GE LP 33 User Manual

GE Consumer & Industrial

Power Protection

L

P

S

3

3

U

_

0

3

0

-

0

4

0

_

U

P

S

_

G

E

_

0

1

D

i

g

i

t

a

l

E

n

e

r

g

y

T

M

L

P

S

e

r

ie

s

Operating Manual

Uninterruptible Power supply

Digital Energy™

LP 33 Series

30 & 40 kVA

208 VAC UL / Series 0

Manufactured by:

GE Zenith Controls

General Electric Company

2501 Pecan Street

Bonham, Texas 75418

T 903 640 7900

T 903 640 7900

www.geindustrial.com/cwc/home

Modifications reserved Page 2/57

OPM_LPS_3UO_30K_40K_0US_V010.doc Operating Manual LP 33 Series 30 & 40 kVA

Model: LP 33 Series / 30 & 40 kVA / Series 0

Date of issue: 01/01/2005

File name: OPM_LPS_3UO_30K_40K_0US_V010

Revision: 1.0

Identification No.

Up-dating

Revision Concerns Date

COPYRIGHT © 2005 by GE Consumer & Industrial

All rights reserved.

The information contained in this publication is intended solely for the purposes indicated.

The present publication and any other documentation supplied with the UPS system is not to be

reproduced, either in part or in its entirety, without the prior written consent of GE.

The illustrations and plans describing the equipment are intended as general reference only and are

not necessarily complete in every detail.

The content of this publication may be subject to modification without prior notice.

Modifications reserved Page 3/57

OPM_LPS_3UO_30K_40K_0US_V010.doc Operating Manual LP 33 Series 30 & 40 kVA

Dear Customer,

We thank you for selecting our products and

are pleased to count you amongst our very

valued customers at GE.

We trust that the use of the LP 33 Series

Uninterruptible Power Supply system,

developed and produced to the highes

t

standards of quality, will give you complete

satisfaction.

Please carefully read the Installation Guide.

It contains all the necessary information abou

t

the installation of the UPS.

Thank you for choosing GE !

START UP AND COMMISSIONING

A GE Global Services Field Engineer must perform start-up and commissioning of the

UPS. Please Contact G.E. Global Services at least two weeks prior to schedule start-up

and commissioning at 1-800-637-1738, or by E-mail at gedeservices@indsys.ge.com

Manufactured by:

Distributed by:

Your service contact:

g

GE Digital Energy

General Electric Company

CH – 6595 Riazzino (Locarno)

Switzerland

Modifications reserved Page 4/57

OPM_LPS_3UO_30K_40K_0US_V010.doc Operating Manual LP 33 Series 30 & 40 kVA

Preface

Congratulations on your choice of a LP 33 Series Uninterruptible Power Supply (UPS).

It will help eliminate load disturbances due to unexpected power problem.

This Installation Guide describes how to prepare the installation site, and it provides

weight and dimensions and procedures for moving, installing and connecting the UPS.

While every care has been taken to ensure the completeness and accuracy of this

manual, GE assumes no responsibility or liability for any losses or damages resulting from

the use of the information contained in this document.

WARNING!

LP 33 Series / 30 & 40 kVA, is a product that needs to be installed by a licensed and

knowledgeable contractor.

We recommend that this manual be kept next to the UPS for future references.

If any problems are encountered with the procedures contained in this manual, please

contact your Service Center before you proceed.

This document shall not be copied or reproduced without the permission of GE.

Some of the information contained in this manual may be changed without notice to

reflect technical improvements.

Safety instructions

Read the safety instructions contained on the following pages carefully before the

installation of the UPS, options and battery system.

Pay attention to the rectangular boxes included in the text:

They contain important information and warning concerning electrical connections and

personnel safety.

Parallel version secured with RPA

When included in the text, this symbol refers to operation needed

only for parallel system.

Modifications reserved Page 5/57

OPM_LPS_3UO_30K_40K_0US_V010.doc Operating Manual LP 33 Series 30 & 40 kVA

Table of contents

Page

1

SAFETY RULES.............................................................................................................................................6

2 INTRODUCTION..........................................................................................................................................9

2.1

GENERAL DESCRIPTION......................................................................................................................................................................9

3 DESCRIPTION............................................................................................................................................10

3.1

BLOCK DIAGRAM AND MAIN ELEMENTS DESCRIPTION.................................................................................................... 10

3.2

OPERATION MODES........................................................................................................................................................................... 11

3.3

RPA PARALLEL SYSTEM.................................................................................................................................................................... 14

3.4

UPS PARALLELED ON THE SAME BATTERY.............................................................................................................................. 15

3.5 SERVICE AND TECHNICAL SUPPORT.......................................................................................................................................... 16

3.6

RECYCLING AT THE END OF SERVICE LIFE .............................................................................................................................. 17

4 LAYOUT......................................................................................................................................................18

4.1

LAYOUT LP 33 SERIES / 30 & 40 KVA......................................................................................................................................... 18

5 SYSTEM HANDLING..................................................................................................................................19

5.1

CONTROL PANEL ................................................................................................................................................................................ 19

5.2 COMMAND PUSH BUTTONS AND SWITCHES ........................................................................................................................ 20

6

LCD SCREEN..............................................................................................................................................21

6.1 METERING SCREENS (METERING)................................................................................................................................................ 21

6.2

EVENT SCREENS (ALARM)................................................................................................................................................................ 23

6.2.1

Alarms list.................................................................................................................................................................................................... 23

6.2.2

Messages list.............................................................................................................................................................................................. 26

6.2.3 Event report LP 33 Series...................................................................................................................................................................... 29

6.3

MENU SCREENS (MENU).................................................................................................................................................................. 30

6.3.1 User parameters screen....................................................................................................................................................................... 31

7 OPERATION ...............................................................................................................................................35

7.1

PROCEDURES FOR SINGLE LP 33 SERIES................................................................................................................................. 35

7.1.1

Start-up of the LP 33 Series................................................................................................................................................................. 35

7.1.2

UPS shutdown with load transfer on manual bypass (Q2)................................................................................................... 37

7.1.3 Start-up following the operation on manual bypass (Q2)..................................................................................................... 39

7.1.4

Complete shutdown ............................................................................................................................................................................... 40

7.1.5

Restore to normal operation after “total off”.............................................................................................................................. 41

7.1.6

Restore to normal operation after “EPO – Emergency Power Off”.................................................................................... 42

7.2

PROCEDURES FOR PARALLEL SYSTEM LP 33 SERIES .........................................................................................................43

7.2.1 Parallel System start-up of the LP 33 Series................................................................................................................................43

7.2.2

Parallel UPS shutdown with load transfer on manual bypass (Q2)................................................................................... 45

7.2.3

Start-up following the operation on maintenance bypass (Q2)......................................................................................... 47

7.2.4

Shutdown of a single unit in a parallel system .......................................................................................................................... 48

7.2.5

Start-up an additional unit in a parallel system ........................................................................................................................ 49

7.2.6 Complete shutdown of a parallel system..................................................................................................................................... 50

7.2.7

Restore to normal operation after “total off”.............................................................................................................................. 51

7.2.8

Restore to normal operation after “EPO – Emergency Power Off”.................................................................................... 52

8 OPTIONS....................................................................................................................................................53

8.1

OPTIONS GENERAL VIEW................................................................................................................................................................ 53

9 MAINTENANCE .........................................................................................................................................54

9.1

GENERAL MAINTENANCE................................................................................................................................................................ 54

9.2 COOLING FAN MAINTENANCE...................................................................................................................................................... 54

9.3

BATTERY MAINTENANCE................................................................................................................................................................. 54

9.4 SERVICE REQUIRED ........................................................................................................................................................................... 55

10

NOTES........................................................................................................................................................56

10.1

NOTES FORM........................................................................................................................................................................................ 56

Modifications reserved Page 6/57

OPM_LPS_3UO_30K_40K_0US_V010.doc Operating Manual LP 33 Series 30 & 40 kVA

1 SAFETY RULES

With this document, GE gives to the user all the necessary information about the correct use of the UPS.

We recommend that this manual be kept next to the UPS for future references.

If any problems are encountered with the procedures contained in this manual, please contact the

nearest Service Center before you proceed.

All UPS installation, maintenance and service work should be performed by qualified service personnel

only.

The KNOWLEDGE and the FULLY compliance of the safety instructions and the warning

contained in this manual are

THE ONLY CONDITION

to avoid any dangerous situations during installation, operation, maintenance work, and

to preserve the maximum reliability of the UPS system.

NOTE !

LP 33 Series / 30 & 40 kVA is a FCC Class A-UPS Product.

While every care has been taken to ensure the completeness and accuracy

of this manual, GE assumes no responsibility or liability for any losses or

damages resulting from the use of the information contained in this

document.

GE

Refuses any responsibility in case of non-observance,

unauthorised alterations or improper use of the

delivered UPS.

Modifications reserved Page 7/57

OPM_LPS_3UO_30K_40K_0US_V010.doc Operating Manual LP 33 Series 30 & 40 kVA

SAVE THESE INSTRUCTIONS

This manual contains important instructions for models LP 33 Series / 10 & 20 kVA that should

be followed during installation and maintenance of the UPS and battery.

GENERAL

- Move the UPS in an upright position in its original package to the final destination

room.

- Check for sufficient floor and elevator loading capacity.

- Check the integrity of the UPS equipment carefully.

If you notice visible damage, do not install or start the UPS. Contact the nearest Service

Center immediately.

- WARNING! RISK OF ELECTRICAL SHOCK: Do not remove covers; there are no user

serviceable parts inside.

- After switching off takes 5 minutes for the DC capacitors to discharge because a lethally

high voltage remains at the terminals of the electrolytic capacitors.

- All maintenance and service work should be performed by qualified service personnel.

The UPS contains its own energy source (battery).

- The field-wiring terminals may be electrically live, even when the UPS is disconnected

from the utility.

- Dangerous voltages may be present during battery operation.

The battery must be disconnected during maintenance or service work.

- This UPS contains potentially hazardous voltages.

- Be aware that the inverter can restart automatically after the utility voltage is restored.

STORAGE

- Store the UPS in a dry location; storage temperature must be within -13°F (-25°C) to

131°F (55°C).

- If the unit is stored for a period exceeding 3 months, the battery must be recharged

periodically (time depending on storage temperature).

BATTERY

- The battery-voltage is dangerous for person’s safety.

- When replacing the battery, use the same number, voltage (V) and capacity (Ah).

- Proper disposal or recycling of the battery is required.

Refer to your local codes for disposal requirements.

- Never dispose of battery in a fire: They may explode.

- Do not open or mutilate battery: Their contents (electrolyte) may be extremely toxic.

If exposed to electrolyte, wash immediately with plenty of water.

- Avoid charging in a sealed container.

- Never short circuit battery. When working with battery, remove watches, rings or other

metal objects, and only use insulated tools.

Modifications reserved Page 8/57

OPM_LPS_3UO_30K_40K_0US_V010.doc Operating Manual LP 33 Series 30 & 40 kVA

Safety symbols and warnings

Safety warnings

The text of this manual contains some warnings to avoid risk to the persons and to avoid damages to

the UPS system and the supplied critical loads.

The non-observance of the warnings reminding hazardous situations could result in human injury and

equipment damages.

Please pay attention to the meaning of the following warnings and symbols.

Throughout this manual the following symbols are defined:

WARNING, if instruction is not followed injury or serious equipment damage

may occur!

CAUTION, internal parts have dangerous voltage present.

Risk of electric shock!

PE (Earth) – GND (Ground)

PROTECTIVE GROUNDING TERMINAL:

A terminal which must be connected to earth ground prior to making any other

connection to the equipment.

A terminal to which or from which an alternating (sine wave) current or voltage

may be applied or supplied.

A terminal to which or from which a direct current or voltage may be applied or

supplied.

This symbol indicated the word “phase”.

This symbol indicates the principal on/off switch in the on position.

This symbol indicates the principal on/off switch in the off position.

Modifications reserved Page 9/57

OPM_LPS_3UO_30K_40K_0US_V010.doc Operating Manual LP 33 Series 30 & 40 kVA

2 INTRODUCTION

2.1 GENERAL DESCRIPTION

The LP 33 Series Uninterruptible Power Supply (UPS) provides the energy supply for critical loads which

need a reliable, continuous free from voltage disturbances and frequency fluctuations supply.

In case the mains fails, or it exceeds the permitted tolerances, the energy to supply the load is furnished

by the battery with a backup time dependent on its capacity, until the mains recovers.

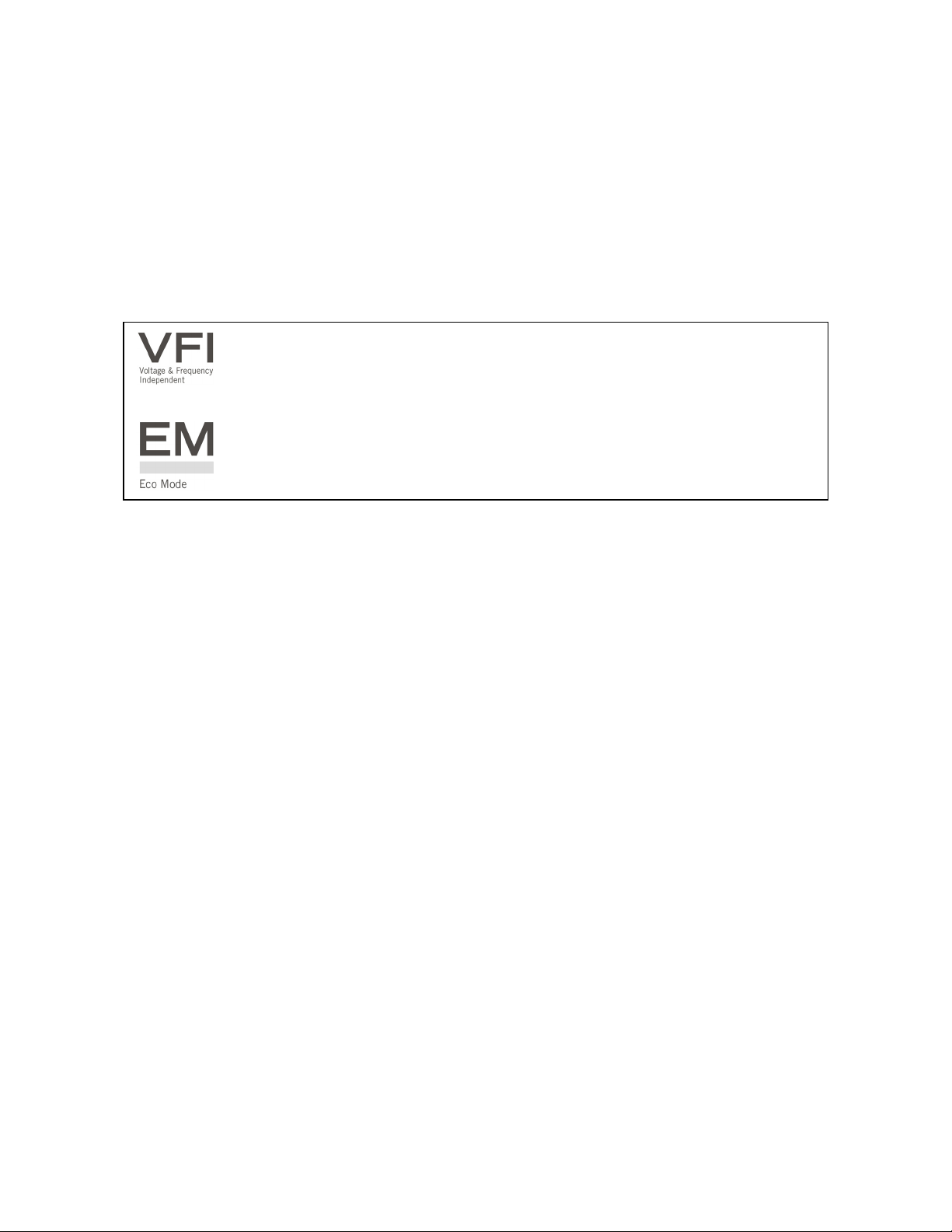

LP 33 Series is a truly VFI double conversion Uninterruptible Power Supply (UPS),

equipped with automatic bypass, where the load is normally supplied by the inverter.

LP 33 Series can be configured, if chosen, for the ECO Mode permitting the maximum

energy saving.

The main typical performances of the LP 33 Series system are the following:

•

VFI (Voltage Frequency Independent) double conversion technology to provide an excellent

quality power supply.

•

Input power factor 0.8.

• Input current THD <10%.

• Automatic bypass and manual bypass to improve reliability and maintenance.

•

Microprocessor controlled supervision.

• Dual AC inputs (optional).

• ECO Mode operation.

• Compact and agreeable design expressly conceived for “Office environment”.

• Low level acoustic sound, 50 dB(A) (10 kVA), 55 dB(A) (20 kVA) and 61 dB (A) (30 & 40 kVA) to avoid

noise to the persons operating in the same environment.

• Multi-language LCD screen.

•

Total battery management: SBM (Superior Battery Management)

• High battery capacity, 22 minutes (10 kVA), 9 minutes (20 kVA), 29 minutes (30 kVA) and 19

minutes (40 kVA), with battery housed in the UPS cabinet.

• Wide rectifier input voltage tolerance: 152 ÷ 240 VAC (phase – phase).

• Wide rectifier input frequency tolerance: +/-10% (54 ÷ 66 for 60 Hz).

•

RPA (Redundant Parallel Architecture) up to 4 units.

• GE Connectivity.

• Compliance with UL standard 1778.

Modifications reserved Page 10/57

OPM_LPS_3UO_30K_40K_0US_V010.doc Operating Manual LP 33 Series 30 & 40 kVA

3 DESCRIPTION

3.1 BLOCK DIAGRAM AND MAIN ELEMENTS DESCRIPTION

Fig. 3.1-1 UPS block diagram

The Uninterruptible Power Supply System LP 33 Series / 30 & 40 kVA can be divided into the following

main elements:

Electronics

The UPS is designed with a microprocessor–controlled supervision and diagnostic system.

Communication between user and UPS is achieved by the front panel consisting of an LCD screen,

displaying the operation modes, the measurements and the events / alarms.

Rectifier

The rectifier converts the 3-phase mains voltage into a controlled and regulated DC-voltage, in order to

supply power to the booster, and to charge the battery through the battery-charger.

Inverter

The inverter converts the DC voltage into a three-phase AC-voltage with constant amplitude and

frequency, which is completely independent from the AC-input voltage.

Automatic Bypass

The automatic bypass consists of a static semiconductor-switch (SSR: Static Switch Relay), used to

provide an uninterrupted transfer of the load from inverter to mains when operating in VFI Mode.

If chosen the ECO Mode, the SSM transfer the load from mains to inverter in case the utility fails.

Back-Feed Protection

All LP 33 Series UPS’s are equipped with an automatic system for the protection against voltage back

feeding towards Utility, through the Bypass (Applied Standard IEC 62040-1).

This protection works automatically by opening contactor K6 (in series with the thyristors of the static

switch) and eventually K7, and acts in case of internal defects of the system, or due to wrong

manipulations on the maintenance bypass Q2.

Manual Bypass

The manual bypass consists of a pair of manual switches Q1 and Q2, which allow the isolation of the

UPS from the load, while still supplying the load with power directly from the mains.

Battery

The battery, normally stored by the battery-charger, supplies the DC energy to inverter in the event of

mains failure.

Modifications reserved Page 11/57

OPM_LPS_3UO_30K_40K_0US_V010.doc Operating Manual LP 33 Series 30 & 40 kVA

3.2 OPERATION MODES

This section describes the different possible operation modes of the UPS explaining the function of the

main modules of the UPS.

VFI (Voltage Frequency Independent) Mode operation

Under normal conditions the load is

permanently powered by the inverter with

constant amplitude and frequency.

The rectifier, powered by the mains, supplies the

inverter and the battery-charger keeps the

battery fully charged.

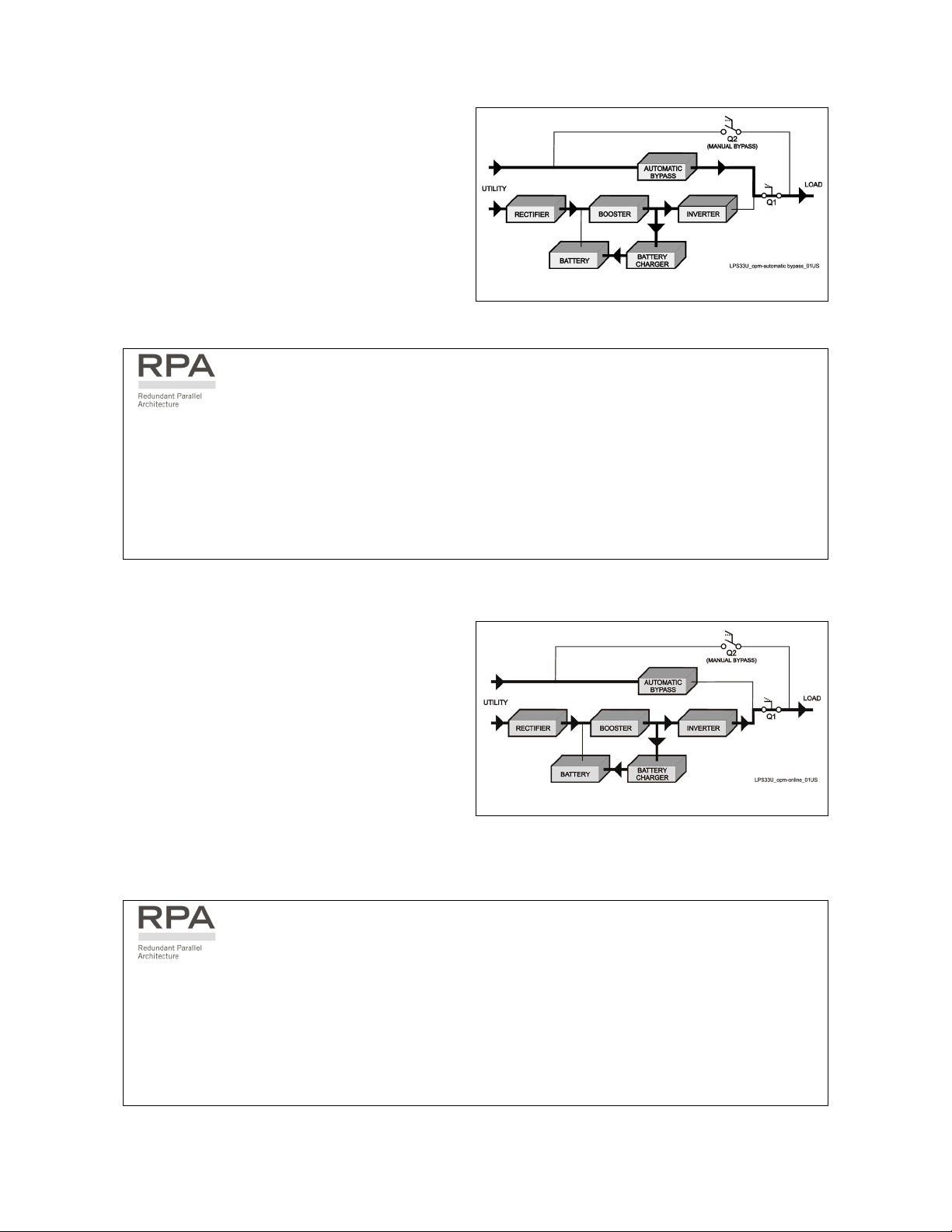

Fig. 3.2-1 Energy flow in VFI Mode operation

The inverter converts the DC voltage in a new AC sine wave voltage with constant amplitude and

frequency independently from the input mains power.

ECO Mode operation (Intelligent Energy Management)

When the ECO Mode is selected, and the mains

power is available, the load is normally powered

through the automatic bypass.

When the mains voltage is detected out of the

prescribed tolerances, the load is automatically

transferred to the inverter.

When the mains recovers, the load returns to

the automatic bypass after a variable time

defined by the control unit.

Fig. 3.2-2 Energy flow in ECO Mode operation

The ECO Mode can be configured directly by the user for higher efficiency, considering the mains

reliability and criticality of the load.

The selection between the two operation modes “VFI Mode and ECO Mode”, or switching between

operation modes at required time, can be done through the UPS control panel (see Section 6.3.1-5).

In case of parallel system

ECO Mode cannot be enabled for RPA Parallel System.

Attention: A single unit equipped with a RPA - Parallel board, must be considered as parallel, thus

disabling ECO Mode.

Modifications reserved Page 12/57

OPM_LPS_3UO_30K_40K_0US_V010.doc Operating Manual LP 33 Series 30 & 40 kVA

Automatic bypass operation

In VFI (Voltage Frequency Independent) operation

mode, the load is permanently supplied by the

inverter but, in case of trouble on the inverter, or

when overload or short-circuit on the output

occur, if the mains voltage do not exceed the

admitted tolerances, the load is instantly

transferred to the mains through the automatic

bypass, taking advantage of the higher short

circuit power.

Fig. 3.2-3 Energy flow in automatic bypass operation

When the inverter recovers, the load will be re-transferred automatically to the inverter.

In case of parallel system

Each unit has its own bypass.

All the bypasses in the system work together, their control being managed in the same manner by

all units.

The units are continuously exchanging information before taking such decision.

In case the inverter of one unit fails, its bypass remains operating.

It is excluded only if the unit is separated from the common bus by opening its output switch Q1.

Mains recovery operation

As soon as the mains recovers, the rectifier starts

up automatically supplying the inverter and the

battery-charger recharges the battery.

In case the inverter has been shut down following

a complete discharge of the battery, when the

mains recovers the system start up automatically.

Fig. 3.2-4 Energy flow at mains recovery operation

When the energy stored in the battery is sufficient to ensure a minimum time of operation with the

actual load, in case of a future mains failure, the load will be retransferred to inverter (if selected VFI

Mode).

In case of parallel system

When the AC input power recovers, the rectifiers will start up sequentially according to their

number in the parallel system in order to avoid an initial inrush current.

The inverters will start up automatically, but only when the battery has recharged enough for a

minimum runtime with the present load.

When enough inverters to supply the load have been restarted, the load will be transferred from the

automatic bypass back to the inverter bus-bars.

Modifications reserved Page 13/57

OPM_LPS_3UO_30K_40K_0US_V010.doc Operating Manual LP 33 Series 30 & 40 kVA

Manual bypass operation

The manual bypass circuit consisting of Q1 and

Q2 manual switches, permits the transfer of the

load directly to the mains without interruption,

leaving the UPS galvanically separated from the

output load.

This type of operation is normally used when the

UPS system must be completely turned off for

maintenance or reparation.

Fig. 3.2-5 Energy flow in manual bypass operation

Mains failure operation

In the event of a mains power failure, the

rectifier and the battery-charger turn OFF,

while the inverter continues to supply the load

without interruption using the energy stored in

the battery.

During the battery discharge, the LCD screen

displays the remaining autonomy, based on the

battery capacity and the applied load.

Fig. 3.2-6 Energy flow during mains failure operation

In the event of an extended mains failure, before the battery is fully discharged, the alarm “stop

operation” warns the user that the UPS will start the shutdown procedures when the indicated time

expired (normally 3 minutes).

In case of parallel system

With parallel system for power capacity:

• With the bypass mains power available as the warning “battery low” occurs on one unit, after

timeout (selectable) the load is transferred to mains.

• With missing bypass mains power as the warning occurs on one unit, the system starts the

timeout (selectable) of “Stop operation” and then the output load shuts down.

With redundant parallel system:

• As the warning battery low occurs on one unit unnecessary to support the present load, after

timeout (selectable) this unit shuts down and the load is shared between the other units.

As the warning occurs on one unit necessary to support the present load, the system starts the

timeout (selectable) of “stop operation” and then the output load shuts down.

Modifications reserved Page 14/57

OPM_LPS_3UO_30K_40K_0US_V010.doc Operating Manual LP 33 Series 30 & 40 kVA

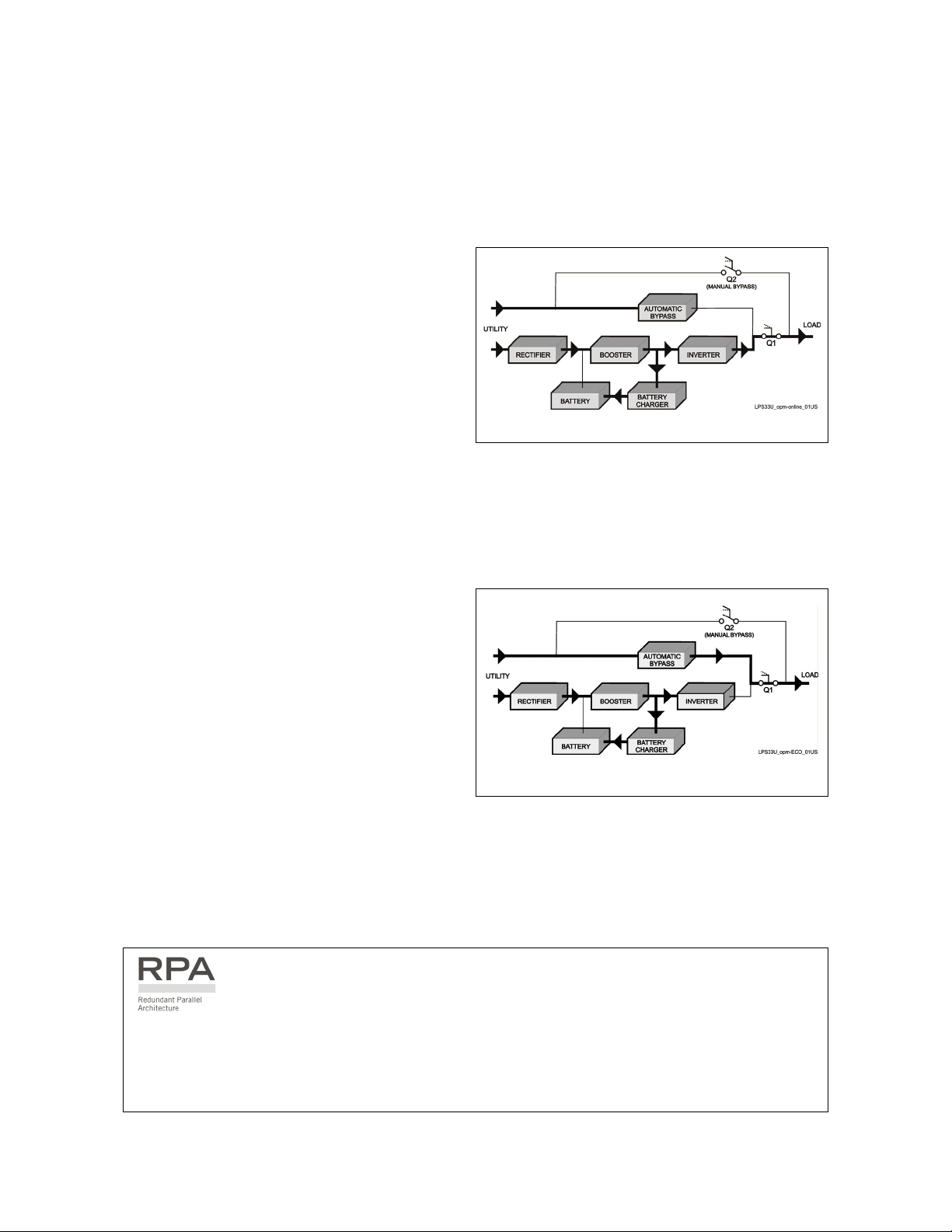

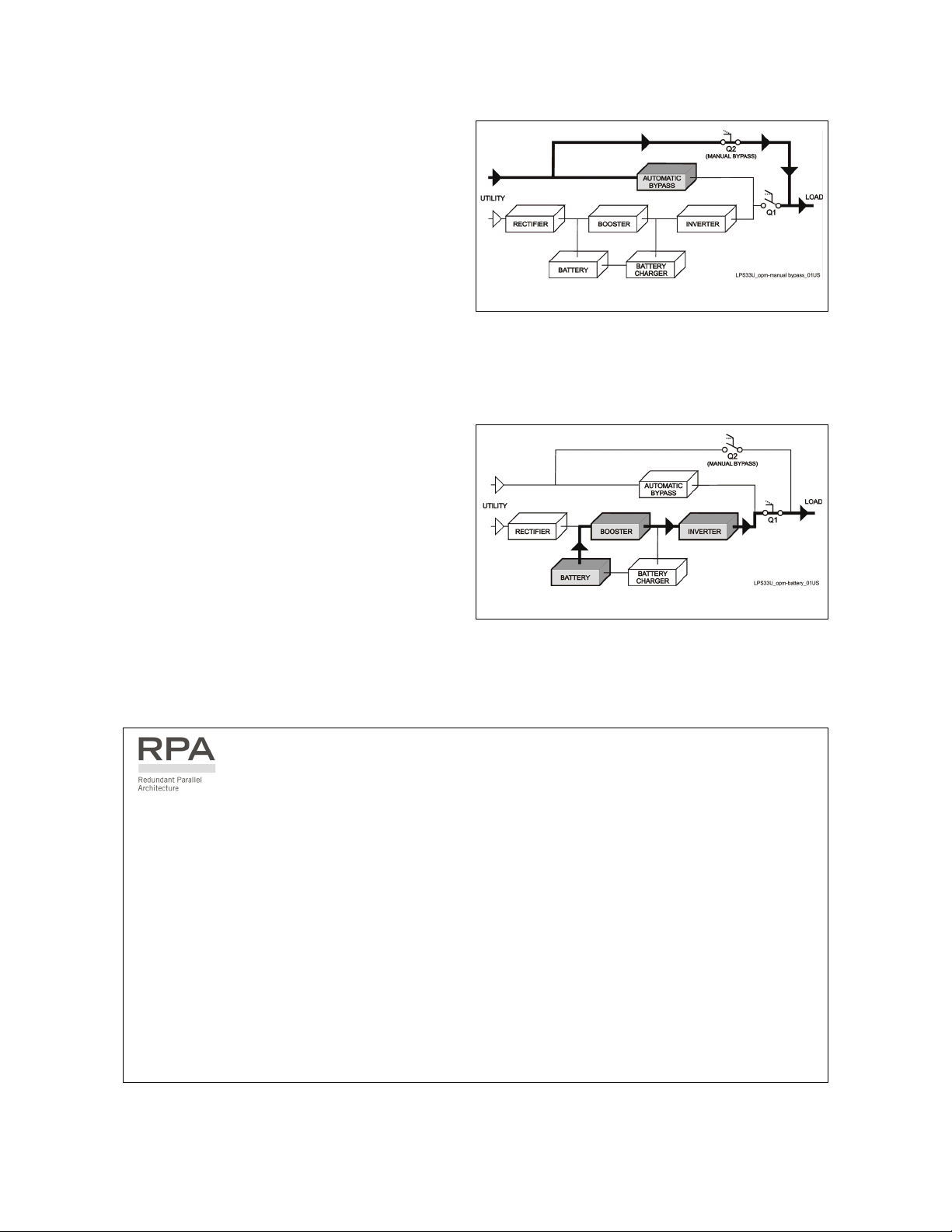

3.3 RPA PARALLEL SYSTEM

The RPA (Redundant Parallel Architecture) allows to extend the unit to a parallel system with 2, 3, or 4

units LP 33 Series connected on the same bus, which ensure the highest reliability rate and increase the

power availability.

Parallel system for power capacity

Two or more units can be paralleled in order to

achieve output power superior to the maximum

power delivered by a single UPS unit.

The maximum total load shared between the n

parallel units can achieve the 100% of the

installed nominal power system.

In the event of one unit fails, the load will be

suddenly transferred to the mains by the

bypass.

Parallel system for redundancy

The parallel system can be defined redundant

only in case the nominal power rating of n-1 units

of n parallel units is sufficient to supply the

required load power.

LPS33U_030-040_RPA system_GE_01

LP 33 Series

1

RPA

Board

LP 33 Series

2

RPA

Board

LP 33 Series

3

RPA

Board

LP 33 Series

4

RPA

Board

F2F1 F3 F4

UTILITY INPU

T

LOA

D

Fig. 3.3-1 RPA system diagram

The load in a parallel redundant system, is equally shared by n units connected on the output bars.

Should one of the parallel units trip off-line, the remaining (n-1) units will share the load maintaining the

applications protected by inverter until the normal situation restores.

Load sharing between parallel units

The control bus exchanging the data between the microprocessors of the paralleled units provide for a

constant proportional load sharing in every load condition.

Management and synchronization of the parallel system

All the units are identical without master and slaves.

One unit is arbitrarily selected as the reference (the first unit connected on power bus) being this unit the

first synchronized with the mains voltage, and all the other units synchronize with the first one.

In case the reference unit fails or it is excluded from the parallel power bus any other unit will take over

the reference role.

The AC input power source of all the bypasses must be the same for all the units of the parallel system

excluding any phase shift between them.

Control bus of the parallel system

A high-speed serial bus, guarantees communication, synchronization and load sharing between the

UPS modules.

Each module controls it’s own function, while the Master (each unit can be Master) controls and

commands the status of the system.

NOTE !

The parallel system exclude more rectifiers connected on common battery.

No transformers, fuses or automatic circuit breakers should be inserted between the

unit’s output and the load common bus bars.

Modifications reserved Page 15/57

OPM_LPS_3UO_30K_40K_0US_V010.doc Operating Manual LP 33 Series 30 & 40 kVA

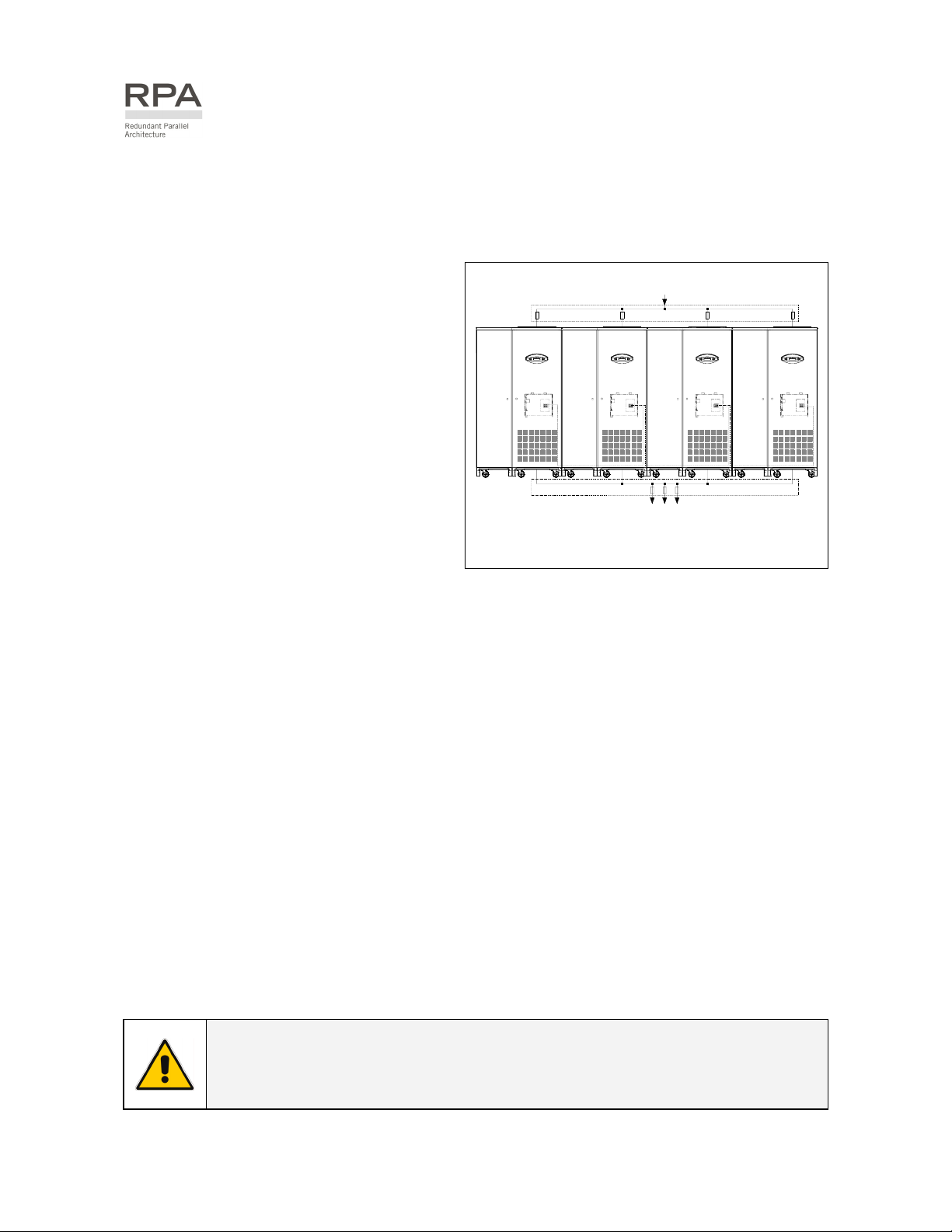

3.4 UPS PARALLELED ON THE SAME BATTERY

NOTE !

A parallel system with a Common Battery for two or more UPS, requires a particular

installation and adequate setting of some parameters, (accessible only through

password), and can therefore only be done by a qualified GE engineer.

Usually each UPS Unit runs with its own Battery.

In case of parallel units running with a Common Battery (max. 4 UPS - see Fig. 3.4-1), the sharing circuit

between the individual UPS is integrated in the communication bus of the system in order to assure an

equal sharing of the Rectifiers output currents.

Fig. 3.4-1 Diagram RPA system with UPS on common battery

1 –

2 –

3 –

4 –

5 –

6 –

7 –

8 –

Rectifier

Inverter

Automatic Bypass

Manual Bypass

Mains Power

Load Bus Bar

External Battery Fuse

Battery

Pay attention to the following recommendations:

•

The units delivered for this functioning mode needs a special parameters setting, so they must be

prepared in advance before the installation.

• The installation must be performed only with the UPS system completely shut down.

• The AC Rectifiers input power (5) must be the same, with clockwise phase rotation for each unit.

•

Each Rectifier must be set for the same floating DC voltage and the same Battery current limitation.

• It is mandatory to install the fuses / MCB (7) on each line connecting the Rectifiers to the common

Battery for maintenance / safety reasons (see Section 4.7.2).

• In case a unit must be powered down for maintenance, switch-OFF the concerned unit before open

the DC fuses / MCB on the Battery line (7).

• If an emergency generator set supplies the UPS, and the free contact “Generator ON” is connected

to the Customer Interface, connect a separate NO free contact on each parallel unit.

• Do not connect the temperature sensor for automatic battery floating voltage compensation.

•

Do not enable the function Boost charge.

Modifications reserved Page 16/57

OPM_LPS_3UO_30K_40K_0US_V010.doc Operating Manual LP 33 Series 30 & 40 kVA

3.5 SERVICE AND TECHNICAL SUPPORT

For any request of technical support please

contact the supplier who provided the system.

Stamp of your Dealer or local responsible of the Technical Assistance

(see page 3)

L

P

S

3

3

U

_

0

3

0

-

0

4

0

_

L

a

b

e

l

i

d

e

n

t

i

f

i

c

a

t

i

o

n

_

G

E

_

0

1

OFF

ON

OFF

ON

kVAOutput Power at Pow. factor

Output Freq. Hz

Output Voltage VAC: 3W + N + PE

Output Current A

lag.Series Product. Year

Input Freq. Hz

Input Voltage VAC: 3W + N + PE

Input Current A

Serial Nr.

Model

g

GE Digital Energy

6595 RIAZZINO (CH)

MADE IN SWITZERLAND

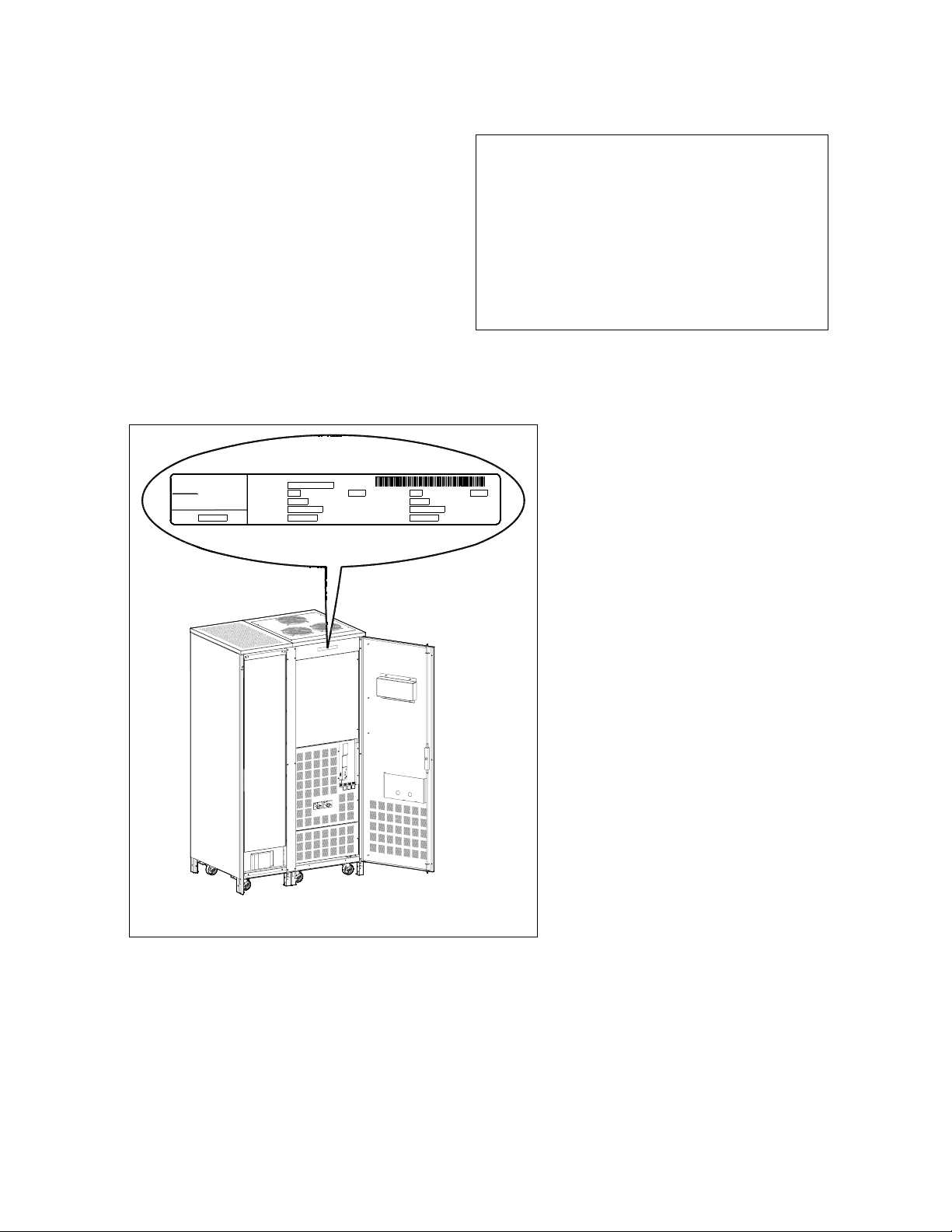

Fig. 3.5-1 Identification label

The requested data permitting to

identify your UPS are marked on the

identification label fixed on the front of

the cabinet, behind the lower front

door.

For fast and efficient Technical Support

solutions, please mention the data

marked on the identification label.

Modifications reserved Page 17/57

OPM_LPS_3UO_30K_40K_0US_V010.doc Operating Manual LP 33 Series 30 & 40 kVA

3.6 RECYCLING AT THE END OF SERVICE LIFE

NOTE !

This product has been designed to respect the environment, using materials

and components respecting eco-design rules.

It does not contain CFCs (Carbon Fluor Clorid) or HCFCs (Halogen Carbon

Fluor Clorid).

GE, in compliance with environment protection recommends to the

User that the UPS equipment, at the end of its service life, must be

recovered conforming to the local applicable regulations.

WARNING !

Leads contained in the batteries is a dangerous substance for the

environment, therefore it must be correctly recycled by specialised

companies!

Modifications reserved Page 18/57

OPM_LPS_3UO_30K_40K_0US_V010.doc Operating Manual LP 33 Series 30 & 40 kVA

4 LAYOUT

4.1 LAYOUT LP 33 Series / 30 & 40 kVA

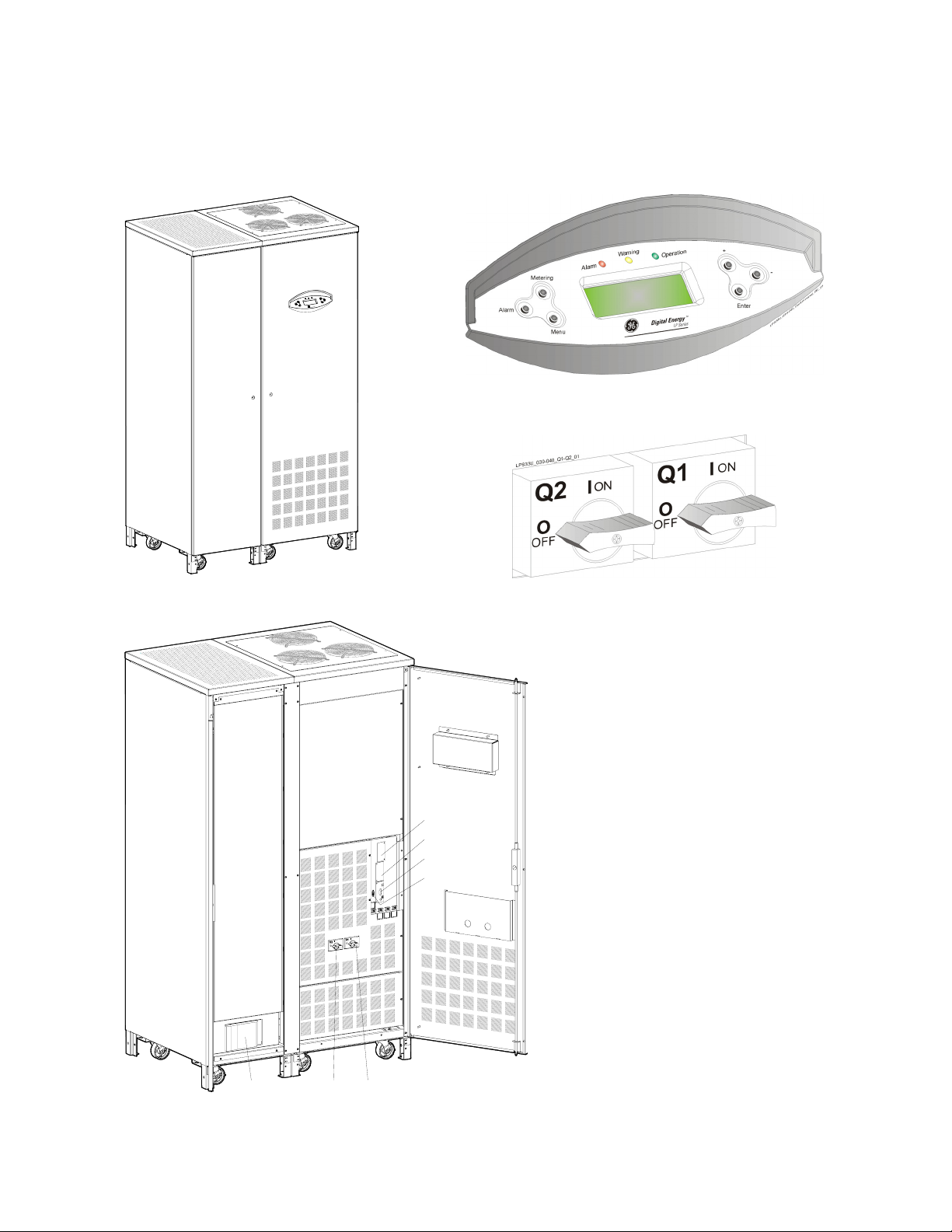

Fig. 4.1-3 Control panel

L

P

S

3

3

U

_

0

3

0

-

0

4

0

_

U

P

S

_

G

E

_

0

1

D

i

g

i

t

a

l

E

n

e

r

g

y

T

M

L

P

S

e

r

i

e

s

Fig. 4.1-1 General view

Fig. 4.1-4 Q1 & Q2 switches

BC Battery cabinet

CI Customer Interface Board (optional)

F5-6-7 Battery fuses

Q1 UPS output switch

Q2 Manual bypass switch

RC Relay card

SNMP Advanced SNMP Card (optional)

L

P

S

3

3

U

_

0

3

0

-

0

4

0

_

U

P

S

_

0

4

OFF

ON

OFF

ON

SNMP

CI

RC

F5-6-7

BC

Q2 Q1

RS232

Fig. 4.1-2 General view with open door

RS232 Serial port RS232

Loading...

Loading...