Bosch HGS256UC-01, HGS252UC-01, HGS445UC-01, HGS446UC-01, HGS442UC-01 Installation Instructions Manual

...

ATTENTION PROPANE USERS: DO NOT ATTEMPT TO CONNECT THiS RANGE

TO PROPANE USING THE NATURAL GAS CONNECTION DESCRIBED IN THIS

MANUAL

PUease see the "LP Conversion Instructions" incUuded in this Uiterature kit to convert this range

for propane use,

Praise read all instructions before using this applianceo

Table of Contents

Safety Instructions and Applicable Codes ........................................................................... i,2

Install Ventilation, Prepare Cabinets and Install Anti=Tip Bracket ............................................... 3

Connect Gas ....................................................................................................................... 4

Test Burner Function ............................................................................................................ 5

Adjust the Flame ................................................................................................................. 6

, Remove all tape and packaging before using the range.

Destroy the carton and plastic bags after unpacking the

range. Never allow children to play with packaging material.

Install only per these installation instructions.

Ask your dealer to recommend a qualified technician and an

authorized repair service. Know how to disconnect the power to

the range atthe circuit breaker or fuse box and the gas supply at

the shutoff in case of an emergency.

Note: This range is not designed for manufactured (mobile)

home installation.

User servicing - Do not repair or replace any part of the

appliance unless specifically recommended in the manuals. All

other servicing should be done by a qualified technician. This

may reduce the risk of personal injury and damage to the range.

PARTS PROVIDED

Anti-Tip Bracket

TOOLS AN DPARTS NEEDED:

* Standard Measuring Tape

* Phillips Head Screwdriver

* !=!/4"Wrench

* Pencil

o =1==20Torx Screwdriver

* 3/8" Nut Driver

o Screws (2) and Anchors (2) for Anti-tip Bracket (Style will

varydepending on mounting surface)

, PipeWrench (2)

* Teflon® Tape* or Pipe Joint Compound (Appropriate for use

with LP gas and Natural gas)

o Channel Lock Pliers

* Gas Leak Test Solution

* Level

* DriUand Ddl[ Bit

* GasSupply Line (Flexible HetalAppliance Connector or Rigid

Pipe)

* GasShut Off Valve (If not already present)

o GIoves and Safety Goggles

f

IIf the informationinthismanualisnotfollowed I

[exactly, a fire orexplosionmay result causing I

[,_propertydamage, personal injury or death,)

@

@

Do not store or use combustible materials,

gasoline or other flammable vapors and

liquids in the vicinity of this or any other

appliance,

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance,

• Do not touch any electrical switch,

• Do not use any phone in your

building,

• Immediately call your gas supplier

from a neighbor's phone, Follow the

gas supplier's instructions,

• If you cannot reach your gas supplier,

call the fire department,

Installation and service must be performed by a

qualified installer, authorized service agency or the

gas supplier,

i CAUTION ]

Do not use the oven or warming drawer (if equipped) for I

storage. J

CAUTION

f Unitis heavy and requires at least 1

two persons or proper equipment |

L t° _°ve" )

* Teflon is a registered trademark of DuPont

Page 2

WARNING

RANGE TIPPING HAZARD

® Allrangescantipand injuryceuJdresuJt.Toprevent

accidentaltippingoftherange, attach ittothefloorby

installingthe Anti-TipDevice supplied.

o Ariskoftipoovermayexistiftheapplianceisnot

installedinaccordance with these instructions.

® Installanti-tipdevicepacked withrange.

o Ifthe range is pulled away from the wall for

cleaning,service,orany otherreason,ensure thatthe

Anti-TipDeviceispropertyreengaged when the range

ispushed backagainstthewaH.Intheeventofabnormal

usage (suchas a person standing,sitting,orleaningon

an open door)_failureto take thispreoautionceuld

resultintippingof the range. Personal injurymight

resultfrom spilledhotliquidsorfrom the range itseff.

J

Improper installation, adjustment, alteration, service or

maintenance can cause injury" or property damage,

Refer to this manual, For assistance or additional

information consult a qualified installer, service agency;

manufacturer or the gas supplier,

J

WARNING

Beforeinstalling,turnpower OFF at

theservicepanel Lock service _neJ

topreventpower from beingturned

ON aocidentaHy.

Avoid drafts across the range, They"will obstruct ventilation

and combustion,

o Never modify or alter the construction of a range by

removing leveling legs, panels, wire covers, anti-tip brackets,/

screws, or any other part of the product,

Notice: DONOT LIE RANGE BY DOOR HANDLE, Remove

the door for easier handling and installation. See Section

'Removing Oven Door' in Use and Care manual.

f

For Massachusetts Installations:

1. Installation must be performed by a qualified or

licensed contractor, plumber or gas fitter qualified or

licensed by the state, province or region where this

appliance is being installed.

2. Shut-off valve must be a "T" handle gas cock.

3. Flexible gas connector must not be longer than 36

inches.

HIGH ALTITUDE IN$TALU_,T_ON NOTE:

Forinstallation at altitudes above 2,000 ft., contact Bosch

Service (800-994-290zt) for special instructions.

IMPORTANT:

LOCAL CODES VARY. INSTALLATIONr ELECTRICAL

CONNECTIONS AND GROUNDING MUST COMPLY WITH ALL

APPLICABLECODES.

Proper Installation =Be sure your appliance is properly

installed and grounded by a qualified technician in accordance

with the National Electrical Code ANSIiNFPA No.7 latest edition

and local electrical code requirements.

This appliance has been tested in accordance with ANSI Z21.1,

Standard for Household Cooking Appliances (USA) and in ac-

cordance with CAN 1.1-M81 Interim Reqt #58 Domestic Gas

Cooktops (CANADA).(In Canada, installation must be inaccor-

dance with the CAN 1-B149.1 and .2 Installation Codes for Gas

Burning Appliances and/or local codes).

The following must be met when testing supply piping system:

a) The appliance and its individual shut-off valve must be

disconnected from the gas supply piping system at test

pressures in excess of :[/2 psig (3.5 kPa).

b) The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or lessthan

1/2 psig (3.5 kPa).

ElectricalSpecifications:

Ranges are rated for use on a :[20 Vi 15 AMP circuit.

TO PREVENT ELECTRICAL SHOCK, THE GROUNDING PRONG

SHOULD NO% UNDER ANY CIRCUMSTANCES, BE CUT OR RE-

ROVED. IT MUST BE PLUGGEDINTO A MATCHING GROUNDING

TYPE RECEPTACLEAND CONNECTED TO A CORRECTLYPOLAR-

IZED :[20-VOLTGRCUIT,

A separate, non GFC[ circuit is recommended unless local code

specifies otherwise.

If there is any doubt as to whether the wall receptacle is prop-

erly grounded, have it checked by a qualified electrician.

Page 3

1o InstaL! Ventilation

Installation of a suitable ventilation system (i.e.; ventilation hood)

above this range is strongly recommended. For most kitchens

with a wall mounted hood, a certified hood rating of not less than

350 CFMisrecommended. Bosch hoods rated at 350 CFMor more

when operated on high meet the above requirement and are

recommended for this purpose. The range hood must beinstalled

according to instructions furnished with the hood.

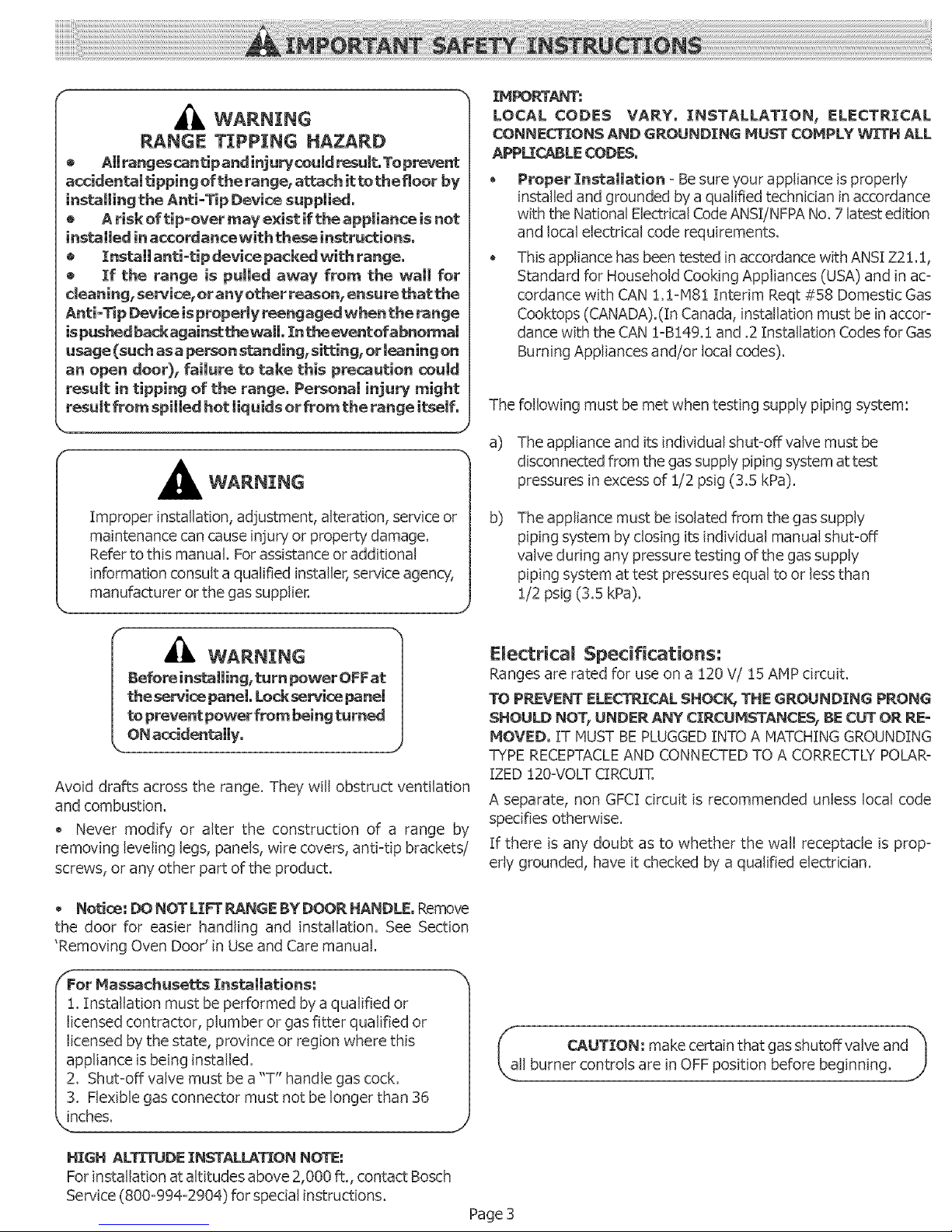

2, Prepare Cabinets (See Figure 1)

This unit can be installed near adjacent walls and projecting

surfaces constructed of combustible materials. There must bea

minimum clearance of 30 inches between the top of the cooking

surface and the bottom of an unprotected wood or metal cabinet;

or 24 inches when bottom of wood or metal cabinet is protected

by not less than 1/4" of flame retardant material covered with

not lessthan No. 28 MSGsheet metal, 0.015 inch stainless steel

or 0.024 inch aluminum or copper, Zero clearance from unit walls

to adjacent vertical combustible walls is permitted on rear, right

and left walls. Clearance from range top to adjacent vertical

walls must be at least 4".

Seal any openings in the wall behind the appliance and in the

floor below the appliance.

Forthe cabinets over the cooking surface and the adjacent cabinets,

the maximum cabinet depth from back wall is 13 inches.

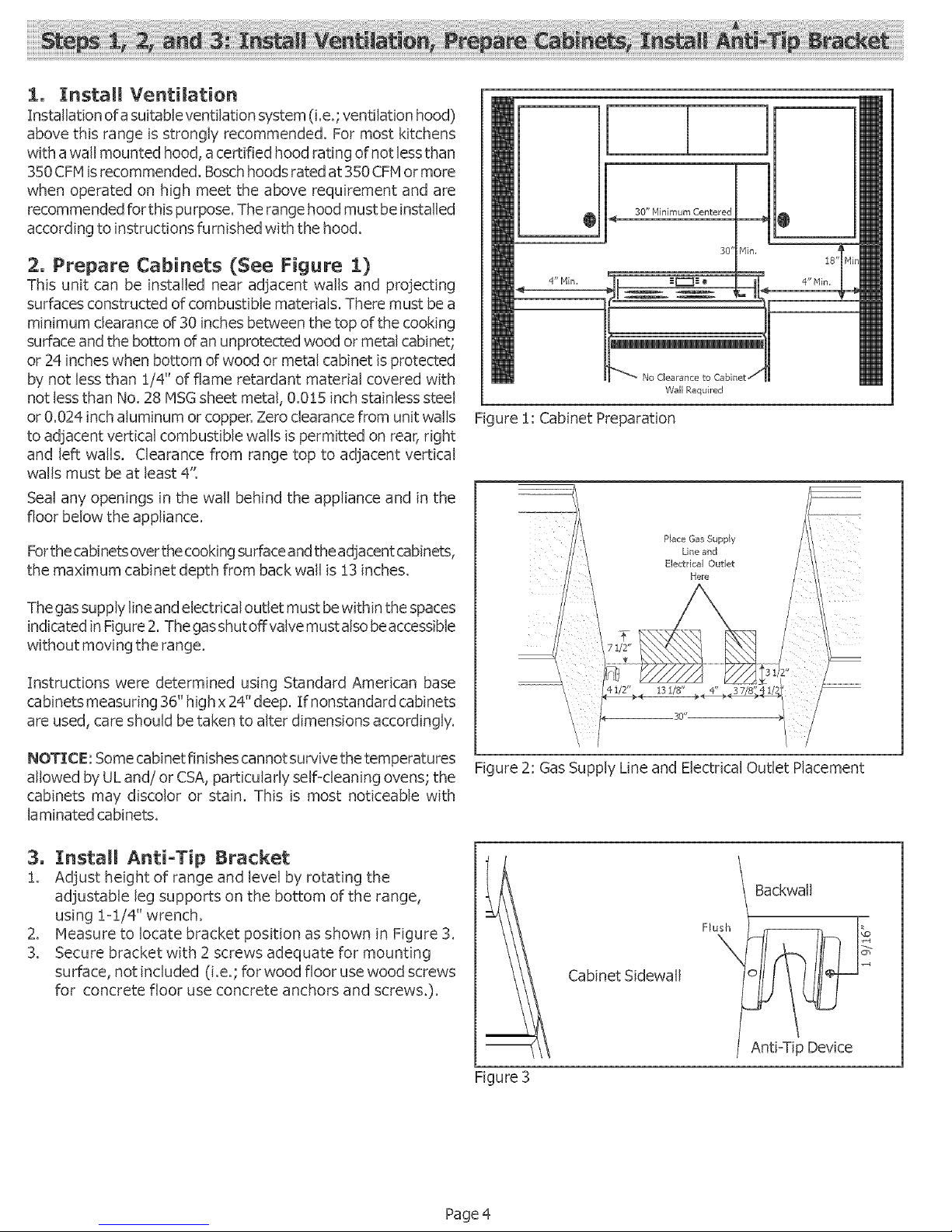

The gassupply line and electrical outlet must be within the spaces

indicated in Figure 2. The gasshutoff valve must also beaccessible

without moving the range.

Instructions were determined using Standard American base

cabinets measuring 36" high x 24" deep. If nonstandard cabinets

are used, care should be taken to alter dimensions accordingly,

NOTIC£: Some cabinet finishes cannot survive the temperatures

allowed by UL and! or CSA, particularly self-cleaning ovens; the

cabinets may discolor or stain, This is most noticeable with

laminated cabinets,

Q

30" Minimum Centered

!

30' P1in,

No Clearance to Cabin

Wall Required

O

18'

4" P1in,

ure 1: Cabinet Preparation

Place Gas Supp}y

Line and

Electrical Outlet

Here

Figure 2: Gas Supply Line and Electrical Outlet Placement

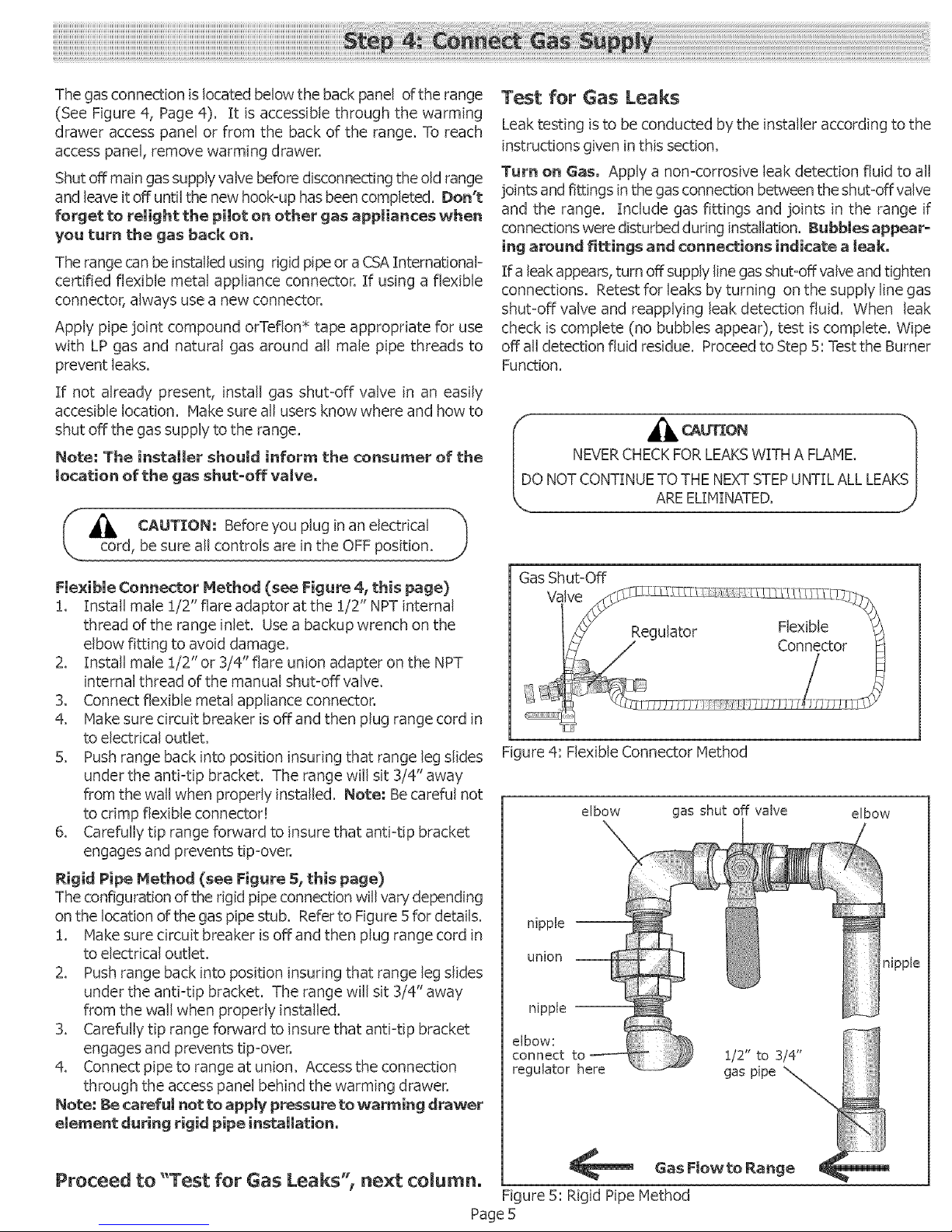

3, ]InstaL! Anti-Tip Bracket

1. Adjust height of range and level by rotating the

adjustable leg supports on the bottom of the range,

using 1-1/4" wrench.

Z Measure to locate bracket position as shown in Figure 3.

3. Secure bracket with 2 screws adequate for mounting

surface, not included (i.e.; for wood floor use wood screws

for concrete floor use concrete anchors and screws0.

Figure 3

Backwall

Cabinet Sidewall

Flush

\

Anti-Tip Device

Page 4

Thegasconnectionislocatedbelowthebackpaneloftherange

(SeeFigure4,Page4). It isaccessiblethroughthewarming

draweraccesspanelorfromthebackof therange.Toreach

accesspanel,removewarmingdrawer.

Shutoffmaingassupplyvalvebeforedisconnectingtheoldrange

andleaveitoffuntilthenewhook-uphasbeencompleted.Don't

forget to reiight thepilot onother gasapplianceswhen

you turn the gas back on.

The range can be installed using rigid pipeor a CSAInternationaF

certified flexible metal appliance connector, If using a flexible

connector, always use a new connector,

Apply pipe joint compound orTeflon* tape appropriate for use

with LP gas and natural gas around all male pipe threads to

prevent leaks.

If not already present, install gas shut-off valve in an easily

accesible location. Make sure all users know where and how to

shut off the gas supply to the range.

Note; The installer should inform the consumer of the

location of the gas shut-off valve,

A CAUTION: Beforeyou plug in an electrical

Flexible Connector Method (see Figure 4, this page}

!. Install male :[/2" flare adaptor at the :[/2" NPT internal

thread of the range inlet. Usea backup wrench on the

elbow fitting to avoid damage.

2. Install male 1/2" or 3/4" flare union adapter on the NPT

internal thread of the manual shut-off valve.

3. Connect flexible metal appliance connector.

zk Make sure circuit breaker is off and then plug range cord in

to electrical outlet.

5. Push range back into position insuring that range leg slides

under the anti-tip bracket. The range will sit 3/4" away

from the wall when properly installed. BIote: Be careful not

to crimp flexible connector!

6. Carefully tip range forward to insure that antFtip bracket

engages and prevents tip-over.

Rigid Pipe Method (see Figure S_this page}

The configuration of the rigid pipe connection will vary depending

on the location of the gas pipe stub. Refer to Figure 5 for details.

!. Make sure circuit breaker is off and then plug range cord in

to electrical outlet.

2. Push range back into position insuring that range leg slides

under the anti-tip bracket. The range will sit 3izV'away

from the wall when properly installed.

3. Carefully tip range forward to insure that antFtip bracket

engages and prevents tip-over.

zk Connect pipe to range at union. Access the connection

through the access panel behind the warming drawer.

Note; Be carefut not to apply pressure to warming drawer

element during rigid pipeinstallation.

Test for Gas Leaks

Leak testing isto be conducted by the installer according to the

instructions given in this section.

Turn on Gas. Apply a nomcorrosive leak detection fluid to all

joints and fittings in the gas connection between the shut-off valve

and the range. Include gas fittings and joints in the range if

connections were disturbed during installation. Bubbiesappear o

ing around fittings and connections indicate a Jeak,

If a leak appears, turn off supply line gas shut-off valve and tighten

connections. Retest for leaks by turning on the supply line gas

shut-off valve and reapplying leak detection fluid. When leak

check is complete (no bubbles appear), test is complete. Wipe

off all detection fluid residue. Proceed to Step 5: Test the Burner

Function.

NEVERCHECKFOR LEAKSWITH A FLAME.

O NOT CONTINUE TO THE NEXTSTEPUNTIL ALLLEA

AREELIMINATED.

Gas Shut-Off

Figure 4: Flexible Connector Method

elbow gas shut off valve elbow

\

nipple --

union

nipple

elbow:

connect

regulator here

Proceed to "Test for Gas Leaks'; next columno

Figure 5: Rigid Pipe Method

Page 5

@pie

1. Turn on Power at Breaker

If LCD screen flashes and beeps continuously, the wiring is in=

correctly installed. Verify that wiring in house is correctly in=

stalled. If so, call Bosch Service.

2o Test Rangetop Burners

Test Burner Ignition, Select a rangetop burner knob. Push

down and turn to the flame symbol. The ignitor/spark module

will produce aclicking sound. Once the air has been purged from

the supply lines, the burner should light within four (4) seconds.

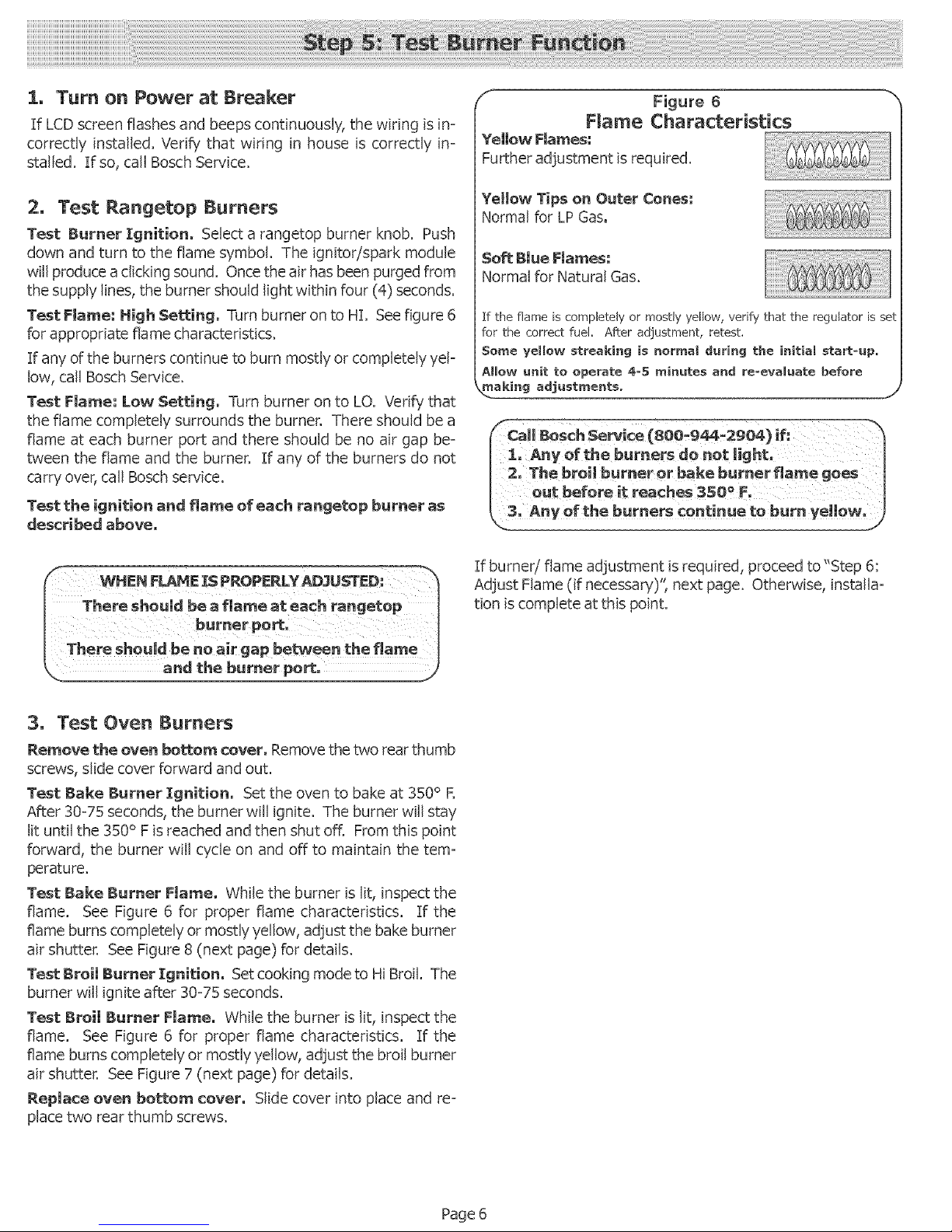

Test Flame: High Se_:ing, Turn burner on to HL Seefigure 6

for appropriate flame characteristics.

If any of the burners continue to burn mostly or completely yeF

low, call Bosch Service.

Test Flame: Low Setting, Turn burner on to LO. Verify that

the flame completely surrounds the burner. There should be a

flame at each burner port and there should be no air gap be-

tween the flame and the burner. If any of the burners do not

carry over, call Boschservice.

Test the ignition and _ame of each rangetep burner as

described above,

Figure 6

Flame Characteristics

Yellow FJames:

Further adjustment is required.

Yellow Tips on Outer Cones:

Normal for LP Gas.

Soft Blue Flames:

Normal for Natural Gas.

If the flame is completely or mostly yellow, verify that the regulator is set

for the correct fuel. After adjustment, retest.

Some yellow streaking is normal during the initial startoup.

AHow unit to operate 4o5 minutes and reoevaUuate before

_aking adjustmentso __ .__j

Call BOSChSerWce (80B19_:2904)if: h

1: Any of the burrJers de not light' q

2' The broi! burner or bake burner flame goes

out before it reaches 3SO o F.

'of the burners continue to burn ye|moW,_

if burner/flame adjustment is required, proceed to"Step 6:

Adjust Flame (if necessary)", next page. Otherwise, installa-

tion is complete at this point.

3, Test Oven Burners

Remove the oven boL_em cover. Remove the two rear thumb

screws, slide cover forward and out.

Test Bake Burner Ignition. Set the oven to bake at 350° R

After 30=75 seconds, the burner will ignite. The burner will stay

lit until the 350° F is reached and then shut off. From this point

forward, the burner will cycle on and off to maintain the tem-

perature.

Test Bake Burner Flame. While the burner is lit, inspect the

flame. See Figure 6 for proper flame characteristics. If the

flame burns completely or mostly yellow, adjust the bake burner

air shutter. See Figure 8 (next page) for details.

Test Broil Burner Ignition. Set cooking mode to Hi Broil. The

burner will ignite after 30=75 seconds.

Test Broil Burner Flame. While the burner is lit, inspect the

flame. See Figure 6 for proper flame characteristics. If the

flame burns completely or mostly yellow, adjust the broil burner

air shutter. See Figure 7 (next page) for details.

Replace oven bottom cover. Slide cover into place and re=

place two rear thumb screws.

Page 6

Loading...

Loading...