Operation Manual

2011

Safety guidelines / Accident prevention

● Please read and observe the information

given in this Operation Manual. This will

enable you to avoid accidents, preserve

the manufacturer’s warranty and maintain

the engine in peak operating condition.

● This engine has been built exclusively for

!

the application specified in the scope of

supply, as described by the equipment

manufacturer and is to be used only for the

intended purpose. Any use exceeding that

scope is considered to be contrary to the

intended purpose. The manufacturer will

not assume responsibility for any damage

resulting therefrom. The risks involved are

to be borne solely by the user.

● Use in accordance with the intended purpose also implies compliance with the conditions laid down by the manufacturer for

operation, maintenance and servicing. The

engine should only be operated by personnel trained in its use and the hazards

involved.

● The relevant accident prevention g uidelines

and other generally accepted safety and

industrial hygiene regulations must be observed.

● When the engine is running, there is a risk

of injury through:

- turning/hot components

- engines with positive ignition

- ignition systems (high electrical voltage)

You must avoid contact at all times!

● Unauthorized engine modifications will invalidate any liability claims against the manufacturer for resultant damage.

Manipulations of the injection and regulating

system may also influence the performance

of t he engine, and its emissions. Adherence

to legislation on pollution c annot be guaranteed under such conditions.

● Do not change, convert or adjust the cooling

air intake area to the blower.

The manufacturer shall n ot be held responsible for any damage which results from

such work.

● When carrying out maintenance/repair operations on the engine, the use of DEUTZ

original parts is prescribed. These are

specially designed for your engine and

guarantee perfect operation.

Non-compliance results in the expiry of the

warranty!

● Maintenance and cleaning of the engine

should only be carried out when the engine

is switched off and has cooled down.

You must ensure that the electrical systems

have been switched off and the ignition

key has been removed.

Accident prevention guidelines concerning

electrical systems (e.g. VDE-0100/-0101/

-0104/-0105 Electrical protective measures

against dangerous touch voltage) are to be

observed.

When cleaning with fluids, all electrical

components are to be covered impermeably.

Engine Serial

Number:

Please enter the engine serial number here.

This number should be quoted when inquiring

about Customer Service, Repairs or Spare

Parts (see Section 2.1).

Te chnical modifications required to improve

our engines are reserved with regard to

specification data and other technical

information contained in this Operation Manual. No parts of this Manual may be

reproduced in any form or by any means

without our written approval.

Operation manual

2011

0297 9929 en

2004

©

Foreword

Dear Customer,

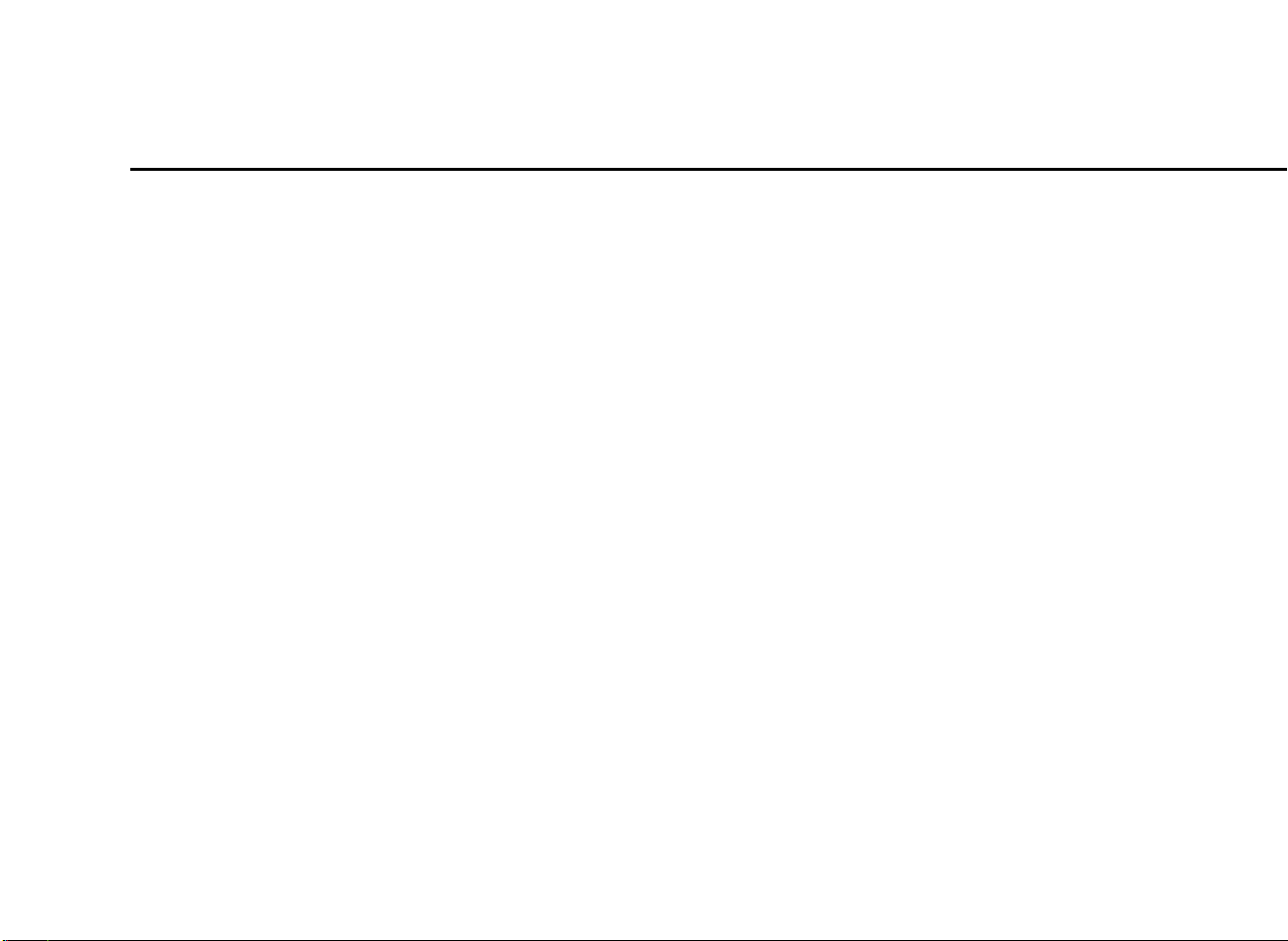

Liquid-cooled Deutz engines are designed

for a large number of applications.

Consequently, a wide range of variants is

offered to meet the requirements of specific

cases.

Your engine is appropriately equipped for the

installation concerned, which means that not

all of the components described in this Operation Manual are necessarily fitted to your

engine.

We have endeavoured to highlight any

differences so that you will be able to locate

the operating and maintenance instructions

relevant to your engine quickly and easily.

Please read this Manual before starting your

engine, and always observe the operating

and maintenance instructions.

We are available to help with any additional

inquiries

Sincerely,

DEUTZ AG

Contents

1. General

Engine Description

2.

2.1 Model

2.1.1 Rating Plate

2.1.2 Position of the Rating Plate

2.1.3Engine Serial Number

2.1.4 Cylinder Numbering

2.1.5 Fuel Delivery Lock

2.2 Engine Illustrations

2.2.1Operation Side:

Example FL 2011

2.2.2 Exhaust Side:

Example FL 2011

2.2.3 Operation Side:

Example BF4L 2011

2.2.4 Exhaust Side:

Example BF4L 2011

2.2.5 Operation Side:

Example FM 2011

2.2.6 Exhaust Side:

Example FM 2011

2.2.7 Operation Side:

Example BFM 2011

2.2.8 Exhaust Side:

Example BFM 2011

2.3 Oil Circuit

2.3.1Lube Oil Circuit Schematic

2.4Fuel System Schematic

2.4.1Fuel System

2.5 Coolant System

2.5.1 Coolant Plan

3. Engine Operation

3.1 Commissioning

3.1.1 Adding Engine Oil

3.1.2 Adding Fuel

3.1.3 Other Preperations

3.1.4 Additional Maintenance Work

3.2 Starting

3.2.1 Electric Starting

3.3 Monitoring Operation

3.3.1 Engine Oil Pressure

3.3.2 Engine Te mperature

3.4 Shutting Off

3.4.1 Mechanical Shut-Off

3.4.2 Electric Shut-Off

3.5 Operating Conditions

3.5.1Winter Operation

3.5.2High Ambient Te mperature, High

Altitude

4. Operating Media

4.1Lube Oil

4.1.1 Quality

4.1.2 Viscosity

4.2 Fuel

4.2.1Quality

4.2.2 Winter-Grade Fuel

Service

5.

5.1 Service Plan

5.2 Scheduled Maintenance Plan

5.3 Maintenance Chart

5.4 Maintenance Work Completed

6. Service and Maintenance

6.1 Lubrication System

6.1.1 Oil Change Intervals

6.1.2 Check Oil Level, Change Engine Oil

6.1.3Changing Oil Filter

6.1.4 Clean/Replace Oil Filter (Cup)

6.2Fuel System

6.2.1 Replace Fuel Filter

6.2.2 Clean/Replace Fuel Filter (Cup)

6.2.3 Clean Stainer of Fuel Filter

6.2.4 Change Fuel Leakage Line

6.3Cooling System

6.3.1Cleaning Intervals

6.4 Combustion Air Filter

6.4.1Cleaning Intervals

6.4.2 Emptying Cyclone-Type Precleaner

6.4.3 Dry Type Air Cleaner

6.5 Belt Drives

6.5.1 Check V-belt

6.5.2 Te nsioning Alternator Belts

6.5.3 Changing Alternator Belts

6.6 Adjustments

6.6.1 Check Valve Clearance, adjust if

necessary

6.6.1.1Valve Clearance Adjustment

Schematic

6.7 Accessories

6.7.1 Battery

6.7.2 Rotary Current Alternator

6.7.3Transportation Shackles

6.8 Engine Cleaning

6.8.1 Engine Cleaning

Contents

7. Faults, Causes and

Remedies

7.1 Fault Table

Engine Preservation

8.

8.1 Preservation

8.1.1Preserving Engine

8.1.2Removing Engine Preservatives

9. Technical Specification

9.1 Engine Specifications and Settings

9.2 To rque Wrench Settings

9.3 To ols

10. Service

2004

©

2004

©

General

DEUTZ Diesel Engines

1

are the product of many years of research

and development. The resulting know-how,

coupled with stringent quality standards,

guarantee their long service life, high reliability

and low fuel consumption.

It goes without saying that DEUTZ Diesel

Engines meet the highest standards for environmental protection.

Beware of Running Engine

Shut the engine down before carrying out

maintenance or repair work. Ensure that the

engine cannot be accidentally started. Risk of

accidents.

When the work is complete, be sure to refit

any panels and guards that may have been

removed.

Never fill the fuel tank while the engine is

running.

Observe industrial safety regulations when

running the engine in an enclosed space or

underground.

Care and Maintenance

Sound care and maintenance practices will

ensure that the engine continues to meet the

requirements placed on it. Recommended

service intervals must be observed and

service and maintenance work carried out

conscientiously.

Special care should be taken under abnormally

demanding operating conditions.

Safety

This symbol i s used for all safety

warnings. Please follow them

carefully. The attention of

!

operating personnel should be

instructions. General safety and accident

prevention regulations laid down by law must

also be observed.

drawn to these safety

Asbestos

Service

Please contact one of our authorized service

representatives in the event of breakdowns

or for spare parts inquiries. Our trained

specialists will carry out repairs quickly and

professionally, using only genuine spare

parts.

Original parts from DEUTZ AG are always

produced in accordance with state-of-theart technology.

Please turn to the end of this manual for

further service information.

California

Proposition 65 Warning

Diesel engine exhaust and some of its

constituents are known to the State of

California to cause cancer, birth defects,

and other reproductive harm.

4

200

©

DEUTZ original parts are

asbestos-free.

Engine Description

Model

2.1

Engine Illustrations

2.2

2.3 Lube Oil Circuit Schematic

2.4 Fuel System Schematic

2

2004

©

Engine Description 2.1 Model

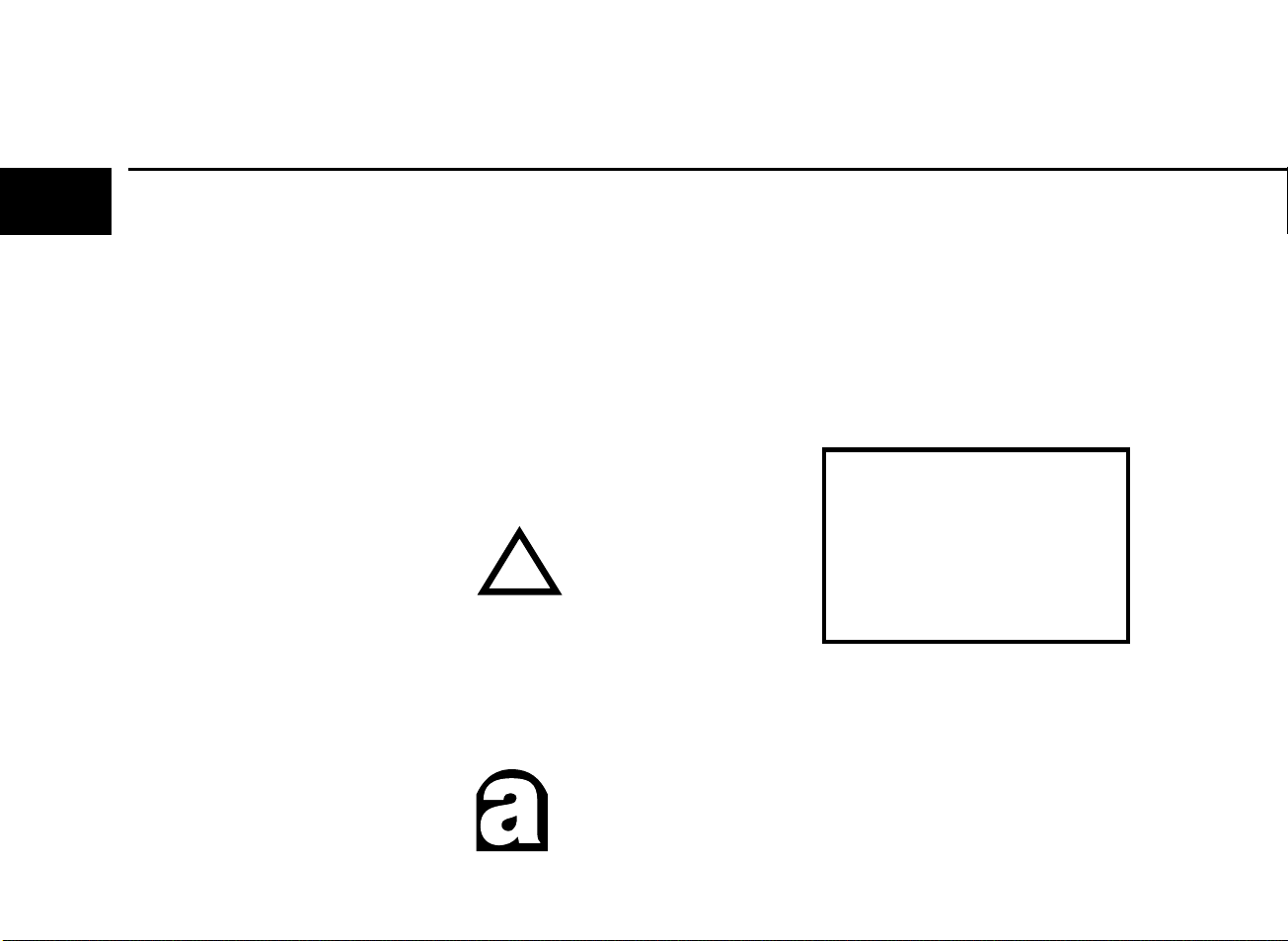

Rating P

2.1.1

late

2

A

The model A , the engine serial number B and

the performance data are stamped on the

rating plate.

The model and engine serial number must be given

when ordering parts.

B

© 26 332 2

Position

2.1.2

of the Rating Plate

C

31 864 0

©

The rating plate C is attached to the valve

cover.

Engine

2.1.3

The engine serial number B is stamped on

the crankcase D as well as the rating plate.

Serial Number

©

31 865 0

2004

©

2.1 Model Engine Description

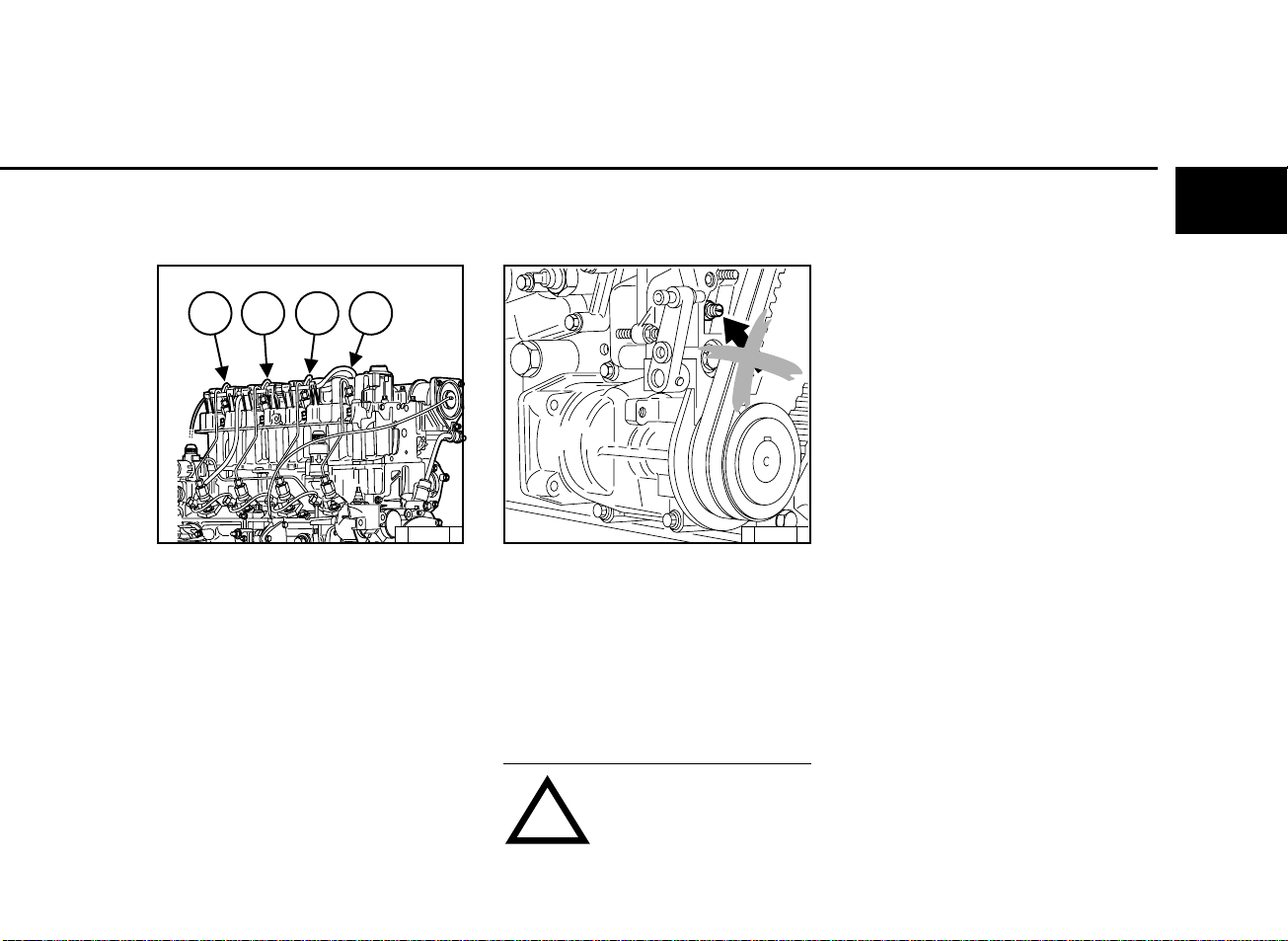

Cylinder

2.1.4

Numbering

1234

26 431

©

Cylinders are numbered consecutively,

beginning at the flywheel.

Fuel

2.1.5

0

The manufacturer shall not be held liable for

damages resulting from adjustments made

to the regulator by the operator.

The lock screws are protected in order to

prevent this:

1. with locking paint on model:

with torque balancer

2.with plastic protective cap on model:

without torque balancer.

Delivery Lock

©

26 387

2

0

Adjustments to the regulator

are to be carried out only by

!

authorised DEUTZ SERVICE

specialists

2004

©

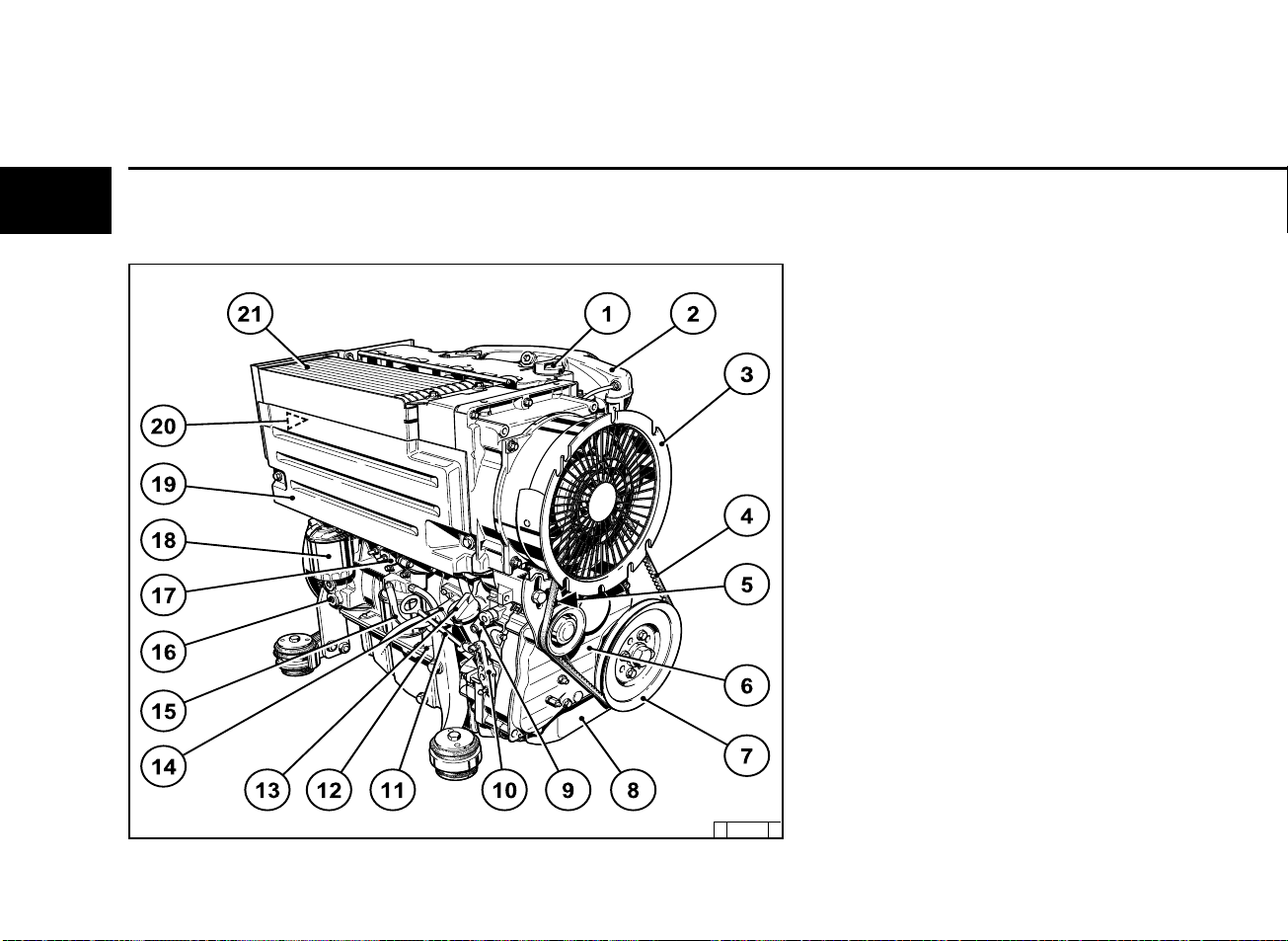

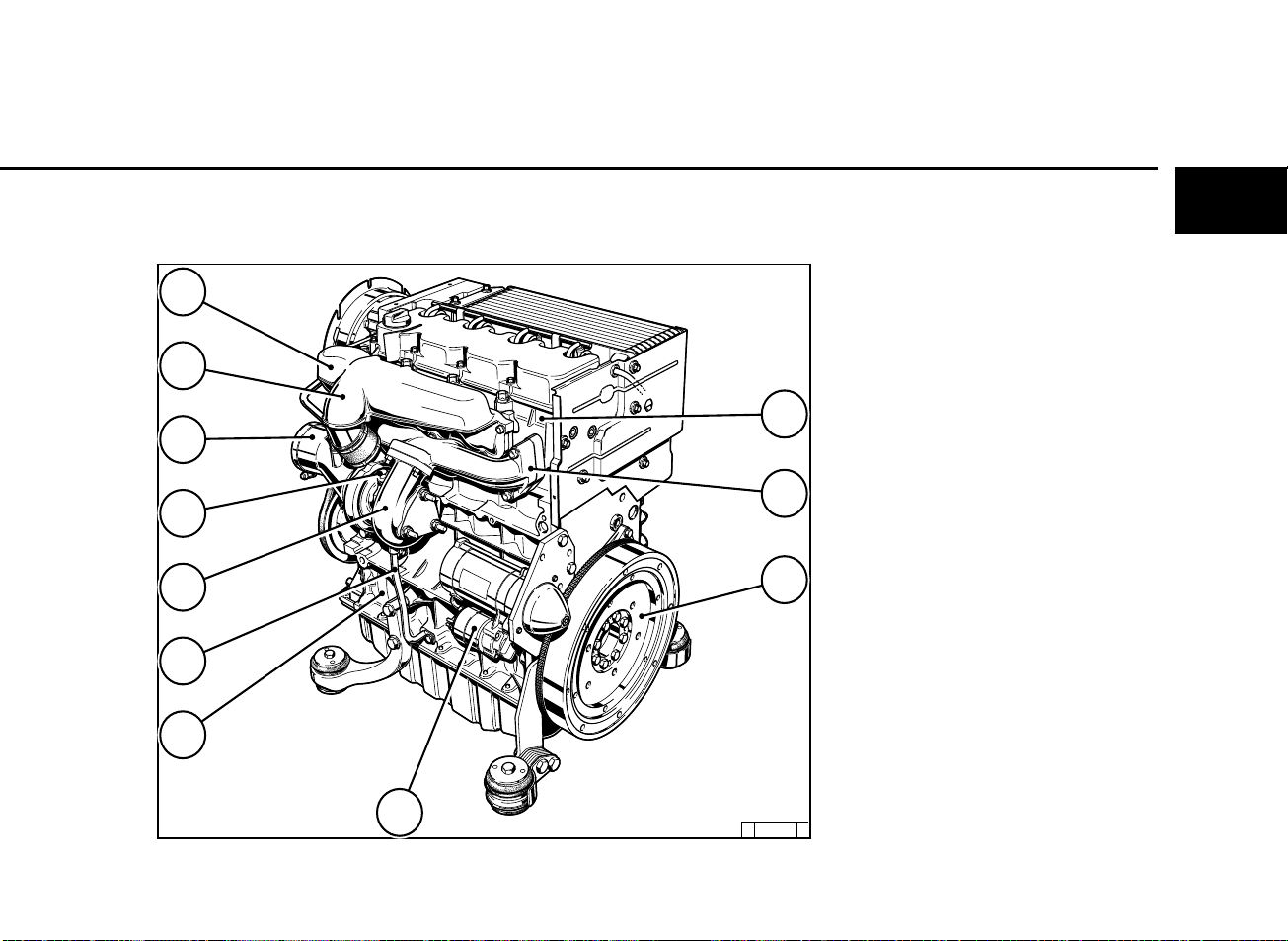

Engine Description 2.2 Engine Illustration

Operation

2.2.1

2

FL 2011

21

20

19

18

17

Side

1Oil filler neck (valve-gear housing cover)

1

2

3

4

5

6

2 Charge-air line / air-intake line

3 Fan with integrated generator

4 Narrow V-belt

5Tractive electromagnet

6 Wheel-house cover

7 V-belt pulley on crankshaft

8 Oil pan

9Shut-off lever

10 Speed control lever

11 Oil dipstick

12 Oil drain plug

13 Crankcase

14 Oil fill point (on side of crankcase)

15 Fuel pump

16 Easy-change fuel filter

17 Connecting facility for oil heater

18 Lube oil replacement filter

19 Removable coolant intake hood

20 Injection pumps

21 Oil cooler

2004

©

16

7

15

9 81214 13 11 10

© 31 873 1

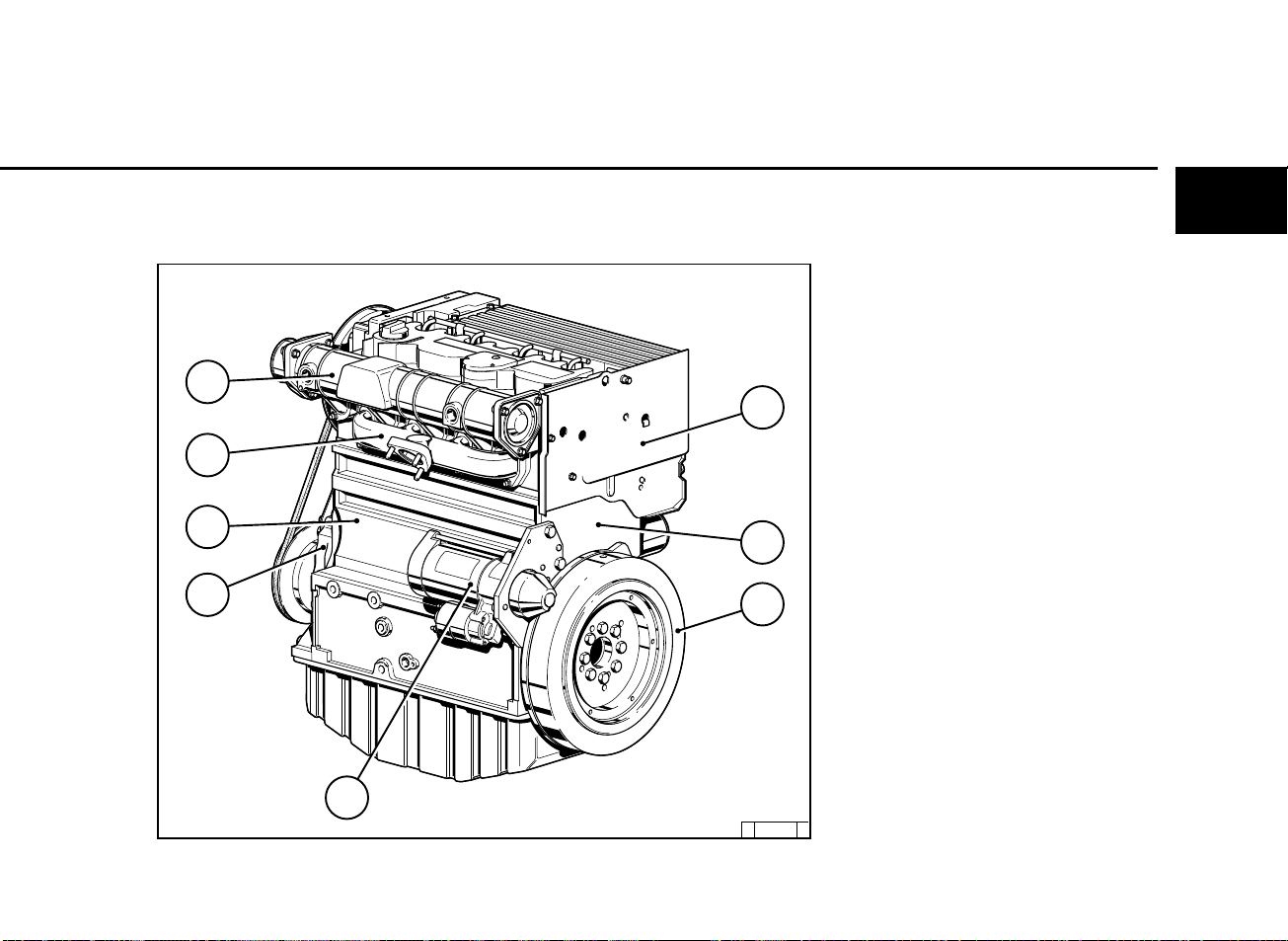

2.2 Engine Illustration Engine Description

Exhaust

2.2.2

FL 2011

29

28

Side

22 Date plate

23 Optional attachment of an SAE housing

24 Flywheel with ring gear

25 Starter

26 Front cover

27 Crankcase

28 Exhaust manifold

29 Air intake pipe

22

2

27

26

26

23

24

© 31 874 1

2004

©

Engine Description 2.2 Engine Illustration

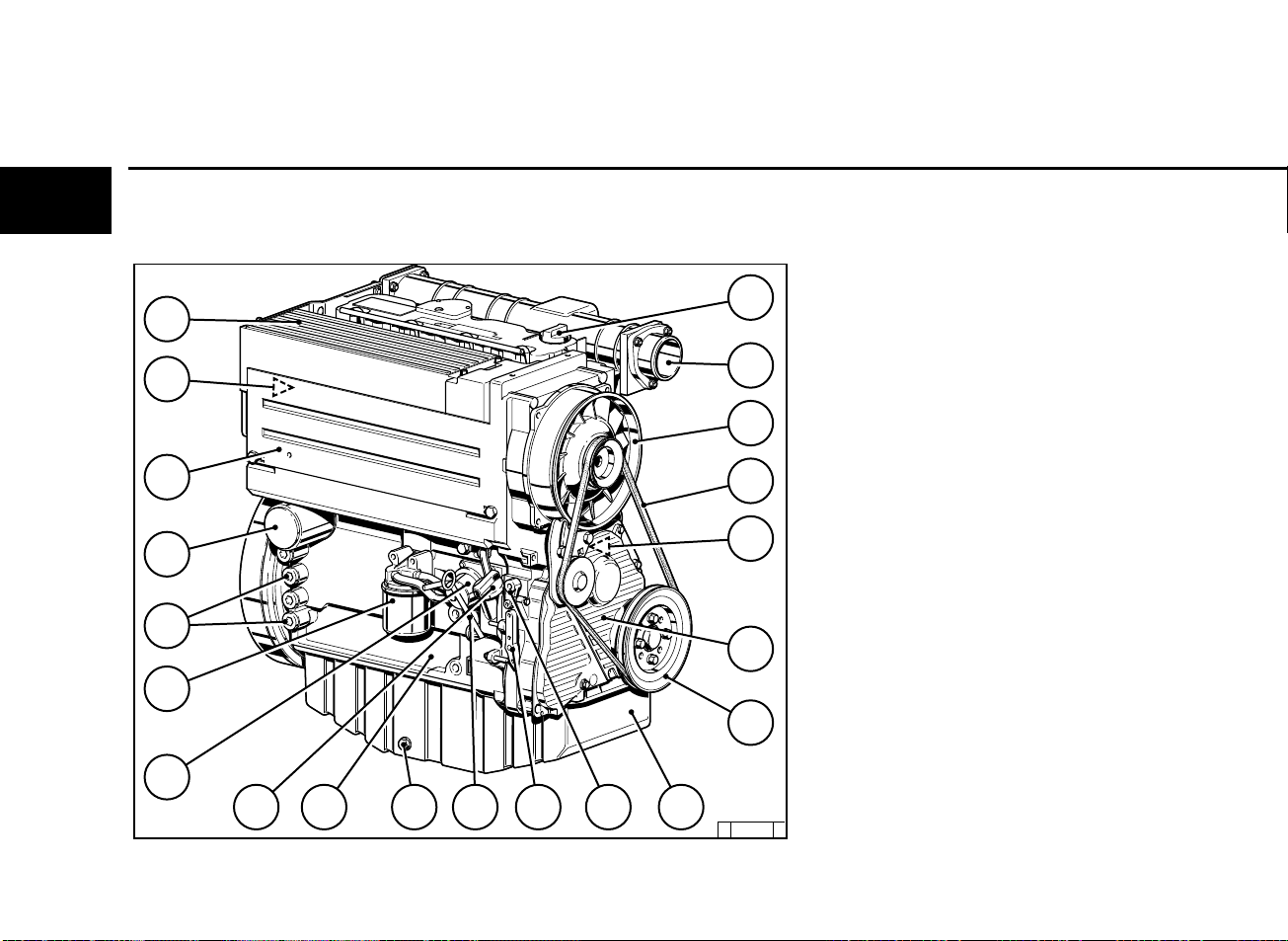

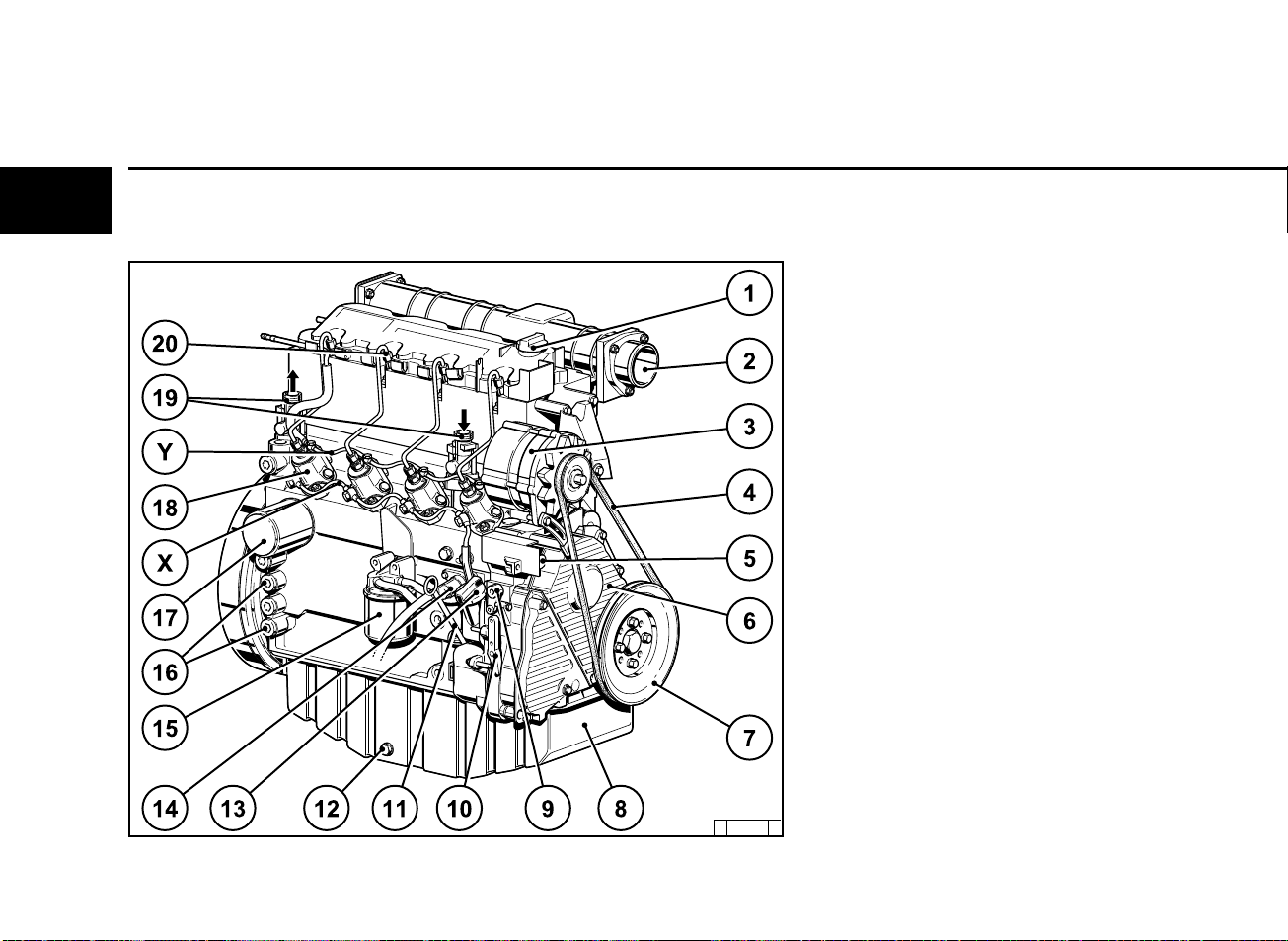

Operation

2.2.3

2

Example: BF4L 2011

Side

1Oil filler neck (valve-gear housing cover)

2 Charge-air line / air-intake line

3 Fan with integrated generator

4 Narrow V-belt

5Tractive electromagnet

6 Wheel-house cover

7 V-belt pulley on crankshaft

8 Oil pan

9Shut-off lever

10 Speed control lever

11 Oil dipstick

12 Crankcase

13 Oil fill point (on side of crankcase)

14 Fuel pump

15 Easy-change fuel filter

16 Connecting facility for oil heater

17 Charge-pressure-dependent full-load stop

(CPD)

18 Lube oil replacement filter

19 Removable coolant intake hood

20 Injection pumps

21 Oil cooler

2004

©

© 31869 2

2.2 Engine Illustration Engine Description

Exhaust

2.2.4

Example: BF4L 2011

32

31

29

27

Side

22

23

22 Cylinder head

23 Exhaust manifold line

24 Flywheel with ring gear

25 Starter

26 Crankcase

27 Lube oil feed line to turbocharger

28 Lube oil return line from turbocharger

29 Induction pipe

30 Turbocharger (TC)

31 Intake manifold

32 Charge-air line

2

30

28

26

25

24

© 31 868 1

2004

©

Engine Description 2.2 Engine Illustration

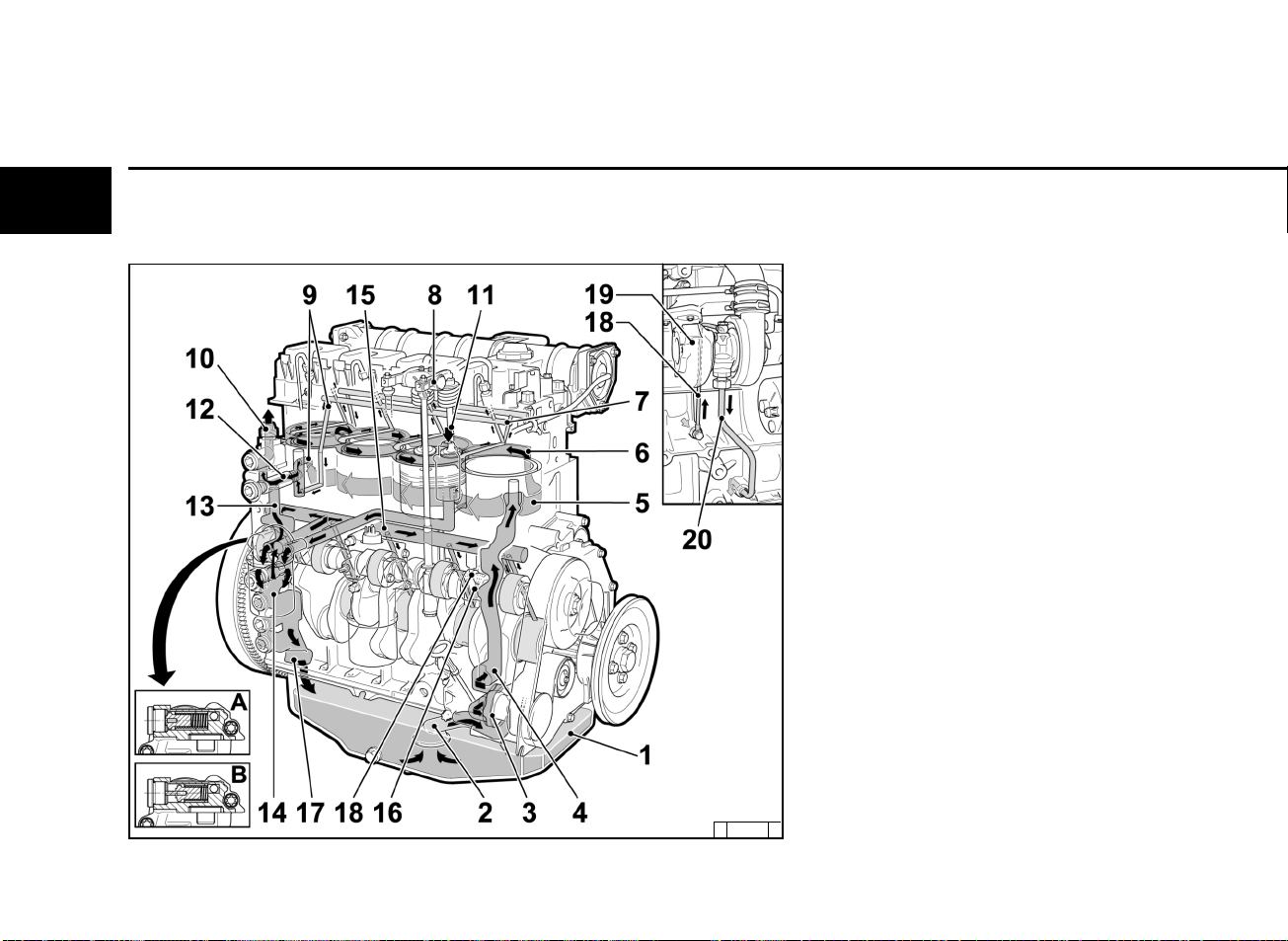

2.2.5 Operation Side

2

FM 2011

1Oil filler neck (valve-gear housing cover)

2 Charge-air line / air-intake line

3 Alternator

4 Narrow V-belt

5 Tractive electromagnet

6 Timing belt cover

7 V-belt pulley on crankshaft

8 Oil pan

9 Shut-off lever

10 Speed control lever

11 Oil dipstick

12 Oil drain plug

13 Oil fill point (on side of crankcase)

14 Fuel pump

15 Easy-change fuel filter

16 Connecting facility for oil heater

17 Lube oil replacement filter

18 Injection pump(s)

19 Oil cooler connection

20 Injection valve(s)

Xfuel to run line

Yfuel back run line

2004

©

31 875 3

©

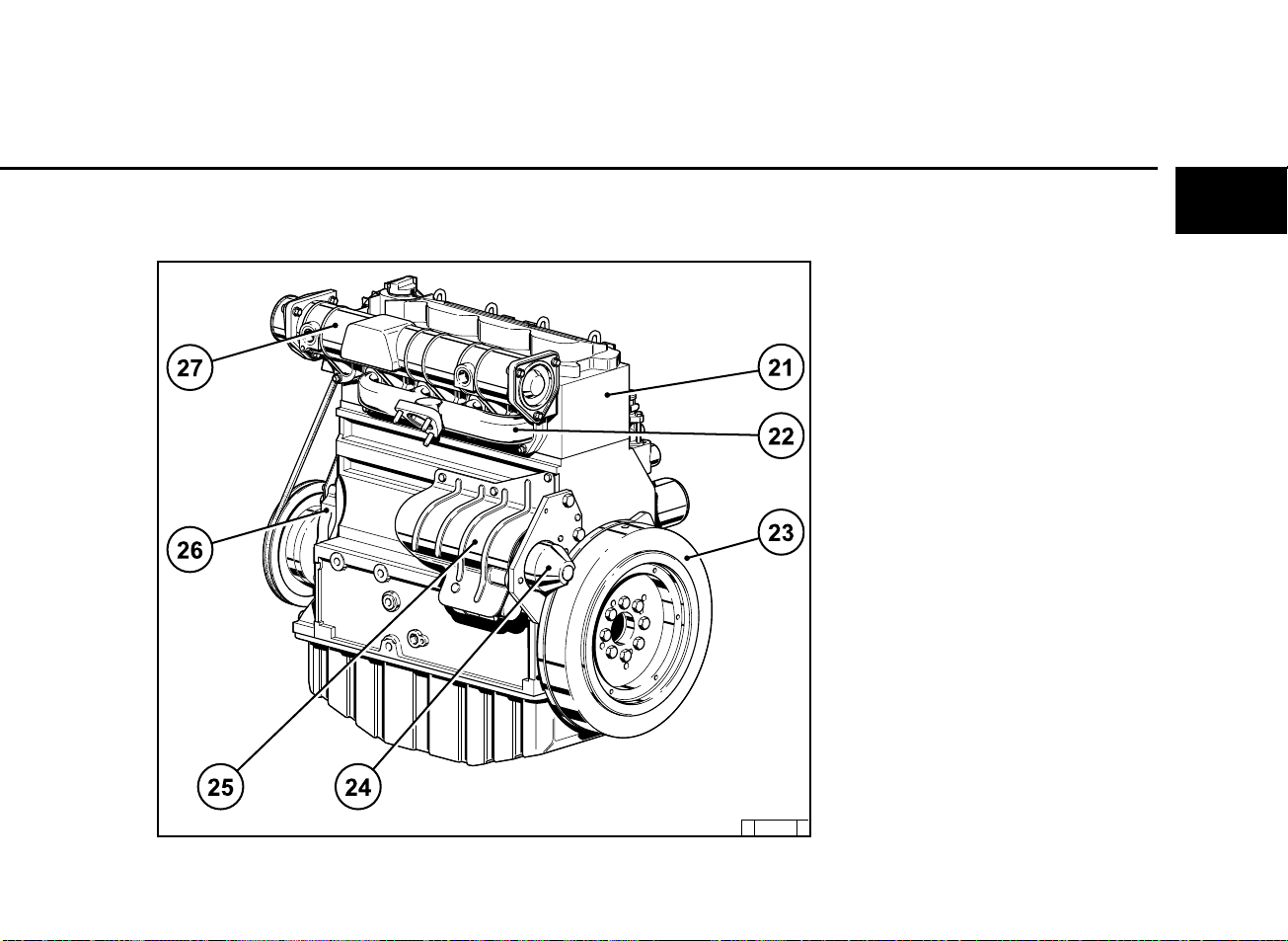

2.2 Engine Illustration Engine Description

Exhaust Side

2.2.6

FM 2011

21 Cylinder head

22 Exhaust manifold

23 Flywheel with ring gear

24 Starter

25 Starter guard (optional)

26 Crankcase

27 Air intake pipe

2

31876 2

©

2004

©

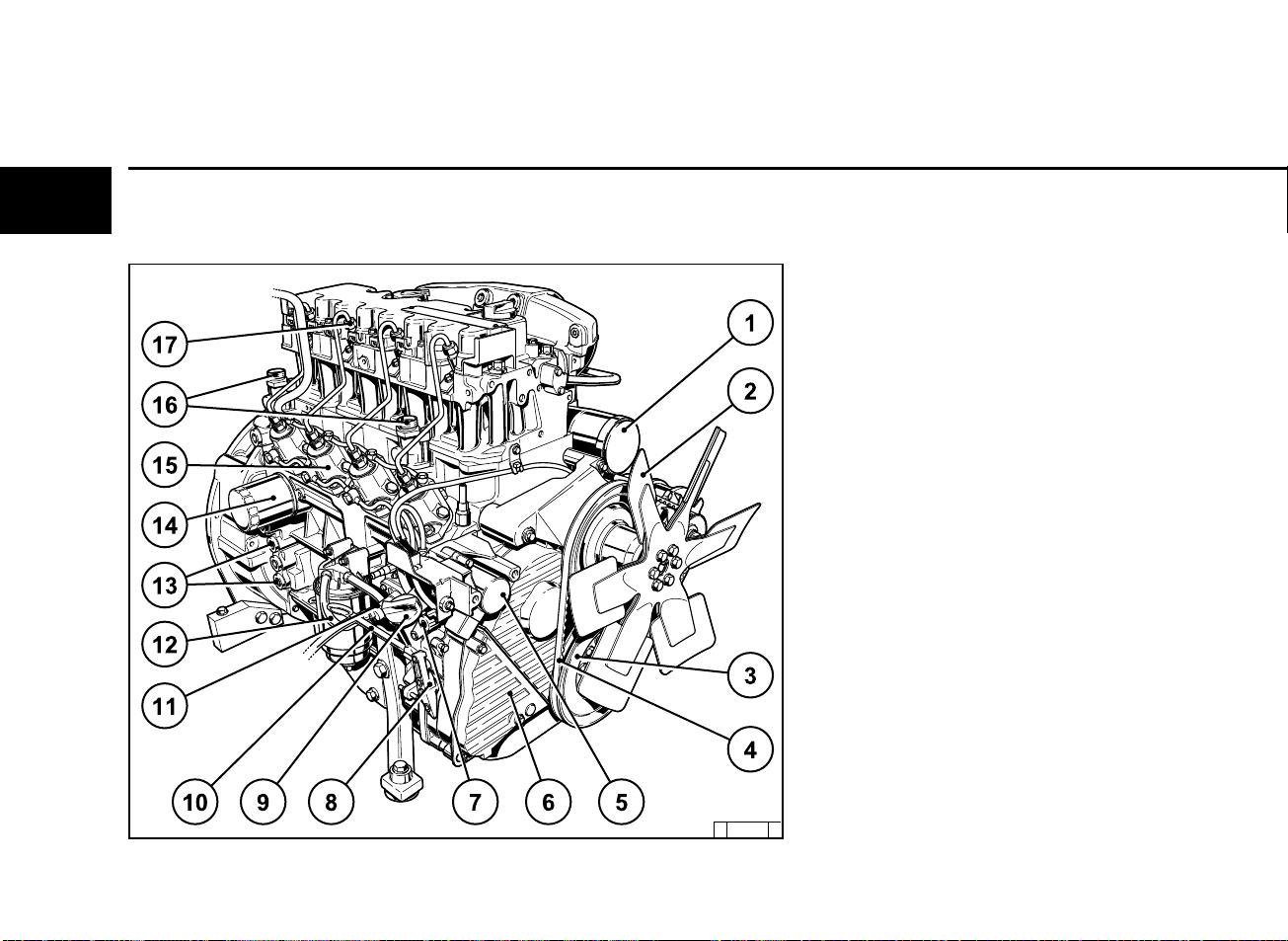

Engine Description 2.2 Engine Illustration

Operation Side

2.2.7

2

BFM 2011

1 Air-intake pipe

2 Fan wheel

3 V-belt pulley on crankshaft

4 Narrow V-belt

5 Tractive electromagnet

6 Timing belt cover

7 Shut-off lever

8 Speed control lever

9 Oil fill point (on side of crankcase)

10 Oil dipstick

11 Fuel pump

12 Easy-change fuel filter

13 Connecting facility for oil heater

14 Lube oil replacement filter

15 Injection pump(s)

16 Oil cooler connection

17 Injection valve(s)

2004

©

© 31 861 3

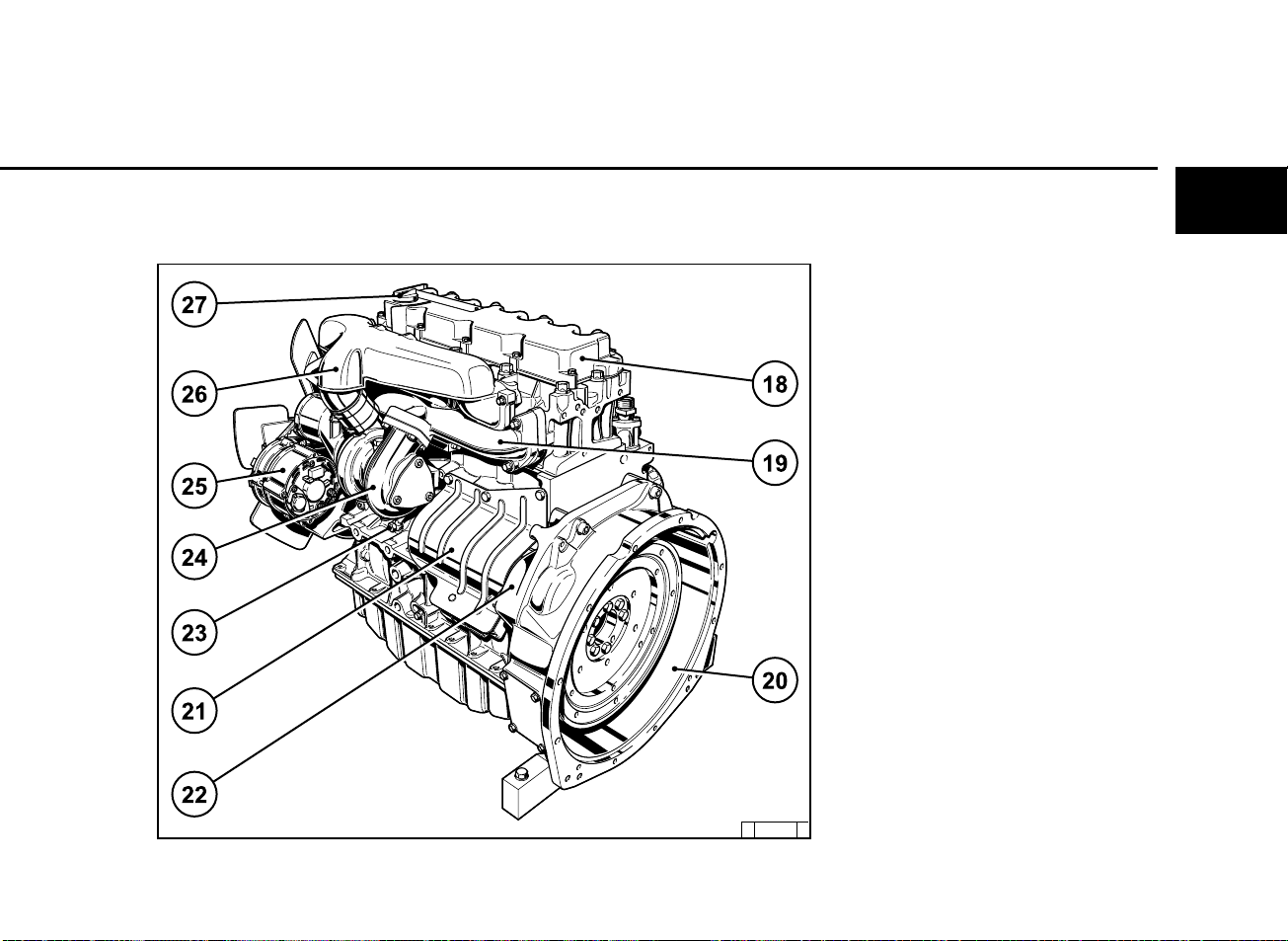

2.2 Engine Illustration Engine Description

Exhaust Side

2.2.8

BFM 2011

18 Crankcase ventilation (optional)

19 Cylinder head cover

20 Exhaust manifold

21 SAE housing

22 Starter

23 Crankcase

24 Turbocharger

25 Generator with cover

26 Charge-air line

27 Oil filler neck

2

© 31 862 3

2004

©

Engine Description 2.3 Oil Circuit

Lube Oil Circuit Schematic

2.3.1

2

1Oil pan

2Oil-intake pipe

3Oil pump

4Main oil duct

5Oil-cooled cylinders

6Cylinder head cooling neck

7Oil duct for rocker arm lubrication

8Rocker arm

9Oil manifold for the thermostat

10 Intake to external engine oil cooler

11 Return from external engine oil cooler

12 Thermostat h ousing with slide thermostat

13 Oil duct to oil filter

14 Oil filter

15 Oil duct to cam, con-rod and crankshaft

bearings

16 Spray nozzle for piston cooling

17 Oil return via crankcase to oil pan

18 Lube oil intake to turbocharger

19 Turbocharger

20 Return from turbocharger to oil pan

Oil filter console with integrated switching

valve for the control o f the hydraulic tappets

(arrow)

Aengine is cold (around an early adjustment

of the beginning of delivery to reach,

the pistons in the pump tappet with oil

become ge feed)

Bengine is warm

2004

©

© 31877 2

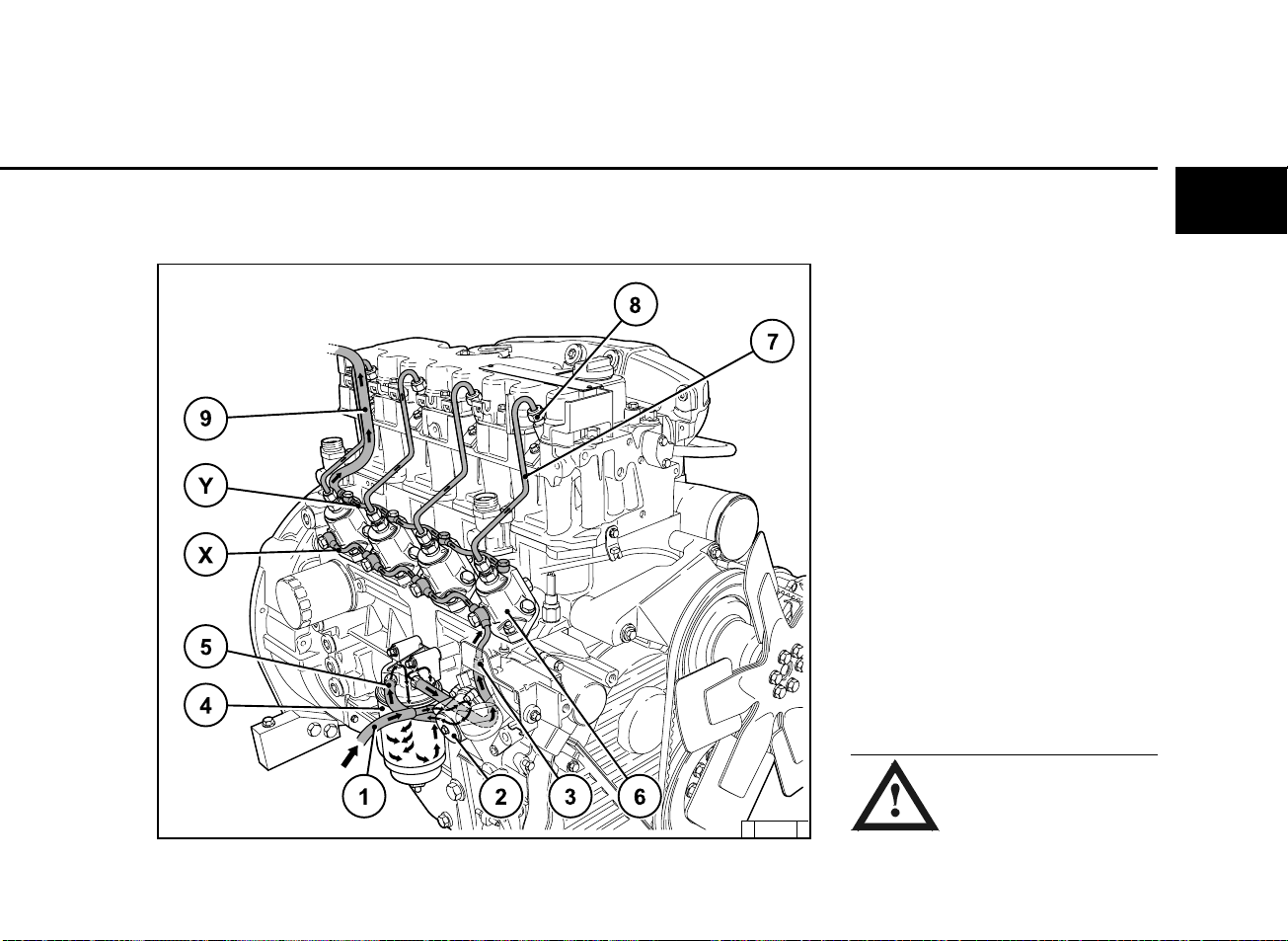

2.4 Fuel System Schematic Engine Description

Fuel System

2.4.1

1 Fuel line from tank to fuel pump

2 Fuel pump

3 Fuel line from fuel pump to easy-change fuel

filter

4Easy-change fuel filter

5Fuel line from filter to injection pump

6 Injection pump

7 Fuel distributor line

8 Injection line

9 Injection valves

xFuel overflow pipe

yFuel return line to tank

2

31 863 2

©

The installation of a fuel pre-filter/

hand pump between the fuel tank

and the engine is prescribed to

protect the engines against dirt in

the fuel.

2004

©

2

2004

©

3.1 Commissioning

3.2 Starting

Monitoring Operation

3.3

Shutting Off

3.4

Engine Operation

3

3

2004

©

Engine Operation

3.1 Commissioning

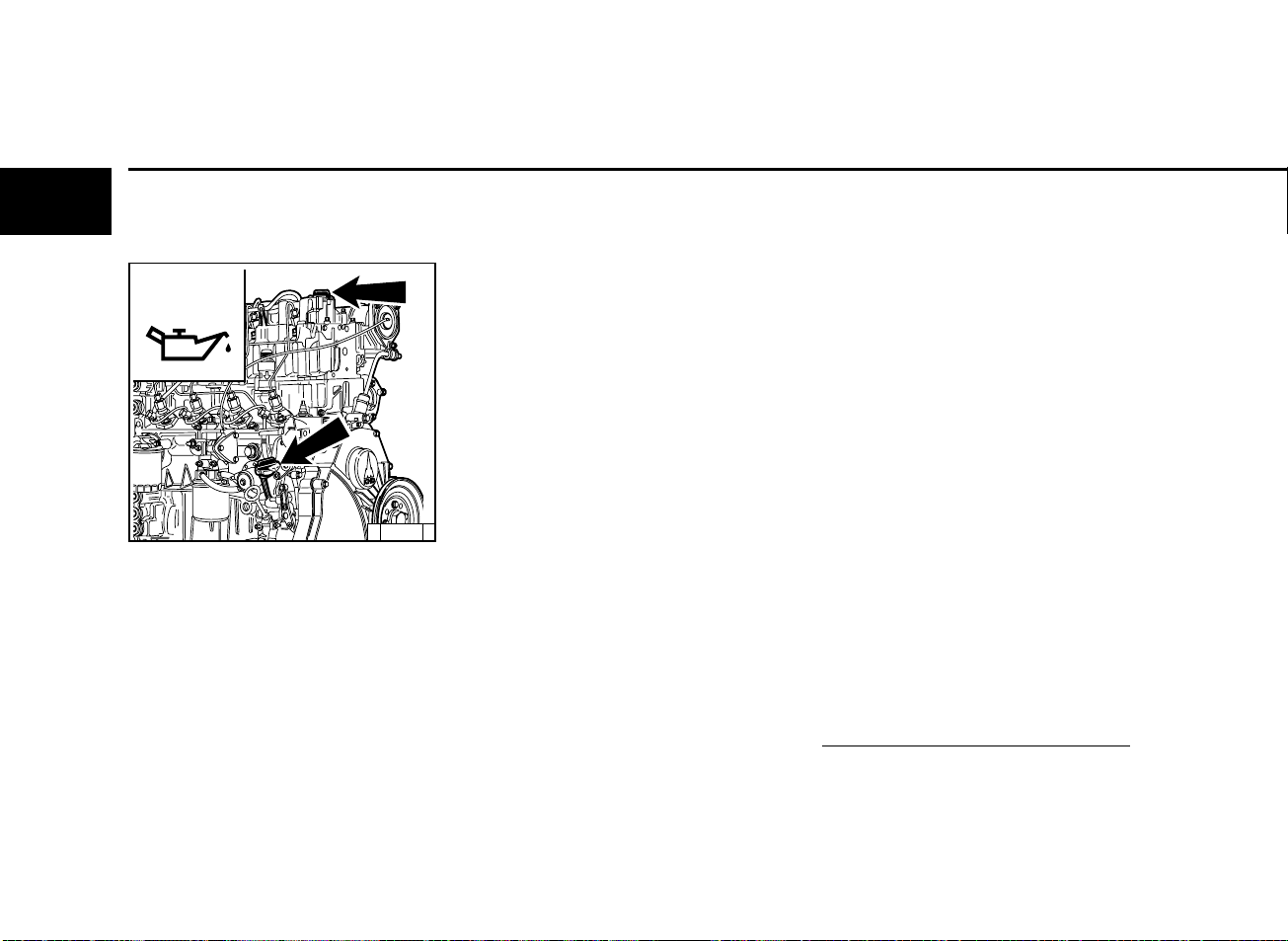

3.1.1 Adding Engine Oil

3

OIL

As a rule, engines are delivered without oil.

Pour lube oil into the oil filler neck (arrow).

For oil grade and viscosity, see 4.1.

2004

©

© 26 432 0

3.1.1.1 Initial Engine Oil Fill-Up

forB/FL 2011

● Fill oil into oil pan up to "Max." mark on engine

dipstick (for oil quantity see 9.1).

● Start engine and allow to run at low idling

speed for approx. 2 mins.

● Switch off engine.

● Check oil level, if necessary, t op up oil to "Max."

mark.

3.1.1.2 Initial Engine Oil Fill-Up

B/FM 2011

● Fill oil into oil pan up to "Min." mark on engine

dipstick.

● In addition, top up oil quantity of supply

hoses and of external oil cooler (according

to manufacturer’s specifications).

● Allow engine to run warm until thermostat opens

(at approx. 95°C).

● Allow engine to run for approx. 2 mins.

● Switch off engine.

● Check oil level, and if necessary, top up oil to

"Max." mark.

If the person operating the engine does not run up

the engine until the thermostat opens, the oil level

may lie above the "Max." mark on the engine

dipstick when delivered. The level can then only be

assessed after the engine has been run up.

3.1 Commissioning Engine Operation

3.1.1.3 Initial Engine Oil Fill-Up

B/FM 2011 Genset Engine

● Fill oil into oil pan up to "Max." mark on engine

dipstick (for oil quantity see 9.1).

● Start engine and allow to run at low idling speed

for approx. 2 mins.

● Switch off engine.

● Check oil level and fill up with oil up to upper

"Max." mark.

3.1.2 Adding Fuel

FUEL

© 26 398 0

Use only commercial-grade diesel fuel. For fuel

grade, see 4.2. Use summer or winter-grade fuel,

depending on the ambient temperature.

3

3

Never fill the tank while the engine

is running.

Ensure cleanliness!

!

Do not spill fuel!

2004

©

Engine Operation 3.1 Commissioning

3.1.3 Other Preparations

3

● Check battery and cable connectors,

see 6.7.1.

● Transport hooks

Remove if fitted (see 6.7.3)

● Trial run

After engine has been prepared, let it run for

about 10 minutes without being loaded.

During and after trial run

-Check engine for leaks.

After engine has been turned off

-Check oil level,

see 6.1.2.

Top up with oil, if necessary,

see 3.1.1.

-Retension V-belt,

see 6.5).

3.1.4 Additional Maintenance Work

When commissioning new and reconditioned engines, the following additional maintenance work

must be carried out:

● Change lube oil,

see 6.1.1. + 6.1.2.

● Change oil filter cartridge,

see 6.1.3.

● Change fuel filter cartridge,

see 6.2.1.

● Check V-belts and retension as necessary,

see 6.5.

● Check engine for leaks

● Check engine mounts, retighten if necessary,

see 9.2.

● Check valve clearance, adjust if necessary,

see 5.1. + 6.6.1.

2004

©

3

3

2004

©

Engine Operation 3.2 Starting

Electric starting

3.2.1

3

Before starting, make sure that nobody is standing in the immediate

vicinity of the engine or driven machine.

!

After repair work:

replaced and that all tools have been removed

from the engine.

When starting with glow plugs, do not use any other

starter substance (e.g. injection with start pilot).

Risk of accident!

Caution: If the speed regulator has been removed, the engine must not be tested under

any circumstances.

Disconnect the battery!

Check that all guards have been

2

1

26 423

©

Without cold start assistance

0

©

25 746

2

Do not actuate the starter for more than 20 seconds. If the engine does not catch, wait a minute

then try again.

If the engine does not catch after two attempts,

2004

refer to the Fault Table (see 7.1).

©

● Where possible, disengage clutch to separate

engine from any driven parts.

● Move speed control lever 1 into idle position.

● Move shut-off handle 2 into operating position.

● Insert key

- Position 0 = no operating voltage

● Turn key clockwise

- Position 1 = operating voltage

- Pilot lights come on

● Push key in and turn further clockwise against

spring pressure.

- Position 2 = no function

- Position 3 = start

● Release key as soon as engine fires

- Pilot lights go out.

3.2 Starting Engine Operation

With cold start assistance

- Glow plug

2

25 746

©

● Insert key

- Position 0 = no operating voltage

● Turn key clockwise

- Position 1 = operating voltage

- Pilot lights come on

● Push key in and turn further clockwise against

spring pressure.

- Position 2 = preheat, hold for approx. 1

minute.

- Preheat lamp comes on

- Position 3 = start

● Release key as soon as engine fires

- Pilot lights go out

3

3

2004

©

Engine Operation 3.3 Monitoring Operation

3.3.1 Engine Oil Pressure

3

Oil Pressure Pilot Light

Oil Pressure Indicator

Oil Pressure Gauge

©

● Oil pressure pilot light comes on with operating

voltage on and engine off.

● Oil pressure pilot light should go out when

engine is running.

2004

©

25 752 1

25 753 0

©

● Pointer must remain in green sector over entire

operating range.

25 754 0

©

● Pointer must indicate minimum oil pressure

(see 9.1).

3.3 Monitoring Operation Engine Operation

3.3.2 Engine Temperature

Engine Te

● Engine temperature gauge pointer should re-

main in green sector most of time. It should

rarely enter yellow-green sector. If pointer enters

orange sector, engine is overheating. Tu rn off

and establish cause from Fault Table (see 7.1).

mperature Gauge

24 985 0

©

3

3

2004

©

Engine Operation 3.4 Shutting Off

3.4.1 Mechanical Shut-Off

3

2

1

● Move speed adjustment lever 1 to low idle.

● Move shut-off lever 2 until engine comes to a

stop.

Charge pilot light and oil pressure pilot light will

come on when engine stops.

● Turn key anticlockwise (to position 0) and remove. Pilot lights will go out.

26 424 0

©

3.4.2 Electric Shut-Off

(Ignition Key)

© 25 746 2

● Turn key anticlockwise (to position 0) and re-

move. Pilot lights will go out.

2004

©

If possible, do not suddenly switch off engine when

under full load.

3.5 Operating Conditions Engine Operation

3.5.1 Winter Operation

● Lube Oil Viscosity

-Select oil viscosity (SAE grade) according to

ambient temperature before starting engine,

see 4.1.2.

-Increase oil change frequency when operating

below -10°C, see 6.1.1.

● Diesel Fuel

-Use winter-grade diesel fuel for operation be

low 0°C, see 4.2.2.

● Additional Maintenance Work

- Drain sludge from fuel tank once a week (undo

sludge drain screw).

- If necessary, allow oil in oil bath air cleaner and

engine oil to settle at ambient temperature.

- Below -20°C, after removing starter if neces

sary, smear ring gear on flywheel via pinion

bore from time to time with cold-resistant

grease.

(e.g. Bosch grease FT 1 V 31).

● Cold Start Assistance

-At temperatures near or below freezing point,

use glow plugs if necessary, see 3.2.1.

This not only lowers starting limit temperature,

but provides easier starting at temperatures

normally not requiring a starting aid.

● Battery

-Efficient cold starting requires that battery is

well-charged, see 6.7.1.

-Starting limit temperatures can be lowered by

4-5°C by heating battery up to about +20°C. (To

do so, remove battery and store in warm place).

26 248 0

©

3

3

2004

©

Engine Operation 3.5 Operating Conditions

3

High Altitude

● Air density decreases as altitude or ambient

temperature increases. As a result of this, the

engine’s maximum output, quality of exhaust

gas, temperature level and, in extreme cases,

starting behaviour, are impaired. Engine can be

used at altitudes up to 1000 m and temperatures

up to 30°C for mobile operations. If the engine is

to operate under more severe conditions (at

higher altitudes or temperatures), it will be necessary to reduce the injected fuel quantity and

thus engine power.

● If you have any doubts about engine operation

under these or similar conditions, ask your engine or equipment supplier whether the engine

has been derated in the interests of reliability,

service life and exhaust gas quality (smoke).

Otherwise contact DEUTZ SERVICE.

High Ambient T

3.5.2

emperature,

C F

0 32

25 901

1

2004

©

4.1 Lube Oil

4.2 Fuel

Operating Media

4

© 2004

Operating Media

4.1 Lube Oil

4

4.1.1 Quality Grade 4.1.2 Viscosity

Lube oils are differentiated by Deutz according to

their performance and quality class. Oils of other,

comparable specifications can be used.

Approved oils:

Deutz DQC IDQC II DQC III

ACEA E2-96 E3/96/E5-02 E4-99

API CF/CF-4 CH-4/CG-4 -

DHD -DHD-1 -

The precise assignment of the admissible

oil qualities to the engines is indicated in chapter

6.1.1.

If in doubt, contact your service representative.

Generally, multi-grade oils shall be used. In closed

heated rooms at temperatures >5°C, also singlegrade oils can be used.

As the viscosity of lube oil is dependent on

temperature, the choice of SAE grade should be

governed by the ambient temperature prevailing at

the engine operating site.

Optimum operating behaviour will be attained if you

take the accompanying oil viscosity diagram as a

guide.

Should the temperature fall temporarily below the

limits of the SAE grade selected, cold starting may

be affected but the engine will not be damaged.

In order to keep wear to a minimum, do not exceed

application limits for extended periods of time.

Synthetic lube oils feature an improved temperature and oxidation stability.

2004

©

Only with preheating

30 298 1

4.2 Fuel Operating Media

Quality

4.2.1

Winter-Grade Fuel

4.2.2

4

Use commercially available diesel fuel with less

than 0.5% sulphur content. If the sulfur content is

higher than 0.5%, oil change intervals should be

reduced (see 6.1.1).

The following fuel specifications/standards

are approved: (refer to TR 0199-3002)

TR 0199-99-3005 supplies details to the fuel

specifications. The following fuel specifications are certified: (see for this TR 0199-99-

3002) TR is to be referred more over the

DEUTZ service organisacion

● Diesel fuel

- DIN E N 590

- BS 2869: A1 and A2

(with A2, take note of the sulfur content!)

- ASTM D 975-88; 1-D and 2-D

- NATO Code F-54and F-75

- ISO 8217 DMX

- ISO 8217 DMA

● Light heating oil

according to DIN 51603

ASTM D 396; 1 and 2

BS 2869 Class D

● Jet fuel

- F34/F35/F44 (kerosene)

- F54 (equivalent to diesel fuel according to

DIN EN 590)

- XF 63 (equivalent to F34+F35 with addi tives)

● Bio diesel fuel

- according to DIN 51606- FAME

Exhaust emission values which may be determined in the cause of type approval tests

always refer to the reference fuel prescribed

by the authorities for the type approval test.

Waxing may occur at low temperatures, clogging

the fuel system and reducing engine efficiency. If

the ambient temperature is less than 0°C, wintergrade fuel (suitable down to -15°C) should be used.

(This fuel is usually available from filling stations

well in advance of the cold months). Diesel fuel

containing additives (Super diesel) is often on sale

as well, for use down to -20°C.

At temperatures below -15°C to -20°C,

kerosene should be added to the diesel

fuel. The relevant percentages are given in

the adjacent diagram.

If summer-grade diesel fuel must be used at

temperatures below 0°C, up to 60% kerosene can be added (see diagram).

In most cases, adequate resistance to cold

can also be obtained by adding a flow improver

(additive). Please inquire at DEUTZ SERVICE.

Diesel fuels must never be mixed

with petrol (Normal and Super

! !

grades)!

0

+32

+23

- 5

+14

- 10

+ 5

- 15

- 20

- 4

- 25

- 13

- 22

- 30

° F

° C

Legend:

ISummer-grade diesel fuel

II Winter-grade diesel fuel

AAmbient temperature

BPercentage of kerosene added

II

0102030405060 %

A

Mix in tank only! Fill with the

appropriate amount of kerosene

first, then add the diesel fuel.

I

B

© 26 441 1

2004

©

4

2004

©

5.1 Service Plan

5.2 Scheduled Maintenance Plan

5.3 Maintenance Chart

Maintenance Work Completed

5.4

Service

5

2004

©

Service 5.1 Service Plan

5

Deutz maintenance and service schedule

fl

prior to or during 1st trial run, check 2x daily during the breaking-in phase or

when commissioning new and overhauled engines

fl

every 10 operating hours or daily

E10 E20 E25 E30 E40 E45 E60 Years

2004

©

in operating hours (OH) every

500 1000

▲

▲

=E

check = adjust = clean

3000 5000 6000

=

replace =

▲

The specified engine maintenance intervals are

permissible recommended maximums. Depending

on usage, reduced maintenance intervals may be

necessary (comply with the unit manufacturer’s

operating instructions).

#

Maintenance must only be carried out by authorise

12

Operation

To p lube oil up if necessary 6.1.2/3.1.4

FL 2011 lube oil, see TC 0199-99-3002 6.1.1/ 6.1.2

BFL 2011 lube oil, see TC 0199-99-3002 6.1.1/ 6.1.2

Oil bath (lube oil quality, see TC 0199-99-3002 / Dry type filter 6.4

Oil filter cartridge FL 20116.1.3

Oil filter cartridge BFL 20116.1.3

Fuel filter cartridge

Change fuel pump/strainer if necessary

Flexible fuel leakage lines, see TC 0138-21-9300 6.2.1/ 6.2.3

Injection valve

Fuel pre-cleaner (halve if the fuel quality is poor) 4.2

Intake air cleaner (if available, maintain according to maintenance indicator) 6.4.3 /6.4.4

Battery and cable connectors 6.7.1

Engine monitoring system, warning system (replace if necessary) 3.3

Valve clearance 6.6.1

V-belt 6.5.

Crankcase pressure vent valve

Timing belt, extreme-duty, see adjacent table

Timing belt, heavy-duty, see adjacent table

Timing belt, light-duty, see adjacent table

Check engine for leaks (visual inspection) –

Engine mount (replace if damaged) 9.2

service personnel

Industrial engines

Section

6.2.2

#

#

#

#

#

#

#

#

5.1 Service Plan

Service

Deutz maintenance and service schedule

fl

prior to or during 1st trial run, check 2x daily during the breaking-in phase or

when commissioning new and overhauled engines

fl

every 10 operating hours or daily

E10 E20 E25 E30 E40 E45 E60 Years

Timing belt change intervals Engine application Engine/ application/operating parameters

in operating hours (OH) every

500 1000

Guideline values in OH Example: Example:

6000 or max. 5 years Generating sets 1500/1800 rpm; pump units, low speed; moderate ambient temperature;

5000 or max. 5 years compressors; rollers; forklift trucks; welding units;

=E

check = adjust = clean

3000 5000 6000

low speed; platform lifts; refrigeration units etc. low dust exposure

ambient

=

replace =

▲

Expansions or modifications for engines with

EPA acceptance

The specified engine maintenance intervals are permissible

recommended maximums. Depending on usage, reduced

maintenance intervals may be necessary (comply with the unit

manufacturer’s operating instructions).

#

12

small dumpers; ski-steer loaders etc. temperature moderate dust exposure

Operation

Injection valve #

Maintenance must only be carried out by authorise

service personnel

wheel loaders;medium to high variable speed; high

Section

5

3000 or max. 5 years agricultural machinery; ski-steer loaders; wheel loaders; drilling high speed; i mpact loads; extreme ambient temperature;

equipment; trench-cutting machines; joint cutters; bulldozers etc.high dust exposure

2004

©

Service 5.2 Scheduled Maintenance Plan

5.2.1 Scheduled Maintenance Plan

5

Intervals Deutz maintenance Operation Carried out by:

at/after and service schedule

50 OH E 10 After commissioning a nd E 45-E 60 Authorised specialists

Daily E 20 Daily checkOperator

250 OH E 25 Inspection Authorised specialists

500 OH E 30 Extended inspection Authorised specialists

1000 OH E 40 Interim o verhaul Authorised specialists

3000 OH E 45 Extended interim o verhaul Authorised specialists

6 000 OH E 60 Partial overhaul Authorised specialists

2004

©

5.3 Maintenance Chart Service

The maintenance c hart shown here is supplied

as a self-adhesive label with each engine. It

should be affixed where it can be seen clearly

on the engine or driven equipment.

Check that this is the case.

If necessary, ask your engine or equipment

supplier for a fresh supply of labels.

Routine work should be carried out according

to the schedule in 5.1.

5

Stop the engine before carrying

out any maintenance work.

2004

©

Service 5.4 Maintenance Work Completed

Op. hours

Date Signature/stamp

5

50-150*

125

375

625

875

1125

1375

1625

1875

2115

2375

2625

* Following commissioning of new and overhauled engines

Duly completed maintenance jobs can be recorded and signed off in the above chart.

Op. hours Signature/stamp

-

250

500

750

1000

1250

1500

1750

2000

2250

2500

2750

Date

5.4 Maintenance Work Completed Service

Op. hours

2875

3125

3375

3625

3875

4125

4375

4625

4875

5125

5375

5625

Date

Signature/stamp Op. hours Date

3000

3250

3500

3750

4000

4250

4500

4750

5000

5250

5500

5750

Signature/stamp

5

Duly completed maintenance jobs can be recorded and signed off in the above chart.

Service 5.4 Maintenance Work Completed

Op. hours

Date Signature/stamp

Op. hours Signature/stamp

Date

5

5875

6125

6375

6625

6875

7125

7375

7625

7825

8125

8375

8625

6000

6250

6500

6750

7000

7250

7500

7750

8000

8250

8500

8750

Duly completed maintenance jobs can be recorded and signed off in the above chart.

5.4 Maintenance Work Completed Service

Op. hours

Date

Signature/stamp Op. hours Date

Signature/stamp

5

Service 5.4 Maintenance Work Completed

Op. hours

Date Signature/stamp

Op. hours Signature/stamp

Date

5

Service and Maintenance

Lubrication System

6.1

uel System

6.2F

6.3 Cooling system

6.4 Combustion Air Filter

Belt Drives

6.5

Adjustments

6.6

Accessories

6.7

Engine Cleaning

6.8

6

2004

C

Service and Maintenance 6.1 Lubrication System

Oil

6.1.1

Change Intervals

6

Oil change intervals are dependent on engine

application and quality of lube oil.

If engine runs fewer hours during year than

stated in table, oil should be changed at least

once a year.

Ta ble refers to following conditions:

- sulphur content max. 0.5% by weight for

diesel fuel

- continuous ambient temperature to

-10°C (+14°F).

If sulphur content is > 0.5 to 1% or continuous

ambient temperature below -10°C (+14°F),

intervals between oil changes should be halved.

In case of fuels containing more than 1%

sulphur, contact your service representative.

Change oil with engine off but still warm (lube oil

temperature approx. 80°C).

C 2004

Gensets a s referred to here are units operating

in parallel with the mains / with each other.

Emergency power units are dealt with in TC

0199-99-1126.

6.1 Lubrication System Service and Maintenance

6.1.1.1 Equipment Engines

Lube oil grade

Deutz lube oil quality class

ACEA-specfication E2-96 E3-96/E5-02 E4-99

API-specfication CF/CF-4 CG-4/CH-4 -

Worldwide specification

special DEUTZ release list

Standard lube oil code for building

equipment and nonraod vehicles

Engine

series Oil use Oil use Oil use

1011/2011

Engine v

Naturalli aspirated engines

Turbocharged engines 250 125 500 250 500 250

ersion

DQC IDQC II DQC III

-DHD-1 -

--see chap. 4.1.2.1

EO.. .EO...C -

EO...A, EO...B

Lube oil change intervals in op. hours

normal high normal high normal high

1000 5001000 500 1000 500

6

2004

C

Service and Maintenance 6.1 Lubrication System

Check Oil

6.1.2

6

Change Engine Oil

6.1.2.1Check Oil Level

Level /

6.1.2.2 Change Engine Oil

25 729 0

©

● Switch engine off before checking oil level.

● Ensure that engine or vehicle is level.

● Remove oil dipstick.

● Wipe dipstick with non-fibrous, clean cloth.

● Insert it to stop and remove again.

● Check oil level, and if necessary, top up to

"MAX" mark.

-If oil level is only just above "MIN" mark,

more oil must be added.

The level must not fall below the "MIN" mark.

C 2004

© 26 022 0 © 26 023 0

● Allow engine to warm up.

● Ensure that engine or vehicle is level.

- Lube oil temperature approx. 80°C.

● Switch off engine.

Caution when draining hot oil:

Risk of scalding!

Do not let used oil run into the

!

soil but collect it in a container!

Dispose of this in accordance

with environmental regulations!

● Place oil tray under engine.

● Unscrew oil drain plug.

● Drain oil.

● Fit oil drain plug with new seal ring and tighten

firmly (for torque, see 9.2)

● Pour in lube oil

- For grade / viscosity, see 4.1

- For quantity, see 9.1

● Check oil level, see 6.1.2.1.

6.1 Lubrication System Service and Maintenance

Changing

6.1.3

Oil Filter

© 25 880 0 © 25 882 0© 25 881 0

6

● Undo lube oil filter cartridge using commercial

tool and spin off.

● Catch any escaping oil.

● Clean any dirt from filter carrier sealing surface.

● Lightly oil rubber gasket of new lube oil filter

cartridge.

Caution is required in case of

hot oil: Risk of scalding!

!

● Manually screw in new cartridge until gasket is

flush.

● Tighten lube oil filter cartridge with another half-

turn.

● Check oil level, see 6.1.2.

● Check oil pressure, see 3.3.1.

● Check lube oil filter cartridge seal for leaks.

2004

C

Service and Maintenance

6.1.4 Clean / Replace

6

6.1 Lubrication System

Oil Filter (Cup)

1

2

3

4

© 30 074 0

Switch off engine.

Loosen lube oil filter cover 1 and unscrew in

anticlockwise direction.

Carefully loosen paper filter cartridge 3 upwards

from guide 4.

Catch any escaping oil.

Replace paper filter cartridge 3.

Clean any dirt from sealing surface of filter

carrier and lube oil filter cover 1 and from guide

4.

Caution is required in case of hot

oil:

Risk of scalding!

C 2004

!

Replace and lightly oil rubber gasket 2.

Carefully insert new paper filter cartridge 3 into

guide 4.

Tighten lube oil filter cover 1 in clockwise

direction (25 Nm).

Start engine.

Check oil level, see 6.1.2.

Check oil pressure, see 3.3.1.

Check lube oil filter attachment for leaks.

6.2 Fuel System Service and Maintenance

Replace

6.2.1

Fuel Filter

© 25 880 0 © 25 882 0© 25 881 0

6

● Close fuel shut-off valve.

● Undo fuel filter cartridge with commercial tool

and spin off.

● Catch any escaping fuel.

● Clean any dirt from filter carrier sealing

surface.

● Apply light film of oil or diesel fuel to rubber

gasket of new fuel filter cartridge.

Keep naked flames away when

working on the

!

fuel system. Do not smoke!

● Manually screw in new cartridge until gasket

is flush.

● Tighten fuel filter cartridge with final half-

turn.

● Open fuel shut-off valve.

● Check for leaks.

2004

C

Service and Maintenance 6.2 Fuel System

6.2.2 Clean / Replace

6

Fuel Filter (Cup)

1

2

3

4

© 30 074 0

● Switch off engine.

● Loosen fuel oil filter cover 1 and unscrew

in anticlockwise direction.

● Carefully loosen paper filter cartridge 3

upwards from guide 4.

● Catch any escaping fuel.

● Replace paper filter cartridge 3.

● Clean any dirt from sealing surface of filter

carrier and fuel filter cover 1 and from

guide 4.

Keep naked flames away when

working on the fuel system. Do

not smoke!

!

C 2004

● Replace and lightly oil rubber gasket 2.

● Carefully insert new paper filter cartridge

3 into guide 4.

● Tighten fuel filter cover 1 in clockwise

direction (25 Nm).

● Start engine.

● Check fuel filter attachment for leaks.

6.2 Fuel System Service and Maintenance

Clean

6.2.3

Strainer of Fuel Filter

2

3

1

© 26 436 0 © 31 867 1

● Close fuel shut-off valve.

● Loosen and unscrew hexagonal nut 1.

● Remove fuel strainer cover 2 (cover and

strainer, one unit).

● Clean fuel strainer 2 with diesel fuel.

Replace if necessary.

● Place seal 3 in position.

Keep naked flames away when

working on the fuel system. Do

not smoke!

!

● Mount fuel strainer cover 2.

● Tighten hexagonal screw 1.

● Check for leaks.

Change

6.2.4

● Close fuel shut-off valve.

● Disconnect rubber hoses 3 from injection

valves.

● Disconnect rubber hose 1 from fuel tank.

● Disconnect rubber hoses 4, 3 and 1 from

unions 2 and dispose of in an environmentally friendly manner.

onnect new rubber hoses 4, 3 and 1 to

● C

unions 2

● Connect rubber hoses 3 to injection valves.

● Connect rubber hose 1 to fuel tank.

● Open fuel shut-off valve.

● Check for leaks after start-up.

Fuel Leakage Line

.

6

2004

C

Service and Maintenance

6.3.1 Cleaning Intervals

6

6.3 Cooling System

● Amount of contamination in cooling system

depends on engine application.

● Oil and fuel residues on engine increase risk of

contamination. Therefore pay special attention

to leaks if engine is used in dusty environments.

● Serious contamination can occur, for example:

-on construction sites where there is a high

level of air-borne dust.

-in harvesting applications where there are high

concentrations of chaff and chopped straw in

vicinity of machine.

● Because applications vary, cleaning intervals

have to be determined from case to case. Cleaning intervals given in table on right can be used

as a guide.

Checking or cleaning intervals

Guideline values OH Engine application

2000 Ships, generating sets in enclosed areas, pumps.

1000 Vehicles on paved roads

500 Tractors, fork-lift trucks, mobile generating sets

250 Vehicles on construction sites and unpaved roads,construc-

tion machines, compressors, underground mining units

125 Agricultural machines, tractors in harvesting applications

6.4 Combustion Air Filter

Service and Maintenance

Cleaning Inter

6.4.1

● Amount of dirt in air cleaner depends on amount

of dust in air and size of air cleaner used. If high

level of dust is anticipated, cyclone-type

precleaner can be fitted to air cleaner.

● Cleaning intervals will have to be determined

from case to case.

● If dry type air filters are used, cleaning should

only be carried out according to service indicator

or service switch.

● Air cleaner servicing is needed when:

- Service indicator

red signal 1 is fully visible when engine is off.

- Service switch

yellow pilot light comes on when engine is

running.

● pressing button on service indicator. Service

indicator is now ready for operation again.

vals

© 25 885 1

Emptying Cyclone-T

6.4.2

ype

Precleaner

© 25 886 0

● Undo wing nut 1 and remove cover 2.

● Remove collector bowl 3 from lower section 4

and empty. Clean leaves, straw and other foreign

matter from lower section of pre-cleaner.

● Reposition collector bowl 3 onto lower section 4,

fasten cover 2 in place by tightening wing nut 1.

6

Never fill collector bowl with oil. Replace collector

bowl if damaged.

Service and Maintenance 6.4 Combustion Air Filter

ype Air Cleaner

y T

Dr

6.4.3

6

Discharge Valve

©

25 888

Filter Cartridges

1

©

25 889

0

● Empty dust discharge valve 1 by pressing apart

lips of discharge slot as indicated by arrows.

● Clean discharge slot from time to time.

● Remove any caked dirt by pressing together

upper section of valve.

● Undo clip fasteners 1.

● Take off hood 2 and remove cartridge 3.

● Clean cartridge, replace at least once a year.

● Clean cartridge 3.

Using dry compressed air (max. 5 bar), blow out

from inside to outside (or in difficult cases, tap

out, taking care not to damage cartridge, or wash

according to manufacturer’s instructions).

● Gaskets on filter cartridge can become damaged

through regular removal and replacement. Check

paper filter (light showing through) and gaskets

for damage.

Replace if necessary.

● After five cleaner services or after two years at

latest, replace safety cartridge 4 (never clean).

To do so:

-Undo hex nut 5 and remove cartridge 4.

-Install new cartridge, fit and tighten hex nut.

● Install cartridge 3, replace hood 2 and do up clip

fasteners 1.

Never clean filter cartridge with petrol or hot fluids.

!

6.5 Belt Drives Service and Maintenance

6.5.1 Check V-belt

© 31 866 0

● Visually inspect entire V-belt for damage.

● Replace damaged V-belts.

● After installing new belts, run engine for 15

minutes, then check belt tension.

● To check tension of V-belt, use tension gauge

(see 9.3).

-Place indicator arm 1 into gauge.

-Position guide 3 on V-belt 2, midway between

pulleys, with stop against edge of belt.

-Push slowly on black pad 4 at right angles to V-

belt 2 until spring is heard or felt to trigger.

26 261 0

©

-Carefully remove gauge without altering position of indicator arm 1.

-Read off value where black indicator arm 1

intersects scale 5 (arrow). For settings, see

9.1.

- If necessary, retension belt and measure again.

6

Check, tension and change belts

only with engine off. Refit belt guard,

if provided.

!

After installing new belts, run engine for 15 minutes, then check belt tension.

Service and Maintenance 6.5 Belt Drives

6.5.2

Te

Changing Alternator Belts

6.5.3

nsioning Alternator Belts

6

3

5

1

4

2

0

31 859

©

● Slacken off bolts 1, 2 and 3.

● Adjust alternator 4 in direction of arrow by

turning bolt 3 until correct belt tension is achieved.

● Retighten bolts 1, 2 and 3.

Check, tension and change belts

only with engine off. Refit belt guard,

if provided.

!

3

5

1

4

2

31 860 0

©

● Slacken off bolts 1, 2 and 3.

● Adjust alternator 4 in direction of arrow by

turning bolt 3.

● Remove and replace belt.

● Adjust alternator 4 against direction of arrow by

turning bolt 3, until correct belt tension is

achieved.

● Retighten bolts 1, 2 and 3.

6.6 Adjustments

Service and Maintenance

6.6.1

Check V

alve Clearance, adjust

if necessary

2

19 691

©

● Remove cylinder head cover.

● Position crankshaft as per schematic, see 6.6.1.1.

● Before adjusting valve clearance, allow engine to

cool down for at least 30 minutes. Oil temperature should be below 80°C.

● Check valve clearance 1 between rocker arm /

tappet contact face 2 and valve stem 3 with feeler

gauge 6 (there should be only slight resistance

when feeler blade is inserted).

For permissible valve clearance, see 9.1.

0

25 893

©

● Adjust valve clearance if necessary:

-Release locknut 4.

-Use Allan key 7 to turn setscrew 5 so that

correct clearance is attained after locknut 4 has

been tightened.

● Check and adjust valve clearance on all cylinders.

● Reinstall cylinder head cover, with new gasket if

necessary.

6

Service and Maintenance

6

6.6.1.1 Valve Clearance Adjust

ments Schematic

1

6.6 Adjustments

● Crankshaft Position 1:

Turn crankshaft until both valves in cylinder 1

overlap (exhaust valve about to close, inlet valve

about to open). Adjust clearance of valves marked

in black on schematic. Mark respective rocker

1 2341 2 1 23

arm with chalk to show that adjustment has been

carried out.

2

● Crankshaft Position 2:

Turn crankshaft one full revolution (360°).

Adjust clearance of valves marked in black on

schematic.

234112 123

© 25 894 4

6.7 Accessories Service and Maintenance

6.7.1 Battery

6.7.1.1

Check Batter

y and Cable

Connectors

© 25 895 0

● Keep battery clean and dry.

● Undo dirty clamps.

● Clean terminal posts (+ and -) and clamps of

battery, and grease with acid-free and acidresistant grease.

● When reassembling, ensure that clamps make

good contact. Tighten clamp bolts hand-tight.

6.7.1.2 Check Electrolyte Level 6.7.1.3 Check Electrolyte Density

© 24 232 3

● Remove sealing caps 1.

● If testers 2 are present:

Electrolyte level should reach base of these.

● Without testers:

Electrolyte level should be 10-15 mm above top

of plates.

● If necessary, top up with distilled water.

● Screw sealing caps back in.

● Measure electrolyte density of individual cells

with commercial hydrometer.

Hydrometer reading (see table on following page)

indicates battery’s state of charge.

During measurement, t emperature of electrolyte

should preferably be +20°C.

© 25 896 0

6

Service and Maintenance 6.7 Accessories

6

Electrolyte density

Normal

1.28

in [kg/ l]

in [°Bé (Baumé scale)*]

Normal

32

Tropical

27

Charge status

well charged

1.20

1.12

*Measurement of electrolyte density in °Bé (Baumé

scale) is out of date and rarely used today.

The gases emitted by the battery

are explosive! Keep sparks and na-

!

Wear protective goggles!

Do not rest tools on the battery!

ked flames away from the battery!

Do not allow battery acid to come

into contact with skin or clothing!

24

16

16

11

semi-charged, re-charge

discharged, immediately charge

6.7 Accessories Service and Maintenance

ansportation Shackles

Tr

y Current Alternator

Rotar

6.7.2

Notes on the three-phase system:

● Never disconnect cables between battery, alternator and regulator while engine is running.

● If, however, it is necessary to start and operate

engine without battery, d isconnect regulator from

alternator before starting.

● Be sure not to confuse battery terminals.

● Replace defective charge pilot lamp bulb imme-

diately.

● When washing engine, cover up alternator and

regulator.

● Touching lead against frame to check whether it

is live must not, under any circumstances, be

carried out with three-phase electrical systems.

● In case of electric welding, connect ground terminal on welder directly to piece being welded.

6.7.3

1

2

31 871 0

©

● Always use proper lifting tackle 1 when transporting engine.

● After transportation and before commissioning

of engine: remove attachment eyes 2.

© 31 870 0

6

Use only correct lifting gear.

!

Service and Maintenance 6.8 Engine Cleaning

6.8.1 Engine Cleaning

6

Preperation

● Switch off engine.

● Remove engine covers and cooling air hood.

Replace them after cleaning and before test run.

● Cover electrical / electronic components and

connections (e.g. alternator, starter, governor,

solenoid).

Using compressed air

● Blow air through engine, taking particular care

not to damage cooler and cooling fins (begin to

blow through air from exhaust side).

Remove dirt which has blown into interior space.

Using cold-cleaning compound

● Spray engine with commercial cold-cleaning

compound and allow to react for approx. 10

mins.

● Spray-clean engine with strong water jet, repeat

if necessary.

● Allow engine to run warm so that remaining

water evaporates.

Using high-pressure device

● Clean engine with steam jet (max. spray pressure of 60 bar, max. steam temperature of 90ºC).

● Allow engine to run warm so that remaining

water evaporates.

Clean the engine only when the engine is switched off.

!

7.1 Fault Table

Faults, Causes and Remedies

7

Faults, Causes and Remedies

7

● Faults are often caused by engine not being

properly operated or maintained.

● Each time fault occurs, check whether all operating and servicing regulations have been complied with.

● Corresponding fault table can be found on adjacent page.

● If you cannot ascertain cause of a fault or cannot

rectify fault, please contact DEUTZ SERVICE.

7.1 Fault T

able

7.1 Fault Ta

ble

Faults, Causes and Remedies

Faults Measures

Engine does not start or is difficult to start Check Ch

Engine starts, but runs irregularly or fails Adjust A

Engine becomes excessively hot. Temperature warning system responds Replace Rp

Engine output is deficient Clean Cl

Engine does not run on all cylinders Top up T

Engine oil pressure is non-existent or excessively low Reduce Rd

Engine oil consumption excessive

Engine smokes - blue

- white

- black

Cause

●

●●

●●

●● ●●

●●●

●●

●● ●●

●● ●

●● ●

●●

●

●

●

●

●

*CPD = Charge pressure-dependent full-load stop

Not declutched (where possible)

Below starting limit temperature

Oil level too low

Oil level too high

Excessive inclination of engine

Incorrect lube oil SAE class or quality

Fuel quality not as per operating manual

Air cleaner clogged / turbocharger defective

Air cleaner service switch / indicator defective

CPD * defective

●

Charge air line leaking

Oil cooler panels clogged

Cooling fan defective, split or loose V-belt

Cooling air temperature rise / heating short circuit

Resistance in cooling system too great / through-flow quantity too small

Battery defective or discharged

Section

Engine Operation

Operating media

Combustion air

Cooling system

Electrics

7

Ch

Ch

T

Ch

Rd

Rp

Rp

Ch / Rp

Ch / Rp

Ch

Ch

Ch / Cl

Ch / Rp

Ch

Ch

Ch / T

Faults, Causes and Remedies

7.1 Fault T

able

7

Faults Measures

Engine does not start or is difficult to start Check Ch

Engine starts, but runs irregularly or fails Adjust A

Engine becomes excessively hot. Temperature warning system responds Replace Rp

Engine output is deficient Clean Cl

Engine does not run on all cylinders Top up T

Engine oil pressure is non-existent or excessively low Reduce Rd

Engine oil consumption excessive

Engine smokes - blue

- white

- black

●

●

●

●● ●●●

●●●

●●●●●●●

Cause

Electric cable connections to starter electrical system loose or oxidised

Starter defective or pinion does not engage

Solenoid defective (release switch)

Incorrect valve clearance

Injection line leaks

Injection valve defective

Section

Electrics

Engine

Ch / Rp

Ch

Ch

Ch

A

Ch

Preservation

8.1

Engine Preservation

8

Engine Preservation

8.1 Preservation

8

If the engine is to remain idle for an extended period

of time, it is necessary to take protective measures to

prevent rusting. The preservative measures described

here will protect the engine for up to 6 month

The procedure will have to be reversed before the

engine is recommissioned.

● Anti-corrosion oils to specification:

MIL-L-21260B

TL 9150-037/2

Nato Code C 640 / 642

● Anti-corrosion media for exterior protection only

to specification:

Nato Code C 632

● Recommended cleaning agent to remove preservatives:

Petroleum benzine

(hazardous materials class A3)

8.1.1 Preserving Engine

8.1.2

Removing Engine

Preservatives

● Clean engine using high-pressure

equipment (or with cold-cleansing agent

s.

in emergency).

● Run engine until warm, then turn off.

● Drain engine oil (see 6.1.2) and fill with anti-

corrosion oil.

● If necessary, clean oil bath cleaner (see 6.4.3)

and fill with anti-corrosion oil.

● Drain fuel tank.

● Make up a mixture of 90% diesel fuel and 10%

anti-corrosion oil, and refill fuel tank.

● Allow engine to run for approx. 10 mins.

● Switch off engine.

● Turn engine over manually several times to pre-

serve cylinders and combustion chamber.

● Remove V-belts and store in wrapped condition.

● Spray grooves on V-belt pulleys with anti-corro-

sion spray.

● Close intake ports and exhaust ports.

● Remove anti-corrosion agent from grooves in

V-belt pulleys.

● Install V-belt, retension after brief operation if

necessary, see 6.5.

● Remove covers from intake port and exhaust

port.

● Commission engine, see also 5.1, note 2.

Technical Specification

Engine Specifications and Settings

9.1

rque Wr

To

9.2

9.3 Tools

ench Settings

9

2004

©

Technical Specification 9.1 Engine Specifications and Settings

9

Model

9

Number of cylinders

Cylinder arrangement

Bore [mm]

Stroke [mm]

Total displacement [cm3]

Compression ratio [ ε]

Working cycle

Combustion system

Direction of rotation

Weight incl. integral cooling system to DIN 70020-A

(without starter, with alternator) approx. [kg]

Engine output [kW (hp)]

Speed [rpm]

Lubrication

SAE oil

Maximum oil temperature in oil pan [°C]

Min. oil pressure in warm condition, oil temperature 110°C

at: 900 rpm (low idling speed) [bar]

1800 rpm [bar]

max. 2800 rpm [bar]

Oil change quantity (oil pan) approx. [ l]

Oil change quantity with filter (standard 0.5 l) approx. (l)

Valve clearance with cold engine

(Engine cooling time at least 30 min.: oil temperature should be below 80°C). [mm]

Start of feed [°crankshaft BTDC]

Injector opening pressure: vehicle/unit [bar]

Firing order of engine

V-belt tension: pretension / retension (after engine has been running under load for 15 mins)[ N]

1)

Engine power, speed, start of delivery are stamped on engine rating plate, see also 2.1.

2)

Approx. values can vary depending on sump and/or cooler design (external cooling system). Upper oil dipstick mark is always authoritative.

3)

Values for engines without engine oil heating.

© 2006

------- F2L 2011 ---------------- F3L 2011 --------------- F4L 2011 -------

------------ 2 --------------------------- 3 -------------------------- 4 ------------

---------------------------------- vertical in line ----------------------------------

------------------------------------------ 94 -----------------------------------------

----------------------------------------- 112 ----------------------------------------

--------- 1554 ---------------------- 2331 --------------------- 3108 ---------

------------------------------------------ 19 -----------------------------------------

------------------------------ 4-stroke diesel engine -----------------------------

------------- Naturally aspirated engine with direct injection ---------------

-------- ------------------ On left when looking at flywheel -------------------

---------- 175 ------------------------ 217 ----------------------- 256 ----------

-------------------------------------------

-------------------------------------------

1)

-------------------------------------------------------------------------

1)

-------------------------------------------------------------------------

------------------------------- Pressure lubrication ------------------------------

-------------------------------------- 20 W 20 -------------------------------------

----------------------------------------- 130 ----------------------------------------

3)

---------------------------------------- 1,4

---------------------------------------- 2,2

------------------------------------------ 3

2)

----------- 6

---------- 6.5

------------------------------------------

2)

------------------------------------------

----------------------- --- Inlet 0.3

-------------------------------------------

---------------------------------------------------------------------

---------------------------------------------------------------------

3)

---------------------------------------------------------------------

3)

-----------------------------------------------------------------------

2)

---------------------------------------

5.5

2)

---------------------------------------

6

+0.1

/ Exhaust 0.5

1

--------------------------------------------------------------------------

+8

--------------------------------------------------------------------

210

10.5

+0.1

------------------------

10

2)

------------------

2)

----------------

---------- 1 - 2---------------------- 1 - 2 - 3 ----------------- 1 - 3 - 4 - 2 ------

----------------------------------- 450 / 350 ±20 ----------------------------------

9.1 Engine Specifications and Settings

Technical Specification

Model

Number of cylinders

Cylinder arrangement

Bore [mm]

Stroke [mm]

Total displacement [cm

Compression ratio [

Working cycle / Combustion system

Direction of rotation

------------------- BF3L 2011 ------------------------------ BF4L 2011 ------

-------------------------------------------

--------------------------

---------------------------------- vertical in line ----------------------------------

------------------------------------------

-----------------------------------------

3

----------------------- 2331 -------------------------------------- 3108 ---------

]

----------------------------------------- 17.5 ----------------------------------------

ε ]

------------- Four-stroke diesel with turbocharging and direct fuel injection

--------------------------Onleft when looking at flywheel -------------------

3-

-----------------------------------------

94

----------------------------------------

112

Weight without cooling system

----------------------------------------

Weight without starter, with alternator as per DIN 70020-A approx. approx. [kg]

Engine output [kW (hp)]

Speed [rpm]

Lubrication

SAE oil

Maximum oil temperature in oil pan [°C]

at: 900 rpm (low idling speed) [bar]

1800 rpm [bar]

max. 2800 rpm [bar]

Oil change quantity (oil pan without cooling system) ca. [l]

Oil change quantity with filter (Standard 0.5 l) approx. (l)

------------------------

-----------------------------------------

.-

-------------------------------------------

------------------------------- Pressure lubrication ------------------------------

--------------------------------------

----------------------------------------- 130 ----------------------------------------

---------------------------------------- 1.4

---------------------------------------- 2.2 3).---------------------------------------

-----------------------------------------

------------------------ 7.5 ---------------------------------------- 102).---------

-------------------------- 8---------------------------------------- 10.5 2).--------

Valve clearance with cold engine

(Engine cooling time at least 30 min.: oil temperature should be below 80°C). [mm]

Injector opening pressure: vehicle/unit [bar]

Start of feed [°crankshaft BTDC]

Firing order of engine

V-belt tension: pretension / retension (after engine has been running under load for 15 mins): [N]

1)

Engine power, speed, start of delivery are stamped on engine rating plate, see also 2.1.

2)

Approx. values can vary depending on sump and/or cooler design (external cooling system). Upper oil dipstick mark is always authoritative.

3)

Values for engines without engine oil heating.

-------------------------- Inlet 0.3

--------------------------------------- 210

-----------------------------------------1)------------------------------------------

.-

----------------------

----------------------------------- 450 / 350 ±20 ----------------------------------

222

W

20

3

+ 0.1 /

Exhaust 0.5

-----------------------------------

3-

-

2

-

1

1)

------------------------------------------

1)

------------------------------------------

-------------------------------------

20

3)

--------------------------------------

.-

3)

---------------------------------------

.-

+ 8

---------------------------------------

4-

257

+ 0.1

------------------------

1-3-4-2 --------

-----------

----------

9

2004

©

Technical Specification 9.1 Engine Specifications and Settings

9

Number of cylinders

9

Cylinder arrangement

Bore [mm]

Stroke [mm]

Total displacement [cm

Compression ratio [ε]

Working cycle

Combustion system

Direction of rotation

Weight without cooling system

Model

(without starter, with alternator) approx.

approx. [kg]

Engine output[kW (hp)]

Speed [rpm]

Lubrication

SAE oil

Maximum oil temperature in oil pan

Min. oil pressure in warm condition, oil temperature 110°C at: 900 rpm (low idling speed)

1800 rpm [bar]

max. 2800 rpm [bar]

Engine with Thermostat

Oil change quantity without external cooler (see 3.1.1.2)/without filter approx.

------ F2M 2011 ---------------- F3M 2011 --------------- F4M 2011 ------

--------------------------

------------

--------------------------

2-

3-

---------------------------------- vertical in line ----------------------------------

-----------------------------------------

------------------------------------------

-----------------------------------------

3

--------- 1554 ---------------------- 2331 --------------------- 3108 ---------

]

------------------------------------------

94

----------------------------------------

112

-----------------------------------------

19

------------------------------ 4-stroke diesel engine -----------------------------

-------------------------- Naturally aspirated engine with direct injection -

-------------------------- On left when looking at flywheel -------------------

------------------------------- Refer to head-office ------------------------------

---------- 169 ------------------------ 210 ----------------------- 248 ----------

-------------------------------------------

-------------------------------------------

1)

-------------------------------------------------------------------------

1)

-------------------------------------------------------------------------

------------------------------- Pressure lubrication ------------------------------

-------------------------------------

20

W

--------------------------------------

----------------------------------------- 130 ----------------------------------------

[°C]

---------------------------------------- 1.4

[bar]

---------------------------------------- 2.2 3).-

20

3)

.---------------------------------------

--------------------------------------

----------------------------------------- 33).----------------------------------------

[l]

----------------------- 5.5

2)

------------------------

.-

2)

10

----------------------

.-

-----------

4-

Oil change quantity without external cooler (see 3.1.1.2) + filter replacement

(standard 0.5 litre) approx.[l]

Genset Engine without Thermostat:

Oil change quantity including external cooler (see 3.1.1.3)/without filter approx. [l]

Oil change quantity including cooler (see 3.1.1.3) + filter replacement (standard 0.5 litre) approx.

Valve clearance with cold engine

(Engine cooling time at least 30 min.: oil temperature should be below 80°C).

Start of feed [°crankshaft BTDC]

Injector opening pressure: vehicle/unit [bar]

Firing order of engine

V-belt tension: pretension / retension (after engine has been running under load for 15 mins): [N]

1)

Engine power, speed, start of delivery are stamped on engine rating plate, see also 2.1.

2)

2004

Approx. values can vary depending on sump and/or cooler design (external cooling system). Upper oil dipstick mark is always authoritative.

©

3)

Values for engines without engine oil heating.

------------------------ 62).------------------------- 10.5 2).---------------------

----------------------- 8.5

[l]

------------------------

[mm]

-------------------------- Inlet 0.3

9

------------------------------------------1).-

2)

------------------------

.-

2)

------------------------

.-

+0.1

/ Exhaust 0.5

-----------------------------------------

2)

13

.-

13.5 2).-

+0.1

------------------------

---------------------------------------- 210 +8---------------------------------------

----------- 1-2 ---------------------- 1 - 2 - 3----------------- 1 - 3 - 4 - 2------

----------------------------------- 450 / 350 ±20 ----------------------------------

----------------------

--------------------

9.1 Engine Specifications and Settings Technical Specification

Model

Number of cylinders

Cylinder arrangement

Bore [mm]

Stroke [mm]

Total displacement [cm

Compression ratio

Working cycle

Combustion system

Direction of rotation

Weight without cooling system

(without starter, with alternator) approx.

Engine output[kW (hp)]

Speed [rpm]

Lubrication

SAE oil

Maximum oil temperature in oil pan

Min. oil pressure in warm condition, oil temperature 110°C at: 900 rpm (low idling speed)

1800 rpm [bar]

max. 2800 rpm [bar]