RIDGID K-50 User Manual

Drain Cleaner

Manual

K-50 Drain Cleaning

Machine

• Français – 15

• Castellano – pág. 31

K-50 Drain Cleaning Machine

Table of Contents

Recording Form For Machine Serial Number .............................................................................................................1

Safety Symbols ..............................................................................................................................................................2

General Power Tool Safety Warnings

Work Area Safety ........................................................................................................................................................2

Electrical Safety...........................................................................................................................................................2

Personal Safety ...........................................................................................................................................................3

Power Tool Use and Care ...........................................................................................................................................3

Service ........................................................................................................................................................................3

Specific Safety Information ..........................................................................................................................................3

Drain Cleaner Safety ...................................................................................................................................................4

RIDGID®Contact Information........................................................................................................................................4

Description, Specifications and Standard Equipment...............................................................................................4

Description ..................................................................................................................................................................5

Specifications ..............................................................................................................................................................5

Standard Equipment....................................................................................................................................................5

Machine Inspection .......................................................................................................................................................5

Machine Set-Up..............................................................................................................................................................6

Set-Up For 5/8" Sectional Cable ...................................................................................................................................6

Set-Up For 5/16" or 3/8" Cable Adapters .........................................................................................................................7

Operating Instructions ..................................................................................................................................................8

Cleaning Drain Using 5/8ʺ Sectional Cable...................................................................................................................8

Cleaning Drain Using 5/16ʺ Or 3/8ʺ Cable Adapter .........................................................................................................9

Special Procedures .....................................................................................................................................................10

Reverse Operation ....................................................................................................................................................10

Brake Adjustment ......................................................................................................................................................10

Accessories .................................................................................................................................................................11

Cable Selection .........................................................................................................................................................11

Accessories ...............................................................................................................................................................11

Tools for C-4, C-6, C-7, C-8, and C-9 .......................................................................................................................11

Maintenance Instructions ...........................................................................................................................................11

Lubrication.................................................................................................................................................................11

Cables .......................................................................................................................................................................11

Clutch Jaw Assembly ................................................................................................................................................12

Cable Containers.......................................................................................................................................................12

Machine Storage ..........................................................................................................................................................12

Service and Repair ......................................................................................................................................................12

Wiring Diagrams ..........................................................................................................................................................13

EC Declaration of Conformity ..........................................................................................................Inside Back Cover

Lifetime Warranty..........................................................................................................................................Back Cover

*Original Instructions - English

278-104-431.10_REV. Cii

Drain Cleaner

K-50 Drain Cleaning Machine

WARNING!

Read this Operator’s Manual

carefully before using this

tool. Failure to understand

and follow the contents of

this manual may result in

electrical shock, re and/or

serious personal injury.

K-50 Drain Cleaning Machine

Record Serial Number below and retain product serial number which is located on nameplate.

Serial

No.

K-50 Drain Cleaning Machine

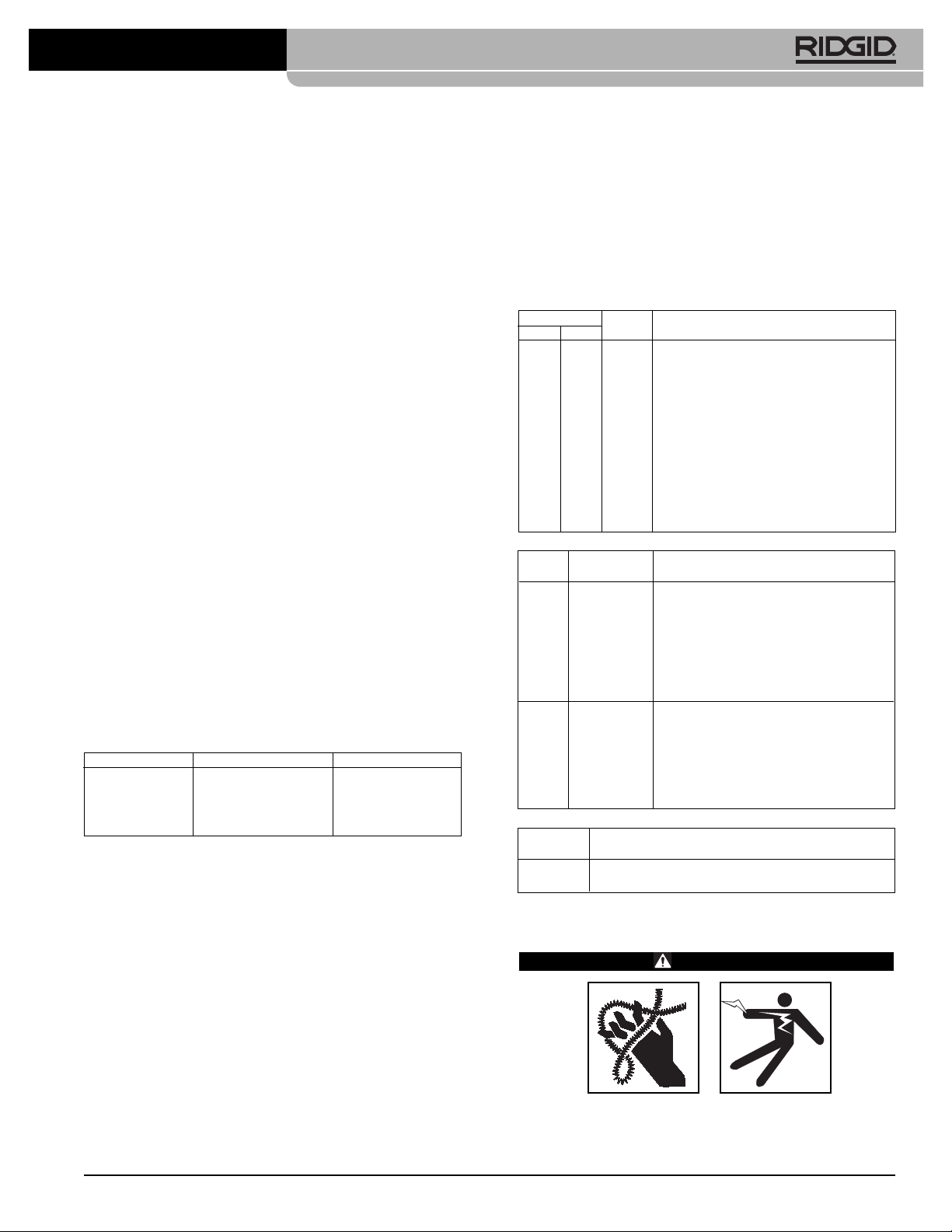

Safety Symbols

In this operator’s manual and on the product, safety symbols and signal words are used to communicate important safety

information. This section is provided to improve understanding of these signal words and symbols.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER

WARNING

CAUTION

NOTICE

NOTICE indicates information that relates to the protection of property.

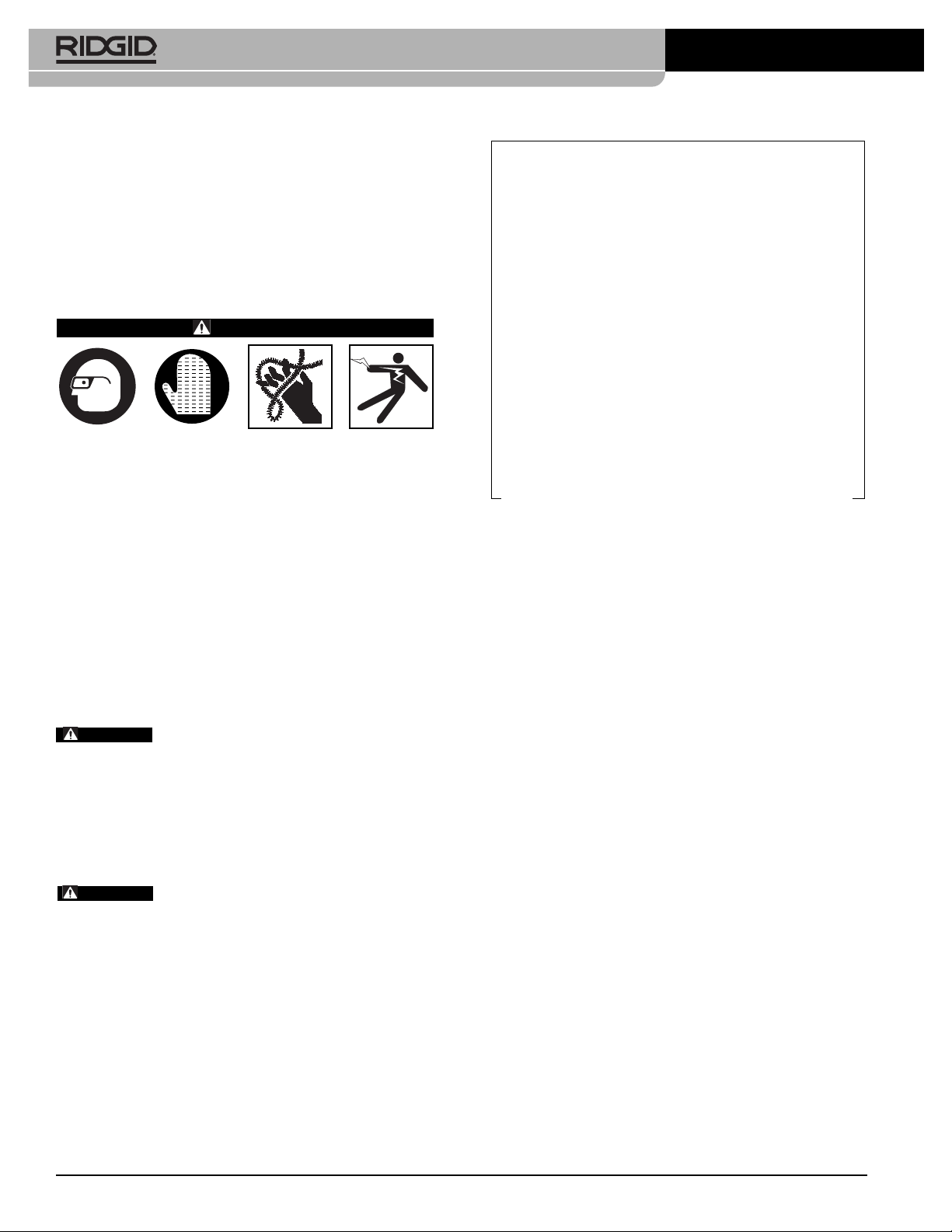

This symbol means read the operator’s manual carefully

before using the equipment. The operator’s manual contains important information on the safe and proper operation of the equipment.

This symbol means always wear safety glasses with

side shields or goggles when handling or using this

equipment to reduce the risk of eye injury.

This symbol indicates the risk of hands, fingers or other

body parts being caught, wrapped or crushed in the

drain cleaning cable.

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

General Power Tool Safety

Warnings*

WARNING

Read all safety warnings, instructions, illustrations and specifications provided with this power

tool. Failure to follow all instructions listed below

may result in electric shock, fire, and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE!

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Work Area Safety

• Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

• Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

• Keep children and by-standers away while operat-

ing a power tool. Distractions can cause you to lose

control.

This symbol indicates the risk of electrical shock.

This symbol means always wear RIDGID drain cleaning

mitts while operating drain cleaner.

This symbol indicates the risk of entanglement in a belt

and pulley.

Electrical Safety

• Power tool plugs must match the outlet. Never

mod ify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools. Unmodi -

fied plugs and matching outlets will reduce risk of electric shock.

• Avoid body contact with earthed or grounded sur-

faces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electrical shock

if your body is earthed or grounded.

• Do not expose power tools to rain or wet condi-

tions. Water entering a power tool will increase the risk

of electrical shock.

• Do not abuse the cord. Never use the cord for car-

rying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of

electric shock.

• When operating a power tool outdoors, use an ex-

tension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric shock.

* The text used in the General Power Tool Safety Warnings section of this manual is verbatim, as required, from the applicable UL/CSA/EN 62841-1 standard.

This section contains general safety practices for many different types of power tools. Not every precaution applies to every tool, and some do not apply to this

tool.

278-104-431.10_REV. C2

K-50 Drain Cleaning Machine

• If operating a power tool in a damp location is unavoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of a GFCI reduces the

risk of electric shock.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use

a power tool while you are tired or under the influence of drugs, alcohol, or medication. A mo ment of

inattention while operating power tools may result in serious personal injury.

• Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

• Prevent unintentional starting. Ensure the switch is

in the OFF position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energizing power tools that have the switch

ON invites accidents.

• Remove any adjusting key or wrench before turning

the power tool ON. A wrench or a key left attached to

a rotating part of the power tool may result in personal

injury.

• Do not overreach. Keep proper footing and bal-

ance at all times. This enables better control of the

power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or jew-

elry. Keep your hair, and clothing away from moving parts. Loose clothes, jewelry, or long hair can be

caught in moving parts.

• If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used. Use of dust col-

lection can reduce dust-related hazards.

• Do not let familiarity gained from frequent use of

tools allow you to become complacent and ignore

tool safety principles. A careless action can cause se-

vere injury within a fraction of a second.

Power Tool Use and Care

• Do not force power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it is designed.

• Do not use power tool if the switch does not turn it

ON and OFF. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

• Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures re-

duce the risk of starting the power tool accidentally.

• Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the tool. Power

tools are dangerous in the hands of untrained users.

• Maintain power tools and accessories. Check for

misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the

power tool’s op er ation. If damaged, have the power

tool repaired before use. Many accidents are caused

by poorly maintained power tools.

• Keep cutting tools sharp and clean. Properly main-

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

• Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into account the working conditions and the work to be

performed. The use of the power tool for operations dif-

ferent from those intended could result in a hazardous

situation.

• Keep handles and grasping surfaces dry, clean

and free from oil and grease. Slippery handles and

grasping surfaces do not allow for safe handling and

control of the tool in unexpected situations.

Service

• Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is maintained.

Specific Safety Information

WARNING

This section contains important safety information that is specific to this tool.

Read these precautions carefully before using the

K-50 Drain Cleaner to reduce the risk of electrical

shock or other serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE!

Keep this manual with machine for use by the operator.

278-104-431.10_REV. C 3

K-50 Drain Cleaning Machine

Drain Cleaner Safety

• Before using the tool, test the ground fault circuit interrupter (GFCI) provided with the power supply

cord to insure it is operating correctly. A properly

operating GFCI reduces the risk of electrical shock.

• Only use extension cords that are protected by a

GFCI. The GFCI on the machine power cord will not

prevent electrical shock from extension cords.

• Only grasp the rotating cable with gloves recom-

mended by the manufacturer. Latex or loose fitting

gloves or rags can become wrapped around the cable

and may result in serious personal injury.

• Do not allow the cutter to stop turning while the

cable is turning. This can overstress the cable and

may cause twisting, kinking or breaking of the cable and

may result in serious personal injury.

• One person must control both the cable and switch.

If the cutter stops rotating, the operator must be able to

turn the tool OFF to prevent the cable from twisting, kinking and breaking.

• Use latex or rubber gloves inside the gloves rec-

ommended by the manufacturer, goggles, face

shields, protective clothing, and respirator when

chemicals, bacteria or other toxic or infectious

substances are suspected to be in a drain line.

Drains may contain chemicals, bacteria and other substances that may cause burns, be toxic or infectious or

may result in other serious personal injury.

• Practice good hygiene. Do not eat or smoke while

handling or operating the tool. After handling or operating drain cleaning equipment, use hot, soapy

water to wash hands and other body parts exposed to drain contents. This will help reduce the risk

of health hazards due to exposure to toxic or infectious

material.

• Only use the drain cleaner for the recommended

drain sizes. Using the wrong size drain cleaner can

lead to twisting, kinking or breaking of the cable and may

result in personal injury.

• Always use the rear guide hose while operating

the tool and ensure the cable does not extend beyond the rear guide hose. This prevents the cable

from whipping which may result in entanglement and

personal injury.

• Keep mitt-covered hand on the cable whenever

the machine is running. This provides better control of

the cable and helps prevent twisting, kinking and breaking of the cable and may result in serious personal injury.

• Position machine cable outlet within 2' (0.6 m) of

the drain inlet or properly support exposed cable

when the distance exceeds 2' (0.6 m). Greater dis-

tances can cause control problems leading to twisting,

kinking or breaking of the cable. Twisting, kinking or

breaking cable may cause striking or crushing injuries.

• One person must control both the cable and the

clutch. Do not lock clutch handle during operation. If the cutter stops rotating, the operator must be

able to release the clutch to prevent twisting, kinking and

breaking of the cable and reduce the risk of injury.

• Do not operate the machine in REV (reverse) rota-

tion except as described in this manual. Operating in

reverse can result in cable damage and is used to

back the cable end out of blockages.

• Do not wear loose clothing or jewelry. Keep your

hair and clothing away from moving parts. Loose

clothing, jewelry or hair can be caught in moving parts.

• Do not operate this machine if operator or machine

is standing in water. Operating machine while in water

increases the risk of electrical shock.

• Do not engage drain cleaner clutch (rotate cable)

while any part of the cable is in the cable carrier.

This may cause striking or crushing injuries.

• Do not use if there is the risk of contact with other

utilities (such as natural gas or electric) during operation. Visual inspection of the drain with a camera is

a good practice. Crossbores, improperly placed utilities

and damaged drains could allow the cutter to contact

and damage the utility. This could cause electrical

shock, gas leaks, fire, explosion or other serious damage or injury.

• Read and understand these instructions and the in-

structions and warnings for all equipment and materials being used before operating this tool to

reduce the risk of serious personal injury.

RIDGID Contact Information

If you have any question concerning this RIDGID®product:

– Contact your local RIDGID

– Visit RIDGID.com to find your local RIDGID contact

point.

– Contact Ridge Tool Technical Service Department at

rtctechservices@emerson.com, or in the U.S. and

Cana da call (800) 519-3456.

®

distributor.

278-104-431.10_REV. C4

K-50 Drain Cleaning Machine

Description, Specifications and

Standard Equipment

Description

The RIDGID K-50 is a portable Drain Cleaning Machine

designed to clean 11/4" to 4" drain "lines. Ap pli cations include sink, shower and floor drains. Capable of running

three different size cables: 5/16", 3/8" and 5/8".

The machine is driven by a 1/6 HP motor that has a

grounded electrical system. An integral Ground Fault In terrupter (GFCI) is built into the line cord. A toggle switch

provides FORWARD/OFF/REVERSE control of the motor.

5

The K-50 is designed to use

cable that has a quick change coupling system for disconnecting tools. The cable is manually fed in and out of

the drain and rotates at a speed of 400 RPM. The rotation

of the cable is controlled by a clutch handle. The cable

stops instantly when the clutch handle is released.

The K-50 is also designed to use with the A-17 Adapters.

Adapters will hold 5/16" or 3/8" continuous length cables.

Rotation of the adapters is controlled by the clutch handle.

The cable adapter is equipped with a quick-acting brake

which immediately stops rotation of the drum when the

clutch handle is pulled upward.

Specifications

Line Capacity ...............Depends on choice of cable.

Recommended Line Size and Reach

Cable Size Line Size Reach

5

/16" Cable

3

/8" Cable 11/4" - 2" 25' - 35'

5

/8" (C-8) 11/4" - 3" 100'

5

/8" (C-9) 2" - 4" 100'

Cable Sizes ..................5/16", 3/8" and 5/8"

Motor

Type ..............................115V/50-60 Hz, Reversible,

/8 diameter sectional-type

Refer to the following chart

for recommendations.

3

/4" - 1" 25' - 50'

230V Available Upon Request

Sound Pressure (LPA)* ......69.2 dB(A), K=3

Sound Power (LWA)*...........74.5 dB(A), K=3

* Sound measurements are measured in accordance with a standardized test per

Standard EN 62841-1.

- Sound emissions may vary due to your location and specific use of these tools.

- Daily exposure levels for sound need to be evaluated for each application and

appropriate safety measures taken when needed. Evaluation of exposure levels should consider the time a tool is switched off and not in use. This may significantly reduce the exposure level over the total working period.

Standard Equipment

Catalog No. Model

115V 230V

58920 76455 K-50 Machine Only

58960 76475 K-50-4 Machine with:

58980 76485 K-50-6 Machine with:

59000 76495 K-50-8 Machine with:

52972 — K-50-9 Machine with:

Model

No. Cable Tools & Accessories

A-30 Six Sections: T-201 Straight Auger

A-40 Six Sections: T-206 Funnel Auger

Model

No. Description

A-17-A Adapter with 25' x

A-17-B Adapter with 35' x

No. Description

– A-30 Cable Kit

– A-17-A Adapter

– A-30 Cable Kit

– A-17-A Adapter

– A-18-B Adapter

– A-30 Cable Kit

– A-40 Cable Kit

5

/8" x 71/2' T-202 Bulb Auger

C-8,

(45', 13.7m) T-205 “C” Cutter

5

/8" x 10' T-215 4-Blade Cutter

C-9,

(60' , 18.3m) T-231 “C” Cutter

T-211 Spade Cutter

A-13 Coupling Pin Key

A-10 Cable Carrier

A-14-6 Rear Guide Hose

A-1 Left-Hand Mitt

A-13 Coupling Pin Key

A-10 Cable Carrier

A-14-610 Rear Guide Hose

A-1 Left-Hand Mitt

5

/16" Cable w/Bulb Auger

3

/8" Cable w/Bulb Auger

Machine Inspection

Rating ............................1/6HP

WARNING

Amps .............................4

Weight...........................37.5 lbs. (17 kgs.)

Dimensions

Length ...........................12" (305mm)

Height ............................17.5" (445mm)

Width .............................13" (330mm)

To prevent serious injury, inspect your Drain

Cleaning Machine. The following inspection procedures should be performed before each use.

278-104-431.10_REV. C 5

K-50 Drain Cleaning Machine

1. Make sure the Drain Cleaning Machine is unplugged

and the directional switch is set to the OFF position.(Figure 1).

2. Inspect the power cord, Ground Fault Circuit Inte r rupter (GFCI) and plug for damage. If the plug has

been modified, is missing the grounding prong or if the

cord is damaged, do not use the Drain Cleaning

Machine until the cord has been replaced.

3. Inspect the Drain Cleaning Machine for any broken,

missing, misaligned or binding parts as well as any

other conditions which may affect the safe and normal

operation of the machine. If any of these conditions

are present, do not use the Drain Cleaning Machine

until any problem has been repaired.

Clutch Handle

FOR/OFF/REV

Switch

WARNING

Worn or damaged cables can break caus-

ing serious injury.

Machine Set-Up

WARNING

Do not not place machine in water. Water entering

the motor can result in electrical shock.

To prevent serious injury, proper set-up of the

machine and work area is required. The following

procedures should be followed to set-up the machine:

Set-Up For 5/8" Sectional Cable

1. Check work area for:

• Adequate lighting

• Grounded electrical outlet

• Clear path to the electrical outlet that does not

contain any sources of heat or oil, sharp edges or

moving parts that may damage electrical cord.

• Dry place for machine and operator. Do not use the

machine while standing in water.

• Flammable liquids, vapors or dust that may ignite.

Figure 1 – K-50 Drain Cleaner

4. Lubricate the Drain Cleaning Machine, if necessary,

according to the Maintenance Instructions.

5. Use tools and accessories that are designed for your

drain cleaner and meet the needs of your application.

The correct tools and accessories allow you to do the

job successfully and safely. Accessories suitable for

use with other equipment may be hazardous when

used with this drain cleaner.

6. Clean any oil, grease or dirt from all equipment handles and controls. This reduces the risk of injury due

to a tool or control slipping from your grip.

7. Inspect the cutting edges of your tools. If necessary,

have them sharpened or replaced prior to using the

Drain Cleaning Machine. Dull or damaged cutting

tools can lead to binding and cable breakage.

8. Inspect cables and couplings for wear and damage.

Cables should be replaced when they become

severely worn or corroded. A worn cable can be identified when the outside coils become flat.

2. Position the Drain Cleaning Machine within 2' of

drain inlet. Greater distance can result in cable twisting or kinking.

3. Make sure FOR/OFF/REV switch is in the OFF position.

Figure 2 – Rear Guide Hose Attachment

278-104-431.10_REV. C6

K-50 Drain Cleaning Machine

4. Attach the rear guide hose by lifting up the lock pin

and sliding guide hose adapter onto the housing until

it locks into place (Figure 2).

WARNING

Do not use machine without rear guide

hose attached. Prevents cable whipping and possible entanglement.

5. Insert first cable into front of machine (female end first)

and push through guide hose until approximately one

foot remains out the front of the machine (Figure 3).

Figure 3 – Inserting Cable Into Front Of Machine

WARNING

To avoid electric shock and electrical

fires, never use an extension cord that is damaged or

does not meet the following requirements:

• The cord has a three-prong plug similar to shown in

Electrical Safety section.

• The cord is rated as “W” or “W-A” if being used out-

doors.

• The cord has sufficient wire thickness (16 AWG - 100').

If the wire thickness is too small, the cord may overheat,

melting the cord’s insulation or causing nearby objects

to ignite.

WARNING

To reduce risk of electrical shock, keep all

electrical connections dry and off the ground. Do not

touch plug with wet hands. Test the Ground Fault Circuit

Interrupter (GFCI) provided with the electric cord to insure

it is operating correctly. When test button is pushed in,

the indicator light should go off. Reactivate by pushing the

reset button in. If indicator light goes on, the machine is

ready to use. If the GFCI does not function correctly, do

not use the machine.

Set-Up For 5/16" or 3/8" Cable Adapters

1. Make sure FOR/OFF/REV switch is in the OFF position.

WARNING

Never couple more than one cable at a

time. Cable will extend behind rear guide tube.

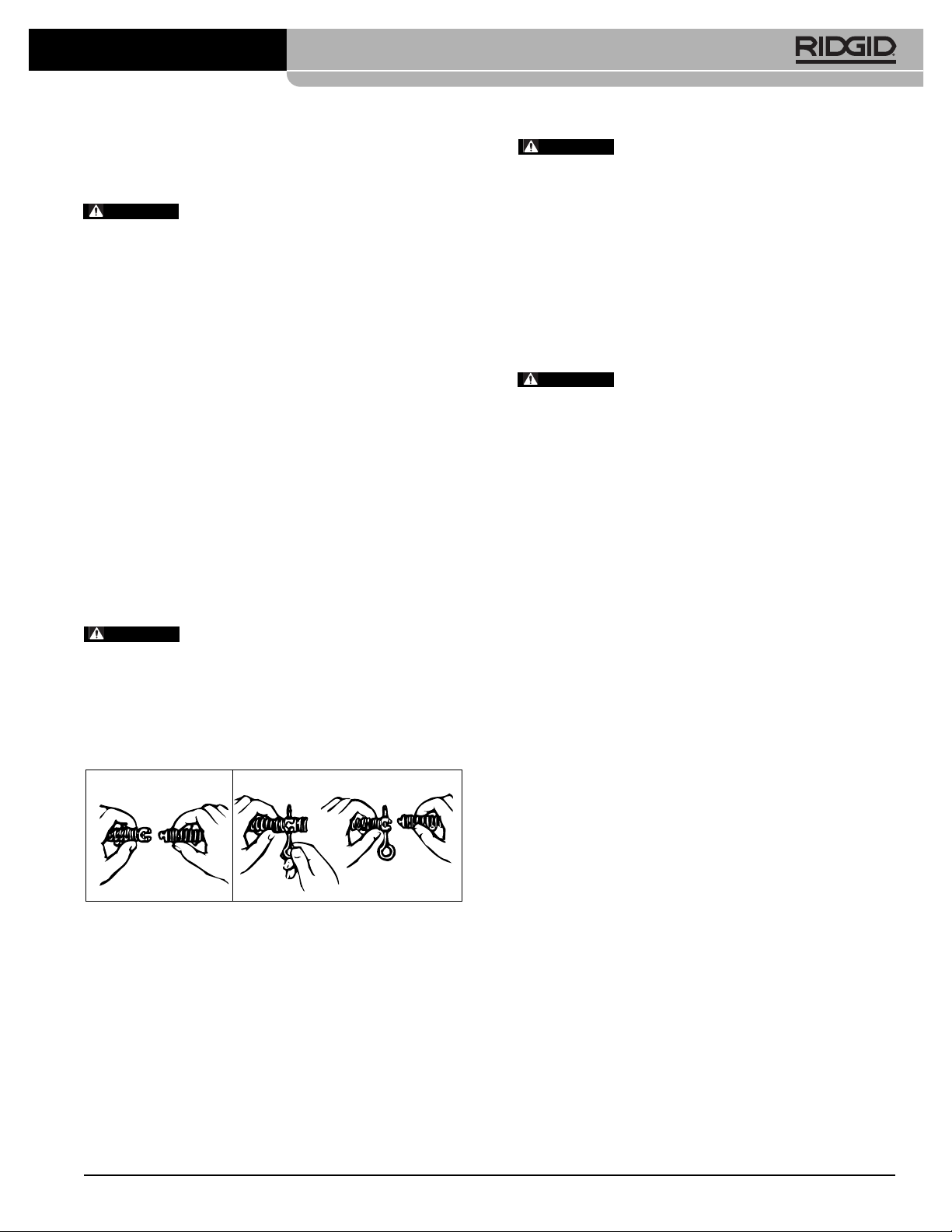

6. Select and install the proper tool to the end of the

cable. The T-Slot Coupler allows the tool to be snap ped into the cable coupler (Figure 4). To remove tool,

use the pin key to depress the plunger and slide the

coupling apart.

To Couple Cable

and Tools

Snap Together Insert Pin

Figure 4 – Coupling and Uncoupling Tools

NOTE! Proper Tool Selection

To Uncouple Cable and Tools

Slide Apart

A good rule of thumb is to use a tool at least 1"

smaller than the line to be cleaned. The style of the

tool is determined by the nature of the job and is left

up to the operator.

7. Plug the Drain Cleaning Machine into the electrical

outlet, making sure to position the power cord along

the clear path selected earlier. If the power cord does

not reach the outlet, use an extension cord in good

condition.

2. Pull ten inches of cable from cable adapter and slide

into back of K-50.

3. Lift plunger pin on cable adapter and depress clutch

handle on machine to allow cable adapter to slip into

drilled hole (Figure 5). Be sure plunger has locked into

machine.

NOTE! By pulling down hard on clutch handle, the adap -

ter will spin. With an upward snap of clutch handle, the adapter will stop instantly, preventing

overrun or kinking. The built-in brake increases

life of cable.

Figure 5 – Cable Adapter Attachment

278-104-431.10_REV. C 7

K-50 Drain Cleaning Machine

4. Position machine as close to line opening as possible

and follow same set-up procedure as described for

use with 5/8" sectional cable.

5. Check that the adapter stops instantly when clutch

handle is pulled upward. If adapter coasts, see Special

Procedures section to adjust brake.

Clutch

Handle

Operating Instructions

WARNING

Wear mitts with rivets provided with machine.

Never grasp a rotating cable with a rag, loose fitting cloth or leather glove that may become

wrapped around the cable causing serious injury.

Always wear eye protection to protect your eyes

against dirt and other foreign objects. Wear rubber

soled, non-slip shoes.

Be very careful when cleaning drains where cleaning compounds have been used. Wear gloves when

handling cable and avoid direct contact to the

skin and especially the eyes and facial area as serious burns can result.

Do not operate if clutch handle is damaged or

does not function properly. Clutch is a safety feature designed to stop rotation of cable or adapters

when released.

CAUTION

tance from inlet to main sewer or septic tank. Over-run ning

cable too far into main sewer or septic tank can cause cables to knot up and prevent their return through small line.

Cleaning Drain using 5/8" Sectional Cable

1. Assume the correct operating posture in order to

maintain proper balance (Figure 6).

WARNING

this posture provides you with the opportunity to safely

keep control of the machine and cable.

• Be sure you can quickly release the clutch handle.

• Hand must be on the cable to control its twisting

action when it hits an obstruction.

• Must have access to FOR/OFF/REVERSE switch.

It is important to know approximate dis-

Should an unexpected situation arise,

Mitten

Cable

FOR/OFF/REV Switch

Figure 6 – Proper Operating Position

2. Without turning the machine on, pull sufficient cable

out of the machine to start tool and cable into the drain

inlet. Push cable into inlet as far as it will go.

3. Pull enough extra cable through machine to form almost a half circle between machine and line opening.

4. Hold cable loosely in mitted hand. Put FOR/OFF/REVERSE switch in FOR (forward) position.

NOTE! The motor will start but cable will not rotate.

5. With mitted hand on cable, push down on clutch handle with opposite hand to engage cable. Push down

on top of the cable loop with a definite snap to advance the cable.

NOTE! A slow or gradual engaging of the clutch handle

causes excessive wear of the jaw set. The clutch

is instant-acting and returning clutch handle to its

original position frees cable instantly.

6. As soon as excess cable has gone into line, release

clutch handle and pull six to ten inches of cable out of

machine with mitted hand.

7. Continue to feed the cable into the line until resistance

or obstruction is encountered. This will become apparent to operator as it will be difficult to feed additional

cable into line and/or the cable will have a tendency to

twist sideways in operator’s hands.

8. If cable loads down in the obstruction, relieve load by

pulling back on cable with short, quick jerks to free

cutter. Slowly advance cable back into the obstruction. Repeat this process until the obstruction is

clear. Remember, make sure the cutter is rotating at

278-104-431.10_REV. C8

K-50 Drain Cleaning Machine

all times and never force the cable. At this point,

pro gress depends upon the sharpness of the tool

and nature of the obstruction.

WARNING

Do not allow tension to build up in the cable. This will

happen if the cutting tool hits a snag and stops turning, but the motor and cable continue to rotate.

Torque builds until the cable suddenly twists, potentially wrapping around your hand or arm. This

can happen quickly and without warning, so proceed slowly and carefully as you feed the cable into

the drain. Releasing clutch handle will stop the

cable rotating and releases the torque. If tool gets

hung up in an obstruction, refer to Reverse Operating

Instructions in the “Special Procedures” section.

9. Once obstruction is cleared, it is recommended that

operator flush debris from line with running water.

Repeat Step 8 several times if necessary for thorough

cleaning job and then work cable through additional

stoppages as required.

10. To add cable, the following procedure should be followed:

• After reaching the end of each cable section, turn

the machine OFF.

• Secure the cable by looping it in the line (Figure 7).

This procedure is especially useful when cleaning a

line that has rapid fall, such as working from a

stack line.

NOTE! By holding the cable against the edge of the

inlet, in the FOR (FORWARD) position, the rotation will rapidly “thread” the cable out of the

line.

• When loop forms, release clutch handle and push

excess cable back through machine. Disconnect

one section at a time.

WARNING

When disconnecting sections, remem-

ber to turn unit off and secure cable in line.

• Once section of cable is removed, insert the secured cable in through the front of the machine

and continue removing sections until tool on last

section of cable is just inside sewer inlet.

WARNING

Never retract tool from sewer inlet while

cable is rotating. Tool can whip causing serious injury.

12. Turn FOR/OFF/REV Switch to OFF position.

13. Pull remaining cable and tool from sewer.

WARNING

After using, thoroughly flush and drain

cables, couplings and tools with water due to damaging

effects of some drain cleaning compounds.

Cleaning Drain Using 5/16" or 3/8" Cable

Adapter

1. Assume the correct operating posture in order to

maintain proper balance (Figure 6).

WARNING

this posture provides you with the opportunity to safely

keep control of the machine and cable.

• Be sure you can quickly release the clutch handle.

Should an unexpected situation arise,

• Hand must be on the cable to control its twisting

action when it hits an obstruction.

• Must have access to FOR/OFF/REVERSE switch.

2. Pull out enough cable by hand to insert into the drain

Figure 7 – Looping Cable In Line

• With line secured, insert another section of cable in

through the front of the machine (female end first)

until approximately one foot remains out the front

of the machine.

• Attach cable to cable in line and resume operation.

11. To retrieve cable from drain line, the following proce-

opening and hand-feed the cable into drain until it

stops feeding easily. Push cable down drain line

keeping your control hand close to the drain opening.

3. Hold cable loosely in mittened hand, put FOR/OFF/

REV SWITCH in FOR (forward) position.

NOTE! The motor will start but cable will not rotate.

4. With mitted hand on cable, push down on clutch

handle with opposite hand to engage adapter.

dure should be followed:

5. Continue hand-feeding the cable slowly until the drain

• Leave FOR/OFF/REV switch in FOR (forward) position.

• Push down on clutch handle to engage cable.

With mitted hand pull cable out of line (if possible)

or hold cable against edge of inlet to thread the

cable out until loop forms in front of the machine.

is opened or blockage is encountered.

WARNING

Keep your cable hand close to the drain

opening to keep control of the cable and help prevent

cable flip-over.

6. When you reach the blockage, work the cable back

278-104-431.10_REV. C 9

K-50 Drain Cleaning Machine

and forth to clear the obstruction. At this point,

progress depends on the type of tool being used

and nature of the blockage. Advance cable slowly.

7. If cable gets hung up in the obstruction, release the

clutch handle to stop the rotation of the cable. Refer

to “Reverse Operation” in the “Special Procedures”

section.

8. Once obstruction is cleared, it is recommended that

operator flush debris from line with running water.

Repeat Step 6 several times if necessary for thorough

cleaning job and then work cable through additional

stoppages as required.

WARNING

Cable is not attached inside drum. When

approaching end of cable, keep hand securely on cable

to avoid losing it down the drain.

9. To withdraw cable from line with machine running,

leave FOR/OFF/REV lever in FORWARD position

and slowly pull cable from drain.

10. As excess cable is retrieved from line, hand-feed

cable back into K-50.

11. Release clutch handle just prior to cable or tool

emerging from drain opening. Cable or tool may contain debris and splash work area.

WARNING

Never retract tool from sewer inlet while

cable is rotating. Tool can whip causing serious injury.

12. Turn FOR/OFF/REV Switch to OFF position.

13. Pull remaining cable and tool from sewer.

After attaching cable adapter to your K-50 Machine, test

for proper braking action as follows:

1. Put switch in FORWARD position to start motor.

2. Push clutch handle forward to engage clutch driver

jaws. Drum will rotate.

3. Pull up on clutch handle to release jaws and activate

brake. Drum should stop turning immediately.

If drum does not stop immediately, readjust brake mechanism as follows:

WARNING

Make sure machine is unplugged from power source

before making any adjustment.

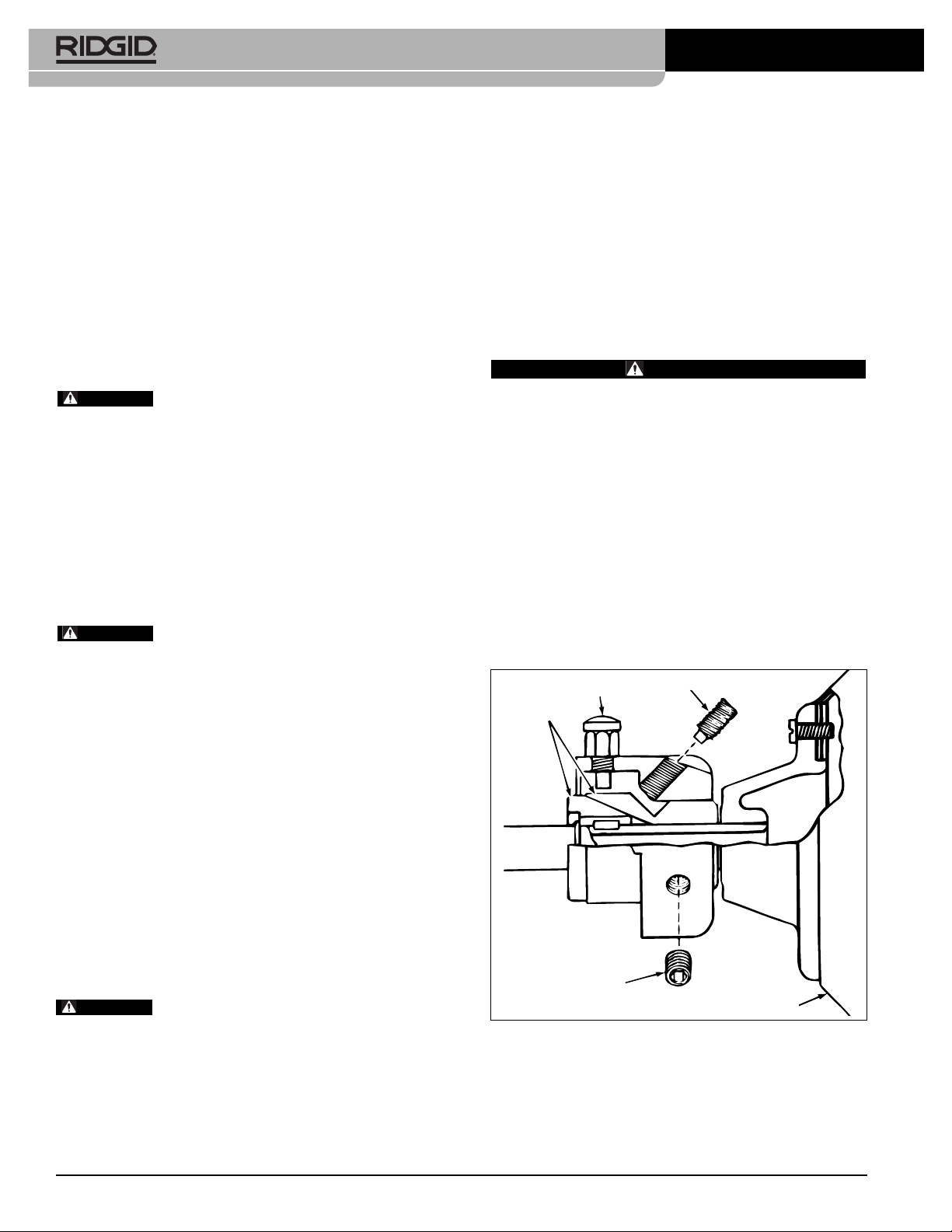

4. Slightly loosen two set screws “A” using a 5/

32

" hex

wrench (Figure 9).

5. Turn set screw “B” clockwise 1/4turn (Figure 9).

6. Operate machine to check for proper braking action.

7. If drum does not stop immediately, repeat Steps 2

and 3 until brake functions properly.

8. Tighten set screws “A” and recheck tension on set

screw “B”.

Due to normal wear, future adjustment will become necessary for effective braking.

Plunger Pin

Brake Drum

“B” Set Screw

Special Procedures

Reverse Operation

Running machine in reverse will cause premature failure

of cable. Use reverse only to free a tool or cable caught in

an obstruction. If this should occur, immediately release

clutch handle and place FOR/OFF/REV switch to OFF position. After motor comes to a complete stop, place

FOR/OFF/REV switch in the REV (reverse) direction.

Engage clutch handle only until cable or tool is free of obstruction. Once it is free, release clutch handle immediately. Turn unit OFF. Run unit in FOR (forward) direction

and follow normal operating procedure.

WARNING

verse) for any other purpose. Operating in reverse can

damage a cable and cause serious injury.

Brake Adjustment

The cable adapter is equipped with a quick-acting brake

which will immediately stop rotation of the drum when the

clutch handle is pulled upwards.

Never operate this machine in REV (re-

“A” Set Screw (2)

Cable Container

Figure 9 – Cable Adapter

278-104-431.10_REV. C10

K-50 Drain Cleaning Machine

Accessories

WARNING

been designed to function with the K-50 Drain Cleaning

Machine. Other accessories suitable for use with other

tools may become hazardous when used on the K-50. To

prevent serious injury, use only the recommended accessories.

Cables

Catalog Model

No. No. Description

62225 C-1 25' (7.6m) w/Bulb Auger

56782 C-1IC

89400 C-21 50' (15.2m) w/Bulb Auger

62235 C-2 25' (7.6m) w/Drop Head Auger

56787 C-2IC

89405 C-22 50' (15.2m) w/Drop Head Auger

62245 C-4 25' (7.6m) w/Male Coupling

62250 C-5 35' (10.7m) w/Bulb Auger

62260 C-6 35' (10.7m) w/Male Coupling

96037 C-6IC 35' (10.7m) w/Male Coupling

62265 C-7 7

62270 C-8 7

51317 C-9 10' (3.0m) Heavy-Duty Wind

Accessories

Catalog Model

No. No. Description

59235 A-14-6 6' Rear Guide Hose

84325 A-14-10 10' Rear Guide Hose

59270 A-18 Front Guide Hose Assembly

59210 A-10 Cable Carrier (Holds 90' C-8, C-9)

59205 A-1 Left-Hand Mitt

59295 A-2 Right-Hand Mitt

59230 A-13 Pin Key,

Adapters with Cable

Catalog Model

No. No. Description

59250 A-17-A Adapter with 25

59255 A-17-B Adapter with 35

59265 A-17-C Adapter with 35

92095 A-17-D Adapter with 250

92100 A-17-E Adapter with 250

Only the following RIDGID products have

5

/16" x 25' (7.6m) Inner Core

w/Bulb Auger

5

/16" x 25' (7.6m) Inner Core

w/Drop Head Auger

1

/2' (2.3m) Tight-Wind

1

/2' (2.3m) All-Purpose Wind

5

/8 Cable

5

' x

w/Bulb Auger

w/Bulb Auger

w/Male Coupling

w/Bulb Auger

w/Drop Head

/16" Cable

3

' x

/8" Cable

3

' x

/8" Cable

' x

' x

5

/16" Cable

5

/16" Cable

Tools for C-4, C-6, C-7, C-8, and C-9

Catalog Model

No. No. Description

62990 T-201 Straight Auger, 5" Long

62995 T-202 Bulb Auger, 1

63000 T-203 Bulb Auger,

1

/8" O.D.

7

/8", O.D.

55457 T-225 Retrieving Auger

62067 T-201A Straight Flex Auger

63065 T-217 Drop Head, 4" Long

54837 T-204 “C” Cutter, 1"

63005 T-205 “C” Cutter, 1

3

/8"

63010 T-206 Funnel Auger, 3" Long

1

63015 T-207 Spiral Cutter, 1

63020 T-208 Spiral Cutter, 1

/4"

1

/2"

63025 T-209 Spiral Cutter, 2"

63030 T-210 Grease Cutter, 1"

63035 T-211 Grease Cutter, 1

63040 T-212 Grease Cutter, 1

63045 T-213 4-Blade Cutter, 1"

63050 T-214 4-Blade Cutter, 1

63055 T-215 4-Blade Cutter, 1

3

/8"

3

/4"

3

/8"

3

/4"

63060 T-216 Chain Knocker, 2"

63280 T-218 Flue Brush, 3"

63070 T-219 Flue Brush, 2

63080 T-220 Flue Brush, 2"

63220 T-221 Flue Brush, 1

52812 T-230 H-D “C” Cutter, 2"

52817 T-231 H-D “C” Cutter, 2

1

/2"

1

/2"

1

/2"

52822 T-232 H-D “C” Cutter, 3"

48482 T-250 Tool Set includes:

– T-203 – T-217

– T-205 – A-13

– T-210

NOTE! See Ridge Tool Catalog for complete list of tools

and accessories.

Maintenance Instructions

WARNING

Make sure machine is unplugged from power

source before performing maintenance or making any adjustment.

Lubrication

Lubricate machine with grease at grease fitting (located on

jaw housing) once a week if used every day; once a

month if used less. Place a drop of oil on each of the bearing points, thrust bearing, clutch jaws, etc., at least once

a year.

Cables

Cables should be thoroughly flushed with water to prevent

damaging effects of sediment and drain cleaning compounds. Periodically lubricate cables and couplings with

RIDGID Cable Rust Inhibitor.

When not in use, store cables indoors to prevent deterioration by the elements.

278-104-431.10_REV. C 11

K-50 Drain Cleaning Machine

Cables should be replaced when they become severely

corroded or worn. A worn cable can be identified when

outside of coils become flat.

Clutch Jaw Assembly (Jaw Set)

The clutch jaw assembly should be periodically cleaned.

1. Place machine on its nose end. Remove the two (2)

socket head cap screws from the rack and pinion

housing with a 1/4" hex key (Figure 10).

hold detergents that contain ammonia. Avoiding use

of these and other types of cleaning agents minimizes the probability of damage.

4. Reinstall the flange assembly to the drum and replace

cable.

Machine Storage

WARNING

doors or well covered in rainy weather. Store the machine in a locked area that is out of reach of children and

people unfamiliar with drain cleaners. This machine can

cause serious injury in the hands of untrained users.

If machine has been exposed to freezing weather, unit

must be run for ten (10) to twenty (20) minutes without

load to warm up. Failing to do this will result in frozen

bearings. If machine is exposed to weather for a period

of time, moisture will form across motor windings causing motor to burn out.

Motor-driven equipment must be kept in-

Service and Repair

WARNING

Figure 10 – Remove Socket Head Cap Screws

2. Remove the rack and pinion housing. The clutch jaw

assembly is contained in the K-50 housing.

3. Clean and lubricate clutch jaw assembly with oil.

4. If worn, replace the clutch jaw assembly.

5. Reinstall the jaws into the housing and replace the

rack and pinion assembly.

6. Attach rack and pinion housing to machine with

socket head cap screws.

Cable Containers

Cable container on 5/16" and 3/8" cable adapter should be

periodically cleaned.

1. Remove cable from the cable adapter. Cable is not attached to inside of drum.

2. Remove three 1/4" screws holding tube and flange to

the drum.

3. Clean inside of drum and flange assembly. Certain

cleaning agents and solvents damage plastic parts.

Some of these are: gasoline, carbon tetrachloride,

chlorinated cleaning solvents, ammonia and house-

The “Maintenance Instructions” will take care of most of

the service needs of this machine. Any problems not addressed by this section should only be handled by a

RIDGID Independent Service Center.

Tool should be taken to a RIDGID Independent Service

Center or returned to the factory. All repairs made by

Ridge service facilities are warranted against defects in

material and workmanship.

WARNING

tical replacement parts should be used. Failure to follow

these instructions may create a risk of electrical shock or

other serious injury.

If you have any questions regarding the service or repair

of this machine, call or write to:

For name and address of your nearest Independent

Authorized Service Center, contact the Ridge Tool Com pany at (800) 519-3456 or RIDGID.com

When servicing this machine, only iden-

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44035-6001

Tel: (800) 519-3456

E-mail: rtctechservices@emerson.com

278-104-431.10_REV. C12

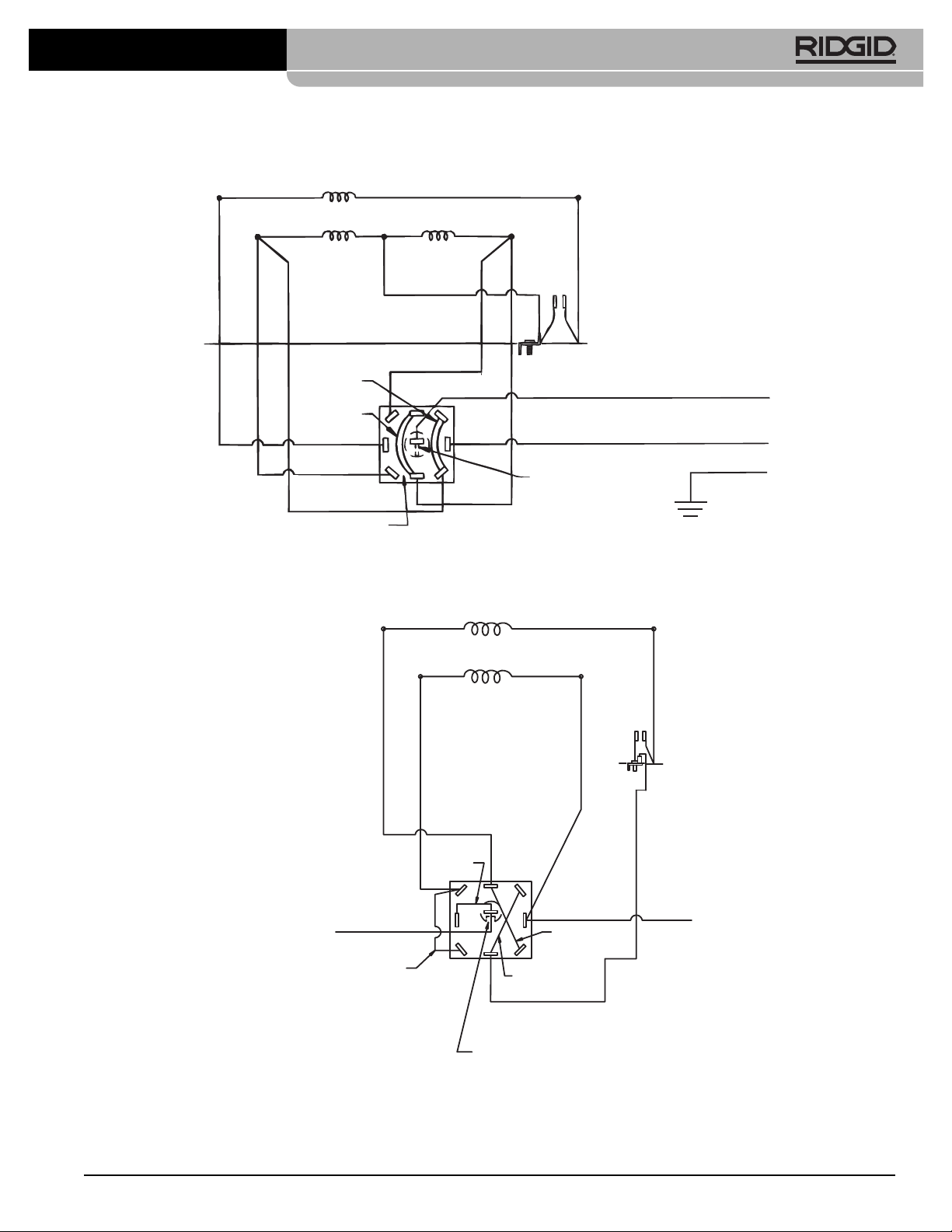

K-50 Drain Cleaning Machine

AUX.

1/2 MAIN

WHT

4

5

K-50 Emerson Motor Wiring 120V 50/60Hz, 230V 50/60Hz

1/2 MAIN

BLK

WHT

YEL

RED

BRN

BRN

JUMPER

BLU

JUMPER

BLU

BLU

WHITE (BLUE)

BLACK (BROWN)

KEYWAY IN

STEM OF

TOGGLE

REAR VIEW

SWITCH

K-50 Allwin Motor Wiring 120V 60Hz, 230V 50Hz

AUX.

MAIN

BLU

T4

BRN

WHITE

BLACK FROM

POWERCORD

YEL

JUMPER

YEL

PINK

JUMPER

RED

JUMPER

BRN

JUMPER

GREEN/YEL

TO MOTOR

GROUND

RED

T5

WHITE FROM

POWERCORD

KEYWAY IN STEM

278-104-431.10_REV. C 13

K-50 Drain Cleaning Machine

278-104-431.10_REV. C14

Loading...

Loading...