tekmar 421 User Manual

- Data Brochure

•

•

•

•

•

•

•

Mixing Reset Module 421

D 421

08/07

1

Information

Brochure

Choose controls

to match

application

2

Application

Brochure

Design your

mechanical

applications

3

Rough-in

Rough-in

instructions

Wiring

wiring

4

Wiring

Brochure

Wiring and

installation of

specific control

5

Data

Brochure

Control settings

and sequence of

operation

6

Job

Record

Record settings &

wiring details for

future reference

Introduction

The Mixing Reset Module 421 provides outdoor reset to a hydronic heating system in order to maximize comfort and

efficiency. The 421 can operate a single on / off boiler and a single mix water temperature. The mix output can operate a

floating action mixing valve or a variable speed injection pump.

Features:

• tN4 Compatible

• Outdoor Reset

• Single On-Off Boiler

• Powered Pump Outputs

• Variable Speed Injection Pump

• Floating Action Valve

• Includes Sensors

Boiler

51

52 55 56 57

H7007B

/

Boil Sens Sup / Ret

Off / Flushing

Meets Class B: Canadian

ICES & FCC Part 15

Made in Canada

Test

Var. Pump Fuse

T2.5 A 250 V

Menu

Item

Variable Speed

Pump

61 62

2.5 A

N

Floating Output:

24 V (ac) 8 VA

Mixing Reset Module 421

C Com Boil MixCls

Opn

5453

Powered Output

RR

Com Out

59

Do not apply power

58

tektra 991-02

Var. Pump: 115V (ac) 2.5 A

Relay Rating: 115V (ac) 5 A

63 64

System P1

Pump

60

tN4

7.5 A

max

N

1 of 20 © 2007 D 421 - 08/07

Table of Contents

•

•

•

•

Boil Sens Sup / Ret

Off / Flushing

/

Table of Contents ...........................................................2

Display and DIP Switches ..............................................2

Dip Switch Settings ................................................2

Access Level ...........................................................3

Display and Symbols Description............................4

User Interface ........................................................5

Display Menus ................................................................6

View Menu ..............................................................6

Adjust Menu ............................................................7

Miscellaneous Menu ...............................................9

Testing the Control .........................................................9

Sequence of Operation ................................................. 11

®

tekmarNet

4 Communication ............................... 11

Outdoor Reset ...................................................... 11

Mixing Operation .................................................. 13

Boiler Temperature Control .................................. 14

Boiler Enable .........................................................15

Pump Operation ................................................... 15

Pump Exercising ...................................................15

Error Messages ............................................................ 16

Troubleshooting ............................................................ 19

Warranty .......................................................................20

Display and DIP Switches

Dip Switch Settings

Set the DIP switch settings prior to making adjustments

to the control through the user interface. Setting the DIP

switches determines which menu items are displayed in

the user interface.

If you change a DIP switch setting while the control is

powered up, the LCD display returns to the View menu.

Lock / Unlock

Use the Lock / Unlock DIP switch to lock and unlock the Access

Level of the 421 and all connected tN4 devices, including

tN4 thermostats. For details, see “Access Levels”

• Once locked, the access level in all devices cannot be

viewed or changed.

• To determine if the control is currently locked a small

segment representing a padlock is viewed in the bottom

right hand corner of the display.

• To unlock the Access Level, set the DIP switch to

Unlock.

• To lock the Access Level, set the DIP switch to Lock.

Boiler

51

52 55 56 57

H7007B

Meets Class B: Canadian

ICES & FCC Part 15

Made in Canada

Test

Var. Pump Fuse

T2.5 A 250 V

Boil Sens Sup / Ret

Off / Flushing

Menu

/

Item

61 62

Variable Speed

Pump

2.5 A

N

C Com Boil MixCls

Floating Output:

Opn

24 V (ac) 8 VA

5453

Powered Output

Mixing Reset Module 421

RR

Com Out

59

58

Do not apply power

tN4

tektra 991-02

Var. Pump: 115V (ac) 2.5 A

Relay Rating: 115V (ac) 5 A

63 64

System P1

Pump

N

60

7.5 A

max

© 2007 D 421 - 08/07 2 of 20

Boiler Sup / Ret

•

•

•

•

•

•

Off / Flushing

Use the Boiler Sensor Supply / Return DIP switch to select

the location of the boiler sensor.

• If the boiler sensor is located on the supply, this DIP

switch should be set to Sup. The 421 is the control that

determines the boiler water temperature. Set the boiler’s

aquastat at least 20°F (11.0°C) higher than the Boiler

Maximum setting.

• If the 421 provides a heat demand to an external boiler

control, this DIP switch must be set to Ret. Install the

boiler sensor on the return side of the boiler loop.

The boiler’s operating temperature is controlled by its

aquastat, or an external boiler reset control.

The Off / Flushing DIP switch selects whether the control

operates a Flushing feature. Heating systems that use

potable water require periodic flushing to prevent the water

from stagnating.

The flushing operation occurs if any zone has not operated

for 7 days. All zones, mixing device(s), and applicable

system pumps are turned on for 4 minutes.

• To activate the Flushing feature, set to Flushing.

• To deactivate the Flushing feature, set to Off.

Access Level

The Access Level restricts the number of Menus, Items,

and Adjustments that can be accessed by the user. The

Access Level setting is found in the Miscellaneous (MISC)

menu. Select the appropriate access level for the people

who work with the control on a regular basis.

There are two Access Level settings:

• Installer (InS): This is the factory default setting. This

access level is sufficient for the normal set up of the

control.

• Advanced (Ad): All of the control settings are available

to the user.

In the following menu tables, the access level the item is

visible in is shown in the access column.

3 of 20 © 2007 D 421 - 08/07

Display

Symbols Description S

Menu Field

Displays the

current menu

Status Field

Displays the current

status of the control’s

inputs, outputs and

operation. Most symbols

in the status field are

only visible when the

VIEW Menu is selected

Symbols Description

Item Field

Displays an

abbreviated name

of the selected item

Number Field

Displays the

current value of

the selected item

PUMP

Displays when the mixing pump is in

operation.

BURNER

Displays when the burner contact is

closed.

LOCK

Displays when the access levels are

locked.

WARNING

Displays when an error exists.

COMMUNICATION BUS

Displays when tN4 thermostats are

connected.

°F, °C, %, HOURS, MINUTES

Units of measurement.

MIX 1 DEMAND

Displays when a mix 1 demand is present.

DEVICE OUTPUT SCALE

Displays output of the injection pump or

mixing valve.

OPEN / CLOSE

Displays whether the actuator is opening or

closing the mixing valve.

© 2007 D 421 - 08/07 4 of 20

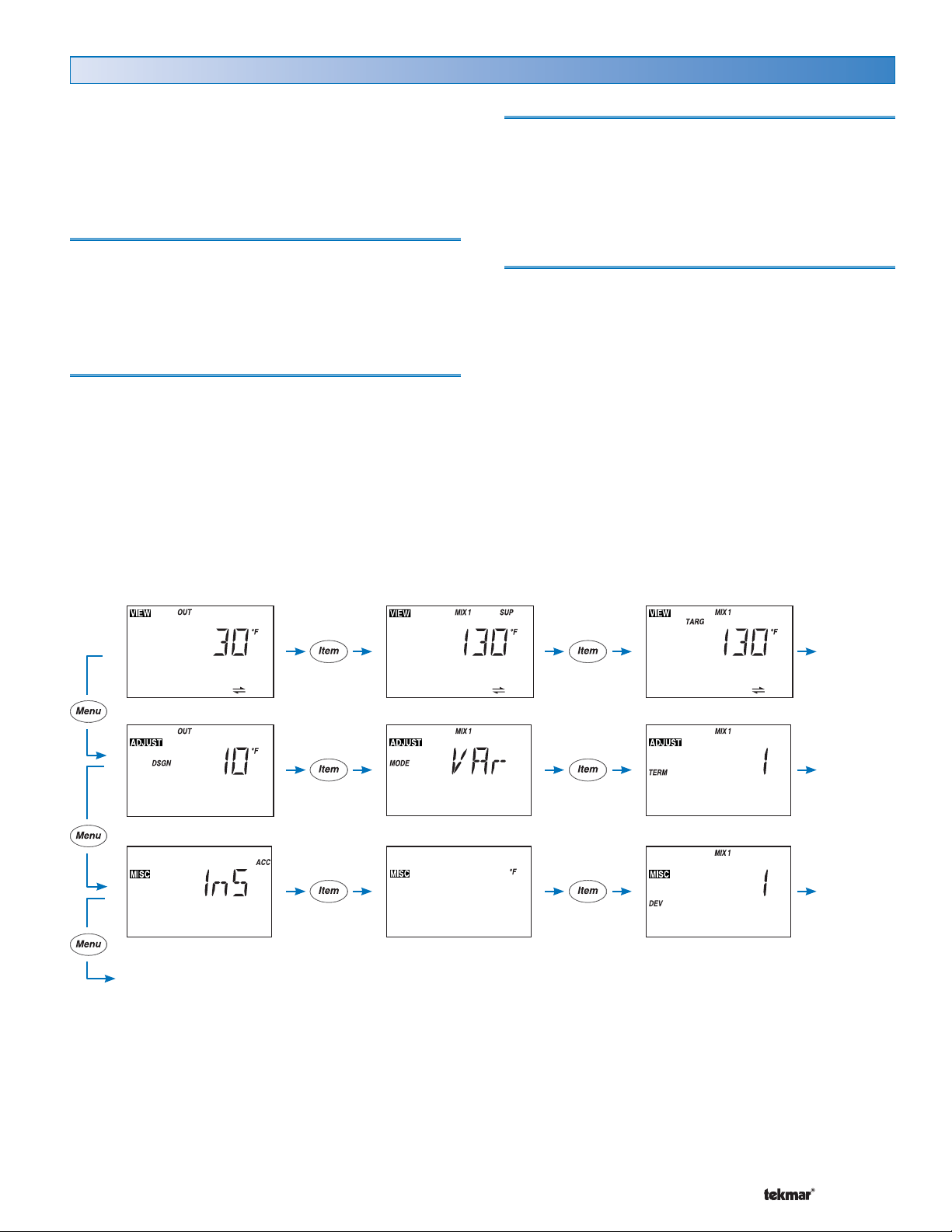

User Interface

•

•

•

•

Use the User Interface available on the Liquid Crystal Display

(LCD) to setup and monitor the operation of the system.

Use the four push buttons to the left of the LCD (Menu,

Item, Up, Down) to select settings. As you enter settings,

record the settings in the Job Record J 421.

Menu

The menus display in the Menu Field at the top left side

of the LCD. Three menus are available: View, Adjust, and

Miscellaneous.

• To select a menu, press and release the Menu button.

Item

In each menu, a group of items can be selected. The

abbreviated name of the selected item displays in the Item

field of the LCD display.

• To view the next available item, press and release the

Item button.

• To view the previous item, hold down the Item button.

and press and release the Up button.

Adjusting a Setting

To adjust a setting:

1. Select the appropriate menu using the Menu button.

2. Select the item using the Item button.

3. Use the Up or Down button to make the adjustment.

Default Item

• To set the default item in the View menu, display the

item for more than five seconds.

After navigating menus, the display reverts back to the

default item after 60 seconds of button inactivity.

Back to View Menu

Continue

to next Item

Continue

to next Item

Continue

to next Item

5 of 20 © 2007 D 421 - 08/07

Display Menus

View Menu (1 of 1)

Item Field Range Access Description

The View menu items display the current operating

temperatures and status information of the system.

VIEW MENU

-76 to 149°F

(-60.0 to 65.0°C)

-22 to 266°F

(-30.0 to 130.0°C)

– – –, 35 to 230°F

(– – –, 1.5 to 110.0°C)

-22 to 266°F

(-30.0 to 130.0°C)

InS

Ad

InS

Ad

Ad

InS

Ad

OUTDOOR SECTION B

Current outdoor air temperature as measured by the

outdoor sensor.

MIX SUPPLY SECTION B

Current mix supply water temperature as measured

by the mix supply sensor.

MIX TARGET SECTION C

The Mix target is the temperature the control is

currently trying to maintain at the mix supply sensor.

“– – –“ is displayed when no heat is required for mix

zones.

BOILER SUPPLY SECTION C

Current boiler supply water temperature as measured

by the boiler sensor.

Note: This item is only available when the Boiler

Sensor Sup / Ret DIP switch is set to Sup.

-22 to 266°F

(-30.0 to 130.0°C)

0 to 9999 hr

After the last item, the control returns to the first item in the menu.

© 2007 D 421 - 08/07 6 of 20

InS

Ad

InS

Ad

BOILER RETURN

Current boiler return water temperature as measured

by the boiler sensor.

Note: This item is only available when the Boiler

Sensor Sup / Ret DIP switch is set to Ret.

BOILER RUN TIME

The total running time of the boiler since this item

was last cleared. To clear this item, press the Up

and Down buttons simultaneously while viewing

this item.

Note: This item is only available when the Boiler

Sensor Sup / Ret DIP switch is set to Sup.

Loading...

Loading...