Wolf Slim Jim Manual

WIE CIRCULAR KNIFE

PARTS & SERVICE MANUAL

20th EDITION - Published April 2009

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SLIM |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

JIM |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Carpet |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Culler |

|

|

|

|

|

|

SERVICE INSTRUCTIONS |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

This is a hazardous type of machinery and should be used with care. Always discon- |

|

|||||||||||

|

|

|

|

|

nect electrical connector before performing repairs, adjustments or maintenance. |

|

|||||||||||

|

|

|

|

|

Be sure machine is properly grounded. Never place hands or any part of your person |

|

|||||||||||

|

|

|

|

|

in the path olllle machine when It'sIn service. Keep tile front guard as tow as pos- |

|

|||||||||||

|

|

|

|

|

sible during operation and completely down when not in use. For personal safety |

|

|||||||||||

|

|

|

|

|

the operator should remove all loose liHing jewelry, shouldn'twear loose or baggy |

|

|||||||||||

|

|

|

|

|

IIHing clothing and persons with long hair should cover or pull it back. |

|

|

||||||||||

|

|

|

|

|

|||||||||||||

|

|

|

Keep the machine dean and properly adjusted, as this will add to its life and efficiency. |

|

|||||||||||||

|

|

|

When ordering: replacement part!. be sure to give Part No., description and machine size. |

|

|||||||||||||

|

|

|

|

|

|||||||||||||

|

MOTOR ROTATION |

Before plodng three phose machines in servi~ be sure the knife rotates in o counter- |

|

||||||||||||||

|

clockwise direction when looking at the nameplate side of the machine. The rotation con |

|

|||||||||||||||

|

|

|

|

||||||||||||||

|

|

|

be checked |

by a flash contact |

at |

the |

electrkol |

connector with |

the |

$Witch |

turned on. |

|

|||||

|

|

|

i |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

~~HB:ii<~;,::l interchange |

two |

wires (not |

ground wire) at |

eleetrical |

connector. |

|

||||||||

|

|

|

|

|

|

~ Should the machine be run in the wrong direction ports could unscrew |

|

||||||||||

|

|

|

|

|

|

machine. Single phose machines always rotate in the proper direction. |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

||||||||

|

LUBRICATION |

The |

greose |

cup in |

the :>tondard should be halF filled with greose. |

Use only a |

good grade |

|

|||||||||

|

of cup greo~e. |

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

To oil s.horpener journals, remove screw in end of bushing shaft and oil. |

Keep emery free |

|

||||||||||||

|

|

|

from oil ond grease. To do this~ |

remove emery and rvb wheels together until they show o |

|

||||||||||||

|

|

|

good surface, or :;:pray with Keep-M-Kieen solution (Order 112100600}. |

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

TO SHARPEN KNIFE |

lt Is |

most essential |

that a keen |

cutting edge |

be |

kept on |

rhe knife at aH times, os rhh |

|

||||||||

|

io:sures clean ood eosy cutting. |

To obtain this, |

the grinding wheels must be kept properly |

|

|||||||||||||

|

|

|

|

||||||||||||||

|

|

|

adjusted. Because of the wear of knife and emery wheels, it |

is necessary to adjust emeries: |

|

||||||||||||

|

|

|

toward the knife to |

ovoid long bevel. |

Wheels must touch |

knife evenly. Adjustment h |

|

||||||||||

|

|

|

mode by releasing screws domping the threaded journals. The journals con then be tvrned |

|

|||||||||||||

|

|

|

to the proper position. Care should be token thot the e:nery wheels do not go too far down |

|

|||||||||||||

|

|

|

on knife. A good bevel of 1/8" makes o good cutting edge. Emeries mvst spin free at all |

|

|||||||||||||

|

|

|

times. |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|||||||||

|

TO REMOVE KNIFE |

To. remove |

koife 1 |

ploce pin in |

hole throvgh |

stondord. Use kniFe wrench and tum knife |

|

||||||||||

|

|

|

nut to left. |

When |

knife wears, move toeplote bock so that knife is about l/16" from end |

|

|||||||||||

|

|

|

of slot. Be sure to tighten screws that secure toeplote. |

|

|

|

|

|

|||||||||

|

|

|

|

|

|||||||||||||

|

TO REMOVE GEAR |

To remove knife gear# hove knife on gear. Then put pin in ~nife and standard and loosen |

|

||||||||||||||

|

|

|

grease cop with pin wrench. Remove knife ond cop. Then remove screw ood wa~her. The |

|

|||||||||||||

|

|

|

gear con then be lifted off. Be sure not to lose any woshe" that moy be under bearing, as |

|

|||||||||||||

|

|

|

they |

adjust |

the mesh of the geol'$, |

When replacing, be svre the $Crew ond cop are tight. |

|

||||||||||

|

|

|

|

|

THE WOLF MACHINE COMPANY |

|

|

|

|

||||||||

|

|

|

|

|

5570 Creek Road • Cincinnati, OH 45242 • USA |

|

|

|

|||||||||

|

|

|

|

|

Phone: 513-791-5194 • FAX 513-791-0925 |

|

|

|

|

||||||||

|

|

1st/Since 1888 |

TOLL FREE 1-800-543-WOLF |

|

|

|

|

|

|

|

|||||||

|

|

e-mail: info@wolfmachine.com • Web Site: www.wolfmachine.com |

|

|

|||||||||||||

From the library of: Superior Sewing Machine & Supply LLC

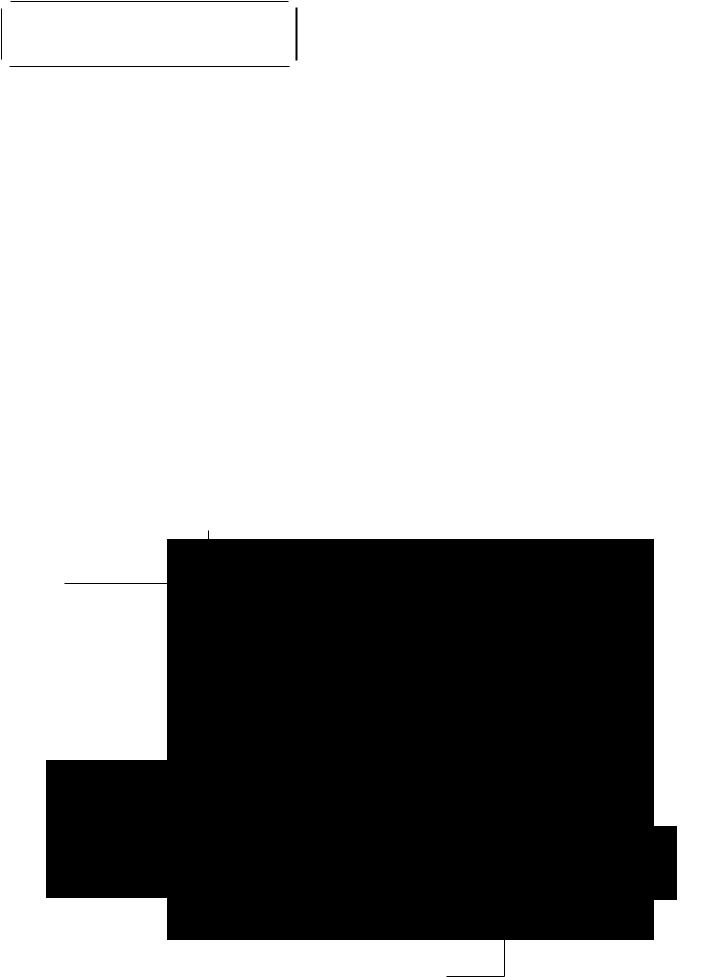

GEARS • STANDARD

BLADE • BASE

4557300

3515000 4557400

3515100 4557500

3515500 4557600

455noo

4565199

4565299

4565399

4565499

4565599

3560000 4559700 4560200

3560100 4559800 4560300

3560200 4559900 4560400

4560000 4560500

4560100 4560600

4560700

BLAZER

CLIPPER

SEE PARTS liST BOTTOM

OF NEXT PAGE FOR

DIFFERENT SIZES, TYPES

OF MATERIALS & NUMBERS,

3285360 |

|

3575050 |

3567000 |

4584350 |

4567200 |

Footplote & Lifter S A

1083099

3576099

45B3l99

4582200

1081000

J? ~

1081100 99003551!

|

1082000 |

~ |

|

|

|

|

1082200 |

|

|

3577000 |

|

|

3582000 |

|

2 |

|

G> |

|

|

4568399'

9902029

4568460'

|

4588559 |

||

|

Footpfole |

||

|

458il599JCoMplete |

||

990f595 __.__, |

Slim Jim |

|

|

|

Carpet Cutter |

|

|

|

Parts marked with an |

|

|

|

asterisk are Slim Jim |

|

|

|

Carpet Cutter paris only. |

|

|

|

|

|

|

\

Q

62

3555000

4555100

4555200

4590100

3285259

3575059

4584159

Footplate Complete

From the library of: Superior Sewing Machine & Supply LLC

NUMBERS FOR MOTOR, ELECTRICAL PLUGS & SWITCH

IN NUMERICAL ORDER

Blazer, Clipper, |

|

|

Slim Jim |

|

Quantity used |

PartN~~-------- |

~De~sc~n~·p~ti~on~------ |

~if~m~o~m~th~an~1~ |

0 1081000

01081100 CJ* 1082000 01082200 1083099 C* 1086400 13813060 D* 3264000 03285259 0 3285299

0* 3285360

•3286559

•3515000

•3515100

•3515500

•3552001

•3555000

•3560000

•3560100

•3560200

•3561500

•3563060

•3564501

•3565098

•3565099

•3566400

•3567000

•3575050

•3575059

•3576099

•3577000

•3578099

•3582000

•3583099

•3586050

•3586600

•3590000

•3504093

4532000

0 . 4552101 D* 4552201 c •4555100 D* 4555200 D* 4557300 0* 4557400 0* 4.557500 C* 4557600 0* 4557700 0 . 4.559393 0* 4559493 0•4559700

O• 4559800 c:: • 4559900

Uffer Spring 7'' lifterPln 7"

Hinge Pin 4-314", 5-1/4" & 6"

Hinge PinT' |

|

Clotll Ufter 7" |

|

Roller Washer |

8 |

Wood Handle |

|

Knife Nut 5-1/4" #24, 6", 7" |

|

Footplate Complete 7" |

|

Footplalo 7" |

|

Footplate & Lifter SA 7" |

|

Roller Complete 5-1/4" #24, 7' |

4 |

Shim tor Bottom Head Bearing .002 |

|

Shim lor Bottom Head Bearing .003 |

|

Shim lor Bottom Head Bearing .005 |

|

Knife Gear, 4" |

|

Bearing Locknut, 4" |

|

Aligning Washer, 4" (.001) |

|

Aligning Washer, 4" (.003) |

|

Aligning Washer, 4" {.005) |

|

Left Hand Scr<m, 4' |

|

4'Rear Knile Guard S.A. |

|

4" Knife Nut |

|

4~ Standard, Aluminum |

|

4" Standard, Korloy |

|

Grease Shield 4" |

|

Toe Plate, 4" |

|

Footplalo & Lifter SA, 4'(After 6103) |

|

Foolplate Complete (After 6/03) |

|

Cloth lifter, 4" (After 6103) |

|

Hinge Pin, 4" (After 6103) |

|

Foo1plate, 4' (After 6103) |

|

Hinge Pin, 4" (Prior to 6/03) |

|

Clot~ Lifter, 4" {Prior to 6103) |

|

Roller Assembly, 4" |

4 |

Roller Washer, 4" |

8 |

Pin Wrench, 4" |

|

KnKe Bearing, 4" #23 |

|

Grease Cap

Knife Gear, 4<114" #22, 5-114'1121, (1-1116" 10) Knife Gear, 5·114' i/24, 6" #18, 7" #19 (2" 10)

Bearing Locknut, 4-314", 5-1/4" #21

Bearing Locknut, 5-114" #24, 6", T Shim lor Bottom Head Bearing (.001) Shim tor Bcttom Head Bearing (.002) Shim lor Bottom Head Bearing (.003) Shim for Bottom Head Bearing (.005) Shim lor Bottom Head Bearing (.01 0)

Knife Bearing, 4-314" #22, 5-114" #21 Knife Bearing, 5-114" #24, 6" #18, 7" #19 Knife Gear Shim, .010 4-3/4", 5-1/4" #21 Knrre Gear Shim, .001 4-3/4", 5-114" #21 Kn~e Gear Shim, .002 4-314", 5·1/4" #21

Blazer, Clipper, |

|

|

Quantity used |

Slim Jim |

|

|

|

Part No. |

Description |

if more than 1 |

|

|

|

|

|

0•4560000 0 . 4560100 0* 45£0200 0* 4560300 0* 4560400 0* 4.560500 0* 4560600 D* 4560700 0 . 4561000 D* 4561100

4561600 * 4562700 0 •4563160

0 . 4563260 c:: 4563360 C45634£0 4.564000

•4564601

•4565198

•4565199

•4.565299

•4565299

4565300

4566498

4565499

4565598

4.565599

•4566200

0 . 4.566500

* 4566600 0 . 4567200 4567300

*4568399

*4566460

4562200

4583199

D • 4584159 0•4584350 0•4564599 0 . 4586159

*4588559

*4566599

*4588600 [] . 4590100

C* 4.590200

• 7230593 D* 7230693 9900355 9900571 9901595 * 9902099

Kn~e Gear Shim .003, 4-314", 5-1/4" 1121 Knile Gear Shim .005, 4-314", 5-114" #21 Knife Gear Shim .001, 5-114" #24, 6", 7" Knife Gear Shim .003, 5-114" #24, 6", 7"

Knife Gear Shim .005, 5-1/4" #24, 6", 7'

Knife Gear Shim .01 o, 5-114" #24, 6", 7'' Knife Gear Shim .032, 5-114" #24, 6", 7' Knife Gear Shim .002, 5-1/4" #24, 6", 7' Lockwasher, 4-3/4", 5-114" #21 Lockwasher, 5-114" #24, 6", 7"

Left Hand Screw (All el(cept 4" sizes)

Rear Knife Guard 4-3/4~ Rear Knife Guard 5-1/4~ Rear Knife Guard

6" Rear Knife Guard

7" Rear Knife Guard ThumbScrew

Kn~e Nut, 4-314", 5-114"#21

Standard, 4-314" Aluminum Standard, 4-314" Korloy Standard, 5-114' #21 Aluminum Standard, 5-1/4" #21 Korloy Standard, 5-1/4" #24 Aluminum Standard, 5-114" #24 Korloy Standard 6" Aluminum Standard 6" Korloy

Standard T Aluminum Standard 7" Korloy

Reducing Collar, 4-314", 5-114" #21 (not shown)

Grease Shield, 4-3/4", 5·114" #21 |

|

Grease Shield, 5-114" #24. 6", 7" |

|

Toe Plate, 4-314, 5-1/4", 6", 7 |

|

Screw to secure Toe Plate |

2 |

Slim Jim Standard |

|

Slim Jim Base S.A. |

|

Lifter Spring, 4-314", 5·114', 6" |

|

Lifter, 4-314", 5-114", t>' |

|

Footplate Complete, 4-314", 5-1/4", 6" |

|

Footplate & LifterS A., 4-314", 5-1/4", 6' |

|

Foolplate, 4-314". 5-114", 6" |

|

Roller SA, 4-314", 5-114", 6 |

4 |

Footplate Complete, Slim Jim |

|

Footplate, Slim Jim |

|

Toe Plate, Slim Jim |

|

Pin Wrench, 4-3/4", 5-1/4", #21 |

|

Pin Wrench, 5-114" #24, 6", 7" |

|

Hardened SCrew |

3 |

Hardened Screw |

3or4 |

Screw to secure Hinge Pin |

2 |

Screw to secure Bottom Head |

3 |

Screw to secure RoUers |

8 |

Roll Pin |

3 |

BLADES

Port No. |

|

Description |

Port No. |

|

De~cripl"ion |

|

Port No. |

Desctlptioo |

•1430770 |

4'' Carbon (1-l/4" 10} |

oel429970 |

5-1(4" Comon (t-11/16" 10) 121 |

01427070 |

6" Carbon |

|||

•1430871 |

4" High Speed 123 |

oet430071 |

5- 1/4" High Sr.>eed |

#21 |

01427173 |

6" Teflon 118 (2" 10) |

||

•1430973 |

4" Teflon |

0•1430173 |

S-1/4" Teflon |

*21 |

01427371 |

6" High Speed |

||

rJel430370 |

4-3/4" Corboo 122 |

0*1431170 |

5-1/4'" Corbon |

*24 |

CJ1428970 |

7" Corbon |

||

[Jel430471 |

4 |

-3/4" High Speed |

0*1431271 |

5 |

-1/4" High Speed |

'24 |

0142'1071 |

7" High Speed 119 (2" 10) |

001430573 |

4 |

-3/4" Teflon (1-11/16" ID) |

0*1431373 |

5 |

-1/4" Teflon {2" ID) |

*24 |

01429173 |

7" Teflon |

|

|

|

|

|

|

|

|

|

Parts NOT COMMON to all maChine are identified with symbols.

C BLAZER • CLIPPER * SLIM JIM Carpet Cutter

3

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...