Page 1

100-231-436 B

MTS Criterion

™

Series 60

Product Manual

Page 2

Copyright information © 2010 MTS Systems Corporation. All rights reserved.

Trademark information MTS is a registered trademark and MTS Criterion and MTS Fundamental are

trademarks of MTS Systems Corporation within the United States. These

trademarks may be protected in other countries.

Proprietary information Software use and license is governed by MTS’ End User License Agreement

which defines all rights retained by MTS and granted to the End User. All

Software is proprietary, confidential, and owned by MTS Systems Corporation

and cannot be copied, reproduced, disassembled, decompiled, reverse

engineered, or distributed without express written consent of MTS.

Software validation and

verification

Publication information

MTS software is developed using established quality practices in accordance

with the requirements detailed in the ISO 9001 standards. Because MTSauthored software is delivered in binary format, it is not user accessible. This

software will not change over time. Many releases are written to be backwards

compatible, creating another form of verification.

The status and validity of MTS’ operating software is also checked during

system verification and routine calibration of MTS hardware. These controlled

calibration processes compare the final test results after statistical analysis

against the predicted response of the calibration standards. With these established

methods, MTS assures its customers that MTS products meet MTS’ exacting

quality standards when initially installed and will continue to perform as intended

over time.

MANUAL PART NUMBER PUBLICATION DATE

100-231-436 A January 2011

100-231-436 B October 2011

2

MTS Criterion™ Series 60 Product Manual

Page 3

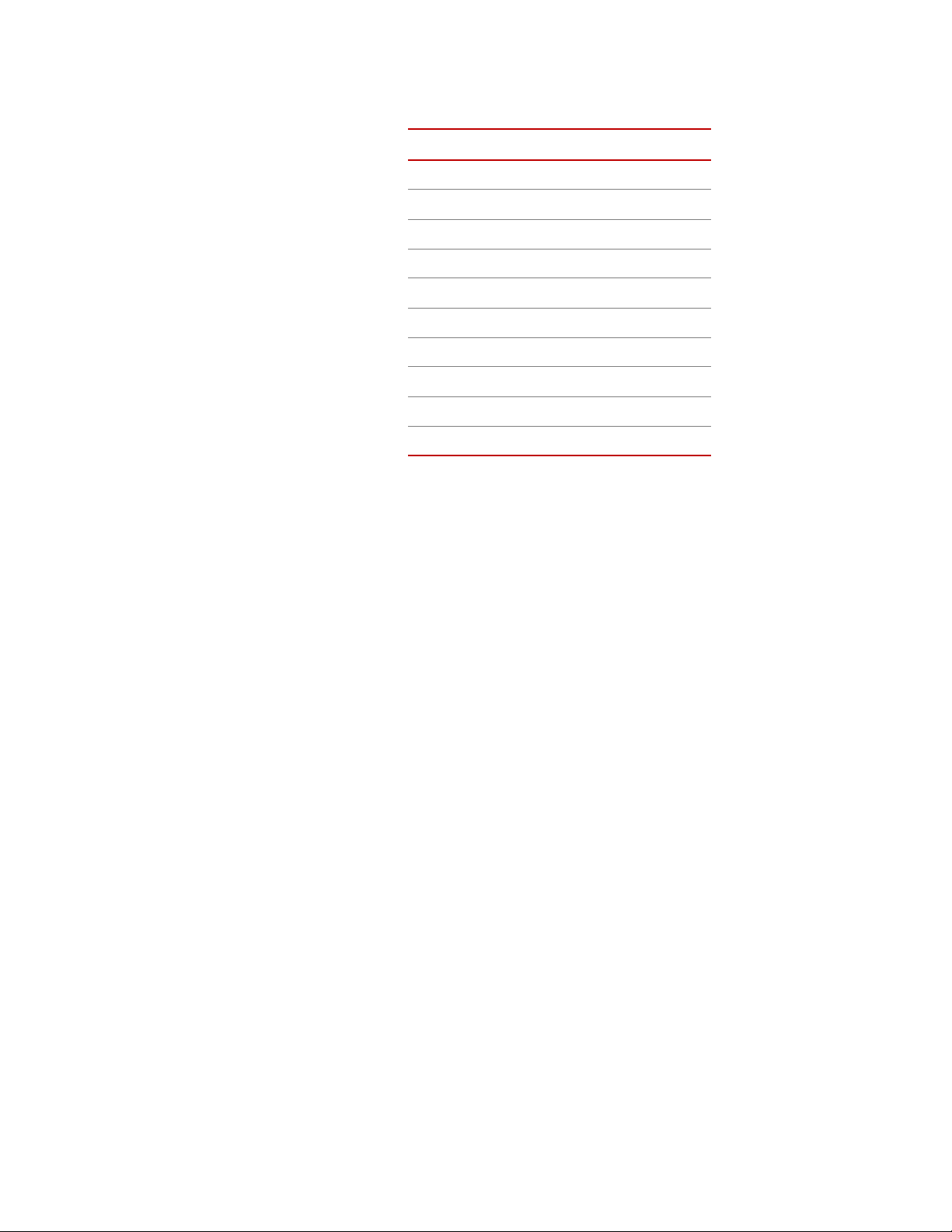

Contents

Contents 3

Technical Support 7

How to Get Technical Support 7

Before You Contact Your MTS Service Representative 7

If You Contact MTS by Phone 8

Preface 11

Before You Begin 11

Conventions 12

Documentation Conventions 12

Introduction 15

About This Manual 15

Inappropriate Use 15

Description 16

Specifications 21

General Specifications – Frame 21

Model Specifications – Frame 22

Specifications – Integrated Operations Platform 24

Dimensions 26

Frame 26

Integrated Operations Platform 27

Safety Enclosure 31

Steps 32

Test Table Detail 33

Platen Transition Plate Detail 34

MTS Criterion™ Series 60 Product Manual Contents

3

Page 4

Safety 37

General Safety Practices 37

Safety Practices Before System Operation 38

Safety Practices While the System Is in Operation 40

Hazard Labels 43

Installation 45

Lifting and Moving Overview 46

Moving Frames and Integrated Operations Platform 48

Machine Location and Ventilation 48

Moving the Load Fame 49

Unloading 49

Moving the Load Unit to Its Final Location 50

Moving the Load Unit with a Forklift 53

Moving the Load Unit with an Overhead Crane 53

Securing the Load Unit 54

Moving the Integrated Operations Platform 56

Unloading 56

Moving the Integrated Operations Platform to Its Final Location 56

Unloading the Steps 58

Installing the Optional Safety Enclosure 59

Installing the Steps 62

Controller Connections 63

Connecting the Main Power 63

Machine-Specific Requirements 63

Installing Cables 64

Controller Connectors 64

Connecting Hoses 72

Adding Oil 73

Operation 75

Travel Limit Switches (Physical Limits) 76

Crush Zone Hazards 77

Fixture mounting 77

Integrated Operations Platform Control Panel 78

Motion Control 79

Handset Control 81

Contents

4

MTS Criterion™ Series 60 Product Manual

Page 5

Maintenance 85

Routine Maintenance Overview Checklist 85

Troubleshooting 89

Decommissioning 91

Appendix 93

Additional Digital I/O Information 93

Declaration of Conformity 95

MTS Criterion™ Series 60 Product Manual Contents

5

Page 6

6

Contents

MTS Criterion™ Series 60 Product Manual

Page 7

Technical Support

How to Get Technical Support

Start with your

manuals

Technical support

methods

Contact your local

MTS authorized sales

The manuals supplied by MTS provide most of the information you need to use

and maintain your equipment. If your equipment includes MTS software, look

for online help and README files that contain additional product information.

If you cannot find answers to your technical questions from these sources, you

can use the internet, e-mail, or telephone to contact MTS for assistance.

MTS provides a full range of support services after your system is installed. If

you have any questions about a system or product, contact MTS in one of the

following ways.

For a list of worldwide sales and service locations and contact information, use

the Global MTS link at the MTS web site:

and service office

www.mts.com > Global MTS > (choose your region in the right-hand

column) > (choose the location closest to you)

E-mail techsupport.shenzhen@mts.com

Before You Contact Your MTS Service Representative

MTS can help you more efficiently if you have the following information

available when you contact us for support.

Know your contract

number and system

number

The contract number contains identifies your equipment type. The number is

usually written on a label on your MTS equipment before the system leaves

MTS. If you do not have or do not know your MTS contract number, contact

your MTS sales engineer.

When you have more than one MTS system, the system model number and serial

number identify which system you are calling about. You can find these numbers

in the papers sent to you when you ordered your system or directly on your

equipment.

Identify the problem Describe the problem you are experiencing and know the answers to the

following questions:

• How long and how often has the problem been occurring?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the

problem started?

• What are the equipment model numbers?

• What is the controller model (if applicable)?

• What is the system test configuration?

MTS Criterion™ Series 60 Product Manual Technical Support

7

Page 8

Know relevant

computer information

If you are experiencing a computer problem, have the following information

available:

• Manufacturer’s name and model number

• Operating software type and service patch information

• Amount of system memory

• Amount of free space on the hard drive in which the application resides

• Current status of hard-drive fragmentation

• Connection status to a corporate network

Know relevant

For software application problems, have the following information available:

software information

• The software application’s name, version number, build number, and if

available, software patch number. This information is displayed briefly

when you launch the application, and can typically be found in the “About”

selection in the “Help” menu.

• It is also helpful if the names of other non-MTS applications that are

running on your computer, such as anti-virus software, screen savers,

keyboard enhancers, print spoolers, and so forth are known and available.

If You Contact MTS by Phone

Your call will be registered by a Call Center agent if you are calling within the

United States or Canada. Before connecting you with a technical support

specialist, the agent will ask you for your contract number, name, company,

company address, and the phone number where you can normally be reached.

If you are calling about an issue that has already been assigned a notification

number, please provide that number. You will be assigned a unique notification

number about any new issue.

Identify system type To assist the Call Center agent with connecting you to the most qualified

technical support specialist available, identify your system as MTS Series 60

Static-Hydraulic Universal Test Systems.

Be prepared to

troubleshoot

Write down relevant

information

Technical Support

8

Prepare yourself for troubleshooting while on the phone:

• Call from a telephone when you are close to the system so that you can try

implementing suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an

experienced user nearby to assist you.

Prepare yourself in case we need to call you back:

• Remember to ask for the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions to be followed, such as data recording

or performance monitoring.

MTS Criterion™ Series 60 Product Manual

Page 9

After you call MTS logs and tracks all calls to ensure that you receive assistance and that action

is taken regarding your problem or request. If you have questions about the status

of your problem or have additional information to report, please contact MTS

again and provide your original notification number.

MTS Criterion™ Series 60 Product Manual Technical Support

9

Page 10

Technical Support

10

MTS Criterion™ Series 60 Product Manual

Page 11

Preface

Before You Begin

Safety first! Before you use your MTS product or system, read and understand the Safety

manual and any other safety information provided with your system. Improper

installation, operation, or maintenance can result in hazardous conditions that can

cause severe personal injury or death, or damage to your equipment and

specimen. Again, read and understand the safety information provided with your

system before you continue. It is very important that you remain aware of

hazards that apply to your system.

Other MTS

documentation

In addition to this manual, you may receive additional documentation in paper or

electronic form.

Manuals located on the product information CD will contain information that

pertains to your test system, such as:

• Hydraulic and/or mechanical accessory manuals

• Assembly drawings

• Parts lists

• Operation instructions

• Preventive maintenance tasks

Controller and application software manuals are typically included on the

software CD distribution disc(s).

MTS Criterion™ Series 60 Product Manual Preface

11

Page 12

Conventions

DANGER

WARNING

CAUTION

Conventions

Documentation Conventions

The following paragraphs describe some of the conventions that are used in your

MTS manuals.

Hazard conventions Hazard notices may be embedded in this manual. These notices contain safety

information that is specific to the activity to be performed. Hazard notices

immediately precede the step or procedure that may lead to an associated hazard.

Read all hazard notices carefully and follow all directions and recommendations.

Three different levels of hazard notices may appear in your manuals. Following

are examples of all three levels.

Note For general safety information, see the safety information provided with

your system.

Danger notices indicate the presence of a hazard with a high level of risk which,

if ignored, will result in death, severe personal injury, or substantial property

damage.

Warning notices indicate the presence of a hazard with a medium level of risk

which, if ignored, can result in death, severe personal injury, or substantial

property damage.

Caution notices indicate the presence of a hazard with a low level of risk which,

if ignored, could cause moderate or minor personal injury or equipment damage,

or could endanger test integrity.

Notes Notes provide additional information about operating your system or highlight

easily overlooked items. For example:

Note Resources that are put back on the hardware lists show up at the end of

the list.

Special terms The first occurrence of special terms is shown in italics.

Illustrations Illustrations appear in this manual to clarify text. They are examples only and do

Electronic manual

conventions

Preface

12

not necessarily represent your actual system configuration, test application, or

software.

This manual is available as an electronic document in the Portable Document

File (PDF) format. It can be viewed on any computer that has Adobe Acrobat

Reader installed.

MTS Criterion™ Series 60 Product Manual

Page 13

Conventions

Hypertext links The electronic document has many hypertext links displayed in a blue font. All

blue words in the body text, along with all contents entries and index page

numbers, are hypertext links. When you click a hypertext link, the application

jumps to the corresponding topic.

MTS Criterion™ Series 60 Product Manual Preface

13

Page 14

Conventions

14

Preface

MTS Criterion™ Series 60 Product Manual

Page 15

Introduction

About This Manual

Purpose This manual provides detailed information about the MTS Criterion Series 60

Inappropriate Use

Contents Description 16

Test Systems. The information includes an overview of all the models available,

installation, operation, maintenance, decommissioning, and trouble shooting.

The purpose of this manual is to help you understand your testing system, its

capabilities, and operating requirements. This manual provides technical

information for all Series 60 Test Systems, from the lowest force model (64.305/

64.305E, 300 kN), to the highest (64.106/64.106E, 1000 kN). Read each section

carefully, and refer to the manual whenever you need assistance.

Before you attempt to use the MTS Criterion Series 60 Test System, read and

understand this manual. Improper installation or operation of this product can

result in hazardous conditions that can cause severe personal injury or death, and

damage your equipment and specimen.

Specifications 21

MTS Criterion™ Series 60 Product Manual Introduction

15

Page 16

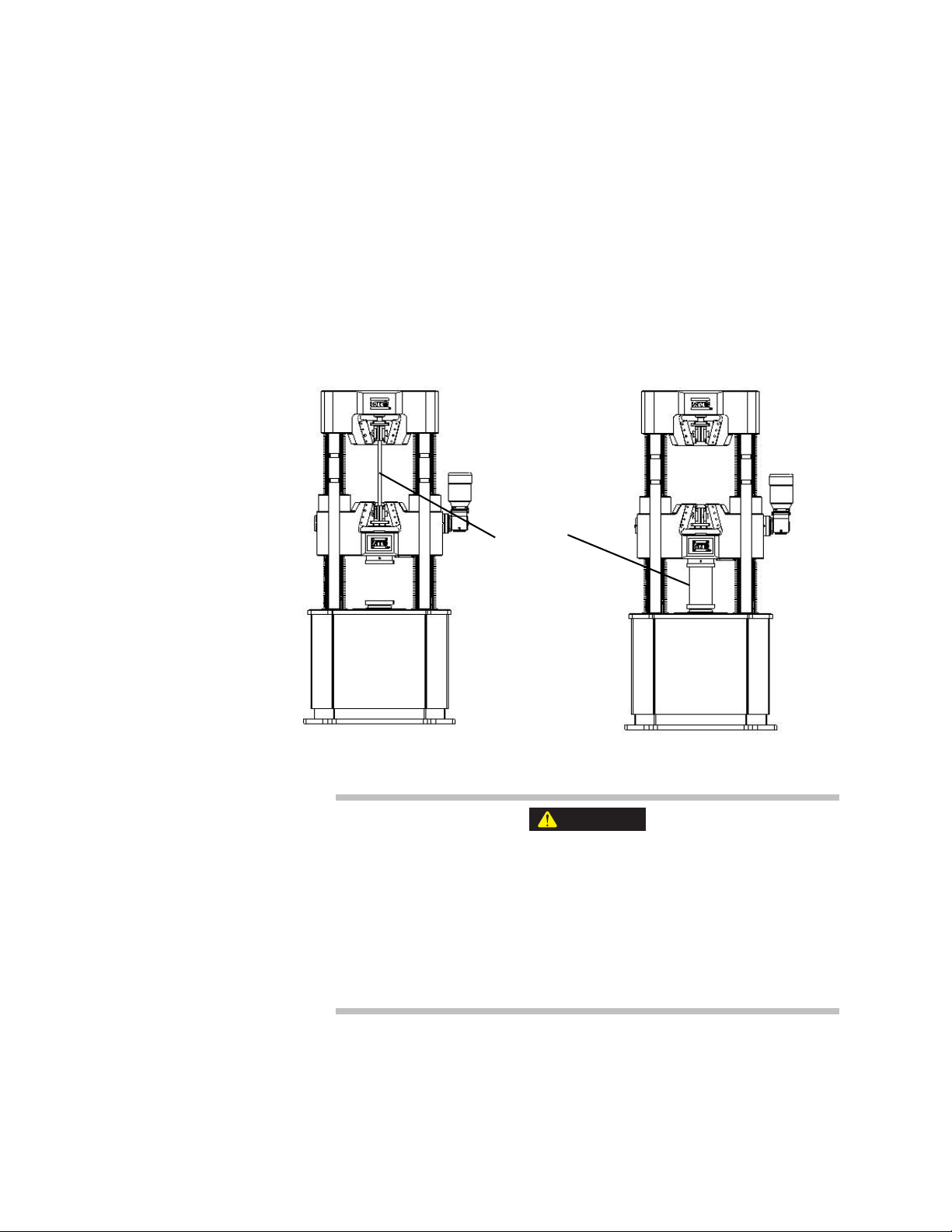

Description

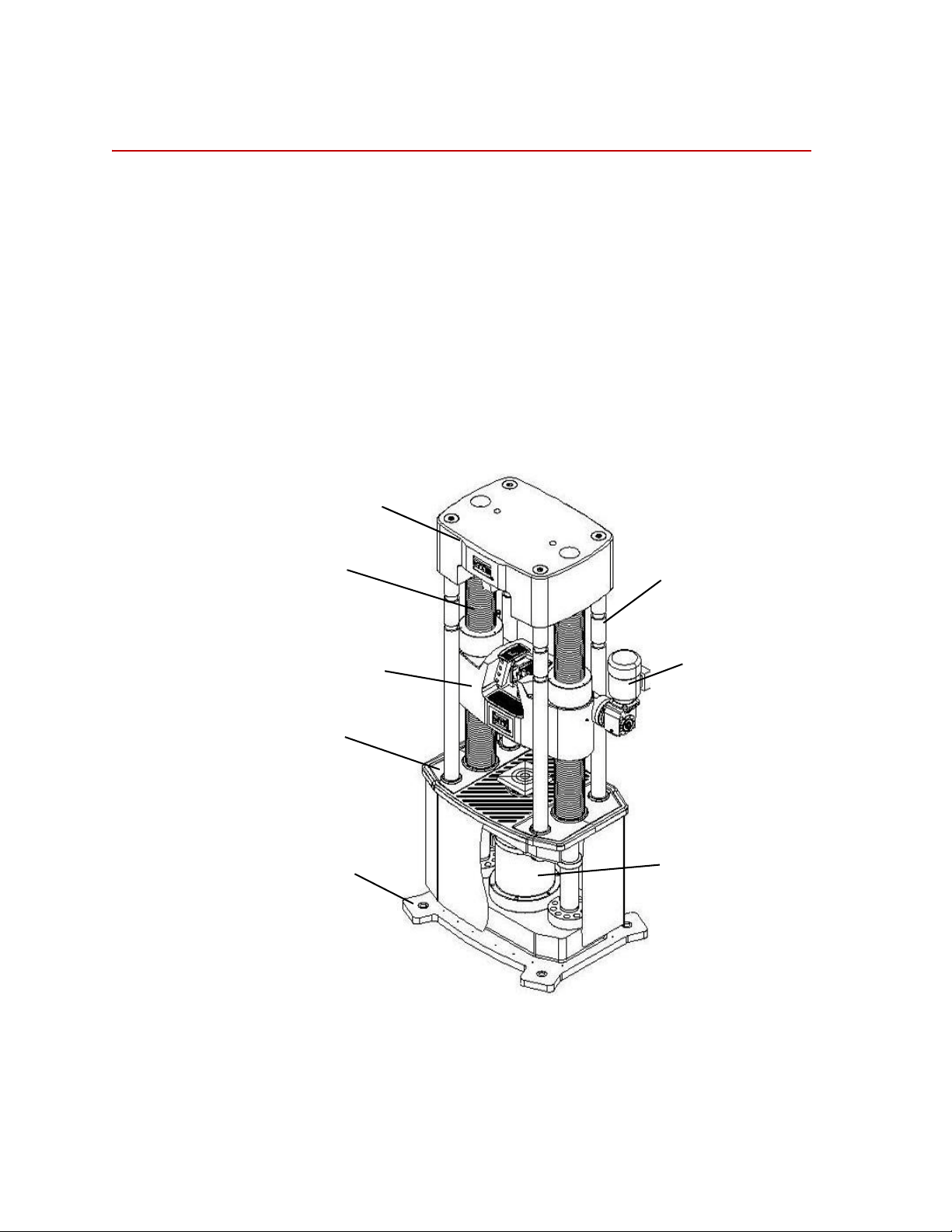

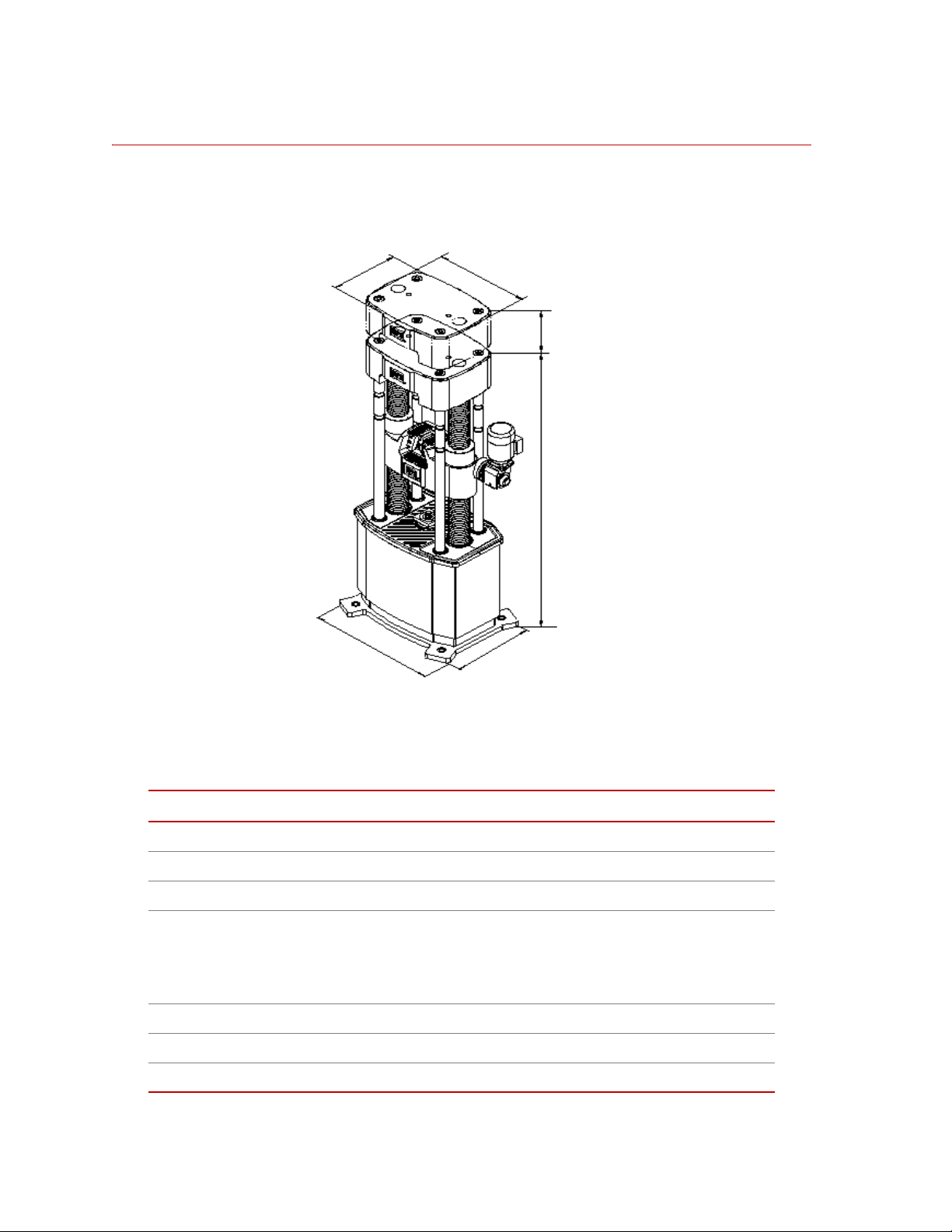

Upper Crosshead

Lead Screw

Lower Crosshead

Tes t Tab l e

Base

Feeding Rod

Crosshead Lift

Motor

Actuator

Description

Frame The frame is composed of a base, actuator, test table, lower crosshead, upper

Every MTS Criterion Series 60 Test System is comprised of a load frame, an

Integrated Operations Platform, and testing software. The following figure shows

the external features of the various MTS Criterion Series 60 frames and

Integrated Operations Platform.

crosshead, feeding rod, and lead screw. The test table is connected to the upper

crosshead by the columns to form a stiff frame, and the test table is connected to

the piston through a load cell. There are two testing spaces in the frame: the

tension space is between the upper and lower crossheads and the compression

space is between the lower crosshead and the test table. Both the tension and

compression spaces can be adjusted by moving the lower crosshead up and down

according to your testing needs.

16

Introduction

MTS Criterion™ Series 60 Product Manual

Page 17

Description

Specimen

Tensile Test

Compression Test

WARNING

When performing a tensile test, the specimen is held by appropriate grips in the

tension space, and the actuator goes up to move the table and the upper crosshead

upward, while the lower crosshead keeps still. This way, tensile load is applied

on the specimen. While tensile load is applied to the specimen, the sensors

measure the load applied, the displacement, and the specimen extension. The

controller handles all the outputs from the sensors and then transfers to the

testing software, and the software provides the results and reports accordingly.

The principle described above also applies to compression test; the only

difference is that the specimen is put between the lower crosshead and the table,

and as the actuator goes up, compressing load is applied on the specimen. If you

have flexural/bend fixtures or shear fixtures, bending/flexural or shearing test can

be done in the compression space.

The lower crosshead is only for adjusting the tensile and compression

spaces.

Applying load on the specimen by adjusting the crosshead position can

cause equipment damage.

Do not apply load by the lower crosshead.

MTS Criterion™ Series 60 Product Manual Introduction

All tests should be performed by moving the actuator.

17

Page 18

Description

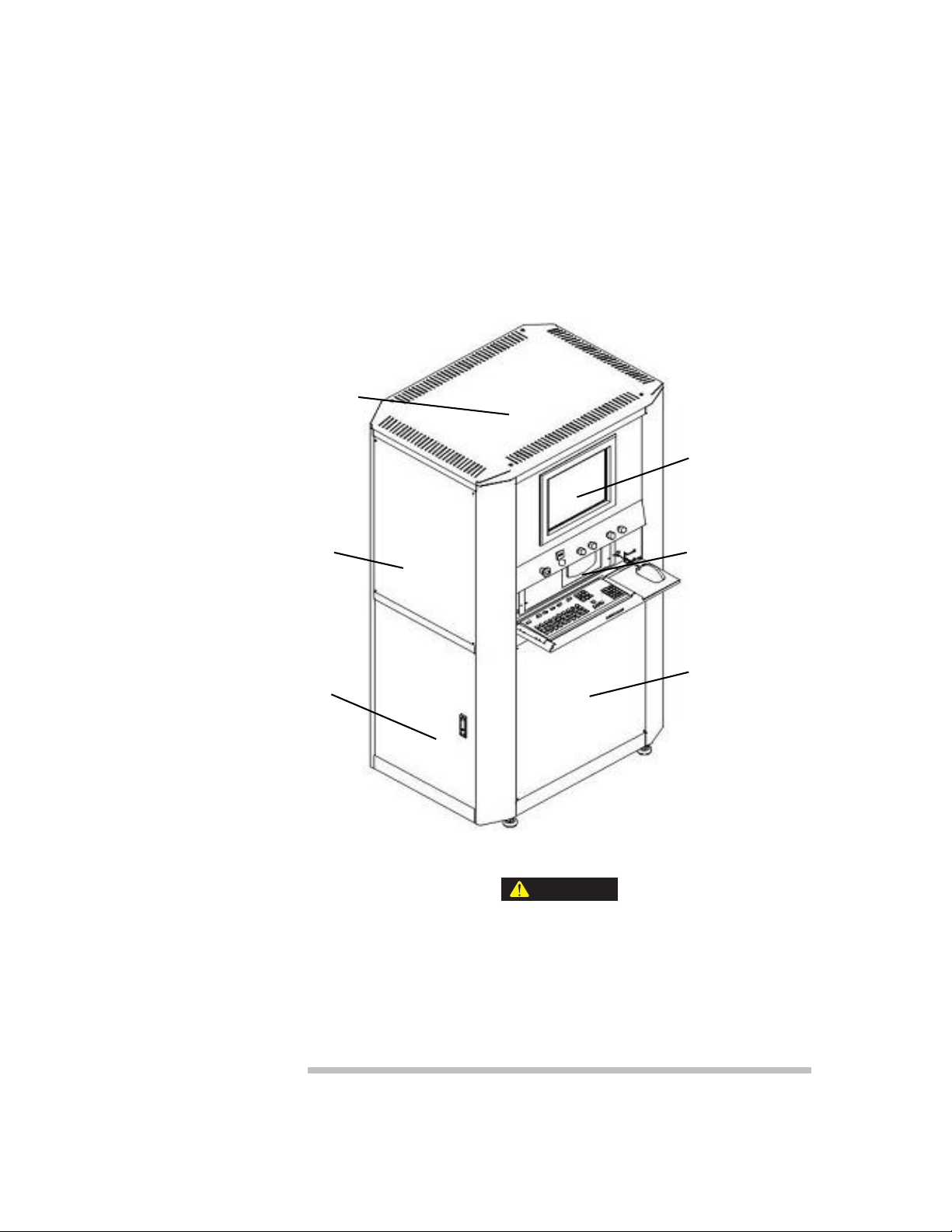

Display

Computer

Pump Assembly

Outer Shell

Subassembly

Relay Box

Controller

WARNING

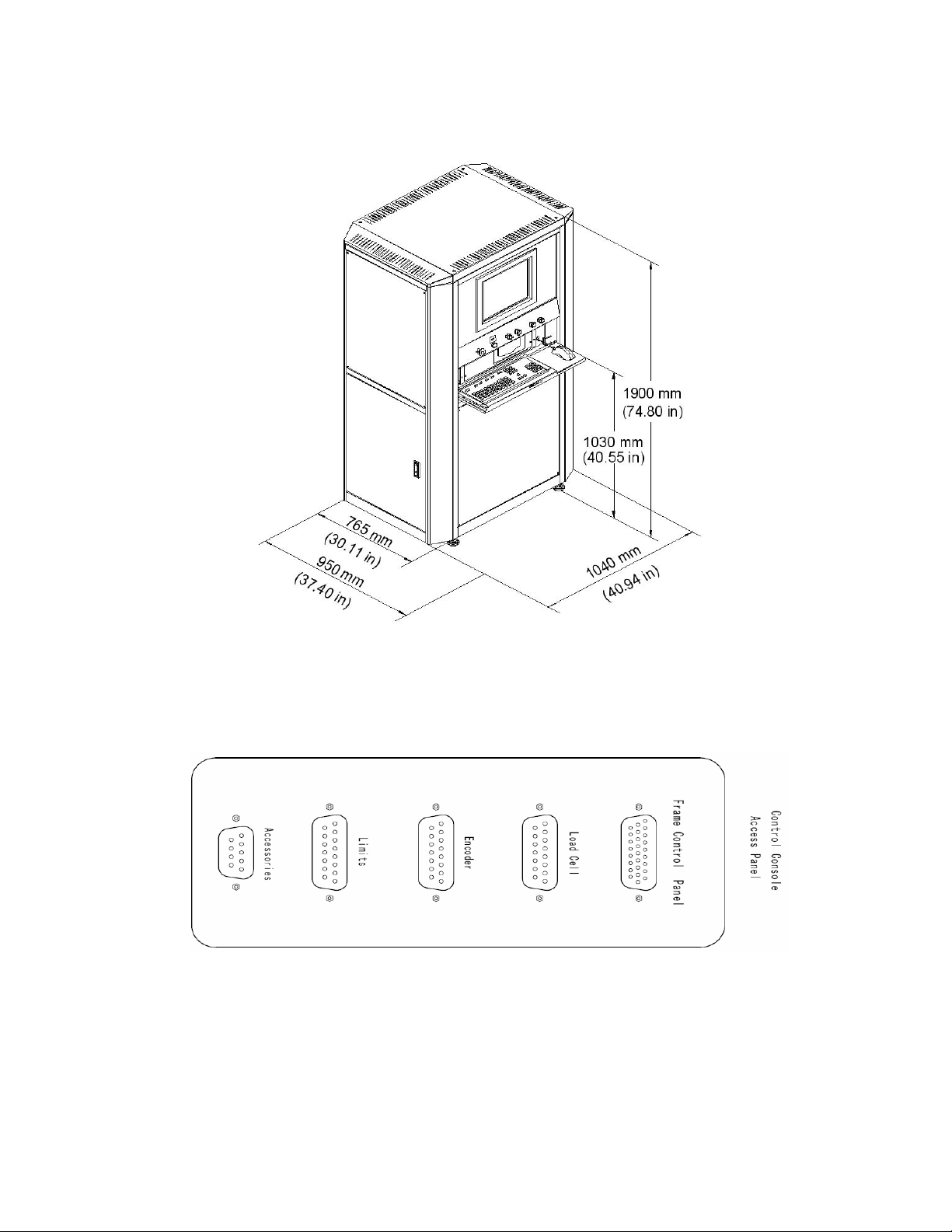

Integrated Operations

Platform

The Integrated Operations Platform is comprised of an electromotor, oil pump,

oil reservoir, air cooler, servovalve, other controlling valves, integrating

manifolds, a temperature sensor, and other hydraulic components. The

servovalve, transducers, controller, and the testing software form a closed-loop

control system. Hydraulic oil temperature is kept at its setting range by an air

cooler. Under normal operating conditions, the temperature should be lower than

60°C (140°F), and its highest temperature cannot exceed 65°C (149°F). If the oil

temperature is higher than 65°C (149°F), turn off the machine and contact MTS.

18

Introduction

Internal to the Integrated Operations Platform is an outlet switch for the

computer and monitor.

Plugging in a device could damage the device or the the Integrated

Operations Platform.

The user should not plug in any device to this outlet switch without consulting

MTS.

MTS Criterion™ Series 60 Product Manual

Page 19

Description

CAUTION

Integrated Operations Platform Properties

PARAMETERS 64.305/64.305E 64.605/64.605E/

64.106/64.106E

Pump motor rating 1.5 kW (2.0 hp) 2.2 kW (2.9 hp)

Maximum

continuous pressure

Maximum flow

capacity (50 Hz)

Maximum flow

capacity (60 Hz)

Filtration 5 microns nominal 5 microns nominal

Reservoir capacity 85 L (22.5 gal) 85 L (22.5 gal)

Mixing different brands of hydraulic fluid can affect the system

performance.

Contaminated hydraulic fluid can cause premature wear of the hydraulic

components in your system.

Do not mix different brands of hydraulic fluid. MTS System Corporation

recommends using Exxon Mobile DTE-25.

23 MPa (3300 psi) 23 MPa (3300 psi)

3.3 L/min (0.9 gpm) 5.1 L/min (1.3 gpm)

4.0 L/min (1.0 gpm) 6.2 L/min (1.6 gpm)

Computer The computer is also an integral part of the system. It runs the testing software

which provides full machine control, data acquisition and management, and

advanced data analysis and presentation. MTS has minimized the amount of

custom electronics required for your system, thereby making it flexible and

reliable. This is done by connecting the frame and the computer via standard

USB 2.0 connectors. See the computer configuration below:.

Monitor and Computer Configuration

DESCRIPTION

Monitor

Model

Brand

Size

Max Resolution

Description

Industrial PC

Model

L1710A

Lenovo Panel

17 inch

1280×1024

Thinkvision LCD

ACP-4000

MTS Criterion™ Series 60 Product Manual Introduction

19

Page 20

Description

Monitor and Computer Configuration (Continued)

D

ESCRIPTION

Brand

Description

Frame controller The frame controller:

• Provides main data and signal processing power.

• Detects the activation of limit switches.

• Provides the interface between the software (computer) and the frame.

• Provides digital servo control—for speed and position accuracy.

• Is responsible for self-ID load cell and frame.

• Includes a handset interface.

• Is programmable, up to 1000 Hz data acquisition rate.

• Manages frame power.

Software Your MTS testing software offers a host of features that will make the material

testing process fast and easy to use. The software has various method templates

available. The method templates in the General Testing Package provide a

starting point in configuring test methods that conform to your testing needs. The

General Testing Package is separated into three specific testing categories.

ADVANTECH

CPU Intel P4(CORE 3.0G)/PCA-6010 mainboard/PCA6113P4R backplane/1G DDR2/160G SATA/DVD

ROM/integrated net card/integrated graphic card/

"ACP-4000"chassis/keyboard and mouse/no mic/300W

AC100V?240V Power

Safety enclosure and

steps

Introduction

20

• MTS Tensile

• MTS Compression

• MTS Flex

Many additional features can be purchased to meet your company’s specific

needs. Some of these features might already be part of the system you ordered, or

they can be added to your system as your requirements change. Refer to the

testing software manual for additional information.

The safety enclosure and steps are optional parts of the system.

The safety enclosure is used to avoid projectile hazards and the steps are used to

facilitate system operation.

MTS Criterion™ Series 60 Product Manual

Page 21

Specifications

This section provides general specifications for the MTS Criterion Series 60

system and illustrations of the test table and platen transition plate.

General Specifications – Frame

The following specifications are for all MTS Criterion Series 60 frames.

Specifications for the specific models are in the following tables.

MTS Criterion Series 60 Specifications

PARAMETER SPECIFICATION

Environmental For indoor use only

Tem per atu re 5-40°C (41°F-104°F)

Relative humidity 5-85%, noncondensing

Specifications

Altitude For use at altitudes up to 2000 m

(6500 ft)

Power 400 V AC 50 Hz or 480 V AC 60 Hz

Insulation over voltage Category II

Pollution degree 2

MTS Criterion™ Series 60 Product Manual Introduction

21

Page 22

Specifications

Model Specifications – Frame

Model Specifications

MODEL 64.305/64.305E MODEL 64.605/

MODEL 64.106/64.106E

64.605E

Rated Force Capacity 300 kN

(67500 lbf)

Number of Columns 6 6 6

Test Spaces

(Single/Dual)

Actuator (Piston)

Stroke

Actuator (Piston)

Speed

(0.0197-7.09 in/min)

Crosshead Speed 220 mm/min

Column Spacing

(Test Space Width)

Maximum Tension Space

Standard

Length

(64.xxx)

Dual Dual Dual

150 mm

(5.91 in)

0.5-180 mm/min

(8.66 in/min)

400 mm

(15.75 in)

525 mm

(20.67 in)

600 kN

(135000 lbf)

200 mm

(7.87 in)

0.5-140 mm/min

(0.0197-5.51 in/

min)

210 mm/min

(8.27 in/min)

430 mm

(16.93 in)

750 mm

(29.53 in)

1000 kN

(225000 lbf)

250 mm

(9.84 in)

0.5-90 mm/min

(0.0197-3.54 in/min)

200 mm/min

(7.87 in/min)

500 mm

(19.69 in)

790 mm

(31.10 in)

22

Extended

Length

(64.xxxE)

Maximum Compression Space

Standard

Length

(64.xxx)

Extended

Length

(64.xxxE)

Diameter of Round

Specimens

Thickness of Flat

Specimens

Introduction

900 mm

(35.43 in)

540 mm

(21.26 in)

935 mm

(36.81 in)

6-32 mm

(0.24-1.26 in)

2-25 mm

(0.08-0.98 in)

1100 mm

(43.31 in)

770 mm

(30.31 in)

1120 mm

(44.09 in)

10-40 mm

(0.39-1.57 in)

2-30 mm

(0.08-1.18 in)

MTS Criterion™ Series 60 Product Manual

1150 mm

(45.28 in)

830 mm

(32.68 in)

1175 mm

(46.26 in)

15-55 mm

(0.59-2.17 in)

2-40 mm

(0.08-1.57 in)

Page 23

Model Specifications (Continued)

M

ODEL 64.305/64.305E MODEL 64.605/

64.605E

Specifications

MODEL 64.106/64.106E

Compression Platen

(Square)

Frame Dimensions

Height

Standard

Length

(64.xxx)

Extended

Length

(64.xxxE)

Width 870 mm

Depth 725 mm

Weight

Standard

Length

(64.xxx)

150×150 mm

(5.91×5.91 in)

2074 mm

(81.65 in)

2470 mm

(97.24 in)

(34.25 in)

(28.54 in)

1950 kg

(4299 lb)

150×150 mm

(5.91×5.91 in)

2390 mm

(94.09 in)

2780 mm

(109.45 in)

1170 mm

(46.06 in)

800 mm

(31.50 in)

3150 kg

(6945 lb)

220×220 mm

(8.66×8.66 in)

2720 mm

(107.09 in)

3130 mm

(123.23 in)

1310 mm

(51.57 in)

910 mm

(35.83 in)

5250 kg

(11574 lb)

Extended

Length

(64.xxxE)

2003 kg

(4416 lb)

3254 kg

(7174 lb)

5400 kg

(11905 lb)

MTS Criterion™ Series 60 Product Manual Introduction

23

Page 24

Specifications

Specifications – Integrated Operations Platform

The following integrated operations platform specifications are common for

models of 64.305/64.305E, 64.605/64.605E, and 64.106/64.106E.

Integrated Operations Platform Specifications

PARAMETER SPECIFICATION

Calibration standard ISO 7500 Class 1 or ASTM E4

Force range 1%-100% of rated force capacity

Force indicating accuracy ± 1% of indicating

Position resolution 0.2 μm

(0.00000787 in)

Position accuracy +/- 1% of indicating

Strain accuracy ASTM E83 or ISO 8513

Security protection over-force, travel limits, over-pressure, over-

temperature, over-current and others

Over force protection 10%

Data acquisition rate 1000 Hz maximum

Control loop rate 1000 Hz

Environmental requirements

Operating temperature range 5-40°C (41-104°F)

Operating humidity 5-85% noncondensing

Storage temperature range 18-49°C (0 -120°F)

Maximum storage humidity 90% noncondensing

Maximum altitude 2000 m (6500 ft)

Integrated Operations Platform power

requirements

Integrated Operations Platform dimensions

Height 1900 mm

400 V 50 Hz / 480 V 60Hz

3~3W+PE

(74.80 in)

24

Introduction

Width 1040 mm

(40.94 in)

MTS Criterion™ Series 60 Product Manual

Page 25

Integrated Operations Platform Specifications (Continued)

Depth 765 mm

(30.11 in)

Weight 400 kg

(882 lb)

Specifications

MTS Criterion™ Series 60 Product Manual Introduction

25

Page 26

Specifications

Series 60 Load Frame

E

F

D

C

A

B

Dimensions

Frame

Series 60 Load Frame Dimensions

Width (A) 870 mm (34.25 in) 1170 mm (46.06 in) 1310 mm (51.57 in)

Depth (B) 725 mm (28.54 in) 800 mm (31.50 in) 910 mm (35.83 in)

Height (C)

Standard length (64.xxx)

Extended length (64.xxxE)

Actuator stroke (D) 150 mm (5.91 in) 200 mm (7.87 in) 250 mm (9.84 in)

Upper crosshead depth (E) 500 mm (19.69 in) 600 mm (23.62 in) 670 mm (26.38 in)

Upper crosshead width (F) 680 mm (26.77 in) 790 mm (31.10 in) 910 mm (35.83 in)

Introduction

26

64.305/64.305E 64.605/64.605E 64.106/64.106E

2074 mm (81.65

in)

2470 mm (97.24

in)

2390 mm (94.09 in)

2780 mm (109.45

in)

MTS Criterion™ Series 60 Product Manual

2720 mm (107.09 in)

3130 mm (123.23 in)

Page 27

Integrated Operations Platform

Series 60 Integrated Operations Platform

Specifications

Control Console Access Panel Connector

Frame Control Panel This is intended to connect the Control Box to the Logic Board. This is used to

transmit the signal on the buttons of the Control Panel.

MTS Criterion™ Series 60 Product Manual Introduction

27

Page 28

Specifications

Pin assignment is as follows:

Pin Assignment

PIN SIGNAL

8 ESTOPIA-

9 ESTOPIB-

10 UP_CLOSE_SW

11 UP_OPEN_SW

12 LO_CLOSE_SW

13 LO_OPEN_SW

14 XHD_DOWN_SW

15 XHD _UP_SW

17 ESTOPIA+

18 ESTOPIB+

19 PANEL INO+

20 PAN E L I N O -

SHELL SHIELD

Load Cell This in intended to connect the stain-gauge load cell to the Insight Controller

Load Cell. It supports the TEDS feature to auto-identify and auto-calibrate the

load cell. Pin Assignment is as follows:

Pin Assignment

PIN SIGNAL

1 EX+

2 EX-

3 No Contact

4 FB+

5 FB-

6 No Contact

7 SHIELD

8 TEDS+

28

Introduction

9 No Contact

10 EXS+

11 No Contact

12 RCAL 1(FBR+)

13 RCAL 2(FBR-)

MTS Criterion™ Series 60 Product Manual

Page 29

Specifications

Pin Assignment (Continued)

P

IN SIGNAL

14 TEDS-

15 EXS-

Encoder This is intended to connect the frame displacement sensor to the encoder on the

Insight Controller. It is DC-powered and collects the digital encoder signals

frome the displacement sensor. Pin Assignment is as follows:

Pin Assignment

PIN SIGNAL

1 A+

2 A-

3 No Contact

4 GND

5 VCC

6 No contact

7 Shield

8 TEDS+

9 No Contact

10 B-

11 No Contact

12 I+

13 I-

14 TEDS-

15 B+

Limits This connector is intended to connect the frame limit and the logic board. It is

used to transmit the state signal of the frame limit. Pin assignment is as follows:

Pin Assignment

PIN SIGNAL

1 PISTON COM

2 PISTON NO

3 XHD UP NC

4 XHD LO COM

5 XHD LO NO

MTS Criterion™ Series 60 Product Manual Introduction

29

Page 30

Specifications

Pin Assignment (Continued)

P

IN SIGNAL

6 No Contact

7 No Contact

8 SHIELD

9 PISTON NC

10 XHD UP COM

11 XHD UP NO

12 XHD LO NC

13 No Contact

14 No Contact

15 No Contact

Accessories The additive connector is intended as the expanding part of the equipment. It is

used according to the request.

30

Introduction

MTS Criterion™ Series 60 Product Manual

Page 31

Safety Enclosure

A

B

C

Specifications

The safety enclosure has a four-sided frame structure to prevent projectile

injuries.

MTS Criterion Series 60 Safety Enclosure Specifications

MODEL WIDTH

(A)

64.305 1280 mm

(50.4 in)

64.605 1410 mm

(55.5 in)

64.106 1560 mm

(61.4 in)

64.305E 1280 mm

(50.4 in)

64.605E 1410 mm

(55.5 in)

64.106E 1560 mm

(61.4 in)

DEPTH

(B)

860 mm

(3

3.9 in)

890 mm

(35.0 in)

1030 mm

(40.6 in)

1360 mm

(53.5 in)

1390 mm

(54.7 in)

1530 mm

(60.2 in)

Note The safety enclosure is optional; it is available upon customer request.To

avoid projectile hazards, the doors of the enclosure must be closed

during tests.

HEIGHT

(GENERAL

FOUNDATION)

(C)

2050 mm

(80.7 in)

2400 mm

(94.5 in)

2713 mm

(106.8 in)

2450 mm

(96.5 in)

2800 mm

(110.2 in)

3120 mm

(122.8 in)

HEIGHT

(SUBSIDED

FOUNDATION)

(C)

- 66 kg

1710 mm

(67.3 in)

1897 mm

(74.7 in)

1760 mm

(69.3 in)

2110 mm

(83.1 in)

2344 mm

(92.3 in)

WEIGHT

(GENERAL

FOUNDATION)

(146 lb)

76 kg

(168 lb)

86 kg

(190 lb)

80 kg

(176 lb)

90 kg

(198 lb)

102 kg

(225 lb)

WEIGHT

(SUBSIDED

FOUNDATION)

-

70 kg

(154 lb)

80 kg

(176 lb)

64 kg

(141 lb)

74 kg

(163 lb)

83 kg

(183 lb)

MTS Criterion™ Series 60 Product Manual Introduction

31

Page 32

Specifications

Steps

64.605/64.305E Steps

64.106/64.605E Steps

64.106E Steps

32

Introduction

MTS Criterion™ Series 60 Product Manual

Page 33

MTS Criterion Series 60 Steps Specifications

Specifications

MODEL WIDTH

64.605 1410 mm

64.106 1570 mm

64.305E 1280 mm

64.605E 1410 mm

64.106E 1570 mm

Test Table Detail

DEPTH

(A)

(55.5 in)

(61.8 in)

(50.4 in)

(55.5 in)

(61.8 in)

Note The steps are optional; they are available upon customer request.

(B)

1200 mm

(47.2 in)

1510 mm

(59.5 in)

1000 mm

(39.4 in)

1550 mm

(61.0 in)

1900 mm

(74.8 in)

HEIGHT

(C)

450 mm

(17.7 in)

620 mm

(24.4 in)

400 mm

(15.7 in)

720 mm

(28.3 in)

1930 mm

(76.0 in)

WEIGHT

100 kg

(221 lb)

120 kg

(265 lb)

90 kg

(198 lb)

120 kg

(265 lb)

160 kg

(353 lb)

If you need to fit bend or shear fixtures, see the following figure for dimensions.

MTS Criterion™ Series 60 Product Manual Introduction

33

Page 34

Specifications

300 kN and 600 kN

Platen Transition Plate Detail

There are several kinds of threaded holes for mounting fixtures in the platen

transition plate.

34

Introduction

MTS Criterion™ Series 60 Product Manual

Page 35

Specifications

1000 kN

MTS Criterion™ Series 60 Product Manual Introduction

35

Page 36

Specifications

36

Introduction

MTS Criterion™ Series 60 Product Manual

Page 37

Safety

General Safety Practices

This section provides information about safety issues that pertain to static

hydraulic systems in general. These issues include statements to the intended use

and foreseeable misuse of the system, the hazard zone, definition for the

graphical hazard labeling that is affixed to your product, and other (more general)

safety information that relates to the high-pressure and high-performance

characteristics of MTS static hydraulic systems.

MTS test systems are designed to generate motions and forces and impart these

motions and forces into a test specimen.

When you prepare to operate the system and during system operation, ensure the

following:

• Do not use or allow personnel to operate the system who are not

• Do not disable safety components or features (including limit detectors).

experienced, trained, or educated in the inherent dangers associated with

high-performance servohydraulics and who are not experienced, trained, or

educated with regard to the intended operation as it applies to this test

system.

• Do not attempt to operate the system without appropriate personal safety

gear (for example, hearing, hand, and eye protection).

• Do not apply improper energy levels for the system. Refer to the Integrated

Operation Platform specifications.

• Do not test a specimen that exceeds the minimum (if applicable) or

maximum allowable mass. Refer to the system specifications.

• Do not use specimens that are combustible, flammable, pressurized, or

explosive.

• Do not use humans as specimens or allow humans to ride in or on the test

specimen or the test system for any purpose unless the system is man-rated

and all associated safety conditions are strictly enforced.

• Do not modify the system or replace system components using parts that are

not MTS component parts or effect repairs using parts or components that

are not manufactured to MTS specifications.

• Do not operate the system in an explosive atmosphere.

• Do not use the system in a test area where uncontrolled access to the test

system is allowed when the system is in operation.

If you have system-related responsibilities (that is, if you are an operator, service

engineer, or maintenance person), you should study safety information carefully

before you attempt to perform any test system procedure.

MTS Criterion™ Series 60 Product Manual Safety

37

Page 38

You should receive training on this system or a similar system to ensure a

thorough knowledge of your equipment and the safety issues that are associated

with its use. In addition, you should gain an understanding of system functions

by studying the other manuals supplied with your test system. Contact MTS for

information about the content and dates of training classes that are offered.

It is very important that you study the following safety information to ensure that

your facility procedures and the system’s operating environment do not

contribute to or result in a hazardous situation. Remember, you cannot eliminate

all the hazards associated with this system, so you must learn and remain aware

of the hazards that apply to your system at all times. Use these safety guidelines

to help learn and identify hazards so that you can establish appropriate training

and operating procedures and acquire appropriate safety equipment (such as

gloves, goggles, and hearing protection).

Each test system operates within a unique environment which includes the

following known variables:

• Facility variables (facility variables include the structure, atmosphere, and

utilities)

• Unauthorized customer modifications to the equipment

• Operator experience and specialization

• Test specimens

Because of these variables (and the possibility of others), your system can

operate under unforeseen circumstances that can result in an operating

environment with unknown hazards.

Improper installation, operation, or maintenance of your system can result in

hazardous conditions that can cause death, personal injury, or damage to the

equipment or to the specimen. Common sense and a thorough knowledge of the

system’s operating capabilities can help to determine an appropriate and safe

approach to its operation.

Safety Practices Before System Operation

Before you apply power to the test system, review and complete all of the safety

practices that are applicable to your system. The goal, by doing this, is to

improve the safety awareness of all personnel involved with the system and to

maintain, through visual inspections, the integrity of specific system

components.

Read all manuals Study the contents of this manual and the other manuals provided with your

system before attempting to perform any system function for the first time.

Procedures that seem relatively simple or intuitively obvious can require a

complete understanding of system operation to avoid unsafe or dangerous

situations.

Locate and read

hazard placards/labels

Find, read, and follow the hazard placard instructions located on the equipment.

These placards are placed strategically on the equipment to call attention to areas

such as known crush points and electrical voltage hazards.

38

Safety

MTS Criterion™ Series 60 Product Manual

Page 39

Locate lockout/tagout

points

Know where the lockout/tagout point is for all of the supply energies associated

with your system. This includes the hydraulic, pneumatic, electric, and water

supplies (as appropriate) for your system to ensure that the system is isolated

from these energies when required.

Know facility safe

procedures

Locate Emergency

Stop buttons

Most facilities have internal procedures and rules regarding safe practices within

the facility. Be aware of these safe practices and incorporate them into your daily

operation of the system.

Know the location of all the system Emergency Stop buttons so that you can

stop the system quickly in an emergency. Ensure that an Emergency Stop button

is located within 2 meters (6 feet) of the operator at all times.

Know controls Before you operate the system for the first time, make a trial run through the

operating procedures with the power off. Locate all hardware and software

controls and know what their functions are and what adjustments they require. If

any control function or operating adjustment is not clear, review the applicable

information until you understand it thoroughly.

Have first aid available Accidents can happen even when you are careful. Arrange your operator

schedules so that a properly trained person is always close by to render first aid.

In addition, ensure that local emergency contact information is posted clearly and

in sight of the system operator.

Know potential crush

and pinch points

Know electrical

hazards

Be aware of potential crush and pinch points on your system and keep personnel

and equipment clear of these areas.

When the system electrical power is turned on, minimize the potential for

electrical shock hazards. Wear clothing and use tools that are properly insulated

for electrical work. Avoid contact with exposed wiring or switch contacts.

Whenever possible, turn off electrical power when you work on or in proximity

to any electrical system component. Observe the same precautions as those given

for any other high-voltage machinery.

Keep bystanders

safely away

Keep bystanders at a safe distance from all equipment. Never allow bystanders to

touch specimens or equipment while the test is running.

Wear proper clothing Do not wear neckties, shop aprons, loose clothing or jewelry, or long hair that

could get caught in equipment and result in an injury. Remove loose clothing or

jewelry and restrain long hair.

Check bolt ratings and

torques

To ensure a reliable product, fasteners (such as bolts and tie rods) used in MTSmanufactured systems are torqued to specific requirements. Overtorquing or

undertorquing a fastener can create a hazardous situation due to the high forces

and pressures present in MTS test systems.

On rare occasions, a fastener can fail even when it is correctly installed. Failure

usually occurs during torquing, but it can occur several days later. Failure of a

fastener can result in a high velocity projectile. Therefore, it is a good practice to

avoid stationing personnel in line with or below assemblies that contain large or

long fasteners.

MTS Criterion™ Series 60 Product Manual Safety

39

Page 40

Practice good

housekeeping

Keep the floors in the work area clean. Do not leave tools, fixtures, or other items

not specific to the test, lying about on the floor, system, or test table.

Protect hoses and

cables

Protect electrical cables from excessive temperatures that can cause the cables to

harden and eventually fail. Ensure that all cables have appropriate strain relief

devices installed at the cable and near the connector plug. Do not use the

connector plug as a strain relief.

Protect all system hoses and cables from sharp or abrasive objects that can cause

the hose or cable to fail. Never walk on hoses or cables or move heavy objects

over them. Consider system layout and route hoses and cables away from areas

that expose them to possible damage.

When removing hydraulic hoses for equipment repair or changing testing

components (for example, hydraulic grips), make sure to cap the hose ends to

avoid spilling hydraulic fluid.

Record changes If you change any operating procedure, write the change and the date of the

change in the appropriate manual.

Provide test area

guards

Do not disable safety

devices

Use protective guards such as cages, enclosures, and special laboratory layouts

when you work with hazardous test specimens (for example, brittle or

fragmenting materials or materials that are internally pressurized).

Your system might have active or passive safety devices installed to prevent

system operation if the device indicates an unsafe condition. Do not disable such

devices as it can result in unexpected system motion.

Use appropriately

sized fuses

Provide adequate

lighting

Provide means to

access out-of-reach

components

Ensure equipment is

secure

Whenever you replace fuses for the system or supply, ensure that you use a fuse

that is appropriately sized and correctly installed. Undersized or oversized fuses

can result in cables that overheat and fuses that explode. Either instance creates a

fire hazard.

Ensure adequate lighting to minimize the chance of operation errors, equipment

damage, and personal injury. You need to see what you are doing.

Make sure you can access system components that might be out of reach while

standing on the floor. For example, ladders or scaffolding might be required to

reach grips on tall load units.

Make sure the equipment is secure or provide vibration isolation. Some testing

can be performed at resonant frequencies that might cause the equipment to

vibrate and move during testing.

Safety Practices While the System Is in Operation

Wear appropriate

personal protection

Wear eye protection when you work with testing machines, breakable specimens,

or when anything characteristic to the specimen could break apart.

Wear ear protection when you work near electric motors, pumps, or other devices

that generate high noise levels. Some systems can create sound pressure levels

that exceed 70 dbA during operation.

40

Safety

MTS Criterion™ Series 60 Product Manual

Page 41

Wear appropriate personal protection equipment (gloves, boots, suits, respirators)

whenever you work with fluids, chemicals, or powders that can irritate or harm

the skin, respiratory system, or eyes.

Expect specimen

temperature changes

Handle chemicals

safely

Know system

interlocks

During cyclic testing, the specimen temperature can become hot enough to cause

burns. Wear personal protection equipment (gloves) when handling specimens.

Whenever you use or handle chemicals (for example, cleaning fluids, hydraulic

fluid, batteries, contaminated parts, electrical fluids, and maintenance waste),

refer to the appropriate MSDS documentation for that material and determine the

appropriate measures and equipment required to handle and use the chemical

safely. Ensure that the chemical is disposed of appropriately.

Interlock devices should always be used and properly adjusted. Interlock devices

are designed to minimize the chance of accidental damage to the test specimen or

the equipment. Test all interlock devices for proper operation immediately before

a test. Do not disable or bypass any interlock devices as doing so could allow

crosshead movement regardless of the true interlock condition.

Know system limits Never rely on system limits, such as mechanical limits or software limits, to

protect you or any personnel. System limits are designed to minimize the chance

of accidental damage to test specimens or to equipment. Test all limits for proper

operation immediately before a test. Always use these limits and adjust them

properly.

Do not disturb sensors Do not bump, wiggle, adjust, disconnect, or otherwise disturb a sensor (such as

an accelerometer or extensometer) or its connecting cable when power is applied.

Ensure secure cables Do not change any cable connections when electrical power is applied. If you

attempt to change a cable connection while the system is in operation, an open

control loop condition can result. An open control loop condition can cause a

rapid, unexpected system response which can result in severe personal injury,

death, or damage to equipment. Also, ensure that all cables are connected after

you make any changes in the system configuration.

Stay alert Avoid long periods of work without adequate rest. In addition, avoid long periods

of repetitious, unvarying, or monotonous work because these conditions can

contribute to accidents and hazardous situations. If you are too familiar with the

work environment, it is easy to overlook potential hazards that exist in that

environment.

Stay clear of moving

equipment/avoid crush

points

MTS Criterion™ Series 60 Product Manual Safety

Stay clear of mechanical linkages, connecting cables, and hoses that move

because you can get pinched, crushed, tangled, or dragged along with the

equipment. High forces generated by the system can pinch, cut, or crush anything

in the path of the equipment and cause serious injury. Stay clear of any potential

crush points. Most test systems can produce sudden, high-force motion. Never

assume that your reactions are fast enough to allow you to escape injury when a

system fails.

41

Page 42

Know the causes of

Ball relief valve of the actuator

unexpected crosshead

motions

The high force and velocity capabilities of MTS systems can be destructive and

dangerous (especially if crosshead motion is unexpected). The most likely causes

of unexpected crosshead response are operator error and equipment failure due to

damage or abuse (such as broken, cut, or crushed cables and hoses; shorted wires;

overstressed feedback devices; and damaged components within the control

loop). Eliminate any condition that could cause unexpected crosshead motion.

Do not use RF

transmitters

Operations for b all

relief valves

Keep radio frequency (RF) transmitters away from the workstation computers,

remote terminals, and consoles. Intense RF fields can cause erratic operation of

the more sensitive circuits in the system.

Rotate the handle of ball valve and make sure the handle is parallel with the

pipe,that is the "open" position.

Safety

42

MTS Criterion™ Series 60 Product Manual

Page 43

Hazard Labels

Ball Relief Valves(4pcs) for Grips

LABEL DESCRIPTION

The following hazard labels and icons are located on the MTS Criterion Series 60

frames.

Lift the machine upright.

Moving parts present.

Moving parts can crush and cut.

Keep hands away from moving parts.

MTS Criterion™ Series 60 Product Manual Safety

43

Page 44

Flying objects.

Danger of eye injury.

Wear safety glasses.

Tip-over hazard.

Use outriggers when machine is standalone.

Do not start, operate, or service machine until you read

and understand the operator’s manual.

Failure to do so could result in serious injury.

To turn the pulley, manually move the crosshead upward

and downward.

Pulleys can be turned by hand when power is disabled.

WEEE The Waste Electrical and Electronic Equipment (WEEE) symbol ( ) means

that the controller and its electronic parts must not be disposed of as unsorted

municipal waste. Proper disposal is required by approved electronic waste

collection agencies. Customers in the EC region who desire to return an end-oflife controller and its electronic parts are encouraged to contact your local MTS

Systems Sales/Service Offices for instructions.

Customer should follow internal safety policies for safe disposal of parts of the

machine. Refer to MSDS for oils and greases that are used on the machine.

44

Safety

MTS Criterion™ Series 60 Product Manual

Page 45

Installation

Contents Lifting and Moving Overview 46

Moving Frames and Integrated Operations Platform 48

Installing the Optional Safety Enclosure 59

Installing the Steps 62

Controller Connections 63

Connecting Hoses 72

Adding Oil 73

MTS Criterion™ Series 60 Product Manual Installation

45

Page 46

Lifting and Moving Overview

WARNING

Lifting and Moving Overview

This section provides guidelines for moving and installing your MTS Criterion

Series 60 Test Systems.

Unless otherwise specified, it is your responsibility to off-load, unpack, and

move the equipment to the final location on your premises. This includes

insurance and safety responsibility.

Before moving the machine from the receiving area to its final location, be sure

to check the dimensions of all doors and passages through which the machine

will travel. Refer to the specification tables in the “Introduction” section of this

manual for dimensions.

To reliably and safely use the equipment, handle it according to the instructions.

Check for any crate damages upon the machine arrival. If you find any damage,

contact MTS as soon as possible and describe the details in the Commissioned

Shipment Receipt.

The MTS Criterion Series 60 frames are heavy.

Moving the frame using improper procedures can injure personnel (for

example strained muscles and back injuries) or damage the frame.

When lifting the frame, take the appropriate precautions to prevent injuries to

yourself. Moving and positioning the MTS Criterion Series 60 frames must be

performed by qualified personnel only.

Do not allow the load frame to drop or topple.

Make sure that your chains, slings, and crane have a working capacity greater

than the load frame’s weight (see the following table).

Make sure that the lifting hoist rings are tight.

Make sure that the crosshead locking bolts are fully tightened.

Lift the load frame only high enough to clear its pallet.

Operate the crane smoothly to prevent breaking shocks to the sling.

MTS Criterion Series 60 frames weigh from 1950 to 5400 kg (4300 to 11905 lb).

Other apparatus such as packaging and accessories add to the overall weight. If

you have any questions, call MTS.

46

Installation

MTS Criterion™ Series 60 Product Manual

Page 47

MODEL LOAD

F

RAME

Lifting and Moving Overview

The following table lists the approximate weight of each load frame model,

Integrated Operations Platform, and optional parts with and without the crate.

The weight specification is for lifting and moving purposes. The weight of

accessories and special fixtures must be added. The actual shipping weight must

be determined by a scale.

Weight Specifications

INTEGRATED

O

PERATIONS

PLATFORM

SAFETY

E

NCLOSURE

(O

PTIONAL)

CRATED

L

OAD

F

RAME

STEPS

(OPTIONAL)

CRATED

L

OAD

F

RAME &

S

AFETY

E

NCLOSURE

CRATED

I

NTEGRATED

O

PERATIONS

P

LATFORM

CRATED

S

TEPS

64.305 1950 kg

(4299 lb)

64.605

Subsided

Foundation

64.106

Subsided

Foundation

64.305E

Subsided

Foundation

64.605E

Subsided

Foundation

3150 kg

(6945 lb)

5250 kg

(11574

2003 kg

(4416 lb)

3254 kg

(7174 lb)

lb)

400 kg

(882 lb)

400 kg

(882 lb)

400 kg

(882 lb)

400 kg

(882 lb)

400 kg

(882 lb)

66 kg

(146 lb)

76 kg

(168 lb)

70 kg

(154 lb)

86 kg

(190 lb)

80 kg

(176 lb)

80 kg

(176 lb)

64 kg

(141 lb)

90 kg

(198 lb)

74 kg

(163 lb)

2086 kg

(4599 lb)

3332 kg

(7346 lb)

5498 kg

(12121

lb)

2107 kg

(4645 lb)

3360 kg

(7408 lb)

- 2152 kg

100 kg

(221 lb)

120 kg

(265 lb)

90 kg

(198 lb)

120 kg

(265 lb)

(12312 lb)

(12110 lb)

(4745 lb)

3408 kg

(7515 lb)

3326 kg

(7334 lb)

5584 kg

5792 kg

2187 kg

(4822 lb)

2019 kg

(4611 lb)

3450 kg

(7607 lb)

3344 kg

(7374 lb)

480 kg

(1058 lb)

480 kg

(1058 lb)

480 kg

(1058 lb)

480 kg

(1058 lb)

480 kg

(1058 lb)

-

250 kg

(551

lb)

300 kg

(662

lb)

250 kg

(551

lb)

300 kg

(662

lb)

64.106E

Subsided

Foundation

MTS Criterion™ Series 60 Product Manual Installation

5400 kg

(11905

lb)

400 kg

(882 lb)

102 kg

(225 lb)

83 kg

(183 lb)

5530 kg

(12192

lb)

160 kg

(353 lb)

5632 kg

(12419 lb)

5511 kg

(12152 lb)

480 kg

(1058 lb)

350 kg

(772

lb)

47

Page 48

Moving Frames and Integrated Operations Platform

WARNING

Moving Frames and Integrated Operations Platform

The packing materials may shift and loosen while moving the frame.

Moving the frame with loose packing materials may cause injury to

personnel and damage to the frame.

Remove the packing materials before moving the frame.

Note Before the FSE arrival, it is the customer’s responsibility to arrange the

off-loading, unpacking, and moving of the testing system to the final site

location.

Note If the testing system needs to be moved to another location after initial

installation, it is the customer’s responsibility to move and remount the

system.

Machine Location and Ventilation

To ensure proper ventilation, locate the load frame approximately 100 mm (4 in)

away from adjacent walls and equipment. Do not block the vent holes of the

machine.

For comfortable working conditions and proper equipment operation, heat

dissipation of the equipment must be considered in providing adequate heating or

air conditioning in the laboratory area. Heat dissipation can be approximated by

summing the heat losses going into the room (1 kVA is equivalent to 860 kcal/hr

[3,400 Btu/hr]) and the gains from other sources such as furnaces and personnel.

48

Installation

MTS Criterion™ Series 60 Product Manual

Page 49

Moving the Load Fame

Unloading

The customer will be responsible for all the unloading process if no Unloading

Service is purchased. In case of special agreement, an MTS field service engineer

can monitor the unloading, storage, and transportation process.

To unload the load frame:

1. Unload the load frame with reference to the lifting position marker

2. Choose suitable slings according to the weight table.

3. Lift the crate with suitable slings as shown in the following figure.

4. Pay attention to the gravity center marker on the crate to ensure

stable and balanced lifting.

Moving Frames and Integrated Operations Platform

and the gravity center marker .

Note If the machine will not be installed right away, store it in a steady, dry and

corrosion free place. MTS is not responsible for damages caused by

improper storage.

MTS Criterion™ Series 60 Product Manual Installation

49

Page 50

Moving Frames and Integrated Operations Platform

Moving the Load Unit to Its Final Location

To move the load frame:

1. Remove the cover board. If you ordered the safety enclosure, take it out and

store it in a suitable place (The MTS field service engineer will install it for

you). Take off the side boards. Remove the mounting bolts for the frame.

Attach customer-supplied hoist rings (M30 for C64.305 / C64.305E, M36

for C64.605 /C64.605E and C64.106 /C64.106E) to the frame.

2. Tie suitable slings to the hoist rings and lift the frame. Remove the pallet

under the frame.

Note The clamps attached should not be removed from the frame.

50

Installation

MTS Criterion™ Series 60 Product Manual

Page 51

Moving Frames and Integrated Operations Platform

3. Put the frame base on a mat and let the frame lay horizontally, remove the

lifting rings on base.

Note When the frame rises, keep a safe distance from the frame to avoid

personal injury.

4. Use a crane to slowly raise the frame to its upright position. As the frame

rises, keep moving the crane to keep the slings as straight as possible. As

there will be shake when the frame raise, please put the side board

(Unpacked from the frame package) under the frame to avoid frame

damages.

MTS Criterion™ Series 60 Product Manual Installation

51

Page 52

Moving Frames and Integrated Operations Platform

5. When the frame is stable in the upright position, lift it to the final location.

6. Move the load unit to its final location and secure the frame to the

foundation. Refer to either

“Moving the Load Unit with a Forklift” on page

53 or “Moving the Load Unit with an Overhead Crane” on page 53.

52

Installation

MTS Criterion™ Series 60 Product Manual

Page 53

Moving the Load Unit with a Forklift

If a fork lift is used, perform the following:

1. Adjust the fork distance and height, make them suitable to extend under the

lower crosshead.

2. Put protective rubber or cloth on the forks and extend them under the lower

crosshead. The two forks should be level and equally loaded.

Note Verify the capacity of the lifting fork.Be absolutely careful not to stop or

transit within the field of action of the lifting fork.

3. Raise the load frame slowly and steadily to a suitable height and move the

load frame to the foundation slowly and steadily.

4. Secure the load frame to the foundation; “Securing the Load Unit” on page

54.

Moving Frames and Integrated Operations Platform

Moving the Load Unit with an Overhead Crane

If an overhead crane is used, perform the following:

1. Choose suitable slings according to the load frame weight.

2. Attach the slings to the customer-supplied lifting ring on the upper

crosshead.

Note Verify the capacity of the overhead crane.Be absolutely careful not to

stop or transit within the field of action of the overhead crane.

MTS Criterion™ Series 60 Product Manual Installation

53

Page 54

Moving Frames and Integrated Operations Platform

Do not exceed 30

o

Supporting

Wood

3. Raise the hook slowly to lift the load frame only high enough to move.

4. Slowly and steadily move the load frame to the foundation.

5. Secure the load frame to the foundation; see “Securing the Load Unit” on

page 54.

Securing the Load Unit

Installation

54

To secure the load unit to the foundation:

1. Put the anchor bolts into the bolt holes. The top of the bolts should be lower

than the top of the foundation.

2. Align the anchor bolt holes on the load frame base with that of the

foundation, and slowly put down the load frame.

3. Put the anchor bolts, which are in the foundation anchor bolt holes, through

the load frame anchor bolt holes. Put the flat washers, spring washers, and

nuts on the bolts leaving 2-4 threads of the bolts on top of the nuts.

4. Center the anchor bolts and grout the anchor holes with cement mixtures.

Keep the anchor bolts at the center of the holes while grouting.

5. Grout the cement mixture to the same level of the groundwork and scrape it

level. After curing the foundation for a while, tighten the anchor bolt nuts.

MTS Criterion™ Series 60 Product Manual

Page 55

Moving Frames and Integrated Operations Platform

Torque Measurements

Model Bolt Diameter Tor que

C64.305/

C64.305E

C64.605/

C64.605E/

C64.106/

C64.106E

Note Diagonally tighten the nuts to avoid non-uniform load.

24 mm

(0.94 in)

30 mm

(1.18 in)

160 N•m

(118 lbf•ft)

320 N•m

(236 lbf•ft)

MTS Criterion™ Series 60 Product Manual Installation

55

Page 56

Moving Frames and Integrated Operations Platform

Moving the Integrated Operations Platform

Unloading

Choose suitable slings according to the Integrated Operations Platform and crate

weight. Wrap the sling through the crate pallet and raise it.

Moving the Integrated Operations Platform to Its Final Location

To move the Integrated Operations Platform:

1. Unpack the Integrated Operations Platform.

2. Choose suitable chains according to the Integrated Operations Platform

weight.

3. Attach the chains to the customer-supplied hoist rings (M16) on the

Integrated Operations Platform and hang the other end to the hook.

56

Installation

MTS Criterion™ Series 60 Product Manual

Page 57

Moving Frames and Integrated Operations Platform

Do not exceed 30

o

Hoist Rings M16

Note Verify the capacity of the overhead crane.Be absolutely careful not to

stop or transit within the field of action of the overhead crane.

4. Raise the hook slowly and move the platform to its final location.

5. Put the platform down and take off the chains. Adjust the levelness with the

feet under the platform.

6. Contact MTS Systems Corporation to arrange for installation services.

Note If you can guarantee the safety, other tools like platform vehicle and

pallet jack can also be used to move the Integrated Operations Platform

to its final location.Other equipment, such as a platform vehicle and

pallet jack, can also be used to move the Integrated Operations Platform

to its final location. Safety guidelines for these methods are not provided

in this manual, but you will need to be aware of safety precautions if

using these methods.

MTS Criterion™ Series 60 Product Manual Installation

57

Page 58

Moving Frames and Integrated Operations Platform

Unloading the Steps

If you have purchased steps, unload them using the correct procedures (see the

Integrated Operations Platform unloading for reference). Store them in a suitable

place and wait for an MTS field service engineer to install them.

58

Installation

MTS Criterion™ Series 60 Product Manual

Page 59

Installing the Optional Safety Enclosure

1

2

3

4

5

6

7

Installing the Optional Safety Enclosure

The Material Testing System and optional equipment are supplied with Product

Information Manuals that allow them to be assembled and integrated to work as

assemblies of machinery.

Customer must evaluate risks due to ejected parts or materials from the test

specimens. If Test Area Guard is not selected by customer, then for protection

against ejected parts or materials from test specimens and to control access to the

machinery, the Customer must provide a Test Area Guard to protect personnel.

① Front ② Front door ③ Handle ④ Back ⑤ Back door ⑥ Connecting rod ⑦

MTS Criterion™ Series 60 Product Manual Installation

Adjustable foot

If you have purchased the safety enclosure, it should be installed per the

following

engineer).

procedure (Generally the enclosure is installed by MTS field service

59

Page 60

Installing the Optional Safety Enclosure

1. Install the ① front part of the safety enclosure to the front of the load unit

and make it symmetric around the load unit. Level the enclosure with the

adjustable feet.

60

Installation

MTS Criterion™ Series 60 Product Manual

Page 61

Installing the Optional Safety Enclosure

Llifting Pads

2. Install the ④ Back and the ⑥ Connecting rod.

3. Install the ②Front door,③Handle, and ⑤Back door, and remove the lifting

pads.

MTS Criterion™ Series 60 Product Manual Installation

61

Page 62

Installing the Steps

Screw Connection

Screw Connection

Attach together with

screws provided with

steps.

Installing the Steps

If you have purchased the steps, they should be installed as below. (Generally the

steps are installed by MTS field service engineer)

62

Installation

MTS Criterion™ Series 60 Product Manual

Page 63

Controller Connections

CAUTION

Connecting the Main Power

MTS Criterion Series 60 systems use an integrated power cord.

Check the power supply before connecting the testing system to it.

An unqualified power supply can cause injury to personnel or damage to

the testing system.

Confirm that the power supply meets MTS' power requirements.

Note Electrical connections must be made by qualified personnel and conform

to local codes and regulations. Local electrical codes supersede any

information found here.

Controller Connections

Electrical connections must be made by qualified personnel and is their

responsibility for using the proper power disconnect along with the correct size

and type of wire and conduit that conforms to all their local electrical codes when

connecting the machine to the building′s main power.

Wire Sizes A main powercable (3W+PE) of 5 meters is provided on the Criterion Series 60

system. The wire type is 4×4 mm

2

(4×12 AWG).

Electrical disconnect The customer is responsible for providing a power disconnect that is easy to

operate and easy to reach. Usually this is integrated into a wall mounted electrical

junction box with over current protection. It must also meet IEC 60947-1 and

IEC 60947-3 standards.

Recommended circuit breakers are of the thermal magnetic type with

characteristics suitable for large inductive loads (D-type trip characteristic).

For the electrical box, the over current device must be Branch circuit rated.

Machine-Specific Requirements

64.305/64.305E • Power 3.75 kW.

• Current 11.6 A maximum.

64.605/64.605E • Power 5.2 kW.

• Current 15 A maximum.

64.106/64.106E • Power 5.2 kW.

• Current 15 A maximum.

MTS Criterion™ Series 60 Product Manual Installation

63

Page 64

Controller Connections

CAUTION

Installing Cables

Controller Connectors

To maintain EMC compliance and help ensure optimal performance, MTS

recommends ordering all system cables from MTS. Cables should be installed so

that they are protected from conditions that could damage the cable.

Exercise care when connecting cables. Ensure that you use the correct cables and

that all connections are secure. When you are finished, double-check to ensure

that all components are connected properly.

Check the power before connecting cables.

Connecting cables with power applied may cause injury to personnel or

damage to the equipment.

Ensure that the power is off before connecting cables.

64

Installation

J1 USB This is a standard USB 2.0 connector that accepts a USB-B cable connector and

connects the computer. This provides a communications interface between the

testing software on the PC and the controller. This is used to allow the software to

change settings in the controller and receive data from the controller.

MTS Criterion™ Series 60 Product Manual

Page 65

Controller Connections

J2 Handset This is intended to interface to the handset. Specifics for this connector are:

• 12 V output power with 200 mA current limit

• RS422 driver (differential)

• RS422 receiver (differential)

• Interlock input. Handset shorts between INTLK+ and INTLK- when it is

connected.

• 8-pin RJ-45 connector

8-Pin Assignment

PIN SIGNAL

1 Transmit +

2 Transmit -

3 +12V

4 INTLK +

5 INTLK -

6 Analog GND

7 Receive +

8 Receive -

J3 Interlock This is intended to connect to a test area enclosure switch that opens when the

door is opened. If not used, a jumper plug (p/n 049-635-901) must be installed. If

you are building a cable, the maximum length is 30.48 m (100 ft) with 24 gauge

wire. The switch should be wired normally closed, such that when the switch

opens, an interlock is generated.

MTS Criterion™ Series 60 Product Manual Installation

65

Page 66

Controller Connections

J4 Encoder This connector is intended for an encoder-based extensometer. Specifics for this

connector are:

• Power: +5 V +/- 0.25 V at 100 mA max

• Signals: Quadrature A and B with index I

• Logic: Differential receivers (can connect single ended)

• Maximum Rate: 100,000 lines/sec = 400,000 counts/sec

Pin assignment is as follows:

Pin Assignment

PIN SIGNAL

1 TEDS data

2 A+

3 A-

4 +5 V

5 I+

6 I-

7 Analog GND

8 B+

9 B-

10 TEDS ground

66

Installation

MTS Criterion™ Series 60 Product Manual

Page 67

Controller Connections

J5 Digital I/O Digital I/O signals include three optically isolated inputs, three optically isolated

outputs, and 12 V power. Functions of each digital input or output are software

selectable. J5 should be connected to J12 to make the controller board and

interface board communicate with each other. Pin assignment is as follows:

Pin Assignment

PIN SIGNAL

1 In 1+

2 In 2+

3 In 3+

4 Out 1+

5 Out 2+

6 Out 3+

7 No Contact

8 +12V

9 In 1-

10 In 2-

11 In 3-

12 Out 1-

13 Out 2-

14

15 Analog GND

Out 3-

J6 and J7 Monitor Two monitor connectors are provided. There are several possible uses for analog

monitor outputs: external data acquisition, tuning, troubleshooting, and so forth.

For tuning, it is desirable to monitor command and feedback, or command and

error, simultaneously while changing the controller parameters. Therefore, two

monitor outputs are provided. Specifics for these connectors are:

• Analog +/-10.5 V

• Calibrated to +/-10 V

• 16-bit resolution minimum

• BNC connectors

MTS Criterion™ Series 60 Product Manual Installation

67

Page 68

Controller Connections

J8 and J9 DC

Conditioner

Two DC Conditioner connectors are provided. The two application-specific

transducers might be biaxial strain gage base extensometers. With external

completion resistors, the DC conditioners could be used with quarter bridge

strain gages. Pin assignment is as follows:

Pin Assignment

PIN SIGNAL

1 TEDS data

2 EX+

3 EX-

4 FB-

5 RCAL1 (FBR+)

6 RCAL2 (FBR-)

7 FB+

8 EXS-

9 EXS+

10 TEDS ground

J10 Aux Pwr This is an auxiliary power connector. It can provide power supply to

external devices. Pin assignment is as follows:

Pin Assignment

PIN SIGNAL

1 +12V (Combined with

Pin 6

2 AGND

3 -12V

4 PGND

5 +5V

6 +12V ( Combined with

Pin 1)

7 AGND

8 DGND

9 +24V

68

Installation

MTS Criterion™ Series 60 Product Manual

Page 69

Controller Connections