KROHNE Summit-8800 User Manual

SUMMIT 8800 Handbook

Flow Computer

Volume 2: Software

© KROHNE 08/2013 - MA SUMMIT 8800 Vol2 R02 en

|

IMPRINT |

|

|

SUMMIT 8800 |

|

|

|

|

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2013 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2 |

www.krohne.com |

08/2013 - MA SUMMIT 8800 Vol2 R02 en |

|

CONTENTS |

|

SUMMIT 8800 |

|

|

|

|

|

1 About this book |

13 |

1.1 Volumes.............................................................................................................................. |

13 |

1.2 Content Volume 1............................................................................................................... |

13 |

1.3 Content Volume 2............................................................................................................... |

13 |

1.4 Content Volume 3............................................................................................................... |

14 |

1.5 Information in this handbook............................................................................................. |

14 |

2 General Information |

15 |

2.1 Software versions used for this guide............................................................................... |

15 |

2.2 Terminology and Abbreviations......................................................................................... |

15 |

2.3 General Controls and Conventions.................................................................................... |

16 |

2.4 ID Data Tree........................................................................................................................ |

17 |

2.4.1 Type of data............................................................................................................................... |

18 |

2.4.2 Colour codes............................................................................................................................. |

19 |

2.5 Specific Requirements for Meters and Volume Convertors.............................................. |

20 |

2.5.1 Numbering formats.................................................................................................................. |

20 |

2.5.2 Alarms....................................................................................................................................... |

20 |

2.5.3 Accountable alarm.................................................................................................................... |

20 |

2.5.4 Optional consequences............................................................................................................. |

20 |

3 Metering principles |

21 |

3.1 Pulse based meters: e.g. turbine/ positive displacement / rotary meter......................... |

21 |

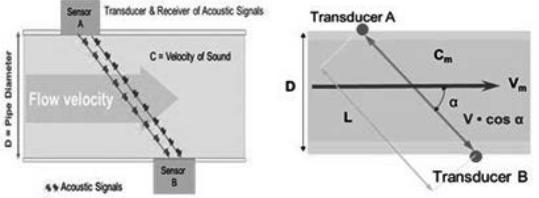

3.2 Ultrasonic meters.............................................................................................................. |

22 |

3.3 Differential pressure (dP) meters: e.g. orifice, venturi and cone meter........................... |

23 |

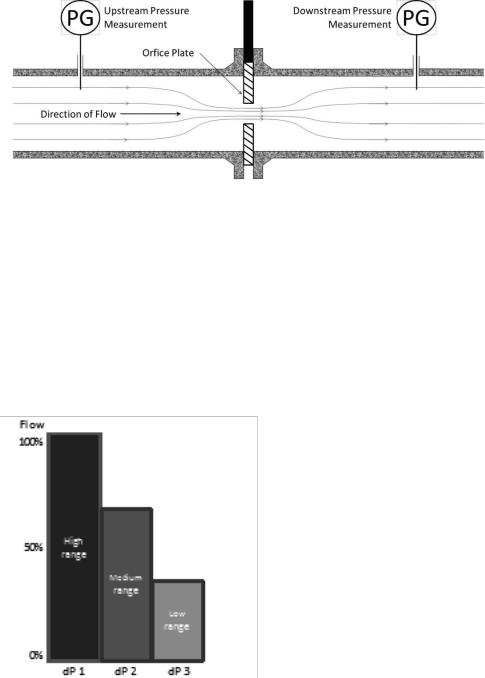

3.3.1 Orifice Plate............................................................................................................................... |

25 |

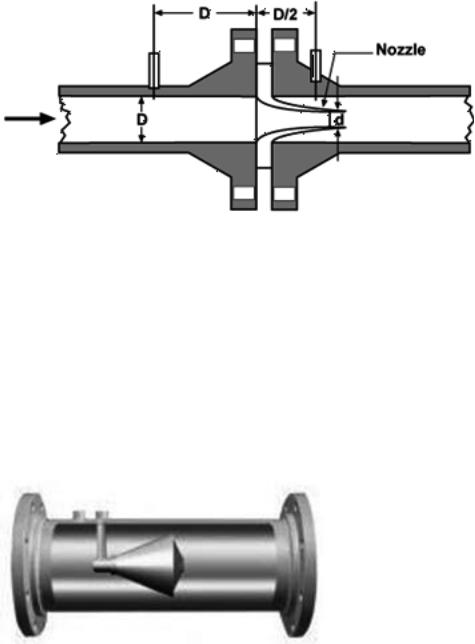

3.3.2 Venturi nozzle............................................................................................................................ |

26 |

3.4 Coriolis meters.................................................................................................................. |

26 |

3.5 Meter corrections............................................................................................................... |

28 |

3.5.1 Gas & steam.............................................................................................................................. |

28 |

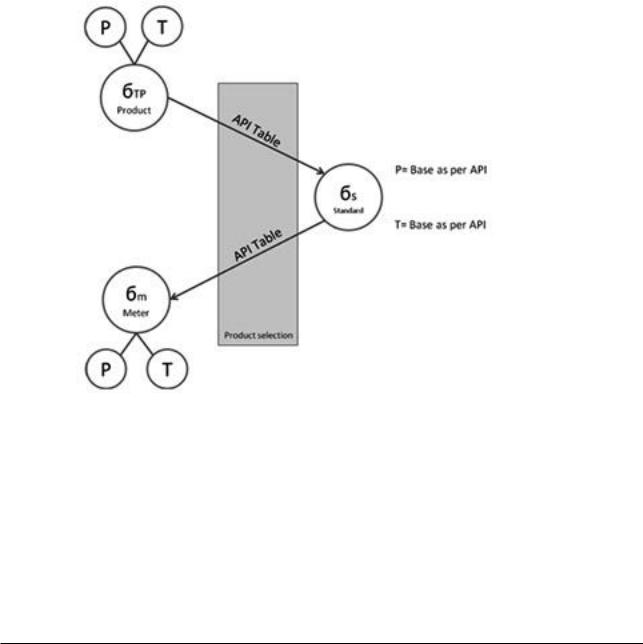

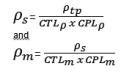

3.5.2 Liquid......................................................................................................................................... |

28 |

3.6 Liquid normalisation.......................................................................................................... |

29 |

3.6.1 Mass and energy....................................................................................................................... |

30 |

3.7 Gas normalisation.............................................................................................................. |

30 |

3.7.1 Equation of state....................................................................................................................... |

31 |

3.7.2 Line and base density............................................................................................................... |

32 |

3.7.3 Relative density/ specific gravity.............................................................................................. |

32 |

3.7.4 Mass and energy....................................................................................................................... |

32 |

3.7.5 Enthalpy.................................................................................................................................... |

32 |

3.8 Stream, station and batch totals........................................................................................ |

33 |

3.9 Run switching..................................................................................................................... |

35 |

08/2013 - MA SUMMIT 8800 Vol2 R02 en |

www.krohne.com |

3 |

CONTENTS |

SUMMIT 8800 |

3.10 Proving............................................................................................................................. |

35 |

3.10.1 Unidirectional ball prover....................................................................................................... |

36 |

3.10.2 Bi-directional pipe prover....................................................................................................... |

36 |

3.10.3 Small volume / piston provers................................................................................................ |

37 |

3.10.4 Master meter.......................................................................................................................... |

37 |

3.10.5 Proving procedure................................................................................................................... |

38 |

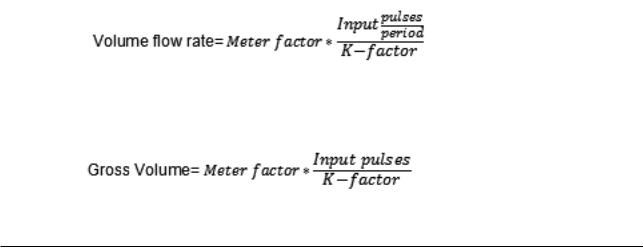

3.10.6 Meter factor and K – factor..................................................................................................... |

41 |

3.10.7 Proving sequence.................................................................................................................... |

42 |

3.10.8 Proving run (ball position)....................................................................................................... |

45 |

3.11 Sampling.......................................................................................................................... |

46 |

4 The configurator |

47 |

4.1 Applications........................................................................................................................ |

47 |

4.2 Measurement devices and signals.................................................................................... |

47 |

4.3 Create a new application................................................................................................... |

47 |

4.4 Main Screen....................................................................................................................... |

50 |

5 Hardware |

51 |

5.1 I/O board Configuration..................................................................................................... |

52 |

5.1.1 HART Input................................................................................................................................ |

53 |

5.1.2 Analog Inputs............................................................................................................................ |

54 |

5.1.3 PRT/ RTD/ PT-100 direct temperature input............................................................................ |

55 |

5.1.4 Digital Inputs............................................................................................................................. |

55 |

5.1.5 Analog Outputs.......................................................................................................................... |

56 |

5.1.6 Digital Outputs.......................................................................................................................... |

56 |

5.1.7 Serial Output............................................................................................................................. |

59 |

5.2 Stream hardware setup..................................................................................................... |

59 |

5.2.1 Flowmeters............................................................................................................................... |

59 |

5.2.2 Temperature transmitter.......................................................................................................... |

64 |

5.2.3 Pressure Transmitter................................................................................................................ |

66 |

5.2.4 Density Transducer................................................................................................................... |

68 |

5.2.5 Density transmitter temperature and pressure....................................................................... |

69 |

5.3 Flow and totals output....................................................................................................... |

70 |

5.4 Alarm outputs.................................................................................................................... |

71 |

6 Stream configuration |

72 |

6.1 Units................................................................................................................................... |

72 |

6.2 Meter selection.................................................................................................................. |

73 |

6.2.1 Pulse based meters: Turbine / PD............................................................................................ |

73 |

6.2.2 Ultrasonic.................................................................................................................................. |

75 |

6.2.3 Differential Pressure................................................................................................................. |

80 |

6.2.4 Coriolis...................................................................................................................................... |

86 |

6.3 Product information........................................................................................................... |

90 |

4 |

www.krohne.com |

08/2013 - MA SUMMIT 8800 Vol2 R02 en |

SUMMIT 8800 |

CONTENTS |

6.4 Flow rates and totals......................................................................................................... |

92 |

6.4.1 Flow rate limits & scaling......................................................................................................... |

92 |

6.4.2 Liquid flow rate correction........................................................................................................ |

93 |

6.4.3 Gas and steam flow rate correction......................................................................................... |

95 |

6.5 Tariff................................................................................................................................... |

97 |

6.6 Pressure............................................................................................................................. |

98 |

6.6.1 Sensor calibration constants.................................................................................................... |

99 |

6.6.2 Advanced................................................................................................................................... |

99 |

6.7 Temperature..................................................................................................................... |

100 |

6.7.1 Sensor calibration constants.................................................................................................. |

101 |

6.7.2 Advanced................................................................................................................................. |

102 |

6.8 Line density...................................................................................................................... |

103 |

6.8.1 Ratio of specific heats (liquid and gas)................................................................................... |

104 |

6.8.2 Viscosity (steam):.................................................................................................................... |

104 |

6.8.3 Solartron/Sarasota transmitter.............................................................................................. |

105 |

6.8.4 TAB measured ........................................................................................................................ |

106 |

6.8.5 TAB serial (liquid only)............................................................................................................ |

106 |

6.8.6 Line density table (includes TAB when liquid)........................................................................ |

106 |

6.8.7 TAB calculated (liquid only).................................................................................................... |

107 |

6.8.8 TAB Z-equation (gas only)....................................................................................................... |

107 |

6.9 Liquid line density at the metering conditions................................................................ |

109 |

6.10 Gas base density, relative density and specific gravity.................................................. |

110 |

6.10.1 Base density.......................................................................................................................... |

110 |

6.10.2 Relative density / Specific gravity......................................................................................... |

112 |

6.10.3 Base sediment and water..................................................................................................... |

113 |

6.11 Heating Value................................................................................................................. |

114 |

6.11.1 GPA 2145............................................................................................................................... |

115 |

6.11.2 TAB Normal and extended.................................................................................................... |

115 |

6.11.3 TAB Select standard.............................................................................................................. |

116 |

6.12 Enthalpy......................................................................................................................... |

116 |

6.13 Gas Data......................................................................................................................... |

118 |

6.13.1 TAB Normal and extended.................................................................................................... |

119 |

6.14 General Calculations...................................................................................................... |

120 |

6.14.1 Pipe constants....................................................................................................................... |

121 |

6.15 Constants....................................................................................................................... |

121 |

6.16 Options........................................................................................................................... |

122 |

6.17 Preset counters.............................................................................................................. |

123 |

7 Run switching |

125 |

7.1 Introduction...................................................................................................................... |

125 |

7.2 General configuration...................................................................................................... |

125 |

7.3 Stream configuration....................................................................................................... |

126 |

7.3.1 General.................................................................................................................................... |

126 |

7.3.2 Valve control............................................................................................................................ |

127 |

7.3.3 Flow control valve................................................................................................................... |

127 |

7.4 Run switching I/O selections........................................................................................... |

128 |

08/2013 - MA SUMMIT 8800 Vol2 R02 en |

www.krohne.com |

5 |

|

CONTENTS |

|

|

SUMMIT 8800 |

|

|

|

|

8 Watchdog |

131 |

|

|

9 Station |

132 |

9.1 Station totals.................................................................................................................... |

132 |

9.2 Station units..................................................................................................................... |

133 |

9.3 Preset counters................................................................................................................ |

133 |

9.4 Pressure........................................................................................................................... |

133 |

9.5 Temperature..................................................................................................................... |

133 |

10 Prover |

134 |

10.1 Prover configuration...................................................................................................... |

134 |

10.1.1 Prover pressure.................................................................................................................... |

135 |

10.1.2 Prover temperature.............................................................................................................. |

136 |

10.1.3 Alarm settings....................................................................................................................... |

137 |

10.1.4 Prover options....................................................................................................................... |

139 |

10.1.5 Calculations.......................................................................................................................... |

144 |

10.1.6 Valve control.......................................................................................................................... |

146 |

10.1.7 Line and base density........................................................................................................... |

147 |

10.2 Modbus link to stream flow computers......................................................................... |

148 |

11 Valves |

150 |

11.1 Analog............................................................................................................................ |

151 |

11.2 Digital............................................................................................................................. |

152 |

11.3 PID ................................................................................................................................. |

153 |

11.4 Feedback........................................................................................................................ |

155 |

11.5 Four way......................................................................................................................... |

157 |

11.6 Digital valve alarm......................................................................................................... |

159 |

12 Sampler |

160 |

12.1 Sampler method............................................................................................................ |

160 |

13 Batching |

168 |

13.1 General........................................................................................................................... |

168 |

6 |

www.krohne.com |

08/2013 - MA SUMMIT 8800 Vol2 R02 en |

|

CONTENTS |

|

SUMMIT 8800 |

|

|

|

|

|

14 Redundancy |

174 |

14.1 Introduction.................................................................................................................... |

174 |

14.2 Global redundancy ........................................................................................................ |

174 |

14.3 Redundancy Parameters............................................................................................... |

175 |

14.4 Redundancy ID’s............................................................................................................. |

176 |

15 Appendix 1: Software versions |

177 |

15.1 Versions/ Revisions........................................................................................................ |

177 |

15.2 Current versions............................................................................................................ |

177 |

15.2.1 Latest version 0.35.0.0.......................................................................................................... |

177 |

15.2.2 Approved version MID2.4.0.0................................................................................................ |

177 |

16 Appendix 2: Liquid calculations |

179 |

16.1 Perform meter curve linearisation................................................................................ |

179 |

16.2 Linear corrected volume flow [m3/h]............................................................................ |

179 |

16.3 Perform meter body correction .................................................................................... |

180 |

16.4 Low flow cut-off control................................................................................................. |

181 |

16.5 Retrieve base density..................................................................................................... |

181 |

16.6 Temperature correction factor to base.......................................................................... |

181 |

16.7 Pressure correction factor to base................................................................................ |

182 |

16.8 Line density.................................................................................................................... |

182 |

16.9 Mass flow [t/h]................................................................................................................ |

182 |

17 Appendix 3: Gas calculations |

184 |

17.1 Perform meter body correction..................................................................................... |

184 |

17.2 Low flow cut-off control................................................................................................. |

185 |

17.3 Perform meter curve linearisation................................................................................ |

185 |

17.4 Calculation for normal volume flow rate....................................................................... |

185 |

17.5 Calculate base and line density..................................................................................... |

186 |

17.6 Calculation for mass flow rate....................................................................................... |

186 |

17.7 Calculation for energy flow rate.................................................................................... |

186 |

17.8 Calculate heating value.................................................................................................. |

186 |

17.9 Integrate flow rates for totalisation............................................................................... |

186 |

08/2013 - MA SUMMIT 8800 Vol2 R02 en |

www.krohne.com |

7 |

|

TABLE OF FIGURES |

|

|

SUMMIT 8800 |

|

|

|

|

Figure 1 Example ID Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

18 |

|

Figure 2 Turbine and rotary meter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

21 |

|

Figure 3 Ultrasonic measurement principle . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

22 |

|

Figure 4 DP measurement principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

24 |

|

Figure 5 Up to 3 dP ranges .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

24 |

|

Figure 6 Orifice meter and plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

25 |

|

Figure 7 Venturi tube layout .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

25 |

|

Figure 8 |

Venturi Nozzle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

26 |

Figure 9 |

V-cone meter .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . |

26 |

Figure 10 Coriolis meter flow principle .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . |

27 |

|

Figure 11 Density calculations for oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

29 |

|

Figure 12 |

Uni-directional prover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

36 |

Figure 13 Bi-directional prover.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. |

.. .. .. .. .. .. .. .. .. .. .. |

36 |

|

Figure 14 Small compact prover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

37 |

|

Figure 15 Master meter loop.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. |

.. .. .. .. .. .. .. .. .. .. .. |

37 |

|

Figure 16 |

Proving flowchart.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

38 |

Figure 17 Proving sequence flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

42 |

|

Figure 18 Proving run flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

45 |

|

Figure 19 Configurator main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

48 |

|

Figure 20 |

Configuration version.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . |

49 |

Figure 21 Configuration machine type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

49 |

|

Figure 22 Main Configurator screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

50 |

|

Figure 23 Configurator I/O board setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

51 |

|

Figure 24 I/O and communication board selected . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

51 |

|

Figure 25 Board configuration window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

52 |

|

Figure 26 Signal selection from a tree. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

53 |

|

Figure 27 Error for a duplicated variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

53 |

|

Figure 28 Configure HART inputs.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . |

54 |

|

Figure 29 Configure analog input.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . |

54 |

|

Figure 30 Configure PRT input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

55 |

|

Figure 31 Configure digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

56 |

|

Figure 32 Configure analog output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

56 |

|

Figure 33 Configure digital output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

57 |

|

Figure 34 Configure pulse outputs.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

57 |

|

Figure 35 Configure alarm output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

58 |

|

Figure 36 Configure State output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

58 |

|

Figure 37 Configure corrected pulse output.. . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . |

59 |

|

Figure 38 Setup of a meter pulse in Hardware selection. . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

60 |

|

Figure 39 Setup of a monitor pulse in Hardware selection. . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

60 |

|

Figure 40 Setup of a Level A dual pulse in Hardware selection . . . . . . . . . . . . |

. . . . . . . . . . . |

60 |

|

Figure 41 Setup of a serial meter in Hardware selection . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

61 |

|

Figure 42 Setup of an Instromet ultrasonic meter in Hardware selection. . . . . . |

. . . . . . . . |

61 |

|

Figure 43 Setup of an Elster gas turbine encoder in Hardware selection.. . . |

. . . . . . . . . . . |

62 |

|

Figure 44 Setup of a analog meter in Hardware selection. . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

62 |

|

Figure 45 Setup of a meter with Hart in Hardware selection . . . . . . . . . . . . . . |

. . . . . . . . . . . |

63 |

|

Figure 46 DP transmitter selection in Hardware input . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

63 |

|

Figure 47 Hart DP transmitter selection in Hardware input. . . . . . . . . . . . . . . |

. . . . . . . . . . . |

64 |

|

Figure 48 Analog DP transmitter selection in Hardware input.. . . . . . . . . . . . . . |

. . . . . . . . . |

64 |

|

Figure 49 Stream and station temperature selection in Hardware input . . . . |

. . . . . . . . . . . |

65 |

|

Figure 50 Temperature input selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

65 |

|

Figure 51 Temperature serial input selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

66 |

|

Figure 52 Stream and station pressure selection in Hardware input. . . . . . . . . . |

. . . . . . . . |

66 |

|

Figure 53 Pressure input selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

67 |

|

Figure 54 Pressure serial input selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

67 |

|

Figure 55 Densitometer input selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

68 |

|

Figure 56 Density input selection.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . |

68 |

|

Figure 57 Density serial input selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

69 |

|

8 |

www.krohne.com |

08/2013 - MA SUMMIT 8800 Vol2 R02 en |

|

TABLE OF FIGURES |

|

SUMMIT 8800 |

|

|

|

|

|

Figure 58 Density temperature and pressure input selection. . . . . . . . . . . . . . . . . . . . . . . |

. |

69 |

Figure 59 Stream and station ouput selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

70 |

Figure 60 Analog and digital pulse output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

70 |

Figure 61 Density serial input selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

71 |

Figure 62 Alarm output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

71 |

Figure 63 Define input engineering units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

72 |

Figure 64 Define output engineering units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

73 |

Figure 65 Define pulse based meter input API level B to E.. . . . . . . . . . . . . . . . . . . . . . . . . |

. |

74 |

Figure 66 Figure 65 define pulse based meter input API level A . . . . . . . . . . . . . . . . . . . . |

. |

74 |

Figure 67 Define meter information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

75 |

Figure 68 Example ultrasonic meter input section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

76 |

Figure 69 Ultrasonic pulse input section for liquid and gas API 5..5 Level B to E. . . . . . . . |

. |

77 |

Figure 70 Ultrasonic pulse input section for liquid API 5..5 level A. . . . . . . . . . . . . . . . . . . |

. |

78 |

Figure 71 Examples ultrasonic meter correction section. . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

79 |

Figure 72 Define meter information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

80 |

Figure 73 Differential pressure General section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

81 |

Figure 74 Define meter information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

83 |

Figure 75 Define the differential pressure transmitter selection. . . . . . . . . . . . . . . . . . . . |

. |

84 |

Figure 76 Define the differential pressure transmitter calibration constants . . . . . . . . . . |

. |

85 |

Figure 77 Define the differential pressure transmitter advanced settings. . . . . . . . . . . . . |

. |

86 |

Figure 78 Example Coriolis meter input section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

87 |

Figure 79 Coriolis pulse input section for liquid and gas API 5..5 Level B to E . . . . . . . . . . |

. |

88 |

Figure 80 Coriolis pulse input section for API 5..5 level A . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

89 |

Figure 81 Coriolis density deviation.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

90 |

Figure 82 Define meter information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

90 |

Figure 83 Product information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

91 |

Figure 84 Flow rate limits & scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

93 |

Figure 85 Liquid Meter and K-factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

94 |

Figure 86 Liquid K-factor Curve.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

95 |

Figure 87 Gas or steam flow rate correction for a 6 point calibration. . . . . . . . . . . . . . . . . |

. |

95 |

Figure 88 Gas or steam flow rate calculations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

96 |

Figure 89 Tariff selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

97 |

Figure 90 Tariff flow rate output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

97 |

Figure 91 Stream pressure selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

98 |

Figure 92 Stream pressure calibration constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

99 |

Figure 93 Stream pressure advanced options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

99 |

Figure 94 Stream temperature selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

101 |

Figure 95 Stream temperature calibration constants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

101 |

Figure 96 Stream temperature advanced options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

102 |

Figure 97 Stream Liquid, gas and steam line density selection. . . . . . . . . . . . . . . . . . . . . . |

. |

104 |

Figure 98 Stream ratio of specific heats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

104 |

Figure 99 Viscosity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

105 |

Figure 100 Density transducer parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

105 |

Figure 101 Liquid and gas measurement selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

106 |

Figure 102 Liquid serial selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

106 |

Figure 103 Line density table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

107 |

Figure 104 Liquid line density calculation method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

107 |

Figure 105 Gas Line density Z-equation method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

108 |

Figure 106 Z-table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

109 |

Figure 107 Meter line density, keypad.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

109 |

Figure 108 Meter line density, calculated. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

110 |

Figure 109 Base density selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

111 |

Figure 110 Compressibility options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

111 |

Figure 111 Relative density options.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

112 |

Figure 112 Basic sediment & water.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

113 |

Figure 113 Heating value selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

114 |

Figure 114 GPA 2145 normal Gas data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

115 |

08/2013 - MA SUMMIT 8800 Vol2 R02 en |

www.krohne.com |

9 |

|

TABLE OF FIGURES |

|

|

SUMMIT 8800 |

|

|

|

|

Figure 115 |

Enthalpy settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

116 |

Figure 116 |

Gas data selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

118 |

Figure 117 Normal Gas data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

119 |

|

Figure 118 Base density of air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

120 |

|

Figure 119 Molecular weight of gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

120 |

|

Figure 120 |

Emission factors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

120 |

Figure 121 |

AGA 10 speed of sound.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

121 |

Figure 122 |

Constants.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

122 |

Figure 123 Stream options selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

122 |

|

Figure 124 |

Preset counters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

124 |

Figure 125 |

Turn run switching on. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

125 |

Figure 126 Stream configuration run switching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

126 |

|

Figure 127 Stream run switching switch conditions.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. |

126 |

||

Figure 128 Stream run switching valve control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

127 |

|

Figure 129 Stream run switching valve control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

128 |

|

Figure 130 Run switching digital input selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

128 |

|

Figure 131 |

Run switch digital output selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

129 |

Figure 132 Flow control valve analogue output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

129 |

|

Figure 133 |

Run switching alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

130 |

Figure 134 Stream run switching alarm selections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

130 |

|

Figure 135 |

Watchdog settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

131 |

Figure 136 Define station totals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

132 |

|

Figure 137 |

Flow computer machine type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

135 |

Figure 138 |

Prover section for liquid and gas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

135 |

Figure 139 |

Prover pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

136 |

Figure 140 |

Prover temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

137 |

Figure 141 Prover alarm settings, re-prove. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

138 |

|

Figure 142 Prover options: general. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

139 |

|

Figure 143 |

Prover options: general, proving points.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

140 |

Figure 144 |

Prover options: general settings, uni-directional prover.. . . . . . . . . . . . . . . . . |

. |

140 |

Figure 145 |

Prover options: general settings, bi-directional prover.. . . . . . . . . . . . . . . . . . |

. |

140 |

Figure 146 |

Prover options: general settings, small volume prover.. . . . . . . . . . . . . . . . . . |

. |

140 |

Figure 147 |

Prover options: general settings, master meter. . . . . . . . . . . . . . . . . . . . . . . . |

. |

141 |

Figure 148 |

Prover options: stability.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

142 |

Figure 149 Prover options: meter correction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

143 |

|

Figure 150 |

Prover options: meter information.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

143 |

Figure 151 Prover calculations, k-factor for liquid and gas . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

144 |

|

Figure 152 |

Prover calculations, pipe correction.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

145 |

Figure 153 |

Prover valve control, bi-directional. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

146 |

Figure 154 Prover valve control, uni-directional or small volume. . . . . . . . . . . . . . . . . . . . |

. |

146 |

|

Figure 155 |

Prover valve control, master metering 3 streams. . . . . . . . . . . . . . . . . . . . . . . |

. |

147 |

Figure 156 Prover line and base density. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

148 |

|

Figure 157 Prover modbus slave configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

149 |

|

Figure 158 |

Valve options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

150 |

Figure 159 |

Analog valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

151 |

Figure 160 Analog valve setpoint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

151 |

|

Figure 161 Select the analog valve output ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

152 |

|

Figure 162 |

Digital valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

152 |

Figure 163 |

Select the digital valve ID.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

153 |

Figure 164 |

PID control loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

153 |

Figure 165 |

PID valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

154 |

Figure 166 |

Select the PID valve ID and the Preset keypad setpoint ID. . . . . . . . . . . . . . . . |

. |

155 |

Figure 167 |

Feedback valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

155 |

Figure 168 |

Open & close feedback action command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

156 |

Figure 169 |

Open & close feedback valve signals: command and feedback.. . . . . . . . . . . . |

. |

156 |

Figure 170 Four way valve configuration for different leak sensors types . . . . . . . . . . . . . |

. |

157 |

|

Figure 171 Four way valve action command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

158 |

|

10 |

www.krohne.com |

08/2013 - MA SUMMIT 8800 Vol2 R02 en |

|

TABLES |

|

SUMMIT 8800 |

|

|

|

|

|

Figure 172 |

Four way valve digital output and input selection.. . . . . . . . . . . . . . . . . . . . . . . |

. |

158 |

Figure 173 Four way valve leak sensor input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

159 |

|

Figure 174 Digital alarm valve output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

159 |

|

Figure 175 Sampler timed based configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

160 |

|

Figure 176 |

Flow based sampler counter selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

161 |

Figure 177 |

Sampler can weighing.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

161 |

Figure 178 Sampler can flow limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

162 |

|

Figure 179 Sampler can calculated can level parameters.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. |

162 |

||

Figure 180 Sampler can calculated volume % full parameters . . . . . . . . . . . . . . . . . . . . . . |

. |

162 |

|

Figure 181 |

Sampler status information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

163 |

Figure 182 |

Sampler digital grab output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

164 |

Figure 183 Sampler can measured can level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

164 |

|

Figure 184 Sampler analogue output selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

165 |

|

Figure 185 Sampler can weight inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

165 |

|

Figure 186 Sampler digital input selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

166 |

|

Figure 187 Sample accountable alarm selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

167 |

|

Figure 188 Batching general selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

168 |

|

Figure 189 Fixed batching trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

169 |

|

Figure 190 Batching fixed batching selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

169 |

|

Figure 191 |

Station batching stream selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

170 |

Figure 192 |

Batching information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

170 |

Figure 193 Batching parameters to be recalculated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

171 |

|

Figure 194 |

Batching digital input selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

172 |

Figure 195 Batching analogue output selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

172 |

|

Figure 196 |

Batching digital output selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

173 |

Figure 197 Batching alarm status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

173 |

|

Figure 198 |

Global redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

175 |

Figure 199 |

Redundancy ID’s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

176 |

08/2013 - MA SUMMIT 8800 Vol2 R02 en |

www.krohne.com |

11 |

|

ABOUT THIS HANDBOOK |

|

01 |

SUMMIT 8800 |

|

|

|

|

IMPORTANT INFORMATION

KROHNE Oil & Gas pursues a policy of continuous development and product improvement. The Information contained in this document is, therefore subject to change without notice. Some display descriptions and menus may not be exactly as described in this handbook. However, due the straight forward nature of the display this should not cause any problem in use.

To the best of our knowledge, the information contained in this document is deemed accurate at time of publication. KROHNE Oil & Gas cannot be held responsible for any errors, omissions, inaccuracies or any losses incurred as a result.

In the design and construction of this equipment and instructions contained in this handbook, due consideration has been given to safety requirements in respect of statutory industrial regulations.

Users are reminded that these regulations similarly apply to installation, operation and maintenance, safety being mainly dependent upon the skill of the operator and strict supervisory control.

12 |

www.krohne.com |

08/2013 - MA SUMMIT 8800 Vol2 R02 en |

|

ABOUT THIS HANDBOOK |

|

SUMMIT 8800 |

01 |

|

|

|

|

1..1 Volumes

This is Volume 2 of 3 of the SUMMIT 8800 Handbook:

Volume 1

Volume 1 is targeted to the electrical, instrumentation and maintenance engineer

This is an introduction to the SUMMIT 8800 flow computer, explaining its architect and layout - providing the user with familiarity and the basic principles of build. The volume describes the Installation and hardware details, its connection to field devices and the calibration.

The manual describes the operation via its display, its web site and the configuration software. Also the operational functional of the Windows software tools are described, including the configurator, the Firmware wizard and the display monitor.

Volume 2

Volume 2 is targeted to the metering software configuration by a metering engineer.

The aim of this volume is to provide information on how to configure a stream and the associated hardware.

The handbook explains the configuration for the different metering technologies, including meters, provers, samplers, valves, redundancy etc.. A step by step handbook using the Configurator software, on the general and basic setup to successfully implement flow measurement based on all the applications and meters selections within the flow computer.

Volume 3

Volume 3 is targeted to the software configuration of the communication.

The manual covers all advance functionality of the SUMMIT 8800 including display configuration, reports, communication protocols, remote access and many more advance options.

1..2 Content Volume 1

Volume 1 concentrates on the daily use of the flow computer

•Chapter 2: Basic functions of the flow computer

•Chapter 3: General information on the flow computer

•Chapter 4: Installation and replacement of the flow computer

•Chapter 5: Hardware details on the computer, its components and boards

•Chapter 6: Connecting to Field Devices

•Chapter 7: Normal operation via the touch screen

•Chapter 8: How to calibration the unit

•Chapter 9: Operation via the optional web site

•Chapter 10: Operational functions of the configuration software, more details in volume 2

•Chapter 11: How to update the firmware

•Chapter 12: Display monitor software to replicate the SUMMIT 8800 screen on a PC and make screen shots

1..3 Content Volume 2

Volume 2 concentrates on the software for the flow computer.

•Chapter 2: General information on the software aspects of the flow computer

•Chapter 3: Details on metering principles

•Chapter 4: Basic functions of configurator

•Chapter 5: Configuration of the hardware of the boards

•Chapter 6: Stream configuration

•Chapter 7: Run switching

•Chapter 8: Watchdog

08/2013 - MA SUMMIT 8800 Vol2 R02 en |

www.krohne.com |

13 |

|

ABOUT THIS HANDBOOK |

|

01 |

SUMMIT 8800 |

|

|

|

|

•Chapter 9: Configure a station

•Chapter 10: Configure a prover or master meter

•Chapter 11: Configure valves

•Chapter 12: Configure a sampler

•Chapter 13: Set-up batching

•Chapter 14: Set two flow computers in redundant configuration

1..4 Content Volume 3

Volume 3 concentrates on the configuration of the SUMMIT 8800

•Chapter 3; Configurator software

•Chapter 4: Date & Time

•Chapter 5: Data Logging

•Chapter 6: Display and web access

•Chapter 7: Reporting

•Chapter 8: Communication

•Chapter 9: General Information

1..5 Information in this handbook

The information in this handbook is intended for the integrator who is responsible to setup and configure the SUMMIT 8800 flow computer for Liquid and or Gas and or Steam application:

Integrators (hereafter designated user) with information of how to install, configure, operate and undertake more complicated service tasks.

This handbook does not cover any devices or peripheral components that are to be installed and connected to the SUMMIT 8800 it is assumed that such devices are installed in accordance with the operating instructions supplied with them.

Disclaimer

KROHNE Oil & Gas take no responsibility for any loss or damages and disclaims all liability for any instructions provided in this handbook. All installations including hazardous area installations are the responsibility of the user, or integrator for all field instrumentation connected to and from the SUMMIT 8800 Flow computer.

Trademarks

SUMMIT 8800 is a trade mark of KROHNE Oil & Gas.

Notifications

KROHNE Oil & Gas reserve the right to modify parts and/or all of the handbook and any other documentation and/ or material without any notification and will not be held liable for any damages or loss that may result in making any such amendments.

Copyright

This document is copyright protected.

KROHNE Oil & Gas does not permit any use of parts, or this entire document in the creation of any documentation, material or any other production. Prior written permission must be obtained directly from KROHNE Oil & Gas for usage of contents. All rights reserved.

Who should use this handbook?

This handbook is intended for the integrator or engineer who is required to configure the flow computer for a stream including devices connected to it.

Versions covered in this handbook

All Versions

14 |

www.krohne.com |

08/2013 - MA SUMMIT 8800 Vol2 R02 en |

|

GENERAL INFORMATION |

|

SUMMIT 8800 |

02 |

|

|

|

|

2..1 Software versions used for this guide

This handbook is based on the software versions as mentioned in Appendix 1: software versions

2..2 Terminology and Abbreviations

AGA |

American Gas Association |

|

|

API |

American Petroleum Institute |

|

|

Communication board |

Single or dual Ethernet network board |

|

|

Configurator |

Windows software tool to configure and communicate to the SUMMIT 8800 |

CP |

Control Panel |

|

|

CPU |

Central Processing Unit |

|

|

CRC32 |

Cyclic Redundancy Check 32 bits. Checksum to ensure validity of information |

|

|

FAT |

Factory Acceptance Test |

|

|

FDS |

Functional Design Specification |

|

|

HMI |

Human-Machine Interface |

HOV |

Hand Operated Valve |

|

|

I/O |

Input / Output |

|

|

ISO |

International Standards Organization |

|

|

KOG |

KROHNE Oil and Gas |

|

|

KVM |

Keyboard / Video / Mouse |

|

|

MOV |

Motor Operated Valve |

MSC |

Metering Supervisory Computer |

|

|

MUT |

Meter Under Test |

|

|

Navigator |

360 optical rotary dial |

|

|

PC |

Personal Computer |

|

|

PRT |

Platinum Resistance Thermometers |

|

|

PSU |

Power Supply Unit |

PT |

Pressure Transmitter |

|

|

Re-try |

Method to repeat communication a number of times before giving an alarm |

|

|

RTD: |

Resistance Temperature Device |

|

|

Run: |

Stream/Meter Run |

|

|

SAT |

Site Acceptance Test |

|

|

SUMMIT 8800 |

Flow computer |

Timestamp |

Time and date at which data is logged |

|

|

Time-out |

Count-down timer to generate an alarm if software stopped running |

|

|

TT |

Temperature Transmitter |

|

|

UFC |

Ultrasonic Flow Converter |

|

|

UFM |

Ultrasonic Flow Meter |

|

|

UFP |

Ultrasonic Flow Processor (KROHNE flow computer ) |

UFS |

Ultrasonic Flow Sensor |

|

|

VOS |

Velocity of Sound |

|

|

ZS |

Ball detector switch |

|

|

XS |

Position 4-way valve |

|

|

XV |

Control 4-way valve |

|

|

08/2013 - MA SUMMIT 8800 Vol2 R02 en |

www.krohne.com |

15 |

|

GENERAL INFORMATION |

|

02 |

SUMMIT 8800 |

|

|

|

|

2..3 General Controls and Conventions

In the configurator software several conventions are being used:

Numeric Data Entry Box

Clear background, black text, used for entering Numeric Data, a value must be entered here Optional: Coloured background, black text used for entering optional Numeric Data. If no value is entered then right click mouse key and select Invalidate, box will show and no number will be entered.

An invalid Number will be shown on the SUMMIT 8800 display as “--------- |

“ and is read serially |

as 1E+38 |

|

Pull-Down Menu |

|

Select a function or option from a list functions or options |

|

Icon |

|

Selects a function or a page. |

|

Tabs

Allows an individual page, sub-page or function to be selected from a series of pages, sub-pag- es or functions.

Expanded item - Fewer items shown.

Non Expanded item +

More items shown.

Option Buttons

Red cross means OFF or No

Green tick means ON or Yes

Data Tree

Items from the Data Tree can be either selected or can be “Dragged and dropped” from the Tree into a selection box; for example when setting up a logging system or a Modbus list, etc.

Yellow Data circle means Read Only. Red data circle means Read and Write.

Hover over

Hold the cursor arrow over any item, button or menu, etc. Do not click any mouse button, the item will be lightly highlighted and information relating to the selection will be illustrated.

Grey Text

Indicates that this item has no function or cannot be entered in this particular mode of the system. The data is shown for information purposes only.

Help Index

Display information that assists the user in configuration.

Naming convention of Variables

In the KROHNE SUMMIT 8800 there are variables used with specific naming.

This naming is chosen to identify a variable and relate it to the correct stream.

16 |

www.krohne.com |

08/2013 - MA SUMMIT 8800 Vol2 R02 en |

|

GENERAL INFORMATION |

|

SUMMIT 8800 |

02 |

|

|

|

|

The most complex variable is explained below and this explanation can be used to interpret all the other variable names.

Example: + ph uVN . 1

+ |

Positive (+) or negative (-) |

|

|

Ph |

Previous (P) or Current (C) period |

|

Pqh – previous 15 minutes |

|

Ph – previous hour |

|

Pd – previous Day |

|

Pm – previous month |

|

Pq – previous quarter of a year |

|

Cqh – current 15 minutes |

|

Ch – current hour |

|

Cd – current Day |

|

Cm – current month |

|

Cq – current quarter of a year |

u |

Type of totals |

|

u – Unhaltable, counts always |

|

m – Maintenance, counts when maintenance is active (optional) |

|

n – Normal, fiscal counters during normal operation |

|

e – Error, fiscal counters with an accountable error |

|

t1 –> t4 – Tarif , fiscal counters based on fiscal thresholds |

VN |

Type of flow |

|

VPulses, pulses counted |

|

Vline, gross volume flow |

|

Vmon, monitored grass volume flow |

|

Vbc (p/t) pressure and temperature corrected gross volume flow |

|

Vbc, linearization corrected (Vbc(p/t))gross volume flow |

|

VN, Normalized volume flow |

|

VN(net), Nett normalized flow |

|

VM, Mass flow |

|

VE, Energy flow |

|

VCO2, carbon dioxide flow |

|

|

1 |

Stream/ Run number |

|

|

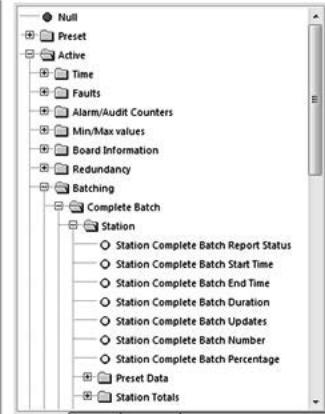

2..4 ID Data Tree

When selecting parameters and options in the Configurator software, the user will be presented with a tree structure for instance:

08/2013 - MA SUMMIT 8800 Vol2 R02 en |

www.krohne.com |

17 |

|

GENERAL INFORMATION |

|

02 |

SUMMIT 8800 |

|

|

|

|

Figure 1 Example ID Tree

This is referred to as the ID tree which, depending on its context, includes folders and several parameters:

2..4..1 Type of data

The rest of this chapter will explain the folders available, the type of selection within the folder and any other corresponding data.

Preset Data

Essential to the configuration of the flow computer. Typical data would be keypad values, operating limits, equation selection, calibration data for Turbines and Densitometers and Orifice plates.

This data would be present in a configuration report, and enables you to see what the flow computer is configured to do.

Used for validation and will form the Data Checksum (visible on the System Information Page). E.g., if a data checksum changes, the setup of the flow computer has changed and potentially calculating different results to what is expected.

Typically configured and left alone, only updated after validation e.g. every 6 month / 1 year.

Active Data

These values cover inputs to the flow computer. E.g., from GC, pressure & temperature transmitters, meters etc..

Also Values calculated in the flow computer. E.g., Flow rates, Z, Averages, Density etc..

Local Data

Data that an operator can change locally to perform maintenance tasks. E.g., turn individual transmitters off without generating alarms. Setting Maintenance mode or Proving Mode.

18 |

www.krohne.com |

08/2013 - MA SUMMIT 8800 Vol2 R02 en |

|

GENERAL INFORMATION |

|

SUMMIT 8800 |

02 |

|

|

|

|

Totals

Totals for the streams and station.

Contents of this folder are stored in the non-volatile RAM and are protected using the battery.

Custom

User defined variables.

Allows calculations, made in a LUA script, to be used in a configuration.

For details, see volume 3.

2..4..2 Colour codes

With each parameter and option, there are corresponding coloured dots that represent the access and status of the particular selection.

General ID tree

|

Red Dot |

Data is Read/Write and can be changed over Modbus. |

|

|

|

|

Yellow Dot |

Data is Read-Only and cannot be changed over Modbus |

|

|

|

Please note that it might be possible to change the values via the screen

90% of the data will be Read Only, but items such as Serial Gas Compositions, Time/Date, MF are commonly written over Modbus.

NOTE: Although the ID may be read/write, the security setting determines whether the ID indeed can be written.

Alarm Tree

The alarm tree is built of all the registers that hold alarm data. Alarm registers are 32-bit integers, where each bit represents a different alarm.

|

Red Dot |

Represents an accountable alarm visible on the alarm list. |

|

|

|

|

Dark Blue Dot |

Represents a non-accountable alarm visible on the alarm list. |

|

|

|

|

Orange Dot |

Represents a warning visible on the alarm list. |

|

|

|

|

Light Blue Dot |

Represents a status alarm, not visible on the alarm list. |

|

|

|

|

Black/Grey Dot |

Represents a hardor software fault alarm visible on the alarm list. |

|

|

|

An example of typical usage would be the General Alarm Register. This is a 32 bit register that indicates up to 32 different alarms in the flow computer. This will contain Status Alarms, for example, 1 bit will indicate if there is a Pressure alarm or not. If the Pressure Status bit is set the user will know that there is a problem with the Pressure.

This should be sufficient information, however if it is not satisfactory, the user can look at the Pressure alarm, this contains 32 different alarms relating to the Pressure measurement, these would be Red Dots as they each can create an entry in the alarm list. By reading this register the user can view exactly what is wrong with the Pressure measurement.

The Light Blue Dots are generally an OR of several other dots. By reading the General register you can quickly see if the unit is healthy, more information can be provided by reading several more registers associated with that parameter.

08/2013 - MA SUMMIT 8800 Vol2 R02 en |

www.krohne.com |

19 |

|

GENERAL INFORMATION |

|

02 |

SUMMIT 8800 |

|

|

|

|

2..5 Specific Requirements for Meters and Volume Convertors

2..5..1 Numbering formats

The number formats used internally in the unit are generally IEEE Double Precision floating point numbers of 64 bit resolution.

It is accepted that such numbers will yield a resolution of better than 14 significant digits.

In the case of Totalisation of Gas, Volumes, Mass and Energy such numbers are always shown to a resolution of 8 digits before the decimal point and 4 after, i.e. 12 significant digits.

Depending upon the required significance of the lowest digit, these values can be scaled by a further multiplier.

2..5..2 Alarms

Each of the various modules that comprise the total operating software, are continuously monitored for correct operation. Depending upon the configuration, the flow computer will complete its allocated tasks within the configured cycle time, 250mS, 500mS or 1 second. Failure to complete the tasks within the time will force the module to complete, and where appropriate, a substitute value issued together with an alarm indication.

For example, if a Calculation fails to complete correctly then a result of 1 or similar will be returned, which allows the unit to continue functioning whilst an accountable alarm is raised, indicating an internal problem.

2..5..3 Accountable alarm

When the value of any measurement item or communication to an associated device that is providing measurement item to the SUMMIT 8800 goes out of range, the flow computer will issue an Accountable Alarm.

When any calculation module or other item that in some way affects the ultimate calculation result goes outside its operating band, i.e. above Pressure Maximum or below Pressure minimum, then the SUMMIT 8800 will issue an Accountable Alarm.

When the SUMMIT 8800 issues an Accountable alarm a number of consequences will occur as follows:

Front panel accountable alarm will turn on and Flash.

Nature of accountable alarm will be shown on the top line of the alarm log. Alarm log will wait for user acknowledgement of alarm.