Graco 17C487, 17C489, 17C721 User Manual

Repair

ProConnect |

334599A |

|

Displacement Pump |

||

EN |

||

For professional use only. |

|

|

Models: 17C487, 17C488, 17C489, 17C721 |

|

Important Safety Instructions

Important Safety Instructions

Read all warnings and instructions in this manual and related manuals. Be familiar with the controls and the proper usage of the equipment. Save these instructions.

ti24850a

Use only genuine Graco replacement parts.

The use of non-Graco replacement parts may void warranty.

Contents

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Trigger Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Dissemble Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Assemble Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pump Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2 |

334599A |

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and explosion:

•Do not spray flammable or combustible materials near an open flame or sources of ignition such as cigarettes, motors, and electrical equipment.

•Paint or solvent flowing through the equipment is able to result in static electricity. Static

electricity creates a risk of fire or explosion in the presence of paint or solvent fumes. All parts of the spray system, including the pump, hose assembly, spray gun, and objects in and around the spray area shall be properly grounded to protect against static discharge and sparks. Use Graco conductive or grounded high-pressure airless paint sprayer hoses.

•Verify that all containers and collection systems are grounded to prevent static discharge. Do not use pail liners unless they are antistatic or conductive.

•Connect to a grounded outlet and use grounded extensions cords. Do not use a 3-to-2 adapter.

•Do not use a paint or a solvent containing halogenated hydrocarbons.

•Do not spray flammable or combustible liquids in a confined area.

•Keep spray area well-ventilated. Keep a good supply of fresh air moving through the area.

•Sprayer generates sparks. Keep pump assembly in a well ventilated area at least 20 feet

(6.1 m) from the spray area when spraying, flushing, cleaning, or servicing. Do not spray pump assembly.

•Do not smoke in the spray area or spray where sparks or flame is present.

•Do not operate light switches, engines, or similar spark producing products in the spray area.

•Keep area clean and free of paint or solvent containers, rags, and other flammable materials.

•Know the contents of the paints and solvents being sprayed. Read all Safety Data Sheets

(SDS) and container labels provided with the paints and solvents. Follow the paint and solvents manufacturer’s safety instructions.

•Fire extinguisher equipment shall be present and working.

334599A |

3 |

Warnings

WARNING

WARNING

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that injection occurs, get immediate surgical treatment.

•Do not aim the gun at, or spray any person or animal.

•Keep hands and other body parts away from the discharge. For example, do not try to stop leaks with any part of the body.

•Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

•Use Graco nozzle tips.

•Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip clogs

while spraying, follow the Pressure Relief Procedure for turning off the unit and relieving the pressure before removing the nozzle tip to clean.

•Equipment maintains pressure after power is shut off. Do not leave the equipment

energized or under pressure while unattended. Follow the Pressure Relief Procedure when the equipment is unattended or not in use, and before servicing, cleaning, or removing parts.

•Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

•This system is capable of producing 3300 psi. Use Graco replacement parts or accessories that are rated a minimum of 3300 psi.

•Always engage the trigger lock when not spraying. Verify the trigger lock is functioning properly.

•Verify that all connections are secure before operating the unit.

•Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or property damage.

•Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing such solvents.

•Do not use chlorine bleach.

•Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for compatibility.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

•Read SDSs to know the specific hazards of the fluids you are using.

•Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is not limited to:

•Protective eyewear, and hearing protection.

•Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

CALIFORNIA PROPOSITION 65

This product contains a chemical known to the State of California to cause cancer, birth defects or other reproductive harm. Wash hands after handling.

4 |

334599A |

Repair

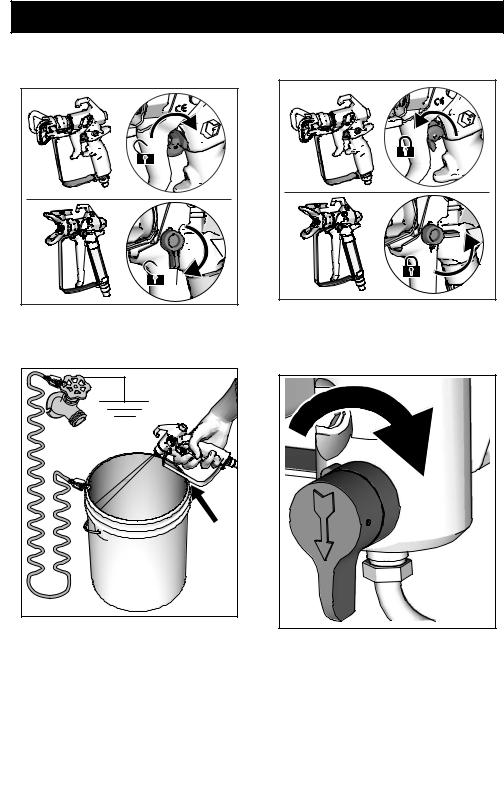

Trigger Lock

Always engage the trigger lock when sprayer is stopped to prevent the gun from being triggered accidentally by hand or if dropped or bumped.

Pressure Relief Procedure

This equipment stays pressurized until pressure is manually relieved. To help prevent serious injury from pressurized fluid, such as skin injection, splashed fluid and moving parts, follow the Pressure Relief Procedure whenever sprayer is stopped and before sprayer is cleaned or checked, and before equipment is serviced.

1.Engage trigger lock.

ti24851a |

2.Turn ON/OFF switch to OFF position. Wait 7 seconds for power to dissipate.

ti24852a |

3.Unplug power cord or shut engine off.

ti24853a

4.Engage trigger lock.

5.Remove tip guard.

334599A |

5 |

Repair

6.Turn pressure control to lowest setting. Disengage trigger lock.

7.Hold a metal part of the gun firmly to a grounded metal pail. Trigger the gun to relieve pressure.

ti24585a |

8.Engage trigger lock.

ti24855a |

9.Open any fluid drain valves in system. Leave drain valves open until ready to spray again.

ti24608a |

6 |

334599A |

Loading...

Loading...