Page 1

Operation and Safety Manual

Keep this manual with the machine at all times.

Model(s)

15BD

19BD

Vertical Lift

ANSI

P/N - 3121153

May 3, 2011

Page 2

NOTES:

Page 3

SECTION - FOREWORD

FOREWORD

This manual is a very important tool! Keep it with the machine at all times.

The purpose of this manual is to provide owners, users, operators, lessors, and lessees with the precautions and

operating procedures essential for the safe and proper machine operation for its intended purpose.

Due to continuous product improvements, JLG Industries, Inc. reserves the right to make specification changes

without prior notification. Contact JLG Industries, Inc. for updated information.

3121153 – JLG Lift – a

Page 4

SECTION - SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

DANGER

CAUTION

NOTICE

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

This is the Safety Alert Symbol. It is used to alert you to the potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid possible

injury or death

INDICATES AN IMMINENTLY HAZARDOUS SITUATION. IF NOT

AVOIDED, WILL RESULT IN SERIOUS INJURY OR DEATH. THIS DECAL

WILL HAVE A RED BACKGROUND.

INDICATES A POTENTIALITY HAZARDOUS SITUATION. IF NOT

AVOIDED, COULD

DECAL WILL HAVE AN ORANGE BACKGROUND.

RESULT IN SERIOUS INJURY OR DEATH. THIS

INDICATES A POTENTIALITY HAZARDOUS SITUATION. IF NOT

AVOIDED, MAY RESULT IN MINOR OR MODERATE INJURY. IT MAY

ALSO ALERT AGAINST UNSAFE PRACTICES. THIS DECAL WILL HAVE

A YELLOW BACKGROUND.

INDICATES INFORMATION OR A COMPANY POLICY THAT RELATES

DIRECTLY OR INDIRECTLY TO THE SAFETY OF PERSONNEL OR PROTECTION OF PROPERTY.

b – JLG Lift – 3121153

Page 5

SECTION - SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

NOTICE

NOTICE

THIS PRODUCT MUST COMPLY WITH ALL SAFETY RELATED BULLETINS. CONTACT JLG INDUSTRIES, INC. OR THE LOCAL AUTHORIZED

JLG REPRESENTATIVE FOR INFORMATION REGARDING SAFETY

RELATED BULLETINS WHICH MAY HAVE BEEN ISSUED FOR THIS

PRODUCT.

For:

• Accident Reporting

• Product Safety Publications

• Current Owner Updates

• Questions Regarding

Product Safety

• Standards and Regulations

Compliance Information

• Questions Regarding Special Product Applications

• Questions Regarding Product Modifications

JLG INDUSTRIES, INC. SENDS SAFETY RELATED BULLETINS TO THE

OWNER OF RECORD OF THIS MACHINE. CONTACT JLG INDUSTRIES,

INC. TO ENSURE THAT THE CURRENT OWNER RECORDS ARE

UPDATED AND ACCURATE.

JLG INDUSTRIES, INC. MUST BE NOTIFIED IMMEDIATELY IN ALL

INSTANCES WHERE JLG PRODUCTS HAVE BEEN INVOLVED IN AN

ACCIDENT INVOLVING BODILY INJURY OR DEATH OF PERSONNEL OR

WHEN SUBSTANTIAL DAMAGE HAS OCCURRED TO PERSONAL

PROPERTY OR THE JLG PRODUCT.

Contact:

Product Safety and Reliability Department

JLG Industries, Inc.

13224 Fountainhead Plaza

Hagerstown, MD 21742

or Your Local JLG Office

(See addresses on manual rear cover)

In USA:

Toll Free: 877-JLG-SAFE (877-554-7233)

Outside USA:

3121153 – JLG Lift – c

Phone: 240-420-2661

E-mail: ProductSafety@JLG.com

Page 6

SECTION - REVISION LOG

REVISION LOG

Original Issue of Manual . . . . . . . . . . . . . . . . . February 5, 2009

Manual Revised . . . . . . . . . . . . . . . . . . . . . . . . . . . .May 3, 2011

d – JLG Lift – 3121153

Page 7

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

FOREWORD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL

WORDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B

Contact:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C

In USA: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C

Outside USA: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C

REVISION LOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D

SECTION - 1 - SAFETY PRECAUTIONS

1.1 GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 PRE-OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Operator Training And Knowledge. . . . . . . . . . . . . . 1-1

Workplace Inspection . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Machine Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Trip and Fall Hazards . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Electrocution Hazards. . . . . . . . . . . . . . . . . . . . . . . . 1-5

Crushing And Collision Hazards. . . . . . . . . . . . . . . . 1-6

1.4 LIFTING MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

SECTION - 2 - USER RESPONSIBILITIES, MACHINE

PREPARATION, AND INSPECTION

2.1 PERSONNEL TRAINING. . . . . . . . . . . . . . . . . . . . . . . . 2-1

Operator Training . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Training Supervision . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Operator Responsibility . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 PREPARATION, INSPECTION, AND MAINTENANCE . 2-2

Pre-Start Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3 WALK-AROUND INSPECTION . . . . . . . . . . . . . . . . . . . 2-5

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.4 FUNCTION CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

SECTION - 3 - MACHINE CONTROLS AND INDICATORS

3.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 CONTROLS AND INDICATORS . . . . . . . . . . . . . . . . . . 3-1

Ground Control Station . . . . . . . . . . . . . . . . . . . . . . . 3-1

Manual Descent Valve Location . . . . . . . . . . . . . . . . 3-2

Platform Control Station . . . . . . . . . . . . . . . . . . . . . . 3-3

18 Ft. Height Limiter - (19BD ONLY - OPTION) . . . . 3-4

Platform Gate Interlock - (OPTION). . . . . . . . . . . . . . 3-4

Platform Gate Lock - (OPTION) -

S/N-0130016195 to Present . . . . . . . . . . . . . . . . . . . 3-4

Platform Foot Control Switches - (OPTION) . . . . . . . 3-5

3121153 – JLG Lift – i

Page 8

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

SECTION - 4 - MACHINE OPERATION

4.1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 OPERATING CHARACTERISTICS AND

LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 SET-UP AND OPERATION . . . . . . . . . . . . . . . . . . . . . . 4-2

Platform Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Platform Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.4 PLATFORM CONFIGURATIONS . . . . . . . . . . . . . . . . . 4-3

4.5 MACHINE SHUT DOWN. . . . . . . . . . . . . . . . . . . . . . . . 4-4

SECTION - 5 - OPTIONAL EQUIPMENT

5.1 OPTIONAL EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . 5-1

28" x 26" Front Entry Gullwing Platform . . . . . . . . . . 5-1

Tool/Bottle Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Platform Foot Control Switch . . . . . . . . . . . . . . . . . . 5-1

Tube Carrier (PVC) . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

18 Ft. Height Limiter - (19BD ONLY - OPTION) . . . . 5-1

Platform Gate Interlock - (OPTION). . . . . . . . . . . . . . 5-1

Platform Gate Lock - (OPTION) -

S/N-0130016195 to Present . . . . . . . . . . . . . . . . . . . 5-2

SECTION - 6 - EMERGENCY PROCEDURES

6.1 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . .6-1

6.2 EMERGENCY OPERATION . . . . . . . . . . . . . . . . . . . . .6-1

Operator Unable to Control Machine. . . . . . . . . . . . . 6-1

Platform Caught Overhead . . . . . . . . . . . . . . . . . . . .6-1

6.3 INCIDENT NOTIFICATION . . . . . . . . . . . . . . . . . . . . . . 6-1

SECTION - 7 - GENERAL SPECIFICATIONS AND OPERATOR

MAINTENANCE

7.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 GENERAL SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . 7-2

Machine Specifications . . . . . . . . . . . . . . . . . . . . . . . 7-2

Serial Number Locations . . . . . . . . . . . . . . . . . . . . . . 7-2

7.3 OPERATOR MAINTENANCE . . . . . . . . . . . . . . . . . . . .7-3

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

SECTION - 8 - INSPECTION AND REPAIR LOG

ii – JLG Lift – 3121153

Page 9

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

LIST OF FIGURES

2-1. Daily Walk-Around inspection . . . . . . . . . . . . . . . . 2-6

3-1. Ground Control Station. . . . . . . . . . . . . . . . . . . . . . 3-2

3-2. Manual Descent Valve Location. . . . . . . . . . . . . . . 3-2

3-3. Platform Control Station. . . . . . . . . . . . . . . . . . . . . 3-3

3-4. Platform Control Footswitch. . . . . . . . . . . . . . . . . . 3-5

3-5. 15BD/19BD - Decal Installation . . . . . . . . . . . . . . . 3-6

1-1 Minimum Approach Distances (M.A.D.) . . . . . . . . . 1-5

2-1 Inspection and Maintenance Table. . . . . . . . . . . . . 2-3

3-1 15BD - Decal Installation . . . . . . . . . . . . . . . . . . . . . 3-7

7-1 Lubrication Specifications . . . . . . . . . . . . . . . . . . . . 7-3

7-1 15BD Lubrication Points . . . . . . . . . . . . . . . . . . . . . 7-4

7-2 Lubrication Intervals for Various Components . . . . 7-5

8-1 Inspection and Repair Log . . . . . . . . . . . . . . . . . . . 8-1

LIST OF TABLES

3121153 – JLG Lift – iii

Page 10

TABLE OF CONTENTS

This page intentionally left blank.

iv – JLG Lift – 3121153

Page 11

SECTION 1 - SAFETY PRECAUTIONS

SECTION 1. SAFETY PRECAUTIONS

1.1 GENERAL

This section outlines the necessary precautions for proper and

safe machine usage and maintenance. For proper machine use, it

is mandatory that a daily routine is established based on the content of this manual. A maintenance program, using the information provided in this manual and the Service and Maintenance

Manual, must also be established by a qualified person and must

be followed to ensure that the machine is safe to operate.

The owner/user/operator/lessor/lessee of the machine should not

accept operating responsibility until this manual has been read,

training is accomplished, and operation of the machine has been

completed under the supervision of an experienced and qualified

operator.

If there are any questions with regard to safety, training, inspection, maintenance, application, and operation, please contact JLG

Industries, Inc. (“JLG”).

FAILURE TO COMPLY WITH THE SAFETY PRECAUTIONS LISTED IN

THIS MANUAL COULD RESULT IN MACHINE DAMAGE, PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

1.2 PRE-OPERATION

Operator Training And Knowledge

• Read and understand this manual before operating the

machine.

• Do not operate this machine until complete training is performed by authorized persons.

• Only authorized and qualified personnel can operate the

machine.

• Read, understand, and obey all DANGERS, WARNINGS,

CAUTIONS, and operating instructions on the machine

and in this manual.

• Use the machine in a manner which is within the scope of

its intended application set by JLG.

3121153 – JLG Lift – 1-1

Page 12

SECTION 1 - SAFETY PRECAUTIONS

• All operating personnel must be familiar with the emergency controls and emergency operation of the machine

as specified in this manual.

• Read, understand, and obey all applicable employer,

local, and governmental regulations as they pertain to

operation of the machine.

Workplace Inspection

• The operator is to take safety measures to avoid all hazards in the work area prior to machine operation.

• Do not operate or raise the platform unless the machine is

properly secured to a suitable floor surface.

• This machine can be operated in temperatures of 0° F to

104° F (-20° C to 40° C). Consult JLG for operation outside this range.

• Do not operate the machine in hazardous environments

unless approved for the purpose by JLG.

Machine Inspection

• Before machine operation, perform inspections and functional checks. Refer to Section 2 of this manual for

detailed instructions.

• Do not operate this machine until it has been serviced and

maintained according to requirements specified in the

Service and Maintenance Manual.

• Ensure all safety devices are operating properly. Modification of these devices is a safety violation.

MODIFICATION OR ALTERATION OF AN AERIAL WORK PLATFORM

SHALL BE MADE ONLY WITH PRIOR WRITTEN PERMISSION FROM THE

MANUFACTURER

• Do not operate any machine on which the safety or

instruction placards or decals are missing or illegible.

• Avoid any build up of debris on platform floor. Keep mud,

oil, grease, and other slippery substances from footwear

and platform floor.

1-2 – JLG Lift – 3121153

Page 13

SECTION 1 - SAFETY PRECAUTIONS

1.3 OPERATION

General

• Always ensure the machine is properly attached to a solid,

firm and level floor surface.

• Do not use the machine for any purpose other than positioning personnel, their tools and equipment.

• Never operate a machine that is not working properly. If a

malfunction occurs, shut down the machine.

• Do not allow personnel to tamper with or operate the

machine from the ground with personnel in the platform,

except in an emergency.

• Do not carry materials directly on platform railing unless

approved by JLG.

• Always ensure that power tools are properly stowed and

never left hanging by their cord from the platform work

area.

• Fully lower mast assembly and shut off all power before

leaving machine.

• When performing welding operations at elevation, precautions must be taken to protect all machine components

from contact with weld splatter or molten metal.

• Never exceed the maximum platform capacity. Distribute

loads evenly in the platform.

• Never attempt to use the machine as a crane.

• Do not increase the platform size with unauthorized deck

extensions or attachments.

• If mast assembly or platform is caught while elevated, the

operator must be removed before attempting to free the

machine. Use cranes, forklift trucks, or other appropriate

equipment to stabilize machine prior to removing personnel.

Trip and Fall Hazards

• JLG Industries, Inc. recommends that the operator in the

platform use an approved fall restraint device with a lanyard attached to the authorized lanyard anchorage point.

For further information regarding fall protection requirements on JLG products, contact JLG Industries, Inc.

3121153 – JLG Lift – 1-3

Page 14

SECTION 1 - SAFETY PRECAUTIONS

• Before operating the machine, make sure all railing and

gates are fastened in their proper position.

• Keep both feet firmly positioned on the platform floor at all

times. Never use ladders, boxes, steps, planks, or similar

items on platform to provide additional reach.

• Never use the mast assembly to enter or leave the platform.

• Use extreme caution when entering or leaving platform.

Ensure that the mast assembly is fully lowered. Face the

machine when entering or leaving the platform. Always

maintain “three point contact” with the machine, using two

hands and one foot or two feet and one hand at all times

during entry and exit.

1-4 – JLG Lift – 3121153

Page 15

SECTION 1 - SAFETY PRECAUTIONS

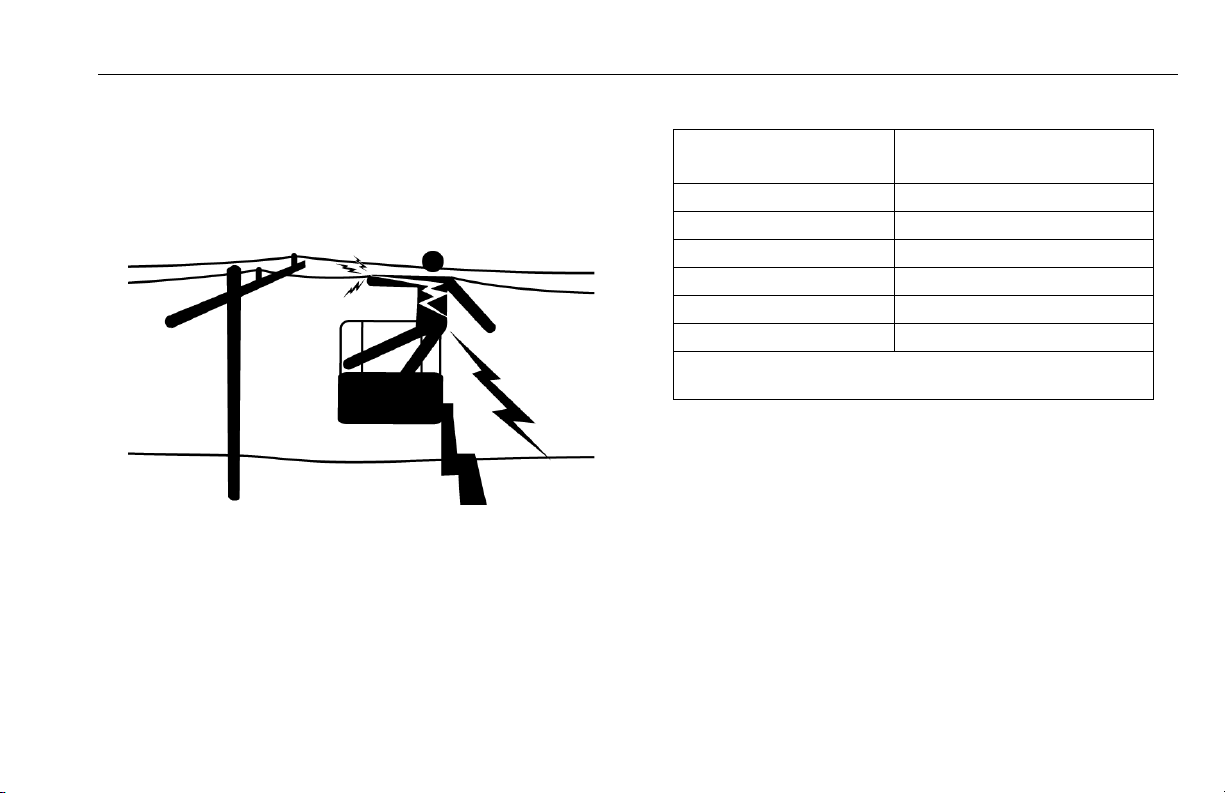

Electrocution Hazards

• This machine is not insulated and does not provide protection from contact or proximity to electrical current.

• Maintain distance from electrical lines, apparatus, or any

energized (exposed or insulated) parts according to the

Minimum Approach Distance (MAD) as shown in Table 1-

1.

• Allow for machine movement and electrical line swaying.

Table 1-1. Minimum Approach Distances (M.A.D.)

Voltage Range

(Phase to Phase)

0 to 50 KV 10 (3)

Over 50KV to 200 KV 15 (5)

Over 200 KV to 350 KV 20 (6)

Over 350 KV to 500 KV 25 (8)

Over 500 KV to 750 KV 35 (11)

Over 750 KV to 1000 KV 45 (14)

NOTE: This requirement shall apply except where employer,

local or governmental regulations are more stringent.

• Maintain a clearance of at least 10 ft. (3m) between any

part of the machine and its occupants, their tools, and

their equipment from any electrical line or apparatus carrying up to 50,000 volts. One foot additional clearance is

required for every additional 30,000 volts or less.

• The minimum approach distance may be reduced if insulating barriers are installed to prevent contact, and the

barriers are rated for the voltage of the line being guarded.

These barriers shall not be part of (or attached to) the

machine. The minimum approach distance shall be

reduced to a distance within the designed working dimensions of the insulating barrier. This determination shall be

MINIMUM APPROACH DISTANCE

in Feet (Meters)

3121153 – JLG Lift – 1-5

Page 16

SECTION 1 - SAFETY PRECAUTIONS

DANGER

made by a qualified person in accordance with the

employer, local, or governmental requirements for work

practices near energized equipment

DO NOT MANEUVER MACHINE OR PERSONNEL INSIDE PROHIBITED

ZONE (MAD). ASSUME ALL ELECTRICAL PARTS AND WIRING ARE

ENERGIZED UNLESS KNOWN OTHERWISE.

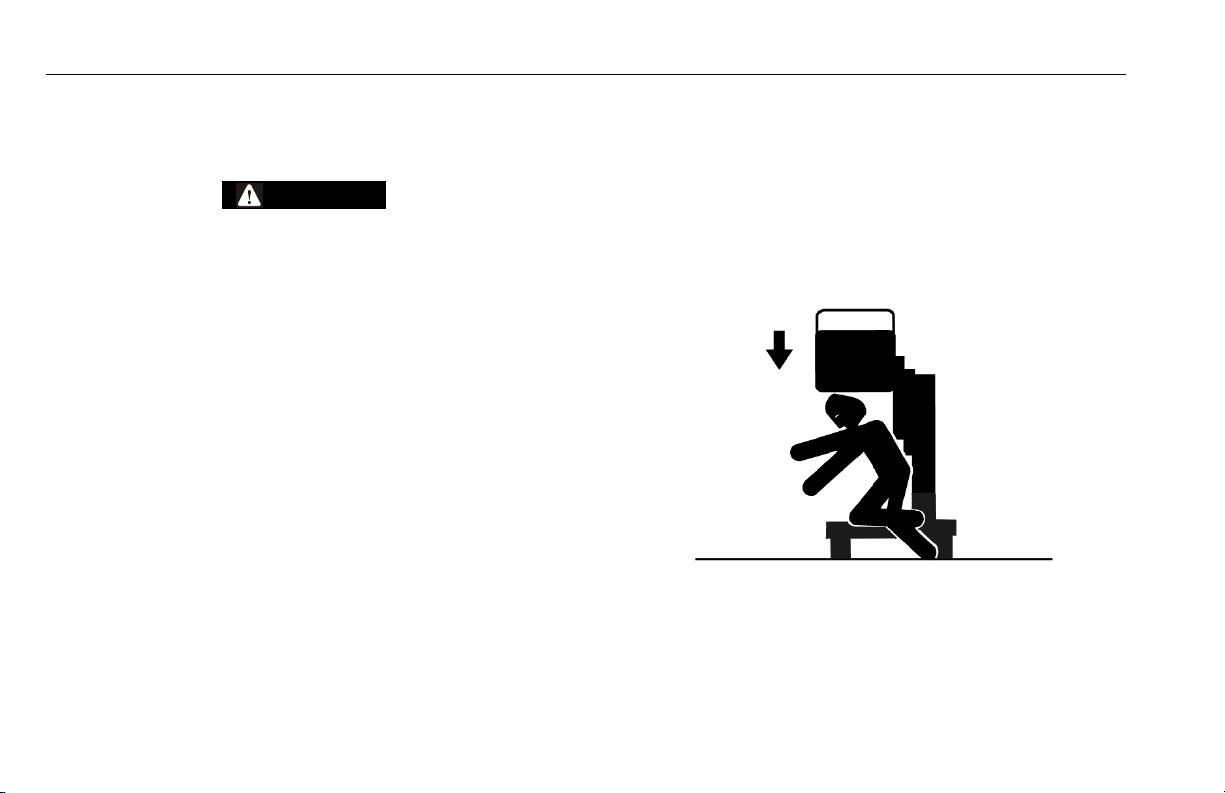

Crushing And Collision Hazards

• Personal protection equipment must be worn by all operating and ground personnel.

• Check work area clearances above, on sides, and bottom

while lifting or lowering the platform.

• During platform operation, keep all body parts inside platform railing.

• Keep non-operating personnel at least 6 ft. (1.8m) away

while operating machine.

1-6 – JLG Lift – 3121153

Page 17

SECTION 1 - SAFETY PRECAUTIONS

• Exercise extreme caution at all times to prevent obstacles

from striking or interfering with operating controls and person in the platform.

• Ensure that operators of other overhead and floor level

machines are aware of the aerial work platform’s presence. Disconnect power to overhead cranes.

• Warn personnel not to work, stand, or walk under a raised

platform. Position barricades on floor as necessary.

1.4 LIFTING MACHINE

• When lifting machine with a forklift, position forks only at

designated areas of the machine. Lift with a forklift of adequate capacity.

• Ensure machine is secure on the forks before transporting. Keep machine as low to the ground as possible.

• Refer to the Machine Operation section of this manual for

lifting information.

3121153 – JLG Lift – 1-7

Page 18

SECTION 1 - SAFETY PRECAUTIONS

NOTES:

1-8 – JLG Lift – 3121153

Page 19

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

SECTION 2. USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

2.1 Personnel Training

The aerial platform is a personnel handling device; so it is necessary that it be operated and maintained only by trained personnel.

Persons under the influence of drugs or alcohol or who are subject

to seizures, dizziness or loss of physical control must not operate

this machine.

Operator Training

Operator training must cover:

1. Use and limitations of the controls in the platform and at

the ground, emergency controls and safety systems.

2. Control labels, instructions, and warnings on the

machine.

3. Rules of the employer and government regulations.

4. Use of approved fall protection device.

5. Enough knowledge of the mechanical operation of the

machine to recognize a malfunction or potential malfunction.

6. The safest means to operate the machine around overhead obstructions and other moving equipment.

7. Means to avoid the hazards of unprotected electrical

conductors.

8. Specific job requirements or machine application.

Training Supervision

Training must be done under the supervision of a qualified person

in an open area free of obstructions until the trainee has developed the ability to safely control and operate the machine.

Operator Responsibility

The operator must be instructed that he/she has the responsibility

and authority to shut down the machine in case of a malfunction or

other unsafe condition of either the machine or the job site.

3121153 – JLG Lift – 2-1

Page 20

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

NOTICE

2.2 Preparation, Inspection, and Maintenance

The following table covers the periodic machine inspections and

maintenance recommended by JLG Industries, Inc. Consult local

regulations for further requirements for aerial work platforms. The

frequency of inspections and maintenance must be increased as

necessary when the machine is used in a harsh or hostile environment; if the machine is used with increased frequency; or if the

machine is used in a severe manner.

JLG INDUSTRIES, INC. RECOGNIZES A FACTORY TRAINED SERVICE

TECHNICIAN AS A PERSON WHO HAS SUCCESSFULLY COMPLETED

THE JLG SERVICE TRAINING SCHOOL FOR THE SPECIFIC JLG PRODUCT MODEL.

2-2 – JLG Lift – 3121153

Page 21

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

Table 2-1. Inspection and Maintenance Table

TYPE FREQUENCY

Pre-Start Inspection Before using each day; or

whenever there’s an Operator change.

Pre-Delivery Inspection

(See Note)

Frequent Inspection In service for 3 months, whichever comes first;

Annual Machine Inspection Annually, no later than 13 months from the date of

Preventative Maintenance At intervals as specified in the Service and Main-

NOTE: Inspection forms are available from JLG. Use the Service and Maintenance Manual to perform inspections.

Before each sale, lease, or rental delivery. Owner, Dealer, or User Qualified JLG

or;

Out of service for a period of more than 3 months;

or

Purchased used.

prior inspection.

tenance Manual.

PRIMARY

RESPONSIBILITY

User or Operator User or Operator Operator and Safety Manual

Owner, Dealer, or User Qualified JLG

Owner, Dealer, or User Factor y Trained

Owner, Dealer, or User Qualified JLG

SERVICE

QUALIFICATION

Mechanic

Mechanic

Service Technician

(Recommended)

Mechanic

Service and Maintenance

Manual and applicable JLG

inspection form

Service and Maintenance

Manual and applicable JLG

inspection form

Service and Maintenance

Manual and applicable JLG

inspection form

Service and Maintenance

Manual

REFERENCE

3121153 – JLG Lift – 2-3

Page 22

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

Pre-Start Inspection

The Pre-Start Inspection should include each of the following:

1. Cleanliness – Check all surfaces for oil leakage or foreign objects. Report any leakage to the proper maintenance personnel.

2. Decals and Placards – Check all for cleanliness and

legibility. Make sure none of the decals and placards are

missing. Make sure all illegible decals and placards are

cleaned or replaced.

3. Operators and Safety Manuals – Make sure a copy of

the Operator and Safety Manual, EMI Safety Manual

(Domestic only), and ANSI Manual of Responsibilities

(Domestic only) is enclosed in the weather resistant

storage container.

4. “Walk-Around” Inspection – Refer to Figure 2-1. and

Section 2.3.

5. Hydraulic Oil – Check the hydraulic oil level. Ensure

hydraulic oil is added as required.

6. Function Check – Once the “Walk-Around” Inspection

is complete, perform a function check of all systems in

an area free of overhead and ground level obstructions.

Refer to Machine Operation section for more specific

instructions on the operation of each function.

IF THE MACHINE DOES NOT OPERATE PROPERLY, TURN OFF THE

MACHINE IMMEDIATELY! REPORT THE PROBLEM TO THE PROPER MAINTENANCE PERSONNEL. DO NOT OPERATE THE MACHINE UNTIL IT IS

DECLARED SAFE FOR OPERATION.

2-4 – JLG Lift – 3121153

Page 23

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

CAUTION

2.3 WALK-AROUND INSPECTION

(See Figure 2-1.)

General

Begin the Walk-Around Inspection at item 1 below. Continue

around machine checking each item in this check list.

TO AVOID POSSIBLE INJURY, BE SURE MACHINE POWER IS OFF DURING WALK-AROUND INSPECTION.

INSPECTION NOTE: On each item, make sure there are no loose

or missing parts, that they are securely fastened and that

no visible damage exists in addition to any other criteria

mentioned.

1. Base Frame - Properly secured to work surface. See

Inspection Note.

2. Manual Descent Control Valve - No evidence of

hydraulic leaks.

3. Motor/Pump/Reservoir Power Unit - No evidence of

hydraulic leaks. Check that hydraulic reservoir fluid level

is filled to the "Fill to Line" mark on the side of the reservoir.

4. Ground Controls - Key switch operable; emergency

stop switch properly set for operation.

5. Mast Assembly - Inspect mast chains and sequence

cables as per inspection note. Control and power cables

properly tensioned and seated in control cable sheaves;

control cable sheaves rotate freely.

6. AC Voltage Junction Box - Secure to support, access

door secure and closed.

7. Platform Controls - Inspect UP/DOWN and Function

Enable buttons as per inspection note. Emergency Stop

switch functions properly. Operation & Safety Manual in

manual storage box.

8. Platform Control Foot Switches (optional) - Inspect

UP and DOWN foot pedals. Ensure foot switch enclosure is properly secured to the platform floor.

9. Platform Assembly - Secure to mast; Properly secured

to mounting brackets; entry gate(s) closing properly.

10. Hourmeter - Hourmeter secure and legible.

3121153 – JLG Lift – 2-5

Page 24

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

1

2

3

4

5

6

7

8

9

10

8

1. Base Frame

2. Manual Descent Control Valve

3. Motor/Pump/Reservoir Power Unit

4. Ground Controls

5. Mast Assembly

6. AC Junction Box Assembly

7. Platform Controls

8. Platform Control Foot Switches (option)

9. Platform Assembly

10. Hourmeter

Figure 2-1. Daily Walk-Around inspection.

(Shown with Standard Platform)

2-6 – JLG Lift – 3121153

Page 25

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

2.4 FUNCTION CHECK

The function check of all systems should be performed in an area

free of overhead and ground level obstructions. Perform a function

check as follows:

1. Set-up machine for operation, according to operating

instructions in Section 4.

2. Enter platform, raise and lower platform 2 ft. to 3 ft.

(.61m to .92 m) several times. Check for smooth elevation and lowering of platform.

3. With the aid of an assistant in the platform, test the manual decent valve. Elevate the platform approximately 12

inches, then activate the manual decent function, pull

and hold the red knob until the platform is completely

lowered.

4. Ensure that all machine functions are disabled when the

Emergency Stop Switch is pressed.

5. With platform completely lowered, check hydraulic oil

level in reservoir at ground control station. Maintain an

oil level to the "Fill to Line" indicator on the side of the

reservoir. NEVER USE HYDRAULIC BRAKE FLUID.

6. If equipped with the optional platform gate interlocks,

verify the lift function does not operate with either gate

open.

NOTE: To verify if the machine is equipped with the optional gate

interlocks, look for a wire harness to exit the platform midrail through a small hole in the midrail near the mast

header.

7. Machines equipped with the optional platform foot

switch controls, check proper operation for elevating

and lowering of the platform.

3121153 – JLG Lift – 2-7

Page 26

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

NOTES:

2-8 – JLG Lift – 3121153

Page 27

SECTION 3 - MACHINE CONTROLS AND INDICATORS

NOTICE

SECTION 3. MACHINE CONTROLS AND INDICATORS

3.1 GENERAL

THE MANUFACTURER HAS NO DIRECT CONTROL OVER MACHINE

APPLICATION AND OPERATION. THE USER AND OPERATOR ARE

RESPONSIBLE FOR CONFORMING WITH GOOD SAFETY PRACTICES.

This section provides the necessary information needed to understand control functions.

3.2 CONTROLS AND INDICATORS

Ground Control Station (See Figure 3-1.)

1. POWER ON/OFF Key Switch

A key switch located on the ground control station controls power to all functions on the machine. The machine

will not operate without the key inserted and turned to the

ON position. When left unattended, removing the key will

prevent unauthorized operaton.

2. EMERGENCY STOP SWITCH

A two position mushroom shaped switch furnishes power

to the platform and ground controls when RESET (ON).

When pushed in (OFF), power is shut off to the platform

and ground controls.

3. HYDRAULIC RESERVOIR/CIRCUIT BREAKER/FUSE

(located inside the ground control station housing)

The hydraulic oil level can be checked through an access

hole in the side of the cover.

NOTE: Check hydraulic oil only when platform is completely low-

ered and after cycling platform up/down a few times.

NOTE: A replaceable 5 Amp fuse for the DC Voltage circuit and a

reset type circuit breaker for the AC Voltage circuit is

located in the AC Junction Box on BD Models.

4. HOURMETER

The machine hourmeter registers pump operation time

during the platform LIFT UP cycle only. The hourmeter is

located on the back of the Ground Control Station on the

pump mounting bracket.

3121153 – JLG Lift – 3-1

Page 28

SECTION 3 - MACHINE CONTROLS AND INDICATORS

2

3

1

4

2

1

Manual Descent Valve Location

(See Figure 3-2.)

Located at the rear and bottom of the base frame. This

PULL TO RELEASE - spring loaded return valve (RED

Knob), allows for lowering of the platform in an emergency

or power failure.

Figure 3-1. Ground Control Station.

1. Power ON/OFF Key Switch

2. Emergency Stop Switch

3. Hydraulic Reservoir/Circuit

Breaker/Fuse

4. Hourmeter

Figure 3-2. Manual Descent Valve Location.

1. Manual Descent Valve 2. Rear of Base Frame Assembly

3-2 – JLG Lift – 3121153

Page 29

SECTION 3 - MACHINE CONTROLS AND INDICATORS

Platform Control Station

(See Figure 3-3.)

1. EMERGENCY STOP SWITCH

A two position mushroom shaped switch furnishes power

to the platform controls when pulled out (ON). When

pushed in (OFF), power is shut off to the platform.

2. PLATFORM UP Button (WHITE)

When depressed simultaneously with ENABLE (GREEN)

button raises the platform.

3. FUNCTION ENABLE Button.

This (GREEN) button must be depressed simultaneously

with either the UP or DOWN platform function buttons in

order to raise or lower the platform.

4. PLATFORM DOWN Button (WHITE).

When depressed simultaneously with ENABLE (GREEN)

button lowers the platform.

Figure 3-3. Platform Control Station.

1. Emergency Stop Switch (RED)

2. Platform UP - (WHITE)

3. Function Enable - (GREEN)

4. Platform DOWN - (WHITE)

3121153 – JLG Lift – 3-3

Page 30

SECTION 3 - MACHINE CONTROLS AND INDICATORS

18 Ft. Height Limiter - (19BD ONLY - OPTION)

19BD machines may be equipped with an 18 ft. height limiter option. This option prevents the platform from elevating beyond a height of 18 ft. Otherwise the platform will

operate normally.

Platform Gate Interlock - (OPTION)

If equipped, the optional platform gate interlock will prevent the platform lift function from operating when either

gate is open.

NOTE: To verify if the machine is equipped with the optional gate

interlocks, look for a wire harness to exit the platform midrail through a small hole in the midrail near the mast

header.

Platform Gate Lock - (OPTION) - S/N-0130016195 to Present

If equipped, the optional platform gate lock will prevent the

platform lift function from operating if the platform gates

are not closed and the lock slide bar is not engaged.

Once the slide bar is engaged and gates locked, the slide

bar will only disengage when the platform is fully lowered.

3-4 – JLG Lift – 3121153

Page 31

SECTION 3 - MACHINE CONTROLS AND INDICATORS

2

1

3

(See Figure 3-4.)

Platform Foot Control Switches - (OPTION)

1. FOOTSWITCH Operation Decal.

Shows which pedal controls platform lift up and lift down.

2. PLATFORM DOWN Pedal.

When depressed simultaneously with FUNCTION

ENABLE button located on the platform control station,

LOWERS the platform.

3. PLATFORM UP Pedal.

When depressed simultaneously with FUNCTION

ENABLE button located on the platform control station,

RAISES the platform.

Figure 3-4. Platform Control Footswitch

1. Footswitch Operation Decal 2. Platform DOWN Pedal

3. Platform UP Pedal

3121153 – JLG Lift – 3-5

Page 32

SECTION 3 - MACHINE CONTROLS AND INDICATORS

1

3

3

3

3

2

4

5

6

15

7

7

8

9

10

10

11

12

13

14

3-6 – JLG Lift – 3121153

Figure 3-5. 15BD/19BD - Decal Installation

Page 33

SECTION 3 - MACHINE CONTROLS AND INDICATORS

Table 3-1. 15BD/19BD - Decal Installation

ITEM # PART NUMBER DESCRIPTION

0272159 DECAL INSTALLATION

1 1700584 Decal - Patent

2 1702631 Decal - Bar Code

3 1703073 Decal - Fork Pockets

4 1705633 Decal - Function Controls

5 1703781 Decal - Electrical Hazard

6 1705635 Decal - Maximum Capacity

7 1705634 Decal - Crushing Hazard

8 1703788 Decal - Manual

9 1705220 Decal - Warning

10 1703072 Decal - No Fork-Lifting Here

11 1705636 Decal - Manual Descent

12 1001111596 Nameplate - Serial Number

13 1702120 Decal - Extension Cord Wire Size

14 1702569 Decal - Electrical Voltage

15 1703166 Decal - Footswitch Operation (optional)

3121153 – JLG Lift – 3-7

Page 34

SECTION 3 - MACHINE CONTROLS AND INDICATORS

NOTES:

3-8 – JLG Lift – 3121153

Page 35

SECTION 4 - MACHINE OPERATION

SECTION 4. MACHINE OPERATION

4.1 DESCRIPTION

This machine is a stationary base frame - bolt down version of

JLG’s manually propelled AM-AC model vertical lift. It features a

work platform mounted to an elevating aluminum mast mechanism. The personnel lift’s intended purpose is to provide personnel (with their tools and supplies) access to areas above ground

level.

The main power is turned on/off at the ground control station, an

emergency stop switch is located directly next to the main power

key switch.

The primary operator control station is located in the platform.

From this control station, the operator can raise and lower the platform. An emergency stop switch is located here also.

A platform manual descent valve is located inside the base frame

at the rear of the machine. This valve will lower the platform to the

ground in an emergency or if a power failure should occur and the

operator in the platform is unable to do so.

4.2 OPERATING CHARACTERISTICS AND LIMITATIONS

Capacities

MACHINE BASE FRAME MUST BE PROPERLY SECURED TO IT’S WORK

AREA MOUNTING SURFACE USING A MINIMUM OF 1/2" (19MM) DIAMETER GRADE 5 FASTENERS (OR EQUIVALENT) AND WIDE FLATWASHERS

BEFORE ATTEMPTING TO OPERATE LIFT.

NOTE: Refer to Service and Maintenance Manual for bolt down

specifications.

The platform can be raised above the stowed position if:

• The machine is properly and securely mounted to a firm

and level surface.

• Load is within manufacturer’s maximum rated capacity.

• All machine functions are operating properly.

3121153 – JLG Lift – 4-1

Page 36

SECTION 4 - MACHINE OPERATION

4.3 SET-UP AND OPERATION

DO NOT ATTEMPT TO RAISE THE PLATFORM UNTIL THE MACHINE IS

PROPERLY SECURED TO THE WORK AREA MOUNTING SURFACE.

To set-up the machine for operation the operator must:

1. Turn key switch to the ON position at the ground control

station.

2. Ensure both emergency stop switches, (one at platform

controls and one at ground controls), are in the RESET

(pulled out) position for operation.

3. Ensure manual decent control valve (red knob) located

on the rear base frame is closed (spring loaded - default

position).

Platform Loading

JLG INDUSTRIES, INC. RECOMMENDS THE OPERATOR IN THE PLATFORM

USE AN APPROVED FALL RESTRAINT DEVICE WITH A LANYARD

ATTACHED TO AN AUTHORIZED LANYARD ANCHORAGE POINT.

The platform maximum rated load capacity is shown on a placard

located on the platform control panel.

Platform Operation

1. Enter platform and close the entry gate(s).

NOTE: Machines equipped with optional entry gate interlocks,

the platform controls will not lift or lower without both

gates completely closed. To verify if the machine is

equipped with the optional gate interlocks, look for a wire

harness to exit the platform midrail through a small hole in

the midrail near the mast header.

2. To raise the platform, depress the FUNCTION ENABLE

button and platform UP button simultaneously. Upon

reaching desired elevation level, release the UP and

FUNCTION ENABLE buttons.

NOTE: Machines equipped with the optional platform foot control

switches, the footswitch is equipped with two pedals, one

labeled UP and one labeled DOWN. These pedals work

the same as the UP/DOWN buttons on the platform control station. The FUNCTION ENABLE button must be

depressed before either foot pedal will raise or lower the

platform.

4-2 – JLG Lift – 3121153

Page 37

ENSURE AREA BENEATH PLATFORM IS FREE OF PERSONNEL AND

1

2

3

OBSTRUCTIONS PRIOR TO LOWERING PLATFORM.

3. To lower platform, depress FUNCTION ENABLE button

and platform DOWN button on control panel simultaneously.

SECTION 4 - MACHINE OPERATION

4.4 Platform Configurations

STANDARD PLATFORM

Model Max. Capacity

15BD and 19BD 350 lb. (160kg)

1. Side Swinging Entry Gate 3. Lanyard Attach Point -

2. Platform Control Station (round bar in corner of mid rail)

3121153 – JLG Lift – 4-3

Page 38

SECTION 4 - MACHINE OPERATION

1

3

2

GULL-WING - FRONT ENTRY PLATFORM - OPTION

Model Max. Capacity

15BD and 19BD 350 lb. (160kg)

1. Front Gull-Wing Entry Gate 3. Lanyard Attach Point - (mounted

2. Entry Gate Latch on side of mast assembly)

4.5 Machine Shut down

1. Ensure that platform is fully lowered, push in the emergency stop at the platform controls. Exit the platform

and push in the emergency stop at the ground control

station. Turn the key switch to the OFF position.

2. If necessary, remove the key from the key switch at the

ground control station to disable the machine from

unauthorized use.

4-4 – JLG Lift – 3121153

Page 39

SECTION 5 - OPTIONAL EQUIPMENT

SECTION 5. OPTIONAL EQUIPMENT

5.1 OPTIONAL EQUIPMENT

The following optional equipment is available for 15BD model

machines:

28" x 26" Front Entry Gullwing Platform

The 28" (71cm) long by 26" (66cm) wide platform features a gull

wing gate opening.

Tool/Bottle Tray

Platform attachment to hold hand tools or other small items

placed in the tray.

Platform Foot Control Switch

This is a dual footswitch operated control that is mounted on the

floor of the platform. These switches in conjunction with the

function enable switch (GREEN) on the platform control panel,

allows control of the UP (raising) and Down (lowering) of the

platform.

Tube Carrier (PVC)

These carriers are mounted to the right side of the mast assembly, just behind the platform rail. They are approximately 3.5 in

in diameter and are approx. 45 inches in length and allow for

storage of materials that may be required while working in the

platform.

18 Ft. Height Limiter - (19BD ONLY - OPTION)

The platform limiter switch when installed on the 19BD model

lift, limits the platform to a maximum height of 18 ft. This can be

useful when platform height must be limited due to ceiling

height, or a specific work height is required.

Platform Gate Interlock - (OPTION)

If equipped, the optional platform gate interlock will prevent the platform lift function from operating with either

gate open.

NOTE: To verify if the machine is equipped with the optional gate

interlocks, look for a wire harness to exit the platform midrail through a small hole in the midrail near the mast

header.

3121153 – JLG Lift – 5-1

Page 40

SECTION 5 - OPTIONAL EQUIPMENT

Platform Gate Lock - (OPTION) - S/N-0130016195 to Present

If equipped, the optional platform gate lock will prevent the

platform lift function from operating if the platform gates

are not closed and the lock slide bar is not engaged.

Once the slide bar is engaged and gates locked, the slide

bar will only disengage when the platform is fully lowered.

5-2 – JLG Lift – 3121153

Page 41

SECTION 6 - EMERGENCY PROCEDURES

NOTICE

SECTION 6. EMERGENCY PROCEDURES

6.1 GENERAL INFORMATION

This section explains the steps to be taken in case of an emergency situation while operating the machine.

6.2 EMERGENCY OPERATION

Operator Unable to Control Machine

IF THE PLATFORM OPERATOR IS PINNED, TRAPPED OR

UNABLE TO OPERATE OR CONTROL THE MACHINE, USE THE

FOLLOWING INSTRUCTIONS AS A GUIDELINE. DO NOT CONTINUE OPERATION IF CONTROLS DO NOT FUNCTION PROPERLY

1. If the operator is unable to lower the platform from the

platform controls, other personnel should operate the

emergency descent control valve located at the rear of

the machines base frame, “Manual Descent Valve Location” on page 3-2, to lower the platform.

2. If necessary, rescue equipment can be used to remove

the platform occupant and stabilize motion of the

machine.

Platform Caught Overhead

If the platform becomes jammed or snagged in overhead structures or equipment, rescue the platform occupant prior to freeing

the machine.

6.3 INCIDENT NOTIFICATION

JLG Industries, Inc. must be notified immediately of any incident

involving a JLG product. Even if no injury or property damage is

evident, the factory should be contacted by telephone and provided with all necessary details.

JLG Phone: USA: 877-JLG-SAFE (554-7233)

(8am till 4:45pm EST)

Email (USA): productsafety@jlg.com

Failure to notify the Manufacturer of an incident involving a JLG

Industries product within 48 hours of such an occurrence may

void any warranty consideration on that particular machine.

FOLLOWING ANY INCIDENT, THOROUGHLY INSPECT THE MACHINE

AND TEST ALL FUNCTIONS. DO NOT ELEVATE PLATFORM UNTIL YOU

ARE SURE THAT ALL DAMAGE HAS BEEN REPAIRED, IF REQUIRED,

AND THAT ALL CONTROLS ARE OPERATING CORRECTLY.

3121153 – JLG Lift – 6-1

Page 42

SECTION 6 - EMERGENCY PROCEDURES

NOTES:

6-2 – JLG Lift – 3121153

Page 43

SECTION 7 - GENERAL SPECIFICATIONS AND OPERATOR MAINTENANCE

SECTION 7. GENERAL SPECIFICATIONS AND OPERATOR MAINTENANCE

7.1 Introduction

This section of the manual provides additional necessary information to the operator for proper operation and maintenance of this

machine.

The maintenance portion of this section is intended as information

to assist the machine operator to perform daily maintenance tasks

only, and does not replace the more thorough Preventive Maintenance and Inspection Schedule included in the Service and Maintenance Manual.

Other Publications Available Specific to this Machine:

Service and Maintenance Manual

ANSI. . . .. . . . . . . .. . . . . .. . . . . .. . . . . .. . . . . 3121154

Illustrated Parts Manual

ANSI. . . .. . . . . . . .. . . . . .. . . . . .. . . . . .. . . . . 3121155

3121153 – JLG Lift – 7-1

Page 44

SECTION 7 - GENERAL SPECIFICATIONS AND OPERATOR MAINTENANCE

7.2 General Specifications

Machine Specifications

SPECIFICATION

Maximum Occupants: (Persons) 1

Maximum Work Load

(Platform Capacity):

Machine Stowed Height: 77.22 in. (1.96 m) 77.81 in. (1.97 m)

Machine Stowed Width: 29.75 in. (75.5 cm)

Maximum Vertical Platform Height

(Ground to Platform Floor - Platform

Fully Extended):

Maximum Step-in Platform Height

(Ground to Platform Floor - Platform

Fully Lowered):

Working Height: 21 ft. (6.4 m) 24.75 ft. (7.54 m)

Standard Platform Size: 27 in. x 23 in.

Platform Speed (seconds) Lift Up: 20 22

( w/ m a x . r a t ed l o a d) L i f t D o w n: 32 - 40 18 - 25

Machine Weight (Platform Empty ): 725 lb. (329 kg) 830 lb. (376 kg)

15BD 19BD

350 lb. (160 kg)

15.25 ft. (4.65 m) 18.75 ft. (5.72 m)

12.75 in. ( cm) 13.37 in. ( cm)

(68.5 cm x 58.5 cm)

SPECIFICATION

System Voltage: 12V DC/120 Volts-60Hz AC

Machine Base Mounting Footprint: 18 in. x 33 in.

15BD 19BD

(45.72 cm x 83.82 cm)

0.75 Dia. Holes

20 in. x 24 in.

(50.8 cm x 60.96 cm)

0.75 Dia. Holes

Serial Number Locations

For machine identification, a serial number plate is affixed to the

machine. The plate is located on the back of the mast, just above

the mast support bracket.

7-2 – JLG Lift – 3121153

Page 45

7.3 Operator Maintenance

Lubrication

Hydraulic Oil (HO)

SECTION 7 - GENERAL SPECIFICATIONS AND OPERATOR MAINTENANCE

Table 7-1. - Lubrication Specifications

HYDRAULIC SYSTEM OPERATING

TEMPERATURE RANGE

+0° F to +180° F (-18° C to -83° C) 10W

+0° F to +210° F (-18° C to +99° C) 10W-20, 10W-30

+50° F to +210° F (+10° C to +99° C) 20W-20

Hydraulic oils must have anti-wear qualities at least to API Service

Classification GL-3, and sufficient chemical stability for mobile

hydraulic system service. JLG Industries, recommends Mobilfluid

424 hydraulic oil, which has an SAE viscosity of 10W-30 and a viscosity index of 152.

For cold weather applications, i.e. when temperatures remain consistently below +20°F (–7°C) JLG recommends using Mobil DTE

13 hydraulic oil.

Aside from JLG recommendations, it is not advisable to mix oils of

different brands or types, as they may not contain the same

required additives or be of comparable viscosities. If use of

hydraulic oil other than Mobilfluid 424 is desired, contact JLG

Industries for proper recommendations.

SAE VISCOSITYGRADE

KEY SPECIFICATIONS

MPG - Multipurpose Grease having a minimum dripping point of 350° F.

Excellent water resistance and adhesive qualities, and being of

extreme pressure type. (Timken OK 40 pounds minimum.)

EPGL - Extreme Pressure Gear Lube (oil) meeting API service classification

G L-5 or MI L-S pe c M IL- L-21 05.

HO - Hydraulic Oil. ISO-Vg grade 32, 46.

CL - Chain Lube. Use a good quality chain lubricant

NOTE: Refer to Lubrication Chart, Table 7-2. for specific lubrica-

tion locations on machine.

3121153 – JLG Lift – 7-3

Page 46

SECTION 7 - GENERAL SPECIFICATIONS AND OPERATOR MAINTENANCE

1

2

Table 1-1. 15BD Lubrication Points (See Table 7-2. on page 7-5)

7-4 – JLG Lift – 3121153

Page 47

SECTION 7 - GENERAL SPECIFICATIONS AND OPERATOR MAINTENANCE

Table 7-2. Lubrication Intervals for Various Components

ITEM COMPONENT

Hydraulic Oil Fill To Line

1

NO/TYPE

LUBE POINTS

(a)

LUBE/METHOD

HO- Check Hyd.

on Reservoir

5 Qt. (4.3 L)

Reservoir

Mast Chains 2 - Per Section Chain Lube - Br ush or

2

HO-Change

H y d. O il

Spray

Oil Level

3

MONTHS

or

5 Hm.Hrs.

INTERVAL HOURS

6

MONTHS

or

10 Hm.Hrs.

1

YEAR

or

20 Hm.Hrs.

(b)

2

YEARS

or

40 Hm.Hrs.

Check hydraulic oil level

(c)

daily.

Change oil after every 40

Hourmeter Hrs. of operation.

Key to Lubricants: MPG - Multipurpose Grease

(See Table 7-1) HO - Hydraulic Oil

Notes: a. Be certain to lubricate like items on each side of the machine.

b. Recommended lubricating intervals are calculated on hourmeter hours (Hm.Hrs.= pump run cycle - lift up - only).

Recommended lubricating intervals are based on normal use. If machine is subjected to severe operating conditions, such as a high

number of cycles, location, corrosive/dirty environment, etc., user must adjust lubricating requirements accordingly.

c. Prior to checking hydraulic oil level, operate machine through one complete cycle of lift function (full up and down). Ensure platform is

fully lowered, failure to do so will result in incorrect oil level reading on the hydraulic reser voir.

COMMENTS

3121153 – JLG Lift – 7-5

Page 48

SECTION 7 - GENERAL SPECIFICATIONS AND OPERATOR MAINTENANCE

NOTES:

7-6 – JLG Lift – 3121153

Page 49

SECTION 8 - INSPECTION AND REPAIR LOG

SECTION 8. INSPECTION AND REPAIR LOG

Table 8-1. Inspection and Repair Log

Date Comments

Machine Serial Number: _________________________

3121153 – JLG Lift – 8-1

Page 50

SECTION 8 - INSPECTION AND REPAIR LOG

Table 8-1. Inspection and Repair Log

Date Comments

Machine Serial Number: _________________________

8-2 – JLG Lift – 3121153

Page 51

TRANSFER OF OWNERSHIP

To Product Owner:

If you now own but ARE NOT the original purchaser of the product covered by this

manual, we would like to know who you are. For the purpose of receiving safety-related

bulletins, it is very important to keep JLG Industries, Inc. updated with the current

ownership of all JLG products. JLG maintains owner information for each JLG product

and uses this information in cases where owner notification is necessary.

Please use this form to provide JLG with updated information with regard to the

current ownership of JLG products. Please return completed form to the JLG Product

Safety & Reliability Department via facsimile or mail to address as specified below.

Thank You,

Product Safety & Reliability Department

JLG Industries, Inc.

13224 Fountainhead Plaza

Hagerstown, MD 21742

USA

Telephone: +1-717-485-6591

Fax: +1-301-745-3713

NOTE: Leased or rented units should not be included on this form.

Mfg. Model: _____________

__________________________________________________

Serial Number: ____________________________________________________________

Previous Owner: ___________________________________________________________

Address: _________________________________________________________________

_________________________________________________________________________

Country: _________________________ Telephone: (_______

) ____________________

Date of Transfer: _________________________________

Current Owner: ____________________________________________________________

Address: _______________

__________________________________________________

_________________________________________________________________________

Country: _________________________ Telephone: (_______

) ____________________

Who in your organization should we notify?

Name: ___________________________________________________________________

Title:____________________________________________________________________

An Oshkosh Corporation Company

Page 52

Page 53

Page 54

JLG Industries, Inc.

31

21153

1 JLG Drive

McConnellsburg PA. 17233-9533

USA

(717) 485-5161

(717) 485-6417

JLG Worldwide Locations

JLG Industries (Australia)

P.O. Box 5119

11 Bolwarra Road

Port Macquarie

N.S.W. 2444

Australia

+61 2 65 811111

+61 2 65 810122

JLG Deutschland GmbH

Max-Planck-Str. 21

D - 27721 Ritterhude - Ihlpohl

Germany

+49 (0)421 69 350 20

+49 (0)421 69 350 45

JLG Polska

UI. Krolewska

00-060 Warsawa

Poland

+48 (0)914 320 245

+48 (0)914 358 200

JLG Latino Americana Ltda.

Rua Eng. Carlos Stevenson,

80-Suite 71

13092-310 Campinas-SP

Brazil

+55 19 3295 0407

+55 19 3295 1025

JLG Equipment Services Ltd.

Rm 1107 Landmark North

39 Lung Sum Avenue

Sheung Shui N. T.

Hong Kong

(852) 2639 5783

(852) 2639 5797

Plataformas Elevadoras

JLG Iberica, S.L.

Trapadella, 2

P.I. Castellbisbal Sur

08755 Castellbisbal, Barcelona

Spain

+34 93 772 4700

+34 93 771 1762

JLG Industries (UK) Ltd

Bentley House

Bentley Avenue

Middleton

Greater Manchester

M24 2GP - England

+44 (0)161 654 1000

+44 (0)161 654 1001

JLG Industries (Italia) s.r.l.

Via Po. 22

20010 Pregnana Milanese - MI

Italy

+39 029 359 5210

+39 029 359 5845

JLG Sverige AB

Enkopingsvagen 150

Box 704

SE - 176 27 Jarfalla

Sweden

+46 (0)850 659 500

+46 (0)850 659 534

JLG France SAS

Z.I. de Baulieu

47400 Fauillet

France

+33 (0)5 53 88 31 70

+33 (0)5 53 88 31 79

Oshkosh - JLG Singapore T. E. P. Ltd.

29 Tuas Ave 4

Jurong Industrial Estate

639379

Singapore

+65-6591-9030

+65-6591-9031

www.jlg.com

Loading...

Loading...