Page 1

Gateway E-842R SAS RAID

USERGUIDE

®

Page 2

Page 3

Contents

Chapter 1: Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Expansion enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

The enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Enclosure chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operator’s panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

The plug-in modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

AC power supply module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Cooling module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Controller module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Battery module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Disk I/O module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Drive carrier module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Dummy carrier modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Blank modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 2: Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Planning your installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Enclosure drive bay numbering convention . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Drive carrier configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Enclosure installation procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Preparing the site and host server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Unpacking the enclosure system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Rack installation prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Rack installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Module installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 2

Enclosure configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Enclosure cabling - single enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Ethernet connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Enclosure cabling - multiple enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Drive slot arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Drive location rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Power cord connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Grounding checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Management interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

StorView Storage Management software . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

VDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Chapter 3: Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Before you begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Power on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Power supply module LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Ops panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Controller module LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Cooling module LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

iii

Page 4

Contents

Disk I/O module LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Starting the drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Disk drive LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Starting StorView . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Power down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Chapter 4: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Initial start-up problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Status indicator LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Power supply module LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

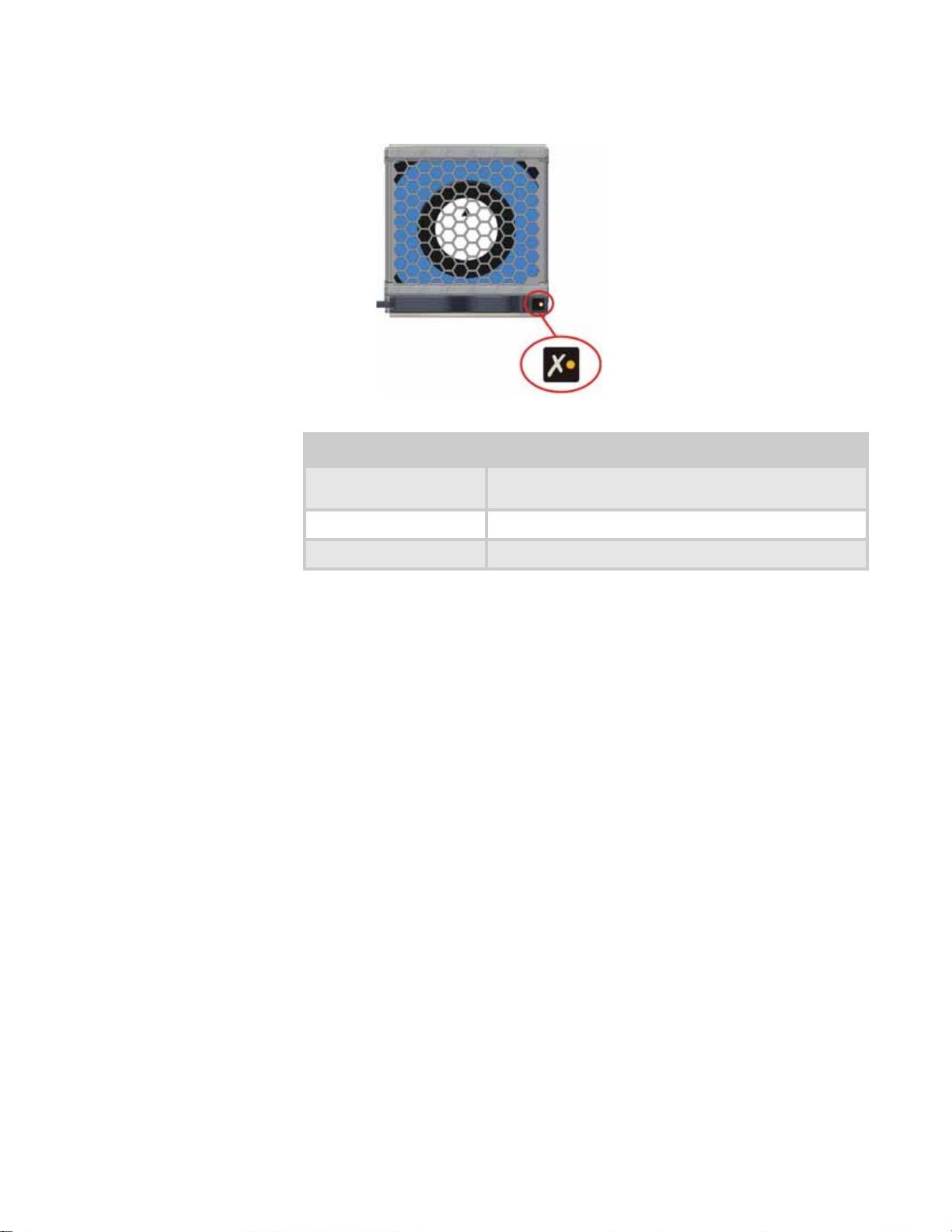

Cooling Module LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Ops panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Controller module LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Disk I/O module LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Drive carrier LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Audible alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3

Audible alarm mute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Drive carrier module faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Auto start failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

System faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Power supply faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Thermal control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Thermal alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Thermal warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Hardware faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Continuous operation during replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Ops panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Replacing a module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Power supply modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

AC Power supply module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Cooling module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Controller module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

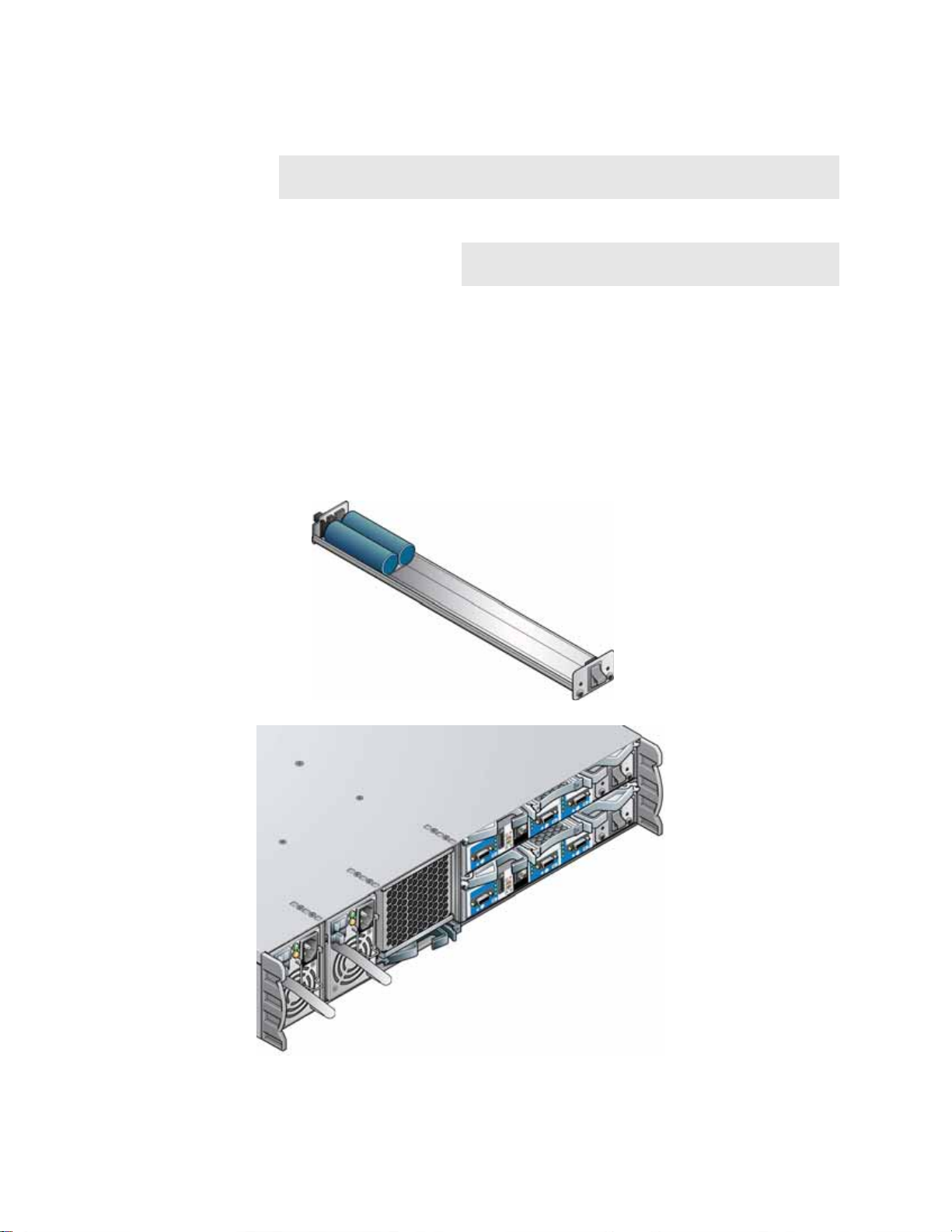

Battery module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Removing a battery module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Installing a battery module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Removing and replacing a disk I/O module . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Drive carrier module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Removing a drive carrier module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Installing a drive carrier module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Dummy drive carrier module removal and replacement . . . . . . . . . . . . . . . .56

Telephone support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Appendix A: Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

iv

Page 5

www.gateway.com

AC power (350 W power supply module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Power supply module safety and EMC compliance . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Controller module specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Disk I/O module specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Drive carrier module specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Appendix B: Legal Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Appendix C: Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

v

Page 6

Contents

vi

Page 7

• Overview

• The enclosure

• The plug-in modules

CHAPTER 1

Introduction

1

Page 8

Overview

CHAPTER 1: Introduction

Important

Mixing of SAS and SATA drives in the same enclosure is only supported in columns,

for example, column 1 is all SAS and column 2 is all SATA. Also, mixing of drives of different

capacities in the same column is not supported.

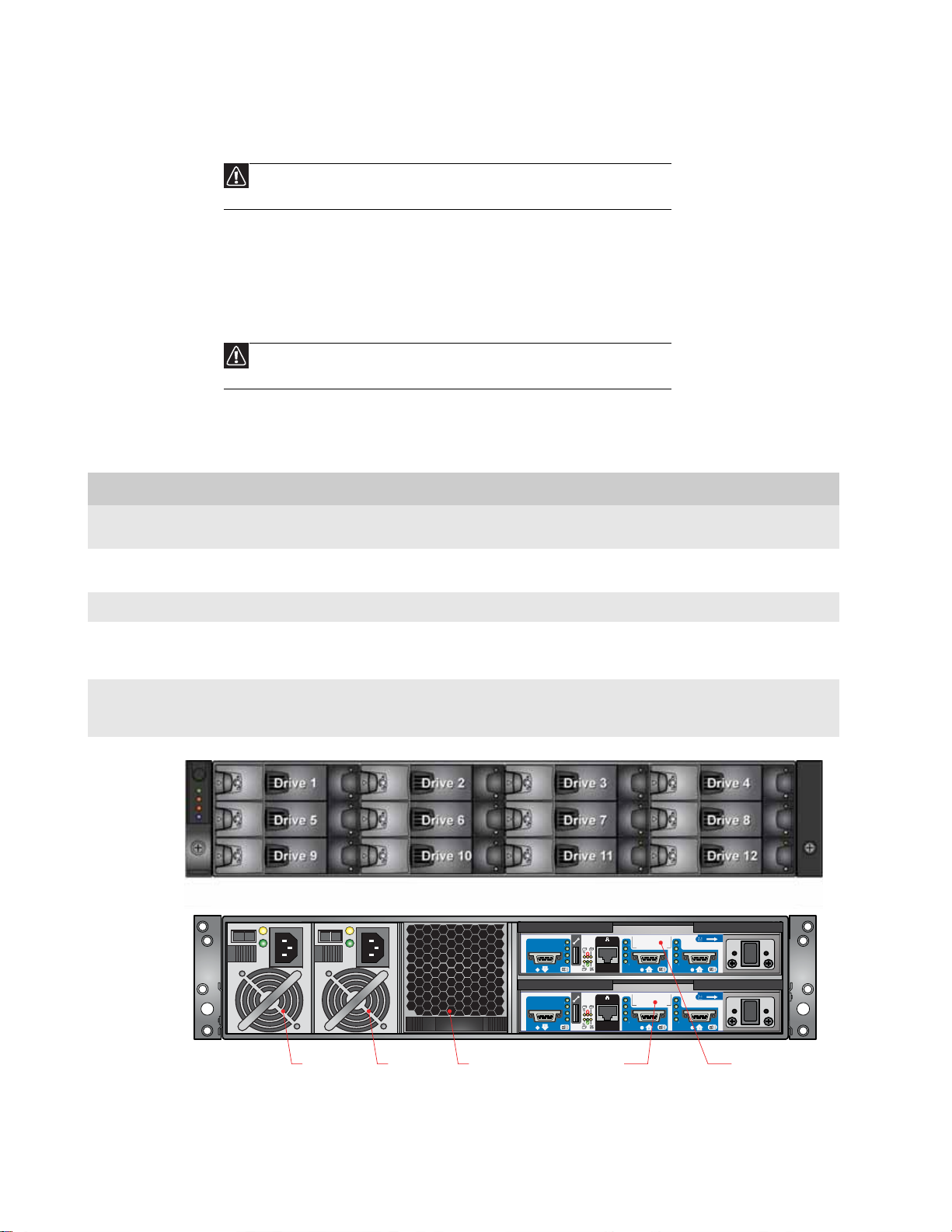

The Gateway E-842R SAS Enclosure Platform is a 2U (rack space) disk drive enclosure, housing

twelve low profile (1-inch high), 3.5-inch form factor hard drives, which can be either:

• 3 GB direct dock SAS disk drives,

• 3 GB direct dock SATA disk drives, or

• 3 GB dual path SATA disk drives through an active/active SATA mux transition card.

The system provides as much as 6TB of data storage per enclosure when 500 GB drives are

installed.

Expansion enclo sure

RAID enclosure expansion is achiev ed b y connecting expansion enclo sures. Multiple enclosur es are

connected together using SAS pat ch cables. You can connect as many as five enclosures. For more

information, see “Enclosure cabling - multiple enclosures” on page 25.

The enc losure

The Gateway E-842R design concept is based on an enclosure subsystem together with a set of

plug-in modules. The enclosure platform, as equipped, includes:

• Chassis and backplane with integrated (front panel mounted) operator’s panel.

• As many as 12 drive carrier modules, containing either:

• 3 GB direct dock SAS disk drives,

• 3 GB direct dock SATA disk drives, or

• 3 GB dual path SATA disk drives through an active/passive SATA mux transition card.

airflow. See “Dummy carrier modules” on page13.

2

Important

Dummy carrier modules must be fitted in all unused drive bays to maintain

Page 9

• Two plug-in power supply modules, 100-240 V AC, 350 W.

• One plug-in cooling fan module.

• Two plug-in controller modules, each incorporating a RAID controller and a StorView

Enclosur e chas sis

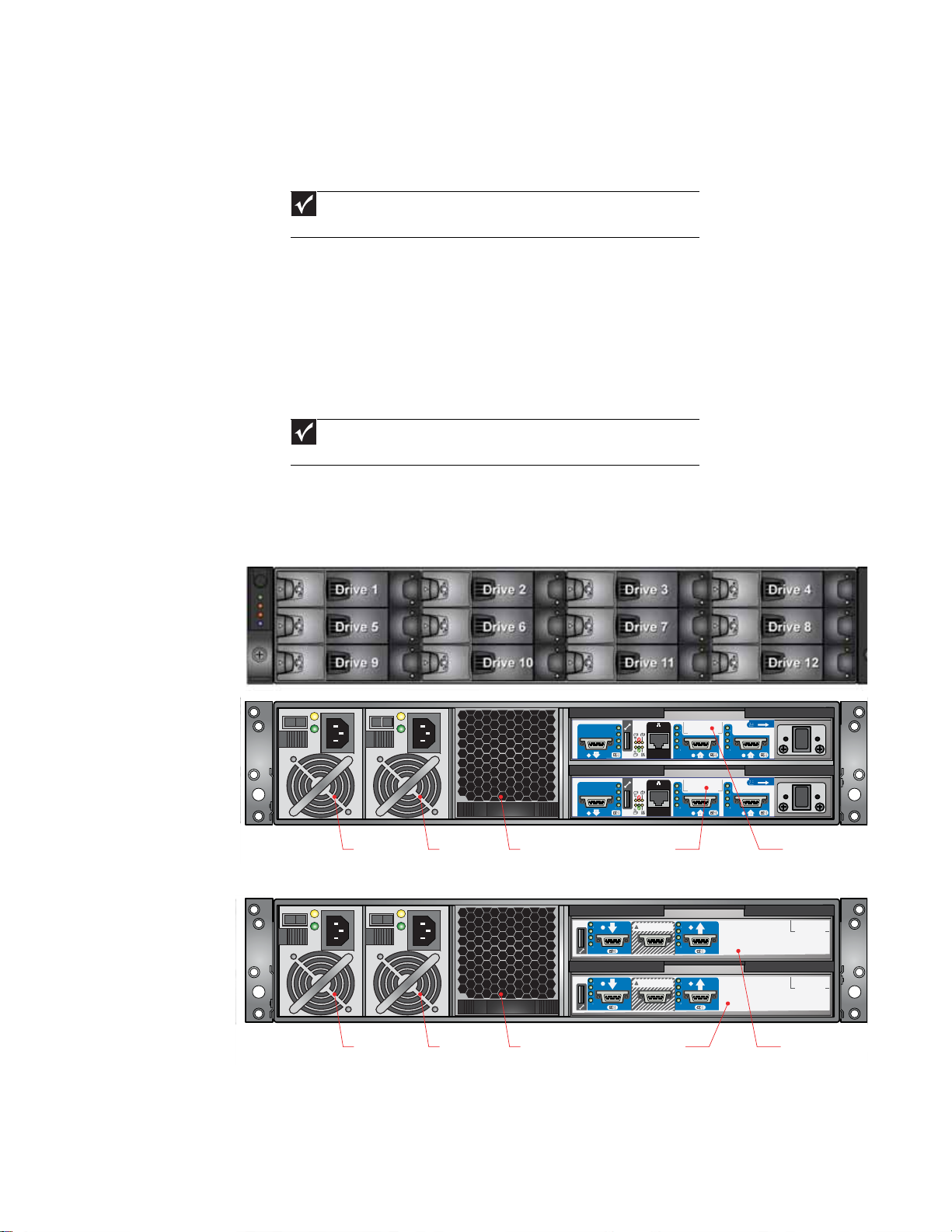

The chassis consists of a sheet metal enclosure assembly containing a backplane printed circuit

board (PCB) and m odule runner system.

• The chassis front panel incorporates an integrated operator’s (Ops) panel.

• The backplane PCB provides logic level signal and low voltage power distribution paths.

• The chassis has 19-inch rack mounting features so it fits into a standard 19-inch rack and

The chassis assembly contains 12 drive bays at the front, each of which accommodates the

appropriate plug-in drive carrier module. The 12 drive bays are arranged in 3 rows of 4 drives per

row . In t he back , the ch assi s ass embly contain s fiv e plug-i n module ba ys t o hou se tw o powe r supply

modules (PSUs), a cooling fan module, and two c ontroller modules, whic h are installed hori z ontally

(one above the other) in the right bay.

www.gateway.com

Management Module.

Important

If only one controller module is installed, a blank module must be installed

in the unused slot.

uses 2 EIA units of rack space (3.5” high).

Important

A drive bay is defined as the space required to house a single 1.0" high, 3.5-

inch disk drive in its carrier module.

0

1

0

1

PSU 1 PSU 2 Cooling Module

RAID en closure (ba ck)

PSU 1 PSU 2 Cooling Module Disk I/O Module 1Disk I/O Module 0

Expansion enclosure (back)

RAID Controller 0

FACTORYUSE ONLY

FACTORYUSE ONLY

RAID Controller 1

3

Page 10

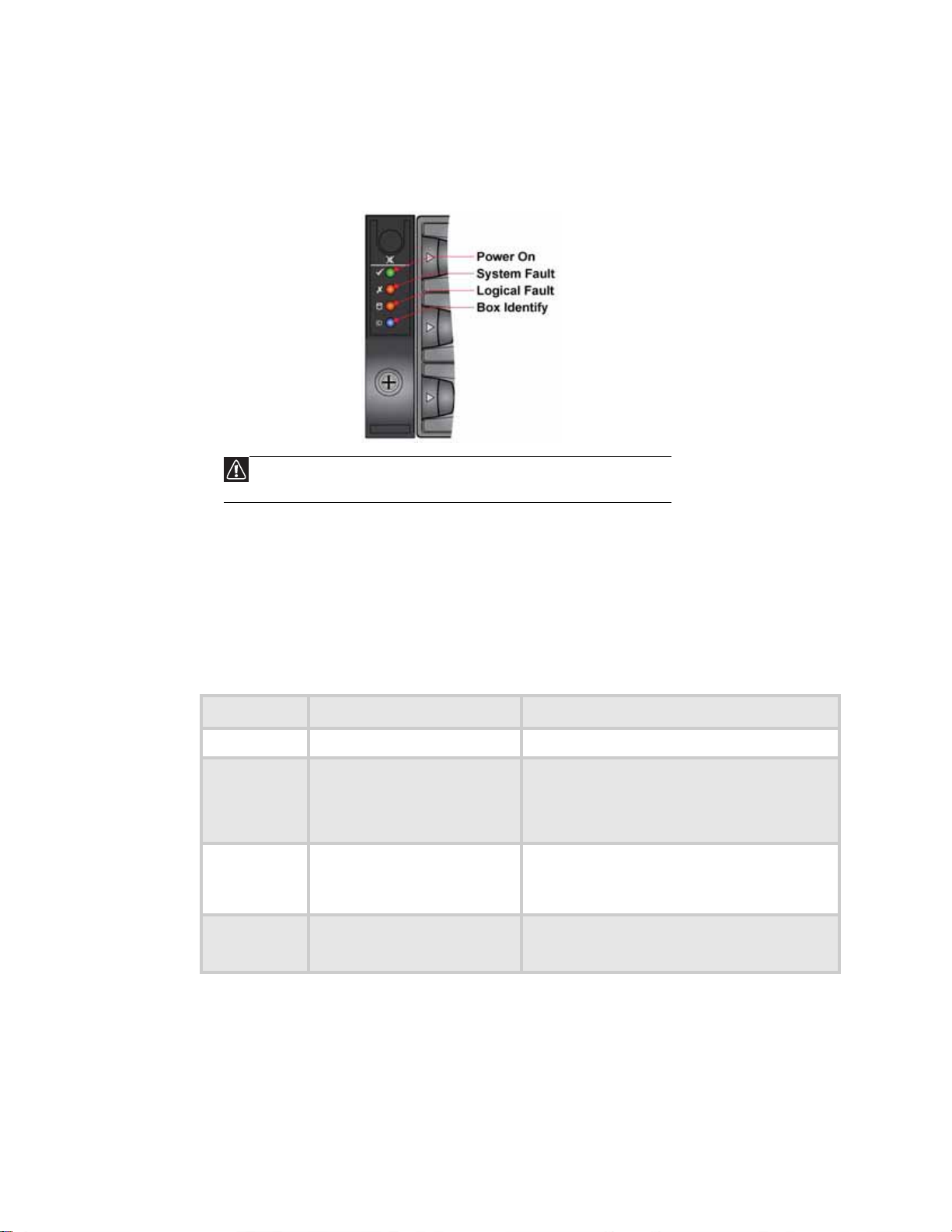

Operator’s panel

The enclosure’ s f ront panel has an integrated operat or’ s (Ops) panel w ith four LEDs. The Ops panel

provides you with a high level indication of the operation of the enclosure. See “Ops panel LEDs”

on page 8 for details of the LED status conditions.

separately. To replace the Ops panel, you must replace the entire enclosure.

CHAPTER 1: Introduction

Caution

The Ops panel is an integral part of the enclosure assembly and cannot be replaced

Alarms

Enclosure replacement should only be performed by trained personnel.

Visible alarms

The functional modules have associated status LEDs. The Ops panel shows a consolidated status

for all modules. LEDs show constant green or blue to indicate good or positive status. Constant

or flashing orange LEDs indicate the presence of a fault within that module.

LED State Description

Power On Co nstant green Good or posit ive status

System Fa ult Constant orange: fault present Indicates a problem with a power supply, cooling, or

controller module. For more information, see the

tables in “Power supply module LEDs” on page 13,

“Cooling Module LED” on page13, and “Controller

module LEDs” on page15.

Logical Fault C onstant orange: fault present Indicates f ailure of a dr iv e module. Th e failing module

is indicated by the Fault LED. For more information,

see the table in “Drive carrier m odul e faults” o n

page 16.

Box Identity Constant bl ue: en closure ident ity You can light this LED through the management

interfaces to indicate which enclosure requires

servi ce act ion s.

4

See “Ops panel LEDs” on page8 for a description of the Ops panel LED states.

Page 11

Audible alarms

The Gateway E-842R enclosure includes an audible alarm which indicates when a fault state is

present. The following conditions activate the audible alarm:

• Fan fau lt

• Voltage out of range

• Over temperature

• Thermal overrun

• Syste m fau l t

• Logi ca l Fa ul t

• Power supply module fault

When the audible alarm sounds, you can mute it b y pressing the Alarm Mute button on the front

panel. For more information, see “Audible alarm mute” on page 16.

The plug-in module s

A Gateway E-842R enclosure requires the following modules for normal operation:

• Two 350 W AC power supply modules.

• One cooling module.

• One or two controller modules.

• As many as 12 drive carrier modules.

• Dummy drive carrier modules, as required.

www.gateway.com

Important

No drive bays should be left comple tely empty. Dummy carriers or bl ank modul es

must be installed in all unused bays.

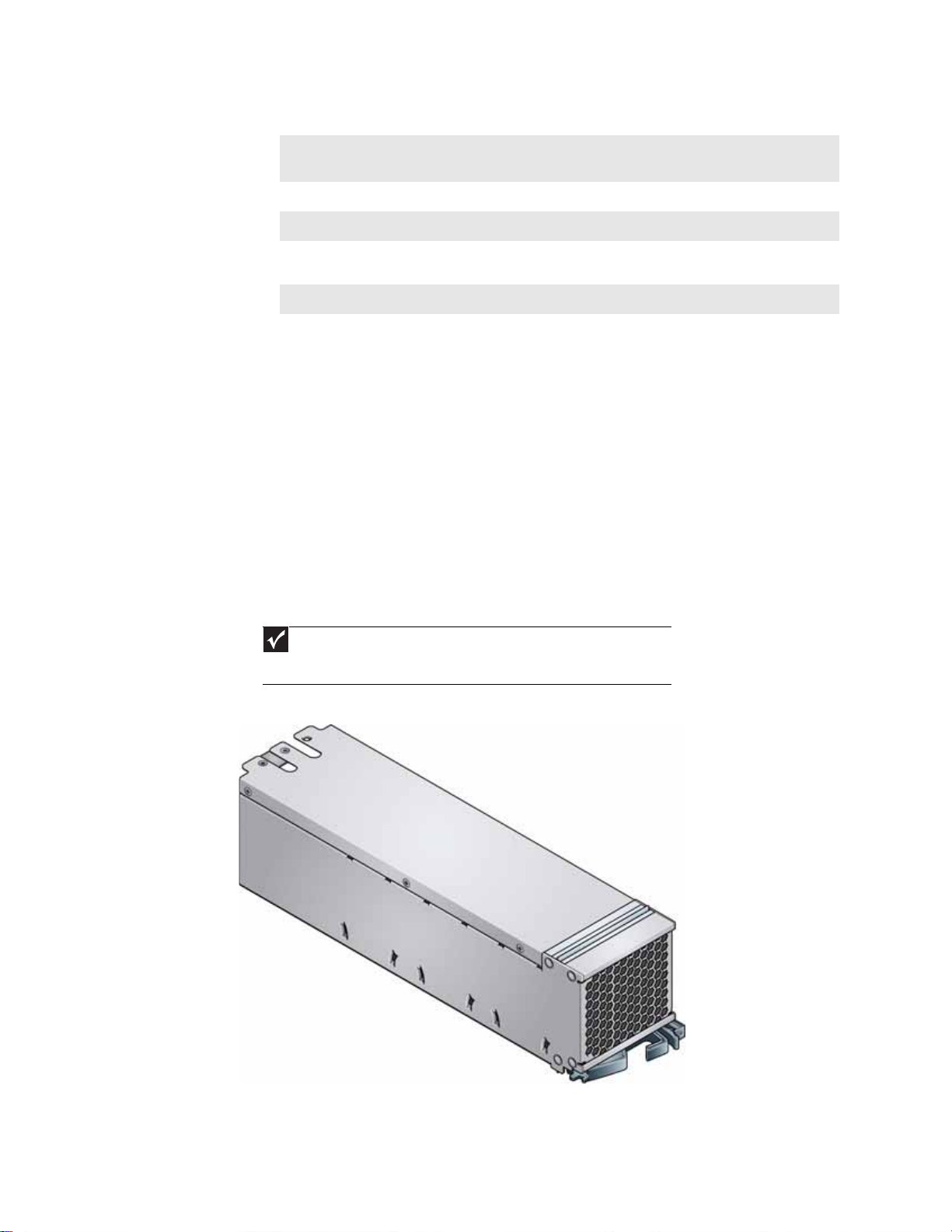

AC po wer suppl y module

Two, 100V-260 VAC 350 W power supply modules are supplied and mounted in the back of the

enclosure as part of the enclosure’s core product.

Power supply module input voltage operating ranges are nominally 115V or 230V AC, selected

automatically.

5

Page 12

CHAPTER 1: Introduction

T wo LEDs mount ed on the r ear panel of the pow er supply module indicate the status of th e module:

Multiple power supply modules

In order to maintain the appropriate airflow, you must always operate the Gateway E-842R with

two power supply modules installed. The two power supply modules operate together so if one

fails, the other maintains the power supply and cooling while you replace the faulty module.

Module replacement should only take a few minutes to perform but must be completed within

10 minutes from removal of the failed module.

Cooling module

The cooling module provides system cooling, thermal monitoring, and control functions.

System airflow is from the front to the back of the enclosure:

Power On & OK

(Green)

Off Off No AC power (either power supply module)

Off On No AC power (this power supply module only)

On Off AC present, power supply module on and OK

On On Power supply module fan fault

Module Fault

(Orange)

Status

Power supply module fault (over temperature, over

voltage, over cur r e nt, or power supply module fan fail)

• Cooling air passes over drives and through the midplane to a central air passage.

• The cooling module pulls air from the air passage and from the controller modules.

Important

The system must be operated with a low pressure rear exhaust installation

(back pressure created by rack doors and obstacles not to exceed 5 pascals (0.5mm

water g au ge) ) .

• The power supply modules pull cooling air fr om t he air pass age at the back of the enc lo sure .

6

Page 13

www.gateway.com

The module has an orange Cooling Module Fault LED.

LED status is described in the following table:

Module Fault (Orange) Status

Off Enclosure Off - Indic ate d by pow er supp ly module and contr oller

Off Enclosure On - Fan OK

On Cooling module fan failure

module OK lights

7

Page 14

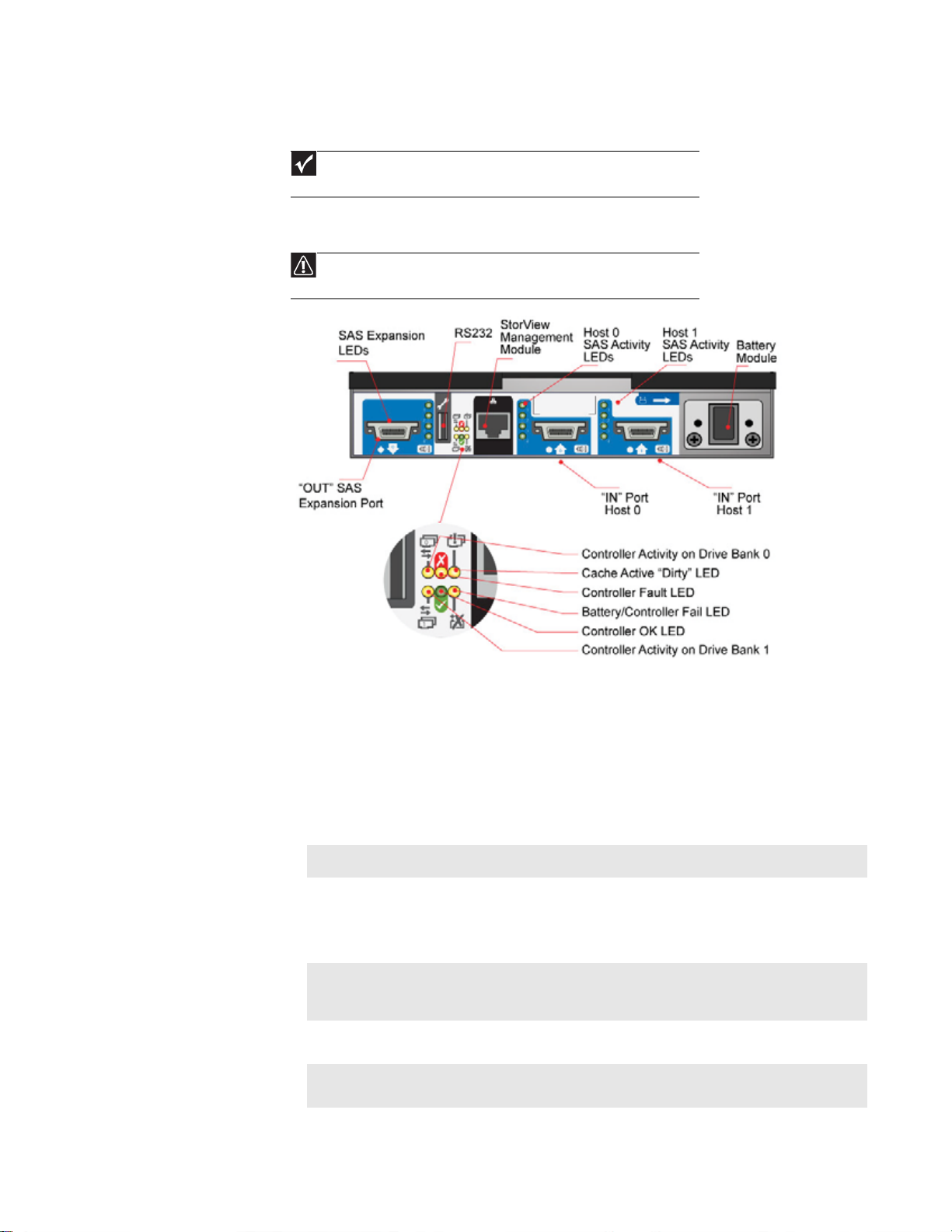

Contr oller module

CHAPTER 1: Introduction

Caution

Operation of the enclosure with any modules missing disrupts the airflow and the

drives do not receive sufficient cooling. All openings must be filled before operating the

enclosure.

When only one controller module is installed, a blank m odule mu st b e ins talled in the vacant

controller module slot at the rear of the enclosure to maintain airflow and ensure correct

operation.

Important

Do not mix Disk I/O modules and RAID Controller modules in the same enclosure. Disk

I/O modules are only installed in the expansion enclosure and RAID Controllers are only

installed in the RAID enclosure.

One or two controller modules (depending on your configuration) are supplied and mounted in

the back of the enclosure as part of the Gateway E-842R enclosure core product.

The plug-in controller modules have been designed for integration into the enclosure, providing

external FC cable interfacing with the host computer system.

The backplane incorporates a connection to each of the SAS ports within the controller modules.

The controller module’s internal processor monitors error conditions on each disk drive port.

Processors housed on the controller modules prov ide enclosure management interfac ing to devices

on the backplane, power supply module, controller module, and Ops panel to monitor internal

functions. These processors operate in a dual active configuration to allow failover.

The module incorporates LED indicators. For the location of the LED indicators, see “Controller

module LEDs” on page 8.

External ports

The RAID controller module has the following external ports:

• Two external (host) SAS ports that allow for fitting of Small Form-Factor Pluggable (SFP)

modules, with auto-bypass at the output. Either or both of these SFP ports can be used to

provide connection to the host controllers. Each host port operates at 3 Gb/s, giving an

effective speed of 6 Gb/s. These ports are also backwards compatible with 2 Gb/s hosts.

• An SAS expansion port suppor ts a s man y as four expansion enclosur es t hr ough an SFF-8470

connector.

8

Page 15

www.gateway.com

• An RJ45 10/100BaseT Ethernet port lets you connect the controller to a network to enable

out-of-band management and monitoring using the embedded StorView GUI software.

Important

Only shielded, Cat 5 (or better) cables should be used for connection to the

Ehternet port for EMC performance.

• There is also an RS232 socket which provides an alternative user interface to the RJ45

connector.

Caution

Although the RS232 port is similar in appearance to a USB port, it requires a

special cable and you should not attach a USB cable to it.

The recommended configurations are shown in “Ethernet connection” on page 24 and “Enclosure

cabling - multiple enclosures” on page25.

StorView Management software

The StorView Storage Management software which is embedded in the controller module is a

full-featured, graphical, HTML-based software suite designed to configure, manage, and monitor

the controller module storage solution. T he module is configured w i th a base IP address t o l et you

connect to it. See “StorView Storage Management software” on page29 or the Gateway E -842R

StorVi ew Sto rag e Ma nag emen t Soft wa re User Gui de for further information.

LED functions LED state Definition

Battery fault Orange When lit, this LED indicates that the backup

Cache active Orange When lit, this LED indicates that the RAID

Controller a ctivity on drive

bank 0

Controller a ctivity on drive

bank 1

Orange When lit, this LED indicate s ac ti vity on the Bank

Orange When lit, this LED indicate s ac ti v i ty on the Bank

battery unit is missing, has low voltage, has

experienced a time-out on charge indicating a

faulty bat t ery, or has exper ience d a fa u lt in the

chargin g circuitr y.

controller cac he has data s a ved in me mory but

not written to the disk array.

0 disk drives.

1 disk drives.

9

Page 16

CHAPTER 1: Introduction

Batt ery module

Each controller module assembly includes a removable battery module (for the location, see

“Controller module” on page8). The battery module contains a replaceable Li-Ion battery pack,

as shown i n the f ol low ing illu str ation. T he bat t ery pack pr ot ec ts the cach e cont ents if th e A C pow er

fails. You can check the amount of battery time available through the Management Interface. The

amount of time available is dependent on the amount of cache in the system.

See “Battery mo dule” on pag e 24 for removal and replacement procedures.

Controller OK Green When lit, this LED indic at e s tha t RAID contr oller

activity is normal.

Controller fault Orange When lit, this LED indicates that a RAID

controller fault has occurred.

Ethernet status Green When lit, this LED indicates that the Ethernet

port has a valid connection.

Orange When lit, this LED indicates that the Ethernet

port has activity.

SAS activity Green When lit, these LEDs show I/O activity on the

specific port lane indicated.

10

Page 17

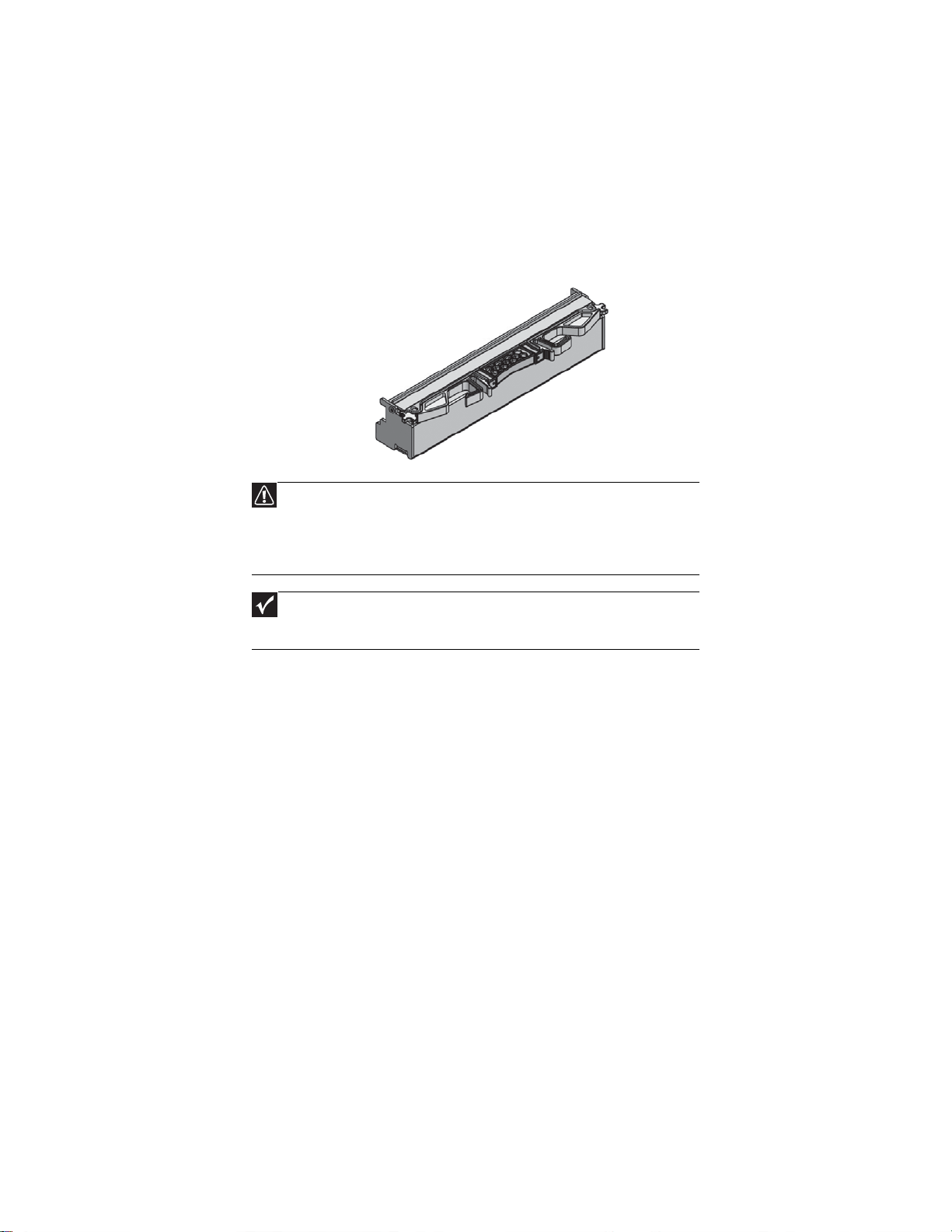

Disk I/O module

The expansion enclosure houses one or two Disk I/O modules. They provide the drive expansion

for the RAID enclosure . When expanding the sy stem, y ou may add up to f our expansion enclos ures.

This will give you a total of five enclosures including the RAID enclosure. A fully loaded system

will provide a total of 60 disk drives.

I/O modules are only installed in the expansion enclosure and RAID Controllers are only

installed in the RAID enclosure.

Processors housed on the Disk I/O modules provide enclosure management and an interface to

the devices on the backplane, PSU, Disk I/O module and Ops panel, which monitor internal

functions. These Disk I/O module processors operate in a master-slave configuration to allow for

failover.

The enclosure may be configured with either one or two modules. If only one Disk I/O module is

installed, a blank module must be installed in the unused bay.

Each SAS connector has four LEDs adjacen t to the connector. The LEDs indica te I/O activity on that

specific SAS port lane where each port has four lanes.

the Disk I/O module in the next E-842R enclosure in a multiple enclosure configuration, See

“Enclosure cabling - multiple enclosures” on page 25 for further information on enclosure

expansion.

www.gateway.com

Important

Do not mix Disk I/O modules and RAID Controller modules in the same enclosure. Disk

Important

The OUT port on the RAID Controller or DIsk I/O module connects to the IN port on

11

Page 18

Driv e carr ier module

The drive carri er module comprises a hard disk mounted in a carrier . Each dri ve bay hou ses a single,

low profile, 1.0-inch high, 3.5-inch form-factor disk drive in its carrier. The carrier has mounting

locations for SAS or SATA drives.

The front cap also supports an ergonomic handle which provides the following functions:

• Inserting the carri ers i nto the drive b ays

• Removing the carriers from drive bays

• Positive “spring loading” of the drive/backplane connector

• An anti- tamper lock op erated by a torx-socket type key

CHAPTER 1: Introduction

Drive status indicat ors

Each drive carrier has two LEDs, an upper (green) and lower (orange). In n ormal operation the

green indicator is ON and flickers as the drive operates. The orange indicator is only ON i f there

is a drive fault. If the green LED is OFF when the orange LED is ON, a power control circuit failure

is indicated.

Power On & OK

(Green)

On Off Normal o peration

On On Drive fault

Off On A power co ntrol circuit failure

Module Fault

(Orange)

Status

Anti-tamper locks

Anti-tamper locks are installed in the drive carrier handles and are accessed through the small

cutout in the latch section of the handle. These locks are provided to disable the normal “pinch”

latch action of the carrier handle.

12

Page 19

Dummy ca rrier mo dules

Dummy carrier modules are provided for fitting in all unused drive bays. They are designed as

integral drive module front caps and must be installed in all unused drive bays to maintain a

balanced airflow.

Blank modules

Caution

Operation of the enclosure with any modules missing disrupts the airflow and the

drives do not receive sufficient cooling. All openings must be filled before operating the

enclosure.

When only one controller module is installed, a blank m odule mu st b e ins talled in the vacant

controller module slot at the rear of the enclosure to maintain airflow and ensure correct

operation.

www.gateway.com

Important

Do not mix Disk I/O modules and RAID Controller modules in the same enclosure. Disk

I/O modules are only installed in the expansion enclosure and RAID Controllers are only

installed in the RAID enclosure.

13

Page 20

CHAPTER 1: Introduction

14

Page 21

CHAPTER 2

Getting Start ed

• Introduction

• Planning your inst allation

• Enclosure installation pr ocedures

• Module installation

• Enclosure conf iguration

• Enclosure cabling - single enc losur e

• Ethernet connec tion

• Enclosure cabling - multiple enclo sure s

• Driv e slot ar rangeme nt

• Po wer cord conne ction

• Grounding checks

• Management int er fa ces

15

Page 22

CHAPTER 2: G etting Sta rted

Introduction

Caution

When connecting the enclosure, use only the power cords supplied or cords which

match the specification quoted in “Specifications” on page29.

This chapter e xplains ho w to install your enclosure int o a n industry-standard, 19-inch rack cabinet

and configure the enclosure sub-system.

Planning y our installation

Caution

Blank modules or dummy carrier modules MUST be installed in ALL unused bays or

the enclosure may overheat.

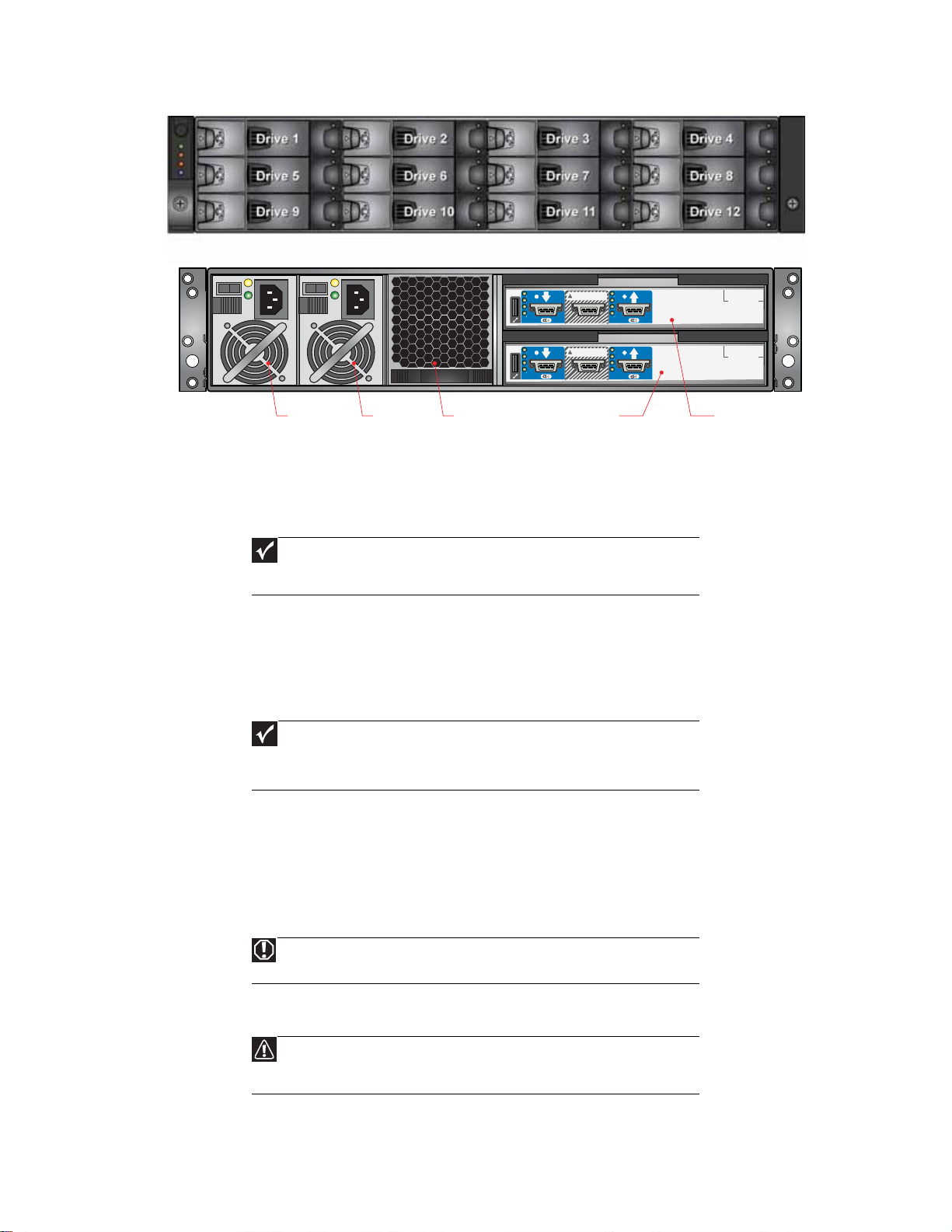

Befor e you begin installation, yo u should become familiar with the con f iguration requirements of

your enclosure , detailed in the f ollow ing table. The corr ect posi tions of each of the optional plug-in

modules are shown in the illustration. See “Ethe rnet connec tion ” on p age24 and “Enclosure cabling

- multiple enclosures” on page 25 for details of controller module configurations.

Module Location

Drive bays All drive bay s mu st hav e a driv e carr ier module or dumm y dri ve carr ier module instal led. No bay s should

Power supply (PSU)

modules

Cooling module Install the cooling module in the rear bay, as shown in the following illustration.

Controller module Two RAID controller modules (or one controller module and one blank module) can be installed,

Disk I/O module Two Disk I/O modules (or one Disk I/O module and one blank module) can be installed, depending on

be left empty.

T wo pow e r suppl y mod ule s mu st be installe d. F ull pow er r edun dancy is pr o v ided w hile a f ault y mo dule

is replaced. Install the power s upp ly modules in the left rear bays, as sho wn in the f oll owing illustrat io n.

depending on the configuration you require. The modules are installed horizontally (one above the

other) in the right rear bay.

the configuration you require. The modules are installed horizontally (one above the other) in the right

rear bay.

0

1

16

PSU 1 PSU 2 Cooling Module

Enclosure module

0

1

RAID Controller 0

RAID Controller 1

Page 23

www.gateway.com

PSU 1 PSU 2 Cooling Module Disk I/O Module 1Disk I/O Module 0

Disk I/O module

Enclo sure dr iv e bay numbering con v ention

FACTORYUSE ONLY

FACTORYUSE ONLY

Important

Drive carrier modules must always be installed in drive locations 1 and 12. This is the

minimum configuration required for the system to operate and provide SES Management

Services.

The enclosure driv e bay numbering conv ention is shown in the illustration on page16. A drive bay

is defined as the space required to house a single 1.0-inch high, 3.5-inch disk drive in its carrier

module.

Driv e carrier conf iguration

Important

Before you begin installation, you should become familiar with the configuration

requirements of your enclosure. There must be a drive present in drive locations 1 and 12

to enable SES communications to operate. Installing drives in both of these bays provides

redundant SES communication paths.

When planning your system configuration, remember that all enclosure drive bays must be filled

with either a drive carrier or dummy drive carrier module. No bays should be left empty.

Enclo sure installation procedur es

Warning

An enclosure with all component parts installed is too heavy for a single person to

safely install alone into a rack cabinet.

The following procedures describe the installation of an enclosure and highlight any critical

requirements and good handling practices you should follow to ensure a successful installation.

Caution

Make sure that you wear a suitable anti-static wrist or ankle strap and observe all

conven ti o nal ESD p recautions when han dl ing modules and compone nts. Avoid c on tact with

such things as backplane components and module connectors.

17

Page 24

CHAPTER 2: G etting Sta rted

Preparing the sit e and host s erver

Important

The E-842R system supports most of the widely used operating systems. However

deployment on M ic r osoft Windows requires t he .i nf dri v e r fil e whic h i s found on the Gat eway

External Storage CD (ESCD). (For Windows Servers, insert the ESCD and install the .inf file.)

Before you begin, make sure t hat the site where you intend to set up and us e your storage system

has the following:

• Standard AC power from an independent source or a rack power distribution unit with a

UPS (universal power supply).

• A host computer with a standard Fibre Channel HBA (host bus adapter) with the latest BIOS

and drive rs. Follo w the instr uction s pro vided wit h y our HBA and inst all the HBA an d its dri ver

software, if necessary.

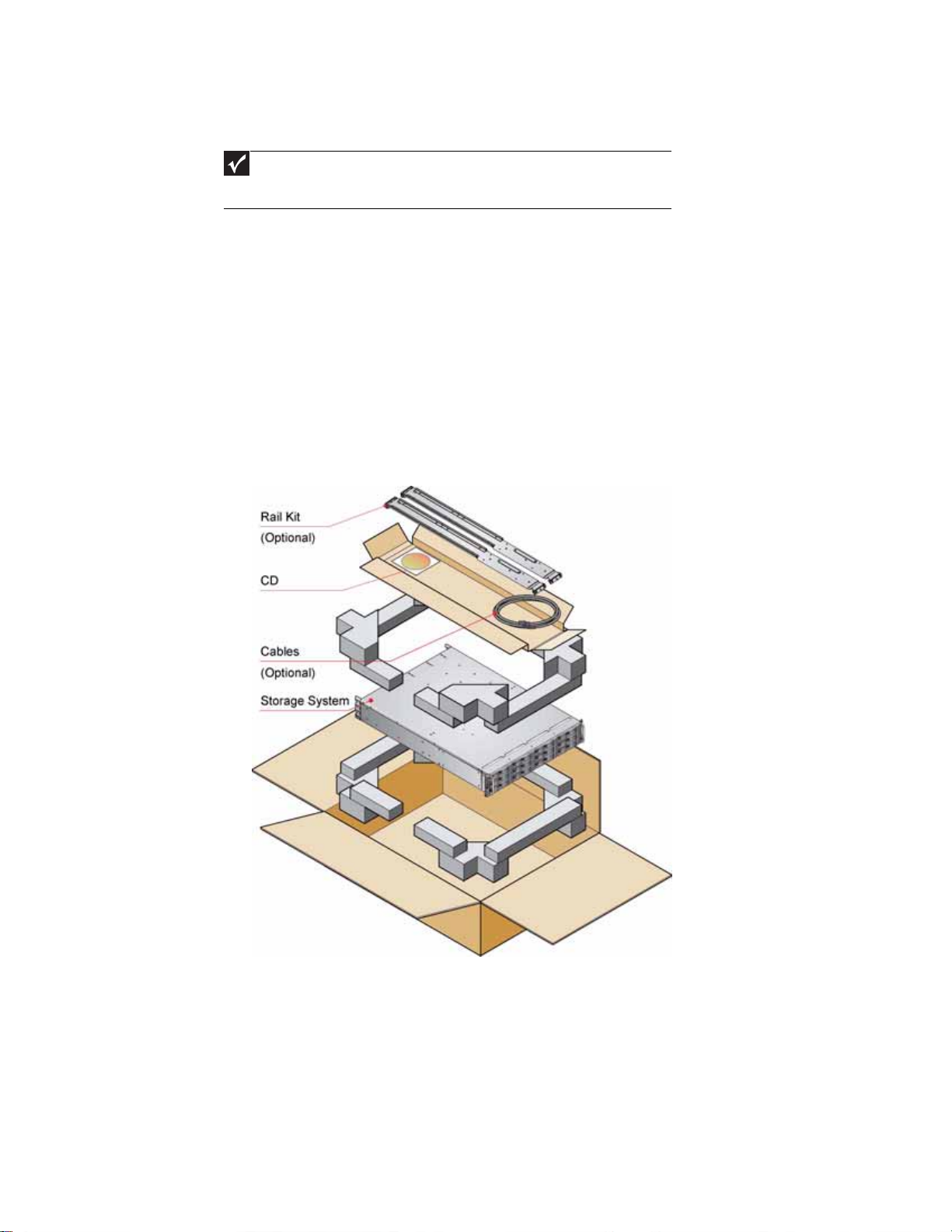

Unpacking t he enclosur e sy stem

The package contents and unpacking procedure are outlined in the following illustration.

The accessory box contains the AC power cord(s), a serial communication cord, and the software

and the Gateway External Storage CD (ESCD). The accessory box insert contains the adjustable rail

slides and hardware parts to rack mount the enclosure.

18

Page 25

Rac k installation prer equisit es

The enclosure is designed for installation into an industry standard, 19-inch cabinet, capable of

holding the unit.

• A minimum depth of 28 inches (700 mm) from the front flange to the back metalwork

(excludes back cabling).

• Up to 70.5 lbs (32 kg) per enclosure, depending on configuration.

• A minimum gap of 1 inch (25 mm) of clearance between the rack cover and the front of the

drawer, and 2 inches (50 mm) of rear clearance between the back of the drawer and the

back of the rack is recommended, in order to maintain the correct airflow around the

enclosure.

• The rack should have a maximum back pressure of 5 pascals (0.5 mm water gauge).

Rack mounting rail kit

A set of mounting rails is a vailable for us e in 19-inch rac k cabi ne ts. T he s e r ails have been designe d

and tested to handle the maximum enclosure weight and to ensure that multiple enclosures may

be installed without loss of space within the rack. Use of other mounting hardware may cause

some loss of rack space.

The rack mounting rail kit also incorporates a rear hold down mechanism to ensure shock and

vibration immunity.

Contact Gateway Customer Care to make sure that suitable mount rails are available for the rack

you are u si ng .

www.gateway.com

Rac k installation procedur e

See the detail drawings supplied with the rack mounting rail kit for additional information.

Installation procedure

To install the rack mounting rail kit:

1 Attach left and right chassis slides to the enclosure sides using 8 M3x4 button head screws.

19

Page 26

CHAPTER 2: G etting Sta rted

2 Assemble the left and right chassis latches using the special chassis latch screws. Make sure

that the la tc h is orientat ed as sh own in th e f ollo w ing illu stra tion, w it h the sp ring ar m locat ed

aga ins t i ts stop (o n the rig ht si de a t t he top, on the le ft s ide at the bo ttom ) .

3 Assem bl e th e ra ck brac kets to th e ra ck p osts as follo ws:

a Fit the location pin at the back of the rail into the rear rail post.

b Extend the rail to fit between the front and rear rack posts.

c Attach the rail to both the front and rear of the rack using the washers and screws

supplied. The screws should be left loose enough to allow for sideways movement of

the rail.

d Tighten the two clamping screws located on the inside of the rear section of the rack

bracket.

Guide pin

Rack bracket

Front rack post

Remove the nut when you use

tapped hole rack posts.

Rea r r ac k p os t

Clamping screws

Slide washer

Square hole rack

Guide pin

Phillips screw

Tapped hole rack

20

Page 27

www.gateway.com

4 Mount the enclosure in the rack as follows:

a Lift the enclosure and align it with the rack rails.

b Carefully insert the chassis slides into the rack rails and push it fully into the cabinet.

c Tighten the re ar screws.

d Withdraw the enclosure until it reaches the hard stops (approximately 15.75 inches

(400 mm)).

e Return the enclosure to the fully installed position and attach to the rack using the

captive thumbscrews on th e front fla nges.

Module installation

The enclosure comes fully populated w ith all plug-in modules i nstalled. For inf ormation on remo val

or replacement of plug-in modules, see “Troubleshooting” on page 11.

Enclo sure configuration

Enclosures are configured with one internal domain of 12 drives per controller module.

Enclo sure cabling - single enclo sure

The RAID controller module provides bi-directional connection between the ho st-side interf ace and

the drives. The drives will not be presented to the Host until they are configured and mapped by

the controller.

21

Page 28

CHAPTER 2: G etting Sta rted

Each E-842R RAID controller module can be connected t o up to tw o independent Host Bus Adaptors.

Some typical configurations utilizing one or two RAID controller modules and either one or two

HBAs are shown in the following.

Single host, single HBA, and single controller connection

22

Dual host, single HBA, and single controller connections

Single host, dual HBAs, and dual controller connections

Page 29

www.gateway.com

Dual hosts, dual HBAs, and dual controller connections

Dual host, single HBA, and dual controller connections

Etherne t connection

Important

Only shielded Cat 5 (or better) cables should be used for connection to the Ethernet

port for EMC conformance.

An RJ-45 10/100BaseT Ethernet port lets you connect the controller to a network to enable out-of

-band management and monitoring using the Embedded StorView GUI software.

Make sure that the PC is connected either directly or through a switched LAN to the Ethernet.

23

Page 30

CHAPTER 2: G etting Sta rted

Enclo sure cabling - multiple enclo sures

Y ou can connect additional expansion enclosure s to an E-84 2R RAID enclosure . Multiple enclosures

are connected t o gether using SAS patch cables, up to a maximum of five enclosures, including the

RAID enclosure. A typical two-expansion enclosure configurati on is shown below . T o fully populate

your installation t o the maximum number of enclo sure s, f ollo w th e ex ample belo w connecti ng the

enclosures in the same fashion for each additional expansion enclosure.

Dri ve slot arr angement

Each enclosure has 12 drives which are referenced by their locations as shown in the following

table. Drives are numbered column/row. For information on installing drive carrier modules, see

“Installing a drive carrier module” on page27.

Column/row 1 2 3 4

1 Drive 1 Drive 2 Drive 3 Drive 4

2 Drive 5 Drive 6 Drive 7 Drive 8

3 Drive 9 Drive 10 Drive 11 Drive 12

24

Page 31

Driv e location rules

The E-842R storage enclosure supports two different types of disk drives, SAS and SATA. In order

to allow optimal configurations to be built, the following rules should be observed:

Different drive types cannot be mixed in the same column.

• Slots 1, 5, 9 = colu mn 1

• Slots 2, 6, 10 = column 2

• Slots 3, 7, 11 = column 3

• Slots 4, 8, 12 = colum n 4

To achieve optimum performance, drives should be populated in the following sequence:

• Initially—Sl ots 2, 6, an d 10

• Then —Sl ots 3, 7, and 11

• Then —Sl ots 1, 5, an d 9

• Then—Slots 4, 8, an d 12

Drive Location Sequence (1)

Column/row 1/# 2/# 3/# 4/#

#/1 - 2 - #/2 - 6 - -

www.gateway.com

#/3 - 10 - -

Drive Location Sequence (2)

Column/row 1/# 2/# 3/# 4/#

#/1 - 2 3 #/2 - 6 7 #/3 - 10 11 -

Drive Location Sequence (3)

Column/row 1/# 2/# 3/# 4/#

#/1 1 2 3 #/2 5 6 7 #/3 9 10 11 -

Drive Location Sequence (4 )

Column/row 1/# 2/# 3/# 4/#

#/1 1 2 3 4

#/2 5 6 7 8

#/3 9 10 11 12

25

Page 32

CHAPTER 2: G etting Sta rted

If you need to change drive technology, a new column of drives should be populated.

Column/row 1/# 2/# 3/# 4/#

#/1 - SAS 2 SATA 3 #/2 - SAS 6 SATA 7 #/3 - - SATA 11 -

All members of the column should have the same drive type.

Drive start

With two active power supply modules installed (required), all drives start immediately.

Activa ting the anti-tamper locks

The anti-tamper locks are installed in the drive carrier handles and are accessed through the small

cutout in the latch section of the handle.

Drives are supplied with the locks set in the locked position.

Important

You cannot install a drive carrier if its anti-tamper lock is activated before installing

it into the enclosure.

To a c t iv a te t he l o c k s:

1 Carefully insert the provided lock key into the cutout in the handle.

2 Rotate the key clockwise until the indicator is visible in the opening b eside the key.

3 Remov e th e key.

4 To deac ti vat e t he lock, r otate the k e y counte r -cloc kw ise until th e indicat or is no longer vis ible

in the opening beside the key.

26

Page 33

www.gateway.com

P ower cor d connection

Caution

Before turning on the enclosure, carry out the grounding checks detailed in

“Grounding checks” on page28.

To attach the power cord:

1 Attach the power cords to the power supply modules. The cable strain relief bale fits over

and onto the power cord. Lift the bale up first, insert the cable, and secure the bale onto

the power cord .

Caution

The power connections must always be disconnected prior to removal of the

power supply module from the enclosure.

2 Attach the power cord to the power distribution unit in the rack or other power source.

3 A Power On LED on the Ops panel indicates whether AC power is present.

Grounding c hecks

Perform these checks to make sure that a safe grounding system is provided.

• If a rack distribution system is being used.

• Make sure that power is removed from the rack.

• Connect the power cord to the rack distribution system and the enclosure.

• If a direct connection is made with the power cord, make sure that it is connected to the

enclosure.

Caution

Some electrical circuits could be damaged if external signal cables or power

control cables are present during the grounding checks.

• Check for continuity between the earth pin on the IEC 320 connector on one of the power

supply modules and any exposed metal surface of the enclosure.

27

Page 34

CHAPTER 2: G etting Sta rted

Management int erface s

The following management interfaces are used to configure, manage, and monitor the controller

module storage solution.

StorV iew St orage Management s oftw are

StorView Storage Managemen t software is a full-featured, graphical, HTM L-based, software suite

designed to configure, manage, and monitor the controller module storage solution.

StorView provides a centralized local and remote management tool to control primary storage

assets v ital t o ensur ing maximum data r elia bility, network up-ti me , and sy s t em s ervic eability. This

tool also lets you manage and monitor the storage system from a host running StorView locally

and from a Web browser across the intranet or Internet.

StorView includes the StorView Server which runs as a background service and is responsible for

managing the installed modules.

The St orVie w Serv er dis cov ers s y st em st ora ge de v ices, man ages and distr ibute s me ssa ge log s, and

communicates with other StorView Servers installed on the same local and external subnet

networks.

A GUI provides the interface in an HTML-based front end which is accessed using a Web browser.

The software incorporates a Web server, Apache 2.0, that provides the interface between the

StorView Server and GUI. During installation, the Web server is automatically configured.

For m ore in form ati on , se e th e Ga teway E-842R StorView Storage Management Application User

Guide.

VDS

RAID contr oller config uratio n utility

The controller module firmware-based programs are accessed through a VT-100 terminal or

emulation.

Introduction

VDS (Virtual Disk Service) is a feature of Microsoft Windows Server 2003. It provides a consistent

interface for managing storage devices and creating volumes.

The Gateway Hardware Provider for VDS enables Virtual Disk Service to be used with the E-842R

RAID controller.

Sy stem requirements

Use of the Gateway Hardware Provider for VDS requires the following:

Hardware:

• An enclosure with an E-842R controller.

Operating System:

• Windows Server 2003 R2 only.

Software:

• A VDS client (optional)

• The Micros oft utility programs Stor age Manager for SANs (optional) and DiskRAID (optional).

28

Page 35

www.gateway.com

Installation

If the VDS service is running, it is stopped automatically while the provider is installed.

Important

The Gate way Hardw are Provid er for VDS can be instal led on a sy stem that alre ad y ha s

VDS providers from other vendors. Likewise, other VDS providers can be installed after

Gateway’s without any conflict.

To install the hardware provider for VDS:

1 Double-click the installer executable.

2 Read the lic ense a greemen t, the n click I Agree to a cc ep t to t he term s a nd co ndi ti ons .

3 Choose a destination folder for the application (or accept the default), then click Install.

4 When you are prompted that the installation is finished, click Close to close the installation

window.

Starting the VDS serv ice

The VDS service starts automatically when a client attempts to access it. However, under some

circumstances, you may need to manually start the VDS service.

To start the VDS service:

1 Click Start, Control Panel, Administrative Tools, then click Services.

2 Select Virtual Disk Services from the list, then click Start.

Using VDS

VDS is a Microsoft standard method for managing storage devices. Therefore, you should refer to

the o ffici al Micr osoft docu me nta ti on at:

http://www.microsoft.com/windowsserversystem/storage/storservices.mspx

The VDS Technical Reference is also available from Microsoft at:

http://technet2.microsoft.com/WindowsServer/en/Library/1dbc6c24-1477-4f73

-a0ae-57b4e90808d81033.mspx

Additional documentation is available from the SDK.

Two helpful tools exist for making use of VDS:

• DiskRAID i s a test too l th at ca n be use d to in terfa ce with VDS . I t i s in clu de d wi th t he VDS

SDK and can also be downloaded from Microsoft or found in the Resource Kit Tools.

• Storage Manager for SA Ns is a program for managing storage area networks that comes as

part of Windows Server 2003.

To install Storage Manager for SANs:

1 In the Windows Control Panel, click Add or Remove Programs, then click Add/Remove

Window s Com pon ents .

2 Select Management and Monitoring Tools from the list, then click Details.

3 Click the Storage Manager for SANs box, then click OK. Follow the on-screen instructions.

Supported VDS functions

The following VDS functions are supported by the Gateway Hardware Provider for VDS:

Object Method name

IEnumVdsObject Clone

Next

Reset

Skip

29

Page 36

CHAPTER 2: G etting Sta rted

Object Method name

IVdsAsync QueryStatus

IVdsController GetPortPropertie s

IVdsControllerControllerPort QueryControllerPorts

IVdsControllerPort Initialize (inte rnal)

IVdsDrive GetProperties

IVdsHwProvider QuerySubSystems

IVdsHwProviderPriv ate QueryIfCreatedLun

IvdsHwProviderType GetPr oviderType

Wait

GetProperties

GetSubSystem

Reset

SetStatus

QueryAssociatedLuns

Initialize (i nternal)

GetController

GetProperties

GetSubsystem

ClearFlags

SetFlags

SetStatus

Initialize (i nternal)

Reenumerate

Refresh

IVdsLun GetProperties

IVdsLunControllerPorts AssociateControllerPorts

IVdsLunNaming SetFriendlyName

IVdsLunPlex GetLun

IVdsMaintenance (controller) PulseMaintenance

IVdsMaintenan ce (c-port) PulseMaintenance

IVdsMaintenan ce (d rive) PulseMaintenance

GetSubsystem

Initialize (i nternal)

QueryHints

QueryMaxLunExtendSize

QueryPlexes

Delete

Extend

SetStatus ("offline" and "online"

only)

SetMask

GetIdentificationData

QueryActiveControllerPorts

GetProperties

QueryExtents

QueryHints

StartMaintenance

StopMaintenance

StartMaintenance

StopMaintenance

StartMaintenance

StopMaintenance

30

Page 37

www.gateway.com

Object Method name

IVdsMaintenan ce (l un) PulseMaintenance

IVdsMaintenance (subsystem) PulseMaintenance

IVdsProvider GetProperties

IVdsProviderPrivate GetObject

IVdsProviderSupport GetVersionSupport

IVdsSubSystem GetDrive

IVdsSubSystemNaming SetFriendlyName

StartMaintenance

StopMaintenance

StartMaintenance

StopMaintenance

OnLoad

OnUnload

GetProperties

GetProvider

QueryControllers

QueryDrives

QueryLuns

QueryMaxLunCreateSize

Reenumerate

SetControllerStatus

Initialize (i nternal)

CreateLun

Known issues and limitations

The following issues and limitations are present in the current release of the Gateway Hardware

Provider for VDS:

• Flashing of drive LEDs cannot be turned off - they can only be set to flash for a specific time

period.

• The following limitations relate to the Se tFriendlyName method in the

“IVdsSubSystemNaming” object:

• The subsy st em cannot be giv en a fr iendl y name until at least one L UN has been cr eat ed.

• If the subsystem is renamed without any other configuration being present, the

subsystem will retain the default name.

• If the subsystem has been renamed, then all L UNs are deleted, the subs y st em name will

revert bac k to the de faul t n ame .

• When using the Extend method in the “IVdsLun” object, if there is insufficient space on the

existing array, a whole new array will be created in the background on which to expand

the LUN.

Existing arrays cannot, in themselves, be extended. This has the following implications:

• RAID 5 arrays have to be extended by a minimum of 3 drives.

• RAID 1 arrays have to be extended by an even number of drives.

If there are an insufficient number of drives or if an incorrect number of drives is explicitly

specified, an invalid arg umen t error oc curs.

31

Page 38

CHAPTER 2: G etting Sta rted

• There are minimum allowable chunk sizes for RAID 0 and RAID 1 arrays (RAID 5 arrays have

no restrictio ns) :

RAID 0:

Number of Drives 1 or 2 3 4 or more

Minimum Chunk Size 256K 128K 64K

RAID 1:

Number of Drives 2 or 4 6 8 or more

Minimum Chunk Size 256K 128K 64K

Stripe size = (chunk size) x (number of non-parity drives in the array).

32

Page 39

www.gateway.com

33

Page 40

• Bef ore y ou begin

• Power on

• Starting the driv es

• Starting StorV iew

• Power down

CHAPTER 3

Operation

7

Page 41

Bef ore y ou begin

Before turnin g on the en closure, ma ke sure tha t all the m od ules are fi rmly seated in th eir correct

bays.

P ower on

Caution

Do not operate this equipment until the ambi ent temperat ure is within the specified

operating range. If the drives have been recently installed, make sure that they have time

to acclimatize before operating them.

Important

See “Ops panel LEDs” on page8 for details of the Ops panel LEDs and related fault

conditions.

To turn on the enclosur e:

Important

The Power On LED on the Ops panel should be lit green at power up to indicate

that the system is functioning correctly. All other Ops panel LEDs are off. If any LEDs

show orange, a problem exists and the procedures in “Troubles hoo ti n g” on pag e11

should be followe d.

CHAPTER 3: Operation

1 Connect AC power cables to the power distribution units (PDUs).

2 Connect AC power cables from the PDUs to the power supply modules.

When the enclosure is turned on, the Power On LED on the Ops panel lights green and the

disk drives start.

Important

If AC power is lo st for any reason, the enclosure re-starts automatically on r estoration

of power.

Po wer su pply modu le LEDs

The power supply modules have 2 LEDs.

• Under normal conditions, the green Power On LED stays on continuously.

• If a problem occurs, the orange Module Fault LED turns on.

The LED states are detailed in “Power supply module LEDs” on page13.

Ops panel LEDs

The Ops panel LEDs are shown in “Ops panel LEDs” on page 14.

Contr oller module LEDs

The controller module LEDs status conditions are defined in “Controller module LEDs” on page 15.

Cooling module LEDs

The cooling module LEDs status conditions are defined in “Cooling Module LED” on page 13.

8

Page 42

Disk I/O module LEDs

The disk I/O module LEDs status conditions are defined in “Dis k I/O module LE Ds” on page 15.

Starting the dr iv es

Unless otherw ise s elec t ed during install ation, all dri v e s in the enc lo sure should start aut omat icall y .

If they do not start, there may be a power problem (an alarm and power fault indication would

normally be active).

Disk drive LEDs

Each drive carrier incorporates two indicators, an upper (green) and lower (orange).

• In normal operation, the green LED is ON and flickers as the drive operates.

• The orange LED is OFF In normal operation. It is only ON if there is a drive fault.

• If the green LED is OFF whe n the or ange LED is ON, a po w er control c ir c uit f ailur e is indicat ed.

www.gateway.com

Starting St orVie w

At start-up , embedded StorVie w looks at t he user pref erences set tings to det ermine if an IP addre ss

exists. If one is d efined, St orVie w init ializ es t he netw ork int erf ace us ing that IP addre ss. In t he e vent

an IP address is not defined, StorV ie w at t e mpts t o get a DHCP IP addr es s. You need to contac t y our

network administrator for the IP address assigned by the DHCP server. To identify the new IP

address, you can look for esv0 or esv1 in your DHCP manager software. If an IP address cannot

be determined, StorView uses a default IP address of 10.1. 1.5 for controller 0 and 10.1.1.6 fo r

controller 1. If an error is encountered, it assigns the embedded StorView server the IP address

10.1.1.7.

The first time you start StorView, you need to configure the network settings. On the first startup,

you are prompted for a user name and passwor d. T he def ault user name is admin and the default

passwo rd is passw ord. You should change your password to protect your array. See the Gateway

E-842 R StorV iew Stora ge Ma na gem ent Soft wa re Us er G ui de for additional information.

P ower do wn

Y ou can turn off t he enclosur e at any time . If cached contents are pr es ent (look at the Cache Acti v e

LED on the controller module), they are saved by the internal battery. If the enclosure is left in

this state for extended periods, the batteries discharge and the cached data is lost. Therefore, we

recommend that you shut down the controller prior to powering off the enclosure, especially if

the unit is to be powered down for an extended period. This ensures that the cache is flushed to

disc and prevents the battery from being discharged. Discharged batteries may also result in

reduced performance when the array is again powered up, because the write-back cache is

disabled until the batteries are fully charged.

To power down the enclosure:

1 Shut down the controller through the GUI interface. For more information, see the Gateway

E-842 R StorV iew Stora ge Ma na gem ent Soft wa re Us er G ui de.

2 Disconnect AC power at the power source.

9

Page 43

CHAPTER 3: Operation

10

Page 44

CHAPTER 4

Troubleshooting

• Overview

• Status indicator LEDs

• Audible alarm

• Driv e carr ier module fa ults

• Troubleshooting

• Hardware faults

• Continuous operation dur ing replacement

• Replacing a module

• Po wer suppl y modules

• Driv e carrier module

• T elephone support

11

Page 45

Overview

The Gateway E-842R enclosure includes a processor and associated monitoring and control logic

to enable it to diagnose problems within the enclosure’s power, cooling, and drive systems.

The sensors f or pow e r and cooling conditions are hous ed wi thin th e pow er suppl y modules. T here

is independent monitoring for each unit.

If a fault is indicated on the Ops panel, see the table in “Ops panel LEDs” on page14.

Initial start -up problems

Faulty cords

First make sure that you have wired up the subsystem correctly. Then, call Gateway Customer Care

for a replacement if:

• Cords are missing or damaged

• Plugs are incorre ct

• Cords are too short

Alarm sounds on power up

See “Audible alarm” on page 15.

CHAPTER 4: Troubleshooting

Green “Signal Good” LED on cont roller module is not li t

• Make sure that the SAS cables are properly connected.

• Try removing and re-inserting the suspect RAID controller.

• If the Fault LED is lit there are a few steps you can take to attempt to diagnose the problem:

• Connect the cable to the RS232 port and to your COM port or terminal. In your terminal

window, access the RAID Configuration Utility (RCU) and examine the event log to

determine if an event occurre d. If an event is li sted, refer to the VT-100 RAID

Configuration Utility User Guide for an explanation of the event. Perform the necessary

troubleshooting from known information.

• Try power cycling the enclosure while monitoring the boot process from the terminal.

Refer to th e V T-100 RAID Configu ration Util ity User Guide - Monitor Mod e.

• If you are still unable to capture and examine the boot process to determine the cause,

contact Gateway Customer Support. Refer to the VT-100 RAID Configuration Utility User

Guide.

Y our computer does not recogni ze the enclosure

• Make sure that the interface cables from the enclosure to the host computer are connected

correctly.

• Make sure that all drive carrier modules are correctly installed and that the LEDs on all

installed drive carrier modules are lit green. Note that the drive LEDs are not be lit during

drive spinup.

• Make sure that there is activity on the SAS connector activity LEDs. Also check for Controller

OK LEDs on both the upper and lower RAID controllers.

12

Page 46

• Check the controller module setup as follows:

Important

For details on how to remove and replace a plug-in module, see “Replacing

a module” on page 19.

• Make sure that the controller module has been correctly installed and all external links

and cables are connected securely.

• Make sure that the maximum cable length has not been exceeded.

• Make sure that the RAID controller module is correctly set up at the Management Interface.

Status indicator LEDs

• Green LEDs are always used for good or positive indication.

• LEDs flashing green or orange indicate that non-critical conditions exist.

• Solid orange LEDs indicate there is a critical fault present within the module.

Po wer su pply modu le LEDs

The Power Supply LED states are detailed in the following table.

• Under normal conditions, the Power On LED should be lit constant green.

• If a problem is detected, the Module Fault LED lights constant orange.

www.gateway.com

Cooling Module LED

The Cooling module has a Module Fault LED (orange), defined in the following table:

Power On & OK

(Green)

Off Off No AC power (either power supply module)

Off On No AC power (this power supply module only)

On Off AC present, power supply module on and OK

On On Fan fault

Status Module Fault (orange)

Enclosure On - Fan OK Off

Fan fa il On

Module Fault

(Orange)

Status

Power supply module fault (over temperature, over

voltage, over current)

Power supply module fan fail

13

Page 47

Ops panel LEDs

CHAPTER 4: Troubleshooting

Important

The Ops panel is supplied as an integral part of the enclosure core product and is not

user re p la ce ab l e.

The Ops panel displays the overall status of all the modules. The Ops panel LEDs are described in

the following table.

Ops panel LEDs Other associated

LEDs or alarm s

Power

On

(Green)

On On On On

On Off Off X

On On X X

On On X X

On X On X

On X On X

System

Fault

(Orange)

XXXOn

Logical

Fault

(Orange)

Box

Identify

(Blue)

Single beep, two

double beeps

Power s u pp ly

module Fault LED

or Cooling Modul e

Fault L ED

RAID Controller

Fault L ED

Drive Fault LED A drive failure has occurred, causing loss of availability

“X” = no bearing on these states

State description

Power On Self Test

Power On, all functions good

Any power supply module fault or fan fault

Over or under temperature

A RAID controller fault

or redundancy.

Array is performing a background function, such as

parity check, initialization, or expansion.

Enclosure identification mode. When lit, it identifies a

specific enclosure.

14

Page 48

Contr oller module LEDs

For details on how to remo v e and replace a controller module see “Control ler module” on page22.

The controller module incorporates the following LED indicators:

LED funct ions LED state Definition

www.gateway.com

Battery fault Orange When lit, this LED indicates that the backup battery unit is missing, has low voltage,

Cache active Orange When lit, this LED indicat e s t hat th e RAID con tr oller cac he ha s da ta saved in memory

Controller activity on

drive bank 0

Controller activity on

drive bank 1

Controller OK Green When lit, this LED indicates that RAID controller activity is normal.

Controller fault Orange When lit, this LED indicates that a RAID controller fault has occurred.

Ethernet status Green When lit, this LED indicates that the Ethernet port has a valid connection.

SAS activity* Green When lit, these LEDs show I/O activity on the specific port lane indicated.

Orange When lit, this LED indicates activity on the Bank 0 disk drives.

Orange When lit, this LED indicates activity on the Bank 1 disk drives.

Orange When lit, this LED indicates that the Ethernet port has activity.

* These LEDs blink on and off when there is module activity.

has experien ced a time-out on char ge , indicat ed a f a ulty bat tery, or has exper ienced

a fault in the charging circuitry.

but not written to the disk array.

Disk I/O module LEDs

LED Functions Description

Drive car rier LEDs

See “Drive carrier module faults” on page 16.

Audible alar m

The enclosure subsystem includes an audible alarm which indicates when a fault state is present.

The following conditions activate the audible alarm:

• Fan fau lt

• Voltage out of range

• Over temperature

• Thermal overrun

• Syste m fau l t

• Logi ca l fa ul t

• Power supply module fault

SAS Act ivity

These LEDs are adjacent to the SAS connectors. When

lit, they indicate I/O activity on a specific port lane (4

lanes).

15

Page 49

CHAPTER 4: Troubleshooting

Audible alarm mute

When the audible alarm sounds, you can mute it by pressing the alarm mute button, located on

the enclosure’s front panel. Automatic muting takes place after two minutes if you do not press

the alarm mute button.

When the alarm is muted, it continues to sound with short intermittent beeps to indicate that a

problem still exists. The alarm turns off when all problems are cleared. (See “Thermal warnings ”

on page 18).

LED test m ode

You can al so use th e al arm m ute b utto n to a ctiva te t he se lf- te st fea tu re for th e L ED s o n th e O ps

panel. The test is activated when you press the mute button while no faults are present. While the

test is running, all LEDs flash.

Dri ve carr ier module faults

Use the green LED and orange LED mounted on the front of each drive carrier module to monitor

disk drive status. The LEDs indicate the following:

State Green Orange

Auto start failure

No drive installed Off Off

Drive power ON On Off

Drive activity On/Blink off Off

Drive impacted On Blink

Drive fault On On

Power control circuit failure Off On

Important

The LED may be off for a length of time during power up.

Green (activity) LED

Orange (fault) LED

16

Unless othe rwise selec t ed at install ation, all dr iv e s in th e enclo sur e should au tomatic ally start af t er

you turn on the enclosure. If this does not occur, there is a power problem (an alarm and power

fault indication would normally be active).

Page 50

Troubleshooting

The following sections describe problems, with possible solutions, which can occur with your

Gateway E-842R Storage Area Network.

System faults

Symptom Cause Action

www.gateway.com

1. Th e CO NT R OL L E R FA ULT

LED lights orange on the

module.

2. The audible alarm sounds.

The ESI processor has

detected an internal

fault on one of the

following modules:

■

Power supply

■

Cooling

■

RAID

Also see “Thermal warnings” on pa ge 18.

Po wer suppl y faults

Symptoms Causes Actions

■

Ops panel SYSTEM FAULT LED

is orange.

■

An orange LED on one or

more power supply mo dules.

■

Audible alarm sounding.

■

Any power fault.

■

A fan failure.

■

A thermal co ndition whic h could

cause power supply module

overheating.

■

Fault on one of the following

modules:

■

Power supply

■

Cooling

■

RAID

■

Removal of 1 power supply

module.

■

Make sure that the AC power connections to power

supply module are live.

■

Disconnect th e power supply module from AC power

and re move the m odul e from t he system , the n

re-install. If the problem persists, replace the power

supply module.

■

Reduce the ambient temperature.

■

Replace the faulty module, as appropriate:

■

■

■

Replace the faulty module as appropriate.

Power supply

Cooling

RAID

Thermal c ontrol

The Gateway E-842R storage enclosure uses extensive thermal monitoring and takes a number of

actions to make sure that component temperatures are kept low and that acoustic noise is

min im ized. Ai rfl ow i s fro m fron t to rea r o f th e e nc los ure.

Symptom Cause Action

If the ambient air is cool

(below 77°F (25°C)) and the

fans are observed to increase

in speed, some airflow

restriction may be caus ing

the internal te mperature rise.

Note: This is not a fault

condition.

The first stage in the the r mal con trol proces s

is fo r th e fa ns to auto ma t ic al ly i nc rea se i n

speed when a thermal threshold is reached.

This may be caused by higher ambient

temperatures in the local environment and

may be perfectly normal.

Note: This threshold changes according to the

number of drives and power su pplies

installed.

■

■

■

■

■

Check the installation for any airflow

restrictions at either the front or rear of the

enclosure. A minimum gap of 1 inch (25 mm)

at the fron t a nd 2 inch es ( 50 mm ) a t the rear

is recommen ded.

Check for restrictions caused by dust build-up

and clean as appropriate.

Check f o r ex ce ssi v e r e-circ ulatio n of h eate d air

from the rear to the front. Installing in a fully

enclosed rack installation is not

recommended.

Make sur e t hat all blank module s ar e in stal led.

Reduce the ambient temperature.

17

Page 51

CHAPTER 4: Troubleshooting

Thermal alarm

Symptom Cause Action

■

Ops panel SYSTEM FAULT LED

is orange.

■

An orange LED on one or

more power supply module.

■

An audible alarm is sounding.

■

Air temperature in the exiting

power supply module is

abo v e 131 °F (5 5 ° C).

■

If the internal temperature

measured in the airflow

through the enclosu re

exceeds a pre-set threshold, a

thermal alarm sounds.

■

Cooling module failure.

■

Make sure that the local ambient environment

temperature is below the upper 104°F (40°C)

specification.

■

Check the installation for any airflow restrictions at

either the front or rear of the enclosure. A minimum gap

of .98 inch (25 mm) at the fr ont and 1.97 inch es (50 mm)

at the rear is recommended.

■

Check for restric tio ns c au s ed b y du st bui ld-up a nd c lean

as appropriate.

■

Check f o r ex c e ssi ve re-circ ulati on of hea te d air from the

rear to the front. Installing in a fully enclosed rack

installation is not recommended.

■

If possible, shutdown the enclosure and investigate the

problem before continuing.

■

Replace the cooling module.

Ther mal war nings

Symptom Cause Action

■

All orange LED s on the Ops

panel and on all drive bays are

flashing.

■

The audible alarm sounds

almost continuously and

cannot be muted.

The temperature is higher than the

thermal alarm threshol d (this shou ld

already have been activated).

OR - All fans have failed.

OR - Only 1 fan is operating and the

inte rn al tem pe ra tu re i s 104 ° F ( 40 °C ) o r

above.

■

■

■

■

Powe r o ff im m e di a te l y.

Check for airflow rest rictions .

Check for power supply modul e faults.

Check for excessive local temperatures.

Hardware faults

Make sure that you have obtained a replacement module of the same type before removin g a ny

fault y m od ul e.

Caution

If your Gateway E-842R enclosure is turned on and you remove any module, replace

it immediately. If the enclosure is used with plug-in modules, dummy carriers, or blank

modules missing for more than a few minutes, the enclosure can overheat, causing power

failure and data loss. Such use invalidates the warranty.

• Replace a faulty drive with a drive of the same type and equal or greater capacity.

• All drive bays must have a drive carrier or dummy carrier module installed in order to

maintain a balanced airflow.

• All of the supplied plug-in power supply units, electronics modules, dummy carriers, and

blank modules must be installed for the air to flow correctly around the cabinet.

18

Page 52

www.gateway.com

Continuou s operation during r eplacement

Important

The power supply module replacement time must be as short as possible because

the Gateway E-842R enclosure is designed to operate with two power supply modules

installed.

Important

The fans wi thin the cooling m odu l e a re not user r e plac e able. In the event of a cooling

fan failure, the complete cooling module must be replaced.

Depending on how your Gateway E-842R enclosure is set up, you can normally replace a failed

dis k u nit wit hou t i nter ru pti ng the use of the syste m.

In addition, each enclosure contains two power supply modules, either of which can maintain

power an d c ool in g to the sub syste m wh ile the oth er is rep la ced .

Ops panel

Important

The Ops panel is an integral part of the enclosure assembly and can only be replaced

with a replacement enclosure. The enclosure should only be replaced by trained personnel.

Re placing a module

Caution

When replacing a module, never leave an empty space in the rear of the enclosure.

Obtain a replacement before removing the problem module.

Caution

Observe all conventional ESD precautions when handling modules and components.

Avoid contact with such things as backplane components and module connectors.

See “Getting Started” on page15 for information on the initial installation of the plug-in modules