tekmar 362 Installation

- Data Brochure

D 362

Mixing Control 362

12/08

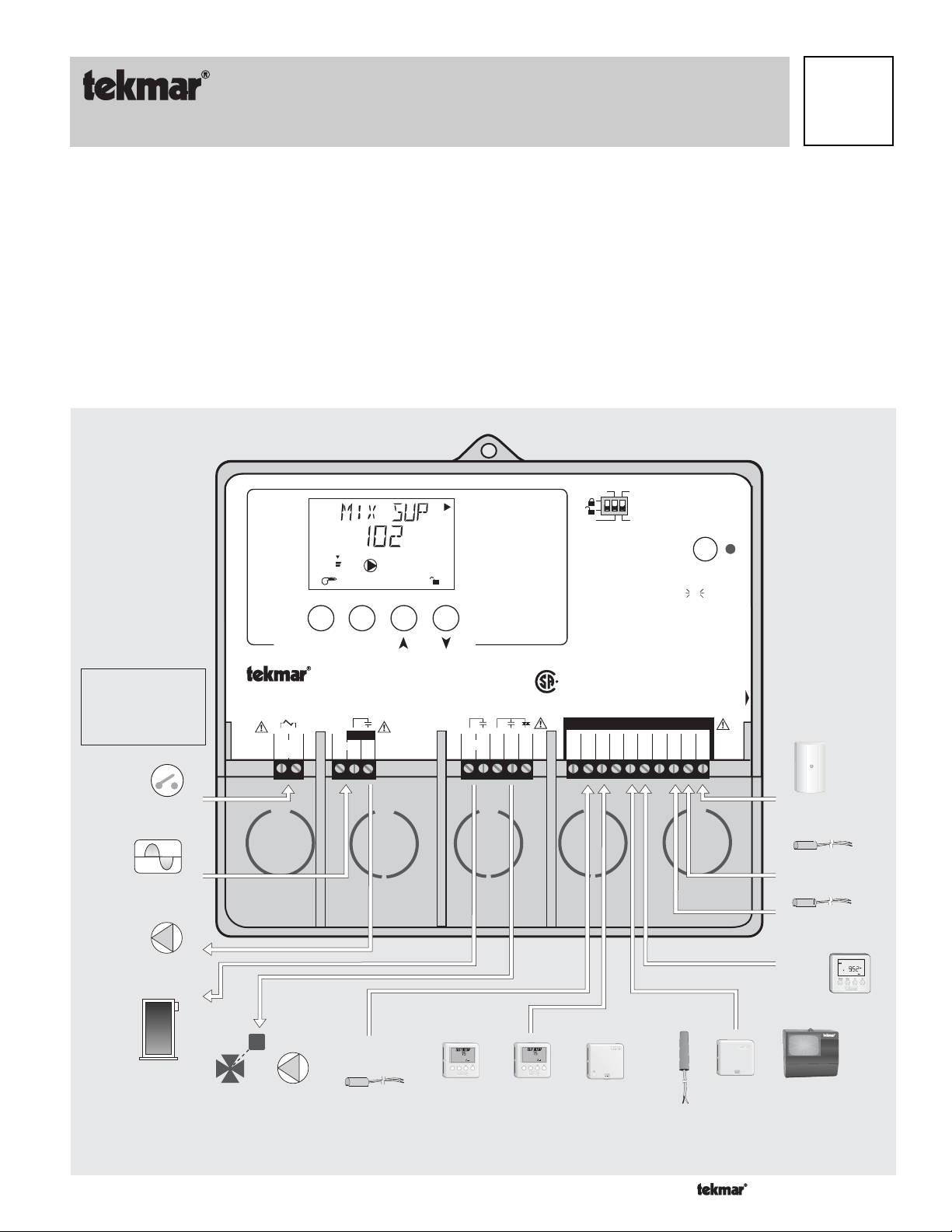

The Mixing Control 362 is a microprocessor based control with two distinct operating modes.

MODE —1— allows the control to provide a reset mixed supply water temperature to a heating system based on outdoor air temperature.

Multiple zone temperature controls can be achieved by using either a conventional thermostat system or by using tekmar Zone Controls

attached to the 362. For single zone heating applications, a single Room Temperature Unit (RTU) can be connected directly to the 362

for zone temperature control.

MODE —2— allows the control to provide a single zone of snow melting. With the addition of a Snow Melting Kit 092, the 362 can

provide slab temperature control and slab ΔT protection. The melting mode is initiated manually either with a demand signal or from the

Snow Melting Kit enabling device.

The 362 incorporates a large Liquid Crystal Display (LCD) in order to provide system status and operating information. The same LCD

is used when setting up and installing the control. Standard features for both modes of operation include boiler return protection,

intelligent boiler operation, Warm Weather Shut Down (WWSD), and pump exercising. As well, with the addition of a new Monitor

feature, it is now possible to track pump and boiler running hours, boiler cycles and high and low sensor temperatures. The 362 also has

a unique feature that allows the control to supply heat to the mixed system from either the boiler or a thermal storage tank.

1 Heating

2 Snow melting

Do not apply power

13

14

tN1/

Com1510K16UnO

tN2

Reset Ratio

Characterized

Heating Curve

17

Com

Sw

Te s t

off

off

red

red

For maximum heat,

press and hold

button for 3 seconds.

18

Mix19Boil20Out

not testing

not testing

testing

testing

testing pausedred

Tes t

Meets Class B:

Canadian ICES

FCC Part 15

Date Code

H1176D

Note:

Mixing demand must be

powered with 20 to 260

V (ac) before the mixing

valve is able to open and

the boiler is able to fire.

View

Open

%

1

Item

Menu

Mixing Control 362

Floating Action / Variable Speed

5

4

3

2

1

Mix

Demand

Power

N L

Pmp

Mix

°

UnOcc

Mix Demand

F

WWSD

Minimum

Maximum

Melting

Idling

7

9

6810

Pwr

Opn Cls

Boiler

Mix

Var

C US

Setback

None

Operating Modes

See product literature

INSTALLATION CATEGORY II

Made in Canada by

tekmar Control Systems Ltd.

tektra 929-04

Power 115 V ±10% 60 Hz 900 VA

R

Relays 230 V (ac) 7.5 A 1/3 hp, pilot duty 240 VA

Var. Pump 230 V (ac) 2.4 A 1/6 hp, fuse T2.5 A 250V

Demands 20 to 260 V (ac) 2 VA

Signal wiring must be rated at least 300 V.

Wiring must be rated 194°F (90°C) minimum

11 12

Com Mix

Ret

Input

Mix Demand

Signal

120 V (ac) Power

Input

Supply

Output

Mixing System

Pump

Output

M

OR

Output

Mixing Valve & Actuating

Motor OR Var. Speed

Driven Pump

Input

Universal

View

F

°

WWSD

1%%2

!

ItemMenu

Input

Room

Temperature

Unit (RTU)

1 of 36

View

F

°

WWSD

1%%2

!

ItemMenu

OR OR

Input

Remote

Display

Module (RDM)

79

8

Input

Snowmelt

Kit

(SMK)

Input

Outdoor

Input

Universal

Input

Universal

Sensor

Input

tekmar

Timer

LR 58233

OR OR

70

tekmar Slab Sensor or Indoor Sensor or

Input

Zone Control

E150539

Copyright © D 362 -12/08

Included

How To Use The Data Brochure

This brochure is organized into four main sections. They are: 1) Sequence

Troubleshooting

Sequence of Operation

apply to your installation.

Control Settings

The

by the control. The control functions of each adjustable item are described in the

. The

Sequence of Operation

, as this contains important information on the overall operation of the control. Then read to the sub sections that

section (starting at DIP Switch Settings) of this brochure describes the various items that are adjusted and displayed

section has four sub sections. We recommend reading

of Operation

Table of Contents

User Interface ........................................... pg 2

Description of Display Elements ............ pg 3

Sequence of Operation ........................... pg 4

Section A: General

Section B: Mixing Reset

Section C: Snow Melting

Section D: Boiler Operation

Installation ................................................ pg 15

Electrical Connections.................. pg 16

Testing The Wiring......................... pg 18

DIP Switch Settings ................................. pg 20

........................ pg 4

............... pg 5

.............. pg 9

......... pg 13

Access Levels ........................................... pg 20

Control Settings ........................................ pg 21

View Menu

Adjust Menu

Schedule Menu

Miscellaneous Menu

RTU Menu

Testing and Troubleshooting .................. pg 28

Monitor Menu

Error Messages

Technical Data .......................................... pg 36

, 2)

Installation

Sequence of Operation

...................................... pg 21

................................... pg 22

.............................. pg 25

...................... pg 25

....................................... pg 26

................................. pg 30

.............................. pg 32

, 3)

Control Settings

Section A: General

.

, and 4)

of the

Limited Warranty ....................................... pg 36

Reference Material: Essay E 003: Characterized Heating Curve and Reset Ratio

E 021: Mixing Methods and Sizing of Variable Speed Injection Pumps

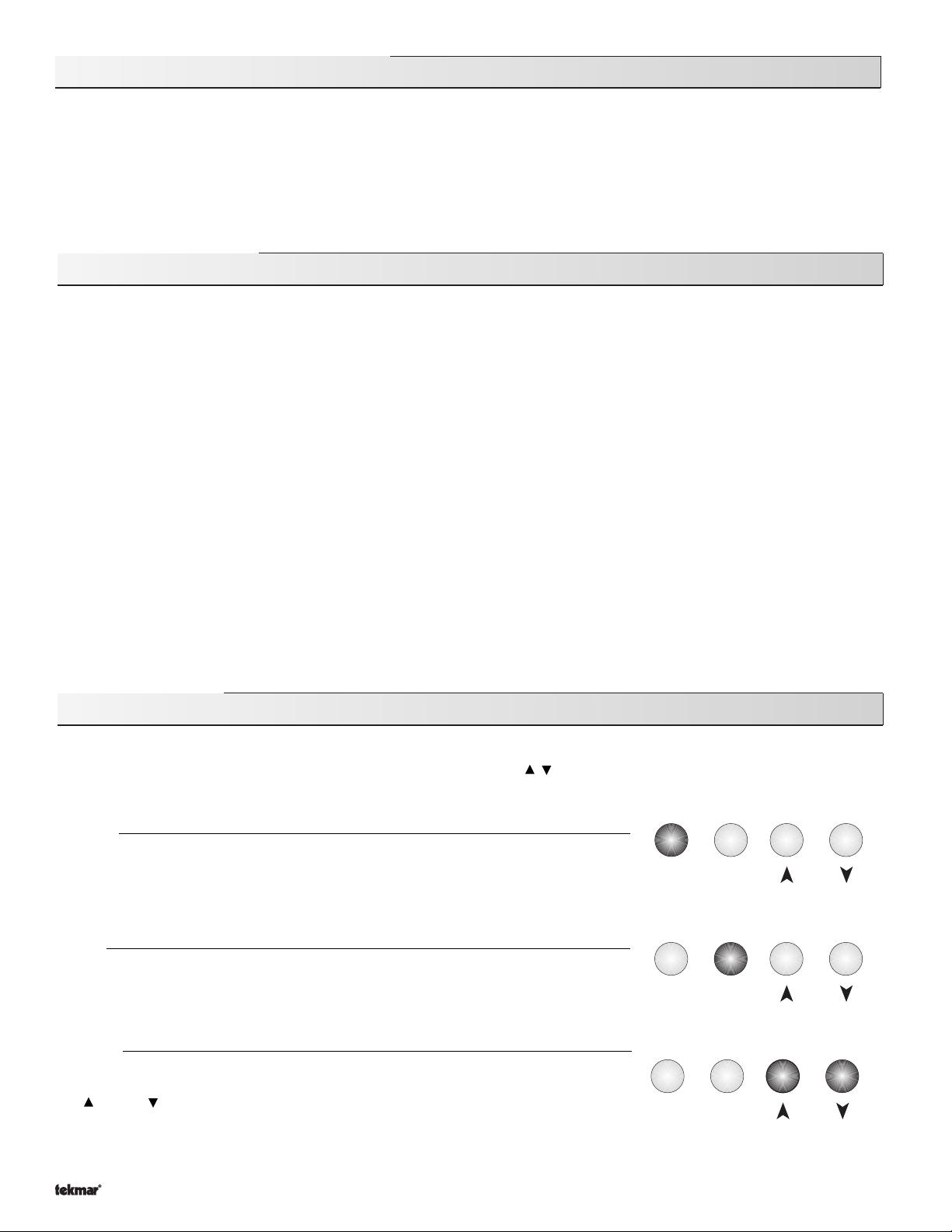

User Interface

The 362 uses a Liquid Crystal Display (LCD) as the method of supplying information. You use the LCD in order to setup and monitor

the operation of your system. The 362 has four push buttons (Menu, Item, , ) for selecting and adjusting settings. As you program

your control, record your settings in the Adjust Menu table which is found in the second half of this brochure.

Menu

All of the items displayed by the control are organized into various menus. These menus are

listed on the left hand side of the display (Menu Field). To select a menu, use the

button. By pressing and releasing the

available menu. Once a menu is selected, there will be a group of items that can be viewed

within that menu.

Item

The abbreviated name of the selected item will be displayed in the item field of the display.

To view the next available item, press and release the

the last available item in a menu, pressing and releasing the

display to the first item in the selected menu.

Adjust

To make an adjustment to a setting in the control, begin by selecting the appropriate menu

Menu

using the

and / or button to make the adjustment.

button. Then select the desired item using the

Menu

button, the display will advance to the next

Item

button. Once you have reached

Item

button will return the

Item

button. Finally, use the

Menu

Menu

Menu

Menu

Item

Item

Item

Additional information can be gained by observing the Status and Pointers fields of the LCD. The status field will indicate which of

the control’s outputs are currently active. Most symbols in the status field are only visible when the View Menu is selected.

Copyright © D 362 -12/08

2 of 36

Display

Item Field

Displays an abbreviated

name of the selected item

Menu Field

Displays the

current menu

Status Field

Displays the current

status of the control’s

inputs, outputs and

operation

View

Adjust

Monitor

Schd

Misc

Open

Close

Menu

%

1

Item

Aux

1

2

UnOcc

DHW

°F°

sec

Number Field

Displays the current value

of the selected item

Mix Demand

WWSD

C

min

hr

Ovr

Minimum

Maximum

Melting

Idling

!

Buttons

Selects Menus, Items and

{

adjusts settings

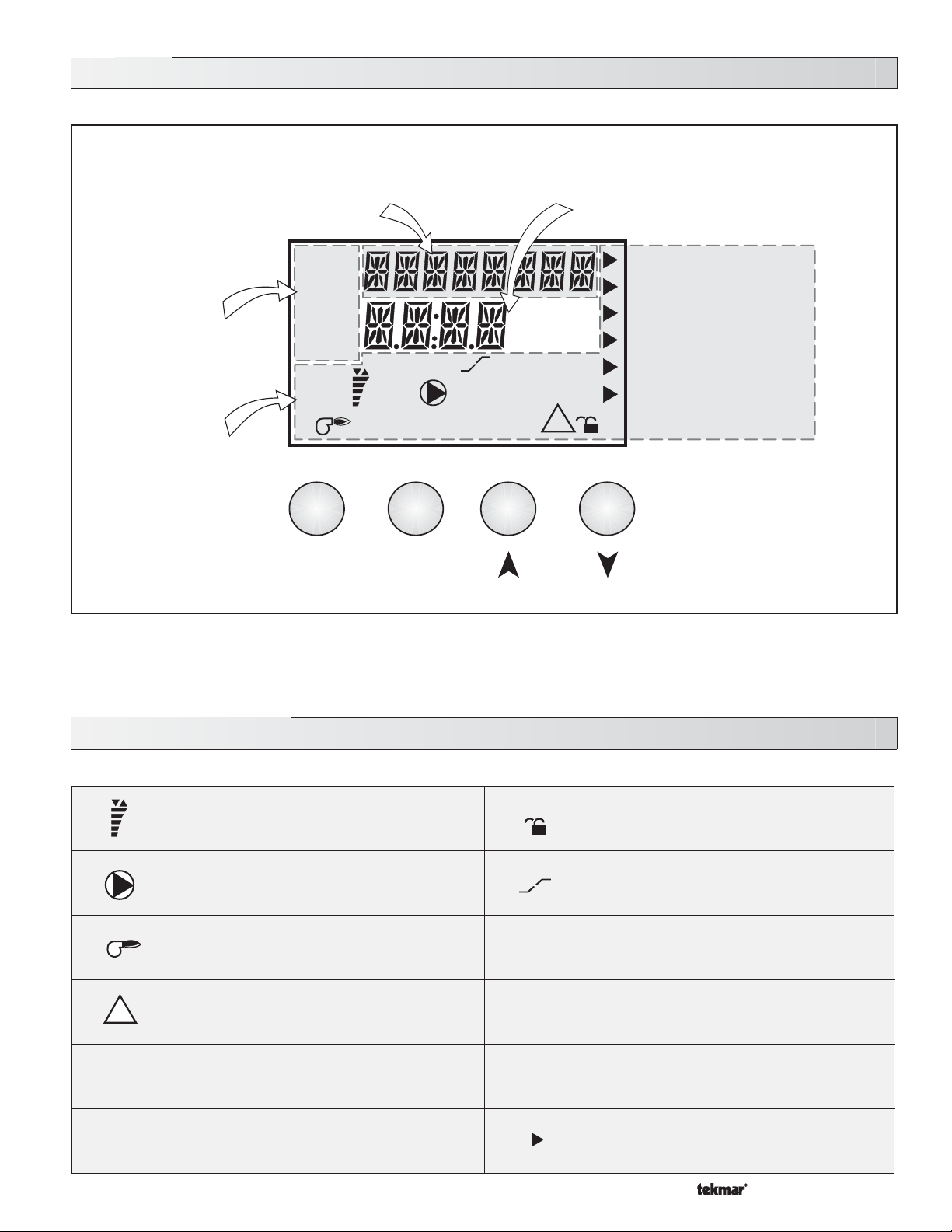

Symbol Description

Mixing Device Output Scale

%

1

!

°

F, °C, sec,

min, hr

Open

Close

Shows output of injection pump or mixing valve.

Arrows show whether the output is increasing

or decreasing.

Pump

Displays when mixing pump is in operation.

Burner

Displays when the boiler relay is turned on.

Warning

Displays when an error exists or a specific

limit has been reached.

°F, °C, sec, min, hr

Units of measurement.

Open / Close

Displays when floating actuator is opening or

closing.

Occ

UnOcc

Ovr

Lock - Unlock

Displays whether control is locked or unlocked.

Boost

Displays when control is in morning boost

after setback.

Occupied Schedule

Displays when the control is in occupied mode.

UnOccupied Schedule

Displays when the control is in

unoccupied mode.

Override

Displays when the control is in override mode.

Pointer

Displays the control operation as indicated by

the text.

3 of 36

Copyright © D 362 -12/08

P1

OR

Mixing

P1

OR

Mixing

Sequence of Operation

Section A

General

Page 4 - 5

Section B

Mode 1:

Heating

Page 5 - 9

Section C

Mode 2:

Snow Melting

Page 9 - 13

Section D

Boiler Operation

Page 13 - 15

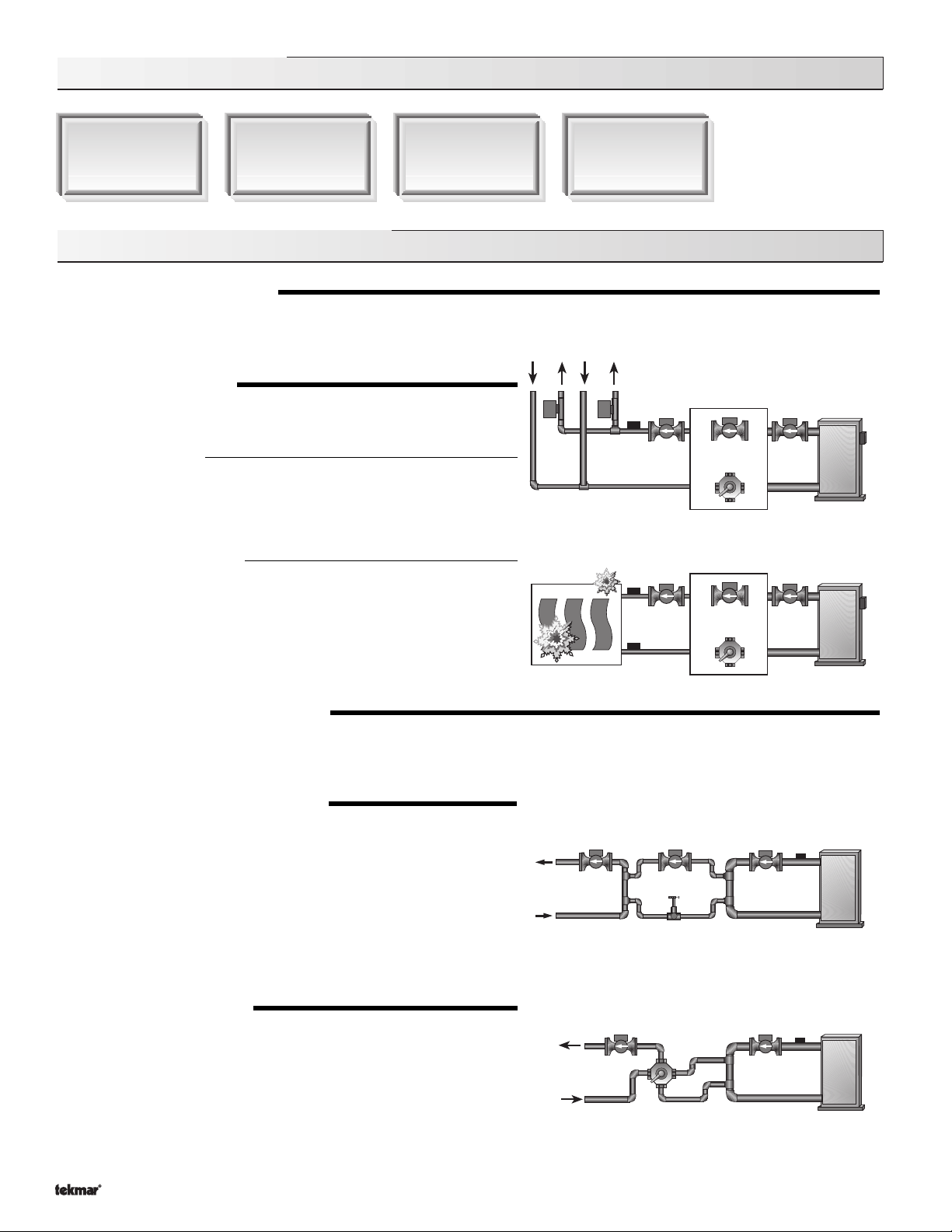

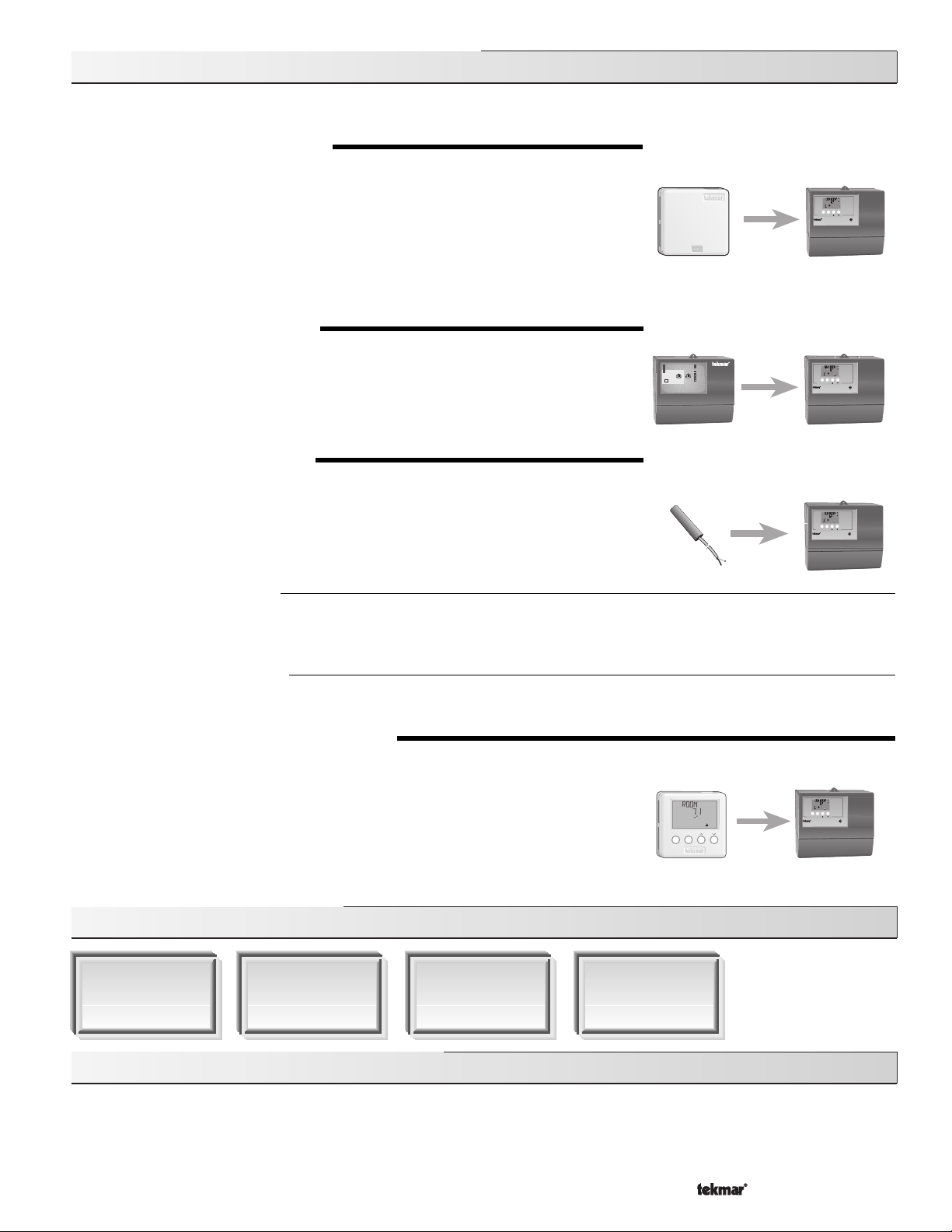

Section A —General Operation

POWERING UP THE CONTROL

When the Mixing Control 362 is powered up, the control displays the control type number in the LCD for 2 seconds. Next, the software

version is displayed for 2 seconds. Finally, the control enters into the normal operating mode and the LCD defaults to displaying the

current outdoor air temperature.

MODES OF OPERATION

The Mixing Control 362 has two distinct operating modes. The mode of

operation for the control is selected in the Adjust Menu.

MODE 1 (Heating)

Mode 1 is the Heating mode of operation. In this mode, the 362 is an

Outdoor Reset control for a building heating system. The 362 uses a

mixing device to vary the supply water temperature to the building

heating system according to the outdoor conditions.

MODE 2 (Snow Melting)

Mode 2 is the Snow Melting mode of operation. In this mode, the 362 is

a Slab Outdoor Reset control for a single zone of snow melting. The 362

uses a mixing device to vary the supply water temperature to a single

zone snow melting system. In the Snow Melting mode, the 362 uses a

slab sensor and mixing return sensor in order to provide slab temperature

control and slab protection. It is recommended to purchase a Snow Melt

Enable Kit 092 when using this mode of operation.

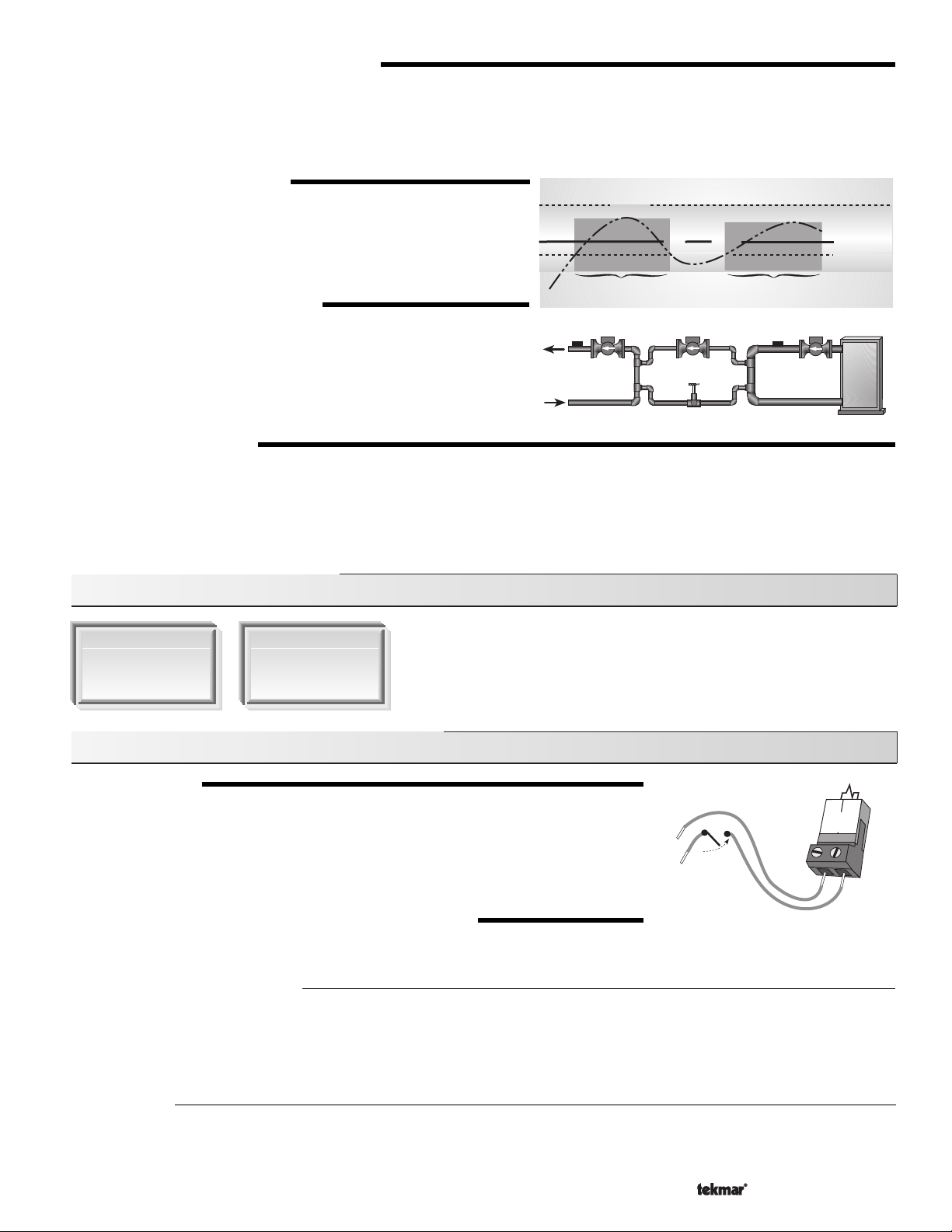

MIXING DEVICE SELECTION (MIXING)

The 362 can supply a lower water temperature to part of the heating system by varying the speed of an injection pump or modulating

a mixing valve. This selection is made under the MIXING item in the

VARIABLE SPEED INJECTION (VAR)

A standard wet rotor circulator is connected to the 362 on the

Cls / Var

output to the circulator when there is a

varies to maintain the correct mixed supply water temperature at the mix

sensor. For correct sizing and piping of the variable speed injection driven

circulator, refer to essay E 021. A visual indication of the current variable

speed output is displayed in the LCD in the form of a segmented bar graph.

Two small indicators at the top of the graph indicate whether the output is

increasing or decreasing.

FLOATING ACTION (FLOT)

A floating action actuator motor is connected to the 362 on the

Opn

motor open or close to maintain the correct supply water temperature at the

mix sensor when there is a

is connected to can be either a 2-way, 3-way or 4-way valve. A visual

indication as to whether the control is currently opening or closing the

mixing valve is displayed in the LCD with the words Open and Close. Also,

a visual indication of the current position of the valve is displayed in the LCD

in the form of a segmented bar graph.

terminals (8 and 10). The 362 increases or decreases the power

, and

Cls / Var

Copyright © D 362 -12/08

terminals (8, 9 and 10). The 362 pulses the actuator

Mix Demand

Adjust Menu

Pwr Mix

Mix Demand

. The mixing valve that the actuator

. The circulator speed

and

Pwr Mix

4 of 36

.

,

MIXING TARGET TEMPERATURE (MIX TRG)

(

RESET RATIO

When in Mode 1, the MIX TRG temperature is determined from either the

the outdoor air temperature. When in Mode 2, the MIX TRG temperature is determined from either the outdoor air temperature and the

desired slab temperature or the Melting and Idling settings. The control displays the temperature that it is currently trying to maintain

as the mixing supply temperature. If the control does not presently have a requirement for heat, it displays “- - -” in the LCD.

&

CHARACTERIZED HEATING CURVE

)

Characterized Heating Curve

or the

Reset Ratio

settings and

MIXING MAXIMUM (MIX MAX)

The MIX MAX sets the highest water temperature that the control is allowed

to calculate as the MIX TRG temperature. If the control does target the MIX

MAX setting, and the MIX SUP temperature is within 5˚F (3˚C) of the MIX

MAX, the

Maximum

pointer is displayed in the LCD while either the MIX

x

i

e

M

d

S

u

p

p

l

y W

a

t

e

r

T

e

r

u

t

a

r

e

p

m

e

MIX MAX

TRG temperature or the MIX SUP temperature is being viewed.

Pointer On

Pointer On

BOILER PROTECTION (BoiL MIN )

The 362 is capable of providing boiler protection from cold mixing system

return water temperatures. If the boiler sensor temperature is cooler than

the Boil MIN setting while the boiler is firing, the 362 reduces the output

from the mixing device. This limits the amount of cool return water to the

boiler and allows the boiler temperature to recover. This feature can only

be used if the Boil SENS item is not set to NONE.

EXERCISING (EXERCISE)

The 362 has a built-in pump and valve exercising function. The exercising period is adjustable and comes factory set at 70 hours. If a

pump or valve output on the control has not been operated at least once during every exercising period, the control turns on the output

for 10 seconds. This minimizes the possibility of a pump or valve seizing during a long period of inactivity. In the case where a mixing

valve is being used as the mixing device, the 362 ensures that the valve operates over its entire range at least once each exercising

period.

Note: The exercising function does not work if power to the control or pumps is disconnected.

Section B: Mixing Reset (Mode —1—)

Section B1

General Mixing

Operation

Section B2

Alternate Mixing

Demands

Section B1: General Mixing Operation (Mode —1—)

MIXING DEMAND

A mixing demand is generated by applying a voltage between 24 and 240 V (ac) across the

Mix Demand

in the LCD. If the 362 is not in WWSD, the 362 closes the

segment is displayed in the LCD. The 362 calculates a MIX TRG supply temperature based

on the outdoor air temperature and settings. If required, the 362 operates the boiler in order

to provide heat to the mixing device.

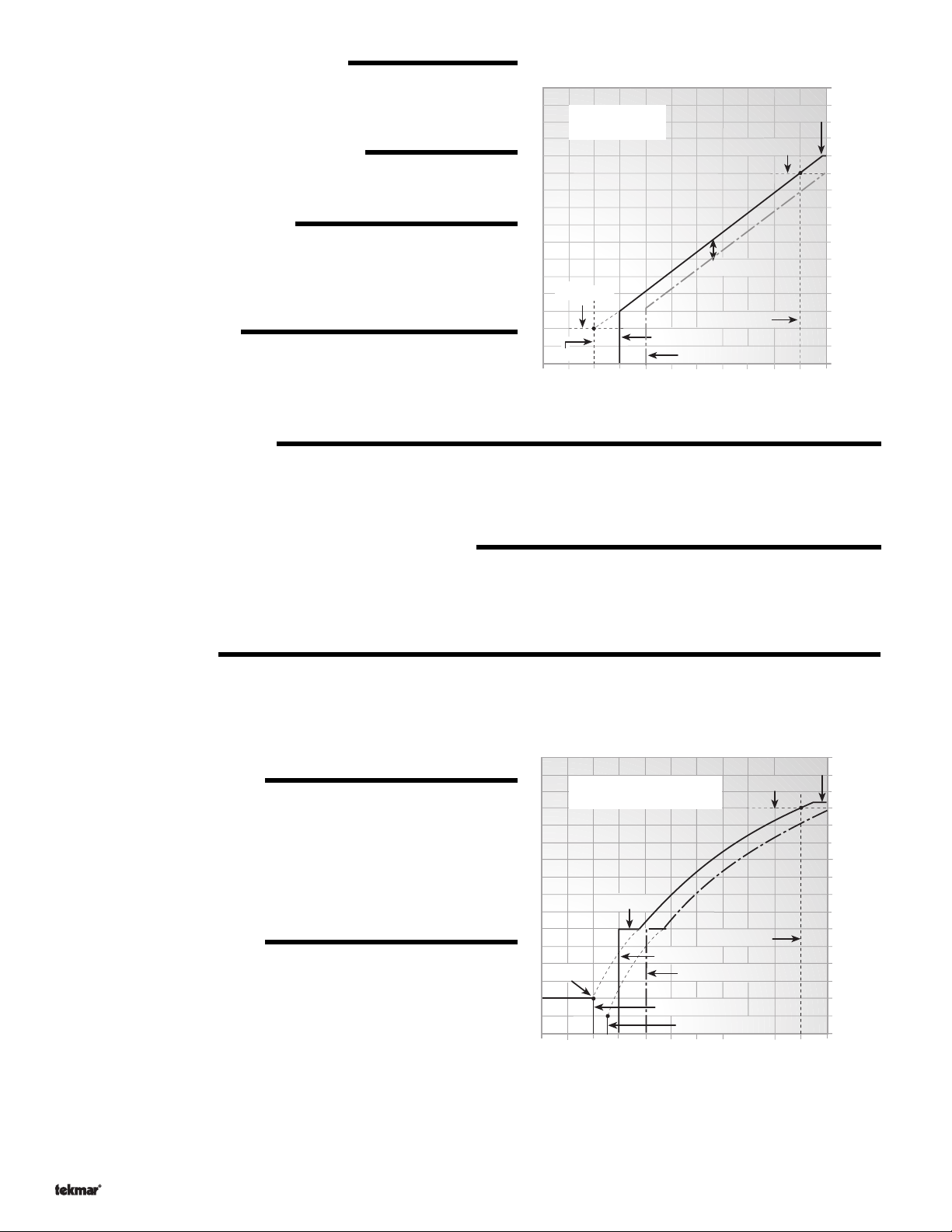

CHARACTERIZED HEATING CURVE OR RESET RATIO

When used as a mixing reset control (MODE 1), the 362 has two methods of varying the supply water temperature based on the outdoor

air temperature. The installer can select either a

Characterized Heating Curve

The

Characterized Heating Curve

indoor temperature is the most accurate. The control takes into account the type of terminal unit that the system is using. Since different

types of terminal units transfer heat to a space using different proportions of radiation, convection and conduction, the supply water

temperature must be controlled differently. Once the control is told what type of terminal unit is used, the control varies the supply

water temperature according to the type of terminal unit. This improves the control of the air temperature in the building.

terminals (1 and 2). Once voltage is applied, the

Mix Pmp

Characterized Heating Curve

method of controlling the supply water temperature based on outdoor air temperature and optionally

Mix Demand

pointer is displayed

contact. The Mixing Pump

or a

24 to 240 V (ac)

Reset Ratio

2

1

Mix

Demand

.

Reset Ratio

The

Reset Ratio

method of controlling the supply water temperature is based solely on the outdoor air temperature. This method does

not take into account the type of terminal unit that the heating system is using and therefore is not as accurate as a

Characterized Heating Curve

.

5 of 36

Copyright © D 362 -12/08

70

(21)

90

(32)

110

(43)

130

(54)

150

(66)

170

(77)

190

(88)

Outdoor Air Temperature

Supply Water Temperature

210

(99)

-20

(-29)

0

(-18)

20

(-7)

40

(5)

60

(16)

80

(27)

MIX DSGN

MIX MAX

MIX MIN

WWSD Unocc

MIX INDOOR

OUT DSGN

Mixing Characterized

Heating Curve

WWSD Occ

50

(10)

MIX ROOM Occ

MIX ROOM Unocc

MIXING START (MIX STRT)

(

RESET RATIO

)

The MIX STRT temperature is the mixing supply water temperature that the

heating system requires when the outdoor air temperature equals the OUT

STRT air temperature.

OUTDOOR START (OUT STRT)

(

RESET RATIO

)

Mixing Reset

Ratio

MIX MAX

MIX DSGN

The OUT STRT temperature is the outdoor air temperature at which the

control provides the MIX STRT supply water temperature to the system.

OUTDOOR DESIGN (OUT DSGN)

(

RESET RATIO

&

CHARACTERIZED HEATING CURVE

)

The OUT DSGN is the outdoor air temperature that is typically the coldest

o

N

l

a

m

r

MIX SETB

k

c

a

b

t

e

S

temperature of the year where the building is located. This temperature is

used when doing heat loss calculations for the building.

MIX DESIGN (MIX DSGN)

Sequence, Section B

(

RESET RATIO

&

CHARACTERIZED HEATING CURVE

)

The MIX DSGN temperature is the supply water temperature required to

heat the mixing zones when the outdoor air is as cold as the Outdoor Design

temperature.

MIX STRT

OUT STRT

80

(27)

WWSD Occ

WWSD Unocc

60

(16)

40

(5)

Outdoor Air Temperature

OUT DSGN

20

(-7)

0

(-18)

MIXING MAXIMUM (MIX MAX)

(

RESET RATIO

The MIX MAX sets the highest water temperature that the control is allowed to calculate as the MIX TRG temperature. If the control does

target the MIX MAX setting, and the MIX SUP temperature is within 5˚F (3˚C) of the MIX MAX, the

LCD while either the MIX TRG temperature or the MIX SUP temperature is being viewed.

&

CHARACTERIZED HEATING CURVE

)

Maximum

pointer is displayed in the

-20

(-29)

210

(99)

190

(88)

170

(77)

150

(66)

130

(54)

110

(43)

90

(32

70

(21)

Supply Water Temperature

WARM WEATHER SHUT DOWN (WWSD) OCC & UNOCC

(

RESET RATIO

When the outdoor air temperature rises above the WWSD setting, the 362 turns on the

is in Warm Weather Shut Down, the

heating system to satisfy this demand.

SETBACK (SETBACK)

(

RESET RATIO

The SETBACK is the amount that the mixing supply water temperature is reduced when the 362 is placed into an

using an internal or an external setback as described later in this section. This setting is only available if the

selected and

MIXING INDOOR (MIX INDR)

(

CHARACTERIZED HEATING CURVE

The MIX INDR is the room temperature used in the original heat loss

calculations for the building. This setting establishes the beginning of the

Characterized Heating Curve

replaces the MIX STRT water temperature and OUT STRT air temperature

settings used by the

MIXING MINIMUM (MIX MIN)

(

CHARACTERIZED HEATING CURVE

The MIX MIN is the lowest temperature that the control is allowed to use as

a MIX TRG temperature. During mild conditions, if the 362 calculates a

MIX TRG temperature that is below the MIX MIN setting, the MIX TRG

temperature is adjusted to match the MIX MIN setting. During this condition,

the

Minimum

temperature or the MIX SUP temperature is being viewed.

If either an Indoor Sensor or a Room Temperature Unit (RTU) is used and

the 362 is operating at the MIX MIN temperature, the Mixing Pump is cycled using Pulse Width Modulation (PWM) with a 15 minute cycle

length. By cycling the Mixing Pump and controlling the flow of supply water, the control provides an average supply water temperature

to the mixing system. This average temperature is equal to the original MIX TRG. This minimizes overheating of the zone while the control

is operating at the MIX MIN temperature.

Copyright © D 362 -12/08

&

CHARACTERIZED HEATING CURVE

Mix Demand

)

pointer is displayed if there is a demand. However, the control does not operate the

)

Setback / None

DIP switch is set to

Setback

.

)

for the mixing zones. This single setting

Reset Ratio

pointer turns on in the LCD when either the MIX TRG

)

.

6 of 36

WWSD

pointer in the display. When the control

UnOccupied

Reset Ratio

mode,

DIP switch is

ROOM OCC & UNOCC (ROOM)

(

CHARACTERIZED HEATING CURVE

The ROOM is the desired room temperature for the mixing zones and it provides a parallel shift of the

The room temperature desired by the occupants is often different from the design indoor temperature (MIX INDR). If the room

temperature is not correct, adjusting the ROOM

Setback / None

DIP switch is set to

)

Characterized Heating Curve

setting increases or decreases the amount of heat available to the building. If the

Setback

, a ROOM setting must be made for both the

Occupied

and

UnOccupied

modes.

.

MIXING TARGET TEMPERATURE (MIX TRG)

(

RESET RATIO

The MIX TRG temperature is determined from either the

temperature. The control displays the temperature that it is currently trying to maintain as the mixing supply temperature. If the control

does not presently have a requirement for heat, it displays “- - -” in the LCD.

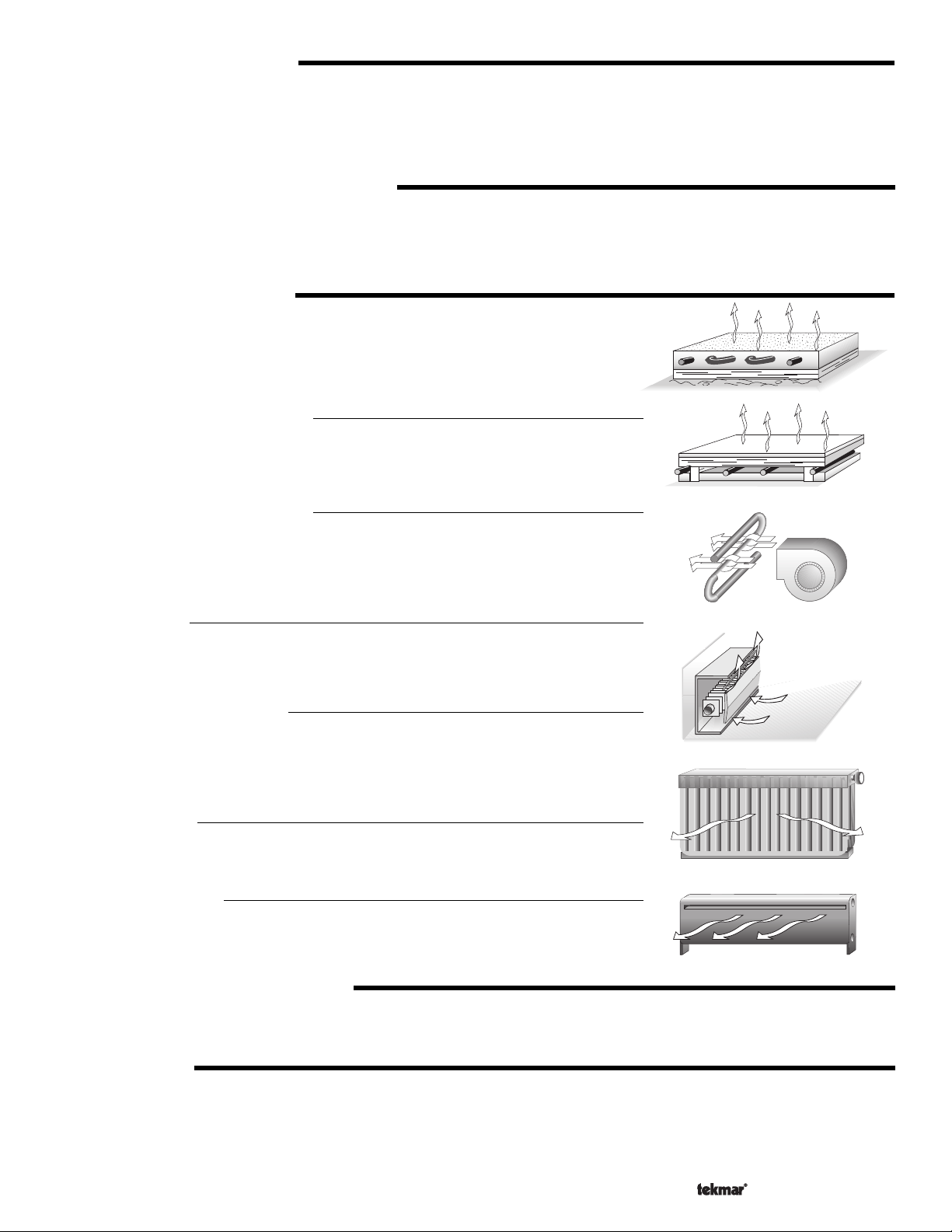

TERMINAL UNITS (TERMINAL)

When using a

unit. The terminal unit determines the shape of the

to how the terminal unit delivers heat into the building space. The 362 provides for selection

between six different terminal unit types: two types of radiant floor heat, fancoil, fin-tube

convector, radiator and baseboard.

Hydronic Radiant Floor

HRF1 is a heavy, or high mass, hydronic radiant floor system. This type of a hydronic radiant

floor is embedded in either a thick concrete or gypsum pour. This heating system has a large

thermal mass and is slow acting.

Hydronic Radiant Floor

HRF2 is a light, or low mass, hydronic radiant floor system. Most commonly, this type of

radiant heating system is either attached to the bottom of a wood sub floor, suspended in

the joist space, or sandwiched between the subfloor and the surface. This type of radiant

system has a relatively low thermal mass and responds faster than a high mass system.

Fancoil

A fancoil terminal unit or air handling unit (AHU) consists of an hydronic heating coil and

either a fan or blower. Air is forced across the coil at a constant velocity by the fan or blower

and is then delivered into the building space.

&

CHARACTERIZED HEATING CURVE

Characterized Heating Curve

(HRF 1)

(HRF 2)

(COIL)

)

Characterized Heating Curve

, the control requires the selection of a terminal

Characterized Heating Curve

or the

according

Reset Ratio

settings and the outdoor air

HRF 1

HRF 2

COIL

Sequence, Section B

Fin–tube Convector

A convector terminal unit is made up of a heating element with fins on it. This type of terminal

unit relies on the natural convection of air across the heating element to deliver heated air

into the space. The amount of natural convection to the space is dependant on the supply

water temperature to the heating element and the room air temperature.

Radiator

A radiator terminal unit has a large heated surface that is exposed to the room. A radiator

provides heat to the room through radiant heat transfer and natural convection.

Baseboard

A baseboard terminal unit is similar to a radiator, but has a low profile and is installed at the

base of the wall. The proportion of heat transferred by radiation from a baseboard is greater

than that from a fin-tube convector.

(RAD)

(BASE)

(CONV)

MIXING PUMP OPERATION (Mix Pmp)

The Mixing Pump contact (

the mixing pump is operated based on the EXERCISE setting in the

PURGE (PURGE)

After the

that the Mixing Pump continues to run is an adjustable time setting. This setting allows any excess heat to be purged out to the heating

system. The Mixing Pump continues to run until the Purging time has elapsed or the mixing supply temperature drops below the MIX

MIN setting. This setting should not be used if the mixing system is zoned using either zone pumps or fast acting zone valves.

Mixing Demand

CONV

RAD

BASE

Mix Pmp

has been satisfied, the 362 can continue to operate the Mixing Pump for a period of time. The length of time

, terminal 5) closes whenever there is a

Adjust

Mixing Demand

Menu.

and the 362 is not in WWSD. During WWSD,

7 of 36

Copyright © D 362 -12/08

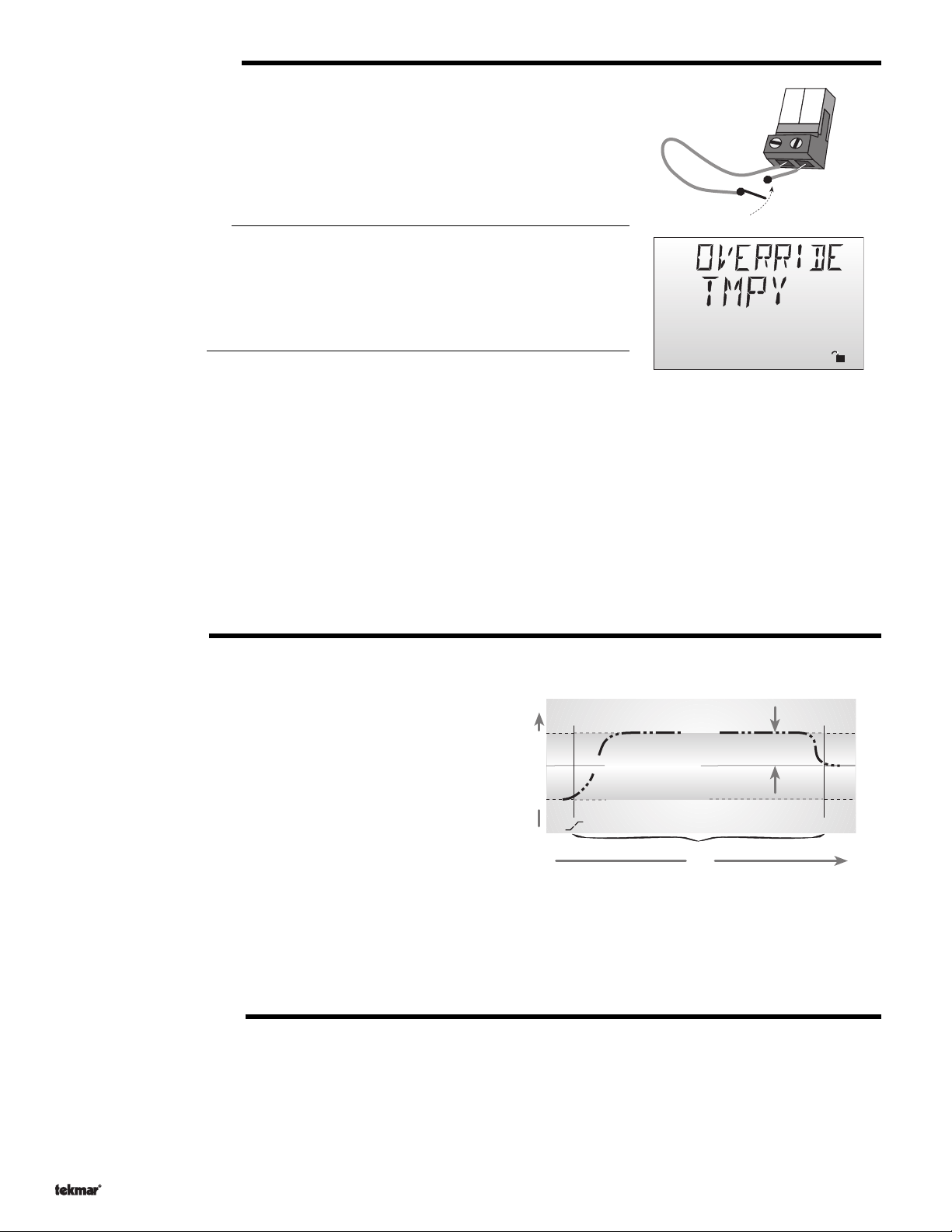

SETBACK (UnOccupied)

To provide greater energy savings, the 362 has a setback capability. With setback, the supply

water temperature in the system is reduced when the building is not used (AWAY) or when

the building is UnOccupied. By reducing the supply water temperature, air temperature in the

space may be reduced even when thermostat(s) are not turned down. This feature is enabled

by setting the

Setback / None DIP

switch to the

Setback

position, and providing either an

external signal or an internal override.

Note: AWAY does not require the DIP switch =

Setback

17

16

UnO

Com

Sw

Timer Switch

External UnOccupied

An external signal can place the 362 into an UnOccupied mode. Any time the

and the

Com

(17) terminals are shorted together, the control operates in the UnOccupied

mode. When in the UnOccupied mode, the

362 adjusts the supply water temperature(s) based on the

the control.

Sequence, Section B

Internal Overrides

The 362 has a number of setback overrides that are selected through the

UnOcc

UnO Sw

segment is displayed in the LCD. The

UnOcc

settings made in

(16)

Schd

UnOcc

Schd

Menu. These

setback overrides have priority over any external setback signal. Any time an override is in

Ovr

effect, the

segment is displayed in the LCD.

Temporary (TMPY)

If a temporary override is selected, the 362 operates in the selected override mode for 3 hours. Once completed, the control reverts

to the previous operation.

Permanent (PERM)

If a permanent override is selected, the 362 operates in the selected override mode until a new override is selected.

Away (AWAY)

If the AWAY override is selected, the 362 operates with a fixed WWSD of 62˚F (17˚C) and a fixed room temperature of 62˚F (17˚C).

BOOSTING (BOOST)

When the control changes from the

enters into a

to the system are raised above their normal values for a period of time to

provide a faster recovery from the building’s setback temperature. The

maximum length of the boost is selected in the user interface. This setting

is only available if a

available for a

Control is used.

Typical settings for the

hours for a building that has a fast responding heating system. For a

building that has a slow responding heating system, a setting between four

hours and eight hours is typical. After a

timer must be adjusted to come out of setback some time in advance of the

desired

BOOST setting. If the building is not up to temperature at the correct time, the BOOST setting should be lengthened and the setback

timer should be adjusted accordingly. If the building is up to temperature before the required time, the BOOST setting should be shortened

and the setback timer should be adjusted accordingly. If the system is operating near its design conditions or if the supply water

temperatures are being limited by settings made in the control, the time required to bring the building up to temperature may be longer

than expected.

Boosting

Occupied

UnOccupied

mode. In this mode, the supply water temperatures

Characterized Heating Curve

Reset Ratio,

and not needed or available if a tekmar Zone

Boost

function vary between 30 minutes and two

Boost

time. This time in advance is normally the same as the

to the

Occupied

mode, it

is selected; It is not

time is selected, the setback

Water Temperature

UnOcc to Occ

Boost

Mix TRG

(Occupied)

Mix

TRG (UnOccupied)

Boost setting - 20 minutes to 8 hours

Time

Self Adjusting

Water Temperature

Ovr

SOFT START (SOF STRT)

The SOF STRT function allows the 362 to slowly ramp the water temperature up to the required supply temperature. By allowing the

temperature in the system to be adjusted slowly, the control reduces any thermal expansion noises and stresses that may be caused

by a quick change in supply water temperature.

Copyright © D 362 -12/08

8 of 36

Section B2: Alternate Mixing Demands (Mode —1—)

In addition to using conventional thermostats to provide a mixing demand as described in Section B1, the 362 can use a number of other

methods to provide a mixing demand.

10K INDOOR SENSOR (10K = INDR)

Set the 10K item to INDR to add an indoor sensor for temperature control of a single zone

mixing system. The indoor sensor is connected to the

In addition, power must be applied to the

section B1. With the indoor sensor connected, the 362 is able to sense the actual room

temperature. With this information, the 362 provides a more constant water flow through the

mixing system. At the same time, indoor temperature feedback fine tunes the supply water

temperature in the mixing system to prevent over heating or under heating. To adjust the room

temperature for the mixing zone, use the ROOM

menu at the control.

10K ZONE CONTROL (10K = ZoIn)

Set the 10K item to ZoIn to add indoor temperature feedback control of multiple mixing zones.

Control of mixing zones is provided by connecting a tekmar zone control to the 362. The zone

control provides its own internal

provide an external

Mix Demand

capable of automatically adjusting the MIX TRG temperature to improve building occupant

comfort and system performance.

10K SLAB SENSOR (10K = SLAB)

Set the 10K item to SLAB to add a slab sensor for temperature control of a single zone mixing

system. The 362 can use a slab sensor to control the actual slab temperature. A slab sensor

is placed in the slab and connected to the

be applied to the

Mix Demand

terminals (1 and 2) as described in Section B1. With the slab

sensor connected, the 362 will limit the mixing supply temperature in order to maintain the slab

sensor between the SLAB MIN and SLAB MAX settings.

Slab Minimum

(SLAB MIN)

The SLAB MIN sets the minimum allowed core temperature of the slab as long as the control is not in a WWSD. Caution should be

used when adjusting the SLAB MIN setting as this may lead to overheating of the zone during mild conditions. If the AWAY setting

is selected in the Schedule menu, the 362 ignores the SLAB MIN setting.

Slab Maximum

(SLAB MAX)

The SLAB MAX sets the maximum allowed core temperature of the slab. If the slab is to be maintained at a fixed core temperature,

set SLAB MAX and SLAB MIN items to the same setting.

ROOM TEMPERATURE UNIT (RTU) 062, 063

If the mixing system consists of a single zone, temperature control of that zone can be provided

by using an RTU. The RTU is connected to the

(11 and 13). In addition, power must be applied to the

described in Section B1. With the RTU connected, the 362 measures the actual room

temperature. With this information, the 362 provides a constant water flow through the mixing

system. At the same time, indoor temperature feedback fine tunes the supply water

temperature in the mixing system to prevent over heating or under heating. The RTU allows

the user to adjust the desired room temperature at the RTU. Remote sensor capability is also

available through an RTU as described in the RTU data brochure.

Com

and

10K

terminals (14 and 15).

Mix Demand

Occupied

terminals (1 and 2) as described in

or

UnOccupied

setting in the Adjust

mixing demand

as described earlier in Section B1. The zone control is

to the 362. In this case, there is no need to

Com

and the

10K

terminals (14 and 15). Power must

Com

and tekmar Net

Mix Demand

TM

tN1/tN2

terminals

terminals (1 and 2) as

tekmar

Indoor Sensor

tekmar

Zone Control

Power

Occupied

UnOccupied

Heat Required

Optimum Start / Stop

24 hr. Timer

System Pump

Timer Active

70°F

(21°C)

12 hrs.

Zone 1 Lo stage

1

• Dial the desired duration

618

of the UnOccupied period.

• Press start button at the time of day

Zone 2 Hi stage

2

you want the UnOcc. period to begin.

Timer Active light turns on.

Zone 3 Lo stage

3

0

24

40

100

(4)

(38)

UnOccupied

Zone 4 Hi stage

4

UnOccupied

Duration

Start

0 = always Occupied

24 = always UnOccupied

Zone Control 368

One & Two Stage

tekmar

Slab Sensor

tekmar

RTU

View

°

F

UnOcc 1

ItemMenu

tekmar

362 Control

Mix Demand

View

Boiler Demand

°

F

DHW Demand

Setpoint Demand

Minimum

1

2

%

Maximum

1

DHW

Item

Menu

R

Universal Reset Control 363

NRTL/C

Mixing, Boiler & DHW

LR 58223

LR 58233

E150539

tekmar 362

Control

Mix Demand

View

Boiler Demand

°

F

DHW Demand

Setpoint Demand

Minimum

2

1

%

Maximum

1

DHW

Item

Menu

R

Universal Reset Control 363

NRTL/C

Mixing, Boiler & DHW

LR 58223

LR 58233

E150539

tekmar

362 Control

Mix Demand

View

Boiler Demand

°

F

DHW Demand

Setpoint Demand

Minimum

2

1

%

Maximum

1

DHW

Item

Menu

R

Universal Reset Control 363

NRTL/C

Mixing, Boiler & DHW

LR 58223

LR 58233

E150539

tekmar

362 Control

Mix Demand

View

Boiler Demand

°

F

DHW Demand

Setpoint Demand

Minimum

2

1

%

Maximum

1

DHW

Item

Menu

Heat

Universal Reset Control 363

Mixing, Boiler & DHW

R

NRTL/C

LR 58223

LR 58233

E150539

Section C: Snow Melting (Mode —2—)

Section C1

General Snow

Melting

Section C2

Snow Melting

Enable / Disable

Section C3

With Slab Sensor

Section C4

Without Slab

Sensor

Section C1: General Snow Melting

The Mixing Control 362 is capable of controlling a single zone snow melting system. In order to provide the best control of the snow

melting system, the 362 should be equipped with an optional tekmar Slab Sensor 072 or 073 and an optional Universal Sensor 071 that

measures the slab return temperature. These can be purchased separately or as part of the Snow Melt Enable Kit 092. The Kit also

includes alternate Start / Stop module 039. With these installed, the 362 is capable of providing the features listed in the following section.

Also described in this section are several different methods of starting and stopping the snow melting system.

9 of 36

Copyright © D 362 -12/08

NOTE: When operating in the Snow Melting mode, the

operation of the contro

SLAB PROTECTION (∆T MAX)

Boiler Sensor on the Return or No Boiler Sensor

(

NON-DEDICATED HEAT SOURCE

If the snow melting system is one of several loads on a boiler or boiler plant, the amount of

heat available to the system can potentially damage the snow melting slab. The 362 controls

a mixing device that is installed between the snow melting slab and the boiler(s). The control

limits the rate at which heat can be applied to the slab through the

is the temperature difference between the slab supply temperature and the slab return

temperature. By limiting this temperature difference, the rate at which heat is applied to the

slab can be controlled and thermal stresses in the slab can be minimized. When the control

is operating at the ∆T MAX, the

in the View menu. This mode of operation only works when the Boil SENS item is set to RET

or NONE.

Boiler Sensor on the Supply

(

DEDICATED HEAT SOURCE

If the snow melting system consists of a snow melting slab and a dedicated boiler, a mixing

device is installed between the snow melting slab and the boiler to protect the boiler from

low operating temperatures. In a dedicated snow melting system with a properly sized

boiler, it is not necessary for the control to provide ∆T protection of the snow melting slab;

Since the boiler output is matched to the slab requirements, it is not possible to heat the slab

too rapidly and cause thermal stresses that will result in damage to the slab. Therefore, the

∆T MAX item in the

When operating a dedicated snow melting system, the 362 is designed to operate the boiler

as efficiently as possible. This mode of operation only works when the Boil SENS item is

set to SUP.

Adjust

)

Maximum

pointer can be seen when viewing the MIX ∆T item

)

menu and the MIX ∆T item in the

Reset Ratio / Characterized Heating Curve DIP switch

∆T MAX setting. The ∆T

View

menu are not available.

has no effect on the

tensile stress

VISCOSITY COMPENSATION (EXCEEDING ∆T MAX)

At low temperatures, the glycol solutions used in snow melting systems become very viscous and difficult to pump. In order to overcome

this condition during a cold start of a snow melting system, the 362 is allowed to exceed the ∆T MAX setting for a period of time in order

to warm the glycol solution. This allows the control to compensate for the high viscosity of the glycol solution and is used when the supply

temperature is below 30˚F (-1˚C). When the control exceeds the

item in the

RAMPING OF THE ∆T

When the control starts applying heat to the slab, the supply temperature to the snow melting system is ramped up over a period of time

until it reaches the maximum allowed ∆T. This function does not occur when the boiler sensor is on the supply.

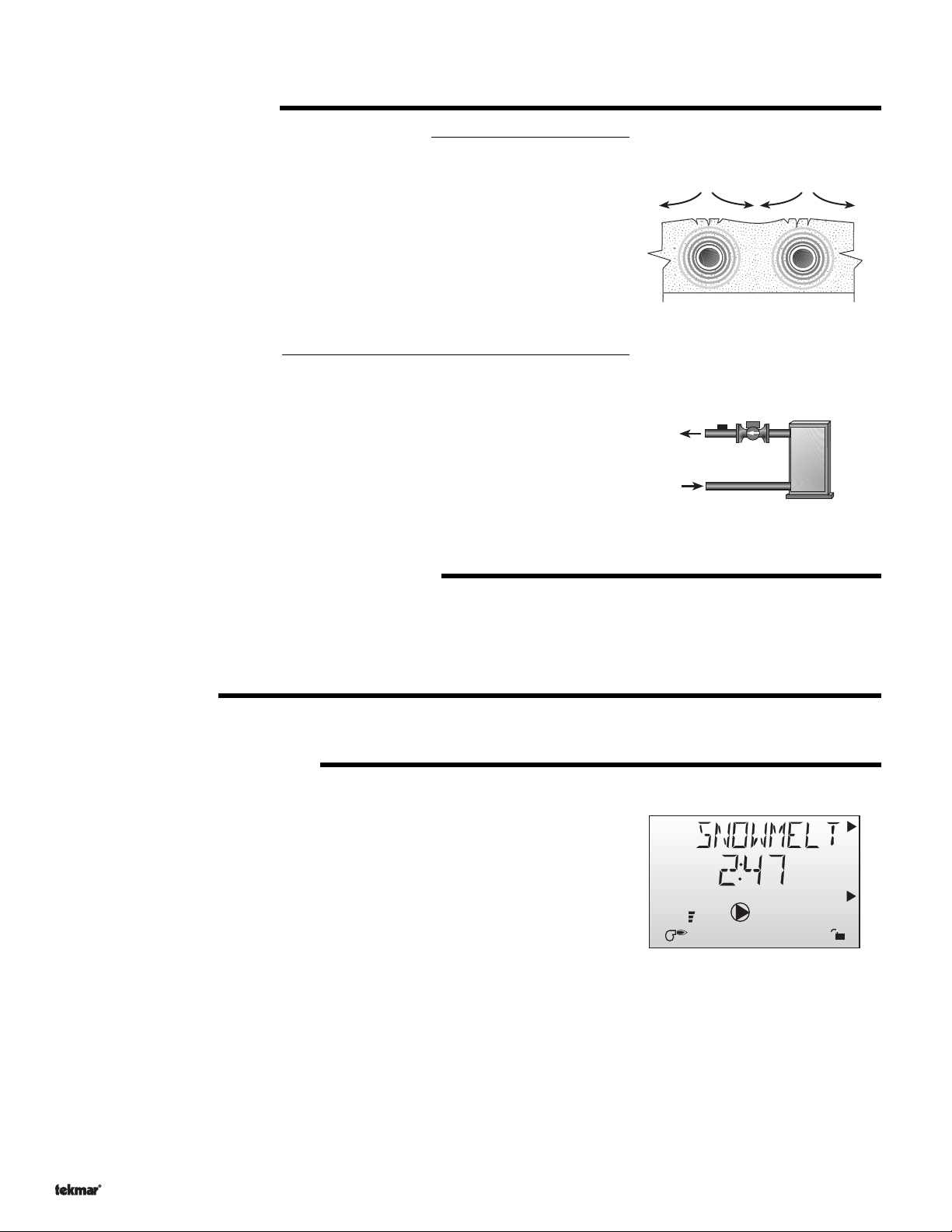

OPERATING STATUS (SNOWMELT)

While in the Snow Melting mode (Mode 2), an additional item is available in the

current operating status of the snow melting system.

• STRT The word STRT is displayed after the snow melting system has been enabled. It is

• STOP The word STOP is displayed for five seconds after the snow melting system has

• IDLE The word IDLE is displayed as long as the control is operating the slab at the idling temperature.

• EXT The word EXT is displayed when the RUN TIME has reached 0:00 and the control still has an external demand for melting. In

• 0:00 to 17:00 hr While the slab is up to temperature, and the control is melting, the remaining RUN TIME is displayed.

• INF If an infinite RUN TIME is selected and the control is melting, INF is displayed.

• WWSD When the control is in a Warm Weather Shut Down, WWSD is displayed.

• CWCO When the control is in a Cold Weather Cut Off, CWCO is displayed

View

menu.

displayed until the slab reaches the melting temperature. If the slab is at the melting

temperature, STRT is displayed for five seconds after the snow melting system has

started operation. This is to verify that the control has entered into the

snow melting mode.

stopped operation. The word STOP is also displayed if either a Remote Start/Stop

Module 039 or Remote Display Module 040 stops the snow melting system and an

external demand is still present.

this situation, the control continues melting until the snow melting demand is removed or the control is stopped.

∆T MAX setting, the

Maximum

View

menu called SNOWMELT. This item displays the

pointer will flash when viewing the MIX ∆T

View

%

1

hr

Copyright © D 362 -12/08

10 of 36

RUNNING TIME (RUN TIME)

The running time is the length of time that the snow melting system operates once the slab has reached the melting temperature. During

the time that the slab is approaching the melting temperature, the RUN TIME does not decrease. Once the slab has reached the melting

temperature, the RUN TIME begins counting down. When the RUN TIME reaches 0:00 as displayed by the SNOWMELT item in the

menu, the 362 has finished Melting.

View

WARM WEATHER SHUT DOWN (WWSD)

When both the slab temperature and the outdoor temperature exceed the

Melting temperature by more than 1.5˚F (1˚C), the control enters into a

WWSD. In a WWSD, the snow melting system is shut down in order to

conserve energy.

COLD WEATHER CUT OUT (CWCO)

Maintaining the slab at either the Melting or Idling temperature during extremely cold temperatures can be expensive or impossible. The

control shuts off the snow melting system once the outdoor air temperature drops below the Cold Weather Cut Out (CWCO) temperature.

While the control is in a CWCO, the word CWCO is displayed in the SNOWMELT item in the View menu. If the control had been started

prior to the CWCO, it resumes the melting mode once the outdoor air temperature rises above the CWCO temperature.

BOILER OPERATION

Refer to section D for a description of the boiler operation.

BOILER PROTECTION (Boil MIN)

The 362 ensures that the boiler supply water temperature remains above

the Boil MIN setting. If the boiler supply water temperature begins to drop

due to the slab return temperature, the mixing device is throttled back to

allow the boiler to recover. This minimizes the time that the boiler operates

below its condensing temperature and prolongs the life of the boiler. The

362 can only provide boiler protection if the Boil SENS item is set to SUP

or RET. The 362 cannot provide boiler protection if the Boil SENS item is

set to NONE.

SNOW MELTING OVERRIDE

Sequence, Section C2

Internal Override

If the AWAY setting is selected in the Schedule menu, the system is shut down. Both the

as long as the control remains in the AWAY mode. The

External Override

While in Mode 2, any signal received on the UnO Sw and COM terminal (16 and 17) is ignored and does not affect the operation of

the control.

MIXING PUMP OPERATION (Mix Pmp)

The Mixing Pump (Mix Pmp) contact closes and remains closed as long as the control is either in the Melting or Idling mode. The Mixing

Pump contact shuts off if the control is in WWSD, CWCO, or if there is no call for Melting or Idling.

PURGE (PURGE)

The Mixing Pump (Mix Pmp) continues to operate for the set PURGE time after the control finishes operation.

Melting

and

Idling

temperatures are ignored

Setback / N one

DIP does not matter for internal overrides.

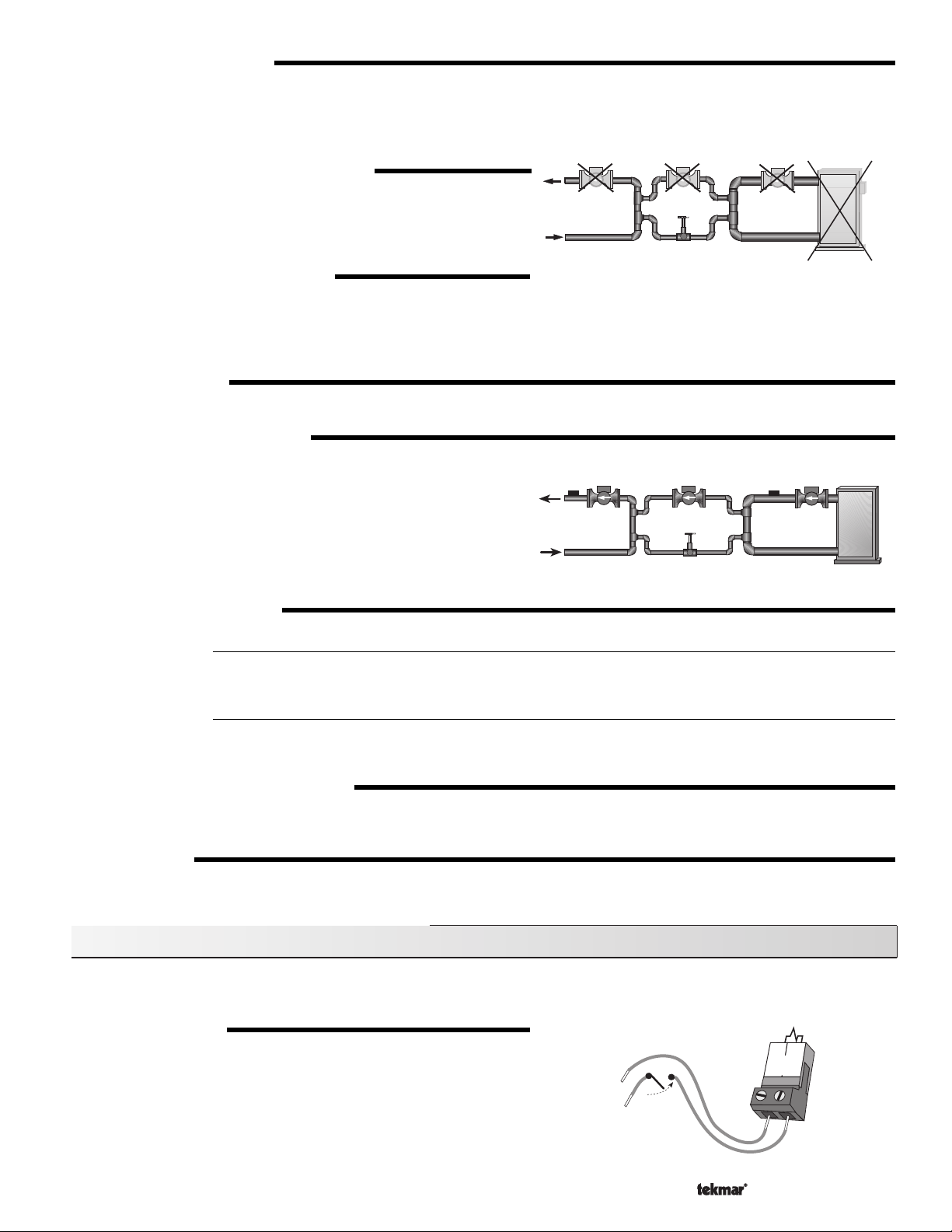

Section C2: Snow Melting Enable (Mode —2—)

There are three methods in which the snow melting system can be enabled on the Mixing Control 362. Either an

Remote Start / Stop Module 039

EXTERNAL DEMAND

An external snow melting demand is generated when a voltage between

24 and 240 V (ac) is applied across

external demand must be present for at least 4 seconds in order to start the

snow melting system. Once started, the slab temperature is increased to

the MELTING setting and maintained at the melting temperature until the

Run Time reaches 0:00. If the Run Time reaches 0:00 and the external

demand is still present, the control continues at the melting temperature

until the external demand is removed or the system is otherwise stopped.

or a

Remote Display Module 040

Mix Demand

(1 and 2) terminals. An

can be used to start the snow melting system.

24 to 240 V (ac)

11 of 36

External Demand

2

1

Mix

Demand

Copyright © D 362 -12/08

, a

Loading...

Loading...