Page 1

Length Gauges

April 2015

Page 2

Length gauges from HEIDEN HAIN offer

high accuracy over long measuring ranges.

These sturdily made gauges are available in

application-oriented versions.

They have a wide range of applications in

production metrology, in multipoint

inspection stations, measuring equipment

monitoring, and as position measuring

devices.

This catalog supersedes all previous

editions, which thereby become invalid.

The basis for ordering from HEIDENHAIN

is always the catalog edition valid when

the contract is made.

2

Standards (ISO, EN, etc.) apply only

where explicitly stated in the catalog.

The Interfaces of HEIDENHAIN

Encoders brochure, ID 1078628-xx,

includes comprehensive descriptions of

all available interfaces as well as general

electrical information.

Page 3

Contents

Length gauges – applications and products

Technical features and mounting information

Specifications

Range of applications, application examples

Length gauges from HEIDENHAIN

Length gauge overview

Measuring principles

Measuring accuracy

Mounting

Setup

Gauging force and plunger actuation

HEIDENHAIN-ACANTO

absolute length gauges

Accuracy Measuring range

± 2 µm 12 mm

30 mm

4

6

8

10

12

16

17

19

22

Accessories

Electrical connection

HEIDENHAIN-CERTO

incremental length gauges

HEIDENHAIN-METRO

incremental length gauges

HEIDENHAIN-METRO

incremental length gauges

HEIDENHAIN-SPECTO

incremental length gauges

Measuring contacts, switch boxes, coupling

Gauge stands, ceramic suction plate,

diaphragm compressor

Cable-type lifter, gauge

stands

Interface electronics

Evaluation electronics units

± 0.1 µm; ± 0.03 µm*

± 0.1 µm; ± 0.05 µm*

± 0.2 µm 12 mm

± 0.5 µm

± 1 µm

± 1 µm 12 mm

For HEIDENHAIN-CERTO

For HEIDENHAIN-ACANTO, HEIDENHAIN-METRO and

HEIDENHAIN-SPECTO

25 mm

60 mm

25 mm

60 mm

100 mm

30 mm

24

26

28

30

32

34

36

38

40

Interfaces

Cables and connecting elements

Service

Calibration according to DAkkS

* After linear length-error compensation in the evaluation electronics

42

46

50

Page 4

Areas of application

In quality assurance

Metrology and production

control

Length gauges from HEIDENHAIN play a

role in incoming goods inspection, fast

dimension checking during production,

statistical process control in production or

quality assurance, or in any application

where fast, reliable and accurate length

measurement is required. Their large

measuring lengths are a particular advantage: whether the part measures 5 mm or

95 mm, it is measured immediately with

one and the same length gauge.

Whatever the application, HEIDENHAIN

has the appropriate length gauge for the

required accuracy. The HEIDENHAIN-

CERTO length gauges offer a very high

accuracy of ± 0.1 µm/± 0.05 µm*/

± 0.03 µm* for extremely precise measurement. Length gauges from the

HEIDENHAIN-METRO program have

accuracy grades as fine as ± 0.2 µm, while

the HEIDENHAIN-SPECTO length gauges,

with ± 1 µm accuracy, offer particularly

compact dimensions.

Gauge block calibration and

measuring device inspection

The regular inspection of measuring

equipment called for by standards, and the

inspection of gauge blocks in particular,

necessitate a large number of reference

standard blocks if the comparative measurement is performed using inductive

gauges. The problem is the small measuring range of inductive gauges: they can

measure length differences of only up to

10 µm. Length gauges, which offer large

measuring ranges together with high

accuracy, greatly simplify the calibration

of measuring devices required to ensure

traceability.

The length gauges of the HEIDENHAIN-

CERTO program with measuring ranges of

25 mm with ± 0.1 µm/± 0.03 µm* accuracy

and 60 mm with ± 0.1 µm/± 0.05 µm*

accuracy are especially well suited for this

task. It permits a significant reduction in

the required number of reference standard

blocks, and recalibrating becomes much

simpler.

* After linear length-error compensation in

the evaluation electronics

Thickness gauging of silicon wafers

Inspection of styli

4

Calibration of

gauge blocks

Page 5

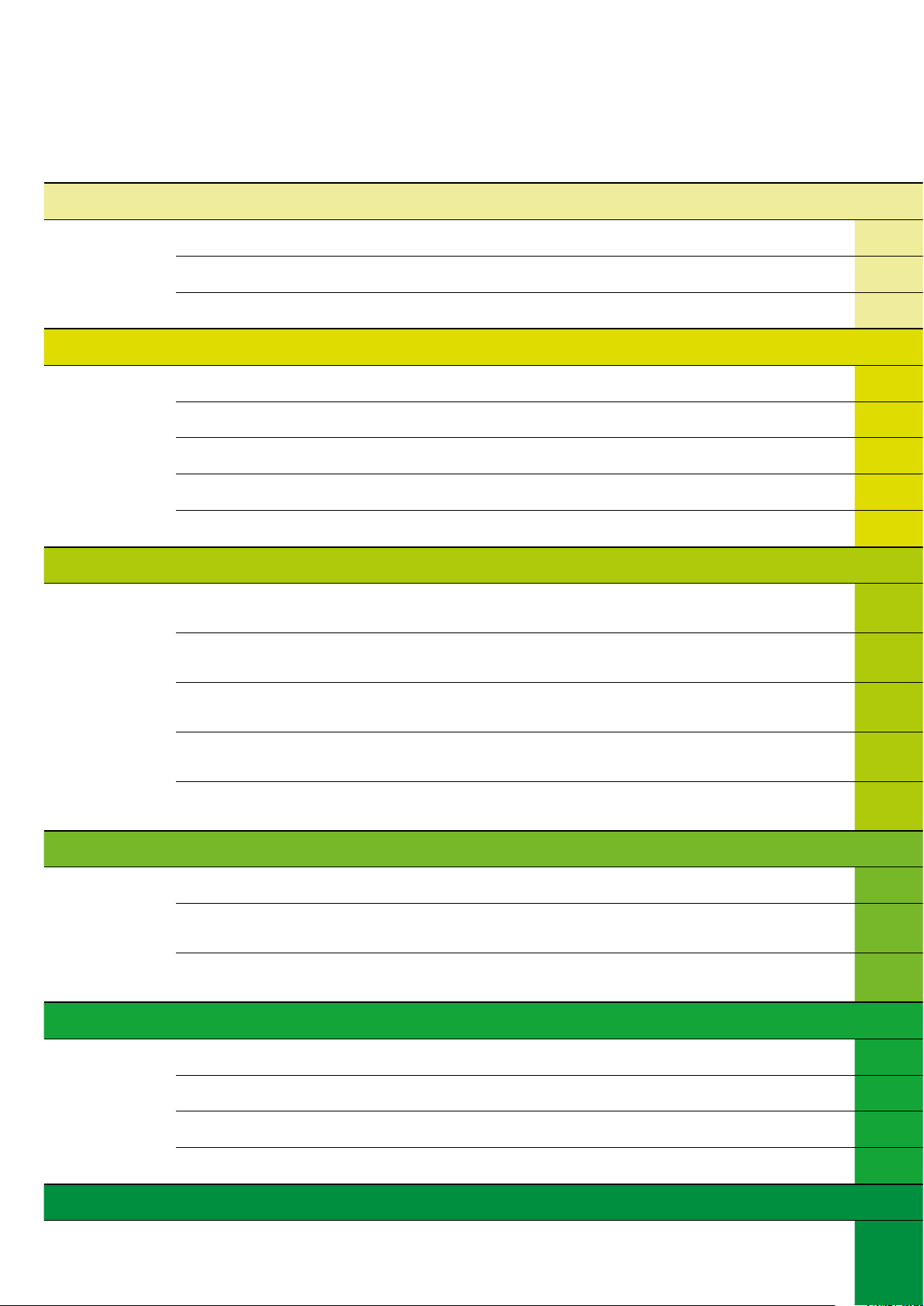

In production

Multipoint inspection

apparatuses

Multipoint inspection apparatuses require

durable length gauges with small dimensions. They should also have relatively large

measuring ranges of several millimeters

with consistent linear accuracy in order to

simplify the construction of inspection

devices—for example by enabling the construction of one device for several masters.

A large measuring length also provides

benefits in master production, because

simpler masters can be used.

Thanks to their small dimensions, the

HEIDENHAIN-ACANTO absolute length

gauges, like the HEIDENHAIN-SPECTO

incremental length gauges, are specially

designed for multi-point measuring

stations. They feature accuracy grades up

to ± 1 µm over measuring ranges up to

30 mm. Higher accuracy requirements

up to ± 0.2 µm can be met with similarly

compact HEIDENHAIN-METRO length

gauges.

Unlike inductive gauges, HEIDENHAINSPECTO length gauges provide stable

measurement over long periods—

eliminating recalibration.

Position measurement

Length gauges from HEIDENHAIN are also

ideal for position measurement on precision linear slides and X-Y tables. Working

with measuring microscopes, for example,

becomes much easier thanks to the digital

readout and the flexible datum setting.

Here, length gauges from the HEIDENHAIN-METRO and HEIDENHAIN-SPECTO

program come into use with large measuring ranges of 30 mm, 60 mm or 100 mm

at consistently high accuracy grades of

± 0.5 µm or ± 1 µm.

In this application as linear measuring

device, the length gauge’s fast installation

in accordance with the Abbe measuring

principle by its clamping shank or planar

mounting surface is of special benefit.

Testing station for

flatness inspection

Position measurement on an X-Y table for lens mounting

Tolerance gauging of

semifinished products

5

Page 6

Length gauges from HEIDENHAIN

A number of arguments speak for HEIDENHAIN length gauges. These include not

only their technical features, but also their

high quality standard and the worldwide

presence of HEIDENHAIN.

Large measuring ranges

HEIDENHAIN length gauges are available

with measuring lengths of 12 mm, 25 mm,

30 mm, 60 mm or 100 mm. so that you

can measure very different parts in one

measuring setup and avoid frequently

changing setups with expensive gauge

blocks or masters.

High accuracy

The high accuracy specifi ed for

HEIDENHAIN length gauges applies over

the entire measuring length. Whether the

part measures 10 mm or 100 mm, its

actual dimension is always measured with

the same high quality. The high repeatability of HEIDENHAIN length gauges

comes into play during comparative

measurements, for example in series

production.

In particular HEIDENHAIN-CERTO length

gauges provide high linear accuracy and

offer resolution in the nanometer range.

Robust design

HEIDENHAIN length gauges are built for

an industrial environment. They feature

consistently high accuracy over a long

period of time as well as high thermal

stability. They can therefore be used in

production equipment and machines.

6

Page 7

Wide range of applications

HEIDENHAIN length gauges are suited for

many applications. Automatic inspection

equipment, manual measuring stations or

positioning equipment—wherever lengths,

spacing, thickness, height or linear motion

are to be measured, HEIDENHAIN length

gauges function quickly, reliably and

accurately.

Absolute position measurement

HEIDENHAIN-ACANTO length gauges operate with absolute measurement over a

range of 12 mm or 30 mm and with high

repeatability. Its particular advantage is that

the measured value is available immediately after switch-on.

Worldwide presence

HEIDENHAIN is represented in all important industrial countries—in most of them

with wholly owned subsidiaries. Sales

engineers and service technicians support

the user on-site with technical information

and servicing in the local language.

Know-how

The high quality of HEIDENHAIN length

gauges is no coincidence. HEIDENHAIN

has been manufacturing high-accuracy

scales for over 70 years, and for many

years it has developed measuring and

testing devices for length and angle

measurement for national standards

laboratories. This know-how makes

HEIDENHAIN an extraordinarily qualifi ed

partner for metrology questions.

7

Page 8

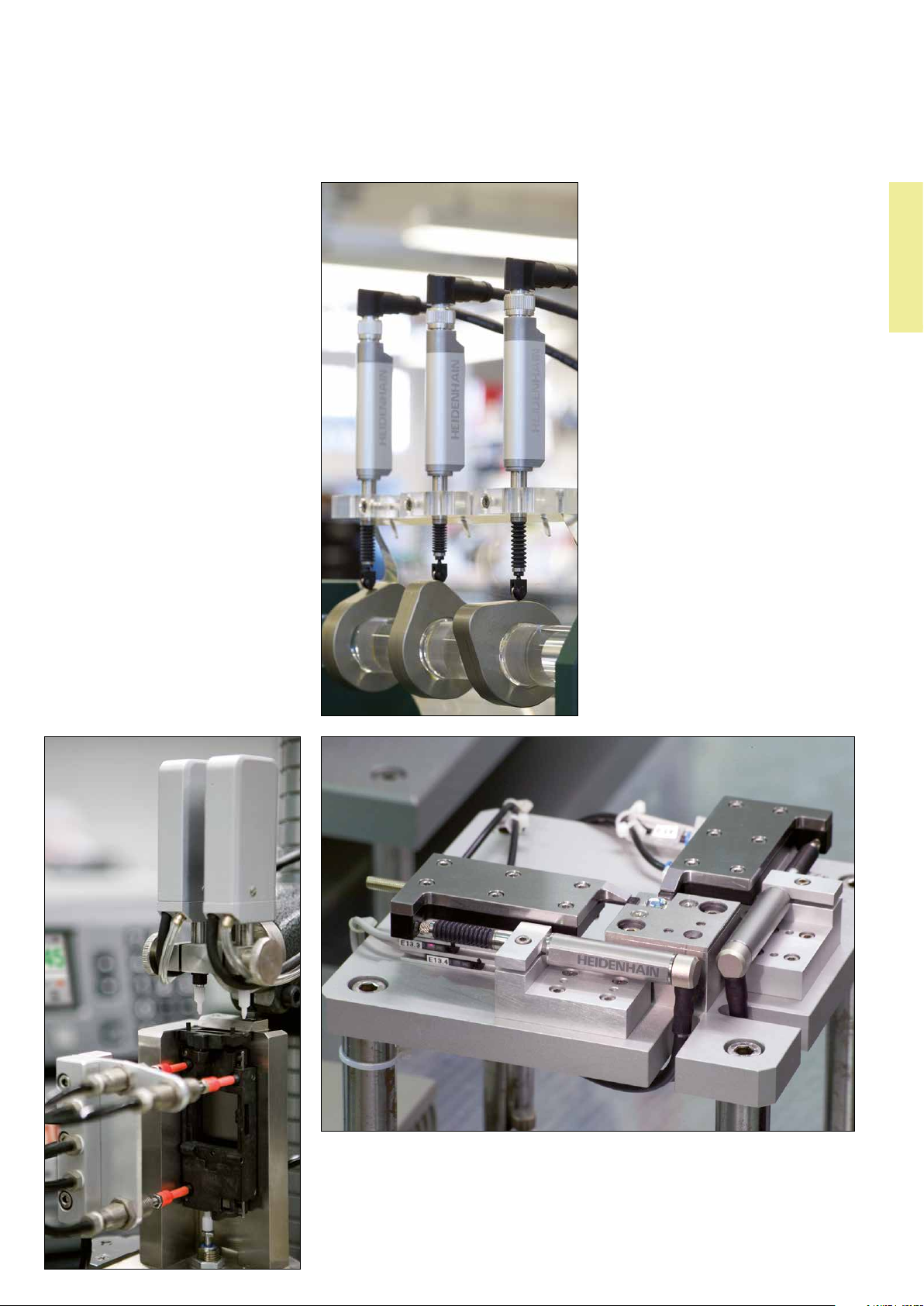

Length gauge overview

Accuracy Measuring range

Plunger actuation

Absolute position measurement

± 2 µm HEIDENHAIN-ACANTO

By measured object

Pneumatic

Incremental linear measurement

± 0.1 µm

± 0.05 µm

± 0.03 µm

± 0.2 µm HEIDENHAIN-METRO

± 0.5 µm

± 1 µm

± 1 µm HEIDENHAIN-SPECTO

*)

After linear length-error compensation in the evaluation electronics

*)

*)

HEIDENHAIN-CERTO

By motor

By external coupling

By cable lifter

or measured object

Pneumatic

HEIDENHAIN-METRO

By motor

By external coupling

By measured object

Pneumatic

CT 6000 CT 2500MT 101 MT 60

8

Page 9

AT 3000

AT 1200

12 mm 25 mm/

30 mm

60 mm 100 mm Page

AT 1218 EnDat

AT 1217 EnDat

AT 3018 EnDat

AT 3017 EnDat

CT 2501 » 11 µA

CT 2502 » 11 µA

PP

PP

CT 6001 » 11 µA

CT 6002 » 11 µA

PP

PP

MT 1271 « TTL

MT 1281 » 1 V

MT 1287 » 1 V

PP

PP

MT 2571 « TTL

MT 2581 » 1 V

MT 2587 » 1 V

PP

PP

MT 60 M » 11 µA

MT 60 K » 11 µA

PP

PP

MT 101 M » 11 µA

MT 101 K » 11 µA

PP

PP

22

24

26

28

ST 1278 « TTL

ST 1288 » 1 V

ST 1277 « TTL

ST 1287 » 1 V

PP

PP

ST 3078 « TTL

ST 3088 » 1 V

ST 3077 « TTL

ST 3087 » 1 V

PP

PP

30

ST 3000 ST 1200MT 2500 MT 1200

AT 3000

AT 1200

9

Page 10

Measuring principles

Measuring standard

HEIDENHAIN length gauges are characterized by long measuring ranges and consistently high accuracy. The basis for both is

the photoelectrical scanning principle.

HEIDENHAIN length gauges use material

measuring standards consisting of absolute or incremental graduations on substrates of glass or glass ceramic. These

measuring standards permit large measuring ranges, are insensitive to vibration and

shock, and have a defined thermal behavior. Changes in atmospheric pressure or

relative humidity have no influence on the

accuracy of the measuring standard—

which is the prerequisite for the high long-

term stability of HEIDENHAIN length

gauges.

HEIDENHAIN manufactures the precision

graduations in specially developed,

photolithographic processes.

• AURODUR: matte-etched lines on goldplated steel tape with typical graduation

period of 40 µm

• METALLUR: contamination-tolerant

graduation of metal lines on gold, with

typical graduation period of 20 µm

• DIADUR: extremely robust chromium

lines on glass (typical graduation period

of 20 µm) or three-dimensional chromium structures (typical graduation period

of 8 µm) on glass

• SUPRADUR phase grating: optically

three dimensional, planar structure;

particularly tolerant to contamination;

typical graduation period of 8 µm and

finer

• OPTODUR phase grating: optically three

dimensional, planar structure with

particularly high reflectance, typical

graduation period of 2 µm and less

Measurement procedure

With the incremental measuring

method, the graduation consists of a

periodic grating structure. The position

information is obtained by counting the

individual increments (measuring steps)

from some point of origin. Since an

absolute reference is required to ascertain

positions, the measuring standard is

provided with an additional track that bears

a reference mark. The absolute position

on the scale, established by the reference

mark, is gated with exactly one signal

period.

The reference mark must therefore be

scanned to establish an absolute reference

or to find the last selected datum.

With the absolute measuring method,

the position value is available from the encoder immediately upon switch-on and can

be called at any time by the subsequent

electronics. There is no need to move the

axes to find the reference position. The absolute position information is read from

the graduated disk, which is formed from

a serial absolute code structure. A separate

incremental track is interpolated for the

position value and at the same time—depending on the interface version—is used

to generate an optional incremental signal.

DIADUR phase grating with

approx. 0.25 µm grating height

Photoelectric scanning

Most HEIDENHAIN encoders operate

using the principle of photoelectric

scanning. Photoelectric scanning of a

measuring standard is contact-free, and as

such, free of wear. This method detects

even very fine lines, no more than a few

microns wide, and generates output

signals with very small signal periods.

The finer the grating period of a measuring

standard is, the greater the effect of diffraction on photoelectric scanning. HEIDENHAIN uses two scanning principles with

linear encoders:

• The imaging scanning principle for

grating periods of 20 µm and 40 µm

• The interferential scanning principle

for very fine graduations with grating

periods of, for example, 8 µm

DIADUR graduation

Along with these very fine grating periods,

these processes permit a high definition

and homogeneity of the line edges.

Together with the photoelectric scanning

method, this high edge definition is a

precondition for the high quality of the

output signals.

The master graduations are manufactured

by HEIDENHAIN on custom-built highprecision dividing engines.

10

5 µm

Page 11

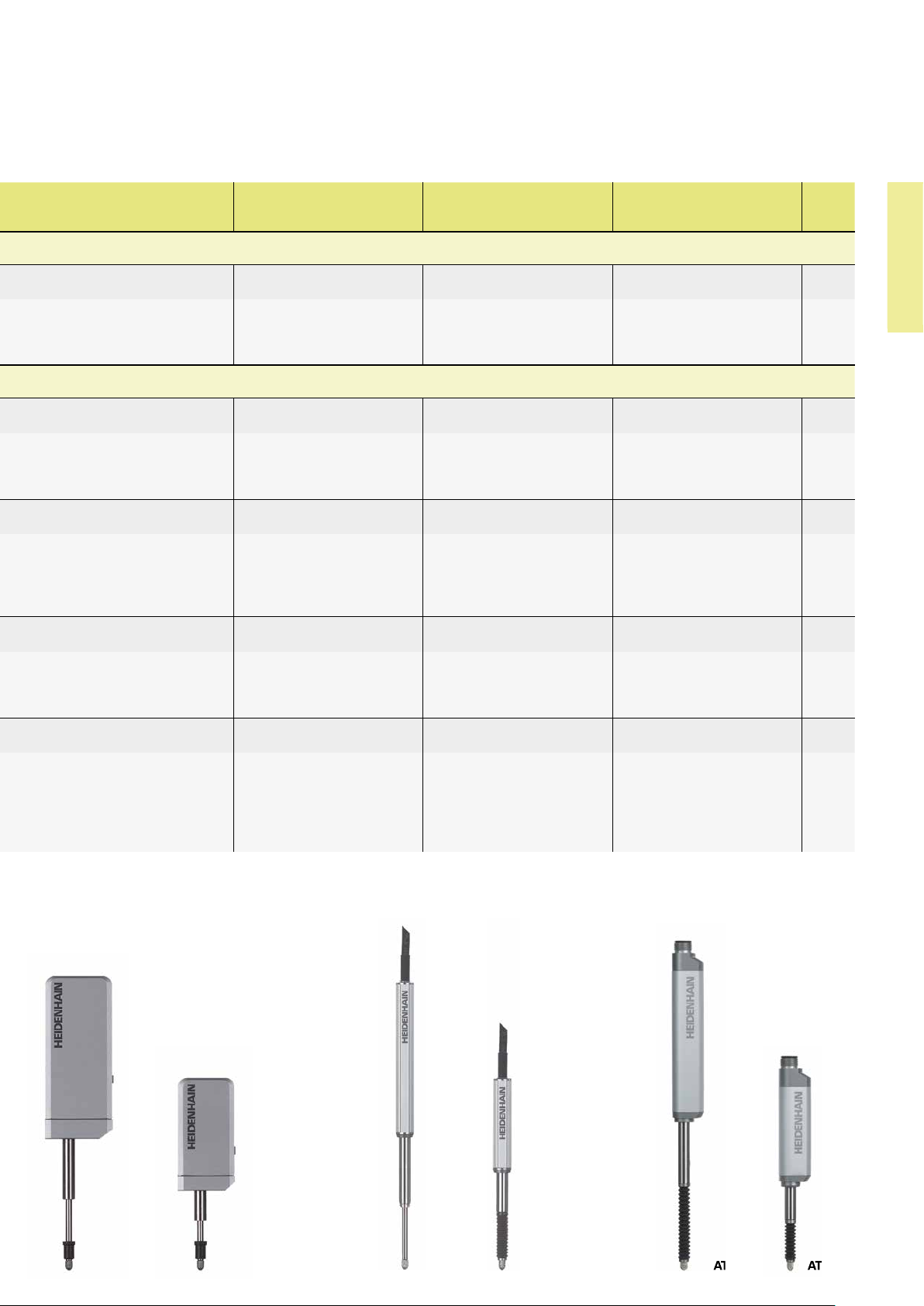

Imaging principle

To put it simply, the imaging scanning principle functions by means of projected-light

signal generation: two scale gratings with

equal or similar grating periods are moved

relative to each other—the scale and the

scanning reticle. The carrier material of the

scanning reticle is transparent, whereas

the graduation on the measuring standard

may be applied to a transparent or reflective surface.

When parallel light passes through a

grating, light and dark surfaces are

projected at a certain distance. An index

grating is located here. When the two

gratings move relative to each other, the

incident light is modulated. If the gaps in

the gratings are aligned, light passes

through. If the lines of one grating coincide

with the gaps of the other, no light passes

through. An array of photovoltaic cells

converts these variations in light intensity

into electrical signals. The specially

structured grating of the scanning reticle

filters the light to generate nearly

sinusoidal output signals.

The smaller the period of the grating

structure is, the closer and more tightly

toleranced the gap must be between the

scanning reticle and scale.

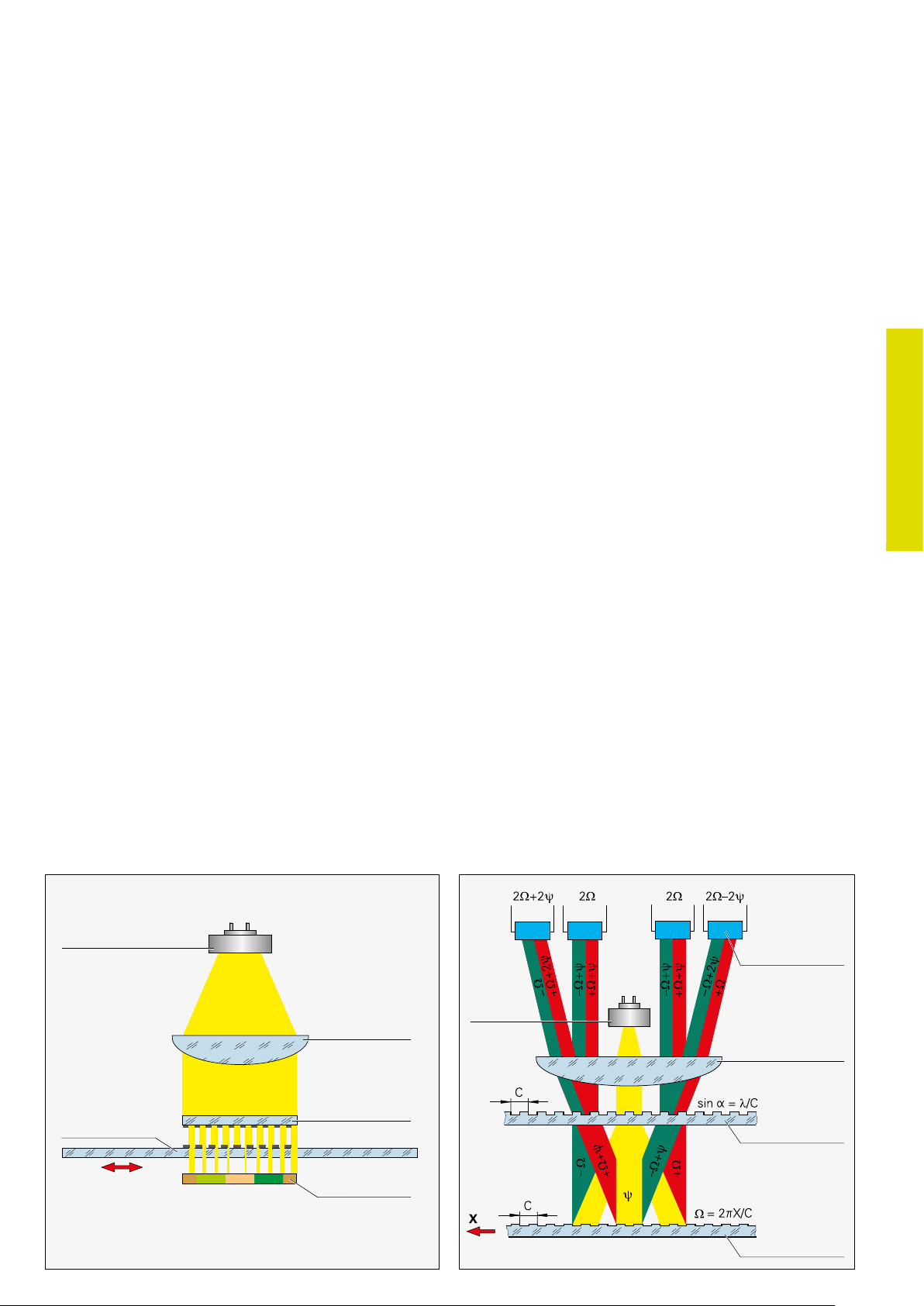

Interferential scanning principle

The interferential scanning principle

exploits the diffraction and interference of

light on a fine graduation to produce

signals used to measure displacement.

A step grating is used as the measuring

standard: reflective lines 0.2 µm high are

applied to a flat, reflective surface. In front

of that is the scanning reticle—a transparent phase grating with the same grating

period as the scale.

When a light wave passes through the

scanning reticle, it is diffracted into three

partial waves of the orders –1, 0, and +1,

with approximately equal luminous

intensity. The waves are diffracted by the

scale such that most of the luminous

intensity is found in the reflected diffraction

orders +1 and –1. These partial waves meet

again at the phase grating of the scanning

reticle where they are diffracted again and

interfere. This produces essentially three

waves that leave the scanning reticle at

different angles. Photovoltaic cells convert

this alternating light intensity into electrical

signals.

A relative motion of the scanning reticle to

the scale causes the diffracted wave fronts

to undergo a phase shift: when the grating

moves by one period, the wave front of the

first order is displaced by one wavelength

in the positive direction, and the wavelength of diffraction order –1 is displaced by

one wavelength in the negative direction.

Since the two waves interfere with each

other when exiting the grating, the waves

are shifted relative to each other by two

wavelengths. This results in two signal periods from the relative motion of just one

grating period.

Interferential encoders function with

grating periods of, for example, 8 µm, 4 µm

and finer. Their scanning signals are largely

free of harmonics and can be highly

interpolated. These encoders are therefore

especially suited for high resolution and

high accuracy.

The HEIDENHAIN-CERTO and the

HEIDENHAIN-METRO length gauges

of the MT 1200 and MT 2500 series

operating according to the interferential

principle.

The HEIDENHAIN-ACANTO, HEIDENHAINSPECTO and the HEIDENHAIN-METRO

length gauges of the MT 60 and MT 100

series operating according to the imaging

principle.

Imaging principle

LED light source

Measuring standard

Condenser lens

Scanning reticle

Photovoltaic

cell array

Interferential scanning principle (optics schematics)

C Grating period

y Phase shift of the light wave when passing through the scanning reticle

Phase shift of the light wave due to motion X of the scale

Photocells

LED light

source

Condenser lens

Scanning reticle

Measuring standard

11

Page 12

Measuring accuracy

The accuracy of linear measurement is

mainly determined by

• the quality of the graduation,

• the quality of the scanning process,

• the quality of the signal processing

electronics,

• the eccentricity of the graduation to the

bearing,

• the error from the scale guideway

relative to the scanning unit, and

• the orthogonality of the length gauge to

the bearing surface.

These factors of influence are comprised

of encoder-specific error and applicationdependent issues. All individual factors of

influence must be considered in order to

assess the attainable overall accuracy.

Error specific to the measuring

device

The error that is specific to the measuring

device is shown in the Specifications as

the system accuracy.

The extreme values of the total error F

with reference to their mean value lie over

the entire measuring length within the

system accuracy ± a. They are measured

during the final inspection and documented

in the calibration chart.

The system accuracy includes

• the homogeneity and period definition of

the graduation,

• the alignment of the graduation,

• the error of the bearing, and

• the position error within one signal

period.

Position error within one signal period

Position errors within one signal period

already become apparent in very small

motions and in repeated measurements.

They are therefore considered separately.

The position error within one signal period

± u results from the quality of the scanning

and—for encoders with integrated pulseshaping or counter electronics—the quality

of the signal-processing electronics.

For encoders with sinusoidal output

signals, however, the errors of the signal

processing electronics are determined by

the subsequent electronics.

The following individual factors influence

the result:

• The size of the signal period

• The homogeneity and period definition

of the graduation

• The quality of scanning filter structures

• The characteristics of the sensors

• The stability and dynamics of further

processing of the analog signals

These deviations are to be considered

when specifying position error within one

signal period.

Position error within one signal period ± u

is specified in percent of the signal period.

For length gauges, the value is typically

better than ± 1% of the signal period. You

will find the specified values in the

Specifications.

Short-range accuracy

The short-range accuracy describes an

error that occurs within a distance of

± 100 µm from a measuring point. It

includes electronic and mechanical

influences of the gauge on the result of

measurement. The values for short-range

accuracy typically lie below the specified

values.

12

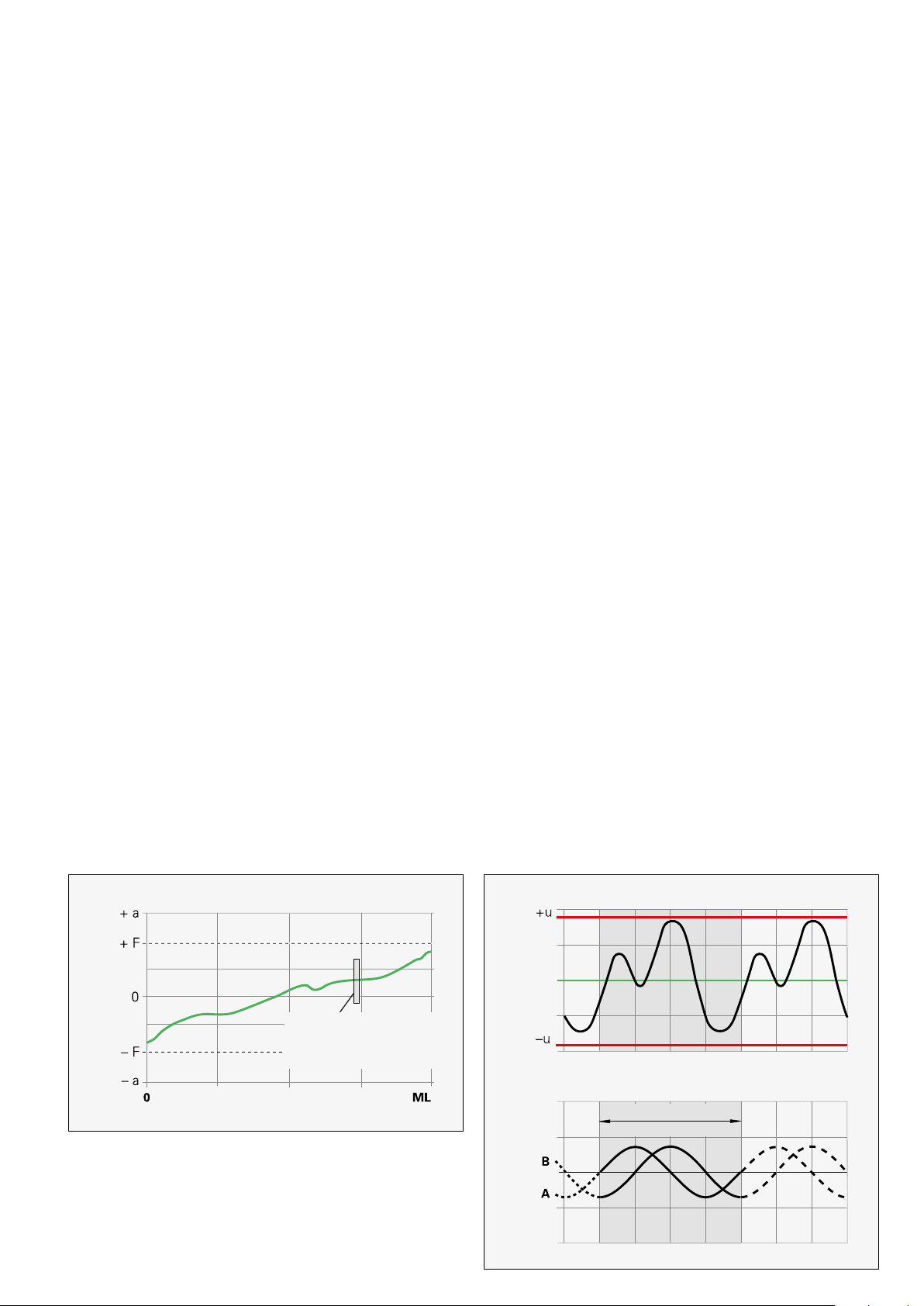

Position error

Position error a over the measuring length ML

Position error within

one signal period

Position

Position error u within one signal period

Position error

Signal level

Signal period

360 °elec.

Page 13

Application-dependent error

Other factors besides the system accuracy

also influence the attainable total accuracy

of measurement. These include in particular the ambient temperature and temperature fluctuations during measurement as

well as a stable, orthogonal measuring

setup.

All components included in the measuring

loop, such as the holder for the measured

object, the gauge stand with holder, and

the length gauge itself, influence the result

of measurement. Expansion or deformation of the measuring setup through mechanical or thermal influences adds directly

to the error.

Mechanical design

A stable measuring assembly must be

ensured. Long lateral elements within the

measuring loop are to be avoided. HEIDENHAIN offers a stable gauge stand as an

accessory. The force resulting from the

measurement must not cause any measurable deformation of the measuring loop.

Length gauges from HEIDENHAIN operate

with small gauging force and have very

little influence on the measuring setup.

Orthogonal mounting

The length gauge is to be mounted so that

its plunger is exactly orthogonal to the

measured object or the surface on which it

rests. Deviations result in measuring error.

The accessory HEIDENHAIN gauge stands

with holders for an 8 mm clamping shank

ensure orthogonal mounting. Length

gauges that provide planar mounting

surfaces are to be adjusted in the direction

parallel to the mounting surface (Y) to be

perpendicular to the measuring plate. A

quick and reliable adjustment is possible

with the aid of a gauge block or a parallel

block. The perpendicularity to the measuring table (X) is already ensured by the

gauge stand.

Thermal characteristics

Temperature variations during measurement cause changes in length or deformation of the measuring setup. After a change

in temperature of 5 K, a steel bar of 200 mm

length expands by 10 µm.

Length changes resulting from a uniform

deviation from the reference temperature

can largely be compensated by resetting

the datum on the measuring plate or a

master; only the expansion of the scale

and measured object go into the result of

measurement.

Temperature changes during measurement

cannot be ascertained mathematically. For

critical components, HEIDENHAIN therefore uses special materials with low coefficients of expansion, such as are found in

the HEIDENHAIN-CERTO gauge stand.

This makes it possible to guarantee the

high accuracy of HEIDENHAIN-CERTO

even at ambient temperatures of 19 °C

to 21 °C and variations of ± 0.1 K during

measurement.

In order to measure with complete

accuracy, the length gauge should be

switched on approximately 15 minutes

before the first measurement.

The measuring loop: All components involved

in the measuring assembly, including the length

gauge

Orthogonal mounting

Thermally induced change in length:

Expansion of the measuring loop components

as a result of heat

13

Page 14

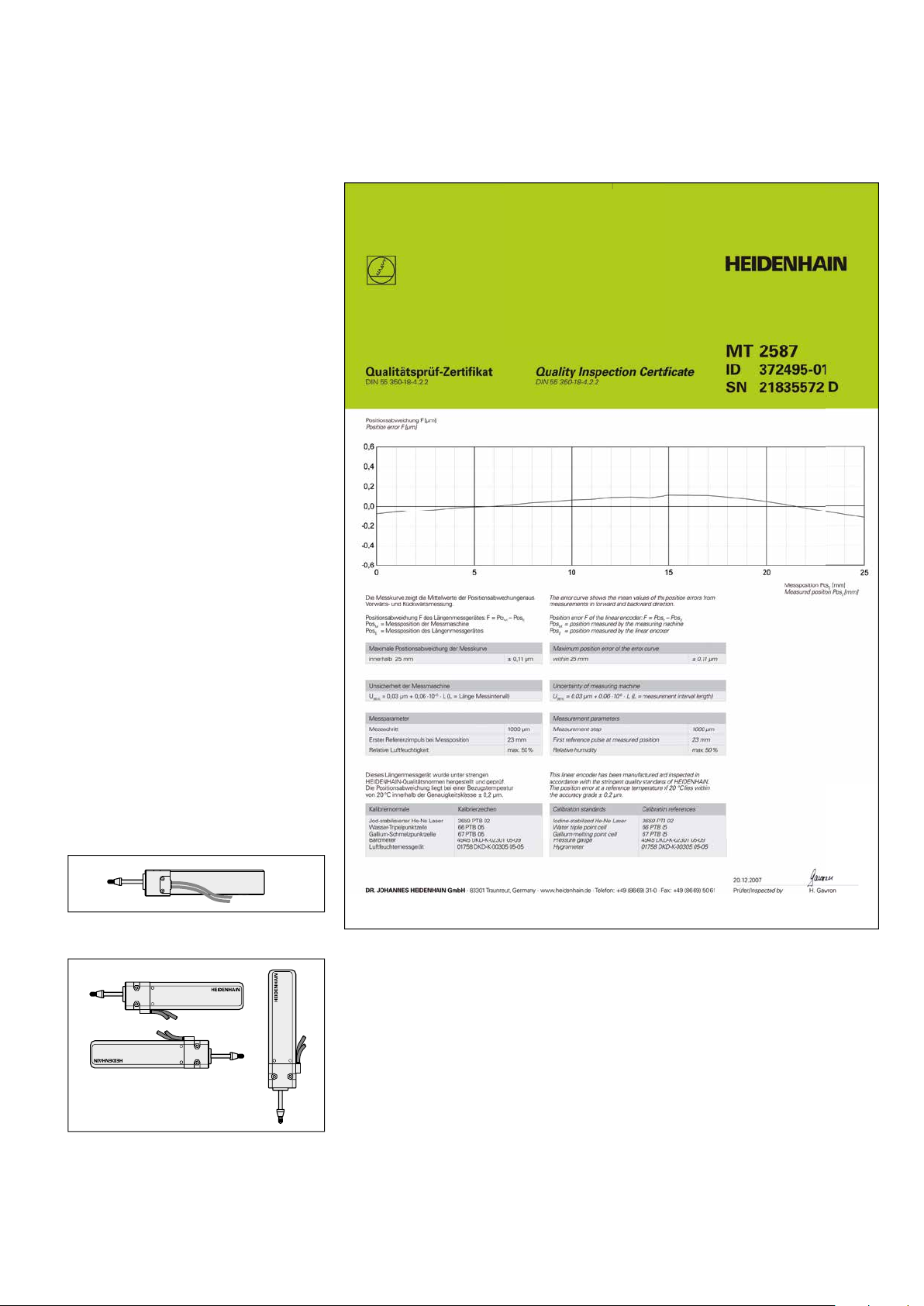

Calibration chart

All HEIDENHAIN length gauges are inspected before shipping for accuracy

and proper function.

They are calibrated for accuracy during

retraction and extension of the plunger. For

HEIDENHAIN-CERTO gauges, the number

of measuring positions is selected to

ascertain very exactly not only the longrange error, but also the position error

within one signal period.

The Quality Inspection Certifi cate

confi rms the specifi ed system accuracy

of each length gauge. The calibration

standards ensure the traceability—as

required by EN ISO 9001—to recognized

national or international standards.

For the HEIDENHAIN-METRO and HEIDENHAIN-CERTO series, a calibration chart

documents the position error over the

measuring range. It also shows the measuring step and the measuring uncertainty

of the calibration measurement.

For HEIDENHAIN-METRO gauges the

calibration chart shows the mean value of

one forward and one backward measuring

stroke.

The HEIDENHAIN-CERTO calibration chart

shows the envelope curve of the measured error. The HEIDENHAIN-CERTO

length gauges are supplied with two calibration charts, each for different operating

attitudes.

1

Operating attitude for calibration chart 1

2

4

3

Example

Temperature range

The length gauges are inspected at a

reference temperature of 20 °C. The

system accuracy given in the calibration

chart applies at this temperature.

Operating attitude for calibration chart 2

14

The operating temperature indicates the

ambient temperature limits between which

the length gauges will function properly.

The storage temperature range of -20 °C

to 60 °C applies for the device in its packaging.

Page 15

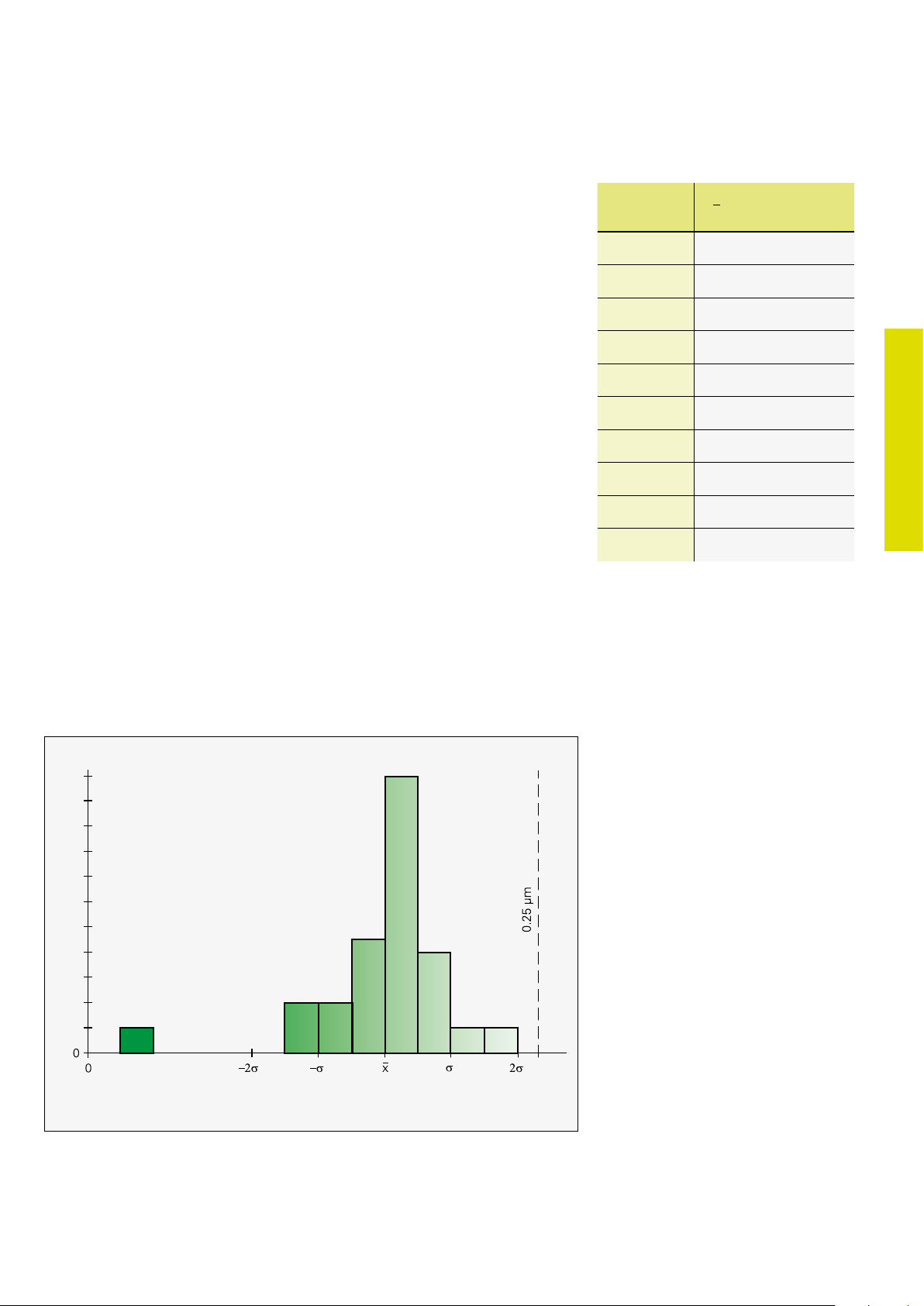

Repeatability

Whereas the system accuracy applies over

the entire measuring range, for some

applications the repeatability is the decisive

factor. It plays an important role in repeated

measurements.

Repeatability is defined in the standards

DIN 32876 and DKD-R 4-3, and describes

a length gauge’s capability to supply very

similar measured values for identical measurands and conditions.

HEIDENHAIN ascertains the repeatability

of the length gauges with five measurements near the lower plunger stop. The

plunger is completely extended and retracted at medium speed. Since the length

gauge was already in operation for at least

10 minutes before this, it is already in a stable thermal state.

The repeatability of the length gauges is

usually better than the values listed in the

table. The characteristic statistical distribution is shown in the diagram, using the

ST 1200 as an example.

Repeatability depends on the

• combinations of materials used in the

components,

• installed electronics,

• optomechanics used, and the

• bearing of the plunger.

Series Repeatability

< x

± 2s

AT 1200

AT 3000

CT 2500

CT 6000

MT 101

MT 1200

MT 2500

MT 60

ST 1200

ST 3000

0.4 µm

0.8 µm

0.02 µm

0.03 µm

0.04 µm

0.03 µm

0.09 µm

0.06 µm

0.25 µm

0.7 µm

Frequency

ST 1200: Statistical distribution of the repeatability

Repeatability

15

Page 16

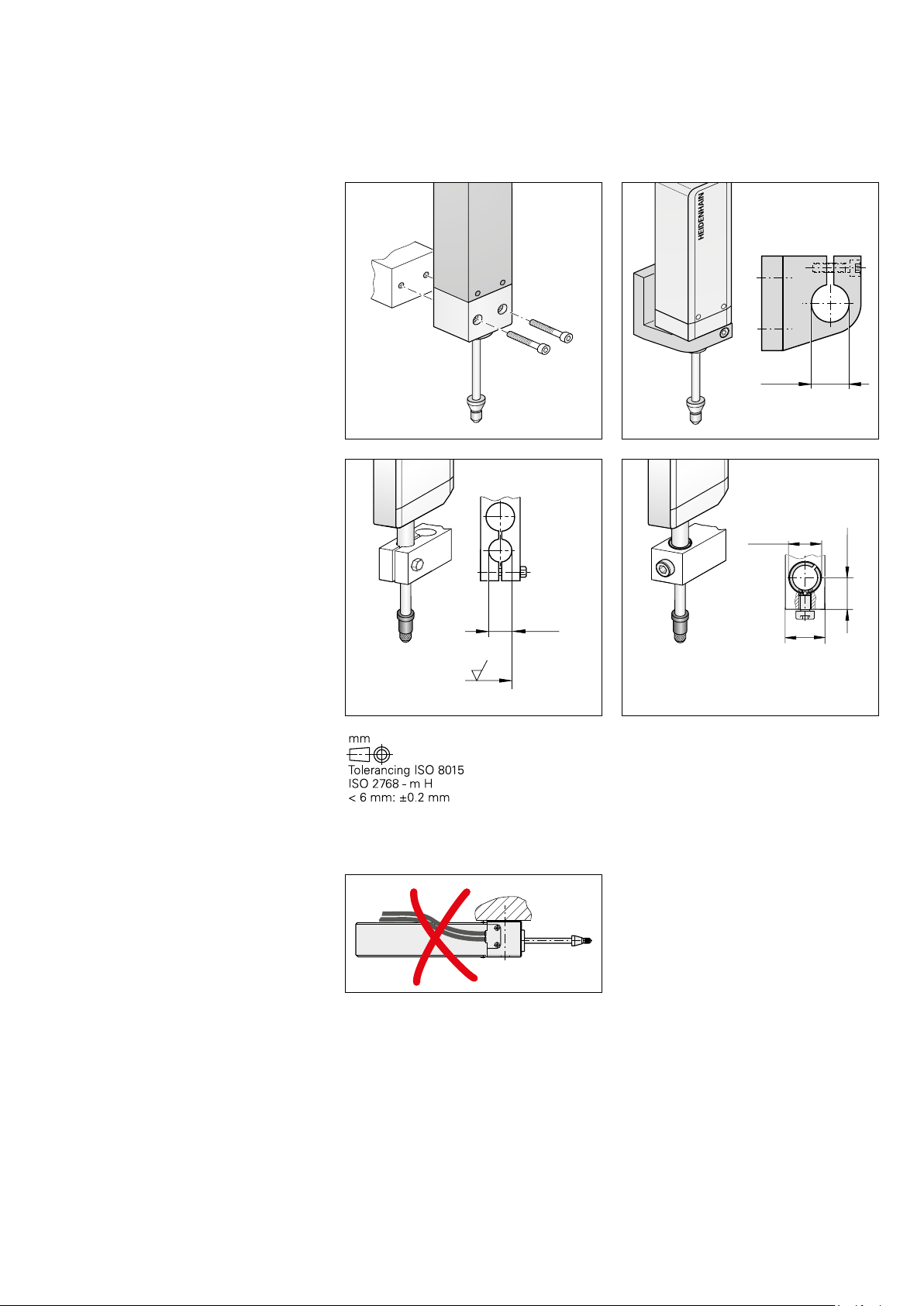

Mounting

Abbe principle

HEIDENHAIN length gauges enable you

to work according to the Abbe measuring

principle: The measured object and scale

must be in alignment to avoid additional

measuring error.

Fastening

The CT 6000, MT 60 and MT 101 length

gauges are fastened by two screws onto a

plane surface. This ensures a mechanically

stable installation of even these large

length gauges. Special holders are available

for fastening the MT 60 and MT 101 to the

MS 100 gauge stand for the HEIDENHAINMETRO (see Accessories).

The CT 2500 is mounted by its standard

clamping shank with 16h8 diameter. A

holder is available for fastening the

HEIDENHAIN-CERTO to the gauge stand

(see Accessories).

The AT, ST, MT 1200 and MT 2500 length

gauges feature a standard clamping shank

with 8h6 diameter. These HEIDENHAIN

length gauges can therefore easily be used

with existing measuring fixtures and

stands.

As an accessory, HEIDENHAIN offers a

special clamping sleeve and screw. It

facilitates fastening the length gauge

securely without overstressing the

clamping shank.

Clamping sleeve ID 386811-01

CT 6000

MT 60

MT 101

CT 2500

–

Secured with clamping sleeve

Operating attitude for HEIDENHAINCERTO

The HEIDENHAIN-CERTO can be operated

at any attitude. However, the mounting

position with horizontal length gauge and

upward facing mounting surface should be

avoided because in such a case no

guarantee can be made for accuracy.

16

Page 17

Setup

HEIDENHAIN length gauges function

according to the Abbe measuring

principle, i.e. the measuring standard and

the plunger are exactly aligned. All

components comprising the measuring

loop, such as the measuring standard,

plunger, holder and scanning head are

designed in terms of their mechanical and

thermal stability for the highest possible

accuracy of the length gauge.

The plungers of the HEIDENHAIN length

gauges are locked against rotation. Their

optimally round form stays unchanged

while stability and thermoconductivity

remain unimpaired. They are provided with

an M2.5 thread to hold measuring contacts

(see Accessories)

The plungers of the HEIDENHAIN-ACANTO

and HEIDENHAIN-SPECTO ST 1200 length

gauges are protected by a rubber bellows.

The bellows are characterized by high resistance to chemical and thermal influences and have a relatively low stiffness. Its

influence on the gauge’s mechanical behavior and the measuring force is therefore

low.

Thermal characteristics

HEIDENHAIN length gauges have a defined thermal behavior. Since temperature

variations during measurement can result

in changes in the measuring loop, HEIDENHAIN uses special materials with low coefficients of expansion Þ

for the compo-

therm

nents of the measuring loop, for example

in the HEIDENHAIN-CERTO length gauges.

The scale is manufactured of Zerodur

(Þ

0 K–1), and the plunger and holder

therm

are of Invar (Þ

1 x 10–6 K–1). This

therm

makes it possible to guarantee its high

measuring accuracy over a relatively large

temperature range.

Acceleration

Length gauges from HEIDENHAIN feature

a sturdy design. Even high vibration and

shock loads have no negative influence on

the accuracy.

However, shock and vibration of any kind is

to be avoided during measurement so as

not to impair the high accuracy of measurement. The maximum values given in the

specifications for shock and vibration apply

to the effect of external acceleration on the

length gauge. They describe only the

mechanical stability of the length gauge,

and imply no guarantee of function or

accuracy.

In the length gauge itself, unchecked

extension of the spring-driven or noncoupled moving plunger can cause high

acceleration onto the measured object or

measuring plate surface. For the MT 1200

and MT 2500 series length gauges, use

the cable-type lifter whenever possible

(see Accessories). The cable lifter features

adjustable pneumatic damping to limit the

extension velocity to an uncritical value.

Design of CT 6000,

MT 60

Measuring standard

(scale)

Scanning unit with light

source and photovoltaic cells

Holder

Ball-bush guide

Plunger

Design of ST 1200

Connecting cable

Scanning unit with light

source, photocells and

scanning electronics

Measuring standard

Ball-bush guide

Plunger

Rubber bellows

Measuring contact

Measuring contact

17

Page 18

Plunger guideway

HEIDENHAIN length gauges are available

with various plunger guides.

The plungers of the HEIDENHAIN-ACANTO

length gauges work with sliding guides.

The sliding guides have the following

properties:

• Sturdiness thanks to few moving parts

• High tolerance to shock and vibration

• High plunger speeds and long service life

thanks to high-quality ceramic bearings

• Less sensitivity to improper clamping

The HEIDENHAIN-METRO, HEIDENHAINCERTO, and HEIDENHAIN-SPECTO length

gauges are equipped with a ball-bush

guide. The following are some of the basic

properties of ball guides in HEIDENHAIN

length gauges:

• Low friction, which makes versions of

length gauges with reduced gauging

force possible

• Safe plunger extension and retraction

even with high radial force

• High precision of the measuring loop

thanks to a guide that is free of play (the

bearing and plunger are specially fitted

during manufacture)

Expendable parts

HEIDENHAIN length gauges contain

components that are subject to wear,

depending on the application and handling.

These include in particular the following

parts:

• Guideway (tested for at least 60 million

strokes*)

• Cable link for CT, MT 60 and MT 101

(tested for at least 1 million strokes*)

• Scraper rings

• Rubber bellows for AT and ST 1200

* With CT, MT 60 M and MT 101 M

only with actuation by switch box

Note

DIADUR is a registered trademark of

DR. JOHANNES HEIDENHAIN GmbH,

Traunreut, Germany.

Zerodur®is a registered trademark of

Schott Glaswerke in Mainz, Germany.

Sliding guide Ball-bush guide

18

Page 19

Gauging force – plunger actuation

Gauging force

Gauging force is the force that the plunger

exercises on the measured object. An

excessively large gauging force can cause

deformation of the measuring contact and

the measured object. If the gauging force

is too small, an existing dust film or other

obstacle may prevent the plunger from

fully contacting the measured object. The

gauging force depends on the type of

plunger actuation.

Plunger actuation by spring

For the AT 1218, AT 3018, MT 12x1, MT 25x1,

ST 12x8 and ST 30x8, the integral spring

extends the plunger to the measuring position and applies the gauging force. In its

resting position, the plunger is extended.

The gauging force depends on the following criteria:

• The operating attitude

• The plunger position, i.e. the force

changes over the measuring range

• The measuring direction, i.e., whether

the gauge measures with extending or

retracting plunger

In the diagrams, the measuring force is

shown over the measuring range for a

retracting and extending plunger in a

horizontal operating attitude.

The gauging forces can be divided into the

following classes:

• Reduced MR: Approx. half the gauging

force of the standard variant.

• Low MW: Gauging force at the

beginning of the measuring range,

approx 0.01 N

• Springless MG: Constant gauging force

over the entire measuring range

In order not to influence the gauging force,

the variants ST 1288 MR and ST 1288 MG

are provided without a rubber bellows. Due

to their low gauging force, the variants

MT 1281 MW, MT 1281 MG and ST 1288 MG

can only be used for measuring vertically

downward. For this reason, the diagram

shows only gauging forces for a vertical

operating orientation.

Plunger actuation by measured object

The complete length gauge is moved

relative to the measured object, normally

while the plunger retracts.

Plunger actuation via cable-type lifter

(MT 12x1, MT 25x1)

Through a cable mechanism, the plunger is

retracted by hand and then extended onto

the measured object. The measurement is

made with extending plunger.

The integral pneumatic damping reduces

the plunger extension speed to prevent

bouncing, for example on very hard materials. This prevents measuring error through

bouncing.

The MT 1281 and ST 1288 length gauges

are available with various gauging forces.

Particularly for fragile materials this makes it

possible to measure without deformation.

Special variants 12 mm measuring range 25 mm/30 mm measuring range

0.35

0.30

0.25

0.20

Gauging force [N]

0.15

0.10

0.05

MT 1281 MW extending

MT 1281 MW retracting

MT 1281 MR extending

MT 1281 MR retracting

ST 1288 MR extending

ST 1288 MR retracting

Gauging force [N]

MT 12x1 extending

MT 12x1 retracting

ST 12x8 extending

ST 12x8 retracting

AT 1218 extending

AT 1218 retracting

2.0

1.8

1.6

1.4

1.2

Gauging force [N]

1.0

0.8

0.6

0.4

MT 25x1 extending

MT 25x1 retracting

ST 30x8 extending

ST 30x8 retracting

AT 3018 extending

AT 3018 retracting

0.00

Distance [mm]

0.2

Distance [mm]

5 10 15 20 25 30

0

Distance [mm]

19

Page 20

Pneumatic plunger actuation

The pneumatically actuated plungers of

the AT 1217, AT 3017, MT 1287, MT 2587,

ST 12x7 and ST 30x7 length gauges are

extended by the application of compressed

air. When the air connection is ventilated,

the integral spring retracts the plunger. to a

protected resting position within the

housing.

The gauging force can be adjusted to the

measuring task through the level of air

pressure. At constant pressure, it depends

on the operating attitude and the plunger

position.

The working pressure defines the pressure

range of the first complete plunger extension up to the maximum specified range.

Note

The compressed air introduced directly into

the length gauges must be properly

conditioned and must comply with the

following quality classes as per ISO 8573-1

(1995 edition):

• Solid contaminants Class 1

(max. particle size 0.1 µm and max.

particle density 0.1 mg/m

• Total oil content: Class 1

(max. oil concentration 0.01 mg/m

at 1 · 10

5

Pa)

3

at 1 · 105 Pa)

3

• Max. pressure dew point: Class 4,

but with reference conditions of

+3 °C at 2 · 10

5

Pa

The diagrams show the respective measuring force for a horizontal operating attitude

depending on the working pressure applied

with the plunger fully extended and fully retracted. These are approximate values that

are subject to changes due to tolerances

and depend on seal wear.

12 mm measuring range

(pneumatically actuated)

MT 12x7 retracted

MT 12x7 extended

ST 12x7 retracted

ST 12x7 extended

AT 1217 retracted

AT 1217 extended

25 mm/30 mm measuring range

(pneumatically actuated)

MT 2587 retracted

MT 2587 extended

ST 30x7 retracted

ST 30x7 extended

AT 3017 retracted

2.4

2.0

AT 3017 extended

HEIDENHAIN offers the DA 400 com-

pressed air unit for purifying compressed

air. The minimum flow rate is 10 l/min.

For more information, ask for our DA 400

Product Information Sheet.

Except for special variants, the diagrams

apply for the horizontal operating

attitude. The following compensation

values are to be taken into account for

other operating attitudes.

Type

Operating attitude vertical

North South

20

Gauging force [N]

Pressure [bars]

1.6

AT 121x

AT 301x

Gauging force [N]

1.2

MT 12xx

MT 25x1

0.8

MT 2587

ST 12x7

0.4

0.0

0.8 1.2 1.6 2.0 2.4 2.8

0.4

Pressure [bars]

ST 12x8

ST 30xx

– 0.12 N

– 0.18 N

– 0.13 N

– 0.17 N

– 0.19 N

– 0.07 N

– 0.08 N

– 0.11 N

+ 0.12 N

+ 0.18 N

+ 0.13 N

+ 0.17 N

+ 0.19 N

+ 0.07 N

+ 0.08 N

+ 0.11 N

Page 21

Motorized plunger actuation

The CT 2501, CT 6001, MT 60 M and

MT 101 M length gauges feature an integral

motor that moves the plunger. It is operated through the switch box either by push

button or over the connection for external

actuation. The plungers of the CT 2501,

CT 6001 and MT 60 M length gauges must

not be moved by hand if the switch box is

connected.

The gauging force of the CT 2501,

CT 6001, and MT 60 M motorized length

gauges is adjustable in three stages

through the switch box. The force remains

constant over the measuring range but

depends on the operating attitude.

Regardless of the operating attitude—

whether it measures vertically downward

(with the SG 101 V switch box) or

horizontally (with the SG 101 H switch

box)—the MT 101 M exercises a constant

gauging force.

CT 2501

MT 60 M MT 101 M

CT 6001

Gauging force

By motor By motor By motor

Vertically downward 1 N/1.25 N/1.75 N 1 N/1.25 N/1.75 N 0.7 N with SG 101 V

Vertically upward –/–/0.75 N –/–/0.75 N –

Horizontal –/0.75 N/1.25 N –/0.75 N/1.25 N 0.7 N with SG 101 H

External plunger actuation by coupling

For the CT 2502, CT 6002, MT 60 K,

MT 101 K and special versions (without

spring) of the MT 1200, MT 2500, and

ST 1288, the plunger is freely movable.

For position measurement, the plunger is

connected by a coupling with a moving

machine element. The force needed to

move the plunger is specified as the

required moving force. It depends on

the operating attitude.

Gauging force

CT 2502

CT 6002

Moving force

MT 60 K MT 101 K

MT 1271 « TTL

MT 1281 » 1 V

1)

Moving force1)Moving force1)– – –

MT 2571 « TTL

MT 2581 » 1 V

PP

ST 1288

PP

Vertically downward 0.6 N 0.35 N 1.7 N 0.13 N 0.17 N 0.2 N

Vertically upward 0.1 N 0.1 N 2 N – – –

Horizontal 0.6 N 0.5 N 0.4 N – – –

1)

Force required to move the plunger or of its weight

21

Page 22

HEIDENHAIN-ACANTO

Absolute length gauges with EnDat interface

• Very compact dimensions

• Splash-proof

• Plain-bush guided plunger

AT 1200

AT 3000

Dimension changes under max. pressure (1.8 bars)

22

ML = Measuring length

= Clamping area

= Air connection for 2 mm tube

Page 23

Mechanical data AT 1218 AT 3018 AT 1217 AT 3017

Plunger actuation

Position of plunger at rest

Measuring standard

System accuracy

By measured object

Extended

Pneumatic

Retracted

DIADUR grating on glass; grating period 188.4 µm

± 2 µm

Position error per signal period ± 0.7 µm

Measuring range

Working pressure

Mech. permissible traversing speed

Radial force

Fastening

12 mm 30 mm 12 mm 30 mm

– 0.7 bar to 1.8 bars 1.1 bars to 1.8 bars

80 m/min 120 m/min 80 m/min 120 m/min

0.5 N (mechanically permissible)

Clamping shank ¬ 8h6

Operating attitude Any

2

Vibration 55 Hz to 2 000 Hz

Shock 11 ms

Operating temperature

100 m/s

500 m/s

10 °C to 40 °C; reference temperature 20 °C

(EN 60 068-2-6)

2

(EN 60 068-2-27)

Protection EN 60 529 IP 67 IP 64

IP 67 upon request

1)

IP 64

1)

Weight without cable 80 g 100 g 80 g 100 g

1)

IP67 with sealing air

Electrical data EnDat

Interface

EnDat 2.2

Ordering designation EnDat 22

Resolution 23 nm 368 nm 23 nm 368 nm

Calculation time t

cal

Clock frequency

Electrical connection

5 µs

8 MHz

M12 flange socket (male) 8-pin

Cable length 100 m with HEIDENHAIN cable

Voltage supply 3.6 V to 14 V DC

Power consumption (max.) 3.6 V: 550 mW

14 V: 650 mW

Current consumption (typical) 5 V: 80 mA (without load)

23

Page 24

HEIDENHAIN-CERTO

Incremental length gauges with ± 0.1 µm/± 0.051) µm*/± 0.03 µm1) accuracy

• For very high accuracy

• For inspection of measuring equipment and gauge blocks

• Ball-bush guided plunger

CT 2500

CT 6000

24

= Reference mark

position

Page 25

Specifications CT 2501 CT 6001 CT 2502 CT 6002

Plunger actuation

Measuring standard

System accuracy

At 19 °C to 21 °C

By motor Via coupling with moving machine part

DIADUR phase grating on Zerodur glass ceramic; grating period 4 µm

± 0.1 µm,

± 0.03 µm

1)

± 0.1 µm,

± 0.05 µm

1)

± 0.1 µm,

± 0.03 µm

1)

Position error per signal period ± 0.02 µm

Short-range accuracy typically 0.03 µm

Reference mark

Measuring range

Radial force

Fastening

One, ≈ 1.7 mm below upper stop

25 mm 60 mm 25 mm 60 mm

0.5 N (mechanically permissible)

Clamping shank

¬ 16h8

Plane surface Clamping shank

¬ 16h8

Operating attitude Any required (for preferred operating attitude see Mounting)

2

Vibration 55 to 2 000 Hz

Shock 11 ms

Operating temperature

100 m/s

1 000 m/s

10 °C to 40 °C; reference temperature 20 °C

(EN 60 068-2-6)

2

(EN 60 068-2-27)

± 0.1 µm,

± 0.05 µm

1)

Plane surface

Protection EN 60 529 IP50

Weight without cable 520 g 700 g 480 g 640 g

Electrical data CT 2501 CT 6001 CT 2502 CT 6002

Interface

» 11 µA

PP

Signal period 2 µm

Measuring velocity 24 m/min (depending on the subsequent electronics)

12 m/min with the ND 28x display unit

Electrical connection*

• Cable 1.5 m with D-sub connector (male), 15-pin

• Cable 1.5 m with M23 connector (male), 9 pin

Interface electronics are integrated in connector.

Cable length 30 m

Voltage supply 5 V DC ± 0.25 V/< 170 mA 5 V DC ± 0.25 V/< 120 mA

Required accessories* For CT 2501 For CT 6001

Switch box

* Please select when ordering

1)

After linear length-error compensation in the evaluation electronics

2)

Force required to move the plunger or of its weight

SG 25 M SG 60 M

25

Page 26

HEIDENHAIN-METRO

Incremental length gauges with ± 0.2 µm accuracy

• High repeatability

• Plunger actuation by cable release, by the workpiece or pneumatically

• Ball-bush guided plunger

MT 1200

L1

L2

L3

MT 12x1 MT 1287

18.5 22.0

10.1 6.2

8.1 4.2

MT 2500

L1

L2

L3

MT 1287

MT 2587

MT 25x1 MT 2587

37.0 41.0

10.1 6.2

8.1 4.2

26

= Reference mark position

= Beginning of measuring length

= Clamping area

= Air connection for 2 mm tube

Page 27

Mechanical data

Plunger actuation

Position of plunger at rest

Measuring standard

System accuracy

MT 1271 « TTL

MT 1281 » 1 V

By cable or measured object

Extended

DIADUR phase grating on Zerodur glass ceramic; grating period 4 µm

± 0.2 µm

MT 2571 « TTL

MT 2581 » 1 V

PP

MT 1287 » 1 VPPMT 2587 » 1 V

PP

Pneumatic

Retracted

Position error per signal period ± 0.02 µm

Short-range accuracy typically 0.03 µm 0.04 µm 0.03 µm 0.04 µm

PP

Reference mark

Measuring range

Working pressure

Radial force

Fastening

≈ 1.7 mm below upper stop

12 mm 25 mm 12 mm 25 mm

– 0.9 bar to 1.4 bars

0.8 N (mechanically permissible)

Clamping shank ¬ 8h6

Operating attitude Any; for version without spring and with low gauging force: vertically downward

2

Vibration 55 Hz to 2 000 Hz

Shock 11 ms

Operating temperature

100 m/s

1 000 m/s

10 °C to 40 °C; reference temperature 20 °C

(EN 60 068-2-6)

2

(EN 60 068-2-27)

Protection EN 60 529 IP50 IP64 (with sealing air)

Weight without cable 100 g 180 g 110 g 190 g

Electrical data MT 1271

MT 2571

MT 128x

MT 258x

Interface

« TTL » 1 V

PP

Integrated interpolation* 5-fold 10-fold –

Signal period 0.4 µm 0.2 µm 2 µm

Mech. permissible traversing speed

Edge separation a at

scanning frequency*/traverse speed

200 kHz 24 m/min

100 kHz 12 m/min

50 kHz 6 m/min

25 kHz 3 m/min

Electrical connection*

(Interface electronics integrated in

connector)

1)

30 m/min

0.23 µs

0.48 µs

0.98 µs

–

–

0.23 µs

0.48 µs

0.98 µs

Cable 1.5 m with D-sub connector (male),

15-pin

–

Cable 1.5 m with

• D-sub connector (male), 15-pin

• M23 connector (male), 12-pin

Cable length 30 m with HEIDENHAIN cable

Voltage supply 5 V DC ± 0.5 V/< 160 mA (without load) 5 V DC ± 0.25 V/< 130 mA

* Please select when ordering

1)

At the corresponding cutoff or scanning frequency

27

Page 28

HEIDENHAIN-METRO

Incremental length gauges with ± 0.5 µm/± 1 µm accuracy

• Large measuring ranges

• For dimensional and positional measurement

• Ball-bush guided plunger

MT 60 M

MT 60

MT 101 M

MT 101

28

= Reference mark position

Page 29

Specifications MT 60 M MT 101 M MT 60 K MT 101 K

Plunger actuation

Measuring standard

System accuracy

By motor Via coupling with moving machine part

DIADUR grating on silica glass; grating period 10 µm

± 0.5 µm ± 1 µm ± 0.5 µm ± 1 µm

Position error per signal period ± 0.1 µm

Reference mark

Measuring range

≈ 1.7 mm from top ≈ 10 mm from top ≈ 1.7 mm from top ≈ 10 mm from top

60 mm 100 mm 60 mm 100 mm

Radial force mech. permissible 0.5 N 2 N 0.5 N 2 N

Fastening

Operating attitude Any Vertically downward

Plane surface

Any

with SG 101 V

Horizontal with

SG 101 H

2

Vibration 55 Hz to 2 000 Hz

Shock 11 ms

Operating temperature

100 m/s

1 000 m/s

10 °C to 40 °C; reference temperature 20 °C

(EN 60 068-2-6)

2

(EN 60 068-2-27)

Protection EN 60 529 IP50

Weight without cable 700 g 1400 g 600 g 1200 g

Electrical data MT 60 M MT 101 M MT 60 K MT 101 K

Interface

» 11 µA

PP

Signal period 10 µm

Measuring velocity 18 m/min 60 m/min 18 m/min 60 m/min

Electrical connection*

Cable 1.5 m with 15-pin D-sub connector (male) or with 9-pin M23 connector (male)

Cable length 30 m with HEIDENHAIN cable

Voltage supply 5 V DC ± 0.25 V

Current requirement < 120 mA < 70 mA

Required accessories* For MT 60 M For MT 101 M

Switch box

SG 60 M Vertical orientation: SG 101 V

Horizontal orientation: SG 101 H

power supply unit

* Please select when ordering

1)

Force required to move the plunger or of its weight

– Required (see Accessories)

29

Page 30

HEIDENHAIN-SPECTO

Incremental length gauges with ± 1 µm accuracy

• Very compact dimensions

• Splash-proof

• Ball-bush guided plunger

ST 1200

ST 3000 ST 12x7

ST 30x7

–

30

= Reference mark position

= Beginning of measuring length

= Clamping area

= Air connection for 2 mm tube

Page 31

Mechanical data

ST 1278 « TTL

ST 1288 » 1 V

Plunger actuation

Position of plunger at rest

Measuring standard

System accuracy

By measured object

Extended

DIADUR grating on glass; grating period 20 µm

± 1 µm

Position error per signal period ± 0.2 µm

Short-range accuracy typically 0.3 µm

ST 3078 « TTL

ST 3088 » 1 V

PP

ST 1277 « TTL

ST 1287 » 1 V

PP

Pneumatic

Retracted

ST 3077 « TTL

ST 3087 » 1 V

PP

PP

Reference mark

Measuring range

Working pressure

Radial force

Fastening

≈ 5 mm below upper stop

12 mm 30 mm 12 mm 30 mm

– 0.7 bar to 2.5 bars 0.8 bar to 2.5 bars

0.8 N (mechanically permissible)

Clamping shank ¬ 8h6

Operating attitude Any

2

Vibration 55 Hz to 2 000 Hz

Shock 11 ms

Operating temperature

100 m/s

1 000 m/s

10 °C to 40 °C; reference temperature 20 °C

(EN 60 068-2-6)

2

(EN 60 068-2-27)

Protection EN 60 529 IP67/IP64 IP 64

Weight without cable 40 g 50 g 40 g 50 g

Electrical data ST 127x

ST 307x

Interface

« TTL » 1 V

ST 128x

ST 308x

PP

Integrated interpolation* 5-fold 10-fold –

Signal period 4 µm 2 µm 20 µm

Edge separation a at

scanning frequency*/traverse speed

100 kHz 72 m/min

1)

50 kHz 60 m/min

25 kHz 30 m/min

Electrical connection*

2)

0.48 µs

0.98 µs

1.98 µs

Cable 1.5 m with D-sub connector (male),

15-pin (integrated interface electronics)

0.23 µs

0.48 µs

0.98 µs

–

Cable 1.5 m with

• D-sub connector (male), 15-pin

• M23 connector (male), 12-pin

Cable outlet* Axial or radial

Cable length 30 m with HEIDENHAIN cable

Voltage supply 5 V DC ± 0.5 V

Current requirement < 195 mA (without load) < 55 mA

* Please select when ordering

1)

Mechanically limited

2)

At the corresponding cutoff or scanning frequency

31

Page 32

Accessories

Measuring contacts

Ball-type contact

Steel ID 202504-01

Carbide ID 202504-02

Ruby ID 202504-03

Pin-type contact

Steel ID 202505-01

Domed contact

Carbide ID 229232-01

Knife-edge contact

Steel ID 202503-01

Flat contact

Steel ID 270922-01

Carbide ID 202506-01

Roller contact, steel

For a low-friction contact with moving surfaces

Crowned ID 202502-03

Cylindrical ID 202502-04

32

Adjustable contact, carbide

For exact parallel alignment to the measuring plate surface

Flat ID 202507-01

Knife-edged ID 202508-01

Page 33

Switch boxes, coupling

Switch boxes for CT 2501, CT 6001,

MT 60 M, MT 101 M

Switch boxes are required for length

gauges with motorized plunger actuation.

The plunger is controlled through two push

buttons or by external signal. The SG 25 M

and SG 60 M switch boxes can adjust the

gauging force in three stages.

SG 25 M

ID 317436-01

SG 60 M

ID 317436-02

SG 1 01 V

For the MT 101 M in vertical operation

ID 361140-01

SG 101 H

For the MT 101 M in horizontal operation

ID 361140-02

Connector (female) 3-pin

For external operation of the switch box

ID 340646-05

1)

1)

1)

Separate power supply required

Power adapter for SG 101 V/H

An adapter to be connected to the switch

box powers the MT 101 M.

Voltage range 100 V to 240 V AC

Exchangeable plug adapter

(U.S. and Euro connectors included in

delivery)

ID 648029-01

Coupling

For connecting the plunger of the length

gauge (specifically for the MT 60 K,

MT 101 K, CT 2502 and CT 6002) to a

moving machine element

ID 206310-01

33

Page 34

Accessories for HEIDENHAIN-CERTO

Gauge stand

CS 200 gauge stand

For length gauges CT 2501*

CT 6001

ID 221310-01

Overall height 350 mm

Base ¬ 250 mm

Column ¬ 58 mm

Weight 15 kg

*) With special holder

The flatness of the CS 200 is determined

with the aid of a Fizeau interferometer.

Holder for CS 200

For the CT 2501 with ¬ 16 mm clamping

shank

ID 324391-01

No chips or flaws

34

Page 35

Ceramic suction plate, diaphragm pump

Ceramic suction plate

Wear-resistant working surface with high

surface quality specifically for inspecting

gauge blocks

ID 223100-01

The gauge block (class 1 or 2)—or any

other object with a plane surface—is

drawn by suction onto the top of the

ceramic plate. The ceramic plate is likewise

drawn to the granite base and held in place

through negative gauge pressure.

Parts for connecting the ceramic suction

plate with the diaphragm pump are among

the items supplied:

Pressure tubing 3 m

T-joint

Connecting piece

Diaphragm pump

Source of suction for drawing the

measured object and ceramic suction plate

Power consumption 20 W

Weight 2.3 kg

Line voltage 230 V AC/50 Hz

ID 754220-01

Line voltage 115 V AC/60 Hz

ID 754220-02

35

Page 36

Accessories for HEIDENHAIN-ACANTO, HEIDENHAIN-METRO

and HEIDENHAIN-SPECTO

Cable-type lifter, gauge stands

Cable lifter

For manual plunger actuation of MT 1200

and MT 2500. The integral pneumatic

damping reduces the plunger extension

speed to prevent bouncing, for example on

very hard materials.

ID 257790-01

MS 200 gauge stand

For length gauges AT

ST

MT 1200

MT 2500

MT 60 M

MT 101 M

ID 244154-01

Total height 346 mm

Base ¬ 250 mm

Column ¬ 58 mm

Weight 18 kg

1)

With special holder

Holder for MS 200

For mounting the length gauges

with ¬ 8 mm clamping shank,

e.g. AT, ST, MT 1200, MT 2500

ID 324391-02

1)

1)

1)

1)

Clamping sleeve

For length gauges AT, ST

MT 1200

MT 2500

For fixing the length gauge reliably without

overloading the 8h6 clamping shank.

Consisting of:

Sleeve, clamping screw

ID 386811-01 (1 piece)

ID 386811-02 (10 pieces)

36

Page 37

MS 45 gauge stand

For length gauges AT

ST

MT 1200

MT 2500

ID 202162-02

Overall height 196.5 mm

Measuring plate ¬ 49 mm

Column ¬ 22 mm

Weight 2.2 kg

MS 100 gauge stand

For length gauges AT

ST

MT 1200

MT 2500

MT 60 M

MT 101 M

ID 202164-02

Overall height 385 mm

Measuring plate 100 mm x 115 mm

Column ¬ 50 mm

Weight 18 kg

1)

With special holder

1)

1)

Holder for MS 100

For mounting the MT 60 M

ID 207479-01

For mounting the MT 101 M

ID 206260-01

37

Page 38

Interface electronics

Interface electronics from HEIDENHAIN

adapt the encoder signals to the interface

of the subsequent electronics. They are

used when the subsequent electronics

cannot directly process the output signals

from HEIDENHAIN encoders, or if

additional interpolation of the signals is

necessary.

Input signals of the interface electronics

Interface electronics from HEIDENHAIN

can be connected to encoders with

sinusoidal signals of 1 V

or 11 µA

the serial interfaces EnDat or SSI can also

be connected to various interface

electronics.

Output signals of the interface

electronics

Interface electronics with the following

interfaces to the subsequent electronics

are available:

• TTL square-wave pulse trains

• EnDat 2.2

• DRIVE-CLiQ

• Fanuc Serial Interface

• Mitsubishi high speed interface

• Yaskawa Serial Interface

• Profi bus

Interpolation of the sinusoidal input

signals

In addition to being converted, the

sinusoidal encoder signals are also

interpolated in the interface electronics.

This permits fi ner measuring steps and, as

a result, higher control quality and better

positioning behavior.

(current signals). Encoders with

PP

(voltage signals)

PP

Box design

Plug design

Version for integration

Formation of a position value

Some interface electronics have an

integrated counting function. Starting from

the last reference point set, an absolute

position value is formed when the

reference mark is traversed, and is

transferred to the subsequent electronics.

Top-hat rail design

38

Page 39

Outputs Inputs Design – Protection class Interpolation1) or

subdivision

Interface Qty. Interface Qty.

Model

« TTL 1 » 1 V

» 11 µA

« TTL/

» 1 V

PP

2 » 1 V

Adjustable

PP

PP

PP

1 Box design – IP 65 5/10-fold

20/25/50/100-fold

Without interpolation

25/50/100/200/400-fold

Plug design – IP 40 5/10/20/25/50/100-fold

Version for integration –

5/10-fold

IP 00

20/25/50/100-fold

1 Box design – IP 65 5/10-fold

20/25/50/100-fold

Without/5-fold

25/50/100/200/400-fold

Version for integration –

5-fold

IP 00

1 Box design – IP 65 2-fold

5/10-fold

IBV 101

IBV 102

IBV 600

IBV 660 B

APE 371

IDP 181

IDP 182

EXE 101

EXE 102

EXE 602 E

EXE 660 B

IDP 101

IBV 6072

IBV 6172

EnDat 2.2 1 » 1 V

PP

1 Box design – IP 65 16 384-fold subdivision

Plug design – IP 40 16 384-fold subdivision

2 Box design – IP 65 16 384-fold subdivision

DRIVE-CLiQ 1 EnDat 2.2 1 Box design – IP 65 –

Fanuc Serial

1 » 1 V

PP

1 Box design – IP 65 16 384-fold subdivision

Interface

Plug design – IP 40 16 384-fold subdivision

2 Box design – IP 65 16 384-fold subdivision

Mitsubishi high

1 » 1 V

PP

1 Box design – IP 65 16 384-fold subdivision

speed interface

Plug design – IP 40 16 384-fold subdivision

2 Box design – IP 65 16 384-fold subdivision

Yaskawa Serial

1 EnDat 2.2

2)

1 Plug design – IP 40 –

Interface

PROFIBUS-DP 1 EnDat 2.1

1)

Switchable

2)

Only LIC 4100 with 5 nm measuring step, LIC 2100 with 50 nm and 100 nm measuring steps

EnDat 2.2 1 Top-hat rail design –

;

5/10-fold and 20/25/50/100fold

IBV 6272

EIB 192

EIB 392

EIB 1512

EIB 2391 S

EIB 192 F

EIB 392 F

EIB 1592 F

EIB 192 M

EIB 392 M

EIB 1592 M

EIB 3391 Y

PROFIBUS

Gateway

39

Page 40

Evaluation electronics units

For measuring and testing tasks

Evaluation electronics from HEIDENHAIN

combine measured value acquisition with

intelligent, application-specifi c further

processing. They are used in many

metrological applications, ranging from

simple measuring stations to complex

inspection systems with multiple

measuring points.

Evaluation units feature interfaces for

various encoder signals. They include units

with integrated display—which can be

used independently—and units that require

a PC for operation.

Unit with integrated display –

e.g. ND 2100 G GAGE-CHEK

ND 200

Evaluation unit for

• Measurement equipment

• Adjustment and inspection equipment

• SPC inspection stations

ND 1100 QUADRA-CHEK

Evaluation electronics for

• Positioning equipment

• Measuring fi xtures

The overview table lists evaluation

electronics for measuring and testing

tasks. You can fi nd comprehensive

information, including on other evaluation

units for 2-D and 3-D measuring tasks, on

the Internet under www.heidenhain.de or

in the product catalog Evaluation

Electronics for Metrology Applications.

Digital readouts for manual machine

tools optimally support the operator with

cycles for milling, drilling and turning. You

can fi nd these digital readouts on the

Internet at www.heidenhain.de or in the

product catalog Digital Readouts and

Linear Encoders for Manually Operated

Machine Tools.

Modular design – MSE 1000

Table-top design – EIB 700

ND 2100 G GAGE-CHEK

Evaluation electronics for

• Multipoint inspection apparatuses

• SPC inspection stations

MSE 1000

Modular evaluation electronics for

• Multipoint inspection apparatuses

• SPC inspection stations

EIB 700

Evaluation electronics for

• Testing stations

• Multipoint inspection apparatuses

• Mobile data acquisition

IK 220

Evaluation electronics for installation in

computer systems with PCI interface for

• Measuring and testing stations

40

Version for integration – IK 220

1)

Optional for ND 287

Page 41

Functions Input Interpolation or

Interface Qty. Interface

subdivision

Output Model

– » 1 V

• Metrological and statistical functions (sorting and

tolerance checking, measurement series, SPC)

• Second encoder

1)

for sum/difference display,

» 11 µA

EnDat

temperature compensation

• Measurement series with min./max. value storage

• Connection for touch probe

• Programming of up to 100 parts

• Graphic display of measurement results

• Sorting and tolerance checking using tolerance and

» 1 V

« TTL

» 1 V

« TTL

EnDat

warning limits

• Measurement series with min./max. value storage

• Entry of formulas and combinations

• Functions for statistical process control (SPC)

• Modular design

• Configurable as desired

• Various interfaces

• Fast communication with higher-level computer

system

• Universal outputs

» 1 V

« TTL

EnDat

Analog

LVDT

HBT

PP

PP

PP

PP

1 4096-fold RS-232-C/V-24

PP

Up to 2

2 10-fold (at 1 V

) RS-232-C/V-24

PP

3

4

4 10-fold (at 1 V

) RS-232-C/V-24

PP

8

Up to 250 4096-fold Ethernet

USB

Ethernet

USB

USB

ND 280

1)

ND 287

ND 1102

ND 1103

ND 1104

ND 2104 G

ND 2108 G

MSE 1000

• Precise position measurement up to 50 kHz

updating rate

• Programmable measured-value inputs

• Internal and external measured-value triggers

• Measured-value memory for approx. 250 000

measured values per channel

• Connection over standard Ethernet interface to

higher-level computer systems

• Programmable measured-value inputs

• Internal and external measured-value triggers

• Measured-value memory for 8192 measured

values per channel

• Optional assemblies for encoder outputs and

external inputs/outputs

» 1 V

» 1 V

PP

PP

» 11 µA

EnDat

SSI

4 4096-fold Ethernet

2 4096-fold PCI bus

PP

EIB 741

EIB 742

IK 220

41

Page 42

Interfaces

Incremental signals » 11 µA

HEIDENHAIN encoders with » 11 µAPP

interface provide current signals. They are

intended for connection to ND position display units or EXE pulse-shaping electronics

from HEIDENHAIN.

The sinusoidal incremental signals I

I

are phase-shifted by 90° elec. and have

2

signal levels of typically 11 µA

illustrated sequence of output signals—I

lagging I

plunger.

The reference mark signal I

ambiguous assignment to the incremental

signals.

—applies for the retracting

1

The Interfaces of HEIDENHAIN

Encoders brochure, ID 1078628-xx,

includes comprehensive descriptions of

all available interfaces as well as general

electrical information.

PP

has an un-

0

. The

and

1

2

PP

Signal period

360° elec.

(rated value)

Pin layout

9-pin

HEIDENHAIN connector

Voltage supply Incremental signals

3 4

housing

4 2 6 1 9 3 11 14 7

U

Brown White – White/

U

= Power supply

P

Vacant pins or wires must not be used!

P

0 V External

shield

9 1 2 5 6 7 8

Internal

shield

Brown

I1+ I1– I2+ I2– I0+ I0–

Green Yellow Blue Red Gray Pink

Shield on housing

Color assignment applies only to extension cable.

15-pin D-sub connector

For ND 28x/PWM 20 or on encoder

42

Page 43

Interfaces

Incremental signals » 1 V

HEIDENHAIN encoders with » 1 VPP

interface provide voltage signals that can

be highly interpolated.

The sinusoidal incremental signals A and

B are phase-shifted by 90° elec. and have

amplitudes of typically 1 V

sequence of output signals—with B

lagging A—applies for the direction of

motion shown in the dimension drawing.

The reference mark signal R has an un-

ambiguous assignment to the incremental

signals. The output signal might be somewhat lower next to the reference mark.

The Interfaces of HEIDENHAIN

Encoders brochure, ID 1078628-xx,

includes comprehensive descriptions of

all available interfaces as well as general

electrical information.

The illustrated

P P.

PP

Signal period

360° elec.

(rated value)

A, B, R measured with oscilloscope in differential mode

Alternative signal

shape

Pin layout

12-pin coupling, M23 12-pin connector, M23

Voltage supply Incremental signals Other signals

Brown/

Shield on housing; U

Sensor: The sensor line is connected in the encoder with the corresponding power line.

Vacant pins or wires must not be used!

Color assignment applies only to extension cable.

12 2 10 11 5 6 8 1 3 4 9 7 /

4 12 2 10 1 9 3 11 14 7 5/6/8/15 13 /

U

P

Green

Sensor

U

Blue White/

= Power supply

P

P

0 V Sensor

0 V

White Brown Green Gray Pink Red Black / Violet Yellow

Green

A+ A– B+ B– R+ R– Vacant Vacant Vacant

15-pin D-sub connector

For ND 28x/PWM 20 or on encoder

43

Page 44

Incremental signals « TTL

HEIDENHAIN encoders with « TTL

interface incorporate electronics that

digitize sinusoidal scanning signals with

or without interpolation.

The incremental signals are transmitted

as the square-wave pulse trains U

U

, phase-shifted by 90° elec. The

a2

a1

and

reference mark signal consists of one or

more reference pulses U

, which are

a0

gated with the incremental signals. In

addition, the integrated electronics produce

their inverted signals ¢, £ and ¤ for

noise-proof transmission. The illustrated

sequence of output signals—with U

lagging U

—applies to the direction of

a1

a2

motion shown in the dimension drawing.

The fault detection signal ¥ indicates

fault conditions such as an interruption in

the supply lines, failure of the light source,

etc.

Signal period 360° elec.

The inverse signals ¢, £, ¤ are not shown.

The distance between two successive

edges of the incremental signals U

U

through 1-fold, 2-fold or 4-fold

a2

a1

and

evaluation is one measuring step.

Fault

Measuring step after

4-fold evaluation

The Interfaces of HEIDENHAIN

Encoders brochure, ID 1078628-xx,

provides comprehensive descriptions of

all available interfaces as well as general

electrical information.

Pin layout

15-pin

D-sub

connector

Voltage supply Incremental signals Other signals

Brown/

Shield on housing; U

Sensor: The sensor line is connected in the encoder with the corresponding power line.

1)

ERO 14xx: Vacant

12 2 10 11 5 6 8 1 3 4 7 / 9

4 12 2 10 1 9 3 11 14 7 13 5/6/8 15

U

P

Green

Sensor

U

0 V Sensor

P

Blue White/

Green

= Power supply

P

2)

Exposed linear encoders: Switchover TTL/11 µAPP for PWT

U

0 V

White Brown Green Gray Pink Red Black Violet – Yellow

¢

a1

Vacant pins or wires must not be used!

Color assignment applies only to extension cable.

12-pin

HEIDENHAIN

connector

U

£

a2

U

¤

a0

¥

1)

Vacant

44

Vacant

2)

Page 45

Interfaces

Position values

The EnDat interface is a digital,

bidirectional interface for encoders. It is

capable both of transmitting position

values as well as transmitting or updating

information stored in the encoder, or saving

new information. Thanks to the serial

transmission method, only four signal

lines are required. The DATA data is

transmitted in synchronism with the

CLOCK signal from the subsequent

electronics. The type of transmission

(position values, parameters, diagnostics,

etc.) is selected through mode commands

that the subsequent electronics send to

the encoder. Some functions are available

only with EnDat 2.2 mode commands.

The Interfaces of HEIDENHAIN

Encoders brochure, ID 1078628-xx,

includes comprehensive descriptions of