Toshiba RAV-SM562KRT-E, RAV-SM802KRT-E INSTALLATION MANUAL

AIR CONDITIONER (SPLIT TYPE)

CLIMATISEUR (TYPE SPLIT)

KLIMAGERÄT (SPLIT-SYSTEM)

CONDIZIONATORE D’ARIA (TIPO SCOMPONIBILE)

APARATO DE AIRE ACONDICIONADO (TIPO SPLIT)

AR CONDICIONADO (TIPO SPLIT)

AIRCONDITIONER (GESPLITST TYPE)

ΚΛΙΜΑΤΙΣΤΙΚΟ ΜΗΧΑΝΗΜΑ (∆ΙΑΙΡΟΎΜΕΝΟΣ ΤΎΠΟΣ)

Indoor Unit/Unité intérieure

Raumeinheit/Unità interna

Unidad interior/Unidade interior

Binnenunit/Εσωτερική Μονάδα

RAV-SM562KRT-E

RAV-SM802KRT-E

INSTALLATION MANUAL

MANUEL D’INSTALLATION

INSTALLATIONS-HANDBUCH

MANUALE D’INSTALLAZIONE

MANUAL DE INSTALACIÓN

MANUAL DE INSTALAÇÃO

INSTALLATIE HANDLEIDING

ΕΓΧΕΙΡΙ∆ΙΟ ΕΓΚΑΤΑΣΤΑΣΗΣ

Please read this Installation Manual carefully before installing the Air Conditioner.

• This Manual describes the installation method of the indoor unit.

• For installation of the outdoor unit, follow the Installation Manual attached to the

outdoor unit.

Veuillez lire attentivement ce Manuel d’installation avant d’installer le climatiseur.

• Ce manuel décrit la procédure d’installation de l’unité intérieure.

• Pour installer l’unité extérieure, reportez-vous au Manuel d’installation fourni avec

l’unité extérieure.

Bitte lesen Sie dieses Handbuch sorgfältig, bevor Sie mit der Installation des Klimagerätes beginnen.

• In diesem Handbuch wird die Installation der Raumeinheit beschrieben.

• Um die Außeneinheit zu installieren, folgen Sie den Anweisungen in dem Handbuch, das der Außeneinheit beiliegt.

Prima di installare il condizionatore d’aria, leggere con attenzione questo manuale d’installazione.

• Questo manuale descrive il metodo d’installazione dell’unità interna.

• Per l’installazione dell’unità esterna, fare riferimento al manuale d’installazione fornito insieme all’unità esterna.

Lea atentamente este Manual de instalación antes de proceder a la instalación del aparato de aire acondicionado.

• Este manual describe el método de instalación de la unidad interior.

• Para la instalación de la unidad exterior, consulte el Manual de instalación que acompaña a la unidad exterior.

Leia atentamente o presente Manual de Instalação antes de instalar o Ar Condicionado.

• O presente manual descreve o método de instalar a unidade interior.

• Para a instalação de uma unidade exterior, siga o Manual de Instalação que acompanha a unidade exterior.

Lees deze installatie handleiding zorgvuldig door voordat u de airconditioner gaat installeren.

• Deze installatie methode beschrijft de installatiemethode van de binnenunit.

• Zie voor de installatie van de buitenunit, de installatiehandleiding bij de buitenunit.

Παρακαλώ διαßάστε προσεχτικά το Ενχειρίδιο Ενκατάστασης πριν απ* την ενκατασταση του Κλιµατιστικού.

• Το παρ*ν Ενχειρίδιο περινράφει τη µέθοδο ενκατάστασης της εσωτερικής µονάδας.

• Για την ενκατάσταση της εξωθερικής µονάδας, ακολουθήστε το Ενχειρίδιο Ενκατάστασης που συνοδεύει

την εξωτερική µονάδα.

<High-Wall Type>/<Type mural haut>

<Wandmontierter Typ>/<Tipo a condotto nascosto>

<Modelo de pared>/<Tipo Mural>

<Hoog-Wandtype>/<Τύττος Υψηλού Τοίχου>

Heat Pump Model/Modèle à thermopompe

Geräte mit Heizung/Modello con pompa di riscaldamento

Modelo con bomba de calor/Modelo de bomba térmica

Model met warmtepomp/Μοντέλο µε Αντλία Θερµ*τητας

ADOPTION OF NEW REFRIGERANT

• This Air Conditioner is a new type which adopts a new refrigerant HFC (R410A) instead of the conventional

refrigerant R22 in order to prevent destruction of the ozone layer.

UTILISATION DU NOUVEAU REFRIGERANT

• Ce climatiseur est d’un type inédit qui utilise le nouveau réfrigérant HFC (R410A) au lieu du réfrigérant

traditionnel R22, afin d’éviter la destruction de la couche d’ozone.

EINFÜHRUNG EINES NEUEN KÜHLMITTELS

• Dies ist ein neuartiges Klimagerät. Anstatt des herkömmlichen Kühlmittels R22 verwendet es das neuen

ozonschicht-schonende HFC Kühlmittel R410A.

ADOZIONE DI UN NUOVO REFRIGERANTE

• Questo condizionatore d’aria è di un tipo nuovo che adotta un nuovo refrigerante HFC (R410A) al posto del

refrigerante convenzionale R22, per prevenire la distruzione dello strato di ozono dell’atmosfera terrestre.

ADOPCIÓN DE NUEVO REFRIGERANTE

• Este aparato de aire acondicionado es un modelo reciente que incorpora el nuevo refrigerante HFC (R410A) en

lugar del refrigerante convencional R22 para así evitar daños en la capa de ozono.

ADOPÇÃO DO NOVO REFRIGERANTE

• Este ar condicionado é um modelo novo que adopta um novo refrigerante HFC (R410A) em vez do refrigerante

convencional R22 para evitar a destruição da cama de ozono.

TOEPASSING VAN EEN NIEUW KOELMIDDEL

• Deze airconditioner is een nieuwe type dat werkt met een nieuw koelmiddel HFC (R410A) in plaats van met het

conventionele koelmiddel R22, als bijdrage om de aantasting van de ozonlaag te reduceren.

YIOΘETHΣH NEOY ΨYKTIKOY

• To παρv Kλιµατιστικ είναι νέος τύπος που υιοθετεί νέο ψυκτικού HFC (R410A) στη θέση του

συµβατικού ψυκτικού R22 προκειµένου να βοηθήσει στην προστασία του ζοντος.

CONTENTS

Accessory parts and parts to be procured locally ........................... 1

1

PRECAUTIONS FOR SAFETY ..................................................... 2

2

INSTALLATION PROCEDURE .................................................... 4

3

SELECTION OF INSTALLATION PLACE .................................... 5

4

INSTALLATION OF INDOOR UNIT .............................................. 5

5

DRAIN PIPING WORK .................................................................. 6

6

REFRIGERANT PIPING ................................................................ 8

7

ELECTRICAL WORK .................................................................. 11

8

TEST RUN ................................................................................... 14

9

TROUBLESHOOTING ................................................................ 15

10

INDOOR UNIT OPERATION WHEN

CONNECTED TO MULTIPLE UNITS ......................................... 17

ENGLISH

FRANÇAIS

DEUTSCH

ITALIANO

ESPAÑOL

PORTUGUÊS

NEDERLANDS

EΛΛΗΝΙΚΑ

SOMMAIRE

INHALT

INDICE

CONTENIDO

ÍNDICE

INHOUD

ΠΕΡΙΕΧΟΜΕΝΑ

Pièces accessoires et pièces non fournies ....................................... 1

1

MESURES DE SECURITE ............................................................ 2

2

PROCEDURE D’INSTALLATION ................................................. 4

3

SELECTION DU LIEU D’INSTALLATION .................................... 5

4

INSTALLATION DE L’UNITE INTERIEURE ................................. 5

5

INSTALLATION DES TUYAUX D’EVACUATION ........................ 6

6

TUYAUTERIE DE FLUIDE FRIGORIGÈNE .................................. 8

7

INSTALLATION ELECTRIQUE .................................................. 11

8

ESSAI DE FONCTIONNEMENT ................................................. 14

9

DEPANNAGE .............................................................................. 15

10

FONCTIONNEMENT DE L’UNITE INTERIEURE EN

CAS DE RACCORDEMENT DE PLUSIEURS UNITES ............. 17

Zubehör und bauseits bereitzustellende Teile .................................. 1

1

SICHERHEITSVORKEHRUNGEN ................................................ 2

2

INSTALLATIONSABLAUF ........................................................... 4

3

AUSWAHL DES AUFSTELLUNGSORTES ................................. 5

4

INSTALLATION DER RAUMEINHEIT .......................................... 5

5

INSTALLATION DER ABLAUFROHRE ....................................... 6

6

KÜHLMITTELLEI TUNGSSYSTEM .............................................. 8

7

ELEKTROINSTALLATION ......................................................... 11

8

TESTLAUF .................................................................................. 14

9

FEHLERBESEITIGUNG .............................................................. 15

10

BETRIEB DER RAUMEINHEIT BEI MEHREREN

ANGESCHLOSSENEN EINHEITEN ........................................... 17

Accessori e parti da acquistare sul posto ......................................... 1

1

PRECAUZIONI PER LA SICUREZZA .......................................... 2

2

PROCEDURA D’INSTALLAZIONE .............................................. 4

3

SCELTA DEL POSTO D’INSTALLAZIONE ................................. 5

4

INSTALLAZIONE DELL’UNITÀ INTERNA ................................... 5

5

LAVORO PER TUBAZIONE DI SCARICO ................................... 6

6

TUBAZIONI DEL REFRIGERANTE .............................................. 8

7

ESECUZIONE DEI COLLEGAMENTI ELETTRICI ..................... 11

8

FUNZIONAMENTO DI PROVA ................................................... 14

9

GUIDA PER I PROBLEMI DI FUNZIONAMENTO ...................... 15

10

FUNZIONAMENTO DELL’UNITA INTERNA

QUANDO È COLLEGATA A PIU UNITA ................................... 17

Componentes accesorios y componentes de obtención local ....... 1

1

PRECAUCIONES PARA SU SEGURIDAD .................................. 2

2

PROCEDIMIENTO DE INSTALACIÓN ......................................... 4

3

SELECCIÓN DEL LUGAR DE INSTALACIÓN ............................ 5

4

INSTALACIÓN DE LA UNIDAD INTERIOR ................................. 5

5

TRABAJOS DE CANALIZACIÓN DE DESAGÜE ........................ 6

6

TUBERÍA DE REFRIGERANTE ................................................... 8

7

TRABAJOS EN EL SISTEMA ELÉCTRICO ............................... 11

8

PRUEBA DE FUNCIONAMIENTO .............................................. 14

9

SOLUCIÓN DE PROBLEMAS .................................................... 15

10

FUNCIONAMIENTO DE LA UNIDAD INTERIOR

CUANDO ESTÁ CONECTADA A VARIAS UNIDADES ............ 17

Acessórios e peças adquiridas localmente ...................................... 1

1

PRECAUÇÕES DE SEGURANÇA ............................................... 2

2

PROCEDIMENTO DE INSTALAÇÃO ........................................... 4

3

SELECÇÃO DO LOCAL DE INSTALAÇÃO ................................ 5

4

INSTALAÇÃO DA UNIDADE INTERIOR ..................................... 5

5

INSTALAÇÃO DA TUBAGEM DE DRENAGEM .......................... 6

6

TUBAGEM DE REFRIGERANTE ................................................. 8

7

LIGAÇÕES ELÉCTRICAS .......................................................... 11

8

ENSAIO DE FUNCIONAMENTO ................................................ 14

9

RESOLUÇÃO DE PROBLEMAS ................................................ 15

10

FUNCIONAMENTO DA UNIDADE INTERIOR

QUANDO ESTÁ LIGADA A VÁRIAS UNIDADES ..................... 17

Accessoires en niet meegeleverde onderdelen ................................ 1

1

VOORZORGSMAATREGELEN VOOR UW VEILIGHEID ............ 2

2

INSTALLATIEPROCEDURE ........................................................ 4

3

KEUZE VAN DE LOCATIE VOOR DE INSTALLATIE ................. 5

4

INSTALLATIE VAN DE BINNENUNIT .......................................... 5

5

AFVOERLEIDINGEN .................................................................... 6

6

KOELMIDDELLEI DINGEN .......................................................... 8

7

ELEKTRISCH GEDEELTE ......................................................... 11

8

WERKINGSTEST ........................................................................ 14

9

STORINGEN VERHELPEN ........................................................ 15

10

WERKING VAN BINNENMODULE BIJ AANSLUITING

OP MEERDERE MODULES ....................................................... 17

Παρελκµενα ανταλλακτικά και εξαρτήµατα απ την

τοπική αγορά ........................................................................................ 1

1 ΠΡΟΦΥΛΑΞΕΙΣ ΑΣΦΑΛΕΙΑΣ ........................................................ 2

2 ∆ΙΑ∆ΙΚΑΣΙΑ ΕΓΚΑΤΑΣΤΑΣΗΣ .................................................... 4

3 ΕΠΙΛΟΓΗ ΤΟΥ ΧΩΡΟΥ ΕΓΚΑΤΑΣΤΑΣΗΣ ................................... 5

4 ΕΓΚΑΤΑΣΤΑΣΗ ΤΗΣ ΕΣΩΤΕΡΙΚΗΣ ΜΟΝΑ∆ΑΣ ......................... 5

5 ΕΓΚΑΤΑΣΤΑΣΗ ΣΩΛΗΝΩΣΕΩΝ ΑΠΟΣΤΡΑΓΓΙΣΗΣ ................... 6

6 ΣΩΛΗΝΩΣΕΙΣ ΨΥΚΤΙΚΟΥ ........................................................... 8

7 ΗΛΕΚΤΡΟΛΟΓΙΚΑ ...................................................................... 11

8 ∆ΟΚΙΜΗ ΛΕΙΤΟΥΡΓΙΑΣ ............................................................. 14

9 ΑΝΤΙΜΕΤΩΠΙΣΗ ΠΡΟΒΛΗΜΑΤΩΝ ........................................... 15

10 ΛΕΙΤΟΥΡΓΙΑ ΤΗΣ ΕΣΩΤΕΡΙΚΗΣ ΜΟΝΑ∆ΑΣ, ΚΑΤΑ

ΤΗ ΣΎΝ∆ΕΣΉ ΤΗΣ ΜΕ ΠΟΛΛΑΠΛΕΣ ΜΟΝΑ∆ΕΣ ................... 17

EN

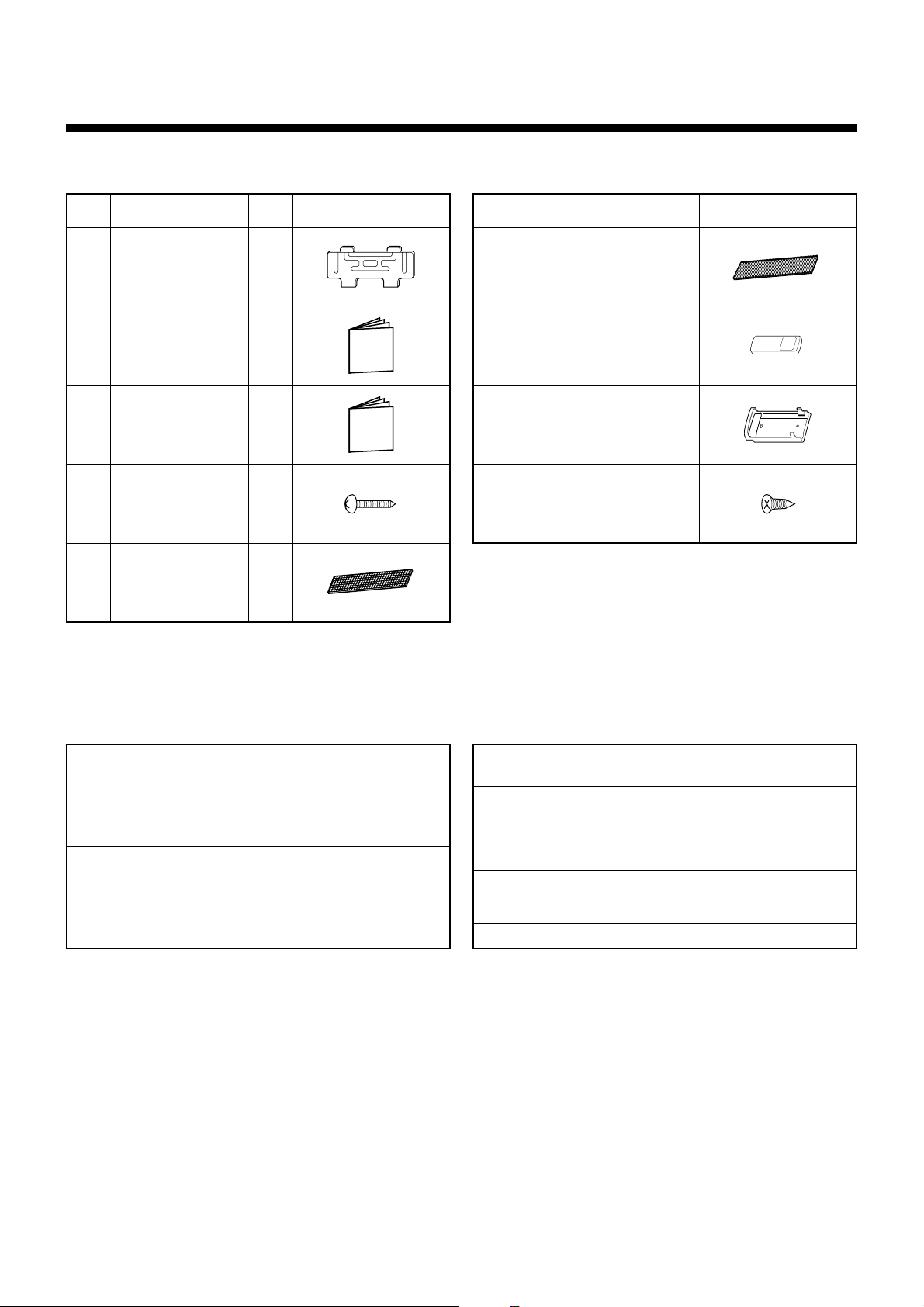

Accessory parts and parts to be procured locally

❑ Accessory parts

Bio-enzyme &

2

Gingko filter

Wireless remote

1

controller

Remote controller

1

holder

Screw for remote

2

control holderler

Connecting pipe (Liquid side)

(6.35 mm (diam.), Nominal (diam.) 1/4" thick 0.8 mm)

RAV-SM562KRT-E

(9.52 mm (diam.), Nominal (diam.) 3/8" thick 0.8 mm)

RAV-SM802KRT-E

Connecting pipe (Gas side)

(12.7 mm (diam.), Nominal (diam.) 1/2" thick 0.8 mm)

RAV-SM562KRT-E

(15.9 mm (diam.), Nominal (diam.) 5/8" thick 1.0 mm)

RAV-SM802KRT-E

1

❑ Parts to be procured locally

Part

Part name Q’ty Shape

No.

Connecting cable

H07RN-F or 245IEC66 (1.5 mm

2

or more)

Thermal insulation for refrigerant pipe

(10 mm or more, thermal insulating foam polyethylene)

Thermal insulation for drain pipe

(10 mm or more, foam polyethylene)

Drain pipe (Outer 16 mm (diam.))

Tapes

Grounding cable (2.0 mm (diam.) or more)

Part

Part name Q’ty Shape

No.

Installation plate 1

Installation Manual 1

Owner’s Manual 1

Mounting screw

8

∅4 mm x 25 mm

Sasa-Zeolite plus filter 2

Wired remote controller is an optional part sold separately.

1

2

3

4

5

6

7

8

9

EN

1

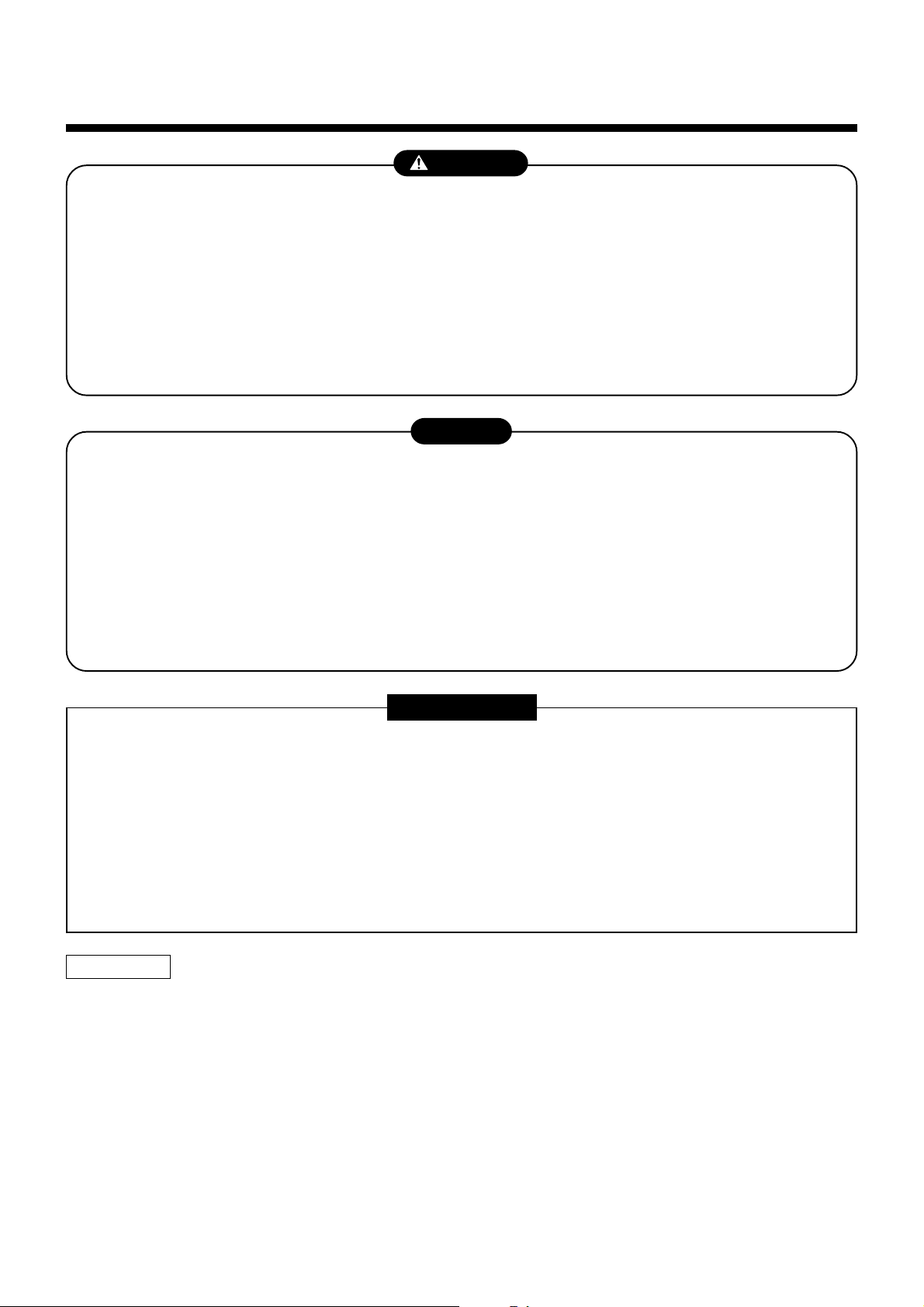

PRECAUTIONS FOR SAFETY

• Ensure that all Local, National and International regulations are satisfied.

• Read this “PRECAUTIONS FOR SAFETY” carefully before Installation.

• The precautions described below include the important items regarding safety. Observe them without fail.

• After the installation work, perform a trial operation to check for any problem.

Follow the Owner’s Manual to explain how to use and maintain the unit to the customer.

• Turn off the main power supply switch (or breaker) before the unit maintenance.

• Ask the customer to keep the Installation Manual together with the Owner’s Manual.

CAUTION

• THIS AIR CONDITIONER ADOPTS THE NEW HFC REFRIGERANT (R410A) WHICH DOES NOT DESTROY

OZONE LAYER.

The characteristics of R410A refrigerant are ; easy to absorb water, oxidizing membrane or oil, and its pressure

is approx. 1.6 times higher than that of refrigerant R22. Accompanied with the new refrigerant, refrigerating oil

has also been changed. Therefore, during installation work, be sure that water, dust, former refrigerant, or

refrigerating oil does not enter the refrigerating cycle.

To prevent charging an incorrect refrigerant and refrigerating oil, the sizes of connecting sections of charging

port of the main unit and installation tools are charged from those for the conventional refrigerant.

Accordingly the exclusive tools are required for the new refrigerant (R410A).

For connecting pipes, use new and clean piping designed for R410A, and please care so that water or dust does

not enter. Moreover, do not use the existing piping because there are problems with pressure-resistance force

and impurity in it.

New refrigerant air conditioner installation

CAUTION

This appliance must be connected to the main power supply by means of a switch with a contact separation of

at least 3 mm.

The installation fuse (25A D type ) must be used for the power supply line of this conditioner.

To disconnect the appliance from main power supply

WARNING

• Ask an authorized dealer or qualified installation professional to install/maintain the air conditioner.

Inappropriate installation may result in water leakage, electric shock or fire.

• Turn off the main power supply switch or breaker before attempting any electrical work.

Make sure all power switches are off. Failure to do so may cause electric shock.

• Connect the connecting cable correctly.

If the connecting cable is connected in a wrong way, electric parts may be damaged.

• When moving the air conditioner for the installation into another place, be very careful not to enter any

gaseous matter other than the specified refrigerant into the refrigeration cycle.

If air or any other gas is mixed in the refrigerant, the gas pressure in the refrigeration cycle becomes

abnormally high and it may resultingly causes pipe burst and injuries on persons.

• Do not modify this unit by removing any of the safety guards or by by-passing any of the safety

interlock switches.

• Exposure of unit to water or other moisture before installation may cause a short-circuit of electrical

parts.

Do not store it in a wet basement or expose to rain or water.

2

ENGLISH

EN

1

PRECAUTIONS FOR SAFETY

• After unpacking the unit, examine it carefully if there are possible damage.

• Do not install in a place that might increase the vibration of the unit.

• To avoid personal injury (with sharp edges), be careful when handling parts.

• Perform installation work properly according to the Installation Manual.

Inappropriate installation may result in water leakage, electric shock or fire.

• When the air conditioner is installed in a small room, provide appropriate measures to ensure that the

concentration of refrigerant leakage occur in the room does not exceed the critical level.

• Install the air conditioner securely in a location where the base can sustain the weight adequately.

• Perform the specified installation work to guard against an earthquake.

If the air conditioner is not installed appropriately, accidents may occur due to the falling unit.

• If refrigerant gas has leaked during the installation work, ventilate the room immediately.

If the leaked refrigerant gas comes in contact with fire, noxious gas may generate.

• After the installation work, confirm that refrigerant gas does not leak.

If refrigerant gas leaks into the room and flows near a fire source, such as a cooking range,

noxious gas might generate.

• Electrical work must be performed by a qualified electrician in accordance with the Installation Manual.

Make sure the air conditioner uses an exclusive power supply.

An insufficient power supply capacity or inappropriate installation may cause fire.

• Use the specified cables for wiring connect the terminals securely fix. To prevent external forces

applied to the terminals from affecting the terminals.

• Conform to the regulations of the local electric company when wiring the power supply.

Inappropriate grounding may cause electric shock.

• Do not install the air conditioner in a location subject to a risk of exposure to a combustible gas.

If a combustible gas leaks, and stays around the unit, a fire may occur.

3

EN

2

INSTALLATION PROCEDURE

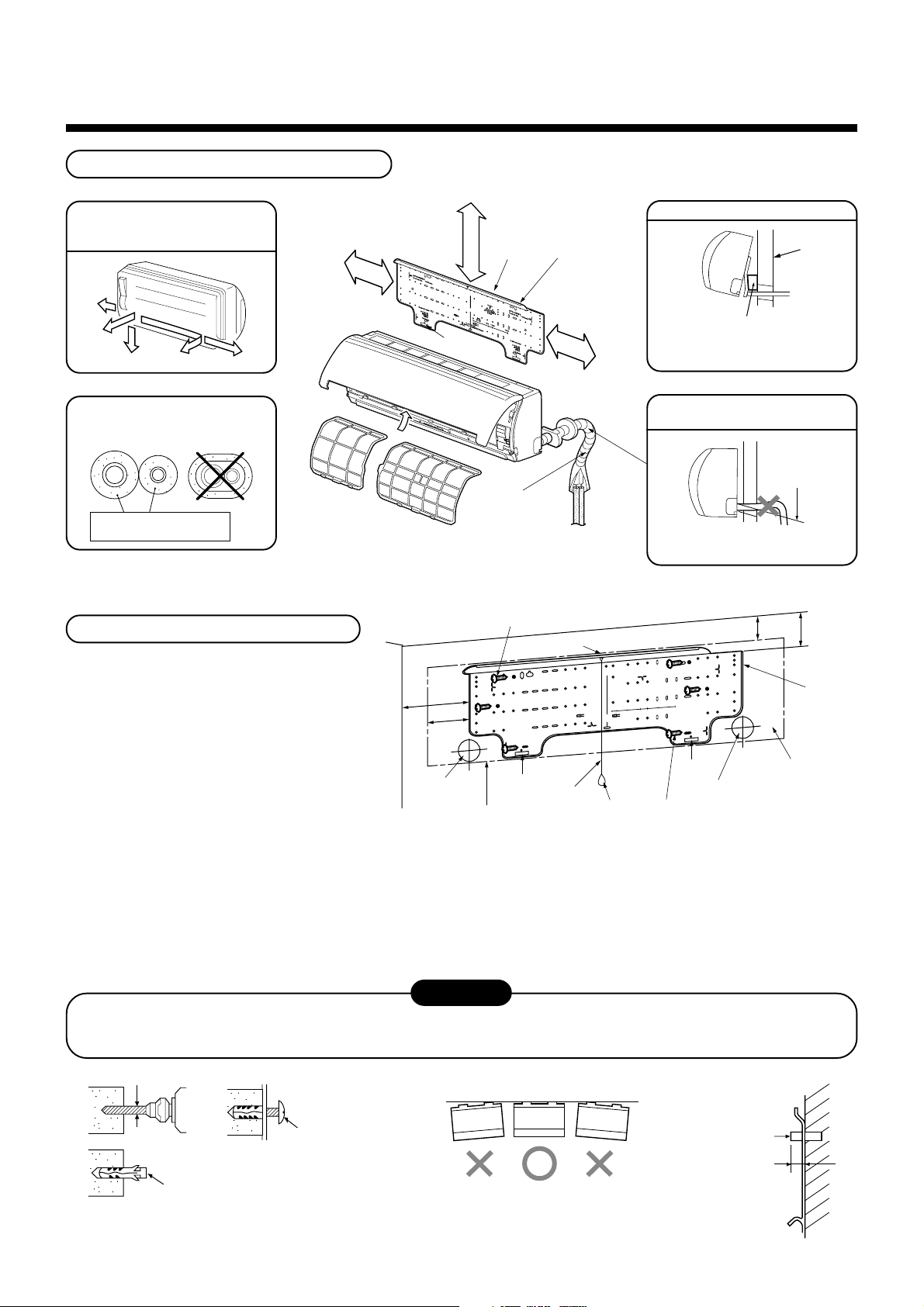

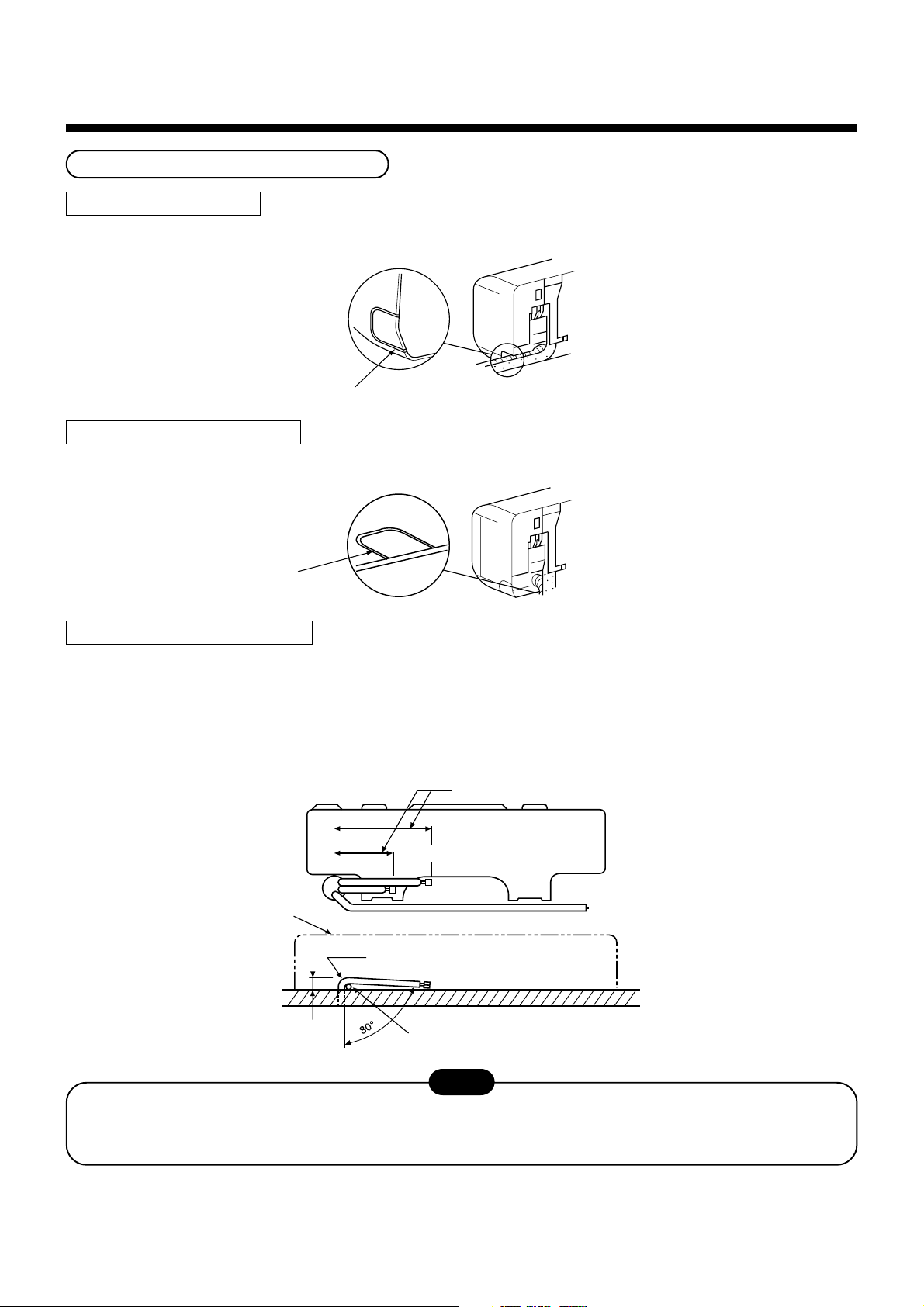

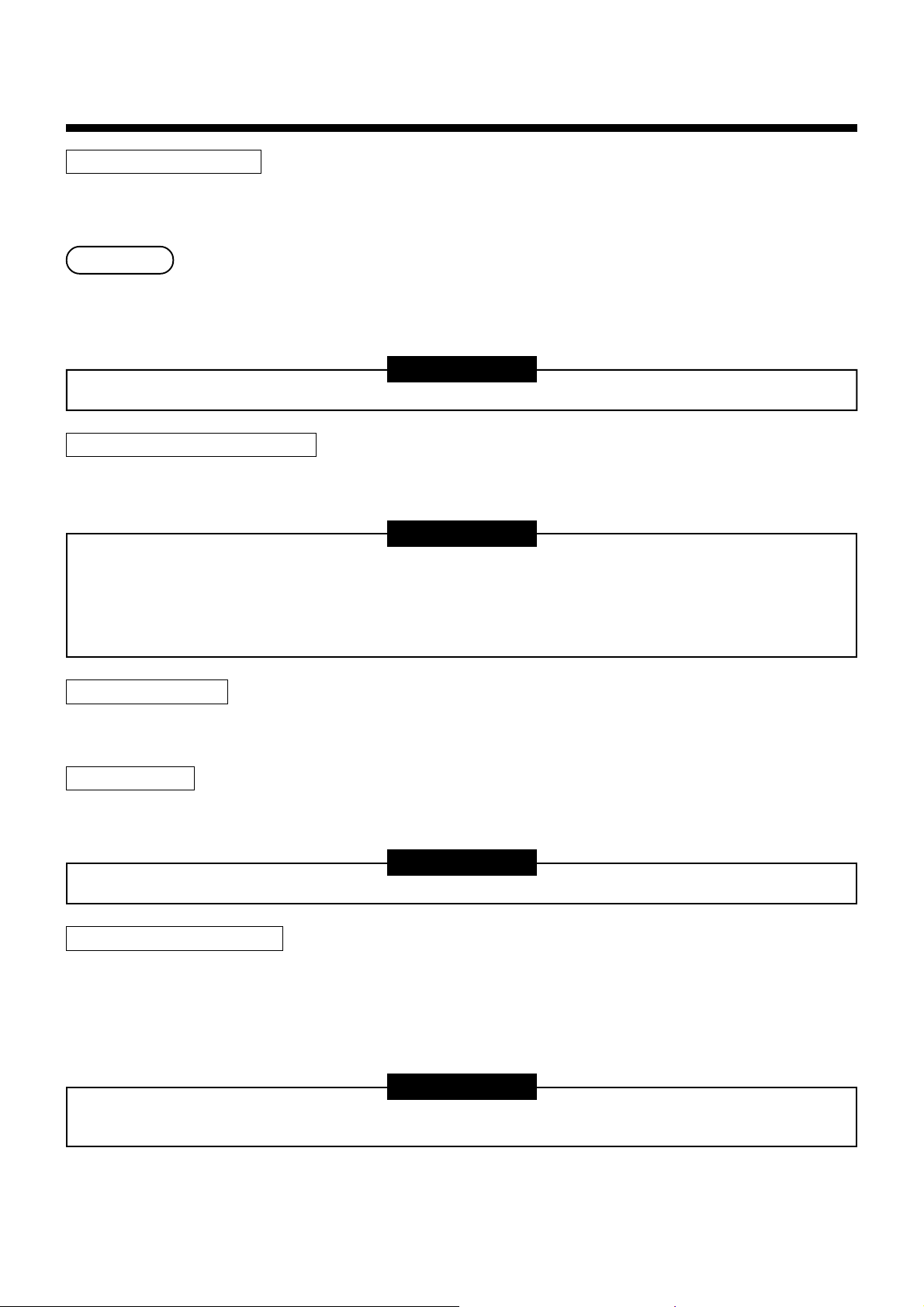

Installation diagram of indoor unit

4

Mounting screw

Hook

Pipe hole

Indoor unit

Thread

Weight

Pipe hole

Mounting screw

Installation

plate

Mounting the installation plate

For installation of the indoor unit.

0

8

0

1

0

0

1

0

0

m

m

1

0

0

m

m

1

8

0

55

65

170

120

Hook

Hook

When the installation plate is directly mounted on the wall

1. Securely fix the installation plate to the wall by screwing it through the upper and lower fixing holes.

2. To mount the installation plate on a concrete wall with anchor bolts, utilize the anchor bolt holes as illustrated in

the above figure.

3. Attach the installation plate horizontally to the wall.

CAUTION

When installing the installation plate with mounting screw, do not use the anchor bolt hole.

Otherwise the unit may fall down and result in personal injury and property damage.

∅5 mm hole

Mounting screw

∅4 x 25 mm

Clip anchor

(local parts)

Projection

15 mm or less

Anchor bolt

Indoor unit

65 mm or more

170 m

m

or m

o

re

170 m

m

or m

ore

Installation plate

Hook

A

ir filter

Shield pipe

Insulate the refrigerant pipes

separately with insulation, not

together.

Hook

The auxiliary piping can be

connected to the left, rear left,

rear, right or bottom.

Right

Rear

Bottom

Rear left

Left

6 mm thick heat resisting

polyethylene foam

For the rear left and left piping

Insert the cushion between the

indoor unit and wall, and tilt the

indoor unit for better operation.

Wall

Do not allow the drain hose to get

slack.

Make sure to run the drain hose

sloped downward.

Cut the piping

hole sloped

slightly.

EN

3

SELECTION OF INSTALLATION PLACE

WARNING

• Install the air conditioner where there is sufficient strength to withstand the weight of the unit.

If the strength is not sufficient, the unit may fall down resulting in injury.

CAUTION

Upon approval of the customer, install the air conditioner in a place that satisfies the following

conditions.

• Place where the unit can be installed horizontally.

• Place where a sufficient servicing space can be ensured for safe maintenance and check.

• Place where drained water will not cause any problem.

Avoid installing in the following places.

• Place exposed to air with high salt content (seaside area), or place exposed to large quantities of sulfide gas

(hot spring). (Should the unit be used in these places, special protective measures are needed.)

• Place exposed to oil, vapor, oil smoke or corrosive gas.

• Place where organic solvent is used nearby.

• Place close to a machine generating high frequency.

• Place where the discharged air blows directly into the window of the neighboring house. (For outdoor unit)

• Place where noise of the outdoor unit is easy to transmit.

(When installing the air conditioner on the boundary with the neighbor, pay due attention to the level of noise.)

• Place with poor ventilation.

• Where the ceiling height is more than 3 m.

• Where the floor/wall/ceiling structure is unable to support the weight of the unit.

4

INSTALLATION OF INDOOR UNIT

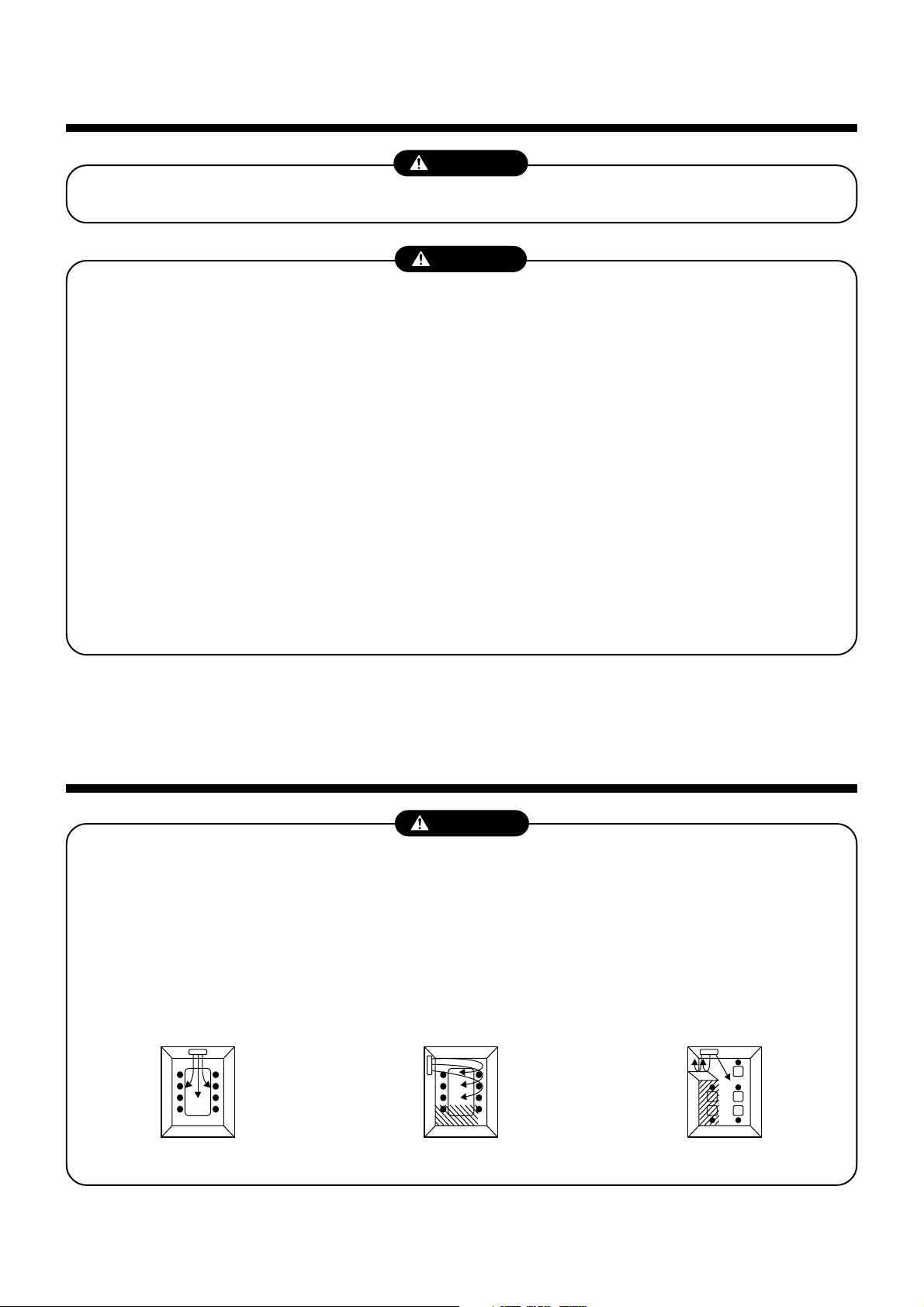

WARNING

• Install the air conditioner certainly at a place to sufficiently withstand the weight.

If the strength is insufficient, the unit may fall down resulting in human injury.

• Perform a specified installation work to guard against an earthquake.

An incomplete installation can cause accidents by the units falling and dropping.

Locate the unit so as to provide uniform circulation of chilled air.

Avoid locating the unit as shown in the bad-marked figures below:

If a good location is not possible, use a fan to circulate the air evenly throughout the room.

Good location

Evenly hot or cooled

Bad location

Shaded area well hot or cooled

Bad location

Shaded area well hot or cooled

5

EN

400 mm

300 mm

43 mm

5

DRAIN PIPING WORK

6

In case of downward pipe exit

• Cut out the knockout portion by the slits with a knife or pair of wire cutters as necessary.

Slit (Body right)

Slit (Body right)

Piping via left-hand connection

Bend the connecting pipe so that it is laid within 43 mm above the wall surface. If the connecting pipe is laid

exceeding 43 mm above the wall surface, the indoor unit could be unstable when set on the wall. When bending the

connecting pipes, always use a suitable bending tool to avoid damaging the pipes.

Bend the connection pipe within a radius of 30 mm.

To connect the pipe after installation of unit (figure)

(To the front of the flare)

Liquid side

Outward form of indoor unit

R 30 mm

Use the handle of a screwdriver, etc.

Gas side

NOTE

If the pipe is bent incorrectly, the indoor unit could be unstable on the wall.

After passing the connecting pipe through the pipe hole, connect the connecting pipe to the auxiliary pipes and

insulate as necessary.

Piping and drain hose installation

In case of right-side exit

• Cut out the knockout portion by the slits with a knife or pair of wire cutters as necessary.

EN

5

DRAIN PIPING WORK

7

Installation plate

Indoor unit

Auxiliary pipes

CAUTION

• Bind the auxiliary pipes (two) and connecting cable with tape tightly. In case of left-side pipe exit and rear-left

exit, bind the auxiliary pipes (two) only with facing tape.

• Carefully arrange pipes so that any pipe does not stick out of the rear plate of the indoor unit.

• Carefully connect the auxiliary pipes and connecting pipes to each other and cut off the insulating tape wound

on the connecting pipe to avoid double-taping at the joint, then seal the joint with vinyl tape, etc.

• In order to reduce the possibility of condensed water being produced within the indoor unit, make sure to

insulate both the connecting pipes.

(Use a suitable form of insulation material specifically design designed for refrigeration pipe work.)

• When bending a pipe, ensure care is taken to prevent pipe damage.

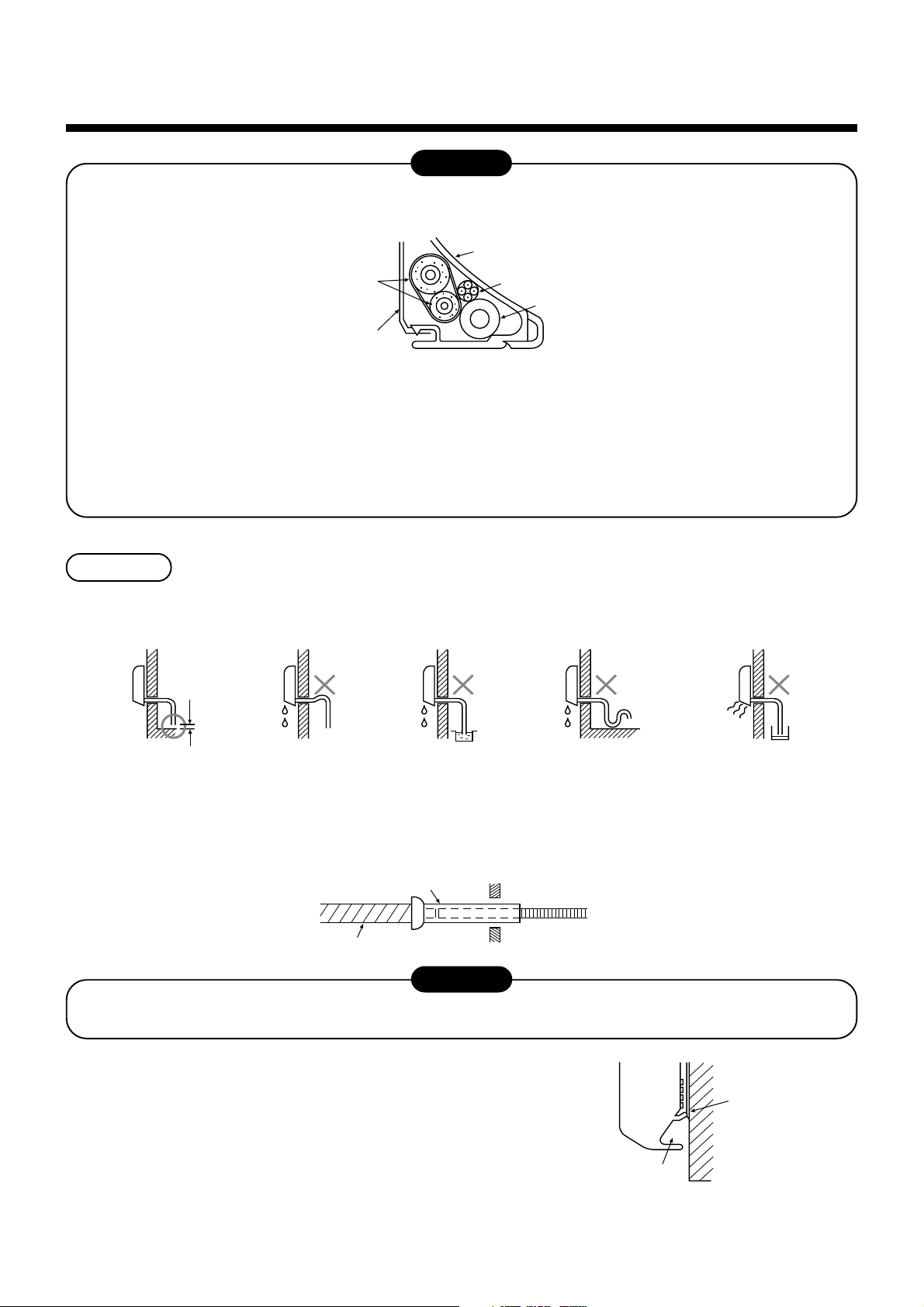

Drainage

1. Run the drain hose sloped downwards.

Do not put the drain hose

end into the drainage ditch.

Extension drain hose

Inside the room

Drain hose

Pipe insulation

CAUTION

Arrange the drain pipe to allow proper drainage from the unit. Incorrect drainage can result in condensation

problems.

This structure of this air conditioner is designed

condensed water, which may form on the back of the

indoor unit, into the drain pan.

Therefore, do not store the power cables and other

parts within the drain guide.

Space for pipes

Drain guide

2. It is not possible to add water to the drain pan to confirm correct drainage. To do this, the unit must be operated

in the COOL mode.

3. When connecting extension drain hose, insulate the connecting part of extension drain hose with pipe insulation

(local procured).

50 mm

or more

Do not rise the

drain hose.

Do not put the drain

hose end into water.

Do not form the drain hose

into the waved shape.

Drain hose

Connecting cable

Wall

EN

8

6

REFRIGERANT PIPING

Refrigerant piping

1. Use copper pipe with 0.8 mm or more thickness.

(In case pipe size is ∅15.9, with 1.0 mm or more.)

2. Flare nut and flare works are also different from those of the conventional refrigerant.

Take out the flare nut attached to the main unit of the air conditioner, and use it.

CAUTION

IMPORTANT 4 POINTS FOR PIPING WORK

1. Remove dust and moisture from the inside of the connecting pipes.

2. Tight connection (between pipes and unit)

3. Evacuate the air in the connecting pipes using VACUUM PUMP.

4. Check the gas leakage. (Connected points)

Permissible piping length and head

They vary according to the outdoor unit. For details, refer to the Installation Manual attached to the outdoor unit.

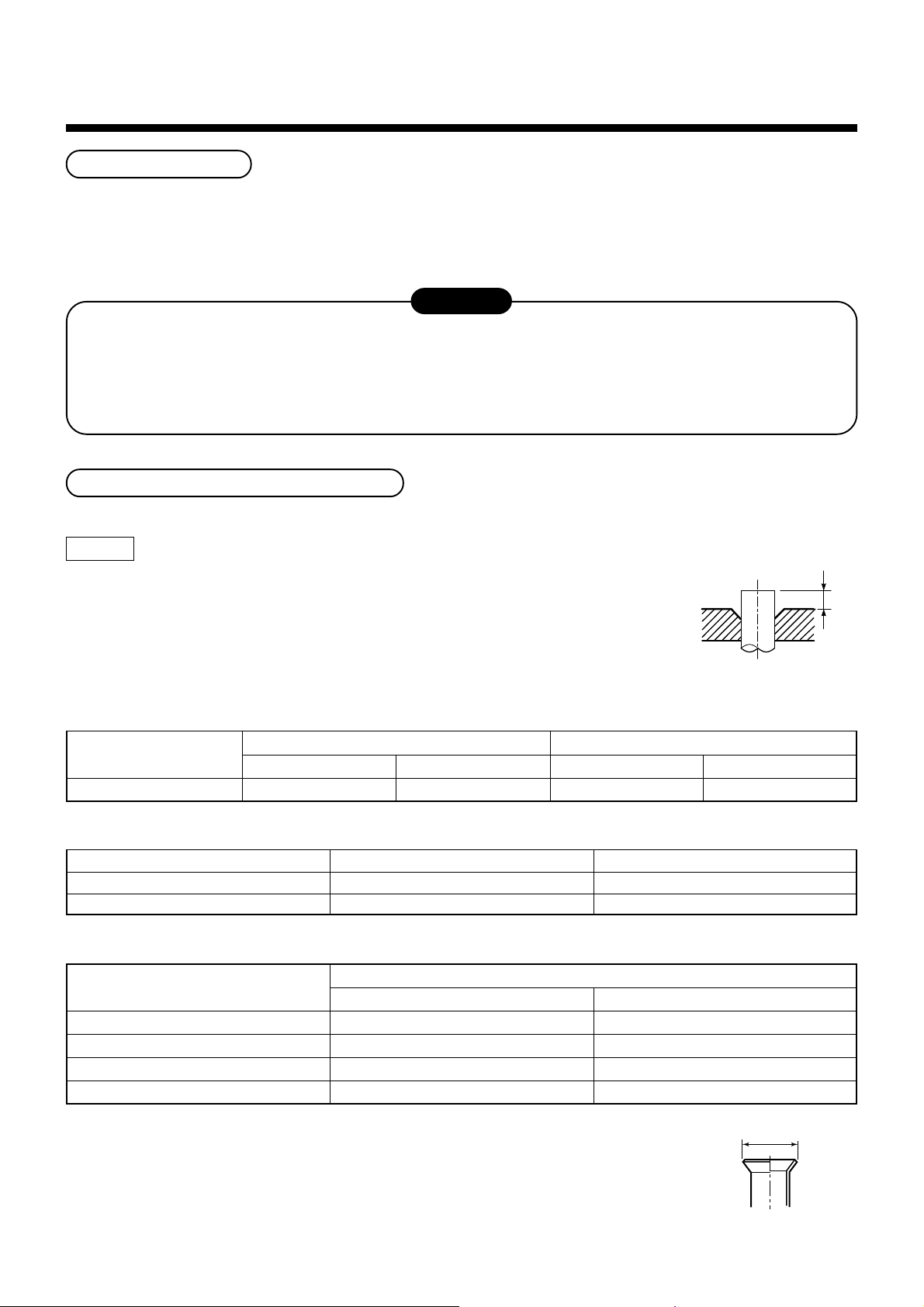

Flaring

Insert a flare nut into the pipe, and flare the pipe.

As the flaring sizes of R410A differ from those of refrigerant R22, the flare tools newly

manufactured for R410A are recommended.

However, the conventional tools can be used by adjusting projection margin of the

copper pipe.

• Projection margin in flaring : B (Unit : mm)

Rigid (Clutch type)

Outer diam. of copper pipe

R410A tool used Conventional tool used

R410A R22 R410A R22

6.4 to 15.9 0 to 0.5 (Same as left) 1.0 to 1.5 0.5 to 1.0

Outer diam. of copper pipe R410A R22

6.4 or 9.5 1.5 to 2.0 1.0 to 1.5

12.7 or 15.9 2.0 to 2.5 1.5 to 2.0

B

Imperial (Wing nut type)

• Flaring diam. meter size : A (Unit : mm)

Outer diam. of copper pipe

R410A R22

6.4 9.1 9.0

9.5 13.2 13.0

12.7 16.6 16.2

15.9 19.7 19.2

+0

–0.4

A

* In case of flaring for R410A with the conventional flare tool, pull it out approx. 0.5 mm

more than that for R22 to adjust to the specified flare size.

The copper pipe gauge is useful for adjusting projection margin size.

A

EN

9

6

REFRIGERANT PIPING

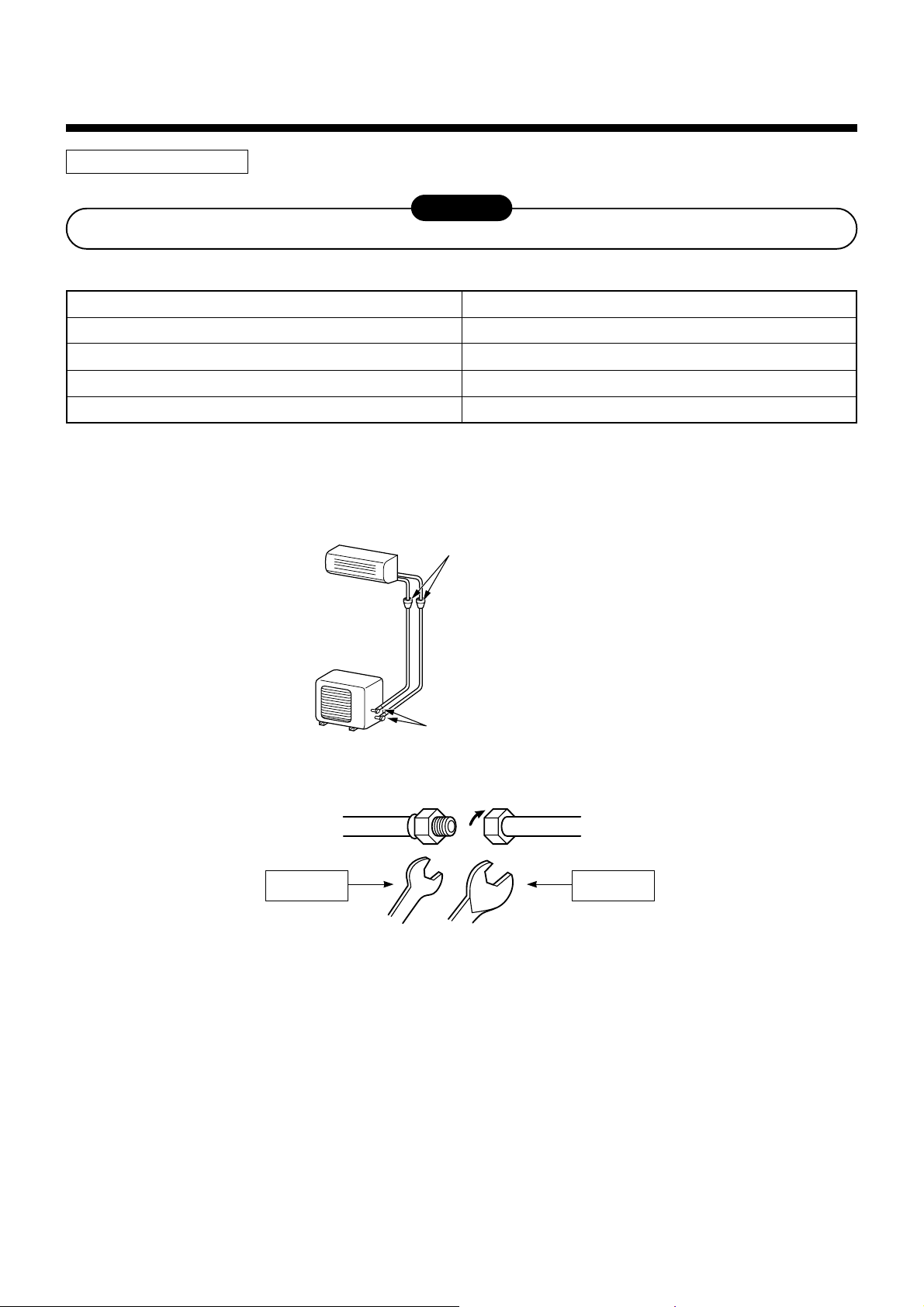

(Unit : N•m)

Outer diam. of copper pipe Tightening torque

6.4 mm (diam.) 14 to 18 (1.4 to 1.8 kgf•m)

9.5 mm (diam.) 33 to 42 (3.3 to 4.2 kgf•m)

12.7 mm (diam.) 50 to 62 (5.0 to 6.2 kgf•m)

15.9 mm (diam.) 68 to 82 (6.8 to 8.2 kgf•m)

• Tightening torque of flare pipe connections

Pressure of R410A is higher than that of R22. (Approx. 1.6 times) Therefore, using a torque wrench, tighten the

flare pipe connecting sections which connect the indoor and outdoor units of the specified tightening torque.

Incorrect connections may cause not only a gas leak, but also a trouble of the refrigeration cycle.

Flare at indoor unit side

Flare at outdoor unit side

Tightening connection

CAUTION

• Do not apply excessive torque. Otherwise, the nut may crack depending on the conditions.

Use a wrench to secure. Use a torque wrench to tighten.

Align the centers of the connecting pipes and tighten the flare nut as far as possible with your fingers. Then tighten

the nut with a spanner and torque wrench as shown in the figure.

Flare nutHalf union

Internally

threaded side

Externally

threaded side

EN

10

REQUIREMENT

For the tools such as charge hose, etc., use those manufactured exclusively for R410A.

Refrigerant amount to be added

For addition of the refrigerant, add refrigerant “R410A” referring to the attached Installation Manual of outdoor unit.

Be sure to use a scale to charge the refrigerant of specified amount.

REQUIREMENT

• Charging an excessive or too little amount of refrigerant causes a trouble of the compressor.

Be sure to charge the refrigerant of specified amount.

• A personnel who charged the refrigerant should write down the pipe length and the added refrigerant amount

in the nameplate attached to the service panel of the outdoor unit. It is necessary to troubleshoot the

compressor and refrigeration cycle malfunction.

REQUIREMENT

Use a leak detector manufactured exclusively for HFC refrigerant (R410A, R134a, etc.).

Thermal insulation process

Apply thermal insulation for the pipes separately at liquid side and gas side.

For the thermal insulation to the pipes at gas side, be sure to use the material with heat-resisting temperature

120°C or higher.

Using the attached thermal insulation material, apply the thermal insulation to the pipe connecting section of the

indoor unit securely without gap.

REQUIREMENT

Apply the thermal insulation to the pipe connecting section of the indoor unit securely up to the root without

exposure of the pipe. (The pipe exposed to the outside causes water leak.)

6

REFRIGERANT PIPING

Air purge

Using a vacuum pump, perform vacuuming from the charge port of valve of the outdoor unit.

For details, follow to the Installation Manual attached to the outdoor unit.

• Never use the refrigerant sealed in the outdoor unit for air purge.

Piping with outdoor unit

• Shape of valve differs according to the outdoor unit.

For details of installation, refer to the Installation Manual of the outdoor unit.

Gas leak check

Check with a leak detector or soap water whether gas leaks or not, from the pipe connecting section or cap of the

valve.

Open the valve fully

Open the valve of the outdoor unit fully. A 4 mm hexagonal wrench is required for opening the valve.

For details, refer to the Installation Manual attached to the outdoor unit.

EN

11

7

ELECTRICAL WORK

WARNING

1. Using the specified cables, ensure to connect the wires, and fix wires securely so that the external

tension to the cables do not affect the connecting part of the terminals.

Incomplete connection or fixation may cause a fire, etc.

2. Be sure to connect earth wire. (Grounding work)

Do not connect the earth wire to gas pipe, city water pipe, lightning rod, or the earth wire of telephone.

Incomplete grounding causes an electric shock.

3. For electric work, strictly follow the Local Regulation in each country and the Installation Manual, and

use an exclusive circuit.

Capacity shortage of power circuit or incomplete installation may cause an electric shock or a fire.

CAUTION

• This indoor unit has no power cord.

• If incorrect/incomplete wiring is carried out, it will cause an electrical fire or smoke.

• Be sure to install an earth leakage breaker that is not tripped by shock waves.

If an earth leakage breaker is not installed, an electric shock may be caused.

• Be sure to use the cord clamps attached to the product.

• Do not damage or scratch the conductive core and inner insulator of power and inter-connecting cables when

peeling them.

• Be sure to comply with local regulations on running the wire from outdoor unit to indoor unit (size of wire and

wiring method etc.)

• Use the power cord and Inter-connecting cable of specified thickness, type, and protective devices required.

REQUIREMENT

• For power supply wiring, strictly conform to the Local Regulation in each country.

• For wiring of power supply of the outdoor units, follow the Installation Manual of each outdoor unit.

• Never connect 220 – 240V power to the terminal blocks (A, B, etc.) for control wiring.

(Otherwise, the system will fail.)

• Perform the electric wiring so that it does not come to contact with the high-temperature part of the pipe.

The coating may melt resulting in an accident.

• After connecting cables to the terminal blocks, provide a trap and fix cables with the cable clamp.

• Run the refrigerant piping line and control wiring line in the same line.

• Do not turn on the power of the indoor unit until vacuuming of the refrigerant pipes completes.

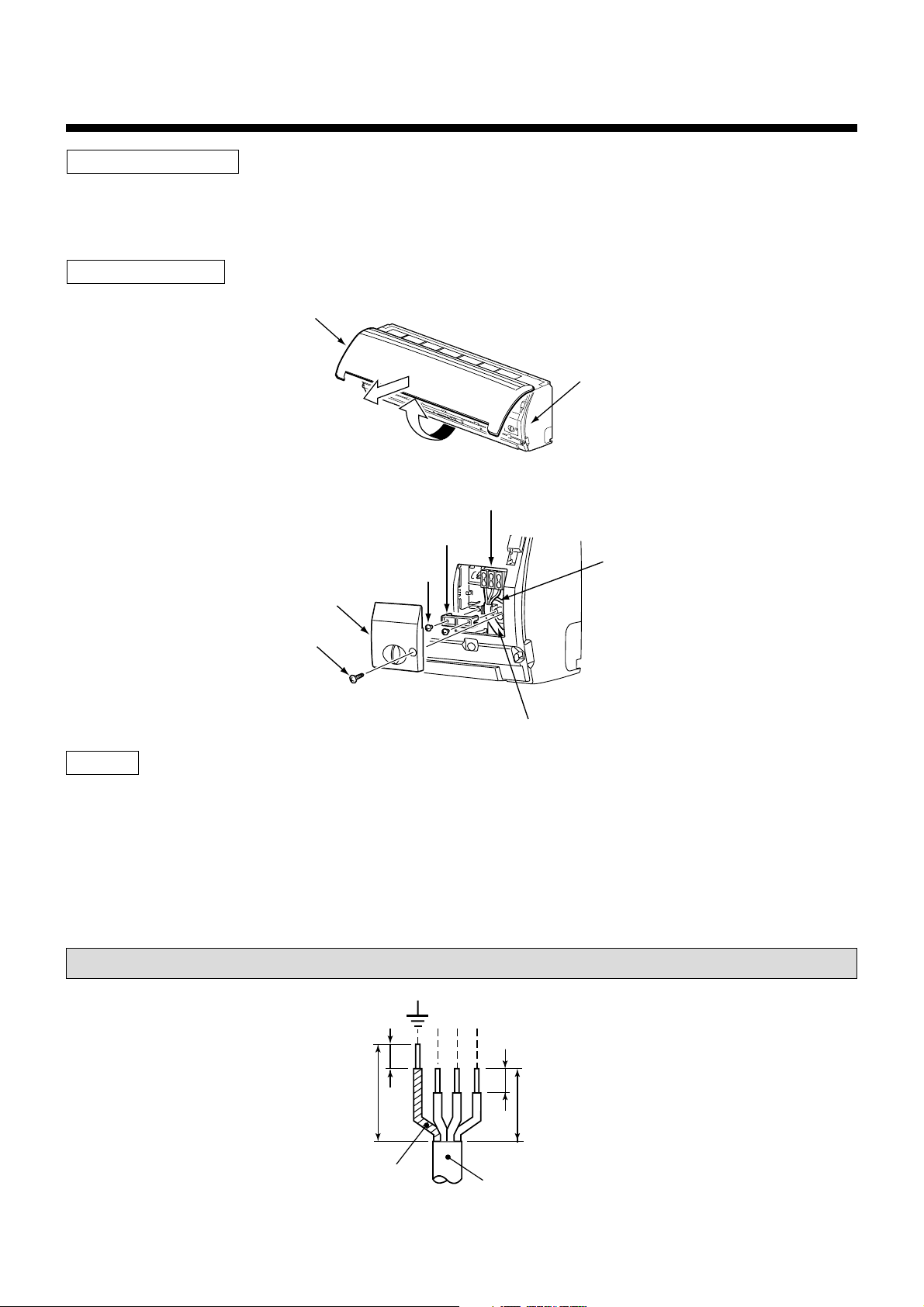

How to wire

1. Connect the connecting cable to the terminal as identified with their respective numbers on the terminal block

of indoor and outdoor unit. H07RN-F or 245IEC66 (1.5 mm

2

or more)

2. Mount a leakage breaker.

3. Insulate the unsheathed redundant cords (conductors) with tape.

4. For inter-unit wiring, do not use a wire jointed to another on the way.

5. Fix the cable with cord clamp.

EN

12

7

ELECTRICAL WORK

Wiring between units

1. Connect the wires between the units correctly.

Errors made in the connections can result in the unit malfunctioning.

2. Connect the control wires between the outdoor unit and indoor unit as shown in the figure below :

Connecting cable

Earth line

Cabling

1. Remove a screw and then remove cover of the electric parts box.

2. Strip wire ends (10 mm).

3. Match wire colors with terminal numbers on indoor and outdoor units’ terminal blocks and firmly screw wires to

the corresponding terminals.

4. Connect the ground wires to the corresponding terminals.

5. Fix the cable with cord clamp.

6. Fix cover of the parts box and the terminal block surely with the fixing screws.

Make a loop on the cable for margin of the length so that the electric parts box can be taken out during servicing.

Connecting cable

Air inlet grille

Front panel

Cord clamp

Terminal cover

Screw

Screw

Earth line

Wiring connections

30

10

10

40

12

3

1

2

Terminal block

Loading...

Loading...