Tecfluid COVOL User Manual

Oscillating

piston flowmeter

series COVOL

Instructions manual

R-MI-COVOL Rev.: 4 English version

PREFACE

Thank you for choosing the oscillating piston flowmeter series

COVOL from Tecfluid S.A.

This instruction manual allows the installation and operation of the

oscillating piston flowmeter series COVOL. It is recommended to

read it before using the equipment.

WARNINGS

This document shall not be copied or disclosed in whole or in

any part by any means, without the written permission of

Tecfluid S.A.

Tecfluid S.A. reserves the right to make changes as deemed

necessary at any time and without notice, in order to improve

the quality and safety, with no obligation to update this manual.

Make sure this manual goes to the end user.

Keep this manual in a place where you can find it when you

need it.

In case of loss, ask for a new manual or download it directly

from our website www.tecfluid.com Downloads section.

Any deviation from the procedures described in this instruction

manual, may cause user safety risks, damage of the unit or

cause errors in the equipment performance.

Do not modify the equipment without permission. Tecfluid S.A.

is not responsible for any problems caused by a change not

allowed. If you need to modify the equipment for any reason,

please contact us in advance.

2

TABLE OF CONTENTS

1 WORKING PRINCIPLE ......................................................................... 4

2 RECEPTION ........................................................................................... 5

3 INSTALLATION .................................................................................... 5

3.1 Filter .......................................................................................... 5

3.2 Open discharge ........................................................................ 6

3.3 Position ..................................................................................... 6

3.4 Straight pipe sections .............................................................. 6

3.5 Valves ....................................................................................... 6

3.6 Pumps ........................................................................................ 6

3.7 Electrical connection ............................................................... 7

4 MAINTENANCE .................................................................................... 8

4.1 Disassembly ............................................................................. 9

4.2 Mounting ................................................................................... 9

4.3 Replacing the reed switch group ............................................ 10

5 PART LIST ............................................................................................ 11

6 TECHNICAL DATA ................................................................................ 12

7 DIMENSIONS ......................................................................................... 13

8 K FACTOR (PULSES / LITRE) .............................................................. 16

9 ADDITIONAL INSTRUCTIONS FOR THE ATEX VERSION ................. 16

9.1 Intrinsic safety .......................................................................... 16

9.2 Flameproof enclosure .............................................................. 16

9.2.1 Earth connection ........................................................................ 17

9.2.2 Maintenance ............................................................................. 17

9.2.3 Technical data for the ATEX version ...................................... 17

9.2.4 Marking ..................................................................................... 18

9.2.5 Dimensions ............................................................................... 19

10 TROUBLESHOOTING ........................................................................... 23

3

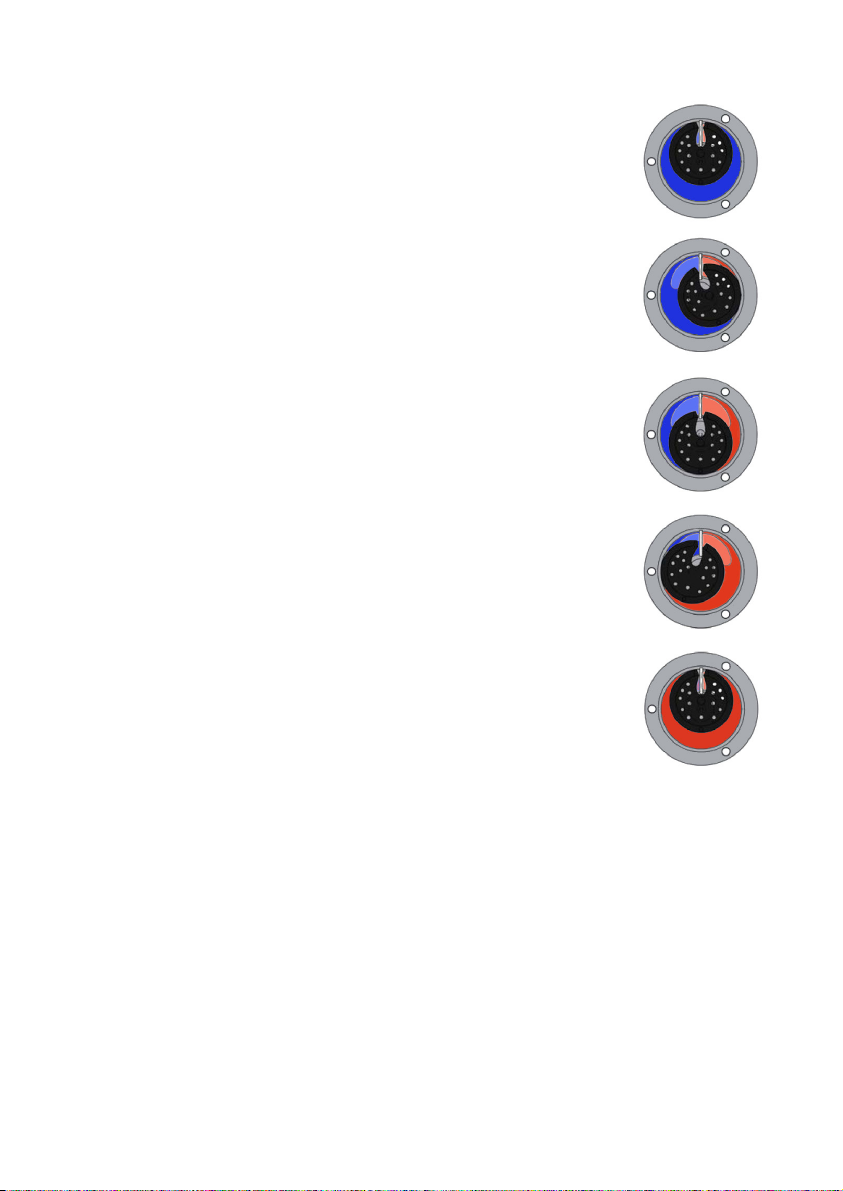

1 WORKING PRINCIPLE

By means of oscillating piston and an annular measuring

chamber.

1– The first figure shows the COVOL flowmeter at the beginning

of a cycle, when the measuring chamber (in blue) is

completely full.

2– The flow of the liquid through the flowmeter makes a force on

the oscillating piston, so that it starts turning. From this moment

the measuring chamber is divided in two parts: inlet (in red) and

outlet (in blue).

3– The liquid fills progressively the inlet measuring chamber (in

red), as it is getting emptied on the outlet (in blue). In the middle

of the cycle (see figure) the two chambers are the same size.

4– At this stage the outlet measuring chamber has already

emptied almost all the liquid corresponding to a cycle, while on

the inlet it is almost filled with the liquid corresponding to the next

cycle.

5- At the end of the cycle, the inlet measuring chamber takes all

the space. From this moment it can be considered that this is

already the outlet chamber, so we are again at the beginning of

the cycle.

As one can see, a constant volume of liquid is moved in each

cycle.

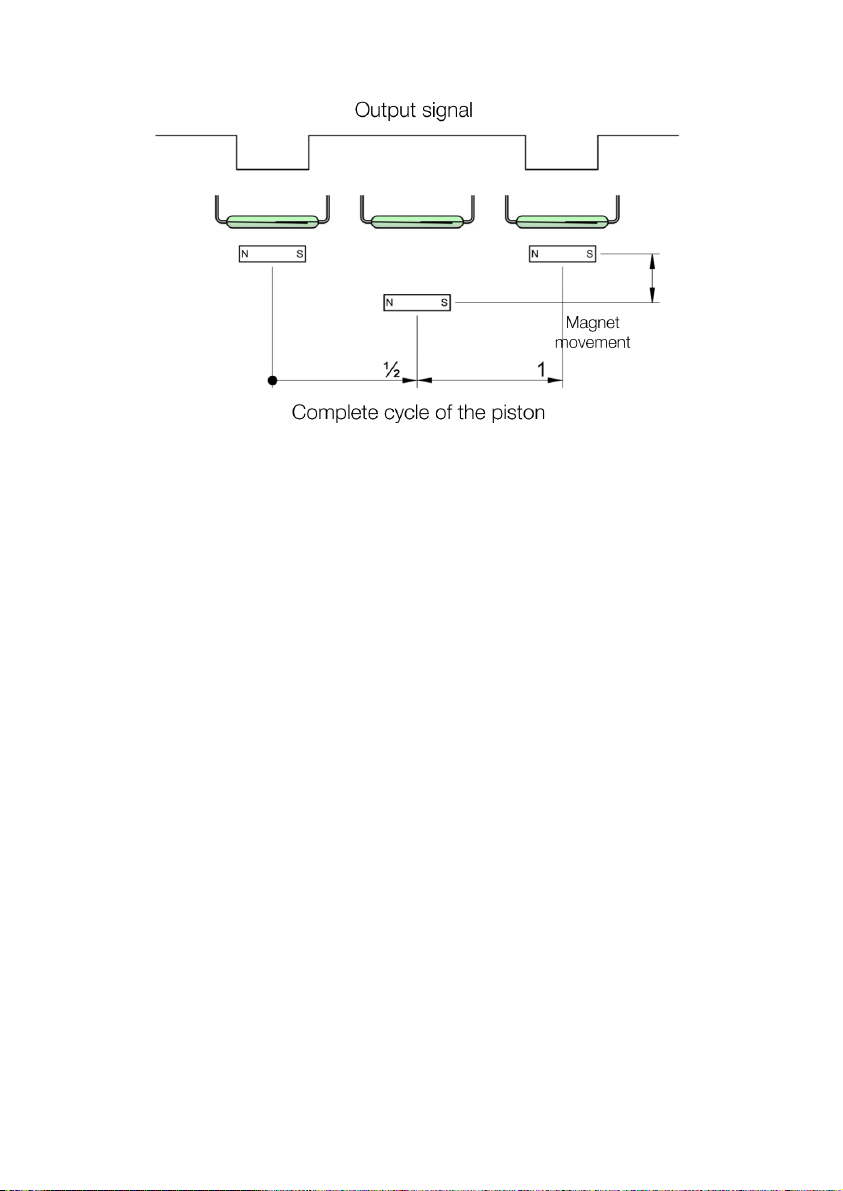

The piston includes a magnet inside that activates a reed switch

each complete turn. The output signal can be treated by means of

an electronic converter.

4

2 RECEPTION

COVOL oscillating piston flowmeters are supplied individually packaged for protection during

transport and storage, including their corresponding instructions manual, for their installation

and use.

All the flowmeters have been verified in our flow rigs, obtaining the K factor for each

device.

3 INSTALLATION

The installation must be made in a point that ensures that the pipe is completely full of

liquid.

Highest points in the installation as well as downwards pipes must be avoided, since air

pockets or vacuums might occur.

In installations where air can be present, a degasser must be installed before the

flowmeter.

Partially full pipe can involve important measurement errors.

3.1 Filter

The installation of a filter before the COVOL oscillating piston is mandatory. This way a

correct performance is guaranteed and severe damage is avoided.

The mesh size must be between 0.1 and 0.2 mm², in order to avoid that bigger particles

can block or get embedded in the oscillating piston, stopping or slowing it and providing

false readings.

5

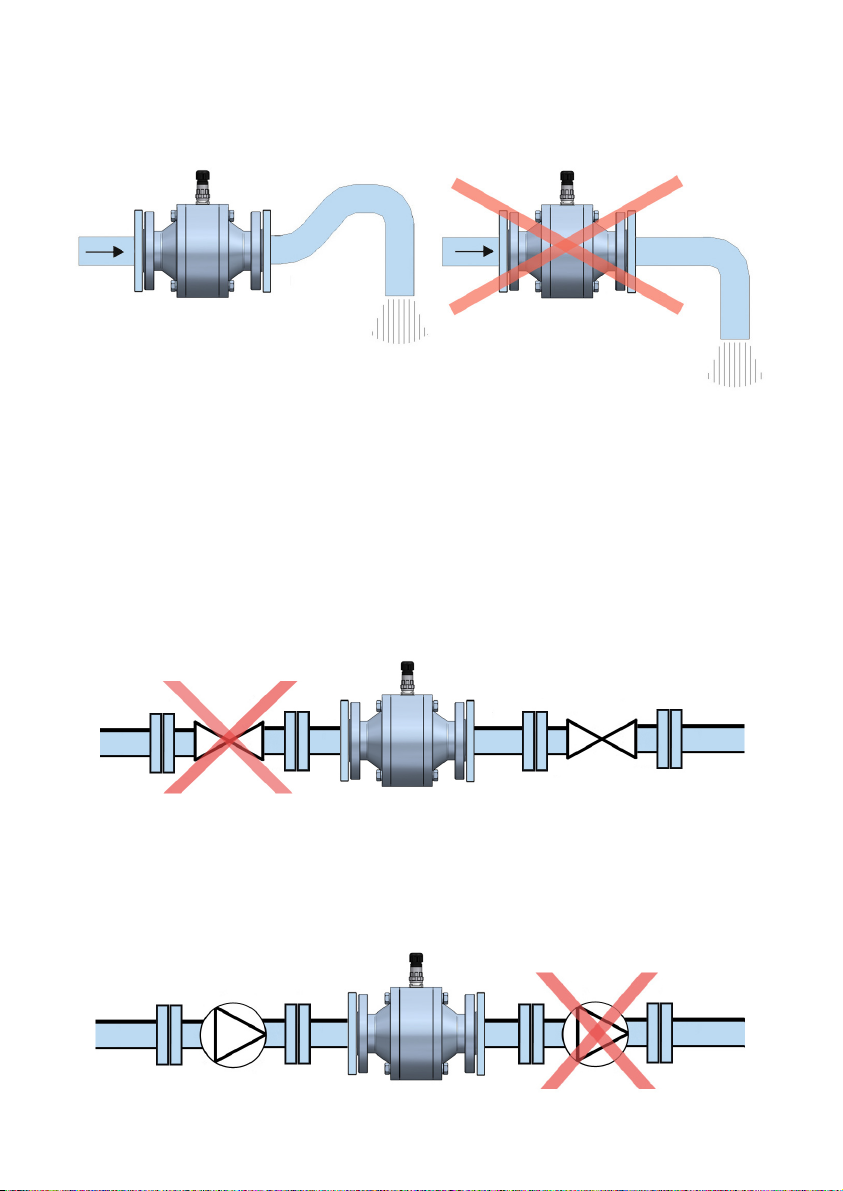

3.2 Open discharge

When the flow measurement is to be made before an open discharge, it is necessary to

install the flowmeter in a section of pipe with a trap which avoids the presence of air inside

the meter.

3.3 Position

The installation and position of the flowmeter can be either vertical, horizontal or inclined.

The flow direction does not affect the flowmeter accuracy.

3.4 Straight pipe sections

Straight pipe run is not required, the flowmeter can be installed just before or after

disturbing elements.

3.5 Valves

Regulating or shut-off valves must always be installed after the flowmeter, in order to

assure that pipe is full of liquid.

3.6 Pumps

Pumps must always be installed before the flowmeter in order to avoid cavitations.

6

This way the presence of air pockets in the flowmeter is avoided, which could cause false

readings. In particular, the associated electronics would show a volume higher than real.

Note: In order to avoid cavitations, the API Std 2534 standard must be taken into

account. This standard states that on the outlet of the flowmeter the pressure must be at

least twice the pressure drop of the flowmeter (in case of COVOL, this pressure drop is

3 mH2O or 0.3 bar, for fluids with viscosity 1 mPa·s at maximum flow rate), plus 1.25

times the vapour pressure of the liquid or its most volatile components.

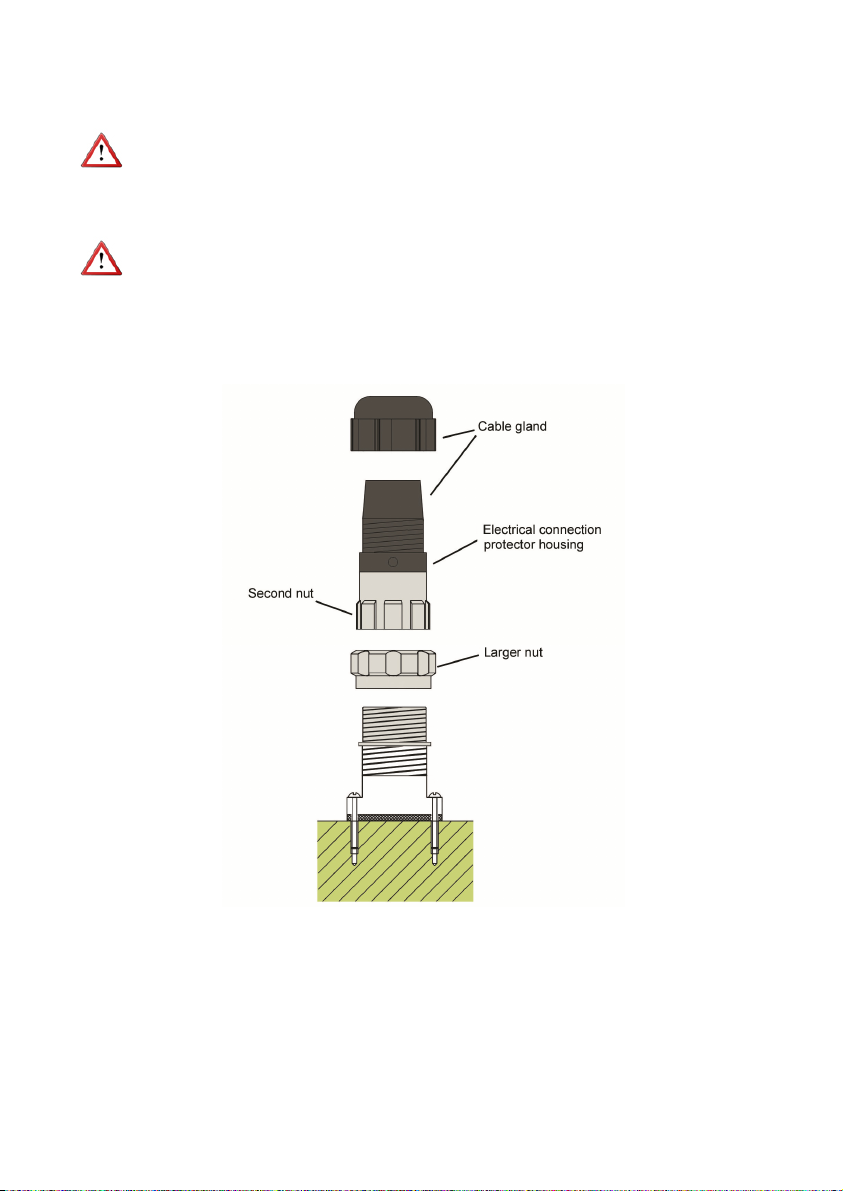

3.7 Electrical connection

It is important to keep the connecting cable between the flowmeter and the associated

electronics away from mains or power supply cables, in order to avoid interferences. In

any case, those should be separated at least 5 cm.

The COVOL oscillating piston flowmeter has a connector fastened to the counter by

means of 4 screws. The connector consists of 3 parts joined by threaded nuts. (See

figure).

Loosening the larger nut in the middle of the connector allows us to withdraw the half

where the cable will be later soldered.

The other half of the connector is fixed to the counter and should not be removed, except

when servicing the detector (See point 4.3 of the MAINTENANCE section).

The removable part of the connector consists of the cable gland at the top and the

electrical connection protector housing.

7

Before starting the installation, check that the cable gland is the right size for the cable to

be used. This will guarantee the instrument will stay watertight. The cable gland used is

for cables with outside diameters between 6 mm and 10 mm.

The electrical connection protector housing is dismounted by loosening the second nut.

When this is removed, the three connector terminals are visible.

The terminals are numbered 1 to 3 and the connection is as follows:

N. 1 & 2: Electrical switch connection.

N. 3: This terminal has a shortcircuit with terminal N.1. Don’t connect

Before soldering the connections, unscrew the cable gland and feed it, together with the

electrical connection protector housing, over the cable.

The joint between the cable and the connector should always be soldered, and should be

tidy and without short circuits between terminals.

Peel the outside insulation to free the inner cables. It is recommended to tin the ends of

the wires to avoid loose ends.

Once the connections have been made, the housing should be mounted screwing it on

and then the cable gland should be tightened to avoid entry of any liquid or humidity.

Once assembled the half of the connector, the mounting in the base has only one position

defined by the keyway between the two parts.

Check that the rubber seal is in its position inside the connector base. If this is the case,

introduce the connector half in the base, positioning by the keyway, and screw on the nut

until the end of the thread is reached.

anything to this terminal.

4 MAINTENANCE

In normal working conditions the COVOL flowmeter has a long life. Normally it will not be

necessary to change any parts.

The life of the parts depends mainly on the abrasive characteristics of the product to be

measured and the flow rate.

The combination of these two factors, together with the construction material of the

flowmeter, makes it difficult to estimate the life of the device in good working conditions

If the maximum flow rate for each DN shown in the chart below is exceeded the life of the

pieces can be considerably reduced.

Flow ranges

DN

10 / ¼" (H) 25-250 500 100

10 40-350 800 100

15 150-1500 2700 20

25 500-4500 9000 10

40 800-8500 15500 4

50 1500-16000 28000 2

80 3000-28000 50000 1

100 5000-60000 104000 0.2

Flow scales

l/h water

Max. intermittent

l/h water

8

pulses / litre

approx.

Loading...

Loading...