Deutz B-F L 1011F, B-FM 1011F Operation Manual

23 Gerade

3

Engine Operation

3.1 Commissioning

3.2 Starting

3.3 Monitoring Systems

3.4 Stopping

3.5 Operating Conditions

24

3

26 432 0

OIL

Engine Operation

3.1 Commissioning

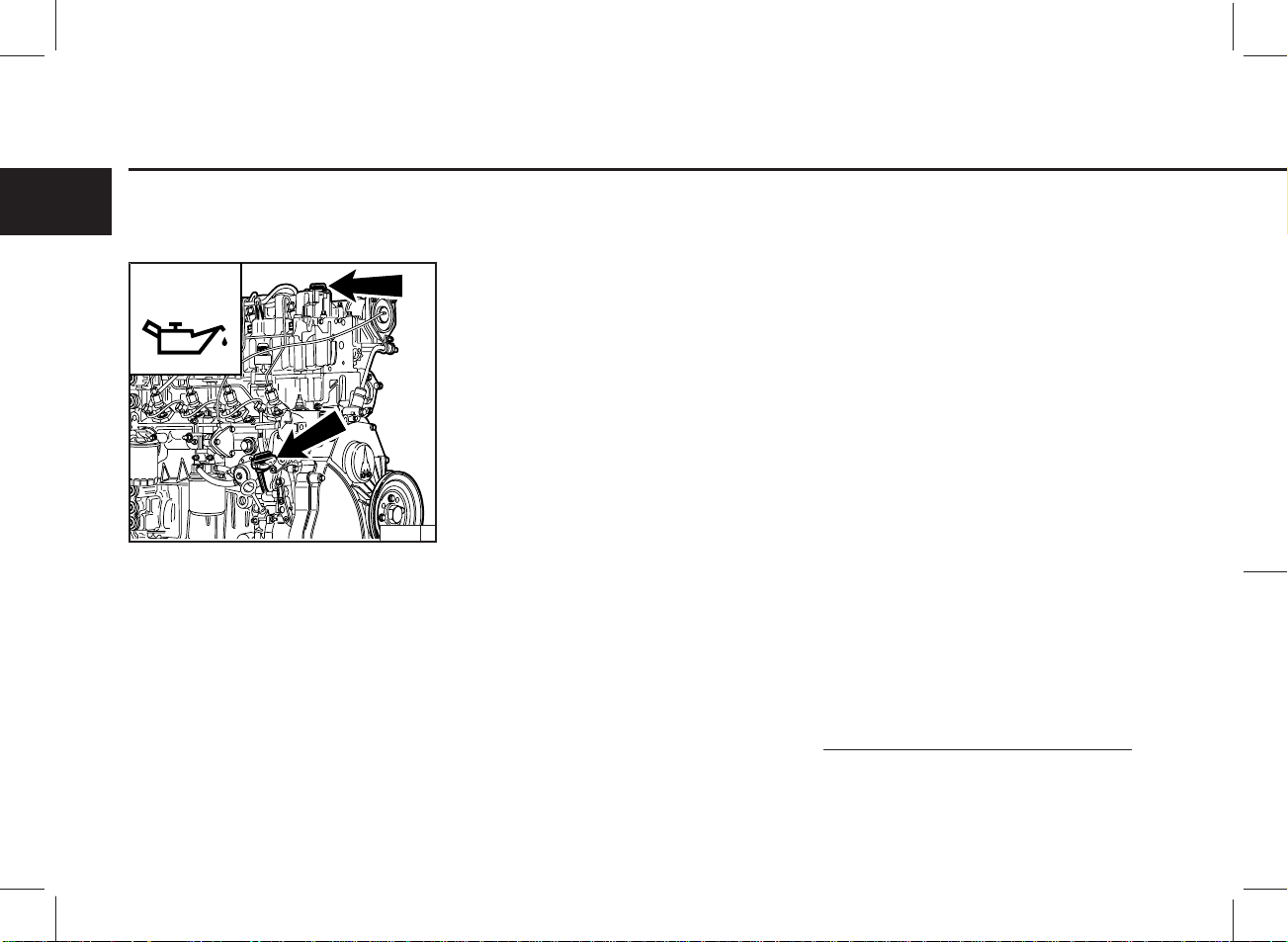

3.1.1 Adding Engine Oil

As a rule, engines are delivered empty of oil.

Pour lube oil into the oil filler neck (arrow).

For oil grade and viscosity, see 4.1.

3.1.1.1 Initial Engine Oil Fill-Up

for B/FM1011F Series

● Fill oil into the oil sump up to the “max.” mark on

the engine dip stick (for oil top-up quantity see

9.1).

● Start the engine and allow to run at a low idling

speed for approx. 2 mins.

● Switch off the engine.

● Check the oil level, if necessary, top up oil to the

„max.“ mark.

If the person operating the engine does not run up

the engine until the thermostat opens, the oil level

may lie above the „max“. mark on the engine dip

stick when delivered. The level can then only be

assessed after the engine has been run up.

3.1.1.2 Initial Engine Oil Fill-up

for B/FM 1011F Series

● Fill oil into the oil sump up to the “min.” mark on

the engine dip stick.

● In addition, top up the oil quantity of the supply

hoses and of the external oil cooler (according to

manufacturer’s details).

● Allow the engine to run warm until the thermostat

opens (at approx. 95

o

C).

● Allow the engine to run for approx. 2 mins.

● Switch off the engine.

● Check the oil level, and if necessary, top up oil to

the „max.“ mark.

25 Gerade

3

24 980 2 26 398 0

! !

FUEL

Engine Operation

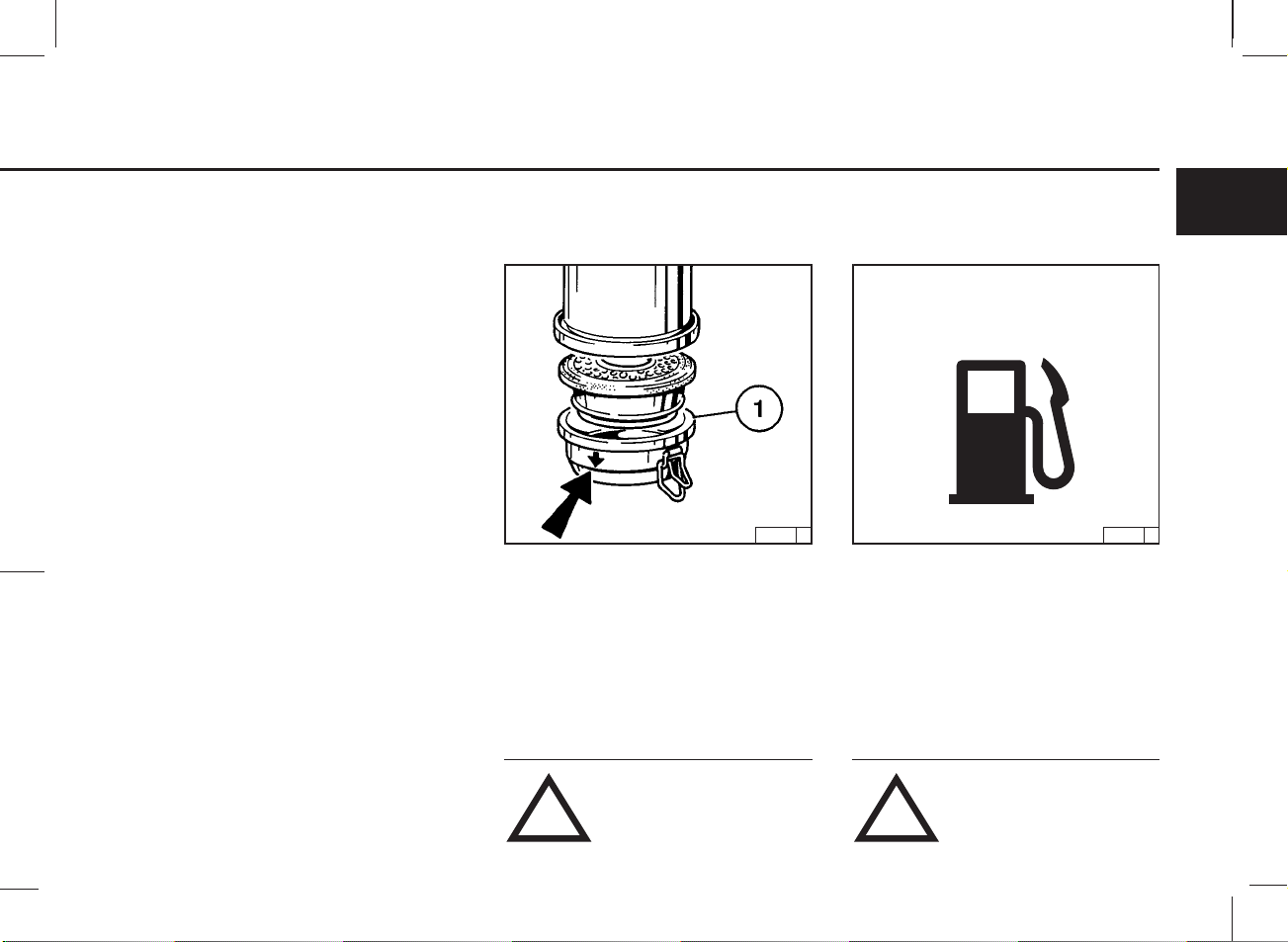

3.1.2 Filling Oil Bath Air Filter with

Engine Oil

Fill oil cup 1 of the oil bath air cleaner with oil up to

the arrow.

For oil grade and viscosity, see 4.1.

Do not fill the precleaner dust col-

lector (if fitted) with oil.

3.1.3 Adding Fuel

Use only commercial-grade diesel fuel. For fuel

grade, see 4.2. Use summer or winter-grade fuel,

depending on the ambient temperature.

Never fill the tank while the engine

is running. Keep the filler cap area

clean and do not spill fuel.

3.1 Commissioning

3.1.1.3 Initial Engine Oil Fill-Up for

B/FM 1011F Genset Engine

● Fill oil into the oil sump up to the “max.” mark on

the engine dip stick (for oil quantity see 9.1).

● Start up the engine and allow to run at a lower

idling speed for approx. 2 mins.

● Switch off the engine.

● Check the oil level and fill up with oil up to the

upper „max.“ mark.

26

3

Engine Operation

3.1.4 Other Preparations

● Check battery and cable connections, see 6.7.1

● Transport hooks

Remove if fitted (see 6.7.3)

● Trial run

After the engine has been prepared, let it run

for about 10 minutes without load.

During and after trial run

– Check the engine for leaks

After the engine has been turned off

– Check the oil level,

see 6.1.2

If necessary, top up oil,

see 3.1.1

– Retension V-belts, see 6.5

● Breaking in

During the break-in phase – about 200 operat-

ing hours – check the oil level twice a day. After

the engine is broken in, checking once a day

will be sufficient.

3.1 Commissioning

3.1.5 Additional Maintenance Work

When commissioning new and reconditioned en-

gines, the following additional maintenance work

must be carried out:

After 50-150 OH

● Change lube oil,

see 6.1.2

● Change oil filter cartridge,

see 6.1.3

● Change fuel filter cartridge,

see 6.2.1

● Check V-belts and retension as necessary,

see 6.5.

● Check the engine for leaks

● Check the engine mount and adjust as neces-

sary, see 9.2

After 500 OH

● Check the valve clearance and adjust as neces-

sary, see 6.6.1.

Loading...

Loading...