Deutz B FM 1008 F Service Manual

Workshop ManualB/FM 100

cardiagn.com

cardiagn.com

© 2001 / 0297 9984

2M |

|

3M |

|

Workshop Manual |

|

F4M |

|

BF4M100 |

|

2M |

|

3M |

|

F4M 100 |

|

0297 9985 en |

cardiagn.com |

In view of continuous design improvements or |

the |

tech |

cifications and the illustrations shown in this Workshop Manual |

||

alteration. Reprinting and reproduction, in part or in whole, ar |

||

written approval. |

© 2001 |

/ 0 |

|

||

cardiagn.com

© 2001 / 0297 9985

F O R E W O R D

Reliable engine operation is dependent on pro This Workshop Manual describes the appropriat engine and engine components. It is presumed The Manual has been laid out to ensure quick placed adjacent to the brief text passages to Aspects of operation and maintenance are deal For spare parts orders the respective spare p This Workshop Manual is not subject to Therefore please refer to the informatio

General information: |

|

- Make sure that this Workshop Manual.comis |

|

- Please read carefully and observe the |

|

avoid accidents and ensure that |

|

|

cardiagn |

or adjustments and that the contents |

|

- Non-compliance with these repair instr |

|

damage as well as personal injuries fo |

|

liability. |

|

- The accident prevention regulations a |

|

safety and occupational medicine are t |

|

- A prerequisite for successful repair i |

|

are available and in perfect working |

|

- Optimal operation economy, reliability |

|

when genuine parts of DEUTZ AG are us |

|

- Engine components such as springs, cla |

|

handled with care. |

|

- Engine repairs must be carried out in |

|

equipment manufacturer. For conversion |

|

specific purpose should be used. |

|

© 2001 / 0

INDEX

This manual contains pertinent information regardi |

||||

injection DieselB/FM engines1008/F. |

type |

|

||

INDEX |

|

|

PAGE |

|

|

TROUBLESHOOTING CHART - B/FM 1008/F SERIES9_________ |

|||

|

SAFETYAND ARNINGW DECALS - SAFETY INSTRUCTIONS10_________ |

|||

I |

GENERAL |

|

|

12 |

|

POWER RATINGS FOR B/FM 1008/F GENSET SPEC DIESEL ENGI |

|||

|

B/FM 1008 SERIES - TECHNICAL SPECIFICATIONS AND |

|||

|

CAPACITIES F2/3/4M 1008, BF4M 1008 __________________ |

|||

|

FLUID CAPACITIES (STANDARD) F2/3/4M 1008, BF4M 1008 __ |

|||

|

FM 1008 F SERIES - TECHNICAL SPECIFICATIONS AND CAPAC |

|||

|

FLUID CAPACITIES (STANDARD) F2/3/4M 1008 F___________ |

|||

|

POWER, TORQUE AND SPECIFIC FUEL CONSUMPTION CURVES F2 |

|||

|

POWER, TORQUE AND SPECIFIC FUEL CONSUMPTION CURVES B/ |

|||

|

SPECIALCRITICALSEALANTDRIVINGANTIDIESELRECOMMENDEDB/FM-1008/FFREEZEFUELTOOLSANDTORQUESTORQUETHREADSERIES/SPECIFICATIONSOILCOOLANTSPECIFICATIONSFORLOCKMAINTENANCESTANDARDSPECIFICATIONSLOCATIONS/DETAILSSCREWSSCHEDULE/ DETAILS -cardiagn.comB/FM |

|||

|

POWER, TORQUE AND SPECIFIC FUEL CONSUMPTION CURVES F2 |

|||

|

GENERAL ENGINEERING DRAWINGS - F2/3M 1008 ___________ |

|||

|

GENERAL ENGINEERING DRAWINGS - B/F4M 1008___________ |

|||

|

GENERAL ENGINEERING DRAWINGS - F2/3/4M 1008 F _______ |

|||

II |

DISASSEMBLY- |

REASSEMBLY__ |

31 |

|

|

Air filter support - (intake manifold) |

32 |

||

|

Air restriction switch ______________________________ |

|||

|

Alternator / cooling fan drive belt_________________ |

|||

|

Camshaft journal / support bore specifications______ |

|||

|

Camshaft journal / support measurement ______________ |

|||

|

Camshaft lobe measurement procedure__________________ |

|||

|

Camshaft lobe specifications ________________________ |

|||

|

Camshaft removal / replacement ______________________ |

|||

|

Camshaft timing pulley ______________________________ |

|||

|

Connecting bearing / rod cap installation___________ |

|||

|

Connecting rod / connecting rod bearings specificatio |

|||

|

Connecting rod alignment ____________________________ |

|||

|

Connecting rod-piston assembly balance ______________ |

|||

|

Cooling fan _________________________________________ |

|||

|

Cooling fan support _________________________________ |

|||

|

Crankcase vacuum regulator valve (B/FM 1008/F) ______ |

|||

|

Crankshaft end play _________________________________ |

|||

|

Crankshaft journal inspection / measurement _________ |

|||

|

Crankshaft journal specifications ___________________ |

|||

|

Crankshaft lubrication drillings-typical ____________ |

|||

|

Crankshaft pulley ___________________________________ |

|||

|

Crankshaft seals - front and rear ___________________ |

|||

©2001 / 0297 9985 |

4 |

|

|

|

|

INDEX |

|

|

PAGE |

|

Crankshaft timing pulley ________________________ |

||

Cylinderclass__________________________________________ |

||

Cylinder |

head installation_______________________ |

|

Cylinder |

head removal ____________________________ |

|

Cylinder |

head tightening procedureF4M 1008/F, B |

|

Cylinder |

head tightening procedureF2/3M 1008/F_ |

|

Cylinder |

inspection / dimensional specifications |

|

Cylinder |

surface finish __________________________ |

|

Dry type |

air filterstandard engine mounted _____ |

|

Exhaust manifold_________________________________ |

||

Flywheel |

/ ring gear_____________________________ |

|

Front / rear main bearing caps / bearings________ |

||

Fuel rail ________________________________________ |

||

Fuel tank - (optional accessory) _________________ |

||

General piston notes ____________________________ |

||

Governor fork____________________________________ |

||

Governor springs_________________________________ |

||

Head gasket selection/ installation _____________ |

||

Hydraulic drive componentsno. 3 pto____________ |

||

Hydraulic pump pto- (no. 3 pto) __________________ |

||

Idler pulley _____________________________________ |

||

Injection pump control rod ______________________ |

||

PistonPistonPistonPistonPistonPistonPistonPistonPistonOilOilOil pumppumppumpremovalprotrusionringringcoolingclass,balance//connectingassemblyassemblyconnectinginspectionendassemblyweightjetsgapto-rodrodlocationBF4Mimbalancethedisassemblyinstallationengine1008and genuineandpistonDeutzcardiagn.comin |

||

Limiting |

speed governor _________________________ |

|

Main and |

connecting rod bearings ________________ |

|

Main bearing caps / bearingscenter _____________ |

||

Main bearing clearance ___________________________ |

||

No. 2 pto (crankshaft pulley) with “ringfeder”- F |

||

Oil bath |

air filter ______________________________ |

|

Oil pan removal / installation___________________

Piston ring to piston land clearance ____________

Piston wrist pin installation / retaining snap ri Precision speed governor -(gensets)______________

Pre-combustion chamber installation ______________

Pre-combustion chamber removal___________________

Pre-combustion chamber ring nut __________________

Pre-combustion chamber-overview__________________

Rocker arm assembly______________________________

Speed governor___________________________________

Speed governor reassembly ________________________

Thrust bearings __________________________________

Thrust surface specifications-crankshaft end _____

play corrections_________________________________

Timing belt / timing pulley arrangement __________

Timing belt cover________________________________

Timing belt installationtiming procedure ______

Timing belt removal _____________________________

Timing belt tension procedure ____________________

Timing belt tensioning proceduresetup __________

Timing pulley - reference marks __________________

Undersized bearingsrod and main _______________

Unit injector check valve ________________________

Unit injector removal / installation _____________

Valve / rocker cover _____________________________

5 ©2001 / 02

INDEX

PAGE

Valve / rocker cover gasket _________________________

Valveadjustment ________________________________________

Valve guide installation guidelines and post installa Valve guides / valve guide bore _____________________

Valve recess and seat sealing width _________________

Valve removal_______________________________________

Valve seats _________________________________________

Valve specifications ________________________________

Valve springs _______________________________________

Valve stem seal installation ________________________

Valve timing angles _________________________________

Valve timing confirmation____________________________

III |

TURBOCHARGER ___________ |

58 |

_ |

Turbochargeridentification ______________________________ |

|||

Turbocharger components _____________________________ |

|||

Turbocharger pressure testing _______________________ |

|||

Turbocharger waste gate adjustement-bench method ____ |

|||

VIV ThermostatCoolantCoolingB/FMCOOLINGFUEL1008/FSYSTEMsystempumpSYSTEMcoolingdetailspressuresystemcheck/radiatorschematic |

cap 6563inspectioncardiagn.com |

||

IV |

LUBRICATION SYSTEM |

60 |

|

Lubrication system

Oil pick-up screen and oil drain back tube__________

Oil pump specification ______________________________

Oil filter __________________________________________

Oil pressure testing________________________________

Barrel and plungerentdetail- (typical) curr |

|

unit injectors (example- 6590-285) __________________ |

|

Barrel and plunger detailearly unit injectors (typi |

|

Early unit injectors________________________________ |

|

Engine timing |

reference marks _______________________ |

Equalization tool installation, plumbing____________ |

|

Fuel filter assembly ________________________________ |

|

Fuel rate adjustment details ________________________ |

|

Fuel system schematic _______________________________ |

|

Fuel system special tools ___________________________ |

|

Fuel transfer |

pump __________________________________ |

Fuel transfer |

pump push rod protrusion ______________ |

Injector ____________________________________________ |

|

Injector nozzle protrusion __________________________ |

|

Late/ intermediate unit injectors ___________________ |

|

Static injection test instrumentationearly unit inj |

|

Static timing |

adjustment ____________________________ |

Tdc determination and static injection timing checkin |

|

Unit injector _______________________________________ |

|

Unit injector |

components ____________________________ |

Unit injector |

delivery equalizationpreparation ____ |

Unit injector |

delivery equalizationpreparation (con |

Unit injector |

fire ring _____________________________ |

Unit injector |

plunger reassembly ____________________ |

©2001 / 0297 9985 |

6 |

INDEX

|

|

PAGE |

Unit injector popping pressuretlow pressuretestingprocedureand adjustm(c |

||

intermediate unit injectors) _____________________ |

||

Unit injector |

popping pressure testing and adjust |

|

injectorsall ref. No’s other than 272, 272-, 27 |

||

Unit injector |

reassembly (cont.) _________________ |

|

Unit injector |

ring nut removal / replacement _____ |

|

Unit injector |

test stand specifications __________ |

|

VII ELECTRICAL SYSTEM |

65 |

|

12V elesctricalhematic-marelli 14V-33A _________________

12V electrical schematic - 20/30 A flywheel alter

12V electrical schematic-iskra 14V-33A ___________

Battery sizing ___________________________________

Battery sizing ___________________________________

Bosch 12V/1.1 kW starter motor (DW 12V) _________

BOSCH 12V/1.6 kW starter motor (DW 12V) __________

Electrical system service precautions / warning __ Engine side wiring harness for the Deutz supplied Flywheel alternator - 12V________________________

Glow plug ________________________________________

Glow plug controller / relay with coolant temp.cardiagn.comS Iskra 14V/33A performance curve __________________

Iskra alternator - 14V/33A _______________________

Deutz supplied control panel ____________________

Marelli AA 125 R, 14V/45A performance curve ______

Marelli alternator (AA 125 R) - 14V-45A__________

Oil pressure (low) switch, coolant temperature (h VIIIPerformancePerformancePerformancePerformanceTemperatureVoltageGovernorHighTESTING(maximum)regulator/ -unitsensorcurvecurvecurvecurveOPERATIONALspeedinjectorconnection----(thermistor)20Aadjustment30ABOSCHBOSCHflywheelflywheel-rackADJUSTEMENTS12V/112V/1detailsadjustment..16alternatorkWkWalternator(flywheel(DW(DW12V)12V)84 staalsta

Idle speed adjustment ____________________________

Injection pump control rod stroke limit adjustmen Power, torque device and speed adjustments-dynamo Torque device adjustment (without dynamometer) ___

Torque device details ____________________________

IX STORAGE |

86 |

Storage |

86 |

Storage - 1 to 6 months__________________________

Storage - in excess of 6 months _________________

Preparing the engine for use after storage _______

7 |

©2001 / 02 |

NOTE

cardiagn.com

©2001 / 0297 9985 |

8 |

|

|

crank |

|

but |

|

|

|

|

|

|

|

|

|

consumption |

|

|

|

|

|

|

||

|

|

|

|

stops |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

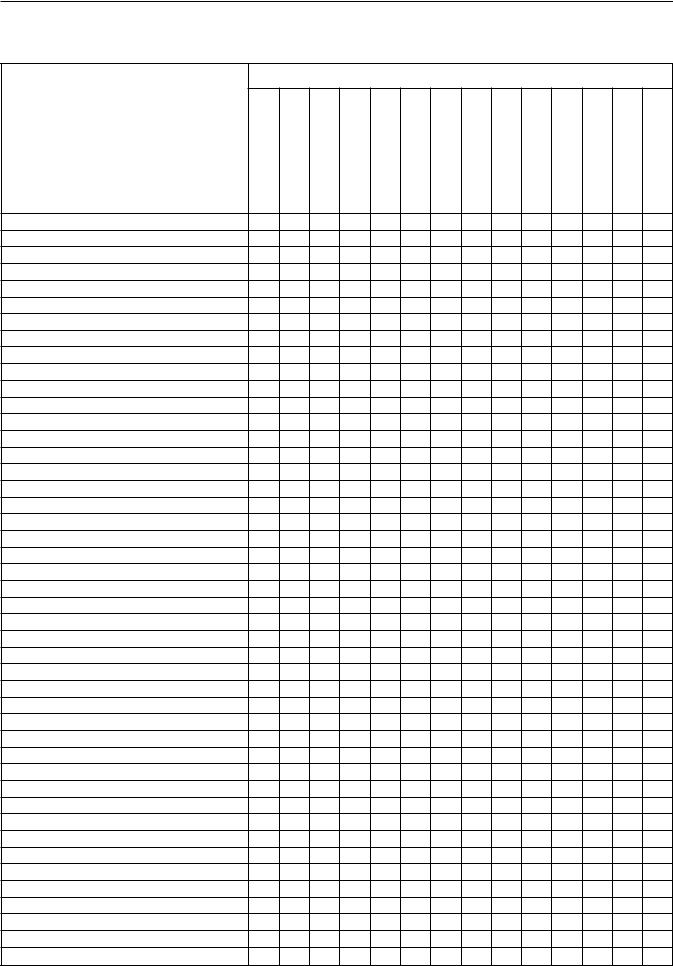

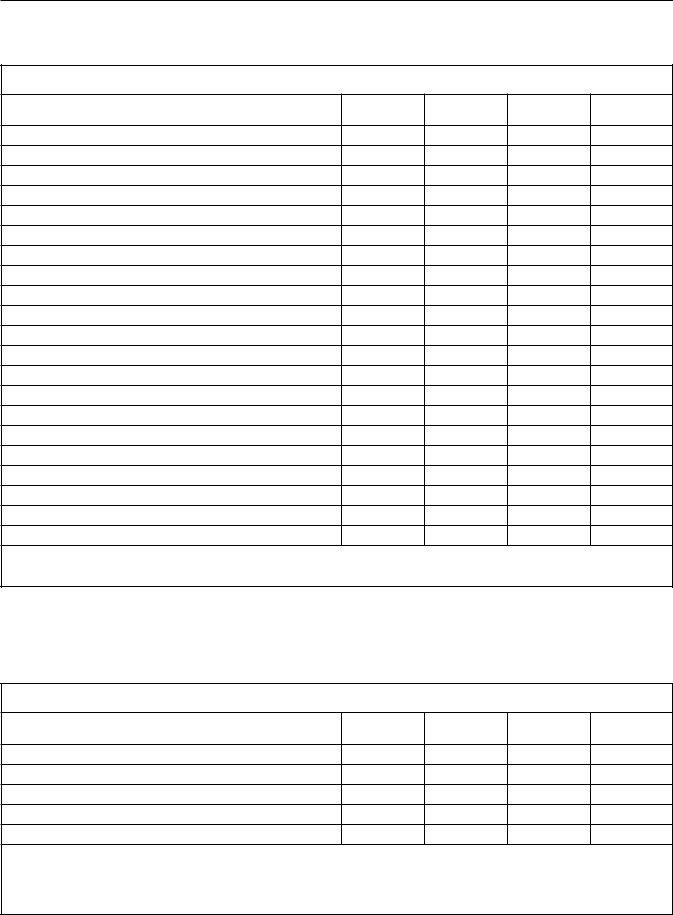

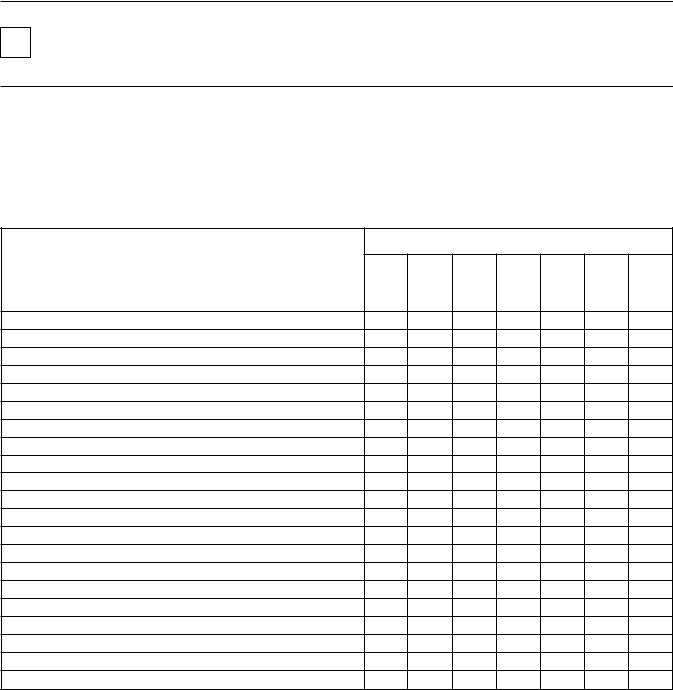

TROUBLESHOOTING CHART-B/FM |

|||||||||||||||||||||

|

|

start |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

TROUBLESHOOTING CHART- B/FM 1008 |

|||||||||||||||||||||

POSSIBLE CAUSEwill |

|

|

acceleration |

smoke |

|

|

oil |

|

exhaust |

knocks |

||||||||||||

|

|

not |

|

|

|

|

|

|

smoke |

|

|

rising |

|

|

|

|

|

|

|

|||

|

|

does |

|

|

|

|

pressure |

oil |

|

|

|

|

|

|

||||||||

|

|

not |

|

RPM |

|

|

|

smoke |

|

level |

|

|

|

|

|

|

|

|||||

|

|

|

|

starts, |

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

SYMPTOM |

|

|

|

|

|

|

|

|

||||

|

|

Engine Engine Engine Poor Unsteady Black White Blue Low Oil Excessive Wet Overheating Engine |

||||||||||||||||||||

Low fuel level |

|

|

• |

• |

• |

• |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Fuel supply/nlinesreturclogged • |

• |

• |

• |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Clogged fuel tank vent |

• |

• |

|

|

|

|

|

|

|

|

• |

|

|

|

|

|

|

|

||||

Fuel pump faulty |

|

|

• |

• |

|

• |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Fuel entrained with air• |

• |

|

|

• |

|

• |

|

|

|

• |

|

|

• |

|

||||||||

Unit injector(s) faulty/• |

worn• |

• |

|

|

|

|

|

|

• |

• |

||||||||||||

Unit injector settings |

•incorrect• |

|

• |

|

• |

|

|

|

|

|

|

|

|

|||||||||

Injection pump rack sticking•• |

• |

|

• |

|

|

• |

|

|

|

|

• |

|

|

• |

||||||||

Oil level too high |

|

|

|

• |

• |

|

|

|

|

|

|

|

|

|

|

|||||||

EngineIncompleteExcessiveAirKeyBatteryBatteryStarterGlowGlowGlowfilterswitchplugplugsplugoverloaded/defectivevoltagebatteryidlecontrollerrelayenginefaultycloggeddefective/inoperabletoolightcablerunlow••••faulty-in•••••loadconnections•operation••••••••corroded•• •••••••cardiagn.com•• |

||||||||||||||||||||||

Improper oil viscosity |

|

|

|

|

|

|

|

|

|

|

• |

• |

• |

• |

• |

• |

|

• |

• |

|||

Oil diluted by fuel |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

Oil pressure relief valve faulty |

|

|

|

|

|

• |

|

|

|

|

|

|

|

|

||||||||

Oil pick-up tube clogged |

|

|

|

|

|

|

|

|

|

• |

|

|

|

|

|

|

|

|

||||

Oil pump air entrained at pick-up tube |

|

• |

|

|

|

|

|

|

|

|

||||||||||||

Excessive parasitic load•• |

|

|

|

|

|

• |

• |

|

• |

|

|

|

|

|

|

|

|

• |

||||

Valve lash |

insufficient•/ excessive |

|

|

|

|

• |

|

|

|

|

||||||||||||

Injection timing out |

of• spec- |

advanced•• |

|

|

|

|

|

|

|

• |

||||||||||||

Injection timing out |

of• spec-• |

retarded• |

|

|

|

|

|

|

|

|

|

|

||||||||||

Governor linkage |

adjustment•• |

incorrect•• |

|

|

|

|

|

|

|

|

|

|

||||||||||

Governor spring |

fatigued• |

or |

defective•• |

|

|

|

|

|

|

|

|

|

|

|||||||||

Idle rpm too low |

|

|

• |

• |

|

|

|

|

|

• |

|

• |

|

|

|

• |

|

• |

|

|

|

|

Piston rings worn or |

stuck• |

|

|

|

|

|

|

|

|

|

|

|

|

• |

||||||||

Piston worn or damaged • |

|

|

|

|

|

|

• |

|

• |

|

|

|

• |

|

• |

|

|

|||||

Cylinders worn or damaged• |

|

|

|

|

|

• |

|

• |

|

|

|

• |

|

• |

|

|

• |

|||||

Valves / valve guides |

worn• |

• |

|

• |

|

|

• |

• |

• |

|

|

|

• |

• |

• |

• |

|

|||||

Valves sticking |

|

|

• |

• |

|

|

|

|

|

• |

|

|

|

|

• |

|||||||

Bearings (main / rod) worn |

|

|

|

|

|

|

|

|

|

|

|

|

• |

|||||||||

Governor / governor linkage•• malfunction••• |

|

|

|

|

|

|

|

• |

|

|||||||||||||

Cylinder head gasket |

damaged• |

|

|

|

|

• |

|

|

|

|

|

|

|

• |

|

|||||||

Thermostat |

stuck or malfunctioning |

|

|

|

|

|

|

|

|

|

|

|||||||||||

Engine seized |

• |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• |

|

|

|||

Radiator clogged (external or internal) |

|

|

|

|

|

|

|

|||||||||||||||

Coolant pump faulty |

|

|

|

• |

• |

|

|

• |

|

|

• |

|

|

• |

• |

|

• |

|||||

Turbocharger faulty |

|

|

|

|

|

|

|

|

|

• |

||||||||||||

9 |

©2001 / 02 |

SAFETY AND WARNING DECALS - SAFETY |

|

SAFETY ANDRNINGW DECALS |

|

DANGER |

CAUTION |

|

! |

Failure to complyFailurewith tohe comply |

|

instructions |

couldinstructionsesult in could |

damage to personstechnicaland damage |

|

property |

machine and/or syst |

●DeutzEnginesessential forare usersbuilt toto complysupply withtheirtheperformancesservicingcardiagn.cominsin recommendations listed below.

●Themeetenginetheessentialhas beensafetymade accordingandhealthtosafeguardinga machine manre

in merit. All uses of the engine beyond those spec conforming to the use defined by Deutz which thus d operations.

●Theconcerningfollowingengineindicationsoperationarein dedicatedparticular,toalongthe usewit

●Thethisusercouldmustleadreadto theseseriousinstructionsdanger for carefullyhispersonaland s vicinity of the machine.

●Theoperationengineandmaytheonlyderivingbe used dangersorassembled.This onconditiona machin

extraordinary maintenance operations which, in the l trained by Deutz and who work in compliance with the

●Variationsremoval of seals,tothe demountingfunctional andparametersrefittingof ofthepartsengi

unauthorized personnel shall relieve Deutz from all comply with the laws in merit.

●Onthestarting,caseof manualmake surestartthat-ups,themakeenginesureisthatas thehorizonrel

or dangerous objects, also considering the movements excluding self-winding starting only), is not permit

●Make sure that the machine is stable to prevent the

©2001 / 0297 9985 |

10 |

SAFETY AND WARNING DECALS - SA

●Become familiar with how to adjust the rotation s

●Nevermonoxide,startantheodourlessengine andinahighlyclosedpoisonousplace or gaswher. this gas can lead to unconsciousness and death.

●Theis dustenginethatmustcannoteasilyoperatecatchinfireplacesunlescontainingspecific have been certified for the machine.

●To prevent fire hazards, always keep the machine

● Childrenderiving fromandanimalstheiroperationmust be .kept at a due dista

●Fuelthe fuelis inflammablecontaineraway.Thealongtank withmust anyonlyragsbe filledsoake

of porous material are soaked in fuel or oil. Mak has not soaked up any fuel or oil.

● spaceFully fortightenthe fuelthetanktoexpandplug .each time after refu

● |

Fuel vapour is highly toxic. Only refuel outdoors |

● |

Do not smoke or use naked flames when refuelling. |

● |

Theand/orenginemachinemustitselfbestarted.Do notin complianceuseauxiliarywithstarth |

● |

Duringparticularoperation,. the surface of the engine can b |

● |

Beforewhilst proceedingtheengine withisrunningany operation. on the engin |

● inThethiscoolantcase,fluidonlycircuitopen theis radiatorunderpressureplug .orNeveexp

|

garments and goggles. If there is an electric fan |

|

|

also start operating when the engine is at a sta |

|

|

standstill. |

cardiagn.com |

● |

Whensafeguardcleaningthe environmenttheoil-cooled.Theairspongyfilter,filteringmake sum |

|

|

reservoir of the separator pre-filter must not be |

|

● Theallowoilthemustoilbetodrainedcome into° whilstC).contactParticularthe enginewithcaretheis skinishotre. |

||

● |

Makesafeguardsure thethatenvironmentthe drained. oil, the oil filter an |

|

● |

Pay attention to the temperature of the oil filte |

|

● |

Onlycontainingcheck,nitritestopup andfromchangebeingthemixedcoolantwith fluidothers |

|

|

dangerous for the health, can form. The coolant f |

|

|

way to safeguard the environment. |

|

● |

Duringdisconnectoperationsand insulatethat involvethepositiveaccesswireto movingofthe |

|

|

starter motor from being energized. |

|

● |

Only check belt tension when the engine is off. |

|

● |

Onlymachine;use inthethiseyeboltscase,installedtheeyeboltsby Deutzinstalledto moveby |

|

11 |

©2001 / 02 |

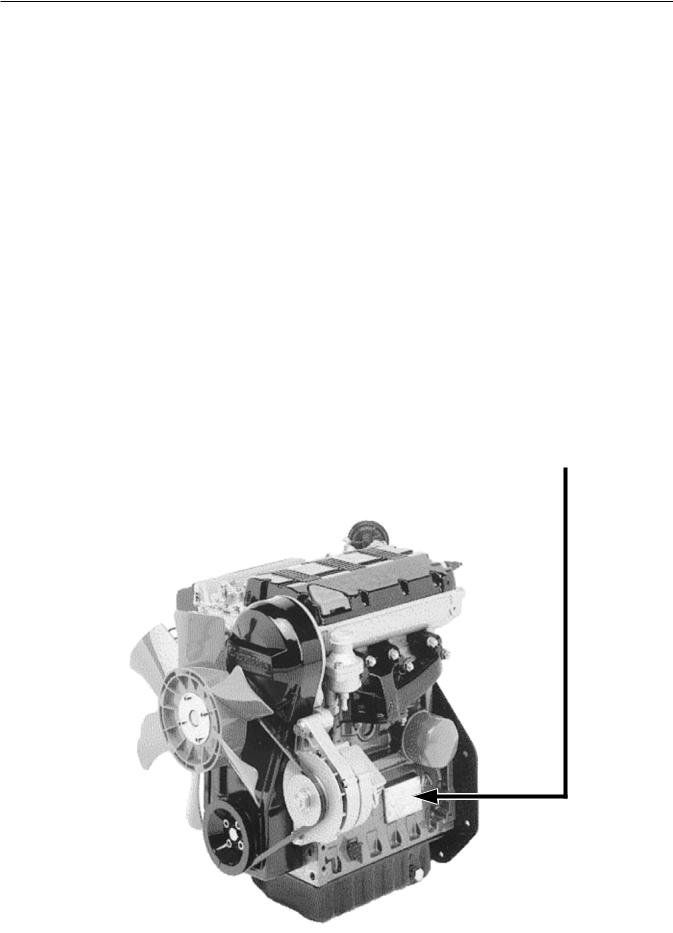

I GENERAL

All pertinent information needed for engine identific data plate. Additionally, the maximum engine speed, “ data plate. The location of the data plate, as shown engines. Please supply the engine data plate informat ordering replacement parts or when making technical i

cardiagn.com

©2001 / 0297 9985 |

12 |

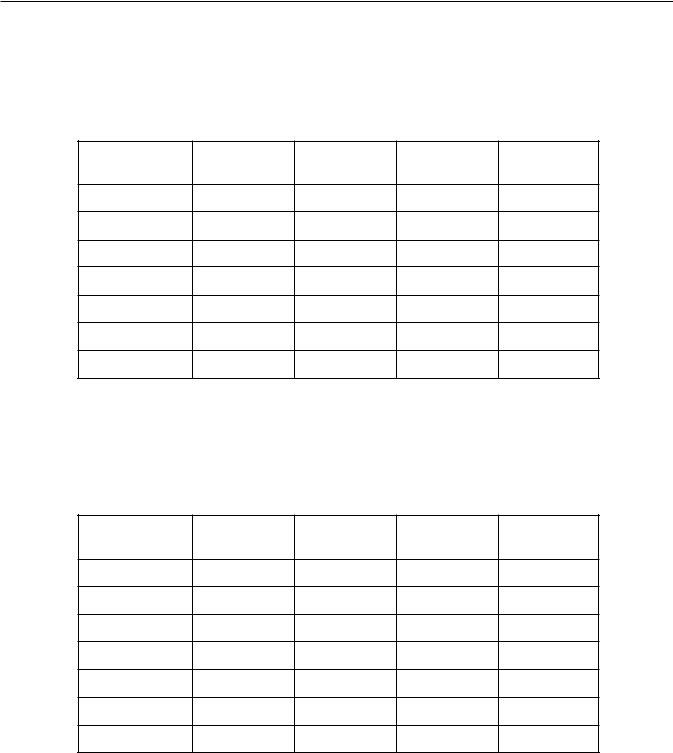

GENERAL POWER RATINGS FOR B/FM 1008/F

DIESEL ENGINES

CONTINUOUS (NA) RATINGkW

ENGINE |

1500 |

1800 |

3000 |

3600 |

|

MODEL |

r/min |

r/min |

r/min |

r/min |

|

F2M 1008 |

4.5 |

5.4 |

9.0 |

9.9 |

|

F3M 1008 |

6.7 |

8.1 |

14.0 |

14.9 |

|

F4M 1008 |

9.0 |

10.8 |

18.9 |

19.9 |

|

BF4M 1008 |

11.7 |

14.0 |

24.8 |

25.8 |

|

F2M 1008 |

F 5.0 |

5.9 |

9.9 |

10.6 |

|

F3M 1008 |

F 7.7 |

9.0 |

14.9 |

16.3 |

cardiagn.com |

F4M 1008 |

F 9.9 |

11.7 |

19.8 |

22.8 |

|

|

|

|

|

|

|

NOTE:THE ABOVE RATINGSYWHEELAREOUTPUT,FL NOT |

ELECTRICAL GEN |

||||

|

INTERMITTENT (NB) RATINGkW |

||||

ENGINE |

1500 |

1800 |

3000 |

3600 |

|

MODEL |

r/min |

r/min |

r/min |

r/min |

|

F2M 1008 |

5.0 |

6.0 |

10.0 |

11.0 |

|

F3M 1008 |

7.5 |

9.0 |

15.5 |

16.5 |

|

F4M 1008 |

10.0 |

12.0 |

21.0 |

22.0 |

|

BF4M 1008 |

13.0 |

15.5 |

27.5 |

28.5 |

|

F2M 1008 |

F 5.5 |

6.5 |

11.0 |

11.7 |

|

F3M 1008 |

F 8.5 |

10.0 |

16.5 |

18 |

|

F4M 1008 |

F11.0 |

13.0 |

22.0 |

25 |

|

NOTE:THE ABOVETINGSRAAREYWHEELFL OUTPUT, NOT ELECTRICAL GEN

POWER RATING STANDARDS

NB-ISO 3046/1-IFN - Maximum intermittent rating with no o NA-ISO 3046/1-ICXN- Continuous rating with 10% intermittent

StandardStandard RatingProduction:° 25C,Conditions100kPa=+/Power- 5%TotalToleranceBarometric Pressure, 30%

Standard/ General: 2%° CperDerationsincrease5 in °temperatuC;1% re100moverover25 mea

13 |

©2001 / 02 |

I |

GENERAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

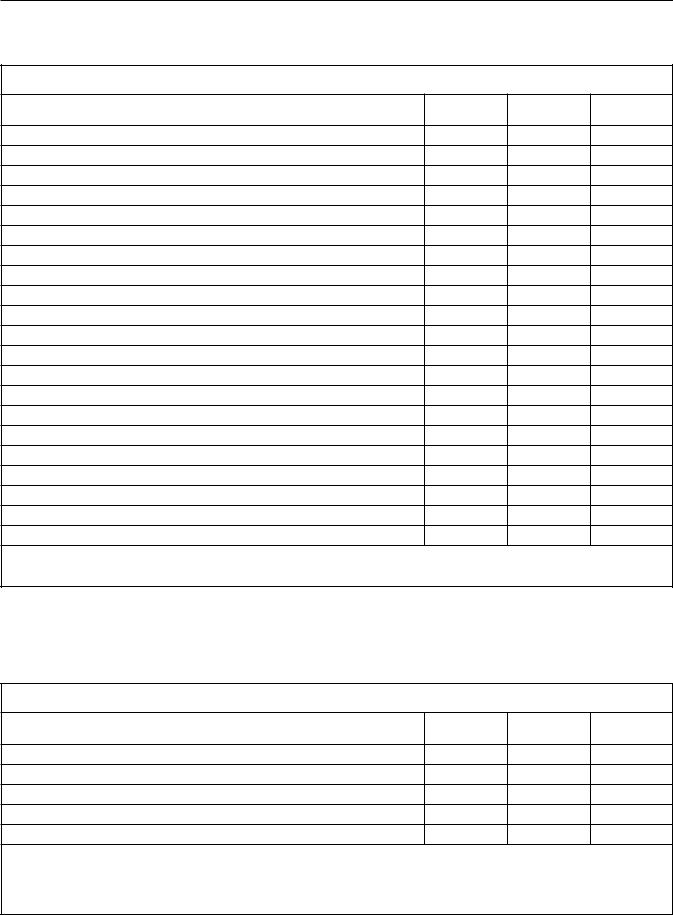

B/FM 1008 SERIESTECHNICAL SPECIFICATI |

|||||||||||||

TECHNICALSPECIFICATIONS |

F2M 1008F3M |

1008 |

4 |

F4M |

1008 |

BF4M |

||||||||

No. of Cylinders |

2 |

3 |

|

|

|

|

|

4 |

|

|

1-3 |

|||

Firing Order |

1-2 |

1-3-2 |

|

72 |

|

1-3-4-2 |

||||||||

Cylinder Bore (mm) |

72 |

72 |

|

|

|

|

|

72 |

|

|

|

|||

Cylinder Stroke (mm) |

75 |

75 |

|

|

|

75 |

|

|

75 |

1222 |

||||

Displacement (cc) |

611 |

916 |

|

|

1222 |

|

|

|||||||

Aspiration Type |

Natural |

|

|

Natural |

Natural |

|||||||||

Compression Ratio |

22.8:1 |

|

22.8:1 |

|

|

22.8:1 |

||||||||

RPMmaximum |

3600 |

3600 |

|

|

|

3600 |

|

|

|

3600 |

||||

Power- (N)- ISO 1585- KW(CV)11-@3600.8(16.r/min0)17.2(23.4) |

|

|

24.4(3 |

|||||||||||

Power- (Nb)- ISO 3046-1 IFN-10KW(CV).3(14.-0)@360015.r/min6(21.2) |

|

|

22.0(3 |

|||||||||||

Power- (Na)- ISO 3046-1 ICXN9-.2(12KW(CV).5)-@360013.7(18r/min.6) |

|

|

19.9(27 |

|||||||||||

Torque(MAX)/rpm @Nb output, 34(Nm).5/2200 |

|

53.5/2000 |

|

75.1/220 |

||||||||||

****RadialAxialInclination-LoadCONTACT(side)(max)(continuous)LoadDEUTZon-CrankshaftAPPLICATIONAPPLICATION- APPLICATION300********(bothENGINEERINGDEPENDENT300********directions)DEPENDENT300********DEPARTMENT-300********(Kg)cardiagn.comFOR |

||||||||||||||

Maximum Torque Available @ N037/1800.PTO (Nm)37/1800 |

|

37/1800 |

||||||||||||

Fuel Consumption (Nb)@3600 rpm282- (g/KWh)300 |

290 |

|

305 |

|

0. |

|||||||||

Oil Consumption (Na)- (Kg/hr)0.007 |

0.012 |

|

0.017 |

|||||||||||

Dry Weight- (Kg) |

65 |

85 |

|

|

|

96 |

|

|

101 |

|

|

|||

Inclination (max)- (30 seconds)35° |

35° |

|

|

35° |

|

|

35° |

|

|

|

||||

Inclination (max)- (60 seconds)30° |

30° |

|

|

30° |

|

|

30° |

|

|

|

||||

FLUID CAPACITIES (STANDARD) |

||||

TECHNICAL SPECIFICATIONS |

F2M 1008 F3M 1008 |

F4M 1008 |

||

Oil Capacity (including oil filter)1.6 -2.(liters)4 3.2 |

4.3 |

|

||

Oil Capacity (less oil filter)1-.5(liters)2.3 |

3.0 |

4.1 |

|

|

Coolant Capacity (including std4..0 radiator)4.9 |

-6.(liters)0 7.5 |

|

||

Coolant Capacity (engine only)0-.9(liters)1.3 |

1.8 |

2.0 |

15.0 |

|

Fuel Tank-standard (OPTIONAL)-4.(liters)3 10.0 |

15.0 |

|

||

NOTE:The above cooling system capacities (including radiator |

||||

series diesel engine is the standard Deutz radiator. D |

||||

standard Deutz radiator. Always refer to your equipment |

||||

©2001 / 0297 9985 |

14 |

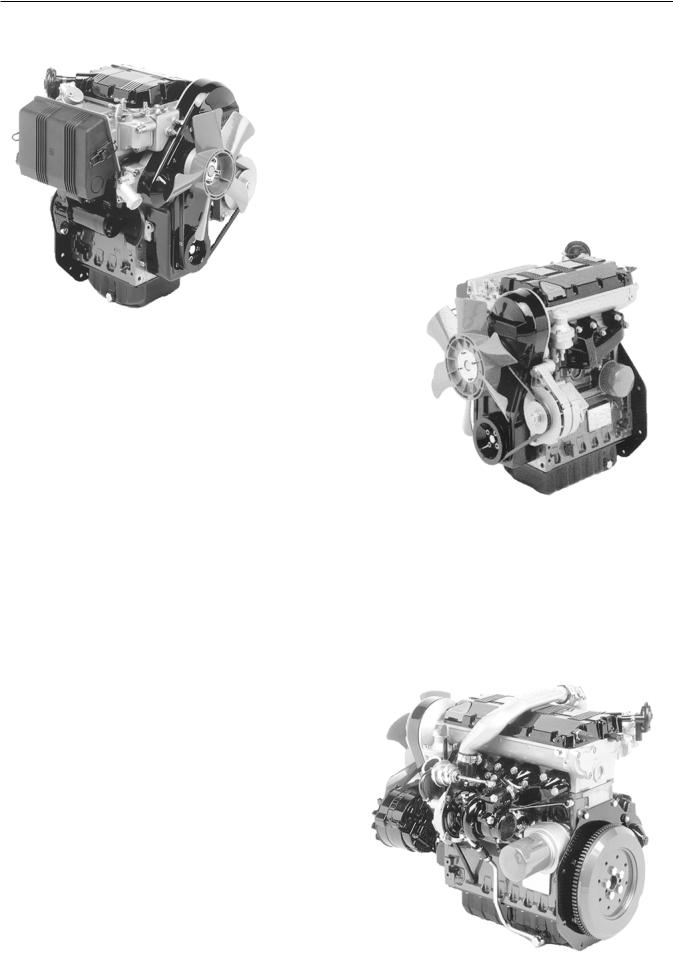

GENERAL

F2M 1008

F3M 1008  F4M 1008

F4M 1008

BF4M 1008

cardiagn.com

15 |

©2001 / 02 |

I |

GENERAL |

|

|

|

|

|

|

|

|

|

|

|

FM 1008 F SERIESTECHNICAL SPECIFICATI |

||||||||||

TECHNICALSPECIFICATIONS |

F2M 1008F3MF |

1008 |

F |

F4M 100 |

|||||||

No. of Cylinders |

2 |

|

3 |

|

4 |

1-3-4- |

|||||

Firing Order |

1-2 |

|

1-3-2 |

75 |

|||||||

Cylinder Bore (mm) |

75 |

75 |

77.6 |

|

|||||||

Cylinder Stroke (mm) |

77.6 |

|

77.6 |

|

|

||||||

Displacement (cc) |

686 |

|

1028 |

1372 |

Nat |

||||||

Aspiration Type |

Natural |

|

|

Natural |

|

||||||

Compression Ratio |

22.8:1 |

|

|

22.8:1 |

|

22.8 |

|||||

RPMmaximum |

3600 |

|

3600 |

|

3600 |

27 |

|||||

Power- (N)- ISO 1585- KW(CV)-@3600 13(17r/min.7) |

|

20(27.2) |

|

|

|||||||

Power- (Nb)- ISO 3046-1 IFN- KW(CV)11-@3600.7(16)r/min18(24.5) |

|

|

|

2 |

|||||||

Power- (Na)- ISO 3046-1 ICXN- KW(CV)10-.@36006(14.4)r/min16.3(22.2) |

|

||||||||||

Torque(MAX)/rpm @Nb output, (Nm) 40/2200 |

|

|

59/2200 |

|

82.5 |

||||||

****RadialAxialInclination-LoadCONTACT(side)(max)(continuous)LoadDEUTZon-CrankshaftAPPLICATIONAPPLICATION- APPLICATION(bothENGINEERINGDEPENDENT****300****directions)DEPENDENT300********DEPARTMENT-300********(Kg)cardiagn.comFOR |

|||||||||||

Maximum Torque Available @ N0. |

3 PTO37/1800(Nm) |

|

|

37/1800 |

|

37/1 |

|||||

Fuel Consumption (Nb)@3600 rpm- |

(g/KWh)320 |

300 |

325 |

0.019 |

|||||||

Oil Consumption (Na)- (Kg/hr) |

0.009 |

|

|

0.013 |

|||||||

Dry Weight- (Kg) |

66 |

87 |

98 |

|

|

|

|

|

|||

Inclination (max)- (30 seconds) |

35° |

35° |

|

35° |

|

|

|

|

|

||

Inclination (max)- (60 seconds) |

30° |

30° |

|

30° |

|

|

|

|

|

||

|

FLUID CAPACITIES (STANDARD) |

F4M |

|||||||||

TECHNICAL SPECIFICATIONS |

F2M 1008 |

|

F3M 1008 |

||||||||

Oil Capacity (including oil filter)-1.(liters)6 2.4 |

3.2 |

|

|

|

|

|

|||||

Oil Capacity (less oil filter)- (liters)1.5 |

2.3 |

3.0 |

|

|

|

|

|

||||

Coolant Capacity (including std. radiator)2.3 |

-4.(liters)9 6.0 |

|

|

|

|

||||||

Coolant Capacity (engine only)- (liters)0.9 |

1.3 |

1.7 |

|

|

|

|

|

||||

Fuel Tank-standard (OPTIONAL)- (liters)4.3 |

4.3 |

10.0 |

|

|

|

|

|||||

NOTE:The above cooling system capacities (including radiator |

|||||||||||

|

series diesel engine is the standard Deutz radiator. D |

||||||||||

|

standard Deutz radiator. Always refer to your equipment |

||||||||||

©2001 / 0297 9985 |

16 |

GENERAL

F2M 1008 F

F3M 1008 F

cardiagn.com

F4M 1008 F

17 |

©2001 / 02 |

I GENERAL

POWER, TORQUE AND SPECIFIC FUEL CONSUM F2/3M1008

F2M 1008

cardiagn.com

N - 80/1269/CEEISO 1585, Gross automotive ratingintermi NBISO 3046/1-IFN - Maximum intermittent rating with no ove NA-ISO 3046/1-ICXN- Continuous rating with 10% intermittent ov M(X)- Torque,NB andatNA ratingsN respectively.

C- Specific fuelNB ratingconsumption. at

StandardStandard RatingProduction° 25C,Conditions:100kPa=+/Power- 5%TotalToleranceBarometric Pressure, 30% Rela

Standard/ General2% ° perCDerations:increase5 in ° temperatueC;1% 100moverover25 mean se

©2001 / 0297 9985 |

18 |

GENERAL

POWER, TORQUE AND SPECIFIC FUEL CONS

F4M1008, BF4M 1008

F4M 1008

cardiagn.com

N - 80/1269/CEEossISOautomotive1585, Gratingintermittent operat NBISO 3046/1-IFN - Maximum intermittent rating with no NA-ISO 3046/1-ICXN- Continuous rating with 10% intermittent M(X)- Torque,NB andatNA ratingsN respectively.

C- Specific fuelNB ratingconsumption. at

StandardStandard RatingProduction° 25C,Conditions:100kPa=+/Power- 5%TotalToleranceBarometric Pressure, 30%

Standard/ General2% ° perCDerations:increase5 in °temperatuC;1% re100moverover25 mea

19 |

©2001 / 02 |

I GENERAL

POWER, TORQUE AND SPECIFIC FUEL CONSUM F2/3/4M1008 F

F2M 1008 F

F4M 1008 F

cardiagn.com

N - 80/1269/CEEISO 1585, Gross automotive ratingintermi NBISO 3046/1-IFN - Maximum intermittent rating with no ove NA-ISO 3046/1-ICXN- Continuous rating with 10% intermittent ov M(X)- Torque,NB andatNA ratingsN respectively.

C- Specific fuelNB ratingconsumption. at

StandardStandard RatingProduction° 25C,Conditions:100kPa=+/Power- 5%TotalToleranceBarometric Pressure, 30% Rela

Standard/ General2% ° perCDerations:increase5 in ° temperatueC;1% 100moverover25 mean se

©2001 / 0297 9985 |

20 |

GENERAL ENGINEERING F2M1008

F3M1008

GENERAL

DRAWINGSF2

cardiagn.com

21 |

©2001 / 02 |

I GENERAL

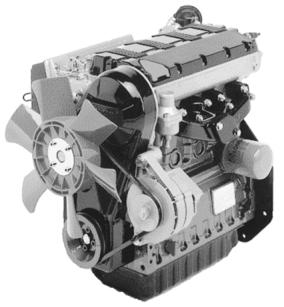

GENERAL ENGINEERING DRAWINGSF4M 100 F4M1008

BF4M1008

cardiagn.com

©2001 / 0297 9985 |

22 |

GENERAL

GENERAL ENGINEERING DRAWINGSF2/ F2M1008F

F3M 1008 F

cardiagn.com

F4M 1008 F

23 |

©2001 / 02 |

I GENERAL

Failureto carry out the operations described in the table |

|||||||

!and/or system |

|

|

|

|

|

|

|

B/FM 1008/F SERIES MAINTENANCE SCH |

|||||||

|

|

|

10 |

MAINTENANCE INTERVAL |

|||

MAINTENANCEhours50OPERATION125 250 500 10002500 |

|||||||

|

|

|

or hourshourshourshourshourshours |

||||

OIL LEVEL CHECK (D) |

|

|

DAILY |

|

|

|

|

|

|

• |

|

|

|

|

|

COOLANT LEVEL CHECK (D) |

|

• |

|

|

|

cardiagn.com |

|

FAN/ ALTERNATOR BELT) INSPECTION ( |

|

|

|

||||

• |

|

|

• |

|

• |

|

|

FAN/ ALTERNATOR BELT REPLACEMENT |

|

|

|||||

AIR FILTER ELEMENT CHECK (DRY TYPE) (*) |

|

|

|

||||

|

|

|

see note |

|

|

|

|

AIR FILTER CHECK (OIL BATH TYPE)• |

(**) |

|

|

|

|||

FLUIDRADIATORINSPECTIONLEAKCORE●(INSPECTION)-•)GENERAL ( |

•• |

|

|

|

|

||

SAFETY GUARD INSPECTION) |

( |

• |

|

|

|

|

|

• |

|

|

|

OIL TYPE) |

|

||

OIL REPLACEMENTINITIAL ONLY-(see RECOMMENDED• |

|

||||||

OIL FILTER REPLACEMENT - INITIAL |

ONLY• |

|

|

|

|||

OIL REPLACEMENT- (see RECOMMENDED OIL•TYPE) |

|

|

|

||||

OIL FILTER REPLACEMENT |

|

|

• |

|

|

|

|

FUEL FILTER REPLACEMENT |

|

|

• |

|

|

|

|

COOLANT HOSE INSPECTION |

|

|

• |

|

|

|

|

FAN/ ALTERNATOR BELT TENSION ADJUSTMENT • |

• |

|

|

||||

VALVE ADJUSTMENT |

|

|

|

|

|

|

|

FUEL INJECTION SYSTEM ADJUSTMENT |

|

• |

•• |

|

|||

COOLANTCLEAN FUELREPLACEMENT●()TANK |

(***) |

|

|

|

|

||

REPLACETIMINGBELT |

|

|

|

|

|

• |

|

(D) Add fluid(s) as required ●(•)((*)) AfterCleanReplaceinspection,asoftenairepairfilterasoradjust,requiredreplaceafterrairas requiredfilterrestriction swi

recommend the removal of air filter elements for purp (**) Service oil bath filter element (upper and lower)

NOTE:In dusty conditions, service the oil bath air fil (***) Replace coolant every 1000 hours or 2 years

NOTES:1. USE ONLY GENUINE DEUTZ REPLACEMENT PARTS. 2. USE ONLY DEUTZ APPROVED FLUIDS.

©2001 / 0297 9985 |

24 |

GENERAL

The engine could be damaged if allowed to operate wi combustion could sharply increase the rotation speed. Use a suitable oil in order to protect the engine.

The lubrication oil influences the performances and l Use of an inferior quality oil or failure to regular compression rings jam and will lead to rapid wear on will also be notably reduced.

Oil viscosity must suit the ambient temperature in wh Old oil can cause skin cancer if repeatedly left in c is inevitable, you are advised to thoroughly wash you Appropriate protective gloves etc should be wore duri Old oil is highly polluting and must be disposed of i

RECOMMENDEDOIL |

|

|

|

AGIPSINT 2000 5W40 specification API SJ/CF ACEA A3-9 |

|||

B3-96 MIL-L-46152 D/E. |

|

|

|

ESSO ULTRA 10W40 specification API SJ/CF ACEA A3-9 |

|||

MIL-L-46152 D/E. |

|

|

|

In countries where AGIP and ESSO products are not av |

|||

use API SJ/CF oil for gasoline-fuelled engines or oil |

|||

with military specification MIL-L-46152 D/E. |

cardiagn.com |

||

OIL SUPPLY (liters) F2M 1008/F |

|||

Standard oil sump |

1.6 |

|

|

filter included |

|

|

|

filter excluded |

1.5 |

|

|

OIL SUPPLY (liters) F3M 1008/F |

|

|

|

Standard oil sump |

2.4 |

|

|

filter included |

|

|

|

filter excluded |

2.3 |

|

|

OIL SUPPLY (liters) F4M 1008/F |

|

|

|

Standard oil sump |

3.2 |

|

|

filter included |

|

|

|

filter excluded |

3.0 |

|

|

OIL SUPPLY (liters) BF4M 1008 |

|

|

|

Standard oil sump |

4.3 |

|

|

filter included |

|

|

|

filter excluded |

4.1 |

|

|

GRADE |

|

|

|

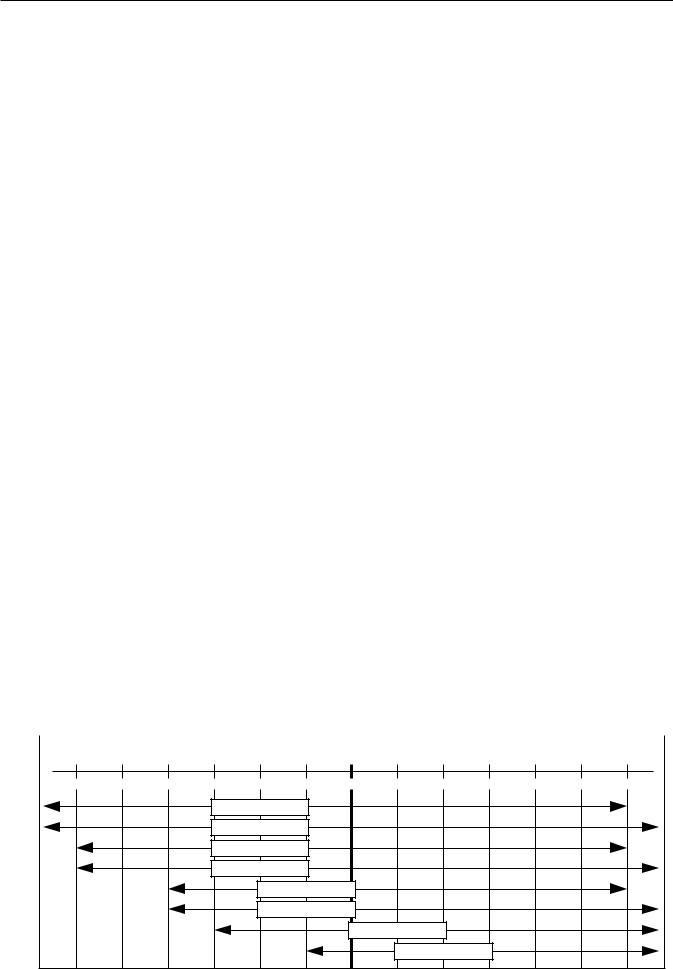

-30-25-20-15-10-5 0 |

5 |

10 |

15 |

20 ° 25C |

SAE 0W-30 |

|

|

|

|

SAE 0W-40 |

|

|

|

|

SAE 5W-30 |

|

|

|

|

SAE 5W-40 |

|

|

|

|

SAE 10W-30 |

|

|

|

|

SAE 10W-40 |

|

|

|

|

SAE 15W-30 |

|

|

||

|

SAE 20W-50 |

|

||

25 |

|

|

|

©2001 / 02 |

Loading...

Loading...