Component Names and Functions of the K3HB-R/P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-5 |

1.3 |

Component Names and Functions of the K3HB-C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-6 |

1.4 |

Internal Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-7 |

Section 2 Preparations

2.1 |

Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-2 |

2.2 |

Using I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-4 |

Section 3 Basic Application Methods

3.1 |

Monitoring Roller Speed: K3HB-R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-2 |

3.2 |

Monitoring Conveyor Speed Difference: K3HB-R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-4 |

3.3 |

Monitoring Conveyor Line Passing Time: K3HB-R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-7 |

3.4 |

Measuring the Operation Time of a Press: K3HB-P. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-9 |

3.5 |

Measuring Workpiece Passing Time between Points A and B: K3HB-P . . . . . . . . . . . . . . |

3-11 |

3.6 |

Measuring the Feed Length of a Sheet: K3HB-C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-13 |

3.7 |

Counting the Number of Workpieces: K3HB-C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-15 |

Section 4 Initial Setup

4.1 |

Initial Setup Example for the K3HB-R. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-2 |

4.2 |

Initial Setup Example for the K3HB-P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-4 |

4.3 |

Initial Setup Example for the K3HB-C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-6 |

Section 5 Functions and Operations

Knowledge Required for Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-2 |

|

5.1 |

Setting the Function for the K3HB-R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-9 |

5.2 |

Setting the Function for the K3HB-P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-16 |

5.3 |

Setting the Function for the K3HB-C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-23 |

5.4 |

Setting Input Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-27 |

5.5 |

Setting Prescale Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-28 |

5.6 |

Setting the Auto-zero Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-31 |

5.7 |

Resetting Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-33 |

5.8 |

Not Performing Measurements for Set Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-34 |

5.9 |

Averaging Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-36 |

5.10 |

Changing Comparative Output Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-39 |

5.11 |

Preventing Output Chattering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-42 |

5.12 |

Outputting for a Set Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-44 |

5.13 |

Delaying Output OFF Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-46 |

5.14 |

Holding Measurement Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-48 |

CONTENTS-1

Contents

5.15 |

Holding Comparative Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-49 |

5.16 |

Allocating Another Output to PASS Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-51 |

5.17 |

Reversing Output Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-53 |

5.18 |

No Output before PASS Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-55 |

5.19 |

Performing Linear Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-57 |

5.20 |

Changing the Display Refresh Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-60 |

5.21 |

Setting a Compensation Value for the Measurement Value . . . . . . . . . . . . . . . . . . . . . . . . . |

5-61 |

5.22 |

Holding Measurement Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-63 |

5.23 |

Holding Maximum and Minimum Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-65 |

5.24 |

Changing Normal Display Values to Maximum and Minimum Values . . . . . . . . . . . . . . . . |

5-67 |

5.25 |

Displaying/Not Displaying Comparative Set Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-68 |

5.26 |

Changing Display Colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-69 |

5.27 |

Using the Position Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-71 |

5.28 |

Automatic Return to Normal Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-73 |

5.29 |

Performing Output Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-74 |

5.30 |

Using Prescale/Comparative Set Value Banks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-75 |

5.31 |

Copying Bank Prescale Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-81 |

5.32 |

Copying Bank Comparative Set Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-82 |

5.33 |

Initializing All Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-83 |

5.34 |

Limiting Key Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-84 |

Section 6 Troubleshooting

6.1 |

Error Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-2 |

6.2 |

Countermeasures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-3 |

Appendices

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-2 |

Model Number Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-7 |

Parameter List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-8 |

Parameter Display Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-17 |

About Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-23 |

“No-Measurement” Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-29 |

Forecasted Cycle Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-30 |

CONTENTS-2

Section 1 Outline

1.1 |

Main Functions and Features of the K3HB ................................ |

1-2 |

1.2 |

Component Names and Functions of the K3HB-R/P................. |

1-5 |

1.3 |

Component Names and Functions of the K3HB-C .................... |

1-6 |

1.4 |

Internal Block Diagram .............................................................. |

1-7 |

Outline

1-1

Outline

Section 1 Outline

1.1 Main Functions and Features of the K3HB

Measurement

Functions of the K3HB-R |

|

Functions of the K3HB-P |

|

Functions of the K3HB-C |

|

The K3HB-R has the following |

The K3HB-P has the following |

The K3HB-C has the following |

|||

six functions for reading and |

six functions for reading and |

three functions for reading |

|

||

displaying input pulses. |

|

displaying input pulses. |

|

and displaying input pulses. |

|

F1: Rpm/circumferential |

|

F1: Passing speed |

|

F1: Individual inputs |

|

speed |

|

F2: Cycle |

|

F2: Phase differential inputs |

|

F2: Absolute ratio |

|

F3: Time difference |

|

F3: Pulse counting input |

|

F3: Error ratio |

|

F4: Time band |

|

|

|

F4: Rotational difference |

|

F5: Measuring length |

|

|

|

F5: Flow rate ratio |

|

F6: Interval |

|

|

|

F6: Passing time |

|

|

|

|

|

→ P.5-9 |

R |

→ P.5-16 |

P |

→ P.5-23 |

C |

|

|

|

|||

Filter

Average processing

Average processing of input signals with extreme changes or noise smooths out the display and makes control stable.

→ P.5-36

R

Input compensation

Input compensation

The compensation input changes the display to the preset compensation value.

→ P.5-61

C

Input types

Specifies the sensor types connected to input A and input B.

→ P.5-27

R P C

Auto-zero time

Enables forced zeroing of the frequency when no pulse has been input for a specific period of time.

→ P.5-31

R

Key operations

Teaching

During scaling, the input value during measurement can be set, as is, as the scaling input value.

→ P.5-30

R C

(Setting Scaling)

Key protection

Limits key-operated level and parameter changes to prevent inadvertent key operations and malfunctions.

→ P.5-84

R P C

1-2

1.1 Main Functions and Features of the K3HB

Outputs

Comparative output pattern

The comparative output pattern can be selected as standard output, zone output, and level output.

→ P.5-39

R P C

PASS output change

Comparative results other than PASS and error signals can be output from the PASS output terminal.

→ P.5-51

R P

Output logic

Reverses the output logic of comparative outputs for comparative results.

→ P.5-53

R P C

Linear output

Outputs currents or voltages proportional to measurement values as they change.

→ P.5-57

R P C

Hysteresis

Prevents comparative output chattering when the measurement value fluctuates slightly near the set value.

→ P.5-42

R

Output OFF delay

Connects the comparative output OFF timing for a set interval. Comparative output ON times can be held when comparative results change quickly.

→ P.5-46

R P C

Startup compensation timer

Constant-time measurements can be stopped by an external signal input.

→ P.5-34

R

Standby sequence

Turns the comparative output OFF until the measurement value enters the PASS range.

→ P.5-55

R P

Output refresh stop

Holds the output status when comparative results outputs other than PASS turn ON.

→ P.5-49

R P

Shot output

Produces a constant comparative output ON time.

→ P.5-44

R P C

Output test

Output operation can be confirmed without actual input signals, by setting test measurement values using the keys.

→ P.5-74

R P C

Display

Display value selection |

|

Display color selection |

|

Display refresh period |

|

||||||

The current display value can |

The PV display color can be |

When inputs change quickly, |

|||||||||

be selected from the present |

set to either green or red. The |

the display refresh period can |

|||||||||

value, the maximum value, |

|

present value color can be |

|

be delayed to reduce |

|

|

|||||

and the minimum value. |

|

switched according to the |

|

flickering and make the |

|

|

|||||

|

|

|

|

status of comparative outputs. |

display easier to read. |

|

|

||||

→ P.5-67 |

R |

P |

C |

→ P.5-69 |

R |

P |

C |

→ P.5-60 |

R |

P |

C |

|

|

|

|||||||||

Position meter |

|

|

|

Scaling |

|

|

|

Comparative set value display |

|||

Displays the current |

|

|

|

Can convert the input signal to |

The comparative set value |

|

|||||

measurement value as a position |

any display value. |

|

|

|

can be set to not display |

|

|||||

in relation to the scaling width on |

|

|

|

|

during operation. |

|

|

|

|||

a meter with 20 sections. |

|

|

|

|

|

|

|

|

|

|

|

→ P.5-71 |

R |

P |

C |

→ P.5-28 |

R |

P |

C |

→ P.5-68 |

R |

P |

C |

|

|

|

|||||||||

Outline

1-3

Outline

Section 1 Outline

Other

Max/Min hold |

|

Bank selection |

|

Bank copy |

|

Holds the maximum and |

Eight comparative set value |

Any bank setting can be |

|||

minimum measurement |

banks can be selected using |

copied to all banks. |

|

||

values. |

|

the keys on the front of the |

|

|

|

|

|

Unit or by external inputs. |

|

|

|

|

|

Groups of comparative set |

|

|

|

|

|

values can be set and can be |

|

|

|

|

|

selected as groups. |

|

|

|

→ P.5-65 |

R P C |

→ P.5-75 |

R P C |

→ P.5-81 |

R P C |

|

|

|

|||

Interruption memory

The measured value can be recorded when the power supply is interrupted.

→ P.5-63

C

1-4

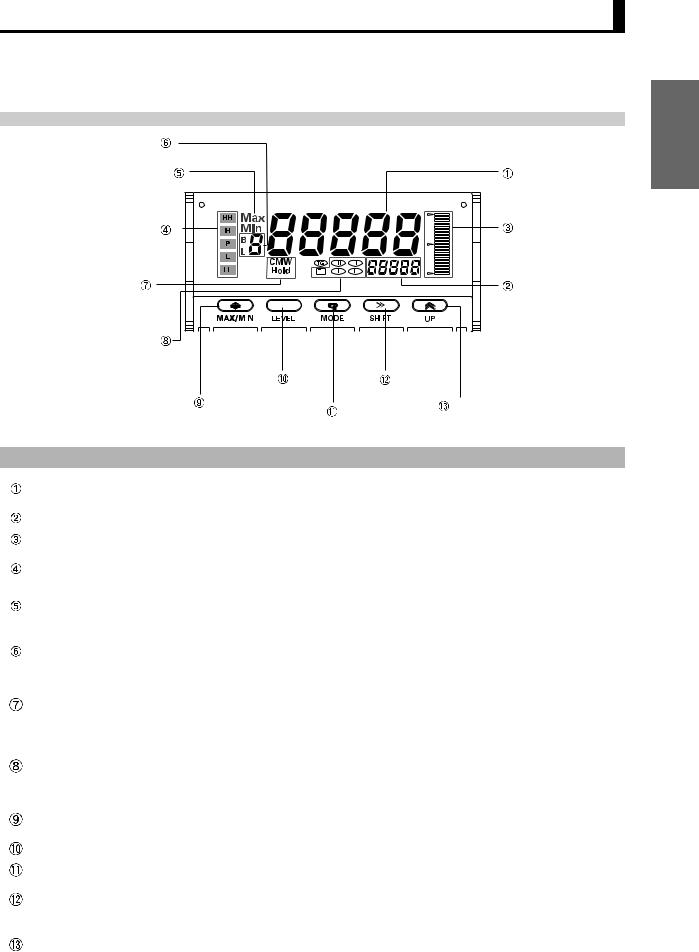

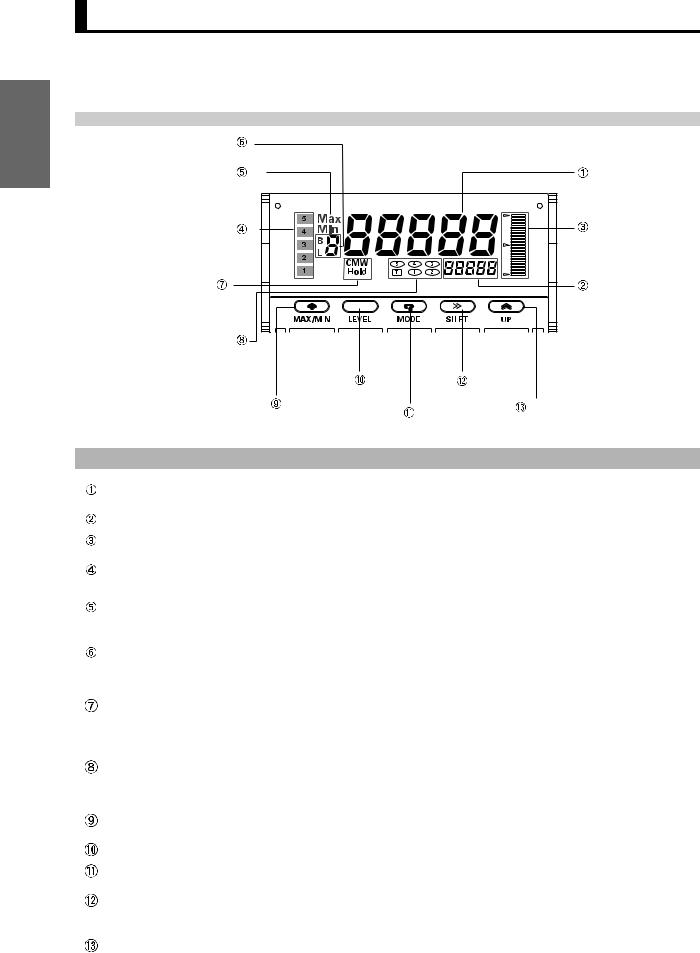

1.2Component Names and Functions of the K3HB-R/P

1.2Component Names and Functions of the K3HB-R/P

Level/bank display |

|

Max/Min status |

PV display |

Comparative output status |

Position meter |

Status indicators |

SV display |

|

SV display status |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LEVEL Key |

SHIFT Key |

||

|

|

MAX/MIN Key |

|

UP Key |

|||

|

|

|

|

|

|||

|

|

|

|

MODE Key |

|

|

|

|

|

|

|

|

|

|

|

No. |

Name |

|

|

|

Function |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PV display |

Displays PVs, maximum values, minimum values, parameter names, and |

|||||

|

|

error names. |

|

|

|

||

|

|

|

|

|

|

|

|

|

SV display |

Displays SVs and monitor values. |

|||||

|

|

|

|

|

|

|

|

|

Position meter |

Displays the position of the PV with respect to a user-set scale. |

|||||

|

|

|

|

|

|

|

|

|

Comparative output |

Display the status of comparative outputs. |

|||||

|

status indicators |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Max/Min status |

Turns ON when the maximum value or minimum value is displayed in RUN |

|||||

|

indicator |

level. |

|

|

|

||

|

|

|

|

|

|

|

|

|

Level/bank display |

In RUN level, displays the bank if the bank function is ON. (Turns OFF if the |

|||||

|

|

bank function is OFF.) |

|

|

|

||

|

|

In other levels, displays the current level. |

|||||

|

|

|

|

|

|

|

|

|

Status indicators |

Hold: Turns ON/OFF when the hold input turns ON/OFF. |

|||||

|

|

CMW:Turns ON when communications writing is ON (enabled) and turns |

|||||

|

|

|

OFF when communications writing is OFF (prohibited). |

||||

|

|

|

|

|

|

|

|

|

SV display status |

T: Turns ON when a parameter for which teaching can be performed is |

|||||

|

indicators |

|

displayed. |

|

|

|

|

|

|

HH, H, L, LL: In RUN level, turn ON when the comparative set values HH, |

|||||

|

|

|

|

H, L, and LL are displayed. |

|||

|

|

|

|

|

|

|

|

|

MAX/MIN Key |

Used to switch the display between the PV, maximum value, and minimum |

|||||

|

|

value and to reset the maximum and minimum values. |

|||||

|

|

|

|

|

|

|

|

|

LEVEL Key |

Used to switch the level. |

|

|

|

||

|

|

|

|

|

|

|

|

|

MODE Key |

Used to switch the displayed parameter. |

|||||

|

|

|

|

|

|

|

|

|

SHIFT Key |

Used to change parameter settings. |

|||||

|

|

When changing a set value, this key is used to move along the digits. |

|||||

|

|

|

|

|

|

|

|

|

UP Key |

When changing a set value, this key is used to change the actual value. |

|||||

|

|

When a measurement value is displayed, this key is used to execute |

|||||

|

|

teaching. |

|

|

|

||

|

|

|

|

|

|

|

|

Outline

1-5

Outline

Section 1 Outline

1.3 Component Names and Functions of the K3HB-C

Level/bank display |

|

Max/Min status |

PV display |

Comparative output status |

Position meter |

Status indicators |

SV display |

|

SV display status |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LEVEL Key |

SHIFT Key |

||

|

|

MAX/MIN Key |

|

UP Key |

|||

|

|

|

|

|

|||

|

|

|

|

MODE Key |

|

|

|

|

|

|

|

|

|

|

|

No. |

Name |

|

|

|

Function |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PV display |

Displays PVs, maximum values, minimum values, parameter names, and |

|||||

|

|

error names. |

|

|

|

||

|

|

|

|

|

|

|

|

|

SV display |

Displays SVs and monitor values. |

|||||

|

|

|

|

|

|

|

|

|

Position meter |

Displays the position of the PV with respect to a user-set scale. |

|||||

|

|

|

|

|

|

|

|

|

Comparative output |

Display the status of comparative outputs. |

|||||

|

status indicators |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Max/Min status |

Turns ON when the maximum value or minimum value is displayed in RUN |

|||||

|

indicator |

level. |

|

|

|

||

|

|

|

|

|

|

|

|

|

Level/bank display |

In RUN level, displays the bank if the bank function is ON. (Turns OFF if the |

|||||

|

|

bank function is OFF.) |

|

|

|

||

|

|

In other levels, displays the current level. |

|||||

|

|

|

|

|

|

|

|

|

Status indicators |

Hold: Turns ON/OFF when the hold input turns ON/OFF. |

|||||

|

|

CMW:Turns ON when communications writing is ON (enabled) and OFF |

|||||

|

|

|

when communications writing is OFF (prohibited). |

||||

|

|

|

|

|

|

|

|

|

SV display status |

T: Turns ON when a parameter for which teaching can be performed is |

|||||

|

indicators |

|

displayed. |

|

|

|

|

|

|

5, 4, 3, 2, or 1: Turns ON when the comparative values 5, 4, 3, 2, or 1 is |

|||||

|

|

|

|

displayed in the RUN level. |

|||

|

|

|

|

|

|

|

|

|

MAX/MIN Key |

Used to switch the display between the PV, maximum value, and minimum |

|||||

|

|

value and to reset the maximum and minimum values. |

|||||

|

|

|

|

|

|

|

|

|

LEVEL Key |

Used to switch the level. |

|

|

|

||

|

|

|

|

|

|

|

|

|

MODE Key |

Used to switch the displayed parameter. |

|||||

|

|

|

|

|

|

|

|

|

SHIFT Key |

Used to change parameter settings. |

|||||

|

|

When changing a set value, this key is used to move along the digits. |

|||||

|

|

|

|

|

|

|

|

|

UP Key |

When changing a set value, this key is used to change the actual value. |

|||||

|

|

When a measurement value is displayed, this key is used to execute |

|||||

|

|

teaching. |

|

|

|

||

|

|

|

|

|

|

|

|

1-6

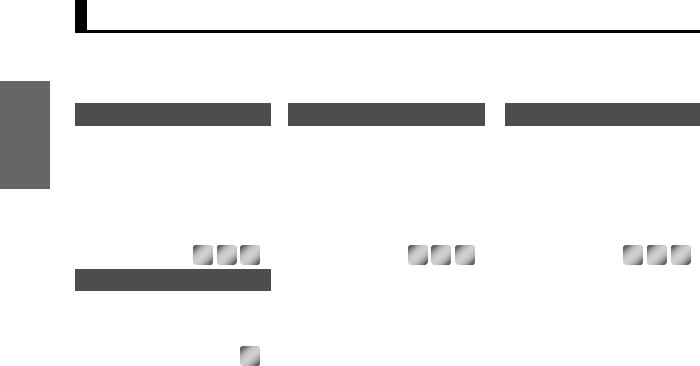

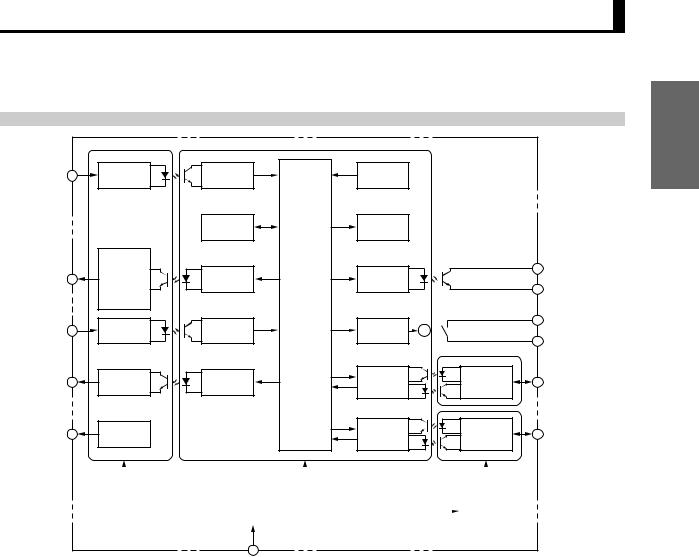

1.4 Internal Block Diagram

1.4 Internal Block Diagram |

Outline |

|||

|

|

Waveform |

||

Pulse input |

Pulse input |

Keys |

||

circuit |

shaping circuit |

|||

|

|

|||

|

|

EEPROM |

Indications |

|

|

|

|

BCD |

|

|

|

|

|

BCD I/O |

• Input circuit |

Drive |

Drive |

|

Transistor |

|

• Output circuit |

|

|||||

circuit |

circuit |

|

output |

|||

|

• Transistor |

|

||||

|

output circuit |

|

Micro- |

|

|

|

|

|

|

|

|

||

|

|

|

computer |

|

|

|

Event input |

Digital input |

Waveform |

Drive |

X |

Relay output |

|

circuit |

shaping circuit |

circuit |

||||

|

|

|

Linear output |

Linear output |

Drive |

Drive |

DeviceNet |

DeviceNet |

|

circuit |

circuit |

circuit |

circuit |

|||

|

|

|||||

Sensor power |

Filter |

|

Drive |

Communi- |

Communications |

|

|

cations |

|||||

supply |

|

circuit |

||||

|

|

driver |

|

|||

|

|

|

|

|

|

VO |

|

VDD |

|

|

|

VCOM |

|

|

|

|

|

VO |

|

|

|

|

|

|

Power supply circuit (isolated) |

DC-DC |

|

||||

|

|

|

|

|

||||

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

Converter (isolated)

Power supply

1-7

Section 1 Outline

Outline

1-8

Section 2 Preparations

2.1 |

Mounting .................................................................................... |

2-2 |

2.2 |

Using I/O.................................................................................... |

2-4 |

Preparations

2-1

Section 2 Preparations

2.1 Mounting

Preparations

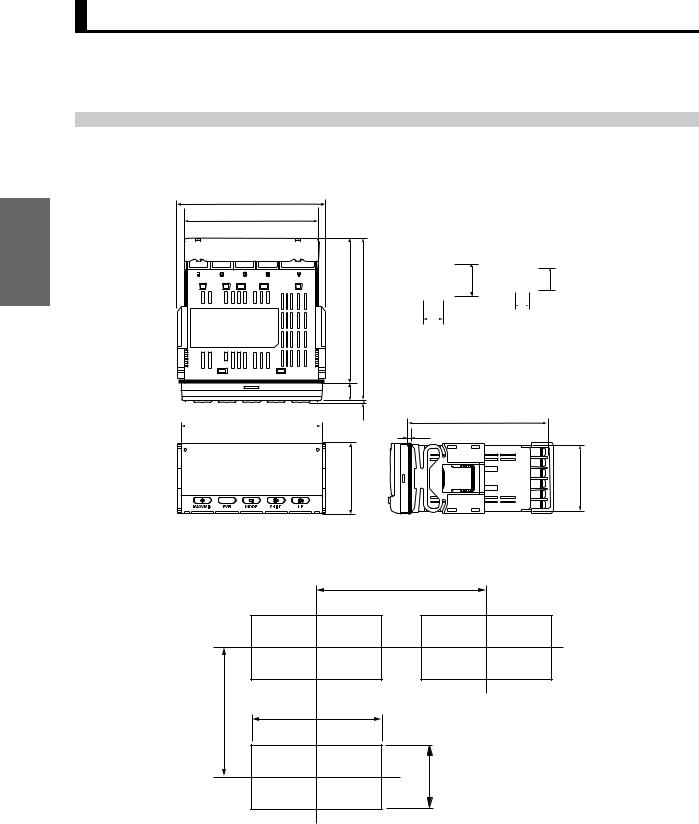

■ External Dimensions

101.2 |

|

|

|

|

|

91 |

|

|

|

|

|

|

|

Character size for main display (mm) |

|||

|

|

PV display |

SV display |

||

|

(112) |

8 |

14.2 |

8 |

4.9 |

100 |

|

|

2.6 |

|

|

|

|

|

|

|

|

|

|

7.6 |

|

|

|

|

12 |

|

96 |

1.3 |

95 (DeviceNet models: 97) |

|

|

2 |

|

48 |

44.8 |

■ Panel Cutout Dimensions

120 min.

75 min.

92 +0-0.8

+0.6 45-0

2-2

2.1 Mounting

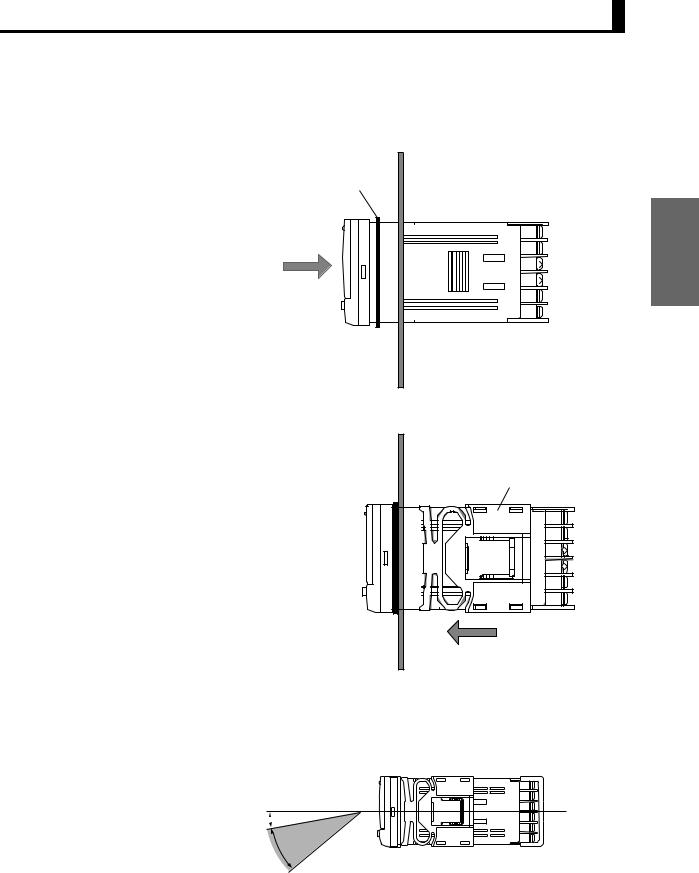

■ Mounting Method

(1)Insert the K3HB into the mounting cutout in the panel.

(2)Insert watertight packing around the Unit to make the mounting watertight.

Watertight packing

Preparations

(3)Insert the adapter into the grooves on the left and right sides of the rear case and push until it reaches the panel and is fixed in place.

Adapter |

■ LCD Field of Vision

The K3HB is designed to have the best visibility at the angles shown in the following diagram.

10˚

10˚

30˚

2-3

Preparations

Section 2 Preparations

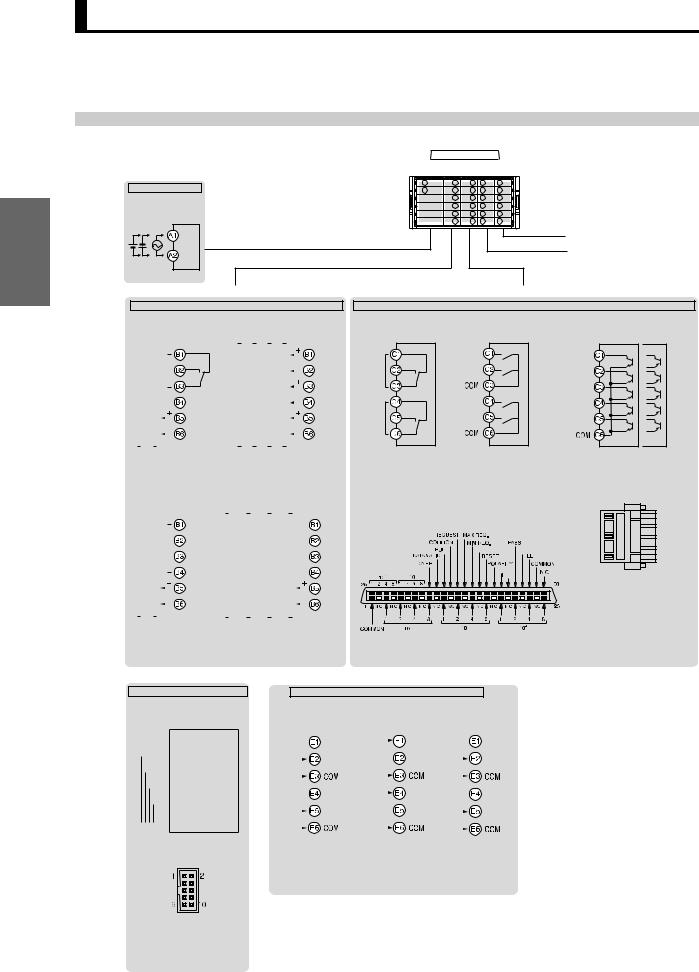

2.2 Using I/O

A

Operating Power Supply

100 to 240 VAC

24 VAC/ VDC

*Check the required power supply type.

B

Sensor Power Supply/Output

Sensor power supply + |

|

|

Sensor power supply + |

||||||||||||||||||||

|

|

|

PASS output |

|

|

|

|

|

linear output |

||||||||||||||

|

|

|

DC12V 80mA PASS (3) |

|

|

|

|

|

|

|

DC10V 100mA N/C 0-5/1-5/0-10V |

|

DC10V 100mA 0-20/4-20mA N/C |

|

DC12V 80mA N/C 0-5/1-5/0-10V |

|

DC12V 80mA 0-20/4-20mA N/C |

|

|

|

|

|

|

|

DC10V 100mA |

|

|

|

|

|

Sensor power supply |

|

|

|

|

|

|

|

|

|

Sensor power supply |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|||||||||||||||||||

<CPB><CPA> |

|

|

<L2B> |

<L2A> |

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

<L1B> |

<L1A> |

|

|

||||||||

Sensor power supply |

Sensor power supply + |

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

communications |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

B(+) |

|

SD |

|

B(+) |

|

SD |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

A(-) |

|

RD |

|

A(-) |

|

RD |

|

|

||||

|

|

|

N/C |

|

|

|

|

|

A(-) B(+) |

|

N/C SG |

|

A(-) B(+) |

|

N/C SG |

|

|

|||||

|

|

|

|

|

|

|

|

supply |

|

|

|

|

|

supply |

||||||||

|

|

|

|

|

|

|

|

|||||||||||||||

|

DC10V 100mA |

|

DC12V 80mA |

|

|

|

|

Sensor power |

|

DC10V 100mA |

|

DC10V 100mA |

|

DC12V 80mA |

|

DC12V 80mA |

|

|

|

|

|

Sensorpower |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

<B> |

<A> |

|

RS-485 |

RS-232C |

RS-485 |

RS-232C |

|

|||||||||||||||

<FLK3B> <FLK1B> <FLK3A> <FLK1A>

Terminal Block

A B C D E

|

|

To E |

|

|

To D |

|

C |

|

Relays/Transistors/BCD/DeviceNet |

||

Relay output |

Relay output |

Transistor output |

<C1> |

<C2> |

<T1><T2> |

|

HH (5) |

NPN PNP |

|

HH (5) |

|

|

|

|

H (4) |

H (4) |

H (4) |

|

||

|

|

PASS (3) |

|

L (2) |

L (2) |

|

|

|

L (2) |

LL (1) |

LL (1) |

* No combinations with CPA/CPB other than relay output.

BCD (NPN Open Collector): <BCD>

• Applicable Connector (Sold separately) HDR-E50MAG1

(HONDA TSUSHIN KOGYO CO., LTD.)

• Special Cable (Sold separately) K32-BCD (OMRON) (HDR-E50MAG1 with 0.3-m cable)

|

(3) |

4 |

|

HOLD (CMP) |

(2) |

||

5 |

|||

|

(1) |

(5)

(5)

(4)

The BCD COMMON is shared.

The pins indicated in the above diagram as blank (white) boxes have been removed.

*Only one of RS-232C/RS-485 communications, BCD, or DeviceNet can be used by each Digital Indicator.

D

Event Input

Models with Terminal Blocks <1><3>

N/C

N/C

S-TMR

S-TMR

HOLD

HOLD

RESET

RESET

COMPENSATION

COMPENSATION

COM

COM

Models with Connectors <2><4>

1: N/C |

2: S-TMR |

3: HOLD |

4: RESET |

5: COMPENSATION |

6: COM |

7: BANK4 |

8: BANK2 |

9: BANK1 |

10: COM |

•Applicable Connector (Sold separately) XG4M-1030 (OMRON)

•Special Cable (Sold separately)

K32-DICN (OMRON) (XG4M-1030 with 3-m cable)

E

Pulse Inputs

NPN Open Collector |

NPN Voltage Pulse |

|

PNP Input: |

|||||||||||

Inputs: K3HB-@NB |

|

Inputs: K3HB-@NB |

|

K3HB-@PB |

||||||||||

|

|

|

|

|

|

|

|

|

|

N/C |

|

|

||

|

N/C |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

INA |

Voltage |

N/C |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

||||

INA |

NPN |

|

|

|

|

|

|

|

INA |

PNP |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N/C |

|

|

|

|

|

N/C |

|

|

N/C |

|

|

||

|

|

|

|

|

INB |

Voltage |

|

|

|

|

|

|

||

INB |

NPN |

|

|

|

|

|

|

|

INB |

PNP |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: E3 and E6, |

|

|

|

|

|

|

||||||||

Note: E3 and E6, |

Note: E3 and E6, |

|||||||||||||

|

as well as B6, |

as well as B6, |

|

as well as B5, |

||||||||||

|

are internally |

|

are internally |

|

are internally |

|||||||||

|

connected. |

|

connected. |

|

connected. |

|||||||||

The following signals depend on the model:

S-TMR: Used by the K3HB-R only.

COMPENSATION: Used by the K3HB-C only.

2-4

2.2 Using I/O

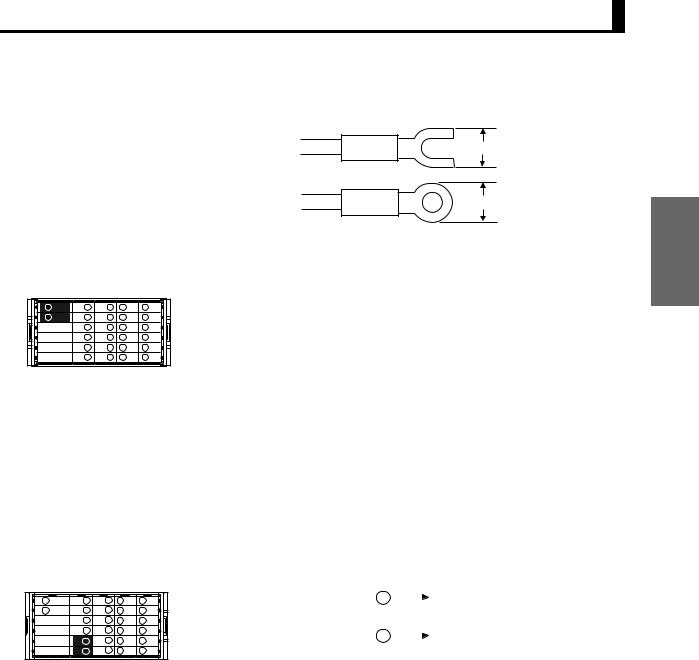

■ Wiring

Use crimp terminals suitable for M3 screws, as shown below.

|

|

5.8 mm max. |

|

|

|

5.8 mm max. |

|

|

|

Use cables with a heat resistance of at least 70ºC. |

|

●Power Supply |

|

|

|

A B C D |

E |

Supply power to terminal numbers A1 and A2. The power supply |

|

specifications are outlined below. |

|||

1 |

|

||

|

100 to 240 VAC, 50/60 Hz, 18 VA max. (at max. load) |

||

2 |

|

||

3 |

|

24 VAC/VDC, 50/60 Hz, 12 VA max./7 W max. (at max. load) |

|

4 |

|

||

5 |

|

(No polarity) |

|

6 |

|

When the power is turned ON, a power supply capacity greater than the rated power supply is required. When multiple Units are being used, make sure that the operating power supply has sufficient capacity.

Complying with UL/CSA Standards

Use an SELV power supply with overcurrent protection for the DC power supply. An SELV power supply has double or reinforced insulation between the input and output, an output voltage of 30 V rms and 42.4 V peak, and is 60 VDC or less.

Recommended Power Supply: S8VS-06024@ (from OMRON)

●Sensor Power Supply

A B C D E

1

2

3

4

5

6

The sensor power can be supplied from terminals B5 and B6. The power supply specifications are outlined below.

12 VDC 80 mA |

B5 |

|

|

|

+ |

|

|

|

|||

or |

|

|

|

|

|

10 VDC 100 mA |

B6 |

|

|

- |

|

|

|||||

Refer to page A-6 for information on the derating curve for the Sensor power supply.

Preparations

2-5

Preparations

Section 2 Preparations

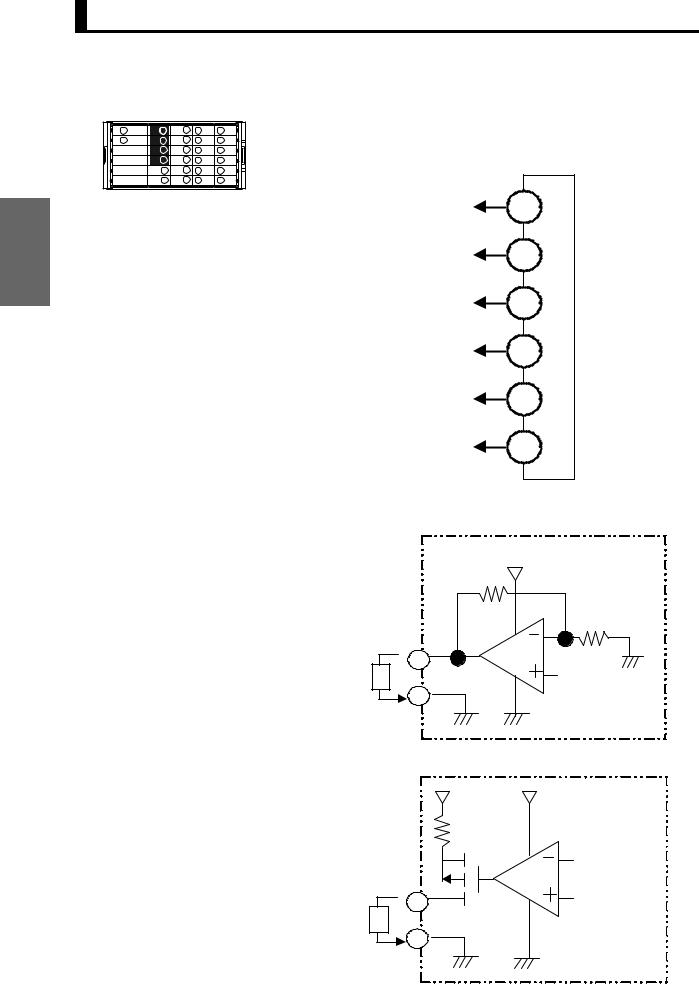

●Linear Outputs

A B C D E

1

2

3

4

5

6

Linear currents and voltages are output between terminals B1 to B2 and between B3 to B4.

Connect a load within the specified range.

Linear output

+ |

|

|

|

B1 |

|

− |

|

|

|

B2 |

|

+ |

|

|

|

B3 |

|

− |

|

|

|

B4 |

supply |

+ |

|

|

|

power |

|

|

B5 |

|

|

|

|

− |

|

Sensor |

|

B6 |

|

|

|

Circuit Diagrams

Linear voltage output

+

B1

B1

5 kΩ min. L

− B2

Linear current output

+

B3

B3

500 Ω min. L

−B4

2-6

2.2 Using I/O

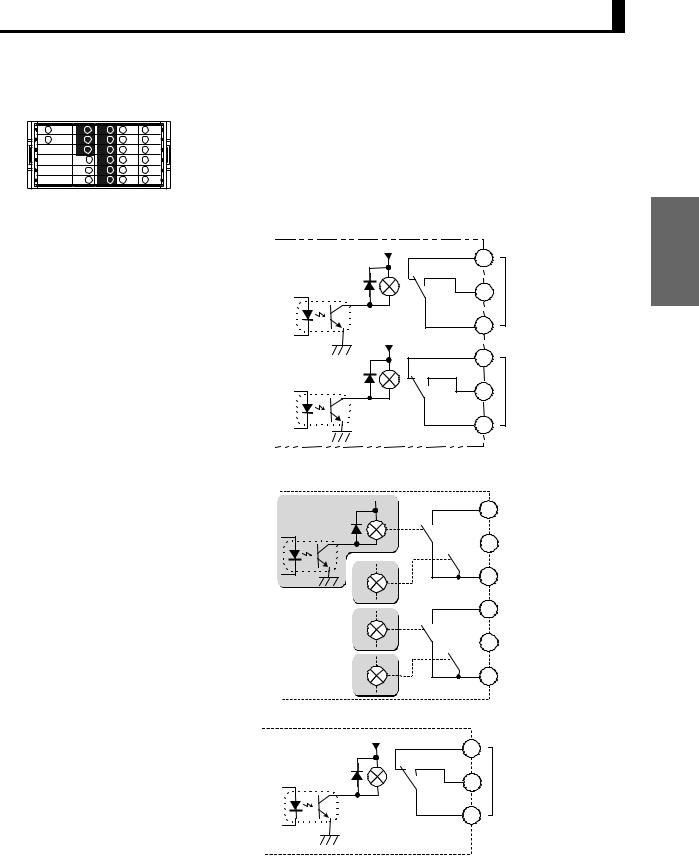

●Comparative Outputs

A |

Comparative outputs are output to terminals B1 to B3 and C1 to C6. |

||

B C D E |

|

|

|

1 |

Connect loads within specifications. |

|

|

2 |

The electrical life expectancy of the relays is 100,000 operations. |

||

3 |

|||

4 |

|

|

|

5 |

K3HB-C outputs are enclosed in parentheses (OUT*). |

||

6 |

|

|

|

|

Circuit Diagrams |

|

|

|

Contact Outputs |

|

|

|

<K34-C1> H (OUT4) and L (OUT2) Output Models |

|

|

|

5 V |

C1 |

|

|

|

|

|

|

|

C2 |

H (OUT4) |

|

|

C3 |

|

|

5 V |

C4 |

|

|

|

|

|

|

|

C5 |

L (OUT2) |

|

|

C6 |

|

<K34-C2> HH (OUT5), H (OUT4), L (OUT2), and LL (OUT1) Output Models

5 V

C1 HH (OUT5)

C2 H (OUT4)

C2 H (OUT4)

C3 COM

C4 L (OUT2)

C5 LL (OUT1)

C5 LL (OUT1)

C6 COM

<K34-CPA> PASS (OUT3) Output Models

5 V

B1

B2 PASS (OUT3)

B3

Preparations

2-7

Loading...

Loading...