MOTOROLA XPC850, XPC860, XPC860T Technical data

查询XPC850供应商

Networking Communication Microprocessors

XPC850 (Rev 0.3)

XPC860

Reliability Report

for

XPC860T

0.42m Single Poly Wafer Fabrication Process

Revision: 5/99

1.0 Purpose and Description

This report summarizes the reliability data for Motorola communication

microprocessors fabricated on the 0.42m single polysilicon process in our wafer

fabrication facility, Mos 11, in Austin, Texas. The current devices fabricated using this

process are given in the table below.

Device Mask Set Design

Revision

XPC850 F98S 0.3 309 x 335 0.42m

XPC860 J24A

H96G

XPC860T J21M 0.2 338 x 347 0.42m

Table 1. Device properties.

All of these devices are currently in their XC phase of product life, which is the

time when design errata are discovered and corrected. Although the 850 and 860 are still

classified as XC devices, they are built using production equipment and processes, and

have completed their reliability qualifications. There are some functional errata on these

devices, which may impact some customers. These errata are expected to be corrected in

revision D of the 860, which we expect to grant MC status to. For a list of current design

errata on these devices, please contact your local Motorola sales person. To locate the

nearest sales office, you can find them on our website at http://mot-sps.com/sales/

sales_web.html

2.0 Assembly / Package Information

B.1

C

Die Size

(mils)

338 x 329

338 x 329

Process

Geometry

0.42m

The XPC850 is assembled in a 256 leaded plastic ball grid array. The XPC860 is

assembled in a 357 lead plastic ball grid array (PBGA). Both packages have been shown

to meet level 3 moisture sensitivity as classified by JEDEC A113. Our volume

production is manufactured in MotorolaÕs Kuala Lumpur, Malaysia facility, however we

have also qualified Citizen Watch Co, in Japan as an alternate assembly site.

2

3.0 Family Qualification Strategy

Motorola uses a ÒfamilyÓ qualification strategy which allows sharing of certain

reliability data across a common design rule / fabrication geometries and packaging types.

Reliability data from other Motorola devices which are designed using the same design

rules and wafer fabrication processes are included with this report.

All of the devices in this report have been in production manufacturing for at least 3

years. The data presented in this report is both data from current production material

and historical data used to qualify devices, processes, and wafer fab and assembly sites.

This report will be updated periodically (typically twice/year) with new reliability data

from subsequent qualifications and reliability monitors.

3

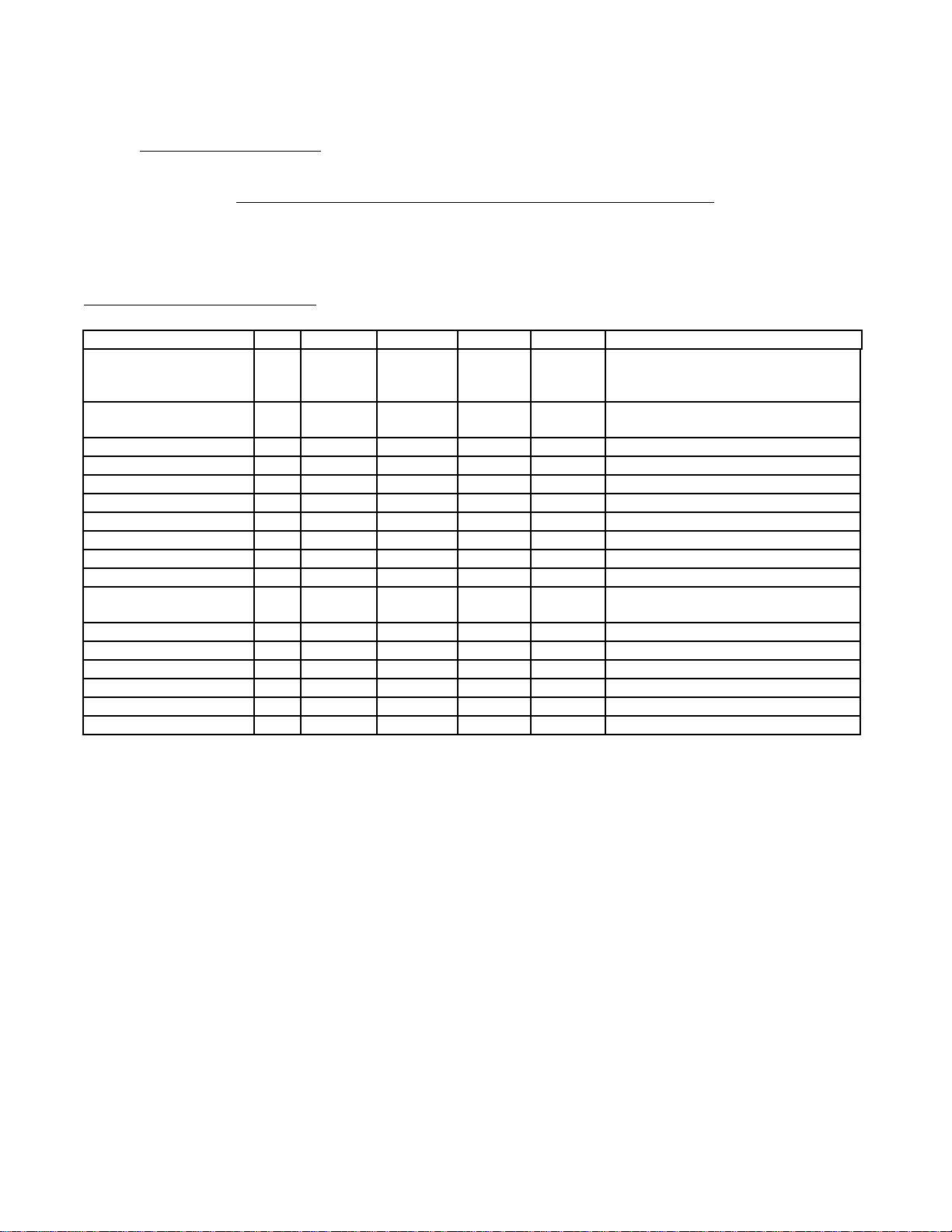

4.0 Qualification Data

Motorola .42m Process Qualification Summary

The following data shows results of our .42m qualifications:

Life Test (+125°C, 4.5V)

Device/Mask Set SS 168 Hrs. 504 Hrs. 1008 Hrs. 2016 Hrs. Failure Details

XPC850 (F98S) rev 0.3 77 1/77 0/76 0/71 --- 168 Hr : Speed degradation failure

1008 Hr: 4 parts missing balls, 1 part

damaged -discounted

XPC850 (F98S) rev 0.3 77 0/77 0/75 0/74 --- 504 /1008 Hr: Damaged part -

discounted

XPC850 (F98S) rev 0.3 77 0/77 0/77 0/72 --- 1008 Hr: Units discounted

XPC850 (F98S) rev 0.3 77 0/77 0/75 0/69 --- 168/504 Hr: Units discounted

XPC860 (J23A) rev A.3 77 0/77 0/77 0/77 0/77 --XPC860 (J23A) rev A.3 77 0/77 0/77 0/77 0/77 ---

XPC860 (J23A) rev A.3 77 0/77 0/77 0/77 0/77 --XPC860 (H96G) rev C.1 77 0/77 0/77 0/77 --XPC860 (H96G) rev C.1 77 0/77 1/77 0/77 --- Functional Failure Ð destroyed in FA

XPC860 (H96G) rev C.1 77 0/77 0/77 0/77 ---

XPC860T (J21M) 77 1/77 0/76 0/75 --- 168 hr: Funct fail, 1008 hr: 1 unit

damaged at test-discounted

68LC060 (G59Y) 77 0/76 0/76 0/63 --- 168/1008 Hr: Parts discounted

68LC060 (G59Y) 77 0/77 0/77 0/77 --- --68LC060 (G59Y) 77 0/77 0/77 0/77 --- --68LC060 (G59Y) 77 0/77 0/77 --- --- --68LC060 (G59Y) 77 1/77 0/76 --- --- 168 Hr: 1 functional fail

Total 1232 3/1231 1/1224 0/1040 0/231 ---

Table 1. Life Test Data.

4

MM

MM

1000.00

100.00

10.00

1.00

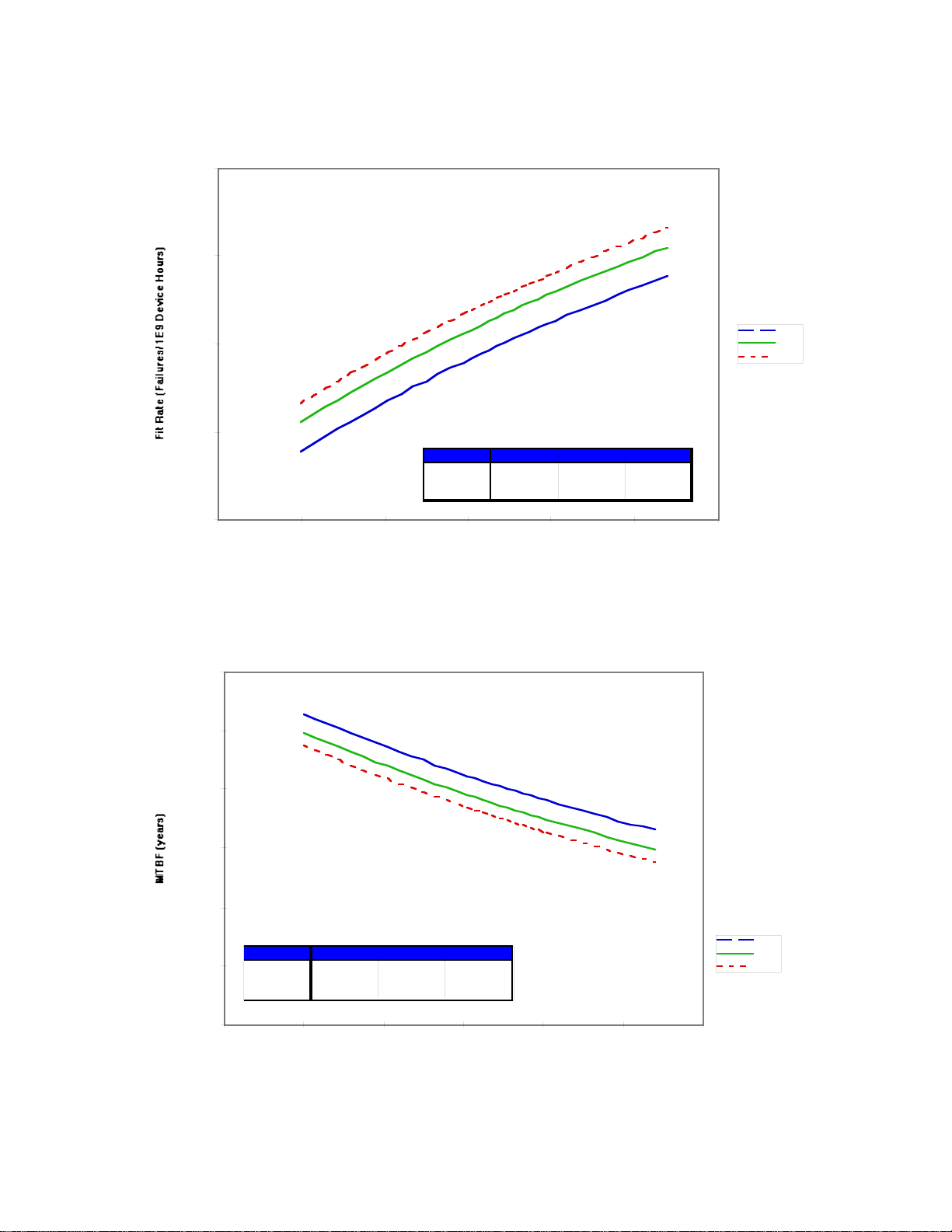

Fit Rate (Failures/1E9 Device Hours)

0.10

0 2 0 40 60 80 100 120

FITs vs Junction Temperature: .42u FIT/MTBF Data

Thermal and Voltage Acceleration

eA = 0.5 eV, Beta = 2.5, 90% Confidence

Tj 3 V 3.3 V 3.5 V

40 °C247

60 °C 6 13 22

80 °C 173659

Junction Temperature (°C)

3 V

3.3 V

3.5 V

1.00E+06

1.00E+05

1.00E+04

1.00E+03

MTBF (years)

1.00E+02

1.00E+01

1.00E+00

0 20 40 60 80 100 120

MTBF vs Junction Temperature: .42u FIT/MTBF Data

mm

mm

Tj 3 V 3.3 V 3.5 V

40 °C 5.4E+4 2.6E+4 1.6E+4

60 °C 1.8E+4 8.4E+3 5.1E+3

80 °C 6.6E+3 3.1E+3 1.9E+3

eA = 0.5 eV, Beta = 2.5, 90% Confidence

Junction Temperature (°C)

Thermal and Voltage Acceleration

3 V

3.3 V

3.5 V

5

Loading...

Loading...