GE OEC UroView 2800 User manual

UroView 2800 Periodic Maintenance Procedure

1

Service

Periodic Maintenance

Contents

Schematics

Illustrated Parts

Installation

Contents

General Instructions ........................................................................................................................................................................4

How To Use The Electronic Checklist Form...................................................................................................................................4

Getting Started With the Checklist..................................................................................................................................................4

Safety ................................................................................................................................................................................................5

Ingress Of Water And Solutions .....................................................................................................................................................5

Unauthorized Modifications ............................................................................................................................................................5

Motorized Mechanical Operation....................................................................................................................................................6

Trained Service Personnel .............................................................................................................................................................6

Electrical Shock..............................................................................................................................................................................6

X-radiation Exposure......................................................................................................................................................................7

Required Tools, Test Equipment, and Supplies............................................................................................................................8

Tools...............................................................................................................................................................................................8

Supplies..........................................................................................................................................................................................8

Test Equipment ..............................................................................................................................................................................9

Safety Inspections ...........................................................................................................................................................................9

Remove Power and Covers............................................................................................................................................................9

Mechanical Inspections ................................................................................................................................................................18

Brakes.......................................................................................................................................................................................18

X-ray-Arm..................................................................................................................................................................................18

Tower Mounting ........................................................................................................................................................................18

Electrical Inspections....................................................................................................................................................................20

Electrical Power Cord ...............................................................................................................................................................20

Interconnect Cable....................................................................................................................................................................20

Hand Control and Foot Switches ..............................................................................................................................................20

Table Motion and X-ray Arm Motion Tests................................................................................................................................20

Power On Inspections ..................................................................................................................................................................24

Initialize without Generator .......................................................................................................................................................24

Fans and Filters ........................................................................................................................................................................24

Table Only Initialization.............................................................................................................................................................30

Initialization With Generator......................................................................................................................................................30

Fast Stop...................................................................................................................................................................................31

UroView 2800 Periodic Maintenance Procedure

2

Service

Periodic Maintenance

Contents

Schematics

Illustrated Parts

Installation

Crash and Splash .....................................................................................................................................................................31

Functional Inspection....................................................................................................................................................................32

Imaging Functions ........................................................................................................................................................................32

Image Orientation .....................................................................................................................................................................32

Image Resolution ......................................................................................................................................................................32

Flat Panel Display Video, Shift and PIP....................................................................................................................................33

Remote Workstation Operation.................................................................................................................................................33

Collimator Control .....................................................................................................................................................................34

X-Ray Functions...........................................................................................................................................................................34

Film Exposure ...........................................................................................................................................................................34

Auto Technique Tracking ..........................................................................................................................................................34

High-level Fluoro Indication ......................................................................................................................................................35

Pulsed Image Indication............................................................................................................................................................35

Digital Spot................................................................................................................................................................................36

Low Dose Mode Operation .......................................................................................................................................................36

Beam Alignment Test ...................................................................................................................................................................36

Fluoro Alignment.......................................................................................................................................................................37

Film Alignment ..........................................................................................................................................................................37

Dose Rate.....................................................................................................................................................................................38

Dose Rate (MAX. kV & mA)......................................................................................................................................................38

High Level Fluoro (HLF)............................................................................................................................................................38

Workstation Controls ....................................................................................................................................................................38

Options Testing ............................................................................................................................................................................40

High Capacity Disk Test............................................................................................................................................................40

VCR Test ..................................................................................................................................................................................40

IR Transmitter Test ...................................................................................................................................................................40

Digital Hardcopy Camera test ...................................................................................................................................................40

Instant Film/Paper (Onboard) Printer........................................................................................................................................40

Thermal Printer Test .................................................................................................................................................................41

DICOM ......................................................................................................................................................................................41

Lubrication......................................................................................................................................................................................42

Lift and Tilt Drive...........................................................................................................................................................................42

I.I./X-ray Arm Carriage..................................................................................................................................................................42

Latitudinal Drive............................................................................................................................................................................43

Longitudinal Drive.........................................................................................................................................................................44

UroView 2800 Periodic Maintenance Procedure

3

Service

Periodic Maintenance

Contents

Schematics

Illustrated Parts

Installation

Miscellaneous.................................................................................................................................................................................47

Dose Area Product Calibration.....................................................................................................................................................47

Battery Replacement....................................................................................................................................................................48

Table Maintenance.......................................................................................................................................................................49

Completing the PM.........................................................................................................................................................................50

Reinstall the Covers .....................................................................................................................................................................50

Final Power-On.............................................................................................................................................................................50

PM Checklist Printing ...................................................................................................................................................................50

UroView 2800 Periodic Maintenance Procedure

4

Service

Periodic Maintenance

Contents

Schematics

Illustrated Parts

Installation

General Instructions

This procedure covers the following service intervals:

• Semi-Annual

• Annual

Use this procedure in conjunction with the UroView 2800 Periodic Maintenance (PM) Checklist form. For the Semi-Annual PM, do

only those procedures listed in the Semi-Annual section of the form. For the Annual PM, do all the procedures in both sections.

Within those sections, the procedure names you see on the form correspond to instructions in this procedure document.

How To Use The Electronic Checklist Form

The 2800 Periodic Maintenance Checklist form has been designed using the Microsoft® Word 2000 form tool and should be

completed on-line. The on-line form contains three types of information fields: text/number fields, checkboxes and pull-down

menus.

You can navigate the form using the tab key or by using your mouse. We recommend that you use the mouse. The steps should

be completed in a vertical order. The tab key tabs horizontally.

For text fields, type in the requested information, such as hospital name, etc. For checkboxes, place the mouse cursor on the

checkbox and click. This will place an X in the checkbox. For pull-down menus choose the appropriate selection when it is

displayed and verify that it is present when you close the field.

To make the on-line PM checklist template available to MS Word, save the template in the Microsoft Office Template directory.

Getting Started With the Checklist

Enter the following required information at the top of the form prior to performing the PM test procedures

1. System ID number in the text field.

2. Start Date in the text field.

UroView 2800 Periodic Maintenance Procedure

5

Service

Periodic Maintenance

Contents

Schematics

Illustrated Parts

Installation

3. Read the elapsed time meter on the Workstation and enter the number on the Checklist.

4. Select whether the PM is semi-annual or annual from the pull-down menu.

5. Complete the customer information: Customer Name, Address, etc.

6. Record the following in the Test Equipment block:

A. Test equipment model numbers

B. Test equipment serial numbers

C. Test equipment calibration due date

Note: Test equipment must have current calibration dates. Do not use test equipment with expired calibration stickers.

Safety

Ingress Of Water And Solutions

The system must never be operated or stored in locations where conductive fluids, like water and saline solution, might spill on

the equipment.

Always unplug the AC power cable from the wall outlet before cleaning the equipment. Do not allow water, soap, or other liquids

to drip into the equipment and cause short circuits, electric shock and fire hazards.

Unauthorized Modifications

Under no circumstances should the safety interlock in the system be a bypassed, jumpered, or otherwise disabled.

Note: All GE OEC systems comply with International Electrotechnical Commission safety standard IEC-60601. Do not

connect any external device to the system that does not meet the requirements of IEC-60601. Only devices provided or

approved by GE OEC Medical Systems, Inc. should be connected to the system.

UroView 2800 Periodic Maintenance Procedure

6

Service

Periodic Maintenance

Contents

Schematics

Illustrated Parts

Installation

Motorized Mechanical Operation

The table and X-ray arm are motorized and should be observed continuously during operation to avoid collision with people and

equipment.

If covers are removed, use extreme care when operating motorized features. Do not wear loose clothing that may be caught by

mechanical mechanisms. Keep hands, fingers, hair, or other body parts clear of motorized equipment while the motors are in

operation.

Trained Service Personnel

Serious injury and property damage can result from incorrectly performed service procedures. Observe all operating and safety

procedures discussed in this document.

WARNING: Procedures shall be performed by service personnel specifically trained by GE OEC Medical

Systems, Inc. to calibrate the UROVIEW 2800.

Electrical Shock

WARNING: This system can generate lethal voltages. Practice safe electrical testing procedures when

performing periodic maintenance procedures.

WARNING: After taking X-rays, the high voltage cables can retain a lethal charge, even if you power down

the system. Even though the contacts are recessed, high voltages can arc several inches from

their terminals if the cables are removed from the connector wells. Use caution when

disconnecting high voltage cables even when the power is turned off. If you remove these

connections, immediately discharge their contacts against the high voltage tank case (ground).

UroView 2800 Periodic Maintenance Procedure

7

Service

Periodic Maintenance

Contents

Schematics

Illustrated Parts

Installation

WARNING: Use caution when working near the generator and its connections. Remove metal rings and

watchbands that may inadvertently come in contact with the terminals. Severe skin burns could

result if such metal articles were shorted across the generator input terminals.

X-radiation Exposure

The X-ray tube assembly produces X-radiation when energized. Never operate this device without X-ray shielding in place. Use

lead shielding and draping to protect personnel.

WARNING: Lead aprons, radiation monitors, and appropriate radiation shields must be utilized for the

protection of all personnel in the vicinity while performing tests. Living human anatomy should

never be used as a phantom or demonstration aid. Do not produce radiation in hallways.

CAUTION: Many of the PCB's in this system contain components, which are sensitive to Electro-Static Discharge

(ESD). Observe ESD safety procedures.

UroView 2800 Periodic Maintenance Procedure

8

Service

Periodic Maintenance

Contents

Schematics

Illustrated Parts

Installation

Required Tools, Test Equipment, and

Supplies

Tools

Spline Driver, .048, (00-900921)

High voltage cable wrench

Metric and SAE Allens ( metric set to include half sizes)

Metric and SAE Socket set and or nut drivers (metric set to include half sizes)

Supplies

Alcohol Prep Pads

Laceration Proof Gloves

Safety Glasses

Tungrease (00-902208)

Paint Kit, touchup

Shim, Tower Base, .125SS qty 4 (00-987198-01)

Shim, Tower Base, .250SS qty 4 (00-987198-02)

UroView 2800 Periodic Maintenance Procedure

9

Service

Periodic Maintenance

Contents

Schematics

Illustrated Parts

Installation

Test Equipment

Digital multimeter and probes Light meter

Pausch Serial Extension Cable (81-821528) Converging line pair resolution tool

Digital level (00-902160) Perpendicularity tool (00-874185)

Laptop computer Radiographic Alignment Tool (00-871980)

Film densitometer 3 copper filters (00-877682)

Plexi Glass Phantom Kit (00-884334-01) Static wrist strap (00-800221)

Dosimeter RUS Software (00-884048)

Fiber Optic Kit (00-884422-01) RUS Cable (00-901559)

VGA Monitor00-901163-01 Keyboard00-900598-01

Lemo Socket Tool T-00207

Safety Inspections

Remove Power and Covers

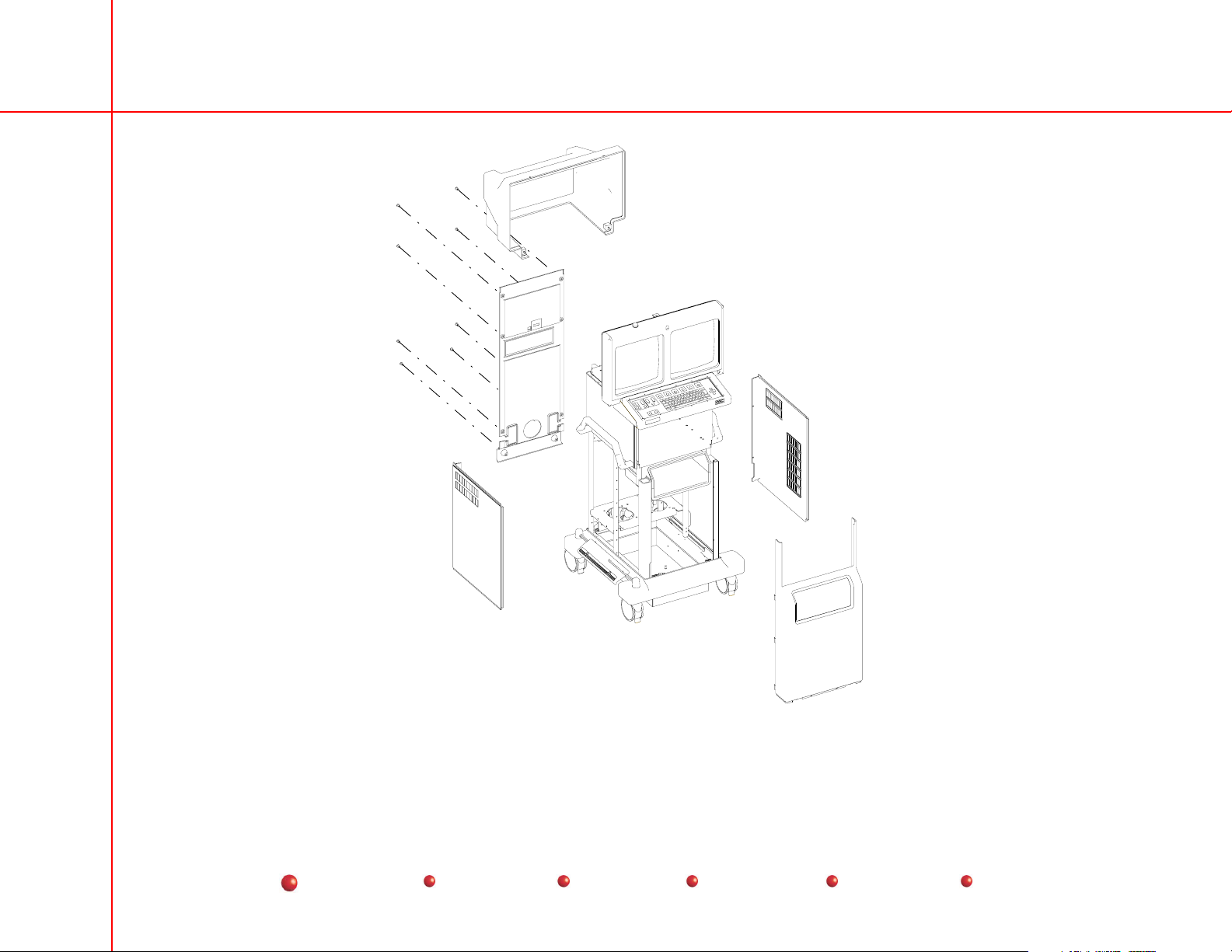

Refer to the illustrations following this page for cover removal.

WARNING: Electrical circuits inside the equipment use voltages that are capable of causing serious injury

or death from electrical shock, even when the Workstation power switch is turned off. Use

appropriate lockout/tag-out precautions.

1. If the system has power applied, place the Workstation power switch in the

OFF

position

UroView 2800 Periodic Maintenance Procedure

10

Service

Periodic Maintenance

Contents

Schematics

Illustrated Parts

Installation

2. At the facility power distribution box, shut off all power, including as applicable 200-208 VAC and 400-480 VAC. Use

lockout/tag-out procedures in compliance with GE OEC safety policies.

3. Separate generator from tower or wall box. Move generator 3 or 4 feet away from tower or wall.

4. Remove the generator covers.

5. Remove the Workstation rear cover, left side cover, and open the electronic card rack rear door.

6. Remove the Tower top and end covers.

7. Remove table movement mechanism covers.

UroView 2800 Periodic Maintenance Procedure

11

Service

Periodic Maintenance

Contents

Schematics

Illustrated Parts

Installation

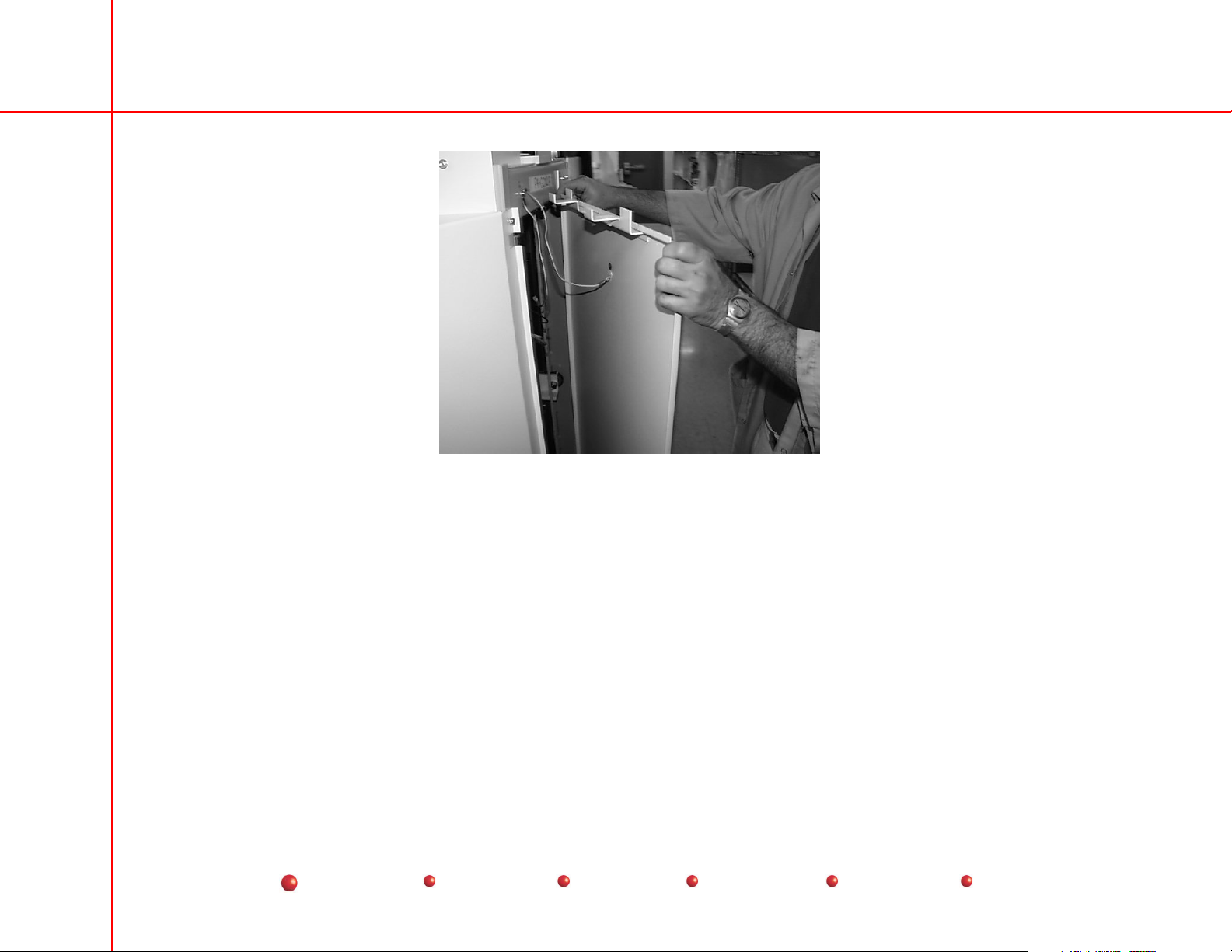

Removing the Workstation Covers

UroView 2800 Periodic Maintenance Procedure

12

Service

Periodic Maintenance

Contents

Schematics

Illustrated Parts

Installation

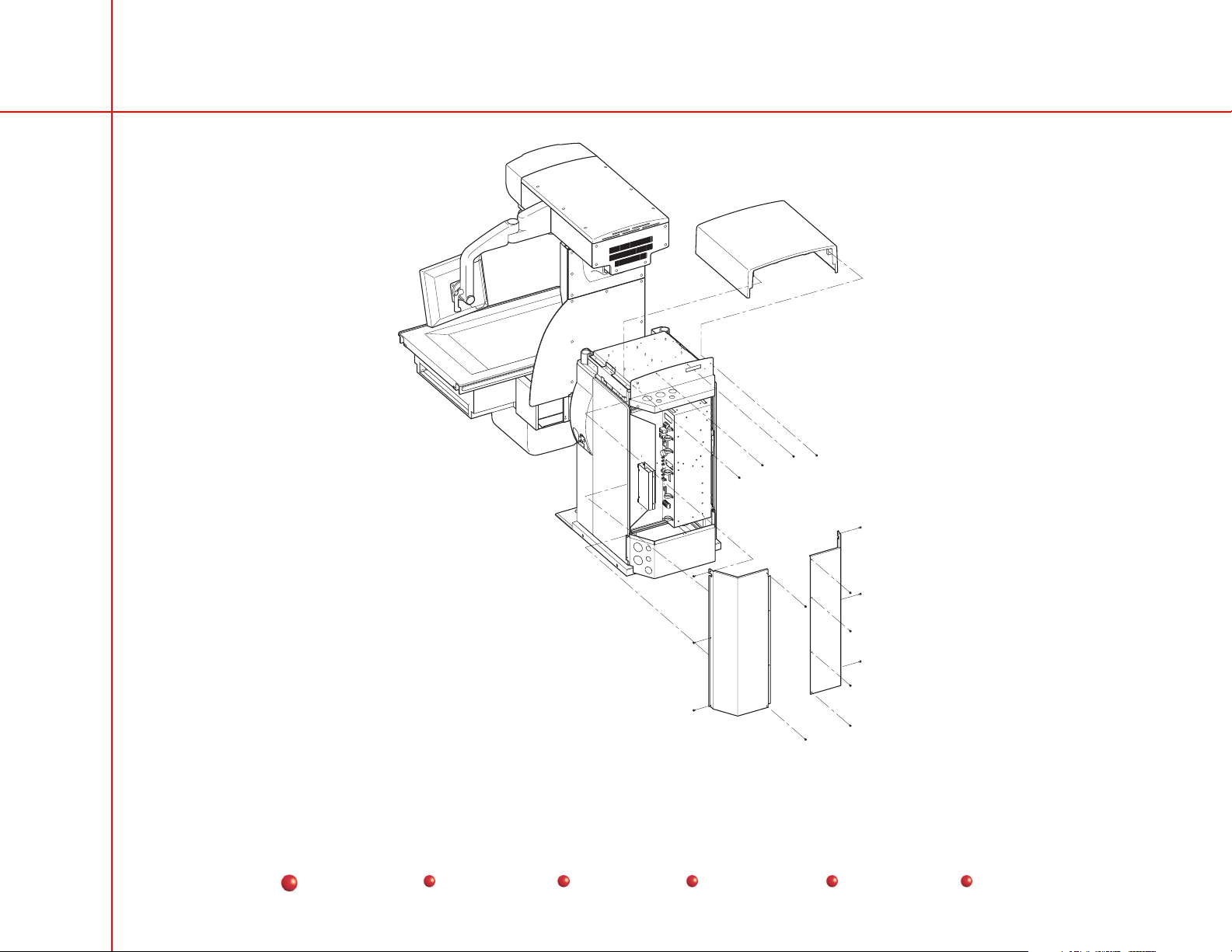

Removing Tower Side Covers

UroView 2800 Periodic Maintenance Procedure

13

Service

Periodic Maintenance

Contents

Schematics

Illustrated Parts

Installation

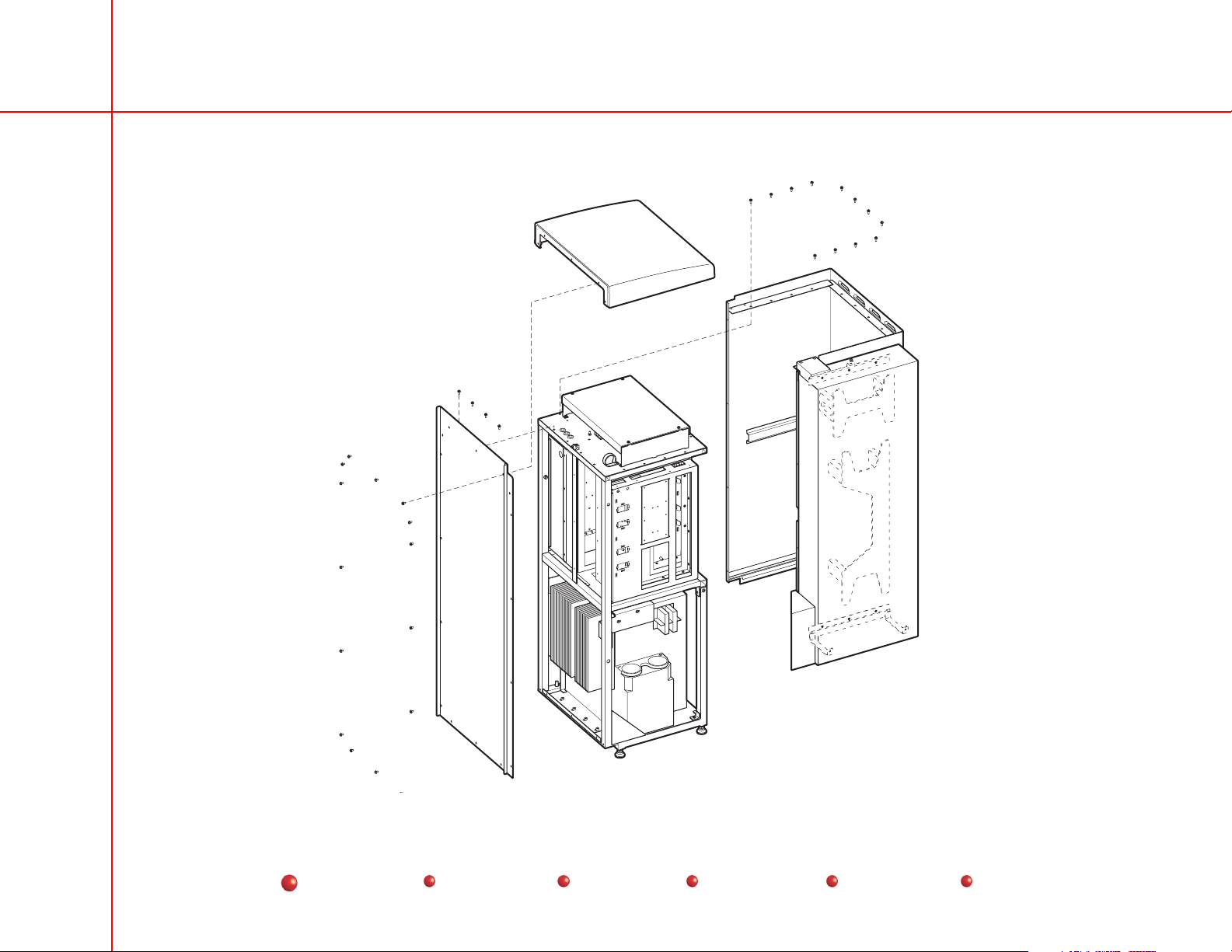

Removing the Tower Top and Upper End Covers

UroView 2800 Periodic Maintenance Procedure

14

Service

Periodic Maintenance

Contents

Schematics

Illustrated Parts

Installation

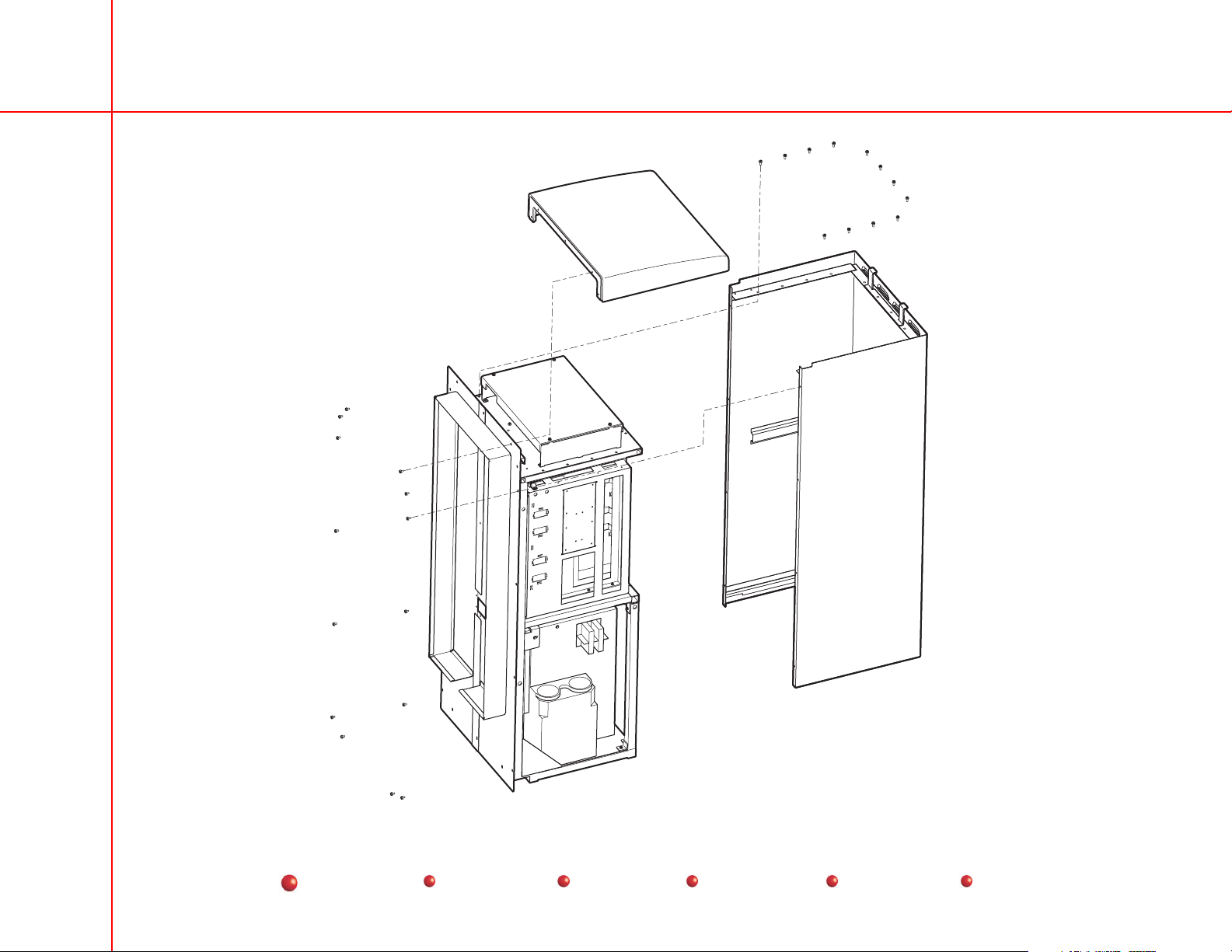

Removing the Generator Covers (Tower Mounted)

UroView 2800 Periodic Maintenance Procedure

15

Service

Periodic Maintenance

Contents

Schematics

Illustrated Parts

Installation

Removing the Generator Covers (Remote Mounted)

UroView 2800 Periodic Maintenance Procedure

16

Service

Periodic Maintenance

Contents

Schematics

Illustrated Parts

Installation

Loading...

Loading...