JLG 1930ES, 3246ES, 2032ES, 2632ES, 2646ES Operation And Safety Manual

Operation and Safety Manual

®

Original Instructions, Keep this manual with the machine at all times.

Models

1930ES/

2032ES/2632ES/

2646ES/3246ES

USA Built - S/N 0200239382 to Present

China Built - S/N B200020297 to Present

Mexico Built - S/N M200000100 to Present

Belgium Built - S/N 1200025021 to Present

ANSI

AS/NZS

P/N - 3121655

July 20, 2018 - Rev H

WARNING

Operating, servicing and maintaining this vehicle or equipment

can expose you to chemicals including engine exhaust, carbon

monoxide, phthalates, and lead, which are known to the State

of California to cause cancer and birth defects or other reproductive harm. To minimize exposure, avoid breathing exhaust,

do not idle the engine except as necessary, service your vehicle

or equipment in a well-ventilated area and wear gloves or wash

your hands frequently when servicing. For more information go

to www.P65Warnings.ca.gov.

FOREWORD

FOREWORD

This manual is a very important tool! Keep it with the machine at all times.

The purpose of this manual is to provide owners, users, operators, lessors, and lessees with the precautions and

operating procedures essential for the safe and proper machine operation for its intended purpose.

Due to continuous product improvements, JLG Industries, Inc. reserves the right to make specification changes

without prior notification. Contact JLG Industries, Inc. for updated information.

IT IS A GOOD PRACTICE TO AVOID PRESSURE-WASHING ELECTRICAL/ELECTRONIC COMPONENTS. SHOULD

PRESSURE-WASHING BE UTILIZED TO WASH AREAS CONTAINING ELECTRICAL/ELECTRONIC COMPONENTS,

JLG INDUSTRIES, INC. RECOMMENDS A MAXIMUM PRESSURE OF 750 PSI (52 BAR) AT A MINIMUM DISTANCE OF 12 INCHES (30.5 CM) AWAY FROM THESE COMPONENTS. IF ELECTRICAL/ELECTRONIC COMPONENTS ARE SPRAYED, SPRAYING MUST NOT BE DIRECT AND BE FOR BRIEF TIME PERIODS TO AVOID HEAVY

SATURATION.

3121655 a

FOREWORD

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

This is the Safety Alert Symbol. It is used to alert you to the potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death

INDICATES AN IMMINENTLY HAZARDOUS SITUATION. IF NOT

AVOIDED, WILL

RESULT IN SERIOUS INJURY OR DEATH. THIS DECAL

WILL HAVE A RED BACKGROUND.

INDICATES A POTENTIALITY HAZARDOUS SITUATION. IF NOT

AVOIDED, MAY

RESULT IN MINOR OR MODERATE INJURY. IT MAY

ALSO ALERT AGAINST UNSAFE PRACTICES. THIS DECAL WILL HAVE A

YELLOW BACKGROUND.

INDICATES A POTENTIALITY HAZARDOUS SITUATION. IF NOT

AVOIDED, COULD

RESULT IN SERIOUS INJURY OR DEATH. THIS DECAL

WILL HAVE AN ORANGE BACKGROUND.

INDICATES INFORMATION OR A COMPANY POLICY THAT RELATES

DIRECTLY OR INDIRECTLY TO THE SAFETY OF PERSONNEL OR PROTECTION OF PROPERTY.

b 3121655

THIS PRODUCT MUST COMPLY WITH ALL SAFETY RELATED BULLETINS. CONTACT JLG INDUSTRIES, INC. OR THE LOCAL AUTHORIZED

JLG REPRESENTATIVE FOR INFORMATION REGARDING SAFETYRELATED BULLETINS WHICH MAY HAVE BEEN ISSUED FOR THIS

PRODUCT.

JLG INDUSTRIES, INC. SENDS SAFETY RELATED BULLETINS TO THE

OWNER OF RECORD OF THIS MACHINE. CONTACT JLG INDUSTRIES,

INC. TO ENSURE THAT THE CURRENT OWNER RECORDS ARE UPDATED

AND ACCURATE.

For:

• Accident Reporting

•Product Safety Publications

• Current Owner

Updates

• Questions Regarding

Product Safety

• Standards and Regulations Compliance Information

• Questions Regarding Special Product Applications

• Questions Regarding

Product Modifications

Contact:

Product Safety and Reliability Department

JLG Industries, Inc.

13224 Fountainhead Plaza

Hagerstown, MD 21742

FOREWORD

JLG INDUSTRIES, INC. MUST BE NOTIFIED IMMEDIATELY IN ALL

INSTANCES WHERE JLG PRODUCTS HAVE BEEN INVOLVED IN AN ACCIDENT INVOLVING BODILY INJURY OR DEATH OF PERSONNEL OR

or Your Local JLG Office

(See addresses on manual rear cover)

In USA:

WHEN SUBSTANTIAL DAMAGE HAS OCCURRED TO PERSONAL PROPERTY OR THE JLG PRODUCT.

Toll Free: 877-JLG-SAFE (877-554-7233)

Outside USA:

3121655 c

Phone: 240-420-2661

E-mail: ProductSafety@JLG.com

FOREWORD

Original Issue - A . . . . . . . . . . . . . . . December 1, 2014

Manual Revised - B . . . . . . . . . . . . . July 22, 2015

Manual Revised - C . . . . . . . . . . . . . March 7, 2016

Manual Revised - D . . . . . . . . . . . . .October 10, 2016

Manual Revised - E . . . . . . . . . . . . . June 19, 2017

Manual Revised - F . . . . . . . . . . . . . October 13, 2017

Manual Revised - G . . . . . . . . . . . . . December 18, 2017

Manual Revised - H . . . . . . . . . . . . .July 20, 2018

REVISION LOG

d 3121655

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

SECTION - 1 - SAFETY PRECAUTIONS

1.1 GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 PRE-OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Operator Training and Knowledge . . . . . . . . . . . 1-2

Workplace Inspection . . . . . . . . . . . . . . . . . . . . . . . 1-2

Machine Inspection . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Trip and Fall Hazards . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Electrocution Hazards . . . . . . . . . . . . . . . . . . . . . . . 1-6

Tipping Hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Crushing and Collision Hazards . . . . . . . . . . . . . . 1-9

1.4 TOWING, LIFTING, AND HAULING . . . . . . . . . . . . . .1-11

1.5 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Maintenance Hazards . . . . . . . . . . . . . . . . . . . . . . 1-11

Battery Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

SECTION - 2 - USER RESPONSIBILITIES, MACHINE PREPARATION & INSPECTION

2.1 PERSONNEL TRAINING. . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Operator Training . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Training Supervision . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Operator Responsibility . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 PREPARATION, INSPECTION, AND

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Pre-Start Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Function Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Walk-Around Inspection . . . . . . . . . . . . . . . . . . . . . 2-6

SECTION - 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

3.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.3 OPERATING CHARACTERISTICS AND

LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Placards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.4 PLATFORM LOADING . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.5 BATTERY CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Battery Charger Fault Codes . . . . . . . . . . . . . . . . . 3-5

3.6 MDI (MULTIFUNCTION DIGITAL INDICATOR) . . . . .3-6

MDI Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.7 GROUND CONTROL STATION. . . . . . . . . . . . . . . . . . . .3-8

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . 3-8

Manual Descent Control . . . . . . . . . . . . . . . . . . . . . 3-9

3121655 i

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

3.8 PLATFORM CONTROL STATION . . . . . . . . . . . . . . . 3-10

3.9 PLATFORM OPERATION . . . . . . . . . . . . . . . . . . . . . . . 3-14

Raising . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Lowering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Arm Guards (If Equipped) . . . . . . . . . . . . . . . . . . . 3-15

Steering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Driving Forward . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Driving in Reverse . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.10 PLATFORM DECK EXTENSION . . . . . . . . . . . . . . . . . 3-17

3.11 PLATFORM RAILS FOLD-DOWN PROCEDURE . . . 3-18

3.12 PARKING AND STOWING . . . . . . . . . . . . . . . . . . . . . . 3-20

3.13 TIE DOWN/LIFT LUGS . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3.14 LIFTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3.15 TOWING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Remote Electric Brake Release. . . . . . . . . . . . . . . 3-24

Push Button Electric Brake Release . . . . . . . . . . 3-24

Mechanical Brake Release. . . . . . . . . . . . . . . . . . . 3-25

SECTION - 4 - EMERGENCY PROCEDURES

4.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Emergency Stop Switch. . . . . . . . . . . . . . . . . . . . . . 4-1

Manual Descent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 EMERGENCY OPERATION . . . . . . . . . . . . . . . . . . . . . . .4-2

Operator Unable to Control Machine . . . . . . . . . 4-2

Platform Caught Overhead . . . . . . . . . . . . . . . . . . . 4-3

Righting of Tipped Machine . . . . . . . . . . . . . . . . . . 4-3

Post-Incident Inspection . . . . . . . . . . . . . . . . . . . . . 4-3

4.3 INCIDENT NOTIFICATION . . . . . . . . . . . . . . . . . . . . . . . 4-3

SECTION - 5 - ACCESSORIES

5.1 1/2 AIRLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.2 ANTI-VANDALISM PACKAGE . . . . . . . . . . . . . . . . . . . . 5-4

5.3 ELECTRICIAN’S TREE. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Preparation and Inspection. . . . . . . . . . . . . . . . . . . 5-5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.4 ELECTRICIAN’S PACKAGE . . . . . . . . . . . . . . . . . . . . . . . 5-6

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Preparation and Inspection. . . . . . . . . . . . . . . . . . . 5-6

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.5 PANEL CARRIER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Preparation and Inspection. . . . . . . . . . . . . . . . . . . 5-8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.6 PIPE RACKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Preparation and Inspection. . . . . . . . . . . . . . . . . 5-10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

ii 3121655

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

5.7 PLANT PACKAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Preparation and Inspection . . . . . . . . . . . . . . . . . 5-11

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.8 PLATFORM BOX COVER . . . . . . . . . . . . . . . . . . . . . . . .5-12

5.9 PLATFORM BOX HANGER . . . . . . . . . . . . . . . . . . . . . .5-12

5.10 PLATFORM RAIL PADDING . . . . . . . . . . . . . . . . . . . . .5-13

Limit Switch Operation . . . . . . . . . . . . . . . . . . . . . 5-13

5.11 PLATFORM WORKLIGHTS . . . . . . . . . . . . . . . . . . . . . .5-14

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.12 PLUMBER’S PACKAGE. . . . . . . . . . . . . . . . . . . . . . . . . .5-15

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Preparation and Inspection . . . . . . . . . . . . . . . . . 5-15

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.13 QUIKWELDER™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Preparation and Inspection . . . . . . . . . . . . . . . . . 5-17

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.14 VISE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Preparation and Inspection . . . . . . . . . . . . . . . . . 5-19

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.15 WORKSTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Preparation and Inspection . . . . . . . . . . . . . . . . . 5-20

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

SECTION - 6 - GENERAL SPECIFICATIONS AND OPERATOR

MAINTENANCE

6.16 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.17 OPERATING SPECIFICATIONS . . . . . . . . . . . . . . . . . . . .6-2

Dimensional Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Battery Charger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Battery Charger/AC Inverter. . . . . . . . . . . . . . . . . . 6-8

Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Critical Stability Weights . . . . . . . . . . . . . . . . . . . . 6-10

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6.18 OPERATOR MAINTENANCE . . . . . . . . . . . . . . . . . . . . 6-12

Scissor Arms - Safety Prop. . . . . . . . . . . . . . . . . . . 6-13

Oil Check Procedure (1) . . . . . . . . . . . . . . . . . . . . . 6-13

Lower (2) & Upper Slide Pads (3). . . . . . . . . . . . . 6-15

6.19 TIRES AND WHEELS . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Tire Wear and Damage. . . . . . . . . . . . . . . . . . . . . . 6-17

Wheel and Tire Replacement. . . . . . . . . . . . . . . . 6-17

Wheel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

6.20 SUPPLEMENTAL INFORMATION . . . . . . . . . . . . . . . 6-18

6.21 DECAL INSTALLATIONS . . . . . . . . . . . . . . . . . . . . . . . 6-19

6.22 DIAGNOSTIC TROUBLE CODES (DTC) . . . . . . . . . . 6-29

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

3121655 iii

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

0-0 Help Comments . . . . . . . . . . . . . . . . . . . . . . . . 6-29

2-1 Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

2-2 Platform Controls . . . . . . . . . . . . . . . . . . . . . . . 6-32

2-3 Ground Controls . . . . . . . . . . . . . . . . . . . . . . . . 6-33

2-5 Function Prevented . . . . . . . . . . . . . . . . . . . . . 6-34

3-1 Line Contactor Open Circuit . . . . . . . . . . . . . 6-36

3-2 Line Contactor Short Circuit . . . . . . . . . . . . . 6-36

3-3 Ground Output Driver. . . . . . . . . . . . . . . . . . . 6-37

4-2 Thermal Limit (SOA). . . . . . . . . . . . . . . . . . . . . 6-39

4-4 Battery Supply . . . . . . . . . . . . . . . . . . . . . . . . . . 6-40

6-6 Communication . . . . . . . . . . . . . . . . . . . . . . . . 6-41

6-7 Accessory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-41

7-7 Electric Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-42

8-1 Tilt Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-43

8-2 Platform Load Sense . . . . . . . . . . . . . . . . . . . . 6-44

9-9 Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-45

SECTION - 7 - INSPECTION AND REPAIR LOG

iv 3121655

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

LIST OF FIGURES

2-1. Switch Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

3-1. Location of Machine Controls (All Models). . . . . . . 3-3

3-2. Ground Control Station Panel. . . . . . . . . . . . . . . . . . . 3-8

3-3. Platform Control Station . . . . . . . . . . . . . . . . . . . . . . .3-10

3-5. Grade and Sideslope - Driving - Platform

Stowed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

3-6. Platform Deck Extension (All Models) . . . . . . . . . .3-17

3-7. Platform Rails - Fold Down Sequence . . . . . . . . . .3-19

3-8. Securing Control Station to Platform . . . . . . . . . . .3-20

3-9. Lifting and Tie Down Diagram . . . . . . . . . . . . . . . . .3-22

3-10. Lifting and Tie Down Chart . . . . . . . . . . . . . . . . . . . .3-23

3-11. Manual Disengage . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

6-1. Lubrication Diagram . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

6-2. Lower Slide Pad Channel . . . . . . . . . . . . . . . . . . . . . .6-15

6-3. Upper Slide Pad Channel . . . . . . . . . . . . . . . . . . . . . .6-16

6-4. Decal Location - 1930ES- Sheet 1. . . . . . . . . . . . . . .6-19

6-5. Decal Location - 1930ES - Sheet 2 . . . . . . . . . . . . . .6-20

6-6. Decal Location - 2032ES & 2632ES - Sheet 1 . . . .6-21

6-7. Decal Location - 2032ES & 2632ES - Sheet 2 . . . .6-22

6-8. Decal Location - 2646ES & 3246ES - Sheet 1 . . . .6-23

6-9. Decal Location - 2646ES & 3246ES - Sheet 2 . . . .6-24

LIST OF TABLES

1-1 Minimum Approach Distances (M.A.D.) . . . . . . . . . 1-7

1-2 Beaufort Scale (For Reference Only) . . . . . . . . . . . . 1-8

2-1 Inspection and Maintenance Table . . . . . . . . . . . . . 2-2

2-2 Tilt Activation vs. Height . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-3 High Drive Speed Cutout Height . . . . . . . . . . . . . . . 2-5

3-1 Battery Charger Flash Codes . . . . . . . . . . . . . . . . . . . 3-5

5-1 Accessories (All Models). . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2 Options/Accessories Relationship Table

(All Models). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

6-1 Operating Specifications . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-2 Platform Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6-3 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-4 Battery Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6-5 Battery Charger Specifications. . . . . . . . . . . . . . . . . . 6-7

6-6 Battery Charger/AC Inverter Specifications. . . . . . 6-8

6-7 Fluid Capacities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6-8 Tire Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6-9 Critical Stability Weights . . . . . . . . . . . . . . . . . . . . . . 6-10

6-10 Hydraulic Oil Specifications . . . . . . . . . . . . . . . . . . . 6-11

6-11 Wheel Torque Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6-12 Decal Location Legend. . . . . . . . . . . . . . . . . . . . . . . . 6-25

7-1 Inspection and Repair Log. . . . . . . . . . . . . . . . . . . . . . 7-1

3121655 v

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

This page left blank intentionally

vi 3121655

SECTION 1. SAFETY PRECAUTIONS

SECTION 1 - SAFETY PRECAUTIONS

1.1 GENERAL

This section outlines the necessary precautions for proper

and safe machine usage and maintenance. In order to promote proper machine usage, it is mandatory that a daily

routine is established based on the content of this manual.

A maintenance program, using the information provided

in this manual and the Service and Maintenance Manual,

must also be established by a qualified person and must

be followed to ensure that the machine is safe to operate.

The owner/user/operator/lessor/lessee of the machine

must not accept operating responsibility until this manual

has been read, training is accomplished, and operation of

the machine has been completed under the supervision of

an experienced and qualified operator.

These sections contain the responsibilities of the owner,

user, operator, lessor, and lessee concerning safety, training, inspection, maintenance, application, and operation.If

there are any questions with regard to safety, training,

inspection, maintenance, application, and operation,

please contact JLG Industries, Inc. (“JLG”).

FAILURE TO COMPLY WITH THE SAFETY PRECAUTIONS LISTED IN THIS MANUAL COULD RESULT IN MACHINE DAMAGE, PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

3121655 1-1

SECTION 1 - SAFETY PRECAUTIONS

1.2 PRE-OPERATION

Operator Training and Knowledge

• The Operation and Safety Manual must be read and understood in its entirety before operating the machine. For clarification, questions, or additional information regarding any

portions of this manual, contact JLG Industries, Inc.

• An operator must not accept operating responsibilities

until adequate training has been given by competent and

authorized persons.

• Allow only those authorized and qualified personnel to

operate the machine who have demonstrated that they

understand the safe and proper operation and maintenance of the unit.

• Read, understand, and obey all DANGERS, WARNINGS, CAUTIONS, and operating instructions on the machine and in

this manual.

• Ensure that the machine is to be used in a manner which is

within the scope of its intended application as determined

by JLG.

• All operating personnel must be familiar with the emergency controls and emergency operation of the machine as

specified in this manual.

• Read, understand, and obey all applicable employer, local,

and governmental regulations as they pertain to your utilization and application of the machine.

Workplace Inspection

• Precautions to avoid all hazards in the work area must be

taken by the user before and during operation of the

machine.

• Do not operate or raise the platform from a position on

trucks, trailers, railway cars, floating vessels, scaffolds or

other equipment unless the application is approved in writing by JLG.

• Before operation, check work area for overhead hazards

such as electric lines, bridge cranes, and other potential

overhead obstructions.

• Check floor surfaces for holes, bumps, drop-offs, obstructions, debris, concealed holes, and other potential hazards.

1-2 3121655

SECTION 1 - SAFETY PRECAUTIONS

• Check the work area for hazardous locations. Do not operate the machine in hazardous environments unless

approved for that purpose by JLG.

• Ensure that the ground conditions are adequate to support

the maximum tire load indicated on the tire load decals

located on the chassis adjacent to each wheel.

• This machine can be operated in nominal ambient temperatures of 0

mize operation outside of this temperature range.

o

F to 104o F (-20o C to 40o C). Consult JLG to opti-

Machine Inspection

• Do not operate this machine until the inspections and functional checks have been performed as specified in Section 2

of this manual.

• Do not operate this machine until it has been serviced and

maintained according to the maintenance and inspection

requirements as specified in the machine’s Service and

Maintenance Manual.

• Ensure all safety devices are operating properly. Modification of these devices is a safety violation.

MODIFICATION OR ALTERATION OF AN AERIAL WORK PLATFORM SHALL BE

MADE ONLY WITH PRIOR WRITTEN PERMISSION FROM THE MANUFACTURER.

• Do not operate any machine on which the safety or instruction placards or decals are missing or illegible.

• Check the machine for modifications to original components. Ensure that any modifications have been approved

by JLG.

• Avoid accumulation of debris on platform deck. Keep mud,

oil, grease, and other slippery substances from footwear

and platform deck.

1.3 OPERATION

General

• Machine operation requires your full attention. Bring the

machine to a full stop before using any device, i.e. cell

phones, two-way radios, etc. that will distract your attention

from safely operating the machine.

• Do not use the machine for any purpose other than positioning personnel, their tools, and equipment.

• Before operation, the user must be familiar with the

machine capabilities and operating characteristics of all

functions.

• Never operate a malfunctioning machine. If a malfunction

occurs, shut down the machine. Remove the unit from service and notify the proper authorities.

3121655 1-3

SECTION 1 - SAFETY PRECAUTIONS

• Do not remove, modify, or disable any safety devices.

• Never slam a control switch or lever through neutral to an

opposite direction. Always return switch to neutral and stop

before moving the switch to the next function. Operate

controls with slow and even pressure.

• Do not allow personnel to tamper with or operate the

machine from the ground with personnel in the platform,

except in an emergency.

• Do not carry materials directly on platform railing unless

approved by JLG.

• When two or more persons are in the platform, the operator

shall be responsible for all machine operations.

• Always ensure that power tools are properly stowed and

never left hanging by their cord from the platform work

area.

• Do not assist a stuck or disabled machine by pushing or

pulling except by pulling at the chassis tie-down lugs.

• Fully lower platform and shut off all power before leaving

machine.

• Remove all rings, watches, and jewelry when operating

machine. Do not wear loose fitting clothing or long hair

unrestrained which may become caught or entangled in

equipment.

• Persons under the influence of drugs or alcohol or who are

subject to seizures, dizziness or loss of physical control must

not operate this machine.

• The following information is provided in accordance with

the requirements of the European Machinery Directive

2006/42/EC and is only applicable to CE machines.

For electric powered machines, the equivalent continuous

A-Weighted sound pressure level at the work platform is

less than 70dB(A).

For combustion engine powered machines, guaranteed

Sound Power Level (LWA) per European Directive 2000/ 14/

EC (Noise Emission in the Environment by Equipment for

Use Outdoors) based on test methods in accordance with

Annex III, Part B, Method 1 and 0 of the directive, is 109 dB.

The vibration total value to which the hand-arm system is

subjected does not exceed 2,5 m/s2. The highest root mean

square value of weighted acceleration to which the whole

body is subjected does not exceed 0,5 m/s2.

1-4 3121655

SECTION 1 - SAFETY PRECAUTIONS

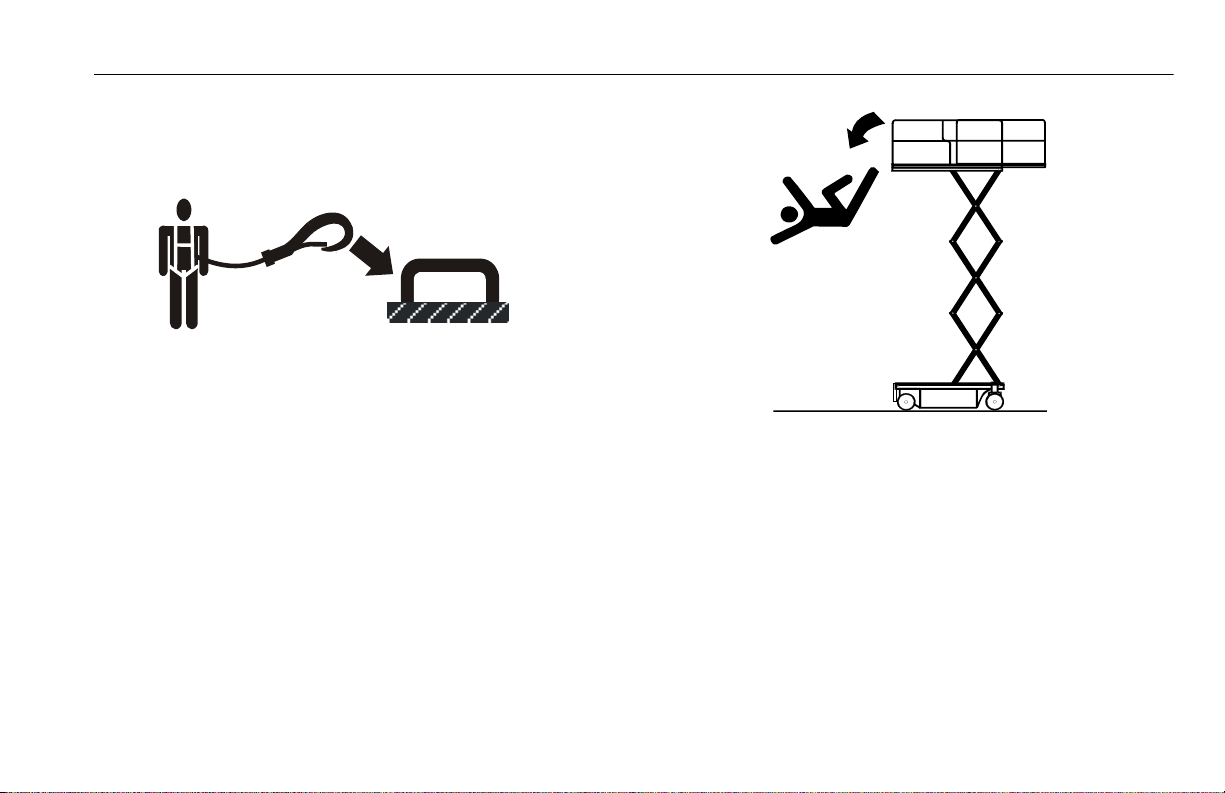

Trip and Fall Hazards

• Prior to operation, ensure all gates and rails are fastened

and secured in their proper position.

• JLG Industries, Inc. recommends that all persons in the platform wear a full body harness with a lanyard attached to an

authorized lanyard anchorage point while operating this

machine. For further information regarding fall protection

requirements on JLG products, contact JLG Industries, Inc.

• Identify the designated lanyard anchorage point(s) at the

platform and securely attach the lanyard. Attach only one

(1) lanyard per lanyard anchorage point.

• Enter and exit only through gate area. Use extreme caution

when entering or leaving platform. Ensure that the platform

assembly is fully lowered. Face the machine when entering

or leaving the platform. Always maintain “three point contact” with the machine, using two hands and one foot or

two feet and one hand at all times during entry and exit.

.

• Keep both feet firmly positioned on the platform floor at all

times. Never position ladders, boxes, steps, planks, or similar items on unit to provide additional reach for any purpose.

• Never use the scissor arm assembly to gain access to or

leave the platform.

• Keep oil, mud, and slippery substances cleaned from footwear and the platform floor.

3121655 1-5

SECTION 1 - SAFETY PRECAUTIONS

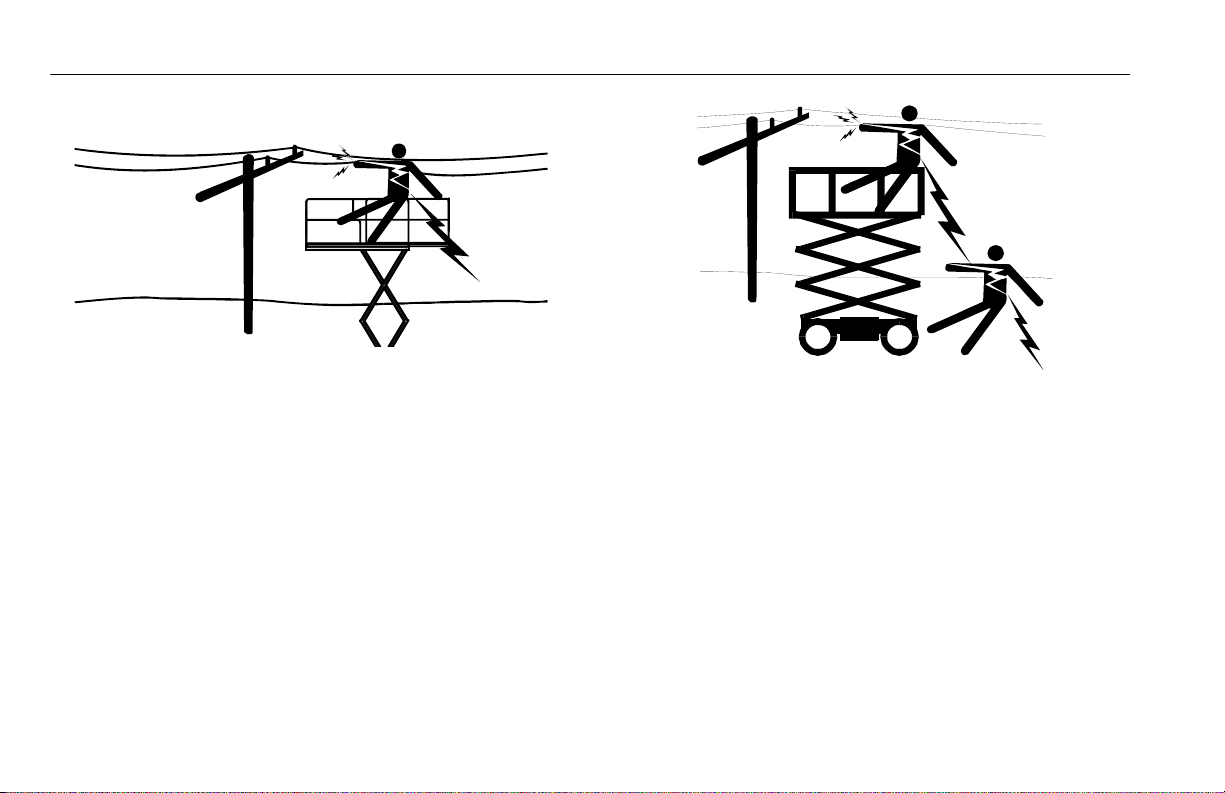

Electrocution Hazards

• This machine is not insulated and does not provide protection from contact or proximity to electrical current.

• Maintain distance from electrical lines, apparatus, or any

energized (exposed or insulated) parts according to the

Minimum Approach Distance (MAD) as shown in Table 1-1.

• Allow for machine movement and electrical line swaying.

• Maintain a clearance of at least 10 ft (3 m) between any part

of the machine and its occupants, their tools, and their

equipment from any electrical line or apparatus carrying up

to 50,000 volts. One foot additional clearance is required for

every additional 30,000 volts or less.

1-6 3121655

• The minimum approach distance may be reduced if insulat-

ing barriers are installed to prevent contact, and the barriers are rated for the voltage of the line being guarded.

These barriers shall not be part of (or attached to) the

machine. The minimum approach distance shall be reduced

to a distance within the designed working dimensions of

the insulating barrier. This determination shall be made by

a qualified person in accordance with the employer, local,

or governmental requirements for work practices near

energized equipment.

DO NOT MANEUVER MACHINE OR PERSONNEL INSIDE PROHIBITED ZONE (MAD).

ASSUME ALL ELECTRICAL PARTS AND WIRING ARE ENERGIZED UNLESS KNOWN OTHERWISE.

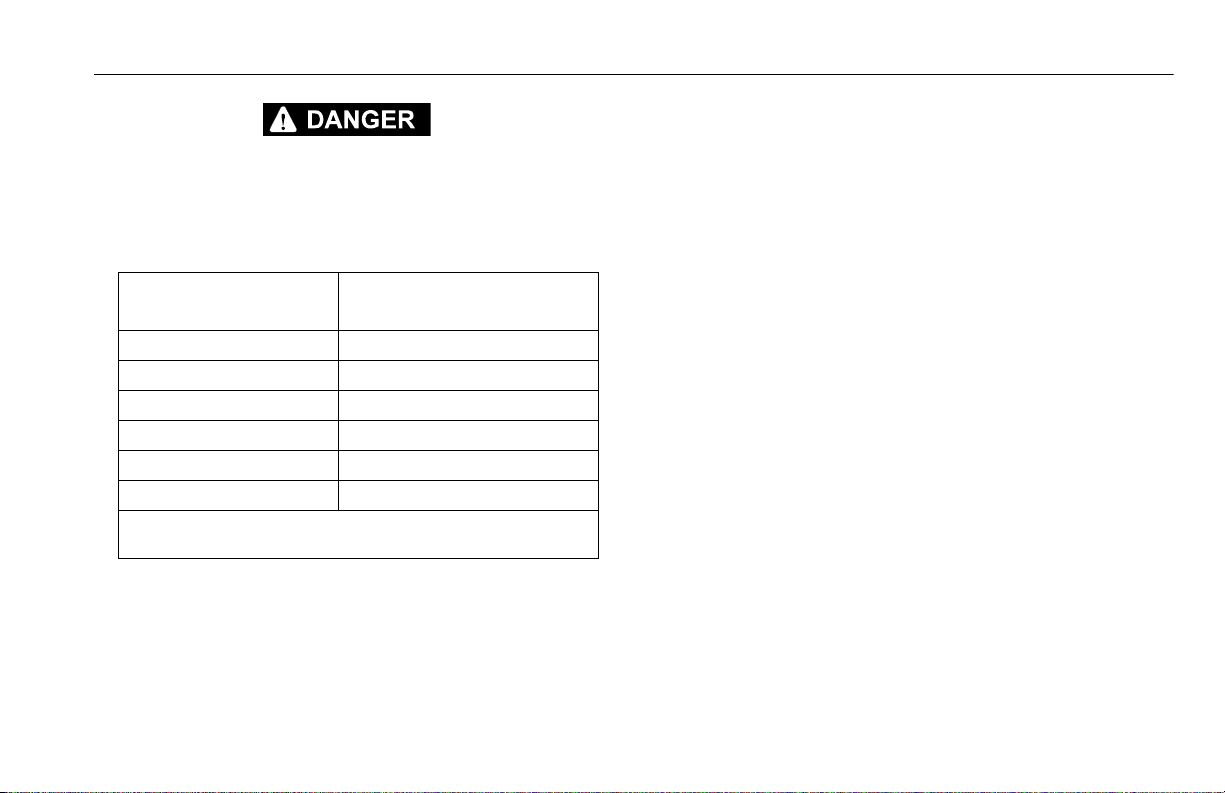

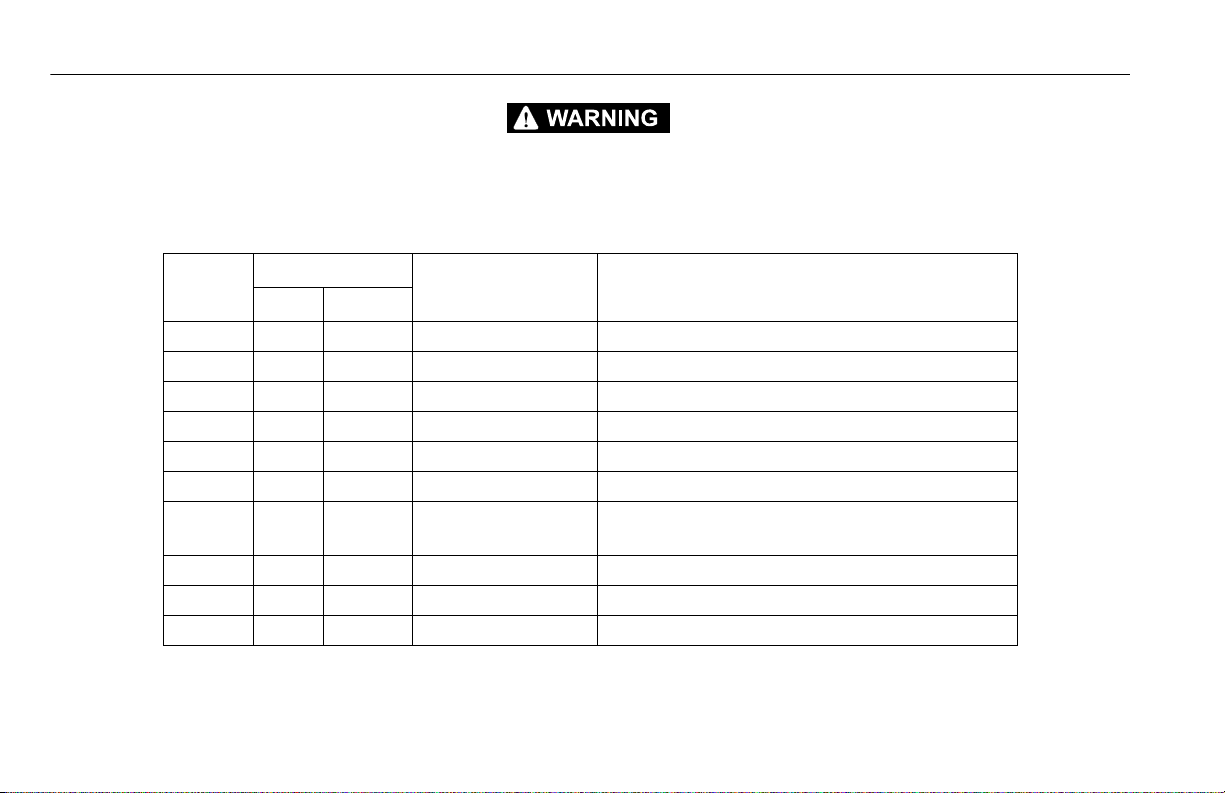

Table 1-1. Minimum Approach Distances (M.A.D.)

VOLTAGE RANGE

(Phase to Phase)

MINIMUM APPROACH DISTANCE

in Feet (Meters)

0 to 50 KV 10 (3)

Over 50KV to 200 KV 15 (5)

Over 200 KV to 350 KV 20 (6)

Over 350 KV to 500 KV 25 (8)

Over 500 KV to 750 KV 35 (11)

Over 750 KV to 1000 KV 45 (14)

NOTE: This requirement shall apply except where employer, local or govern-

mental regulations are more stringent.

SECTION 1 - SAFETY PRECAUTIONS

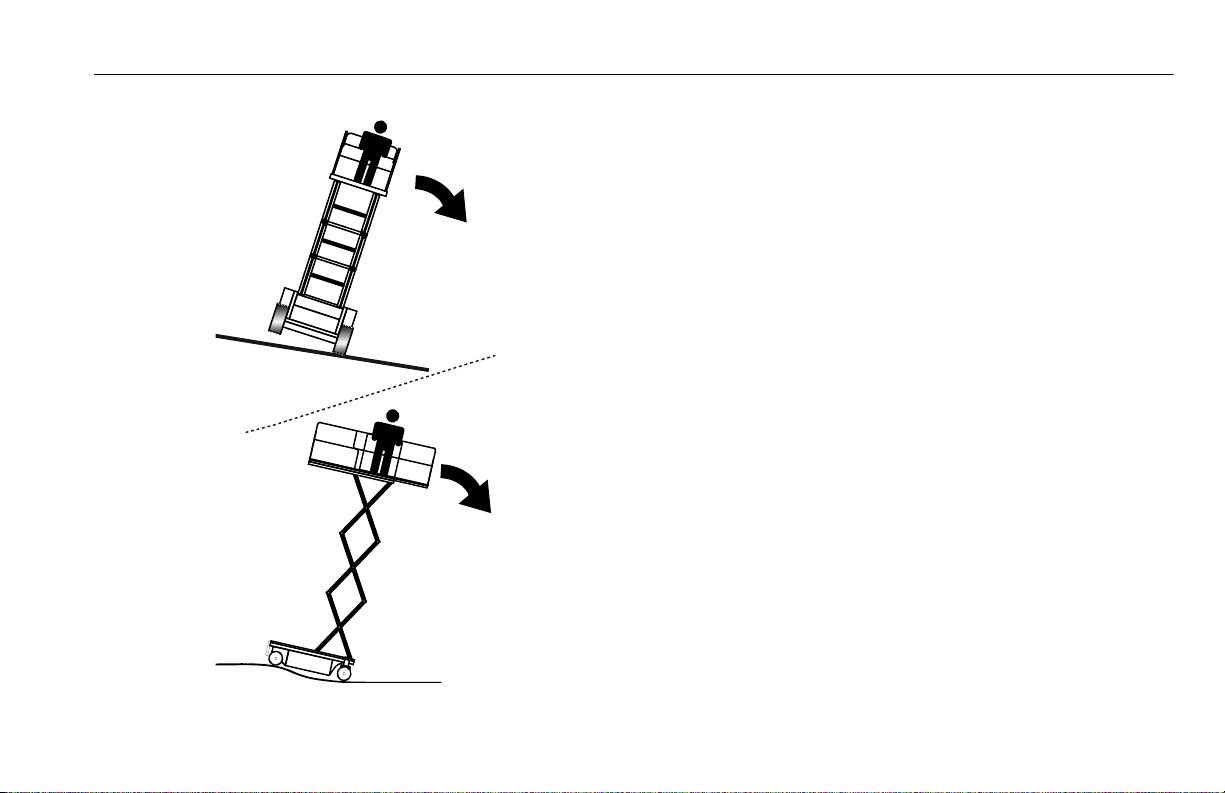

Tipping Hazards

• Ensure that the ground conditions are adequate to support

the maximum tire load indicated on the tire load decals

located on the chassis adjacent to each wheel. Do not travel

on unsupported surfaces.

• The user must be familiar with the driving surface before

driving. Do not exceed the allowable sideslope and grade

while driving.

• Do not elevate platform or drive with platform elevated

while on or near a sloping, uneven, or soft surface. Ensure

machine is positioned on a firm, level and smooth surface

before elevating platform or driving with the platform in

the elevated position.

• Before driving on floors, bridges, trucks, and other surfaces,

check allowable capacity of the surfaces.

• Never exceed the maximum work load as specified on the

platform. Keep all loads within the confines of the platform,

unless authorized by JLG.

• Keep the chassis of the machine a minimum of 2 ft. (0.6m)

from holes, bumps, drop-offs, obstructions, debris, concealed holes, and other potential hazards at the ground

level.

• Do not operate the machine when wind conditions exceed

specifications shown in Section 6 or as shown on the capacity placard on the platform billboard.

3121655 1-7

SECTION 1 - SAFETY PRECAUTIONS

DO NOT OPERATE THE MACHINE WHEN WIND CONDITIONS EXCEED SPECIFICATIONS SHOWN IN SECTION 6 OR AS SHOWN ON THE CAPACITY PLACARD ON THE PLATFORM BILLBOARD.

Table 1-2. Beaufort Scale (For Reference Only)

BEAUFORT

NUMBER

WIND SPEED

DESCRIPTION LAND CONDITIONS

mph m/s

0 0 0-0.2 Calm Calm. Smoke rises vertically.

1 1-3 0.3-1.5 Light air Wind motion visible in smoke.

2 4-7 1.6-3.3 Light breeze Wind felt on exposed skin. Leaves rustle.

3 8-12 3.4-5.4 Gentle breeze Leaves and smaller twigs in constant motion.

4 13-18 5.5-7.9 Moderate breeze Dust and loose paper raised. Small branches begin to move.

5 19-24 8.0-10.7 Fresh breeze Smaller trees sway.

6 25-31 10.8-13.8 Strong breeze Large branches in motion. Flags waving near horizontal. Umbrella

use becomes difficult.

7 32-38 13.9-17.1 Near Gale/Moderate Gale Whole trees in motion. Effort needed to walk against the wind.

8 39-46 17.2-20.7 Fresh Gale Twigs broken from trees. Cars veer on road.

9 47-54 20.8-24.4 Strong Gale Light structure damage.

1-8 3121655

SECTION 1 - SAFETY PRECAUTIONS

• Never attempt to use the machine as a crane. Do not tie-off

machine to any adjacent structure. Never attach wire, cable,

or any similar items to platform.

• Do not cover the platform sides or carry large surface-area

items in the platform when operating outdoors. The addition of such items increases the exposed wind area of the

machine.

• Do not increase the platform size with unauthorized deck

extensions or attachments.

• If the scissor arm assembly or platform is caught so that one

or more wheels are off the ground, all persons must be

removed before attempting to free the machine. Use

cranes, forklift trucks, or other appropriate equipment to

stabilize machine and remove personnel.

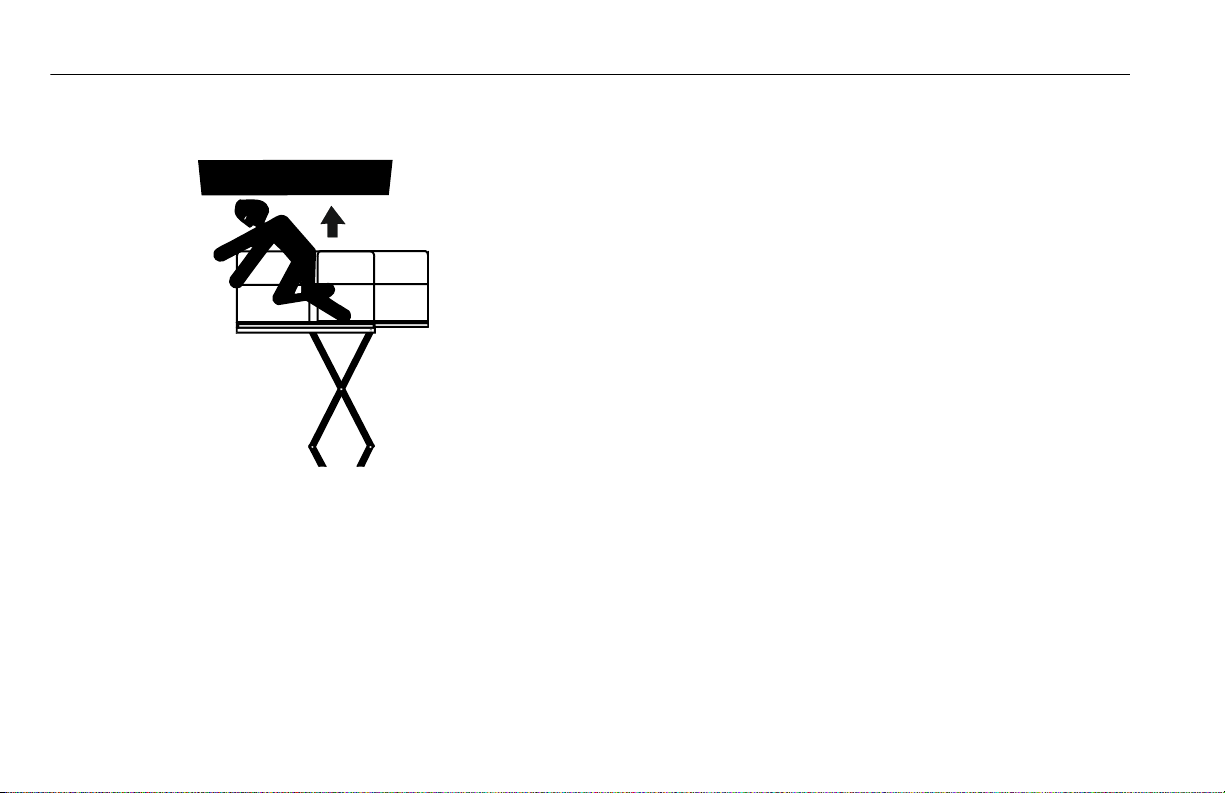

Crushing and Collision Hazards

• Approved head gear must be worn by all operating and

ground personnel.

• Keep hands and limbs out of the scissor arm assembly during operation and when elevated without safety prop

engaged.

• Watch for obstructions around machine and overhead

when driving. Check clearances above, on sides, and bottom of platform when lifting or lowering platform.

3121655 1-9

SECTION 1 - SAFETY PRECAUTIONS

• During operation, keep all body parts inside platform railing.

• Always post a lookout when driving in areas where vision is

obstructed.

• Keep non-operating personnel at least 6 ft (1.8 m) away

from machine during all operations.

• Under all travel conditions, the operator must limit travel

speed according to conditions of ground surface, congestion, visibility, slope, location of personnel, and other factors.

• Be aware of stopping distances in all drive speeds. When

driving in high speed, switch to low speed before stopping.

Travel grades in low speed only.

• Do not use high speed drive in restricted or close quarters

or when driving in reverse.

• Exercise extreme caution at all times to prevent obstacles

from striking or interfering with operating controls and persons in the platform.

• Ensure that operators of other overhead and floor level

machines are aware of the aerial work platform’s presence.

Disconnect power to overhead cranes. Barricade floor area

if necessary.

• Do not operate over ground personnel. Warn personnel not

to work, stand, or walk under a raised platform. Position

barricades on floor as necessary.

1-10 3121655

SECTION 1 - SAFETY PRECAUTIONS

1.4 TOWING, LIFTING, AND HAULING

• Never allow personnel in platform while towing, lifting, or

hauling.

• This machine should not be towed, except in the event of

emergency, malfunction, power failure, or loading/unloading. Refer to emergency towing procedures.

• Ensure platform is fully retracted and completely empty of

tools prior to towing, lifting or hauling.

• When lifting machine with a forklift, position forks only at

designated areas of the machine. Lift with a forklift of adequate capacity.

• Refer to Section 3 for lifting information.

1.5 MAINTENANCE

This sub-section contains general safety precautions which

must be observed during maintenance of this machine. Additional precautions to be observed during machine maintenance are inserted at the appropriate points in this manual

and in the Service and Maintenance Manual. It is of utmost

importance that maintenance personnel pay strict attention

to these precautions to avoid possible injury to personnel or

damage to the machine or property. A maintenance program

must be established by a qualified person and must be followed to ensure that the machine is safe.

Maintenance Hazards

• Shut off power to all controls and ensure that all moving

parts are secured from inadvertent motion prior to performing any adjustments or repairs.

• Never work under an elevated platform until it has been

fully lowered to the full down position, if possible, or otherwise supported and restrained from movement with appropriate safety props, blocking, or overhead supports.

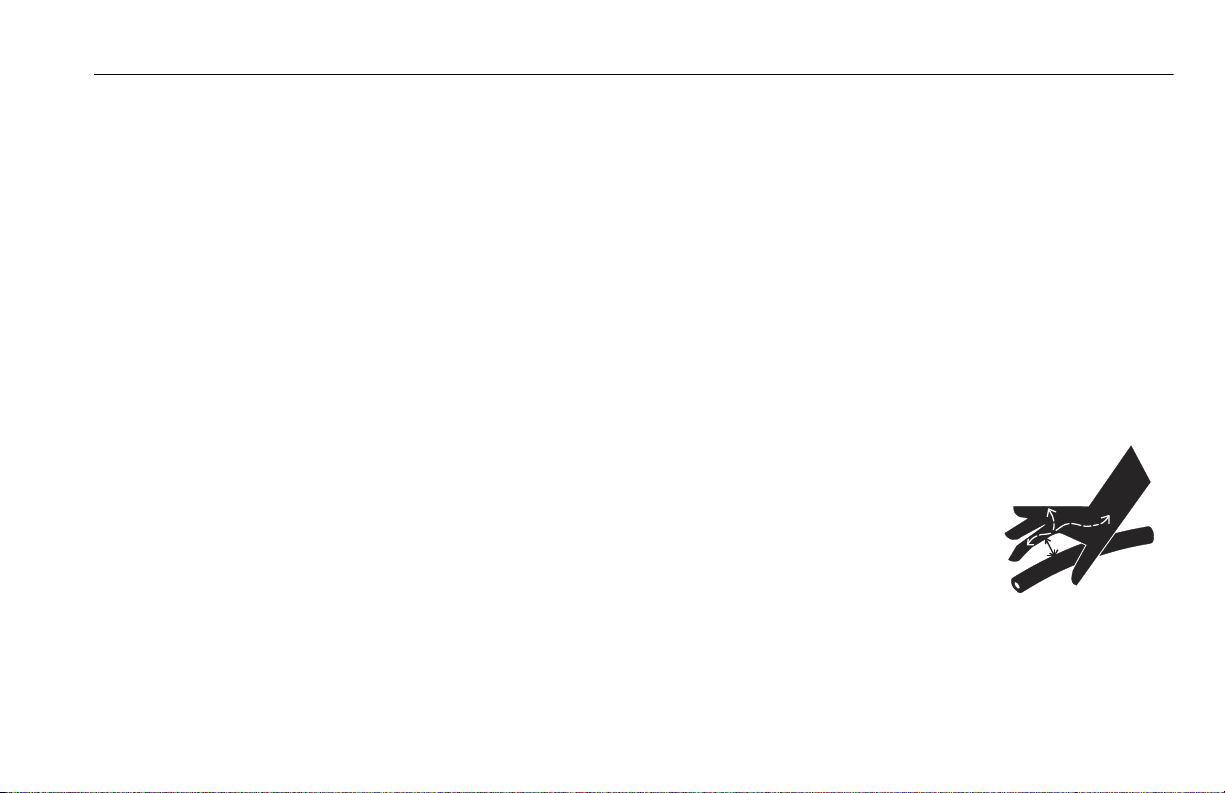

• DO NOT attempt to repair or tighten any hydraulic hoses or

fittings while the machine is powered on or when the

hydraulic system is under pressure.

• Always relieve hydraulic pressure

from all hydraulic circuits before

loosening or removing hydraulic

components.

• DO NOT use your hand to check for

leaks. Use a piece of cardboard or

paper to search for leaks. Wear

gloves to help protect hands from

spraying fluid.

• Ensure replacement parts or components are identical or

equivalent to original parts or components.

3121655 1-11

SECTION 1 - SAFETY PRECAUTIONS

• Never attempt to move heavy parts without the aid of a

mechanical device. Do not allow heavy objects to rest in an

unstable position. Ensure adequate support is provided

when raising components of the machine.

• Use only approved non-flammable cleaning solvents.

• Do not replace items critical to stability, such as batteries or

solid tires, with items of different weight or specification.

Do not modify unit in any way to affect stability.

• Reference the Service and Maintenance Manual for the

weights of critical stability items.

MODIFICATION OR ALTERATION OF AN AERIAL WORK PLATFORM SHALL BE

MADE ONLY WITH PRIOR WRITTEN PERMISSION FROM THE MANUFACTURER.

Battery Hazards

• Always disconnect batteries when servicing electrical components or when performing welding on the machine.

• Do not allow smoking, open flame, or sparks near battery

during charging or servicing.

• Do not contact tools or other metal objects across the battery terminals.

• Always wear hand, eye, and face protection when servicing

batteries. Ensure that battery acid does not come in contact

with skin or clothing.

BATTERY FLUID IS HIGHLY CORROSIVE. AVOID CONTACT WITH SKIN AND

CLOTHING AT ALL TIMES. IMMEDIATELY RINSE ANY CONTACTED AREA WITH

CLEAN WATER AND SEEK MEDICAL ATTENTION.

• Charge batteries only in a well ventilated area.

• Avoid overfilling the battery fluid level. Add distilled water

to batteries only after the batteries are fully charged.

1-12 3121655

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION & INSPECTION

SECTION 2. USER RESPONSIBILITIES, MACHINE PREPARATION & INSPECTION

2.1 PERSONNEL TRAINING

The aerial platform is a personnel handling device; so it is necessary that it be operated and maintained only by trained personnel.

Persons under the influence of drugs or alcohol or who are

subject to seizures, dizziness or loss of physical control must

not operate this machine.

Operator Training

Operator training must cover:

1. Use and limitations of the controls in the platform and

at the ground, emergency controls and safety systems.

2. Control labels, instructions, and warnings on the

machine.

3. Rules of the employer and government regulations.

4. Use of approved fall protection device.

5. Enough knowledge of the mechanical operation of

the machine to recognize a malfunction or potential

malfunction.

6. The safest means to operate the machine where overhead obstructions, other moving equipment, and

obstacles, depressions, holes, drop-offs.

7. Means to avoid the hazards of unprotected electrical

conductors.

8. Specific job requirements or machine application.

Training Supervision

Training must be done under the supervision of a qualified

person in an open area free of obstructions until the trainee

has developed the ability to safely control and operate the

machine.

Operator Responsibility

The operator must be instructed that he/she has the responsibility and authority to shut down the machine in case of a

malfunction or other unsafe condition of either the machine

or the job site.

3121655 2-1

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION & INSPECTION

NOTICE

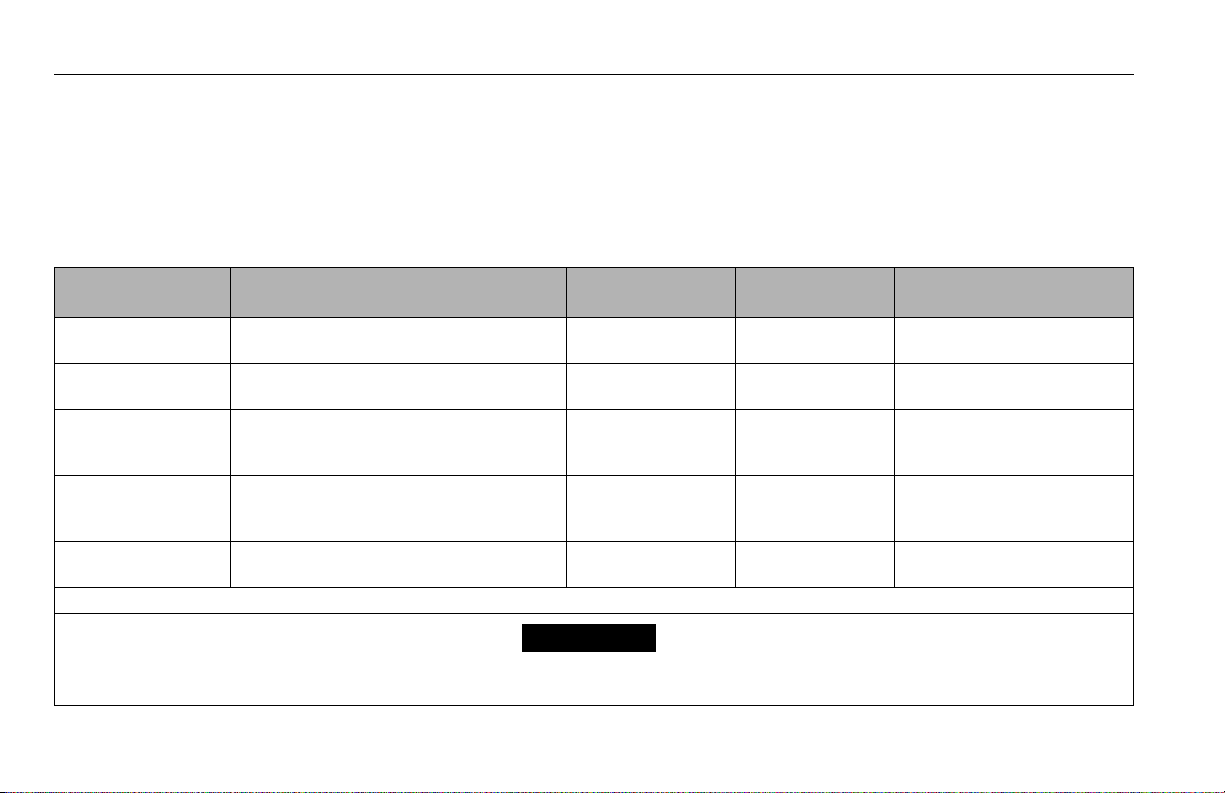

2.2 PREPARATION, INSPECTION, AND MAINTENANCE

The table below covers the periodic machine inspections and maintenance recommended by JLG Industries, Inc. Consult local regulations for further requirements for aerial work platforms. The frequency of inspections and maintenance must be increased as

necessary when the machine is used in a harsh or hostile environment, if the machine is used with increased frequency, or if the

machine is used in a severe manner.

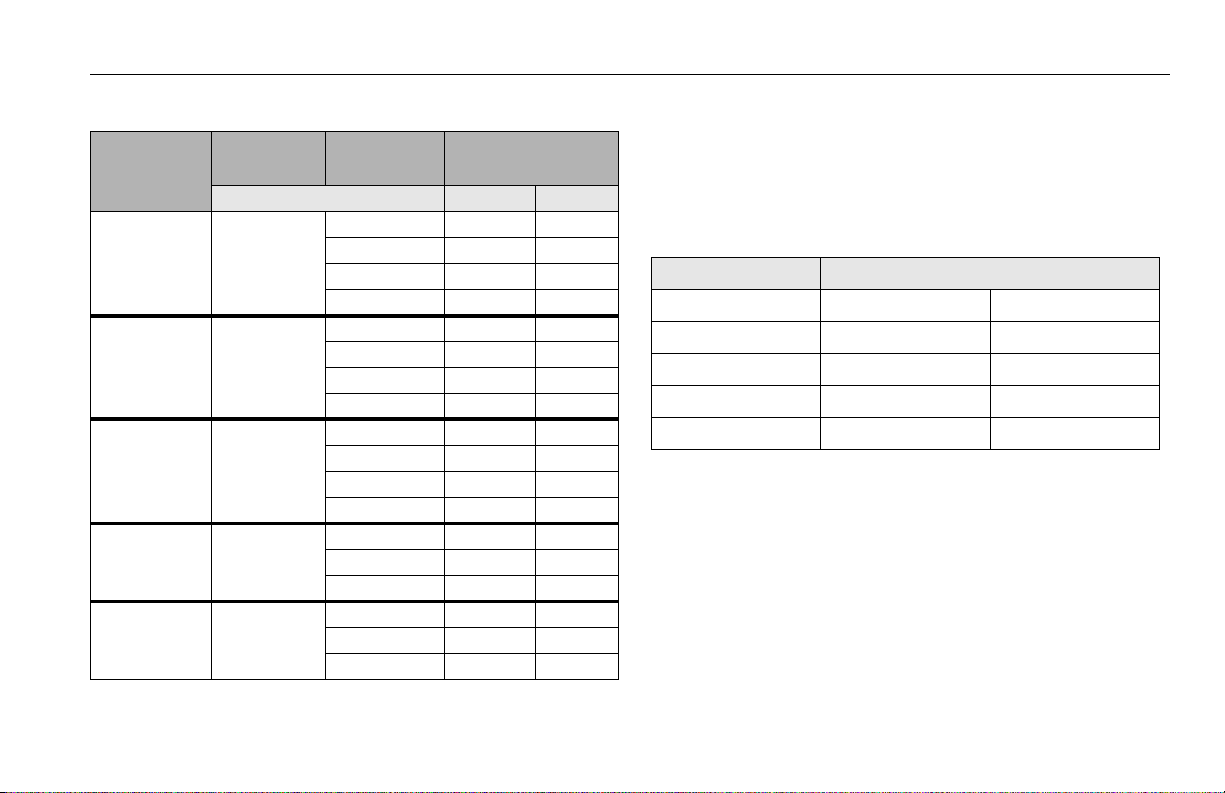

Table 2-1. Inspection and Maintenance Table

Type Frequency

Pre-Star t Inspec tion

Pre-Deli very Inspe ction

(see note below)

Frequent Inspec tion

Annual Machine

Inspection

(see note below)

Preventative Maintenance

NOTE: Inspection forms are available from JLG. Use the Ser vice and Maintenance Manual to perform inspections.

JLG INDUSTRIES, INC. RECOGNIZES A FACTORY-TRAINED SERVICE TECHNICIAN AS A PERSON WHO HAS SUCCESSFULLY COMPLETED THE JLG SERVICE TRAINING SCHOOL FOR THE SPECIFIC JLG PRODUCT MODEL.

2-2 3121655

Before using each day; or

whenever there’s an Operator change.

Before each sale, lease, or rental delivery. Owner, Dealer, or User Qualified JLG Mechanic

In service for 3 months or 150 hours, whichever comes

first; or Out of service for a period of more than 3

months; or Purchased used.

Annually, no later than 13 months from the date of

prior inspection.

At intervals as specified in the Service and Maintenance Manual.

Primary

Responsibility

User or Operator User or Operator Operation and Safety Manual

Owner, Dealer, or User Qualified JLG Mechanic

Owner, Dealer, or User

Owner, Dealer, or User Qualified JLG Mechanic Ser vice and Maintenance Manual

Service

Qualification

Fac to ry Trai ne d

Service Technician

(Recommended)

Reference

Service and Maintenance Manual and

applicable JLG inspection form

Service and Maintenance Manual and

applicable JLG inspection form

Service and Maintenance Manual and

applicable JLG inspection form

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION & INSPECTION

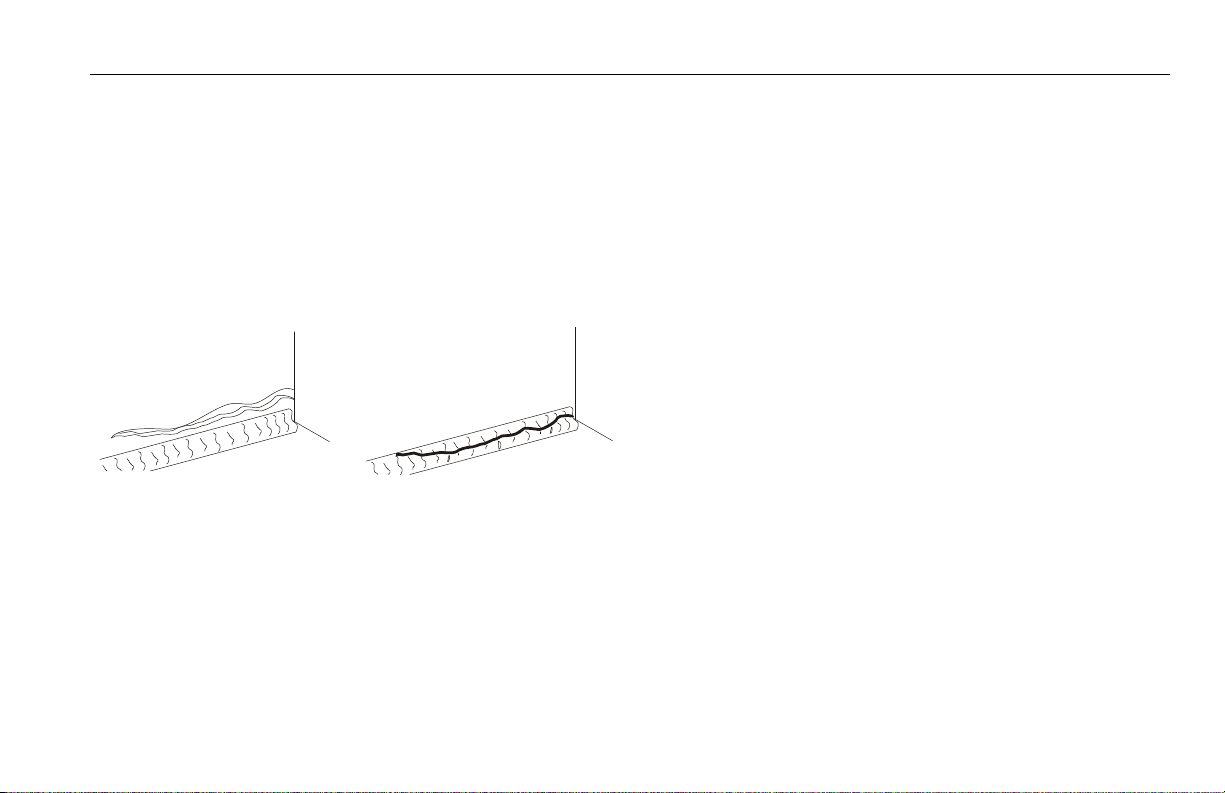

Parent Meta l Crac k

Wel d Cra ck

Pre-Start Inspection

The Pre-Start Inspection should include each of the following:

1. Cleanliness – Check all surfaces for leakage (oil, fuel,

or battery fluid) or foreign objects. Report any leakage

to the proper maintenance personnel.

2. Structure – Inspect the machine structure for dents,

damage, weld or parent metal cracks or other discrepancies.

3. Decals and Placards – Check all for cleanliness and

legibility. Make sure none of the decals and placards

are missing. Make sure all illegible decals and placards

are cleaned or replaced.

4. Operation and Safety Manuals – Make sure a copy of

the Operator and Safety Manual, AEM Safety Manual

(ANSI markets only), and ANSI Manual of Responsibili-

ties (ANSI markets only) is enclosed in the weather

resistant storage container.

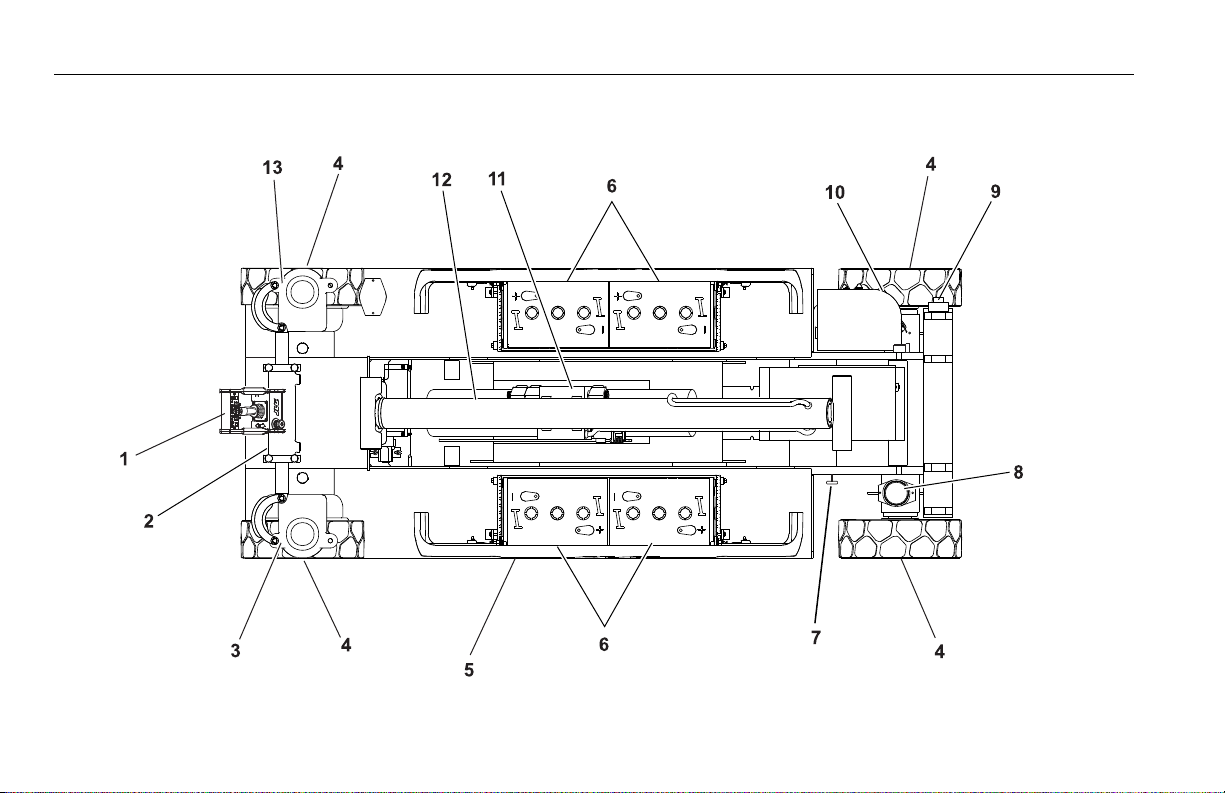

5. Walk-Around Inspection – Refer to Figure 2-1.

6. Battery – Charge as required.

7. Fuel (Combustion Engine Powered Machines) – Add

the proper fuel as necessary.

8. Engine Oil Supply (If equipped) – Ensure the engine

oil level is at the full mark on the dipstick and the filler

cap is secure.

9. Fluid Levels – Check the hydraulic oil level. Ensure

hydraulic oil is added as required.

10. Accessories/Attachments – Refer to the accessories

section in this manual for specific inspection, operation, and maintenance instructions for accessories

that can be installed on this machine.

11. Function Check – Once the Walk-Around Inspection is

complete, perform a functional check of all systems in

an area free of overhead and ground level obstructions. Refer to Section 3 for more specific operating

instructions.

3121655 2-3

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION & INSPECTION

Function Check

Perform the Function Check as follows:

1. From the ground control console with no load in the

platform:

a. Check that all guards protecting the function con-

trol switches and controllers are in place.

b. Operate all functions and check all limiting and

cutout switches.

c. Check manual descent.

d. Ensure that all machine functions are disabled

when the Emergency Stop Button is depressed.

2. From the platform control console:

a. Ensure that the control console is firmly secured

in the proper location.

b. Check that all guards protecting the function con-

trol switches and controllers are in place.

c. Operate all functions and check all limiting and

cutout switches.

d. Ensure that all machine functions are disabled

when the Emergency Stop Button is depressed.

3. With the platform in the transport (stowed) position:

a. Drive the machine on a grade, not to exceed the

rated gradeability, and stop to ensure the brakes

hold.

b. Check the tilt indicator light to ensure proper

operation. The light should be illuminated when

tilted.

2-4 3121655

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION & INSPECTION

Table 2-2. Tilt Activation vs. Height

Tilt Setting

Model

1930ES 3

2032ES 3

2632ES 3

2646ES 3

3246ES 3

(front to back)

Tilt Setting

(side to side)

Degrees Feet Meters

1.5 18.75 (Full) 5.7

2144.3

2.5 11 3.4

392.7

1.5 20 (Full) 6

2154.5

2.5 12 3.7

3103

1.5 25.4 (Full) 7.7

2206

2.5 16 4.9

3134

2 26 (Full) 7.9

2.5 22 6.7

3206

2 31.75 (Full) 9.7

2.5 22 6.7

3206

Maximum Deck

Elevation

NOTE: For Japanese specification machines labeled "Ministry of

Labor Notification #70," the Tilt Setting is 5 degrees (front

to back and side to side) regardless of elevated platform

height.

Table 2-3. High Drive Speed Cutout Height

Model High Drive Speed Cutout Height

1930ES 54 in 1.4 m

2032ES 66 in 1.7 m

2632ES 76 in 1.9 m

2646ES 76 in 1.9 m

3246ES 76 in 1.9 m

3121655 2-5

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION & INSPECTION

Walk-Around Inspection

2-6 3121655

Loading...

Loading...