KEYENCE TM-3000 User Manual

TM-3000

Setup guide

This guide describes the basic operations for TM-3000.

For operation details, see "User's Manual".

High-speed 2D Measurement Sensor

I

Introduction

Wiring

Installation

P 2

P 2

I -1

I -2

II

Operational Flow for Measurement

Operational flow for measurement

II

-1

III

Measurement – diameter and step height of a stepped shaft

Diameter measurement

Step height measurement

Measuring the outer diameter of a target

Measuring the step height of a target

III

-1

III

-2

IV

Settings/Operations Used for All Measurements

Master registration

Measurement setting

Area setting

Registering an image to be used as a measurement standard

Making detailed measurement settings

Specifying measurement points

IV

-1

IV

-2

IV

-3

V

Position correction

Measuring correcting the margin of error

caused by the position change of the target

V

-1

VI

Frequently Used Settings

External Trigger

Offset

Scaling

Tolerance

Initialization

Measuring synchronizing with the external signal input

Setting the displayed value to an arbitrary value

Correcting measured values

Making the tolerance setting

Restoring the default status

VI

-1

VI

-2

VI

-3

VI

-4

VI

-5

VII

Settings for Data Saving

Data storage function

Excel transfer function

Image storage function

Image capture function

Storing measurement data

Displaying the storage data on the Excel file

Saving the image data of measurement targets

Saving the monitor images

VII

-1

VII

-2

VII

-3

VII

-4

P 3

P 9

P 6

P 7

P 8

P10

P10

P11

P11

P11

P12

P13

P14

P15

P 4

P 5

Setting for Correcting the Position of the Target

96M11229

2

I -

11

Manual P1-18

This section explains the wiring and installation of this unit.

Wiring

I -

22

Manual P1-11

Installation

Introduction

I

To obtain the measurement image in the best condition, place the measurement target at the focus mark

indicated on the TR base.

Make wiring and connection for this unit as illustrated below.

Target

Introduction

ReceiverTransmitter

Focus mark

TR base

Console

Head B

Controller

24 VDC power supply

Head A

Head-to-controller cable

(0.7 m/2 m/5 m/10 m/20 m/30 m)

TM-3000

POWER

ON

CON

SOLE

I/O

OU

T

MONITOR

HEAD-B

HEAD-A

ETHERNET

RS-232C

USB

S

D CARD

Monitor

3

II -

11

Operational flow for measurement

Manual P5-37

This section explains settings required to perform measurement.

This measurement sensor measures outer diameters or the distances based on the edge information

(boundary of a bright and a dark part of the image) of measured images.

For detailed measurement content, specify the “Measurement type” in the “Measurement setting” and set.

Set the target within the measurement area and perform the

master registration.

Select the measurement type according to the measured content.

(The “Measurement type” can be selected in the measurement setting.)

Setting procedure

Step 1

Step 2

Measurement types T

Diameter :

Maximum diameter

Intersection (X and Y coordinates)

Intersection

distance

Distance between point

and straight line

Y position (Y axis)

X position (X axis)

Step height :

Step height

Width :

Minimum diameter

Width

Angle

Radius

Roundness

Pitch

Manual

P5-43

Manual

P5-48

Manual

P5-52

Y position :

X position :

Coordinate :

Manual

P5-46

Manual

P5-50

Manual

P5-63

Distance :

Intersection distance :

Area :

Manual

P5-54

Manual

P5-56

Manual

P5-65

Angle :

Manual

P5-58

Radius :

Roundness :

Manual

P5-60

Manual

P5-62

Pitch :

Manual

P5-70

Diameter, step height, width

The maximum diameter and minimum diameter

within the specified range, and step height and

width between detected edges are measured.

Angle

This measures the angle made by the detected

two straight lines or the tilt from the arbitrary line.

Radius, roundness

This measures the radius of specified arc

and the roundness.

Pitch

This measures the maximum, minimum or

average pitch within the specified range.

Y position, X position, coordinate

Y position, X position of detected edge, or

coordinate at the specified point is measured.

Distance, intersection distance, area

This measures the distance between the specified two

points, such as distance between center of circle and

intersection, and also measures the area.

Operational Flow for Measurement

Operational Flow for Measurement

II

Area

Tilt from the arbitrary line

* If position change, etc. occurs for the measurement target, use the position correction

function (page 9 in this manual).

The measurement area is corrected by the amount of change and the target

measurement is taken.

Distance between the centers of two targets

4

III

-

11

Manual P5-43

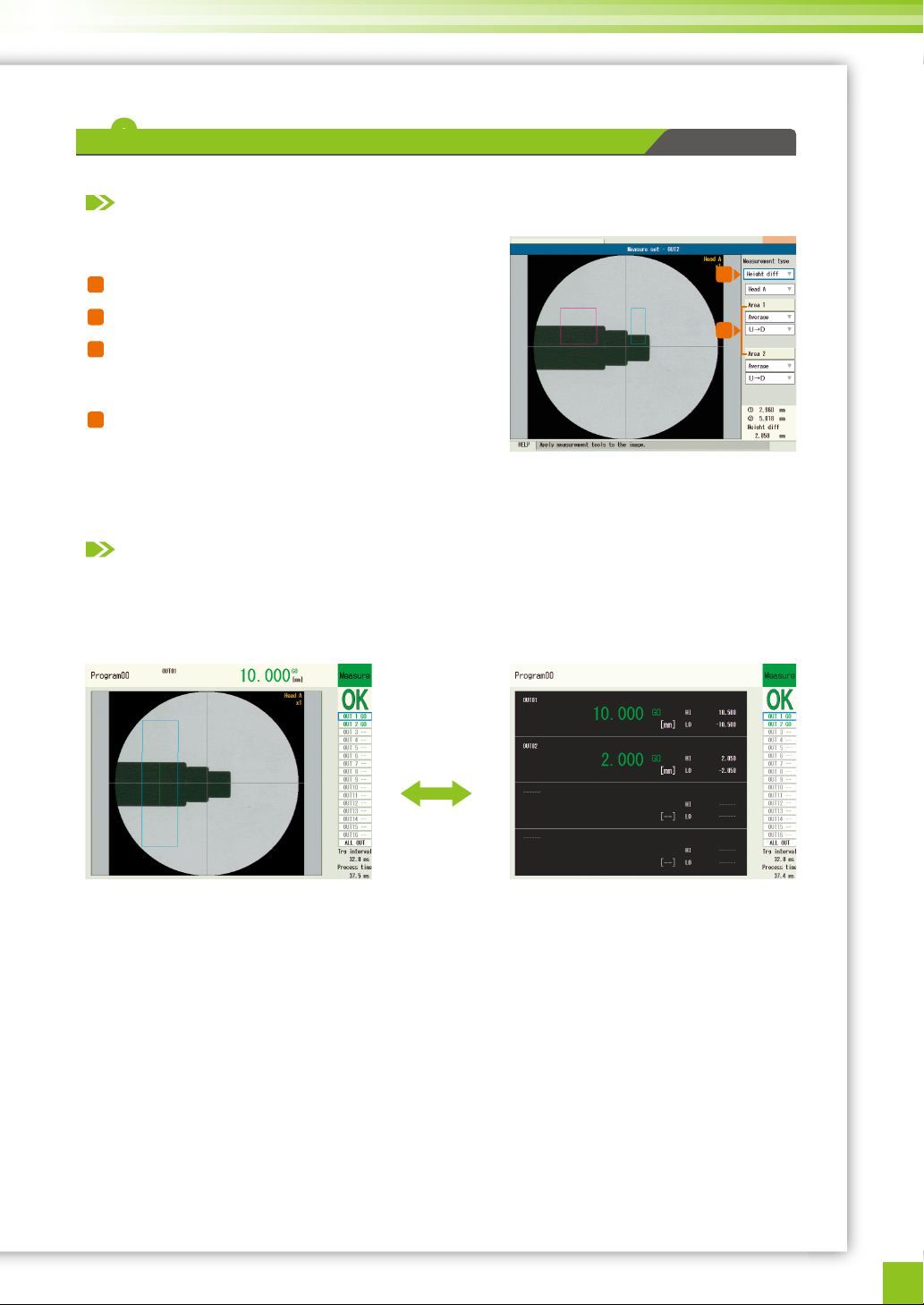

Make the detailed settings for each OUT.

Measure the diameter for OUT1 and step height for OUT2 respectively.

Perform the master registration beforehand for this measurement.

For setting the master registration, see page 6 in this manual.

Slide the [PROG/RUN] switch on the side of the console to

display the settings screen (screen 1).

The screen switches from the measurement screen to the setting

screen.

Select “Measure set” on screen 1.

Press the [ENTER] key on the console to select the item.

Select “OUT1” on screen 2.

Select “Diameter” in “Measurement type” on screen 3

Select “Area 1” and set the area vertically long.

For area operation, see page 8 in this manual.

Confirm the “Measured content” is set to “Average” and “Tilt

corr” is set to “ON”.

* Setting the tilt correction (Tilt corr) to “ON” enables the diameter to

be measured correctly even if the target has a tilt.

Press the [ESCAPE] key on the console to return to screen 2.

The diameter measurement setting (1) is complete.

This measures the stepped shaft.

Diameter measurement

XXX

Measuring the outer diameter of a target

(1) Diameter

measurement

(2) Step height measurement

Setting procedure

Screen 2

Screen 3

Screen 1

III

I

I

I

I

1

2

3

4

5

6

1

2

3

4

5

Measurement – diameter and step height of a stepped shaft

Measurement – diameter and step height of a stepped shaft

5

Select OUT2 on screen 2 and make the setting for measuring (2) the step height.

Sliding the [PROG/RUN] switch on the side of the console switches from the setting screen to the

measurement screen.

The measurement results for (1) Diameter and (2) Step Height are displayed.

To set scaling or tolerance for measurement values, see page11 in this manual.

Select “OUT2” on screen 2 on the previous page.

Select “Step Height” for “Measurement type” on screen 4.

Select “Area 1/Area 2” on screen 4 and set the area as

shown on screen 4.

For area operation, see page 8 in this manual.

Press the [ESCAPE] key on the console to return to screen 1.

The step height measurement setting (2) is complete.

* To measure correcting the tilt, see the position correction function (page 8 in this manual).

Pressing the [SCREEN] key

switches the screen according

to each setting.

Screen 4

III

-

22

Manual P5-48

Step height measurement

XXX

Measuring the step height of a target

Setting procedure

Checking the measurement status

[SCREEN]

8

9

7

8

9

10

Loading...

Loading...