Deutz BFM 1008F Service Manual

Workshop ManualB/FM 100

© 2001 / 0297 9984

Workshop ManualF4M 100

2M3M

BF4M 2M3M

F4M 100

0297 9985 en

In view of continuous designs, theimprovementstechnical orspe cifications and the illukstratiohopMansualshownare insubjectthis alteration. Reprinting andin reproduction,whole,are subjectin partto our written approval.

© 2001 / 0

© 2001 / 0297 9985

F O R E W O R D

Reliable engine operationexecutedis dependentrepairs ason welpro |

||||

This Workshop Manual describesationsfortheanyappreoparirat |

||||

engine and engine componentshiswork.Itwillis presumedbecarri. |

||||

The Manual has been laidhensionout toofensurethe contentsquick |

||||

placed adjacent to thelybriefshow textheworkinpassagesoperto |

||||

Aspects of operation andinmaintenancethe respectivare dealOp |

||||

For spare parts ordersataloguthe respectiveshould besparerefep |

||||

This |

Workshop |

Manualeerings notchangesubjectservicet tois |

||

Therefore please |

referour |

toTechnicalthe informatioCirculaepair |

||

General information: |

|

|||

- |

Please read carefullygivenandobservein thistheWor |

|||

- |

avoid |

accidents |

andalwaysenurefunctionthat |

|

Make sure that this WorkshopilableforManual this |

||||

|

or adjustments and thatstoodthe. contents a |

|||

- |

Non-compliance with thresulterepairin malfuncinstr |

|||

|

damage as well as personalanufacturerinjuriesshallfo |

|||

- |

liability. |

|

|

|

The accident preventiongenreguralationslyrecogna |

||||

|

safety and occupational. medicine are t |

|||

- |

A prerequisite for equiredsccssfulequipment,repair ih |

|||

- |

are available and in perfect working |

|||

Optimal operation economy,ityof reliabilitytheengine |

||||

- |

when genuine |

parts of DEUTZ AG are us |

||

Engine components |

suchngs,as springs,etc.may claca |

|||

|

handled with care. |

|

||

- |

Engine repairs must beithcarriintendedoutusein |

|||

|

equipment manufacturer. approvedForconversionby DEU |

|||

|

specific purpose should be used. |

|||

© 2001 / 0

INDEX

This manual contains pergtinentherepairinformationof DEUTZregardiwater |

|||||

injection DieselB/FM engines1008/F. |

type |

|

|

||

INDEX |

|

|

PAGE |

|

|

|

TROUBLESHOOTING CHART - B/FM 1008/F SERIES9_________ |

||||

|

SAFETY AND WARNING DECALS - SAFETY INSTRUCTIONS10 |

____ |

|||

I |

GENERAL _________________ |

12 |

|

||

|

POWER RATINGS FOR B/FM 1008/F GENSET SPEC DIESEL ENGI |

||||

|

B/FM 1008 SERIES - TECHNICAL SPECIFICATIONS AND |

|

|||

|

CAPACITIES F2/3/4M 1008, BF4M 1008 __________________ |

||||

|

FLUID CAPACITIES (STANDARD) F2/3/4M 1008, BF4M 1008 __ |

||||

|

FM 1008 F SERIES - TECHNICACITIESLSP CIF2/3/4MICATIONS1008AND FCAP_____ |

||||

|

FLUID CAPACITIES (STANDARD) F2/3/4M 1008 F___________ |

||||

|

POWER, TORQUE AND SPECIFIC FUEL CONSUMPTION CURVES F2 |

||||

|

POWER, TORQUE AND SPECIFIC FUEL CONSUMPTION CURVES B/ |

||||

|

POWER, TORQUE AND SPECIFIC FUEL CONSUMPTION CURVES F2 |

||||

|

GENERAL ENGINEERING DRAWINGS - F2/3M 1008 ___________ |

||||

|

GENERAL ENGINEERING DRAWINGS - B/F4M 1008___________ |

||||

|

GENERAL ENGINEERING DRAWINGS - F2/3/4M 1008 F _______ |

||||

|

B/FM 1008/F SERIES MAINTENANCE SCHEDULE _____________ |

||||

|

RECOMMENDED OIL______________________________________ |

||||

|

DIESEL FUEL SPECIFICATIONS __________________________ |

||||

|

ANTI-FREEZE / COOLANT SPECIFICATIONS / DETAILS - B/FM |

||||

|

DRIVING TORQUES FOR STANDARD SCREWS _________________ |

||||

|

SEALANT AND THREAD LOCK LOCATIONS/DETAILS ___________ |

||||

|

CRITICAL TORQUE SPECIFICATIONS ______________________ |

||||

|

SPECIAL TOOLS_______________________________________ |

||||

II |

DISASSEMBLY- |

REASSEMBLY |

31 |

|

|

|

Air filter support - (intake manifold) ______________ |

||||

|

Air restriction switch ______________________________ |

||||

|

Alternator / cooling fan drive belt_________________ |

||||

|

Camshaft journal / support bore specifications______ |

||||

|

Camshaft journal / support measurement ______________ |

||||

|

Camshaft lobe measurement procedure__________________ |

||||

|

Camshaft lobe specifications ________________________ |

||||

|

Camshaft removal / replacement ______________________ |

||||

|

Camshaft timing pulley ______________________________ |

||||

|

Connecting bearing / rod cap installation___________ |

||||

|

Connecting rod / connectingions rod bearings specificat |

||||

|

Connecting rod alignment ____________________________ |

||||

|

Connecting rod-piston assembly balance ______________ |

||||

|

Cooling fan _________________________________________ |

||||

|

Cooling fan support _________________________________ |

||||

|

Crankcase vacuum regulator valve (B/FM 1008/F) ______ |

||||

|

Crankshaft end play _________________________________ |

||||

|

Crankshaft journal inspection / measurement _________ |

||||

|

Crankshaft journal specifications ___________________ |

||||

|

Crankshaft lubrication drillings-typical ____________ |

||||

|

Crankshaft pulley ___________________________________ |

||||

|

Crankshaft seals - front and rear ___________________ |

||||

© 2001 / 0297 9985 |

4 |

|

|

|

|

INDEX

PAGE

Crankshaft timing pulley ________________________

Cylinder class __________________________________

Cylinder head installation_______________________

Cylinder head removal ____________________________

Cylinder head tightening procedureF4M 1008/F, B Cylinder head tightening procedureF2/3M 1008/F_ Cylinder inspection / dimensional specifications Cylinder surface finish __________________________

Dry type air filterstandard engine mounted _____

Exhaust manifold_________________________________

Flywheel / ring gear_____________________________

Front / rear main bearing caps / bearings________

Fuel rail ________________________________________

Fuel tank - (optional accessory) _________________

General piston notes ____________________________

Governor fork____________________________________

Governor springs_________________________________

Head gasket selection/ installation _____________

Hydraulic drive componentsno. 3 pto____________

Hydraulic pump pto- (no. 3 pto) __________________

Idler pulley _____________________________________

Injection pump control rod ______________________

Limiting speed governor _________________________

Main and connecting rod bearings ________________

Main bearing caps / bearingscenter _____________

Main bearing clearance ___________________________

No. 2 pto (crankshaft pulley) with “ringfeder”- F Oil bath air filter ______________________________

Oil pan removal / installation___________________

Oil pump assembly ________________________________

Oil pump assembly to the engine__________________

Oil pump inspection ______________________________

Piston / connecting rod disassembly and piston in Piston / connecting rod installation _____________

Piston balance ___________________________________

Piston class, weight imbalance and genuine Deutz Piston cooling jetsBF4M 1008 ___________________

Piston protrusion________________________________

Piston removal___________________________________

Piston ring assembly location ____________________

Piston ring end gap______________________________

Piston ring to piston land clearance ____________

Piston wrist pin installation / retaining snap ri Precision speed governor -(gensets)______________

Pre-combustion chamber installation ______________

Pre-combustion chamber removal___________________

Pre-combustion chamber ring nut __________________

Pre-combustion chamber-overview__________________

Rocker arm assembly______________________________

Speed governor___________________________________

Speed governor reassembly ________________________

Thrust bearings __________________________________

Thrust surface specifications-crankshaft end _____

play corrections_________________________________

Timing belt / timing pulley arrangement __________

Timing belt cover________________________________

Timing belt installationtiming procedure ______

Timing belt removal _____________________________

Timing belt tension procedure ____________________

Timing belt tensioning proceduresetup __________

Timing pulley - reference marks __________________

Undersized bearingsrod and main _______________

Unit injector check valve ________________________

Unit injector removal / installation _____________

Valve / rocker cover _____________________________

5 |

© 2001 / 0 |

INDEX

Valve

Valve

Valve

Valve

Valve

Valve

Valve

Valve

Valve

Valve

Valve

Valve

PAGE

/ rocker cover gasket _________________________

adjustment ____________________________________

guide installation guidelines and post installa guides / valve guide bore _____________________

recess and seat sealing width _________________

removal_______________________________________

seats _________________________________________

specifications ________________________________

springs _______________________________________

stem seal installation ________________________

timing angles _________________________________

timing confirmation____________________________

III TURBOCHARGER ___________ |

58 |

_ |

||

|

Turbocharger identification _________________________ |

|||

|

Turbocharger components _____________________________ |

|||

|

Turbocharger pressure testing _______________________ |

|||

|

Turbocharger waste gate adjustement-bench method ____ |

|||

IV |

LUBRICATION SYSTEM ______ |

60 |

|

|

|

Lubrication system __________________________________ |

|||

|

Oil pick-up screen and oil drain back tube__________ |

|||

|

Oil pump specification ______________________________ |

|||

|

Oil filter __________________________________________ |

|||

|

Oil pressure testing________________________________ |

|||

V |

COOLING SYSTEM ___________ |

63 |

|

|

|

B/FM 1008/F cooling system schematic ________________ |

|||

|

Cooling system pressureoncheck/radiator cap inspecti |

|

||

|

Coolant pump details ________________________________ |

|||

|

Thermostat __________________________________________ |

|||

VI |

FUEL SYSTEM____________ |

65 |

|

|

|

Barrel and plunger detail- (typical) current ________ |

|||

|

unit injectors (example- 6590-285) __________________ |

|||

|

Barrel and plunger detailearly unit injectors (typi |

|||

|

Early unit injectors________________________________ |

|||

|

Engine timing reference marks _______________________ |

|||

|

Equalization tool installation, plumbing____________ |

|||

|

Fuel filter assembly ________________________________ |

|||

|

Fuel rate adjustment details ________________________ |

|||

|

Fuel system schematic _______________________________ |

|||

|

Fuel system special tools ___________________________ |

|||

|

Fuel transfer pump __________________________________ |

|||

|

Fuel transfer pump push rod protrusion ______________ |

|||

|

Injector ____________________________________________ |

|||

|

Injector nozzle protrusion __________________________ |

|||

|

Late/ intermediate unit injectors ___________________ |

|||

|

Static injection testnjectorsinstrumentationearly unit i |

|

||

|

Static timing adjustment ____________________________ |

|||

|

Tdc determination and ingstatic injection timing check |

|

||

|

Unit injector _______________________________________ |

|||

|

Unit injector components ____________________________ |

|||

|

Unit injector delivery equalizationpreparation ____ |

|||

|

Unit injector delivery equalizationpreparation (con |

|||

|

Unit injector fire ring _____________________________ |

|||

|

Unit injector plunger reassembly ____________________ |

|||

© 2001 / 0297 9985 |

6 |

|

|

|

INDEX

PAGE

Unit injector popping ntpressurelow prtessureting proceandadurejustm( intermediate unit injectors) _____________________

Unit injector popping pressure testing and adjust injectorsall ref. No’s other than 272, 272-, 27 Unit injector reassembly (cont.) _________________

Unit injector ring nut removal / replacement _____

Unit injector test stand specifications __________

VII ELECTRICAL SYSTEM 65

12V electrical schematic-marelli 14V-33A _________

12V electrical schematic - 20/30 A flywheel alter

12V electrical schematic-iskra 14V-33A ___________

Battery sizing ___________________________________

Battery sizing ___________________________________

Bosch 12V/1.1 kW starter motor (DW 12V) _________

BOSCH 12V/1.6 kW starter motor (DW 12V) __________

Electrical system service precautions / warning __ Engine side wiring harness for the Deutz supplied Flywheel alternator - 12V________________________

Glow plug ________________________________________

Glow plug controller / relay with coolant temp. S Iskra 14V/33A performance curve __________________

Iskra alternator - 14V/33A _______________________

Deutz supplied control panel ____________________

Marelli AA 125 R, 14V/45A performance curve ______

Marelli alternator (AA 125 R) - 14V-45A__________

Oil pressure (low) switch, coolant temperature (h Performance curve - 20A flywheel alternator______

Performance curve - 30A flywheel alternator______

Performance curve - BOSCH 12V/1.1 kW (DW 12V) sta Performance curve - BOSCH 12V/1.6 kW (DW 12V) sta Temperature sensor (thermistor)__________________

Voltage regulator connection details (flywheel al

VIII TESTING-OPERATIONAL-ADJUSTEMENTS 84

Governor / unit injector rack adjustment ________

High (maximum) speed adjustment __________________

Idle speed adjustment ____________________________

Injection pump control rod stroke limit adjustmen Power, torque device and speed adjustments-dynamo Torque device adjustment (without dynamometer) ___

Torque device details ____________________________

IX STORAGE ________________ |

86 |

|||

Storage __________________________________________ |

||||

Storage |

- 1 to 6 months__________________________ |

|||

Storage |

- |

in excess of 6 |

months _________________ |

|

Preparing |

the engine for |

use after storage _______ |

||

7 |

© 2001 / 0 |

NOTE

© 2001 / 0297 9985 |

8 |

|

|

|

|

stops |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

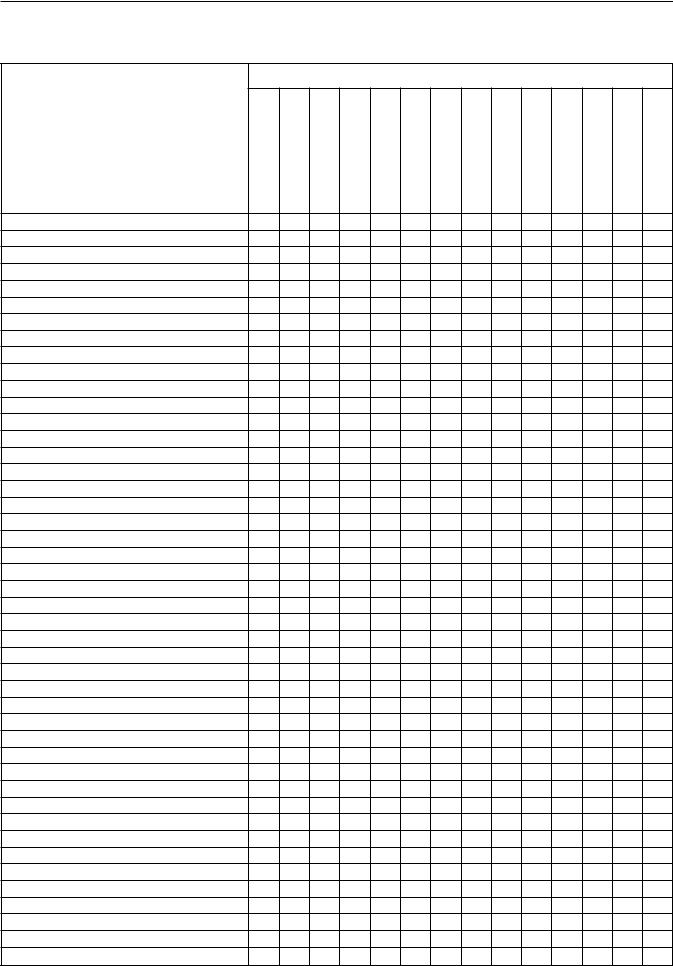

TROUBLESHOOTING CHART-B/FM |

||||||||||||||||||||||||

|

|

|

start |

|

|

|

|

|

|

|

|

|

|

consumption |

|

|

|

|

|

|

|

|

|

||

|

|

crank |

but |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

TROUBLESHOOTING CHART- B/FM 1008 |

||||||||||||||||||||||||

|

|

|

not |

|

|

|

|

|

|

|

|

|

rising |

|

|

|

|

|

|

|

|

|

|

||

|

|

not |

|

|

RPM |

SYMPTOM |

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

pressure |

oil |

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

does |

|

|

|

smoke smoke |

|

|

|

|

|

|

|

|

|

|||||||||

POSSIBLE CAUSEwill |

starts, |

|

|

|

|

|

smoke |

|

level |

exhaust |

|

knocks |

|||||||||||||

|

acceleration |

|

|

|

|

|

oil |

|

|

||||||||||||||||

|

|

Engine Engine Engine Poor Unsteady Black White Blue Low Oil Excessive Wet Overheating Engine |

|||||||||||||||||||||||

Low fuel level |

|

|

• |

• |

|

|

• |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel supply/ return lines• •clogged•• |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

Clogged fuel tank vent |

• |

• |

|

|

• |

|

|

|

|

|

|

• |

|

|

|

|

|

|

|

|

|

|

|||

Fuel pump faulty |

|

|

• |

|

• |

• |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Fuel entrained with air• |

• |

|

• |

|

• |

|

|

|

• |

|

|

|

|

|

• |

|

|||||||||

Unit injector(s) faulty/• |

worn• |

• |

|

|

|

|

|

|

|

• |

• |

||||||||||||||

Unit injector settings |

•incorrect• |

• |

|

|

• |

|

|

|

|

|

|

|

|

|

|

||||||||||

Injection pump rack |

sticking•• |

• |

• |

|

|

|

• |

|

|

|

|

|

|

• |

|

|

• |

||||||||

Oil level too high |

|

|

|

• |

• |

|

|

|

|

• |

|

|

|

• |

|

• |

|||||||||

Improper oil viscosity |

|

|

|

|

|

|

|

|

|

|

• |

• |

• |

|

• |

|

|

• |

|||||||

Oil diluted by fuel |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

Oil pressure relief valve faulty |

|

|

|

|

|

• |

|

|

|

|

|

|

|

|

|

|

|

||||||||

Oil pick-up tube clogged |

|

|

|

|

|

|

|

|

|

• |

|

|

|

|

|

|

|

|

|

|

|

||||

Oil pump air entrained at pick-up tube |

|

• |

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

Glow plugs faulty |

|

• |

|

|

|

|

|

|

• |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Glow plug controller |

faulty• |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Glow plug relay inoperable• |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Starter defective |

• |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Battery voltage too |

low• |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Battery / battery cable• connections corroded |

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

Key switch defective |

• |

• |

|

|

• |

• |

• |

|

|

|

|

|

|

|

|

• |

|

• |

• |

||||||

Air filter clogged |

|

|

|

|

|

|

|

|

|

• |

• |

||||||||||||||

Excessive idle / light load operation• • |

|

|

|

|

|

|

|

|

|

||||||||||||||||

Incomplete engine run-in |

• |

|

• |

• |

|

• |

• |

|

|

|

• |

|

|

• |

|

|

|

• |

|||||||

Engine overloaded |

|

• |

|

• |

|

|

|

|

|

|

|

|

• |

|

|

|

|

||||||||

Excessive parasitic load• • |

|

|

|

|

|

• |

|

• |

|

|

|

|

|

|

|

|

|

|

|

• |

|||||

Valve lash |

insufficient•/ excessive |

|

|

|

|

|

• |

|

|

|

|

|

|||||||||||||

Injection timing out |

of• spec- |

advanced•• |

|

|

|

|

|

|

|

|

|

• |

|||||||||||||

Injection timing out |

of• spec-• |

retarded• |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

Governor linkage |

adjustment•• |

|

incorrect•• |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

Governor spring |

fatigued• |

or |

|

defective•• |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

Idle rpm too low |

|

|

• |

• |

|

|

|

|

|

• |

|

• |

|

|

|

|

• |

|

• |

|

|

|

|||

Piston rings worn or stuck• |

|

|

|

|

|

|

|

|

|

|

|

|

|

• |

|||||||||||

Piston worn or damaged • |

|

|

|

|

|

|

• |

|

• |

|

|

|

|

• |

|

• |

|

|

|||||||

Cylinders worn or damaged• |

|

|

|

|

|

• |

|

• |

|

|

|

|

• |

|

• |

|

|

• |

|||||||

Valves / valve guides worn• |

|

• |

• |

|

|

• |

• |

• |

|

|

|

|

• |

• |

• |

• |

|

||||||||

Valves sticking |

|

|

• |

• |

|

|

|

|

|

• |

|

|

|

|

|

|

|

• |

|||||||

Bearings (main / rod) worn |

|

malfunction••• |

|

|

|

|

|

|

|

• |

|||||||||||||||

Governor / |

governor |

linkage•• |

|

|

|

|

|

|

|

|

|

|

|

• |

|

||||||||||

Cylinder head gasket |

damaged• |

|

|

|

|

• |

|

|

|

|

|

|

|

|

|

• |

|

||||||||

Thermostat |

stuck or malfunctioning |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

Engine seized |

|

• |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• |

|

|

|||

Radiator clogged (external or internal) |

|

|

|

|

|

|

|

|

|

||||||||||||||||

Coolant pump faulty |

|

|

|

• |

• |

• |

|

|

|

• |

|

|

|

|

• |

• |

|

• |

|||||||

Turbocharger faulty |

|

|

|

|

|

|

|

|

|

|

|

• |

|||||||||||||

9 |

© 2001 / 0 |

SAFETY AND WARNING DECALS - SAFETY |

|

SAFETY ANDRNINGW DECALS |

|

DANGER |

CAUTION |

|

! |

Failure to complyFailurewith tohe comply |

|

instructions |

couldinstructionsesult in could |

damage to personstechnicaland damage |

|

property |

machine and/or syst |

SAFETY INSTRUCTIONS

●DeutzessentialEnginesfor areusersbuilttostructionsscomplyintoasupplysafewithgivenandtheirthelonginservicingperformathe-esults,lastingtherelatisafetceiniw recommendations listed below.

●Themeetenginetheessentialhas beensafetymadeequisitesufaacandcordingturer'shealthhavetobeenspecificatisafeguardingmachinetakent,tolawsasnsmanr p

in merit. All uses of theficallyengineestablishedbeyond thosecannotasspect conforming to the use declinesfined byallDeutzliabilwhitychom forthussuchand operations.

●Theconcerningfollowingengineindicationsoperationthofthearetheinrelativededicatparticular,machineroutinedintoorderalongthemainteksusewito

●Thethisusercouldmustleadreadto theseseriousbecomeinstructionsdangerfamiliarfor carefullyhiswithpersonallurethe operaandtods vicinity of the machine.

●Theoperationengineandmaytheonlyderivingbeisusednealsobydangersortechniciansessentialassembled.Thiswheoncowhonaveditareitsmachiall,ioncomad

extraordinary maintenancelatteropercase,tionsmustwhich,onlyecificallinbethecarr trained by Deutz and whoe existingwork compliancedocumentationwith. th

●Variationsremoval of seals,tothe demountingfunctionne,ribedadjustmentslandparameinrefittingtheerstooperationoftheofthespeed,fuelpartsandngif

unauthorized personnel shall relieve Deutz from all comply with the laws in merit.

●Onthestarting,caseof manualmake surestartntallativethat-ups,astheactionspossible,makeengineurecanisunlessthtakeasittingdifferthehorizoplactherewal.m

or dangerous objects, alsomadeconsideringby the operatorthe movementord.Pull(thusexcluding self-winding startingenan only),emergencyis .not permit ● Make sure that the machine rturningisstable. to prevent the

© 2001 / 0297 9985 |

10 |

SAFETY AND WARNING DECALS - SA

● Become familiar with how top adjusttheenginethe .rotation s

●Nevermonoxide,startantheodourlessenginehereandinngthyaishighlyclosedstainsufficientspoisonousplaceinplacesorventilsgaswhercarwhests. this gas can lead to unconsciousness and death.

●Theis dustenginethatmustcannoteasilyadequoperflacatmmableteechinandfireplmclearlyatceunlesrials,containdicatespecificintakeneingexpthe have been certified for the machine.

●To prevent fire hazards, alwaysmeterkeepfromthebuildingsmachine

● derivingChildren fromandanimalstheiroperationmustfrombe .keptoperating machinesduedista

●Fuelthe fuelis inflammablecontaineraway.Thehenalongtheank enginewithmustanyonlyis ragsoffbel.filledsoakeandThorm

of porous material aresuresoakedthatinthefuelgroundor oiloris.floostaMak has not soaked up any fuel or oil.

● Fullyspace fortightenthe fuelthetanktoingexpandplug.Do .eachnot filltime theafteranrefukaderi

●Fuel vapour is highlyrtoxicin a.welOnlyventilatedrefueloutdoorsplace

●Do not smoke or use naked flames when refuelling.

●Theand/orenginemachinemustitselfbestarted.gpecificDoaidsnotn hatcomplianceuseinstructionswereauxiliarynotwithineinstaengith(rl Startpilot’).

●Beforeguards havestarting,been refittedremoveserviceany.toolsthethatenginewereand/oallused

●Duringparticularoperation,. the omesurfacedangerouslyof the enginehot.Avoidtemcan b

●Beforewhilst proceedingtheengine withisrunningany operation. on the engin

●Thein thiscoolantcase,fluidonlycircuitopencarrytheisoutradiatorunderany inspectionspressureplug d.orandNeveexpun

garments and goggles.doIfnotthereapproachis an theelectricenginesthefanw also start operating whentill.theOnlyenginecleanistheat coolanissta standstill.

●Whensafeguardcleaningthe environmtheoil-thaterialcoolednt.theTheinairoldspongyoilfilter,-oilcooledfilteringismakediairnspooilsufirdsem

|

reservoir |

of the separatorilled withpre-filteroil. must not be |

|

● allowThe oilthemustoilbetodrainedcomeilinto° TwhilstC)~.contact80Particularthe enginewithcaretheis skinishotnore. |

|||

● |

safeguardMake sure |

thethatenvironmentthe drainedtheoil.oil,tcontainstheoil |

filterarewaydispinano |

● |

Pay attention to the temperaturelteritselfof theis |

replacedoilfilte. |

|

●Onlycontainingcheck,nitritestopup andfromatchangethedobeinengineotgthemixedcontaincoolantiswithoffthesefluidothersandne",suc

dangerous for the health,idiscanpollutingform. Theandcoolantmustthehecf way to safeguard the environment.

●Duringdisconnectoperationsand insulatethattteryinvtstheolveftpothesitipreaccessengineventwiretoaccidentatopand/ormovingofthe starter motor from being energized.

●Only check belt tension when the engine is off.

●Onlymachine;use inthethiseyeboltscase,einstallmanufacturertheengineyeboltse.d ThesbyDshouldeinstalledutzliftingobethemoveusebypoie

11 |

© 2001 / 0 |

I GENERAL

All pertinent informationicationneededan sparforenginepartsomidentifordtheringengi data plate. Additionally,“K”thenumbermaximumand engineapprovalspeed,enginecod s data plate. The location below,oftheisdataidenticalplate, forasustrialshowall engines. Please supply ationheengineto yourdataAuthorizedplate informwhenDEUTZ ordering replacement partsinquiriesor when. making technical

© 2001 / 0297 9985 |

12 |

Loading...

Loading...