Fluke 36 Service Manual

®

36 AC/DC True Rms

Clamp Meter

Service Information

WWarning

Do not service the Meter unless you are qualified to do so. The service information provided in this document is for the use of qualified personnel only.

To avoid electrical shock or personal injury: Always remove the test leads and input signals from the Meter before opening the case.

Use caution when working with voltages above 60V dc or 30V ac.

WWarning

To avoid false readings, which could lead to possible electric shock or personal injury, replace the battery as soon as the battery indicator appears.

Y Caution

The Meter is protected throughout by double insulation or reinforced insulation. When servicing the Meter, use only specified replacement parts.

Caution

Caution

This Meter contains parts that can be damaged by static discharge. Follow the standard practices for handling static sensitive devices.

Introduction

This Service Information document provides the following service information for the 36 AC/DC True Rms Clamp Meter (hereafter referred to as the Meter):

∙Product specifications

∙Required equipment

∙Performance test procedure and test values

∙Preparing for calibration

∙Calibration procedure and adjustments

∙AC amps test

∙Replacement parts

For operating information, refer to the Instruction Sheet that came with the Meter.

PN 200409

September 1996 Rev. 1, 2/98

©1996, 1998 Fluke Corporation. All rights reserved. Printed in U.S.A. Product names are trademarks of their respective companies.

1

36 AC/DC True Rms

Clamp Meter

Service

The Meter is warranted to be free from defects in material and workmanship for one year.

The warranty does not cover abuse, batteries or fuses, or damage caused by using the Meter outside its rated specifications or operating environment. The complete warranty statement is in the Meter’s Instruction Sheet.

To contact Fluke, call one of the following telephone numbers:

USA and Canada: 1-888-99-FLUKE (1-888-993-5853)

Europe: +31 402-678-200

Japan: +81-3-3434-0181

Singapore: +65-*-276-6196

Anywhere in the world: +1-425-356-5500

Or, visit Fluke’s Web site at www.fluke.com.

To order replacement parts, call 1-800-526-4731.

Outside U.S.A. contact your nearest service center.

Service, repairs, and replacement parts are warranted for 90 days.

Product Specifications

Measurement Accuracy

The accuracy of the Meter is specified for one year after calibration, at 18°C to 28°C (64°F to 82°F), with relative humidity to 90%.

The Meter is true rms sensing and calibrated to the rms value of a sine wave input.

General Specifications

General specifications are shown in Table 1.

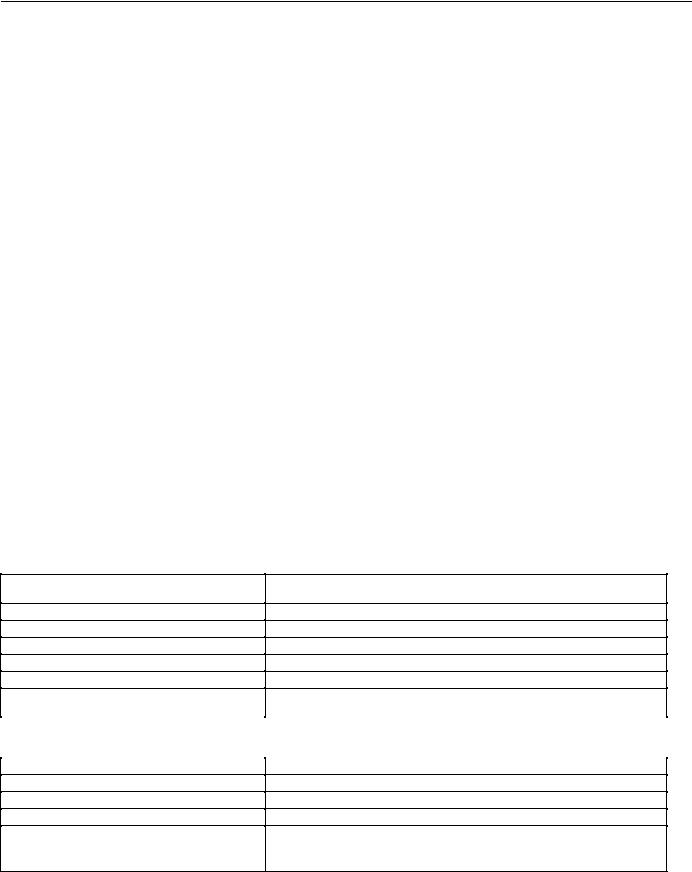

Table 1. General Specifications

Maximum voltage and frequency between any terminal and earth ground

Operating Temperature

Operating Altitude

Storage Altitude

Storage Temperature

Temperature Coefficient

Electromagnetic Compatibility

600V, 400 Hz

−10°C to +50°C ( −14°F to 122°F)

2,000 meters (6,562 ft)

10,000 meters (32,808 ft)

−20°C to +60°C indefinite ( −4°F to 140°F)

0.05 x (specified accuracy)/°C (<18°C or >28°C; <64 °F or >82°F)

If RF field ≤ 1.6 V/m, total accuracy = specified accuracy;

If RF field = 3 V/m, total accuracy = specified accuracy + 3.6% of range

Operating Humidity |

To 30°C (85°F), 95% relative humidity; |

|

|

To 40°C (104°F), |

75% relative humidity; |

|

To 50°C (122°F), |

45% relative humidity |

Battery Type

Battery Life

Jaw Size

Size (HxWxL)

Safety

9V, NEDA 1604A or IEC 6LR61

Alkaline, 60 hours continuous

One 3 cm (1.2 inch) conductor, or two 2.46 cm (0.97 inch) conductors

4.5 cm x 9.5 cm x 25 cm (1.77 x 3.75 x 9.8 inches)

UL 3111,  , TÜV,

, TÜV,

Complies with IEC 1010-1 for use in 600V, CAT III locations (industrial)

2

Required Equipment

Table 1. General Specifications (cont)

Case Protection

MAX Hold Feature

Continuity

Rms Settling Time

True Rms Sensing

IP 30 per IEC 529

Accuracy: add 10 digits to ac and dc specification;

Acquisition time: 250 ms (ac); 10 ms (dc)

Beeper on at £30W;

Beeper off at ³70W

The rms converter has a longer settling time for displays reading <100 counts. The display may read up to 5 digits with no voltage or current inputs.

True rms sensing provides more accurate readings on circuits containing harmonics or distorted waveforms. An instrument with true rms reading indicates the true heat-providing current, which may cause overheated conductors, connections, breakers, or transformers.

Functional Specifications

Functional specifications are shown in Table 2.

Table 2. Functional Specifications

Function |

Range |

Accuracy* |

N

F

1000A |

0-600A, 1.9% Rdg + 4 dgts |

1000A |

600-1000A, 3% Rdg + 3 dgts |

200A |

0-200A, 1.9% Rdg + 7 dgts |

600V |

1.0% Rdg + 3 dgts |

200V |

|

O |

600A |

10-600A, 2% Rdg + 3 dgts |

|

(45-400 Hz) |

200A |

0.5-200A, 2% Rdg + 5 dgts |

|

G |

600V |

1.5% Rdg + 3 dgts |

|

(45-400 Hz) |

200V |

|

|

J |

200W |

1.2% Rdg + 5 dgts |

|

|

|

Crest |

Overload Protectionm |

|

|

Factor |

|

N |

1000A |

|

1000A |

|

1000A |

NA |

|

|

200A |

|

|

F |

600V |

NA |

1200V rms continuous |

|

200V |

|

|

O |

600A |

2 £ CF £ 3, |

600A continuous |

(45-400 Hz) |

200A |

add 2% Rdg |

(CF £3) |

G |

600V |

£3 (peak voltage £933V) |

1200V rms |

(45-400 Hz) |

200V |

|

|

J |

200W |

NA |

660V rms continuous |

* See electromagnetic compatibility specification under "General Specifications."

3

36 AC/DC True Rms

Clamp Meter

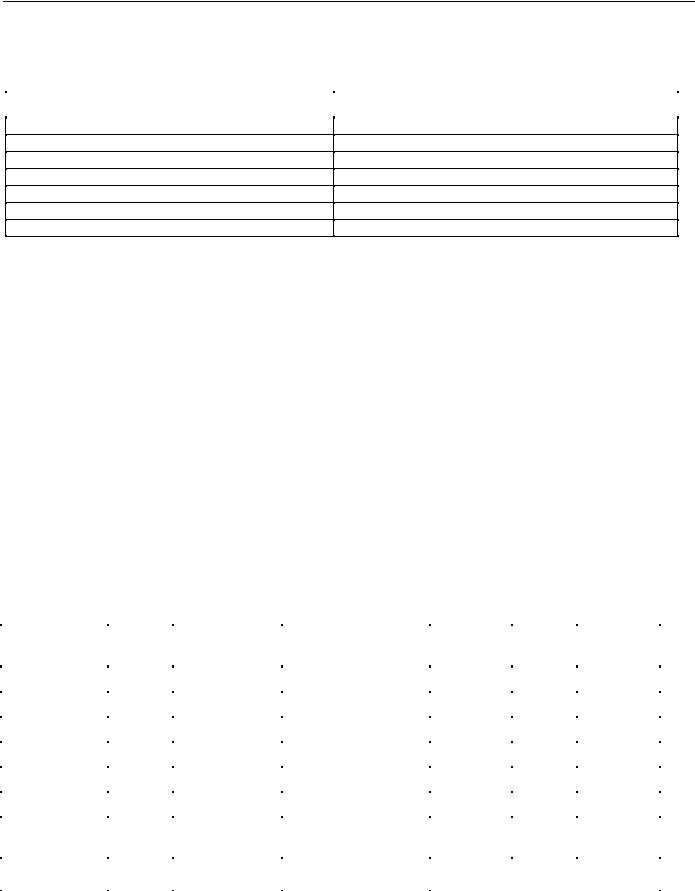

Required Equipment

Equipment required for the performance test and calibration procedure is shown in Table 3.

Table 3. Required Equipment

Equipment |

Recommended Model |

|

|

AC Calibrator

Digital Multimeter (DMM)

Transconductance Amplifier

Resistor, MF, 31.6Ω, 1%

Resistor, MF, 34.8Ω, 1%

Resistor, MF, 61.9Ω, 1%

50-Turn Current Coil

Fluke 5700A or 5500A

Any Fluke model

Fluke 5220A

Fluke P/N 296673

Fluke P/N 343897

Fluke P/N 305961

Fluke 5500A/Coil

Performance Test

PWarning

To avoid shock, do not execute the performance tests unless the Meter is fully assembled.

The performance test verifies that the Meter is working properly and performs to specification. To test each of the Meter’s functions and operating ranges, do the following:

1.Connect the source to the Meter’s VΩ and COM input jacks.

2.Referring to Table 4, put the Meter in the function and range for Function Test number 1 (i.e., the 200V dc function).

3.Apply the first indicated output (i.e., 20.0V dc) from the source.

4.The reading on the Meter display should be within the low and high values shown (i.e., 19.5 and 20.5, respectively).

5.Repeat steps 1-4 for each function and range in Table 4. (Tests 9-15 require the 50-Turn Current Coil; tests 11-15 require the 50-Turn Current Coil and Transconductance Amplifier.)

If the Meter fails to perform within the low-high range indicated for each test in Table 4, the Meter needs to be calibrated and adjusted, or requires some repair.

|

|

|

Table 4. Performance Test Values |

|

|

||

|

|

|

|

|

|

|

|

|

Function |

Meter |

|

|

|

|

|

|

Test |

Range |

Source |

Output |

Measured |

Low |

High |

|

|

|

|

|

|

|

|

1. |

DC Volts |

200V |

5700A or 5500A |

20.0V dc |

20.0V |

19.5V |

20.5V |

|

|

|

|

|

|

|

|

|

|

|

|

100.0V dc |

100.0V |

98.7V |

101.3V |

|

|

|

|

|

|

|

|

|

|

|

|

−200.0V dc |

−200.0V |

−202.3V |

−197.7V |

2. |

AC Volts |

200V |

5700A or 5500A |

200V at 50, 60, & 400 Hz |

200.0V |

196.7V |

203.3V |

|

|

|

|

|

|

|

|

3. |

DC Volts |

600V |

5700A or 5500A |

−600V dc |

−600V |

−609V |

−591V |

4. |

AC Volts |

600V |

5700A or 5500A |

100V at 50, 60, & 400 Hz |

100 |

95 |

105 |

|

|

|

|

|

|

|

|

5. |

AC Volts |

600V |

5700A or 5500A |

100V at 60 Hz |

100V |

85V |

115V |

|

MAX Hold |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Apply voltage. Press MAX button. |

||

|

|

|

|

|

Remove voltage. Check limits |

||

4

Loading...

Loading...