fanuc 0i A Connection Manual

GE Fanuc Automation

Computer Numerical Control Products

Series 0i―Model A

Connection Manual (Hardware)

GFZ-63503EN/01 |

May 2000 |

GFL-001

Warnings, Cautions, and Notes as Used in this Publication

Warning

Warning notices are used in this publication to emphasize that hazardous voltages, currents, temperatures, or other conditions that could cause personal injury exist in this equipment or may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a Warning notice is used.

Caution

Caution notices are used where equipment might be damaged if care is not taken.

Note

Notes merely call attention to information that is especially significant to understanding and operating the equipment.

This document is based on information available at the time of its publication. While efforts have been made to be accurate, the information contained herein does not purport to cover all details or variations in hardware or software, nor to provide for every possible contingency in connection with installation, operation, or maintenance. Features may be described herein which are not present in all hardware and software systems. GE Fanuc Automation assumes no obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness of the information contained herein. No warranties of merchantability or fitness for purpose shall apply.

©Copyright 2000 GE Fanuc Automation North America, Inc.

All Rights Reserved.

B–63503EN/01 |

DEFINITION OF WARNING, CAUTION, AND NOTE |

|

|

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the machine. Precautions are classified into Warning and Caution according to their bearing on safety. Also, supplementary information is described as a Note. Read the Warning, Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a damage of both the user being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

` Read this manual carefully, and store it in a safe place.

s–1

B–63503EN/01 |

PREFACE |

|

|

PREFACE

This manual describes the electrical and structural specifications required for connecting the FANUC Series 0i CNC control unit to a machine tool. The manual outlines the components commonly used for FANUC CNC control units, as shown in the configuration diagram in Chapter 2, and supplies additional information on using these components with the Series 0i. Refer to individual manuals for the detailed specifications of each model.

Applicable models |

The models covered by this manual, and their abbreviations are: |

||

|

|

|

|

|

Product name |

Abbreviation |

|

|

|

|

|

|

FANUC Series 0i–TA |

0i–TA |

Series 0i |

|

|

|

|

|

FANUC Series 0i–MA |

0i–MA |

|

|

|

||

|

|

|

|

p–1

PREFACE B–63503EN/01

Configuration of the |

This manual consists of Chapters 1 to 15 and Appendixes. |

manual |

|

|

|

Chapter title |

Description |

|

|

Chapter 1

CONFIGURATION

Chapter 2

TOTAL CONNECTION DIAGRAM

Chapter 3

INSTALLATION

Outlines connections for the Series 0i and guides the reader concerning additional details.

This chapter shows the total connection diagram.

This chapter describes the installation conditions for the Series 0i.

1)Required power supply

2)Heat generated

3)Connector arrangement on the control unit

4)Noise prevention

Chapter 4

CONNECTING THE POWER SUPPLY

Chapter 5

CONNECTING PERIPHERAL UNITS

This chapter describes how to connect the power supply.

This chapter describes how to connect the following peripheral devices:

1)Display devices (CRT and LCD display)

2)MDI units

3)I/O devices (via RS232C)

4)Manual pulse generators

Chapter 6

CONNECTING THE SPINDLE UNIT

Chapter 7

SERVO INTERFACE

Chapter 8

CONNECTING THE MACHINE INTERFACE I/O

Chapter 9

CONNECTION TO FANUC I/O Link

Chapter 10

EMERGENCY STOP SIGNAL

Chapter 11

HIGH–SPEED SERIAL BUS (HSSB)

Appendix

This chapter describes how to connect the spindle servo unit, the spindle motor.

This chapter describes how to connect the servo unit and the servo unit.

This chapter describes the addresses and connector pins for signals transferred between the Series 0i and the machine.

Describes the built–in I/O board.

This chapter describes the use of FANUC I/O Link to expand the machine interface I/O.

This chapter describes the handling of emergency stop signals. The user must read this chapter before attempting to operate the CNC.

This chapter describes the high–speed serial bus (HSSB) supported by the Series 0i.

AExternal dimensions of units

B20–pin interface connectors and cables

CConnection cables

DOptical fiber cable

EAttaching a CRT protecting cover

FMachine operator’s panel

p–2

B–63503EN/01 |

PREFACE |

|

|

Related manuals

Manuals related to control motor a series

The table below lists manuals related to the Series 0i. In the table, this manual is marked with an asterisk (*).

Manuals Related to the Series 0i

Manual name |

Specification |

|

number |

|

|

|

|

|

|

|

|

DESCRIPTIONS |

B–62502EN |

|

|

|

|

|

|

CONNECTION MANUAL (Hardware) |

B–62503EN |

* |

|

|

|

|

|

CONNECTION MANUAL (Function) |

B–62503EN–1 |

|

|

|

|

|

|

OPERATOR’S MANUAL (For Lathe) |

B–63504EN |

|

|

|

|

|

|

OPERATOR’S MANUAL (For Machining Center) |

B–62514EN |

|

|

|

|

|

|

MAINTENANCE MANUAL |

B–62505EN |

|

|

|

|

|

|

PARAMETER MANUAL |

B–62510EN |

|

|

|

|

|

|

PROGRAMMING MANUAL |

B–61803E–1 |

|

|

(Macro Compiler / Macro Executer) |

|

||

|

|

|

|

|

|

|

|

FAPT MACRO COMPILER PROGRAMMING MANUAL |

B–66102E |

|

|

|

|

|

|

Manuals related to control motor a series |

|

||

|

|

|

|

Manual name |

|

Specification |

|

|

number |

|

|

|

|

|

|

|

|

|

|

FANUC AC SERVO MOTOR a series DESCRIPTIONS |

|

B–65142E |

|

|

|

|

|

FANUC AC SERVO MOTOR a series PARAMETER |

|

B–65150E |

|

MANUAL |

|

|

|

|

|

|

|

|

|

|

|

FANUC AC SPINDLE MOTOR a series DESCRIPTIONS |

|

B–65152E |

|

|

|

|

|

FANUC AC SPINDLE MOTOR a series PARAMETER |

|

B–65160E |

|

MANUAL |

|

|

|

|

|

|

|

|

|

|

|

FANUC SERVO AMPLIFIER a series DESCRIPTIONS |

|

B–65162E |

|

|

|

|

|

FANUC SERVO MOTOR a series MAINTENANCE |

|

B–65165E |

|

MANUAL |

|

|

|

|

|

|

|

|

|

|

|

p–3

B–63503EN/01 |

Table of Contents |

DEFINITION OF WARNING, CAUTION, AND NOTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . s–1

PREFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p–1

1. CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 NAME OF EACH PART OF CONTROL UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 1.2 GENERAL OF HARDWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. TOTAL CONNECTION DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 |

ENVIRONMENT FOR INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

|

3.1.1 Environmental Requirements Outside the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

|

3.1.2 |

Installation Requirements of CNC and Servo Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

3.2 |

POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

|

|

3.2.1 |

Power Supply for CNC Control Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

3.3DESIGN AND INSTALLATION CONDITIONS OF THE MACHINE TOOL

MAGNETIC CABINET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 3.4 THERMAL DESIGN OF THE CABINET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 3.4.1 Temperature Rise Within the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 3.4.2 Cooling by Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 3.4.3 Heat Loss of Each Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 3.5 ACTION AGAINST NOISE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 3.5.1 Separating Signal Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 3.5.2 Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 3.5.3 Connecting the Signal Ground (SG) of the Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 3.5.4 Noise Suppressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 3.5.5 Cable Clamp and Shield Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 3.6 CONTROL UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 3.6.1 Installation of the Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 3.7 CABLE LEAD–IN DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 3.8 CONNECTOR LAYOUT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4. POWER SUPPLY CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 4.2 TURNING ON AND OFF THE POWER TO THE CONTROL UNIT . . . . . . . . . . . . . . . . . . . . . . . 30 4.2.1 Power Supply for the Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 4.2.2 +24 V Input Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 4.2.3 Procedure for Turning On the Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 4.2.4 Procedure for Turning Off the Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 4.3 CABLE FOR POWER SUPPLY TO CONTROL UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 4.4 BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 4.4.1 Battery for Memory Backup (3VDC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 4.4.2 Battery for Separate Absolute Pulse Coders (6VDC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5. CONNECTION TO CNC PERIPHERALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

39 |

5.1 CONNECTION TO THE DISPLAY UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

c–1

TABLE OF CONTENTS |

B–63503EN/01 |

|

|

5.1.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 5.1.2 Connection to Display Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 5.1.3 9″ CRT Display Unit Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 5.1.4 8.4″ LCD Units Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 5.1.5 Adjusting the TFT Color LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.2 CONNECTION OF MDI UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 5.2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 5.2.2 Connection to the MDI Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 5.2.3 Connection to the Standard MDI Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46 5.2.4 Varied MDI Key Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.3 CONNECTING I/O DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 5.3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 5.3.2 Connecting I/O Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 5.3.3 RS–232–C Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 5.3.4 RS–232–C Interface Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 5.3.5 FANUC Handy File Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.4 CONNECTING THE MANUAL PULSE GENERATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 5.4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 5.4.2 Connection to Manual Pulse Generators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61 5.4.3 Cable Length When Only One Manual Pulse Generator is Used . . . . . . . . . . . . . . . . . . . . . . . 62

6. SPINDLE CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

63 |

6.1 SERIAL SPINDLE INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64 6.2 ANALOG SPINDLE INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 6.3 POSITION CODER INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7. SERVO INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.1 OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68 7.1.1 Interface to the Servo Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68 7.1.2 Separate Type Detector Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70 7.1.3 Connection of Battery for Separate Type Absolute Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8. CONNECTING MACHINE INTERFACE I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

8.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79 8.2 CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 8.2.1 DI Signals and Receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 8.2.2 DO Signals and Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 8.3 BUILT–IN I/O CARD CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81 8.3.1 Connector Pin Arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82 8.3.2 Connecting DI/DO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83 8.3.3 I/O Signal Requirements and External Power Supply for DO . . . . . . . . . . . . . . . . . . . . . . . . . . 93 8.4 CONNECTION TO THE HIGH–SPEED SKIP (HDI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

9. CONNECTION TO FANUC I/O Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

9.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 9.2 CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

c–2

B–63503EN/01 |

TABLE OF CONTENTS |

|

|

9.2.1 Connection of FANUC I/O Link by Electric Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103 9.3 UNITS THAT CAN BE CONNECTED USING FANUC I/O Link . . . . . . . . . . . . . . . . . . . . . . . . . 104 9.4 Connection to Machine operator’s panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105 9.4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105 9.4.2 Total Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106 9.4.3 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107 9.4.3.1 Pin assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107 9.4.3.2 Power supply connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108 9.4.3.3 I/O link connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109 9.4.3.4 Emergency stop signal connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 9.4.3.5 Power ON/OFF control signal connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 9.4.3.6 DI (input signal) connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111 9.4.3.7 DO (output signal) connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113 9.4.3.8 Connector (on the cable side) specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114 9.4.4 DI/DO Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115 9.4.4.1 Keyboard of main panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115 9.4.4.2 Override signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116 9.4.5 DI/DO Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117 9.4.6 Connector Locations of Main Panel B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117 9.4.7 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118 9.4.7.1 Environmental requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118 9.4.7.2 Order specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118 9.4.7.3 Main panel A/B specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119 9.4.7.4 Sub panel B1 specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119 9.4.7.5 Power supply specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119 9.4.7.6 General–purpose DI signal definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 9.4.7.7 General–purpose DO signal definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 9.4.8 Key Symbol Indication on Machine Operator’s Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121 9.4.8.1 Meaning of key symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121 9.4.8.2 Detachable key top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123 9.4.9 Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124 9.5 CONNECTION OF OPERATOR’S PANEL I/O MODULE (FOR MATRIX INPUT) . . . . . . . . . . 127 9.5.1 Overall Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127 9.5.2 Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128 9.5.3 DI/DO Connector Pin Arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129 9.5.4 DI (General–purpose Input Signal) Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130 9.5.5 DI (Matrix Input Signal) Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132 9.5.6 DO (Output Signal) Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133 9.5.7 External View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137 9.5.8 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138 9.5.9 Other Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140 9.6 CONNECTION TO THE OPERATOR’S PANEL I/O MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . 144 9.6.1 Overall Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144 9.6.2 Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145 9.6.3 DI/DO Connector Pin Arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146 9.6.4 DI (General–purpose Input Signal) Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147 9.6.5 DO (Output Signal) Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

c–3

TABLE OF CONTENTS |

B–63503EN/01 |

|

|

9.6.6 External View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153 9.6.7 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154 9.6.8 Other Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156 9.7 CONNECTING THE FANUC SERVO UNIT β SERIES WITH I/O Link . . . . . . . . . . . . . . . . . . . 160 9.7.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160 9.7.2 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161 9.7.3 Maximum Number of Units that can be Connected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162 9.7.4 Address Assignment by Ladder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

10. EMERGENCY STOP SIGNAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

11. HIGH–SPEED SERIAL BUS (HSSB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

11.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166 11.2 CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167 11.3 CONNECTION DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168 11.4 PERSONAL COMPUTER SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169 11.5 INSTALLATION ENVIRONMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170 11.6 HANDLING PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170 11.7 PROCEDURE FOR INSTALLING PERSONAL COMPUTER INTERFACE BOARDS . . . . . . . . 171 11.8 RECOMMENDED CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

APPENDIX

A. EXTERNAL DIMENSIONS OF EACH UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

B. 20–PIN INTERFACE CONNECTORS AND CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

B.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215 B.2 BOARD–MOUNTED CONNECTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215 B.3 CABLE CONNECTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216 B.4 RECOMMENDED CONNECTORS, APPLICABLE HOUSINGS, AND CABLES . . . . . . . . . . . . 218

C. CONNECTION CABLE (SUPPLIED FROM US) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

D. OPTICAL FIBER CABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

E. ATTACHING A CRT PROTECTIVE COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

c–4

B–63503EN/01 |

1. CONFIGURATION |

|

|

1 CONFIGURATION

1

1. CONFIGURATION |

B–63503EN/01 |

|

|

1.1

NAME OF EACH PART OF CONTROL UNIT

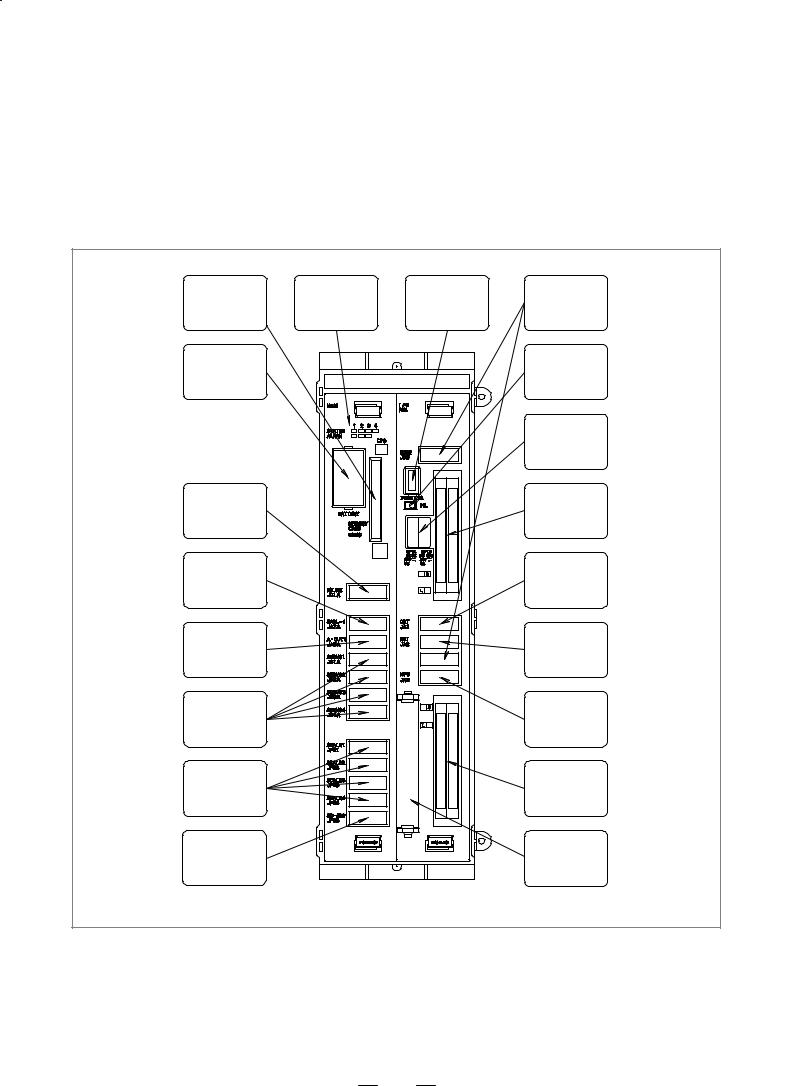

The following figure shows the configuration of FANUC Series 0i control unit.

This manual describes how to connect the units illustrated in this diagram. The numbers in parentheses shown in the diagram are section references for this manual.

Memory card |

LED for display |

Fuse |

II/O device I/F |

slot |

of status/alarm |

|

connector |

|

|

|

(5.3) |

Memory back |

|

|

Power supply |

|

|

pilot lamp |

|

up battery |

|

|

|

|

|

|

|

(4.4) |

|

|

|

|

|

|

Power supply |

|

|

|

connector |

|

|

|

(4.3) |

I/O Link |

|

|

Machine I/F |

connecter |

|

|

connector |

(9) |

|

|

(8.3) |

Serial spindle or |

|

|

Display unit |

position coder |

|

|

connector |

connector |

|

|

|

(6.1,6.3) |

|

|

(5.1) |

Serial spindle or |

|

|

MDI connector |

analog spindle |

|

|

|

connector |

|

|

|

(6.2) |

|

|

(5.2) |

Servo amp |

|

|

Manual pulse |

connector |

|

|

generator |

|

|

|

connector |

(7.1.1) |

|

|

(5.4) |

Separate type |

|

|

Machine I/F |

detector |

|

|

connector |

I/F connector |

|

|

|

(7.1.2) |

|

|

(8.3) |

Separate type ABS |

|

|

Mini slot |

pulse coder battery |

|

|

|

connector |

|

|

High–speed serial |

(7.1.3) |

|

|

bus (*) (11) |

Series 0i control unit (2–slot)

2

B–63503EN/01 |

1. CONFIGURATION |

|

|

1.2

GENERAL OF HARDWARE

|

Main board |

|

I/O board |

|

|

|

|

S |

Main CPU |

S |

Power PCB (built–in) |

S |

Memory |

|

DC–DC converter |

|

System software, |

S |

DI/DO |

|

Macro program, |

S |

Reader/puncher I/F |

|

Ladder program, |

S |

MDI control |

|

Parameter, and etc. |

S |

Display control |

S |

PMC control |

S |

Manual pulse generator |

S |

I/O Link control |

|

control |

SServo control

SSpindle control

SMemory card I/F

SLED display

Main I/O

Mini slot

S HSSB board

2–slot

2–slot

3

2. TOTAL CONNECTION DIAGRAM B–63503EN/01

2 TOTAL CONNECTION DIAGRAM

|

Power |

C Main board |

supply |

o |

24VDC |

n |

|

t |

Units that can be |

r |

connected with the |

o |

I/O Link |

l |

|

u |

|

n |

|

i |

|

t |

|

Analog spindle amplifier

Serial spindle amplifier

Servo amplifier

M–axis servo motor

N–axis servo motor

Position coder

Analog spindle

Position coder

Serial spindle

L–axis servo motor

4th axis servo motor

L–axis scale

M–axis scale

N–axis scale

4th axis scale

ABS BATTERY for scale

NOTE

Either an analog or serial spindle can be used. For details of spindle and servo motor connection, refer to the relevant manuals.

4

B–63503EN/01 |

|

|

2. TOTAL CONNECTION DIAGRAM |

||

I/O Board D |

|

|

|

|

|

C |

I/O Board |

|

|

|

|

o |

|

|

|

|

|

n |

|

Power supply |

|

|

|

t |

Power supply unit |

24VDC |

|

|

|

r |

|

|

|

Display unit |

|

o |

DC–IN (CP1A) |

|

|

|

|

|

|

|

|

||

l |

|

|

|

|

|

DC–OUT(CP1B) |

|

|

|

(CN2)DC–IN |

|

|

|

|

|

||

u |

|

|

|

|

(CN1)CRT |

n |

CRT(JA1) |

|

|

|

|

|

|

|

(JA1)LCD |

||

i |

|

|

|

||

|

|

|

|

|

|

t |

|

|

|

|

|

|

|

|

|

|

MDI unit |

|

MDI(JA2) |

|

|

|

(CK1)MDI |

|

R232C–1(JD5A) |

RS–232–C I/O device (channel 1) |

|

||

|

R232C–2(JD5B) |

RS–232–C I/O device (channel 2) |

|

||

|

MPG(JA3) |

|

|

|

|

|

|

MPG |

MPG |

MPG |

(Two units for 0i–TA) |

|

DIDO–1(CB104) |

|

|

|

|

|

DIDO–2(CB105) |

Machine side DI/DO |

|

|

|

|

DIDO–3(CB106) |

|

|

||

|

|

|

|

|

|

|

DIDO–4(CB107) |

|

|

|

|

When the high–speed serial bus (HSSB) is used

C |

High–speed serial |

o |

|

n |

bus interface board |

t |

(installed in a mini– |

r |

|

o |

slot) |

l |

|

u |

COP7 |

n |

|

i |

|

t |

|

Personal computer

High–speed serial bus interface board

COP7

5

3. INSTALLATION |

B–63503EN/01 |

|

|

3 INSTALLATION

6

B–63503EN/01 3. INSTALLATION

3.1

ENVIRONMENT FOR INSTALLATION

3.1.1 |

The peripheral units, such as the control unit and CRT/MDI, have been |

|||||

Environmental |

designed on the assumption that they are housed in closed cabinets. In |

|||||

Requirements Outside |

this manual “cabinet” refers to the following: |

|

|

|||

(1)Cabinet manufactured by the machine tool builder for housing the |

||||||

the Cabinet |

||||||

control unit or peripheral units; |

|

|

|

|||

|

|

|

|

|||

|

(2)Cabinet for housing the flexible turnkey system provided by FANUC ; |

|||||

|

(3)Operation pendant, manufactured by the machine tool builder, for |

|||||

|

housing the CRT/MDI unit or operator’s panel. |

|

|

|||

|

(4)Equivalent to the above. |

|

|

|

||

|

The environmental conditions when installing these cabinets shall |

|||||

|

conform to the following table. Section 3.3 describes the installation and |

|||||

|

design conditions of a cabinet satisfying these conditions. |

|||||

|

|

|

|

|

|

|

|

Room temperature |

In operation |

|

0°C to 45°C |

||

|

|

|

|

|

||

|

In storage or transportation |

–20°C to 60°C |

||||

|

|

|||||

|

|

|

|

|

|

|

|

Change in |

1.1°C /minute max. |

|

|

||

|

temperature |

|

|

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Relative humidity |

Normal |

|

75% or less |

||

|

|

|

|

|

||

|

|

Temporary(within 1 month) |

95% or less |

|||

|

|

|

|

|

|

|

|

Vibration |

In operation: |

0.5G or less |

|

|

|

|

|

|

|

|

||

|

|

Normal machine shop environment |

|

|

||

|

Environment |

(The environment must be considered if the cabinets |

||||

|

are in a location where the density of dust, coolant, and/ |

|||||

|

|

|||||

|

|

or organic solvent is relatively high.) |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.1.2 |

|

|

|

|

|

|

Installation

Requirements of CNC

and Servo Unit

Room temperature |

In operation |

0°C to +55°C |

|

|

|

||

In storage or transportation |

–20°C to +60°C |

||

|

|||

|

|

|

|

Relative humidity |

95% RH or less (no condensation) |

|

|

|

|

|

|

Vibration |

0.5 G or less |

|

|

|

|

||

Environment |

The unit shall not be exposed direct to cutting oil, lubri- |

||

cant or cutting chips. |

|

||

|

|

||

|

|

|

|

7

3. INSTALLATION B–63503EN/01

3.2

POWER SUPPLY

3.2.1 |

The following units related to the CNC control unit require input power |

||

Power Supply for CNC |

of 24 VDC "10%. |

|

|

|

|

|

|

Control Units |

|

Table 3.2.1 Power supply |

|

|

|

|

|

|

Unit |

Power supply |

Power supply |

|

|

voltage |

|

|

|

|

|

|

0i control unit |

24 VDC"10% |

3.5A (only control unit) |

|

|

"10% includes |

|

|

9″ CRT/MDI unit |

0.8A |

|

|

momentary surges |

||

|

|

and ripples. |

|

|

8.4″ TFT color unit |

0.8A |

|

|

|

||

|

|

|

|

8

B–63503EN/01 |

3. INSTALLATION |

|

|

3.3

DESIGN AND

INSTALLATION CONDITIONS OF THE MACHINE TOOL MAGNETIC CABINET

When a cabinet is designed, it must satisfy the environmental conditions described in Sec. 3.1. In addition, the magnetic interference on the CRT screen, noise resistance, and maintenance requirements must be considered. The cabinet design must meet the following conditions :

(1)The cabinet must be fully closed.

The cabinet must be designed to prevent the entry of airborne dust,coolant,and organic solvent.

Cabinets that let in air may be desined for the servo amplifier and servo transformer provided that they :

DUse an air filter on the air inlet ;

DPlace the ventilating fan so that it does not blow air directly toward the unit;

DControl the air flow so that no dust or coolant enters the air outlet

(2)The cabinet must be designed to maintain a difference in temperature of 10°C or less between the air in the cabinet and the outside air when the temperature in the cabinet increases.

See Sec. 3.4 for the details on thermal design of the cabinet.

(3)A closed cabinet must be equipped with a fan to circulate the air within.

The fan must be adjusted so that the air moves at 0.5 m/sec along the surface of each installed unit.

CAUTION

If the air blows directly from the fan to the unit, dust easily abheres to the unit. This may cause the unit to fail.

(4)For the air to move easily, a clearance of 100 mm is required between each unit and the wall of the cabinet.

(5)Packing materials must be used for the cable port and the door in oreder to seal the cabinet.

Because the CRT unit uses a voltage of approximatery 11 kV, airborne dust gathers easily. If the cabinet is insufficiently sealed, dust passes through the gap and abheres to the unit. This may cause the insulation of the unit to deteriorate.

(6)The display unit and other display units must be installed in a location where coolant cannot be poured directly on it. The unit does have a dust–proof front panel.

(7)Noise must be minimized.

As the machine and the CNC unit are reduced in size, the parts that generate noise may be placed near noise–sensitive parts in the magnetics cabinet.

The CNC unit is built to protect it from external noise. Cabinet design to minimize noise generation and to prevent it from being transmitted to the CNC unit is necessary. See Sec. 3.5 for details of noise elimination/management.

(8)The units must be installed or arranged in the cabinet so that they are easy to inspect and maintain.

9

3. INSTALLATION |

B–63503EN/01 |

|

|

(9)The CRT screen can be distorted by magnetic interference.

Arranging magnetic sources must be done with care.

If magnetic sources (such as transformers, fan motors, electromagnetic contactors, solenoids, and relays) are located near the CRT display, they frequently distort the display screen. To prevent this, the CRT display and the magnetic sources generatlly must be kept 300 mm apart. If the CRT display and the magnetic sources are not 300 mm apart, the screen distortion may be suppressed by changing the direction in which the magnetic sources are installed.

The magnetic intensity is not constant, and it is often increased by magnetic interference from multiple magnetic sources interacting with each other. As a result, simply keeping the CRT and the magnetic sources 300 mm apart may not be enough to prevent the distortion. If they cannot be kept apart, or if the CRT screen remains distorted despite the distance, cover the screen with a magnetic shield.

10

B–63503EN/01 |

3. INSTALLATION |

|

|

3.4

THERMAL DESIGN OF THE CABINET

The purpose of the thermal design of the cabinet is to limit the difference in temperature between the air in the cabinet and the outside air to 10°C or less when the temperature in the cabinet increases.

The internal air temperature of the cabinet increases when the units and parts installed in the cabinet generate heat. Since the generated heat is radiated from the surface of the cabinet, the temperature of the air in the cabinet and the outside air balance at certain heat levels. If the amount of heat generated is constant, the larger the surface area of the cabinet, the less the internal temperature rises. The thermal design of the cabinet refers to calculating the heat generated in the cabinet, evaluating the surface area of the cabinet, and enlarging that surface area by installing heat exchangers in the cabinet, if necessary. Such a design method is described in the following subsections.

3.4.1 |

The cooling capacity of a cabinet made of sheet metal is generally 6 W/°C |

||

Temperature Rise |

per 1m2 surface area, that is, when the 6W heat source is contained in a |

||

cabinet having a surface area of 1 m2, the temperature of the air in the |

|||

Within the Cabinet |

|||

cabinet rises by 1°C. In this case the surface area of the cabinet refers to |

|||

|

|||

|

the area useful in cooling , that is, the area obtained by subtracting the area |

||

|

of the cabinet touching the floor from the total surface area of the cabinet. |

||

|

There are two preconditions : The air in the cabinet must be circuited by |

||

|

the fun, and the temperature of the air in the cabinet must be almost |

||

|

constant. |

||

|

The following expression must then be satisfied to limit the difference in |

||

|

temperature between the air in the cabinet and the outside air to 10°C or |

||

|

less when the temperature in the cabinet rises: |

||

|

Internal heat loss P [W] x 6 [W/m2 S @ °C ] × surface area S [m2] |

||

|

× 10 [°C] of rise in temperature |

||

|

For example, a cabinet having a surface area of 4m2 has a cooling capacity |

||

|

of 24W/°C. To limit the internal temperature increase to 10°C under these |

||

|

conditions, the internal heat must not exceed 240W. If the actual internal |

||

|

heat is 320W, however, the temperature in the cabinet rises by 13°C or |

||

|

more. When this happens, the cooling capacity of the cabinet must be |

||

|

improved using the heat exchanger described next. |

||

|

|

|

|

3.4.2 |

If the temperature rise cannot be limited to 10°C by the cooling capacity |

||

Cooling by Heat |

of the cabinet, a heat exchanger must be added. The heat exchanger |

||

forcibly applies the air from both the inside and outside of the cabinet to |

|||

Exchanger |

|||

the cooling fin to obtain effective cooling. The heat exchanger enlarges |

|||

|

|||

|

the surface area. |

||

11

3. INSTALLATION |

B–63503EN/01 |

|

|

3.4.3

Heat Loss of Each Unit

|

Name |

Heat loss |

|

|

|

Control unit |

Series 0i |

60W |

|

|

|

Display unit |

9″CRT/MDI unit |

14W |

|

|

|

|

8.4″LCD/MDI |

20W |

|

color unit |

|

|

|

|

I/O unit |

AIF01A, AIF01B |

1.2W |

|

|

|

|

AID32A, AID32B |

1.2W+0.23W number of ON points |

|

|

|

|

AID16C, AID16D |

0.1W+0.21W number of ON points |

|

|

|

|

AID32E, AID32F |

0.1W+0.23W number of ON points |

|

|

|

Multi–tap transformer |

51W |

|

|

|

|

12

B–63503EN/01 |

|

|

3. INSTALLATION |

|||

|

|

|

|

|

|

|

3.5 |

The CNC has been steadily reduced in size using surface–mount and |

|||||

ACTION AGAINST |

custom LSI technologies for electronic components. The CNC also is |

|||||

designed to be protected from external noise. However, it is difficult to |

||||||

NOISE |

||||||

measure the level and frequency of noise quantitatively, and noise has |

||||||

|

many uncertain factors. It is important to prevent both noise from being |

|||||

|

generated and generated noise from being introduced into the CNC. This |

|||||

|

precaution improves the stability of the CNC machine tool system. |

|||||

|

The CNC component units are often installed close to the parts generating |

|||||

|

noise in the power magnetics cabinet. Possible noise sources into the |

|||||

|

CNC are capacitive coupling, electromagnetic induction, and ground |

|||||

|

loops. |

|

|

|

|

|

|

When designing the power magnetics cabinet, guard against noise in the |

|||||

|

machine as described in the following section. |

|||||

|

|

|

|

|

||

3.5.1 |

The cables used for the CNC machine tool are classified as listed in the |

|||||

Separating Signal |

following table: |

|

|

|

||

Process the cables in each group as described in the action column. |

||||||

Lines |

||||||

|

Group |

Signal line |

Action |

|||

|

|

|

|

|||

|

|

Primary AC power line |

Bind the cables in group A sep- |

|||

|

|

|

arately (Note 1) from groups B |

|||

|

|

Secondary AC power line |

||||

|

|

and C, or cover group A with |

||||

|

|

|

an electromagnetic shield |

|||

|

|

AC/DC power lines (containing the |

||||

|

|

(Note 2). |

||||

|

A |

power lines for the servo and |

See Subsec. 3.5.4 and con- |

|||

|

|

spindle motors) |

||||

|

|

nect spark killers or diodes with |

||||

|

|

|

||||

|

|

AC/DC solenoid |

the solenoid and relay. |

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

AC/DC relay |

|

|

|

|

|

|

|

|

|||

|

|

DC solenoid (24VDC) |

Connect diodes with DC sole- |

|||

|

|

|

noid and relay. |

|||

|

|

|

|

|

|

|

DC relay (24VDC)

BDI/DO cable between the CNC and power magnetics cabinet

DI/DO cable between the CNC and machine

Bind the cables in group B separately from group A, or cover group B with an electromagnetic shield.

Separate group B as far from Group C as possible.

It is more desirable to cover group B with the shield.

13

3. INSTALLATION |

|

B–63503EN/01 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Group |

Signal line |

Action |

|

|

|

|

|

|

Cable between the CNC and servo amplifier

Cable for position and velocity feedback

Cable between the CNC and spindle amplifier

Cable for the position coder

Cable for the position coder

C

Cable for the manual pulse generator

Cable between the CNC and the CRT/MDI

RS–232–C and RS–422 interface cable

Cable for the battery

Cable for the battery

Other cables to be covered with the shield

Bind the cables in group C separately from group A, or cover group C with an electromagnetic shield.

Separate group C as far from Group B as possible.

Be sure to perfrom shield processing in Subsec. 3.5.5.

NOTE

1The groups must be 10 cm or more apart from one another when binding the cables in each group.

2The electromagnetic shield refers to shielding between groups with grounded steel plates.

|

Cabinet |

|

|

Spindle |

Servo |

Control |

|

amp. |

amp. |

unit |

|

|

|

|

Cable of group B, C |

|

|

|

Duct |

|

|

|

To operator’s |

|

|

|

panel, |

|

|

|

motor, etc. |

|

Cable of group A |

|

Section |

|

|

Group A |

Group B, C |

|

|

|

Cover |

14

B–63503EN/01 |

3. INSTALLATION |

|

|

3.5.2

Ground

Notes on connecting the ground systems

The following ground systems are provided for the CNC machine tool:

(1)Signal ground system (SG)

The signal ground (SG) supplies the reference voltage (0 V) of the electrical signal system.

(2)Frame ground system (FG)

The frame ground system (FG) is used for safety, and suppressing external and internal noises. In the frame ground system, the frames, cases of the units, panels, and shields for the interface cables between the units are connected.

(3)System ground system

The system ground system is used to connect the frame ground systems connected between devices or units with the ground.

|

|

|

Signal ground system |

Power |

|

|

Frame ground sysytem |

Servo |

CNC |

System ground system |

|

magnet- |

amplifier |

control |

|

ics |

|

unit |

Operator’s |

unit |

|

|

panel |

|

|

|

|

|

|

|

Machine |

|

|

|

tool |

Power |

|

|

|

magnetics |

|

|

|

cabinet |

|

|

|

|

Distribution board |

|

|

D Connect the signal ground with the frame ground (FG) at only one place in the CNC control unit.

DThe grounding resistance of the system ground shall be 100 ohms or less (class 3 grounding).

DThe system ground cable must have enough cross–sectional area to safely carry the accidental current flow into the system ground when an accident such as a short circuit occurs.

(Generally, it must have the cross–sectional area of the AC power cable or more.)

DUse the cable containing the AC power wire and the system ground wire so that power is supplied with the ground wire connected.

15

3. INSTALLATION |

B–63503EN/01 |

|

|

3.5.3

Connecting the Signal Ground (SG) of the Control Unit

|

|

|

Control unit |

|

|

||

MAIN |

|

|

|

I/O |

|

|

|

|

|

|

|

PSU |

|

|

|

1 |

2 |

3 |

4 |

|

|

|

|

STATUS |

|

|

|

|

|

|

|

ALARM |

|

|

CPS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MPG |

|

|

|

|

|

|

|

JA3B |

|

|

|

|

|

|

|

FUSE75A |

|

|

|

|

|

|

|

PIL |

|

|

|

BATTERY |

|

|

|

|

|

|

|

MEMORY |

|

|

|

|

|

|

|

CARD |

|

|

|

|

|

|

|

CNMC |

|

|

|

|

|

|

|

|

|

|

|

CP1ACP1B |

|

|

|

|

|

|

|

DCIN DCOUT |

|

|

|

|

|

|

|

24V |

24V |

|

|

|

|

|

RSW1 |

5A |

1A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R |

|

|

IOL INK |

|

|

|

|

L |

|

|

|

|

|

|

|

|

|

|

JD 1A |

|

|

|

|

|

|

|

SPDL–1 |

|

|

|

CRT |

|

|

|

JA 7A |

|

|

|

JA1 |

|

|

|

A–OUT |

|

|

|

MDI |

|

|

|

JA 8A |

|

|

|

JA2 |

|

|

|

SERVO1 |

|

|

|

R232–1 |

|

|

|

JS1A |

|

|

|

|

|

|

|

|

|

|

JD5A |

|

|

|

|

|

|

|

|

|

|

|

|

SERVO2 |

|

|

|

R232–2 |

|

|

|

JS2A |

|

|

|

JD5B |

|

|

|

SERVO3 |

|

|

|

|

|

|

|

JS3A |

|

|

|

|

|

|

|

SERVO4 |

|

|

|

|

|

|

|

JS4A |

|

|

|

|

R |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

|

|

SCALE1 |

|

|

|

|

|

|

|

JF21 |

|

|

|

|

|

|

|

SCALE2 |

|

|

|

|

|

M3 terminal for |

|

JF22 |

|

|

|

|

|

|

|

SCALE3 |

|

|

|

|

|

signal ground (SG) |

Ground plate |

JF23 |

|

|

|

|

|

|

|

SCALE4 |

|

|

|

|

MINI |

|

|

JF24 |

|

|

|

|

|

|

|

|

|

|

|

SLOT |

|

|

|

|

|

|

|

|

|

|

|

SC–ABS |

|

|

|

|

|

|

|

JF25 |

|

|

|

|

|

|

|

|

FANUC |

|

FANUC |

|

|

||

|

FA- |

|

|

|

|

|

|

|

NUC |

|

|

|

|

|

|

Ground cable |

|

|

|

|

|

|

M3 |

|

|

|

|

|

|

|

|

(upper 2mm2) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ground cable |

Frame |

= |

Ground plate of |

System ground |

|

|||

ground |

|

||||||

(FG) |

|

the cabinet |

|

|

|||

Connect the 0 V line of the electronic circuit in the control unit with the ground plate of the cabinet via the signal ground (SG) terminal.

The SG terminal is located below the main board of the control unit.

16

B–63503EN/01 |

3. INSTALLATION |

|

|

Approx. 15mm

MDI |

CRT |

M4 stud

Approx. 20 mm (for 9″ CRT/MDI unit) |

9″ CRT/MDI unit |

Approx. 150 mm (for 8.4″ LCD/MDI unit) |

8.4″ LCD/MDI unit |

17

3. INSTALLATION |

B–63503EN/01 |

|

|

3.5.4

Noise Suppressor

Notes on selecting the spark killer

The AC/DC solenoid and relay are used in the power magnetics cabinet.

A high pulse voltage is caused by coil inductance when these devices are turned on or off.

This pulse voltage induced through the cable causes the electronic circuits to be disturbed.

DUse a spark killer consisting of a resistor and capacitor in series. This type of spark killer is called a CR spark killer.(Use it under AC)

(A varistor is useful in clamping the peak voltage of the pulse voltage, but cannot suppress the sudden rise of the pulse voltage. FANUC therefore recommends a CR spark killer.)

DThe reference capacitance and resistance of the spark killer shall conform to the following based on the current (I (A)) and DC resistance of the stationary coil:

1)Resistance (R) : Equivalent DC resistance of the coil

|

I2 |

I2 |

|||

2) Capacitance (C) : |

|

to |

|

( F) |

|

10 |

20 |

||||

|

|

|

|||

I : Current at stationary state of the coil

|

R |

C |

Equivalent circuit of the spark killer |

|

|

AC |

Spark killer |

|

relay |

|

|

Motor

Spark killer

Mount the noise eliminator near a motor or a relay coil.

NOTE

Use a CR–type noise eliminator. Varistor–type noise eliminators clamp the peak pulse voltage but cannot suppress a sharp rising edge.

Diode (used for direct–current circuits)

Diode |

|

|

Use a diode which can withstand a |

||

|

||

DC relay |

voltage up to two times the applied |

|

voltage and a current up to two times |

||

|

||

|

the applied current. |

|

|

|

18

B–63503EN/01 |

3. INSTALLATION |

|

|

3.5.5

Cable Clamp and Shield Processing

The CNC cables that require shielding should be clamped by the method shown below. This cable clamp treatment is for both cable support and proper grounding of the shield. To insure stable CNC system operation, follow this cable clamp method.

Partially peel out the sheath and expose the shield. Push and clamp by the plate metal fittings for clamp at the part. The ground plate must be made by the machine tool builder, and set as follows :

Ground plate |

Cable |

Metal fittings |

for clamp |

40mm – 80mm |

Fig.3.5.5(a) Cable clamp (1)

19

3. INSTALLATION |

B–63503EN/01 |

|

|

Machine side installation board

Control unit

Ground plate

Metal fittings for clamp

Shield cover

Fig.3.5.5(b) Cable clamp (2)

Prepare ground plate like the following figure.

Ground terminal |

(grounded) |

Hole for securing metal fitting clamp |

Mount screw hole |

Fig.3.5.5(c) Ground plate

For the ground plate, use a metal plate of 2 mm or thicker, which surface is plated with nickel.

20

Loading...

Loading...