Thomson TS 830 Manual

TS 830

AUTOMATIC TRANSFER SWITCHES

INSTALLATION, OPERATING &

SERVICE MANUAL

PM059 REV 6 08/05/05

9087A – 198th Street, Langley, BC Canada V1M 3B1 Telephone (604) 888-0110 Telefax (604) 888-3381 E-Mail: info@thomsontechnology.com www.thomsontechnology.com

TS 830 TRANSFER SWITCH

TABLE OF CONTENTS

1. |

PRODUCT REVISION HISTORY |

1 |

|

2. |

EQUIPMENT STORAGE |

1 |

|

3. |

NOTES TO INSTALLER |

2 |

|

|

3.1. |

ELECTRICAL CONNECTIONS |

2 |

|

3.2. TRANSFER SWITCHES WITH ADJUSTABLE OVER CURRENT PROTECTION |

2 |

|

|

3.3. TRANSFER SWITCHES WITH MULTI-TAP VOLTAGE CAPABILITY |

3 |

|

|

3.4. SYSTEM PHASING-HIGH LEG DELTA SYSTEMS |

3 |

|

|

3.5. REMOTE START CONTACT FIELD WIRING |

4 |

|

|

3.6. |

DIELECTRIC TESTING |

5 |

|

3.7. INSTALLATION OF OPEN TYPE TRANSFER SWITCHES |

5 |

|

4. |

GENERAL DESCRIPTION |

5 |

|

|

4.1. |

PRODUCT MODEL CODE |

6 |

5. |

GENERAL THEORY OF OPERATION |

8 |

|

|

5.1. STANDARD AUTOMATIC TRANSFER SWITCH |

8 |

|

|

5.2. |

TEST MODES |

9 |

6. |

OVER CURRENT PROTECTION |

10 |

|

7. |

GENERAL NOTES ON SERVICING ATS MECHANISM |

10 |

|

8. |

TRANSFER SWITCH MECHANISM – 100 - 800 AMP (HS STYLE) |

11 |

|

|

8.1. |

MANUAL OPERATION |

12 |

9. |

TRANSFER SWITCH MECHANISM – 1000A1600 AMP (T STYLE) |

12 |

|

|

9.1. |

MANUAL OPERATION |

13 |

10. |

RECOMMENDED MAINTENANCE |

14 |

|

11. |

FRONT VIEW (TYPICAL) 3 / 4 POLE 100A-400A TRANSFER MECHANISM (HS |

|

|

STYLE) |

15 |

|

|

PM059 REV 6 08/05/05 |

Thomson Technology |

|

|

TS 830 TRANSFER SWITCH

12. FRONT VIEW (TYPICAL) 3 / 4 POLE 100A-400A TRANSFER MECHANISM (HS |

|

STYLE) (FRONT COVER REMOVED) |

16 |

13.FRONT VIEW (TYPICAL) 3 / 4 POLE 630A-800A TRANSFER MECHANISM (HS STYLE) 17

14.FRONT VIEW (TYPICAL) 3 / 4 POLE 630A-800A TRANSFER MECHANISM (HS

STYLE) (FRONT COVER REMOVED) |

18 |

|

15. |

FRONT VIEW (TYPICAL) 3 / 4 POLE 600A-1600A TRANSFER MECHANISM |

19 |

16. |

CABLE TERMINAL INFORMATION |

20 |

17. |

ELECTRICAL RATINGS |

20 |

18. |

TROUBLESHOOTING |

21 |

19. |

REPLACEMENT PARTS |

22 |

20. |

PRODUCT RETURN POLICY |

23 |

21. |

NOTES |

24 |

PM059 REV 6 08/05/05 |

Thomson Technology |

|

|

TS 830 TRANSFER SWITCH

1.PRODUCT REVISION HISTORY

The following information provides an historical summary of changes made to this product since the original release.

Operating & Service Manual Version

Rev 6 08/05/05 Revision to add HS Style Mechanism 630A-800A

Rev 5 07/10/10 Revision to add HS Style Mechanism 100-400A

Rev 4 07/03/26 Revision to add MEC 310 controller

Rev 3 04/12/21 Revisions to incorporate the new model coding.

Rev 2 04/03/10 Revisions to mechanism style 1000A, 1200A & 1600A.

Rev 1 03/04/15 Revisions to text, dimensions, & cable specifications.

Rev 0 02/12/20 Original release.

Contact Thomson Technology, to obtain applicable instruction manuals or if in doubt about any matter relating to installation, operation or maintenance. Soft copy of the most current version is available at www.thomsontechnology.com.

NOTE: All information contained in this manual is for reference only and is subject to change without notice.

2. EQUIPMENT STORAGE

The following procedures are required for correct storage of the transfer switch prior to installation.

CAUTION!!!

Failure to store equipment as specified may cause damage and void warranty.

Before storing, unpack sufficiently to check for concealed damage. If concealed damage is found, notify Thomson Technology and the Carrier immediately.

Repack with the original, or equivalent packing materials. Protect from physical damage. Do not stack.

Store indoor in a clean, dry, well-ventilated area free of corrosive agents including fumes, salt and concrete/cement dust. Apply heat as necessary to prevent condensation.

The following storage temperature and humidity must be maintained: -20 to +70°Celsius, 95% Humidity non-condensing.

PM059 REV 6 08/05/05 |

1 |

Thomson Technology |

TS 830 TRANSFER SWITCH

3.NOTES TO INSTALLER

Before opening the transfer switch enclosure to perform any service task, or to manually transfer the mechanism, it is imperative to isolate the transfer switch from any possible source of power. Failure to do so may result in serious personal injury or death due to electrical shock.

CAUTION!!!

All installation and/or service work performed must be done by qualified personnel only. Failure to do so may cause personal injury or death.

3.1.ELECTRICAL CONNECTIONS

To ensure satisfactory installation of this equipment be sure to observe "Cable Terminal Information” regarding power cable connection tightness located in this manual.

All mechanical and electrical connections must be checked for tightness prior to placing this equipment in service to ensure proper operation and to validate applicable warranty coverage.

3.2.TRANSFER SWITCHES WITH ADJUSTABLE OVER CURRENT PROTECTION

Standard models of automatic transfer switches incorporate integral over current protection. Transfer switches rated 1000A or higher are supplied with adjustable over current protection trip units. For models of transfer switch with integral over current protection, the over current protection must be set prior to operation. The equipment will be shipped from the factory with a long-time current setting of 100% (of the equipment rating) and maximum shorttime/instantaneous current and time delay settings.

WARNING!

Do Not Energize this equipment until device settings have been verified to ensure proper system protection & coordination. Failure to do so may result in equipment failure.

Refer to Section 5.1.3 of this manual for additional information on operation of the Transfer switch following an over current trip condition.

PM059 REV 6 08/05/05 |

2 |

Thomson Technology |

TS 830 TRANSFER SWITCH

Refer to information supplied with the transfer switch documentation package for adjustment procedures on the power switching units over current protection trip unit. Contact the factory if any additional information is required.

3.3.TRANSFER SWITCHES WITH MULTI-TAP VOLTAGE CAPABILITY

If the transfer switch has programmable multi-tap voltage capability confirm the transfer switch has been configured for the correct system voltage prior to installation.

WARNING!

Failure to confirm and match transfer switch voltage with the system voltage could cause serious equipment damage.

The voltage selections and connections are shown on the engineered drawings attached to each transfer switch. The factory default settings will be indicated on the calibration label attached on the inside of the enclosure door (supplied loose on open style models). A blank label is included to record the applicable settings if the configuration is changed from the factory default settings.

To change the transfer switch configuration the following must be accomplished:

•Change voltage taps on potential transformers (PT’s) to correct system voltage (refer to drawings)

•Change program setting in the applicable controller used on the transfer switch (e.g. TSC 80, TSC 800, MEC 2, MEC 20, MEC 310) for nominal system voltage. Refer to the applicable controller instruction manual for further information.

•Once the PT voltage taps and controller has been re-programmed to correct operating voltage, the “control circuit isolation plug” on the mechanism, may be reconnected, prior to voltage energization.

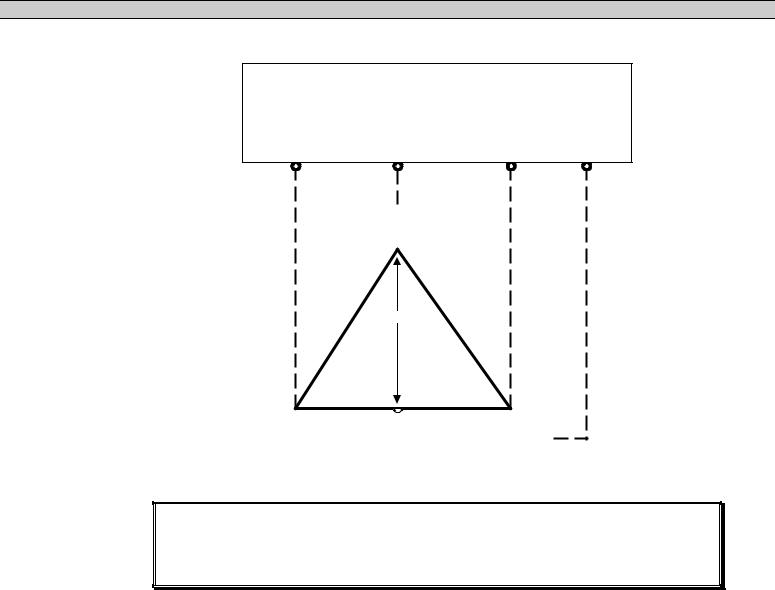

3.4.SYSTEM PHASING-HIGH LEG DELTA SYSTEMS

For systems using high leg delta 240V 3 phase 4 wire systems, connection of supply conductors must have the correct phasing as shown below.

WARNING!

Failure to match correct system phasing

will result in serious damage to the

controller.

PM059 REV 6 08/05/05 |

3 |

Thomson Technology |

TS 830 TRANSFER SWITCH

Autom atic Transfer

Switch (Utility Supply)

PH A |

PH B |

PH C |

Neural |

(UA) |

(UB) |

(UC) |

(N) |

B

(O range)

(High Leg)

240V |

208V |

240V |

A |

120V |

|

|

|

|

120V |

|

|

|

|

|

C |

||||

|

||||||||||||||||

(Red) |

|

|

|

|

|

|

|

|

|

|

|

|

|

(Yellow) |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N

(W hite)

CAUTION!!!

All installation and/or service work performed must be done by qualified personnel only. Failure to do so may cause personal injury or death.

Where transfer switches are supplied without power isolation transformers (PT1 & PT2) for ATS control logic it is essential that the orientation of phase conductors of the supply source be arranged such that the phase of highest potential with respect to ground is not connected to the power supply inputs to the controller (The A Phase for both supplies). Failure to do so will result in equipment damage.

Per NEC Article 384-3 (f) “The B phase shall be that phase having the higher voltage to ground on a 3-phase, 4-wire delta connected systems.”

3.5.REMOTE START CONTACT FIELD WIRING

For applications using TSC 80, 800 controllers, as a minimum, the remote engine start control field wiring shall conform to the local regulatory authority on electrical installations. Field wiring of a remote start contact from a transfer switch to a control

PM059 REV 6 08/05/05 |

4 |

Thomson Technology |

TS 830 TRANSFER SWITCH

panel should conform to the following guidelines to avoid possible controller

malfunction and/or damage.

3.5.1.Minimum #14 AWG (2.5mm2) wire size shall be used for distances up to 500ft (150m)1). For distances exceeding 500 ft. (150m) consult Thomson Technology.

3.5.2.Remote start contact wires should be run in a separate conduit.

3.5.3.Avoid wiring near AC power cables to prevent pick-up of induced voltages.

3.5.4.An interposing relay may be required if field-wiring distance is excessively long (i.e. greater than 500 feet (150m) and/or if a remote contact has a resistance of greater than 5.0 ohms.

3.5.5.The remote start contact must be voltage free (i.e. dry contact). The use of a “powered” contact will damage the transfer controller.

3.6.DIELECTRIC TESTING

Do not perform any high voltage dielectric testing on the transfer switch with the controller connected into the circuit, as serious damage will occur to the controller. All AC control fuses and/or control circuit breakers or control circuit isolation plugs connected to the controller must be removed if high voltage dielectric testing is performed on the transfer switch.

3.7.INSTALLATION OF OPEN TYPE TRANSFER SWITCHES

Please contact Thomson Technology for additional information.

4.GENERAL DESCRIPTION

Thomson Technology TS 830 series of Automatic Transfer Switches employ two mechanically interlocked enclosed contact power switching units and a microprocessor based controller to automatically transfer system load to a generator supply in the event of a utility supply failure. System load is then automatically re-transferred back to the utility supply following restoration of the utility power source to within normal operating limits. Transfer switches with MEC 2, MEC 20 or MEC 310 controllers installed have integral engine-genset auto start control & monitoring features and therefore these applications do not require an engine-mounted auto start control panel.

The standard TS 830 series Automatic Transfer Switch is rated for 100% system load and does not require upstream over current protection. Refer to Section 6 of this manual for detailed information on over current protection.

PM059 REV 6 08/05/05 |

5 |

Thomson Technology |

Loading...

Loading...