Philips LC7.1L LA Service Manual

Color Television Chassis

ME7

ME5P

LC7.1L

LA

ME5P

ME7

H_17260_000.eps

Contents Page Contents Page

1. Technical Specifications, Connections, and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 7

3. Directions for Use 8

4. Mechanical Instructions 9

5. Service Modes, Error Codes, and Fault Finding 16

6. Block Diagrams, Test Point Overview, and

Waveforms

Wiring Diagram 26” (ME5P) 27

Wiring Diagram 26” - 32” (ME7) 28

Wiring Diagram LCD with AmbiLight (ME7) 29

Wiring Diagram 37” - 42” LCD with 1080p (ME7)31

Wiring Diagram 37” - 42” LCD (ME7) 30

Wiring Diagram 42” LCD with AmbiLight (ME7) 32

Wiring Diagram 47” - 52” LCD with 1080p (ME7)33

Block Diagram Video 34

Block Diagram Audio 35

Block Diagram Control & Clock Signals 36

Test Point Overview SSB (Overview Bot. Side) 37-41

I2C IC’s Overview 42

Supply Lines Overview 43

7. Circuit Diagrams and PWB Layouts Diagram PWB

AmbiLight Inverter: FPGA Power & Control(AI1) 44 48-49

AmbiLight Inverter: FPGA I/O Banks (AI2) 45 48-49

AmbiLight Inverter: FPGA LVDS (AI3) 46 48-49

AmbiLight Inverter: DC/DC (32” Only) (AI4) 47 48-49

SSB: DC/DC (B02) 50 61-70

SSB: Tuner & Demodulator (B03A) 51 61-70

SSB: Micro Processor (B04A) 52 61-70

SSB: Video Processor (B04B) 53 61-70

SSB: PNX2015: Audio Processor (B04C) 54 61-70

SSB: YPBPR & Rear IO (B06A) 55 61-70

SSB: I/O Scart 1 & 2 (B06B) 56 61-70

SSB: HDMI (B06C) 57 61-70

©

Copyright 2007 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

SSB: Headphone Amp & Muting (B06D) 58 61-70

SSB: Audio (B07) 59 61-70

SSB: SRP List 60 61-70

Side A/V Panel (D) 71 72

Keyboard Control Panel (ME7) (E) 73 74

Keyboard Control Panel (ME5P) (E) 75 76

1080p Panel: On Chip uController (F1) 77 84

1080p Panel: Flash & NVM (F2) 78 84

1080p Panel: LVDS In (F3) 78 84

1080p Panel: LVDS Out (F4) 79 84

1080p Panel: Supply In (F5) 80 84

1080p Panel: DDR SDRAM (F6) 81 84

1080p Panel: DC Power Supply (F7) 82 84

Layout 1080p Panel (Top Side) (F8) 83 84

Front IR / LED Panel (ME7) (J) 85 86

Front IR / LED Panel (ME5P) (J) 87 87

8. Alignments 89

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 94

Abbreviation List 101

IC Data Sheets 103

10. Spare Parts List 108

11. Revision List 114

050707

Published by WS 0771 BU CD Customer Service Printed in the Netherlands Subject to modification EN 3122 785 17263

EN 2 LC7.1L LA1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 Technical Specifications

1.2 Connection Overview

1.3 Chassis Overview

Notes:

• Figures can deviate due to the different set executions.

• Specifications are indicative (subject to change).

1.1 Technical Specifications

1.1.1 Vision

Display type : LCD

Screen size : 26" (66 cm), 16:9

: 32" (81 cm), 16:9

: 37" (94 cm), 16:9

: 42" (107 cm), 16:9

Resolution (H × V pixels) : 1366 × 768

Min. contrast ratio : 3500:1 (26")

Min. light output (cd/m

Typ. response time (ms) : 8

Viewing angle (H × V degrees) : 178 × 178 (32 and

Tuning system : PLL

TV Color systems : PAL M/N

Video playback : PAL

Supported computer formats : 1024 × 768

Supported video formats : 640 × 480i - 1fH

Presets/channels : 125 presets

Tuner bands : VHF

2

) : 500

: 52" (132 cm), 16:9

: 1920 × 1080

(42PFL5432,

52PFL5432)

: 4000:1 (32")

: 5000:1 (37 and 42")

: 4000:1 (42PFL5432)

: 7500:1 (52PFL5432)

42")

: 170 × 170

(37PFL5322,

42PFL5432,

52PFL5432)

:NTSC

:NTSC

@ 60, 70, 75, 85 Hz

: 640 × 480

@ 60, 72, 75, 85 Hz

: 720 × 400 @ 70 Hz

: 720 × 576i - 1fH

: 640 × 480p - 2fH

: 720 × 576p - 2fH

: 1920 × 1080p - 3fH

: 1280 × 720p - 3fH

: UHF

: S-band

: Hyper-band

1.1.3 Miscellaneous

Power supply:

- Mains voltage (V

- Mains frequency (Hz) : 50 / 60

Ambient conditions:

- Temperature range (°C) : +5 to +40

- Maximum humidity : 90% R.H.

Power consumption (values are indicative)

- Normal operation (W) : ≈ 120 (26")

- Stand-by (W) : < 1

Dimensions (W × H × D mm) : 682 × 473 × 114 (26")

Weight (kg) : 12.0 (26")

) : 100 - 240

AC

: ≈ 150 (32")

: ≈ 175 (37")

: ≈ 240 (42")

: ≈ 340 (52")

: 805 × 547 × 116 (32")

: 935 × 626 × 116 (37")

: 1046 × 669 × 116(42")

: 1289 × 835 × 124(52")

: 14.2 (32")

: 23.0 (37")

: 33.5 (42")

: 40.0 (52")

1.1.2 Sound

Sound systems : SAP

Equalizer : 7-bands

Maximum power (W

Sound enhancement : Auto Volume Leveller

):2× 10

RMS

: Incredible Surround

Technical Specifications, Connections, and Chassis Overview

1.2 Connection Overview

Figure 1-1 Side and rear I/O connections

H_17260_033.eps

050707

EN 3LC7.1L LA 1.

Note: The following connector color abbreviations are used

(acc. to DIN/IEC 757): Bk= Black, Bu= Blue, Gn= Green, Gy=

Grey, Rd= Red, Wh= White, and Ye= Yellow.

1.2.1 Side Connections

Headphone - Out

Bk - Headphone 32 - 600 ohm / 10 mW rt

Cinch: Video CVBS - In, Audio - In

Rd - Audio R 0.5 V

Wh - Audio L 0.5 V

Ye - Video CVBS 1 V

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

/ 75 ohm jq

PP

S-Video (Hosiden): Video Y/C - In

1 -Ground Y Gnd H

2 -Ground C Gnd H

3 - Video Y 1 V

4 - Video C 0.3 V

/ 75 ohm j

PP

P / 75 ohm j

PP

1.2.2 Rear Connections

CVI-1: Cinch: Video YPbPr - In, Audio - In

Gn - Video Y 1 V

Bu - Video Pb 0.7 V

Rd - Video Pr 0.7 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

Aerial - In

- - F-type (US) Coax, 75 ohm D

Service Connector (ComPair)

1 - SDA-S I

2 - SCL-S I

2

C Data (0 - 5 V) jk

2

C Clock (0 - 5 V) j

3 - Ground Gnd H

AV: Cinch: Video CVBS - In, Audio - In

Ye - Video CVBS 1 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

AV: S-Video (Hosiden): Video Y/C - In

1 - Ground Y Gnd H

2 - Ground C Gnd H

3 - Video Y 1 V

4 - Video C 0.3 V

/ 75 ohm j

PP

P / 75 ohm j

PP

HDMI 1 & 2: Digital Video, Digital Audio - In

19

18 2

1

E_06532_017.eps

250505

Figure 1-2 HDMI (type A) connector

1 - D2+ Data channel j

2 - Shield Gnd H

3 - D2- Data channel j

4 - D1+ Data channel j

5 - Shield Gnd H

6 - D1- Data channel j

7 - D0+ Data channel j

8 - Shield Gnd H

9 - D0- Data channel j

10 - CLK+ Data channel j

11 - Shield Gnd H

12 - CLK- Data channel j

13 - n.c.

14 - n.c.

15 - DDC_SCL DDC clock j

16 - DDC_SDA DDC data jk

17 - Ground Gnd H

18 - +5V j

19 - HPD Hot Plug Detect j

20 - Ground Gnd H

CVI-2: Cinch: Video YPbPr - In, Audio - In

Gn - Video Y 1 V

Bu - Video Pb 0.7 V

Rd - Video Pr 0.7 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

EN 4 LC7.1L LA1.

Technical Specifications, Connections, and Chassis Overview

PC - VGA: Video 2fH RGB/YPbPr - In

1

5

6

11

10

15

E_06532_002.eps

050404

Figure 1-3 VGA Connector

1 - Video Red/Pr 0.7 V

2 - Video Green/Y 0.7 V

3 - Video Blue/Pb 0.7 V

4-n.c.

/ 75 ohm j

PP

/ 75 ohm j

PP

/ 75 ohm j

PP

5 - Ground Gnd H

6 - Ground Red Gnd H

7 - Ground Green Gnd H

8 - Ground Blue Gnd H

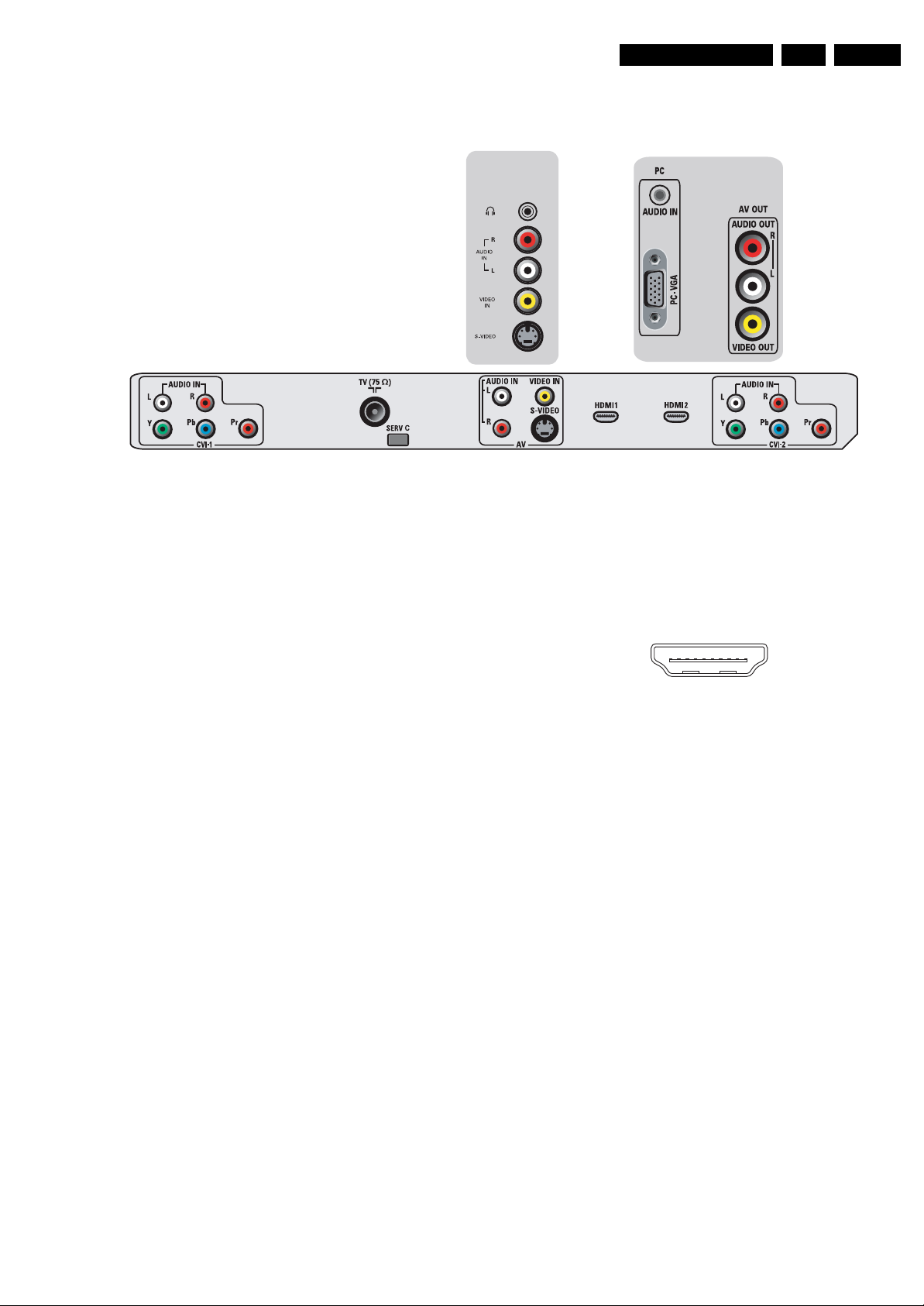

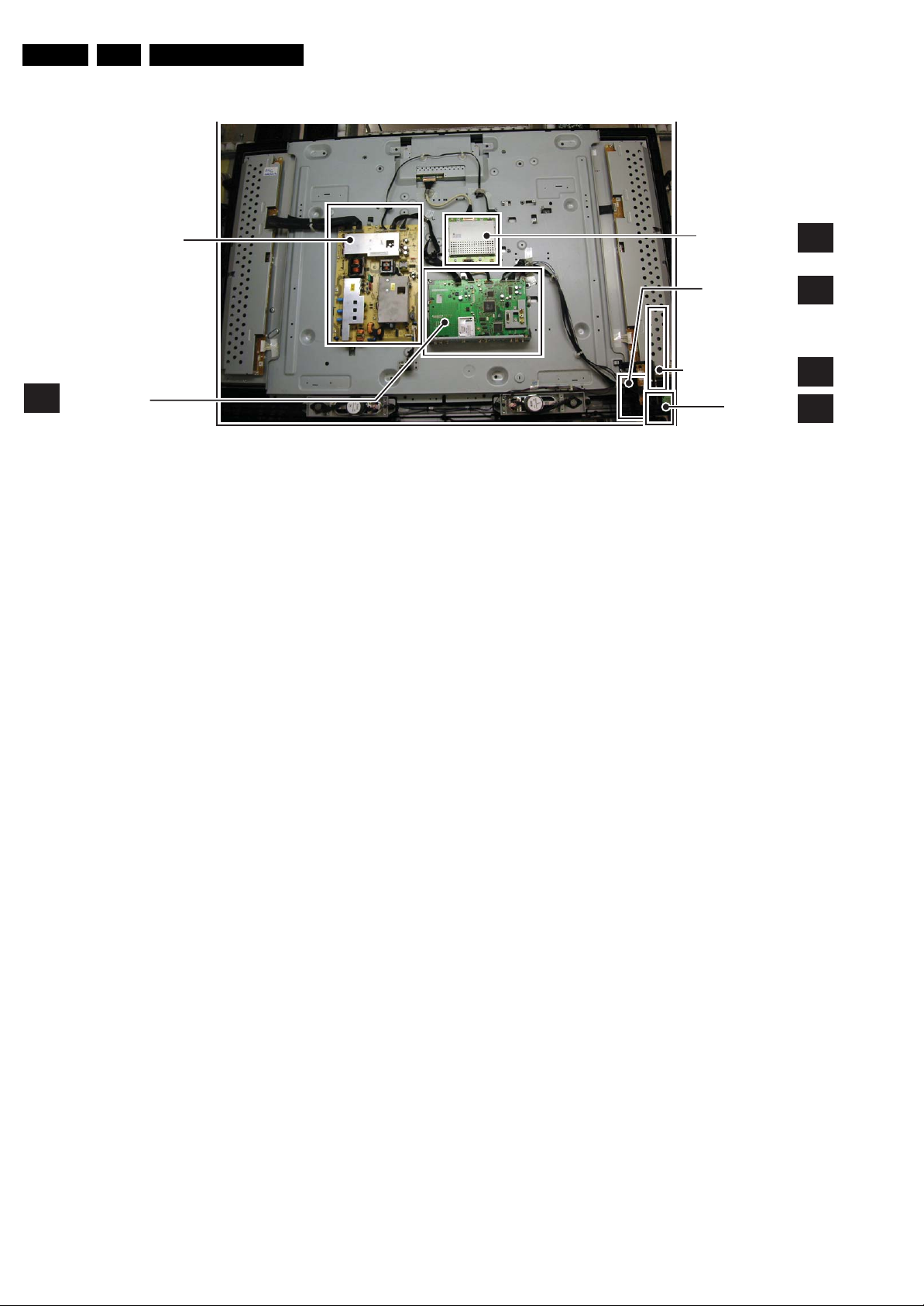

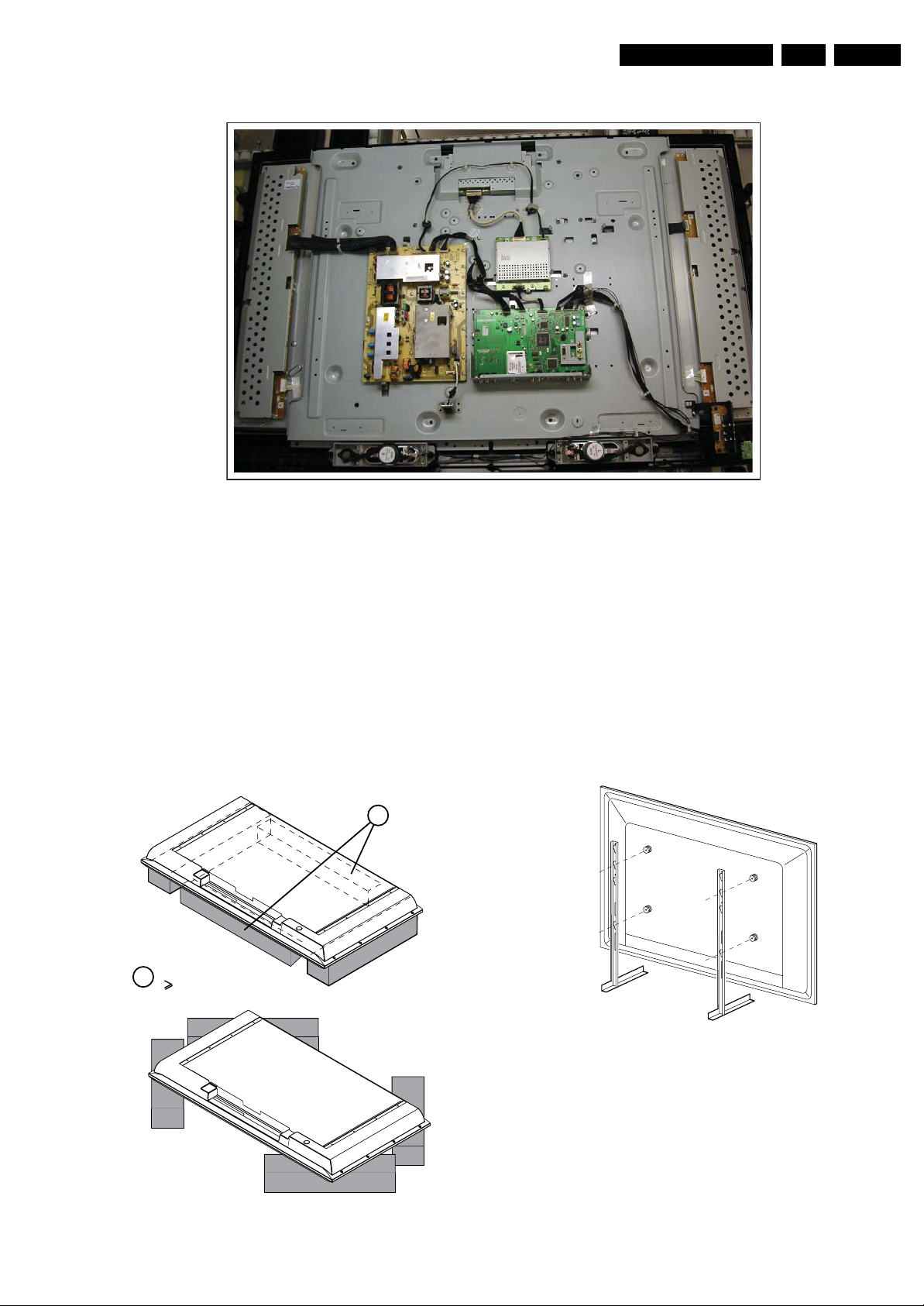

1.3 Chassis Overview

POWER SUPPLY UNIT

9-+5V

10 - Ground Sync Gnd H

+5 V j

DC

11 - n.c.

12 - DDC_SDA DDC data j

13 - H-sync 0 - 5 V j

14 - V-sync 0 - 5 V j

15 - DDC_SCL DDC clock j

PC - Mini Jack: Audio - In

Bk - Audio R + L 0.5 V

/ 10 kohm oj

RMS

AV Out - Cinch: Video CVBS - Out, Audio - Out

Rd - Audio R 0.5 V

Wh - Audio L 0.5 V

Ye - Video CVBS 1 V

/ 10 kohm kq

RMS

/10 kohm kq

RMS

/ 75 ohm kq

PP

CONTROL BOARD

E

SMALL SIGNAL

B

BOARD

POWER SUPPLY UNIT

SMALL SIGNAL

B

BOARD

Figure 1-4 PWB/CBA locations (26" models, ME5P styling)

SIDE I/O PANEL

LED PANEL

H_17260_034.eps

SIDE I/O PANEL

CONTROL BOARD

LED PANEL

H_17260_035.eps

D

J

060707

D

E

J

060707

Figure 1-5 PWB/CBA locations (32" models, ME7 styling)

Technical Specifications, Connections, and Chassis Overview

EN 5LC7.1L LA 1.

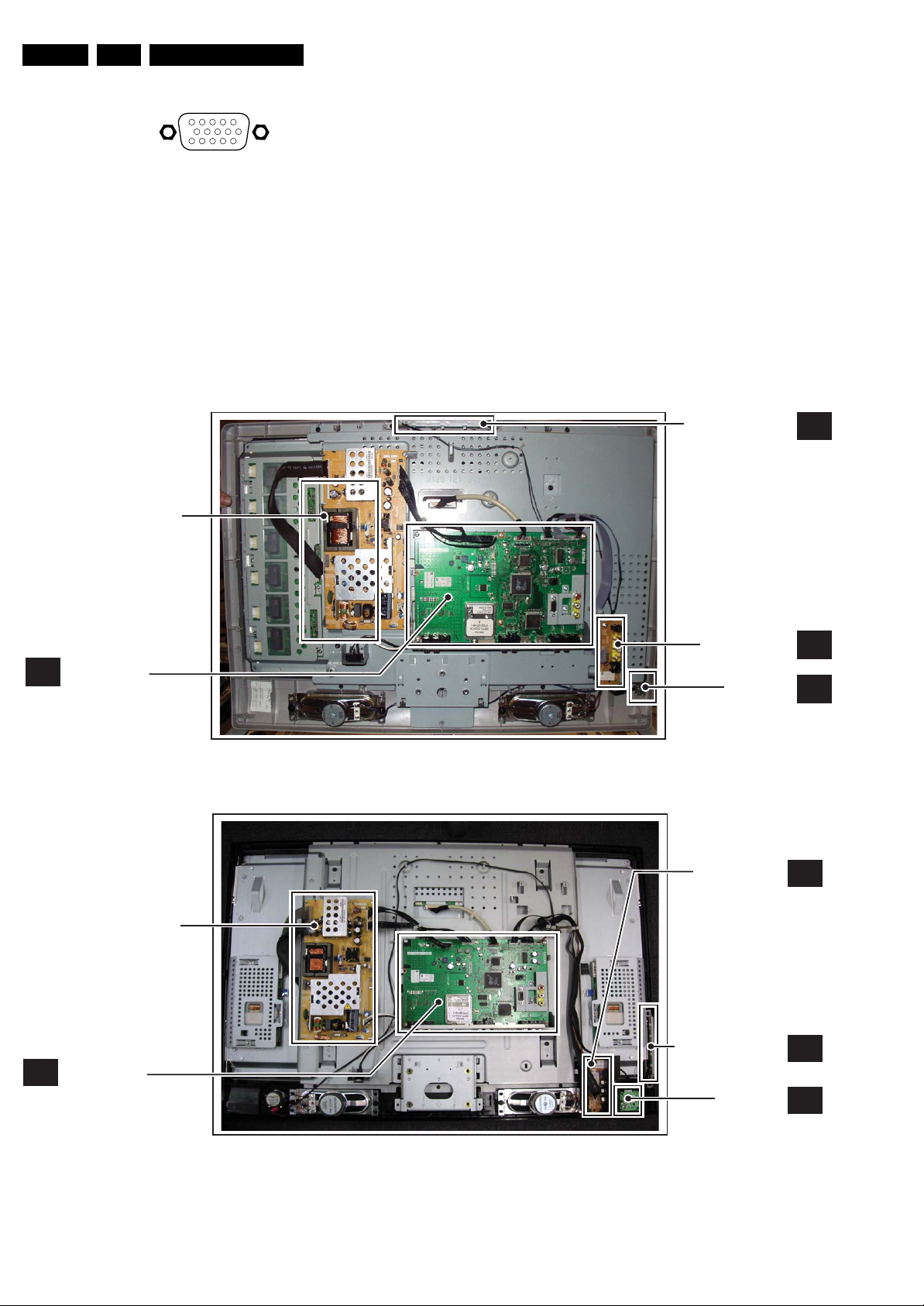

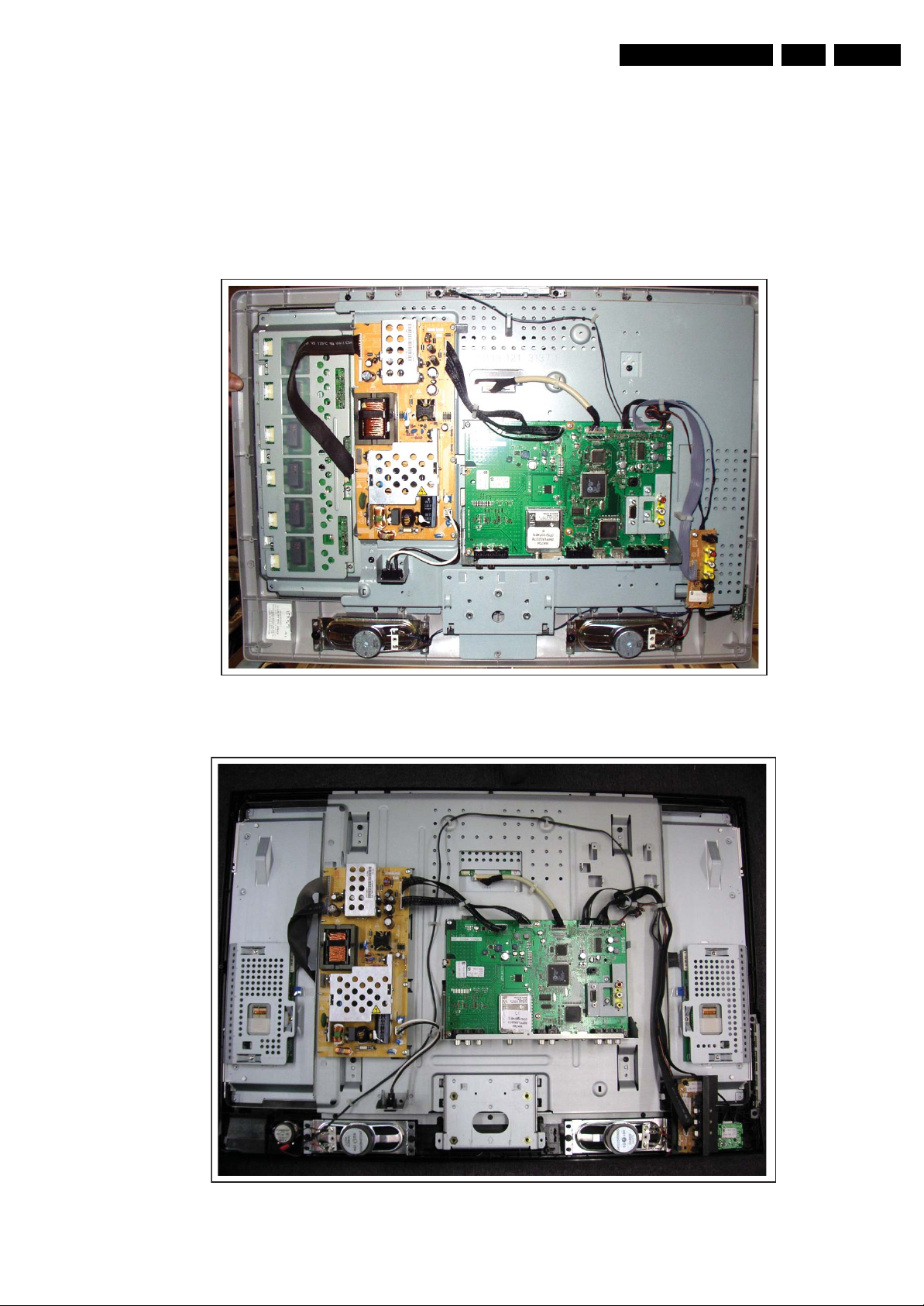

POWER SUPPLY UNIT

SMALL SIGNAL

B

BOARD

1080p PANEL

F

POWER SUPPLY UNIT

Figure 1-6 PWB/CBA locations (37” and 42” models without 1080p module, ME7 styling)

AMBILIGHT

INTERFACE PANEL

SIDE I/O PANEL

CONTROL BOARD

LED PANEL

H_17261_006.eps

SIDE I/O PANEL

AI

D

E

J

041007

D

SMALL SIGNAL

B

BOARD

Figure 1-7 PWB/CBA locations (42” models with 1080p module, ME7 styling)

CONTROL PANEL

LED PANEL

G_16860_092.eps

E

J

150307

EN 6 LC7.1L LA1.

Technical Specifications, Connections, and Chassis Overview

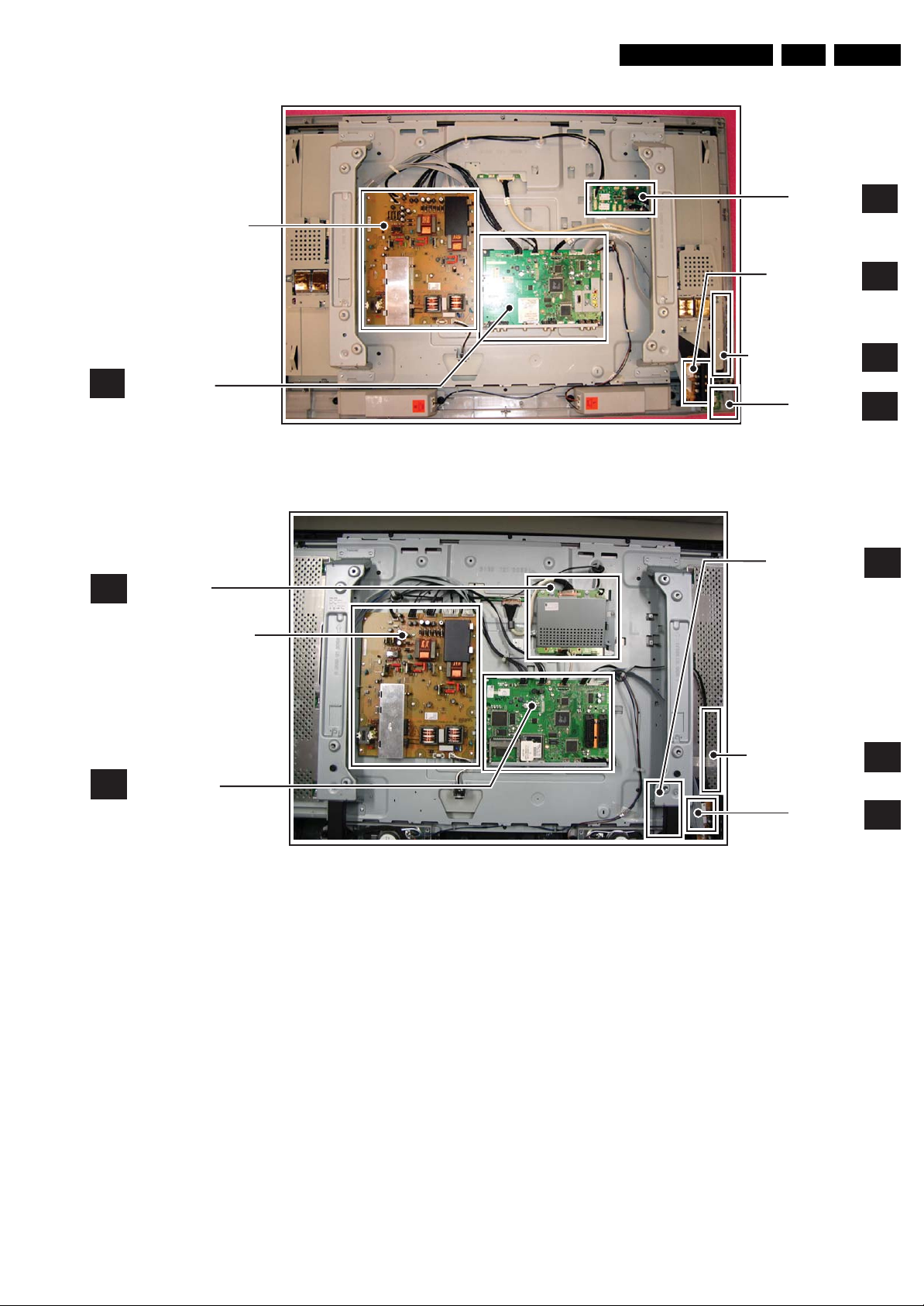

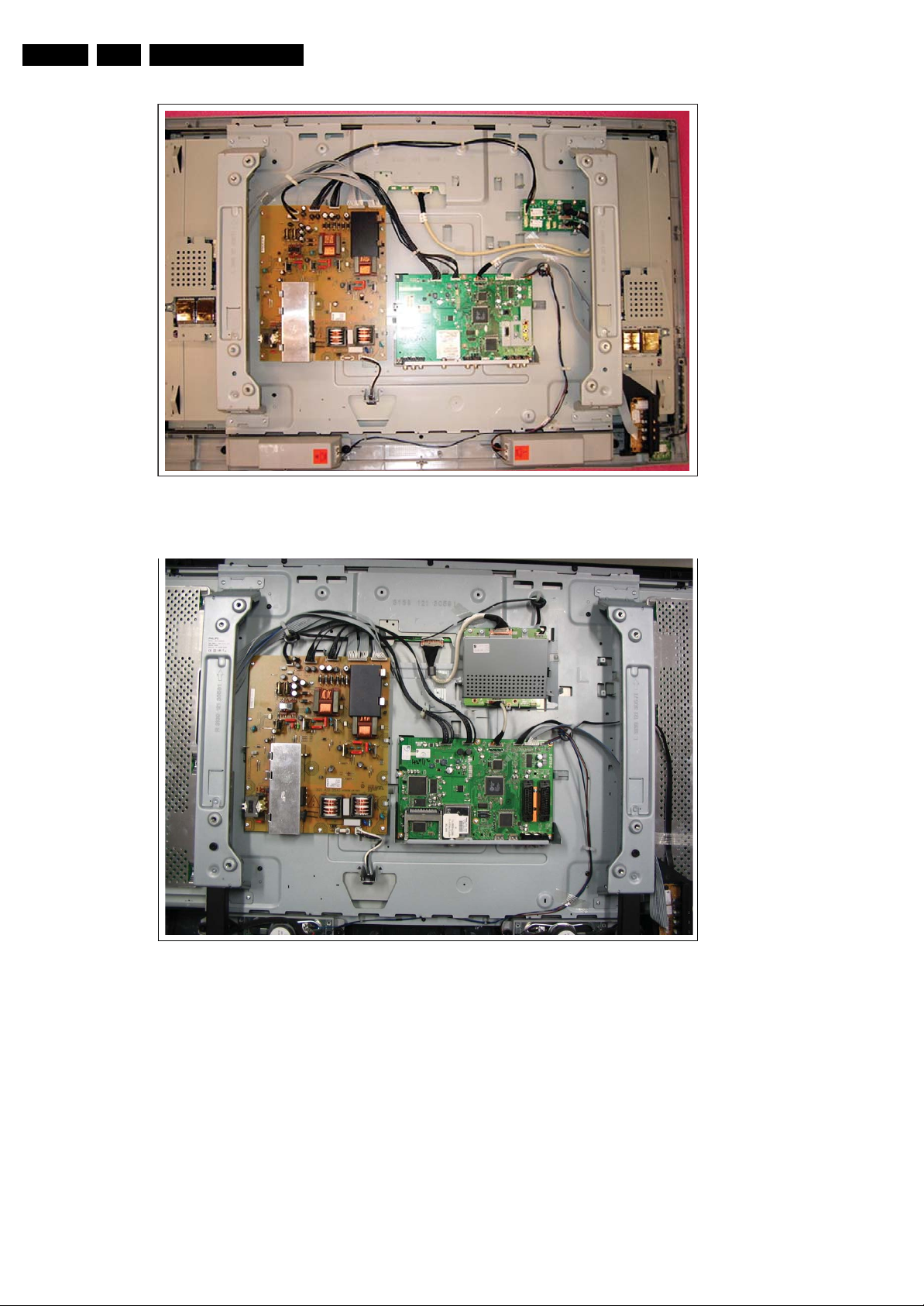

POWER SUPPLY UNIT

SMALL SIGNAL

B

BOARD

Figure 1-8 PWB/CBA locations (52" models, ME7 styling)

1080p BOLT-ON

PA NE L

SIDE I/O PANEL

CONTROL BOARD

LED PANEL

H_17261_008.eps

F

D

E

J

041007

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

EN 7LC7.1L LA 2.

Index of this chapter:

2.1 Safety Instructions

2.2 Warnings

2.3 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the “on” position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 Mohm and 12 Mohm.

4. Switch “off” the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

Service Default Mode (see chapter 5) with a color bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

• Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic” and the “double-D symbol”, are

trademarks of Dolby Laboratories.

2.3.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an “E” or an “R” (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (μ= × 10

nano-farads (n= × 10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An “asterisk” (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.3.3 BGA (Ball Grid Array) ICs

Introduction

For more information on how to handle BGA devices, visit this

URL: www.atyourservice.ce.philips.com (needs subscription,

not available for all regions). After login, select “Magazine”,

then go to “Repair downloads”. Here you will find Information

on how to deal with BGA-ICs.

-9

), or pico-farads (p= × 10

-12

-6

),

).

2.2 Warnings

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential. Available

ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable) 4822

310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched “on”.

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

2.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

BGA Temperature Profiles

For BGA-ICs, you must use the correct temperature-profile,

which is coupled to the 12NC. For an overview of these profiles,

visit the website www.atyourservice.ce.philips.com (needs

subscription, but is not available for all regions).

You will find this and more technical information within the

“Magazine”, chapter “Repair downloads”.

For additional questions please contact your local repair help

desk.

2.3.4 Lead-free Soldering

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilize the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilized at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

EN 8 LC7.1L LA3.

Directions for Use

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

2.3.5 Alternative BOM identification

The third digit in the serial number (example:

AG2B0335000001) indicates the number of the alternative

B.O.M. (Bill Of Materials) that has been used for producing the

specific TV set. In general, it is possible that the same TV

model on the market is produced with e.g. two different types

of displays, coming from two different suppliers. This will then

result in sets which have the same CTN (Commercial Type

Number; e.g. 28PW9515/12) but which have a different B.O.M.

number.

By looking at the third digit of the serial number, one can

identify which B.O.M. is used for the TV set he is working with.

If the third digit of the serial number contains the number “1”

(example: AG1B033500001), then the TV set has been

manufactured according to B.O.M. number 1. If the third digit is

a “2” (example: AG2B0335000001), then the set has been

produced according to B.O.M. no. 2. This is important for

ordering the correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26= 35 different B.O.M.s can be

indicated by the third digit of the serial number.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 1 and 2 refer to the production center (e.g.

AG is Bruges), digit 3 refers to the B.O.M. code, digit 4 refers

to the Service version change code, digits 5 and 6 refer to the

production year, and digits 7 and 8 refer to production week (in

example below it is 2006 week 17). The 6 last digits contain the

serial number.

MODEL :

PROD.NO:

2.3.6 Board Level Repair (BLR) or Component Level Repair (CLR)

If a board is defective, consult your repair procedure to decide

if the board has to be exchanged or if it should be repaired on

component level.

If your repair procedure says the board should be exchanged

completely, do not solder on the defective board. Otherwise, it

cannot be returned to the O.E.M. supplier for back charging!

2.3.7 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

• Always respect voltages. While some may not be

32PF9968/10

AG 1A0617 000001

Figure 2-1 Serial number (example)

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

MADE IN BELGIUM

220-240V 50/60Hz

VHF+S+H+UHF

S

~

BJ3.0E LA

E_06532_024.eps

128W

130606

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

4. Mechanical Instructions

Mechanical Instructions

EN 9LC7.1L LA 4.

Index of this chapter:

4.1 Cable Dressing

4.2 Service Positions

4.3 Assy/Panel Removal

4.4 Set Re-assembly

4.1 Cable Dressing

Notes:

• Figures below can deviate slightly from the actual situation,

due to the different set executions.

• Follow the disassemble instructions in described order.

They apply to the 32" sets.

Figure 4-1 Cable dressing (26" models)

H_17260_041.eps

050707

Figure 4-2 Cable dressing (32" models)

H_17260_042.eps

060707

EN 10 LC7.1L LA4.

Mechanical Instructions

H_17261_007.eps

031007

Figure 4-3 Cable dressing (37 and 42” models without 1080p module)

G_16860_091.eps

150307

Figure 4-4 Cable dressing (42” models with 1080p module)

Mechanical Instructions

H_17261_009.eps

031007

EN 11LC7.1L LA 4.

4.2 Service Positions

For easy servicing of this set, there are a few possibilities

created:

• The buffers from the packaging.

• Foam bars (created for Service).

• Aluminium service stands (created for Service).

Note: the aluminium service stands can only be used when the

set is equipped with so-called “mushrooms”. Otherwise use the

original stand that comes with the set.

4.2.1 Foam Bars

Required for sets

1

42"

Figure 4-5 Cable dressing (52" models)

The foam bars (order code 3122 785 90580 for two pieces) can

be used for all types and sizes of Flat TVs. See figure “Foam

bars” for details. Sets with a display of 42" and larger, require

four foam bars [1]. Ensure that the foam bars are always

supporting the cabinet and never only the display. Caution:

Failure to follow these guidelines can seriously damage the

display!

By laying the TV face down on the (ESD protective) foam bars,

a stable situation is created to perform measurements and

alignments. By placing a mirror under the TV, you can monitor

the screen.

4.2.2 Aluminium Stands

1

E_06532_039.eps

290507

Figure 4-6 Foam bars

E_06532_018.eps

171106

Figure 4-7 Aluminium stands

The MkII aluminium stands with order code 3122 785 90690,

can also be used to do measurements, alignments, and

duration tests. The stands can be (dis)mounted quick and easy

by means of sliding them in/out the “mushrooms”. The stands

are backwards compatible with the earlier models.

Important: For (older) FTV sets without these “mushrooms”, it

is obligatory to use the provided screws, otherwise it is possible

to damage the monitor inside!

EN 12 LC7.1L LA4.

s

7

4.3 Assy/Panel Removal

4.3.1 Rear Cover

Warning: Disconnect the mains power cord before you remove

the rear cover.

1. Place the TV set upside down on a table top, using the

foam bars (see part “Service Position”).

2. Remove rear cover screws and the stand (if mounted).

3. Remove rear cover.

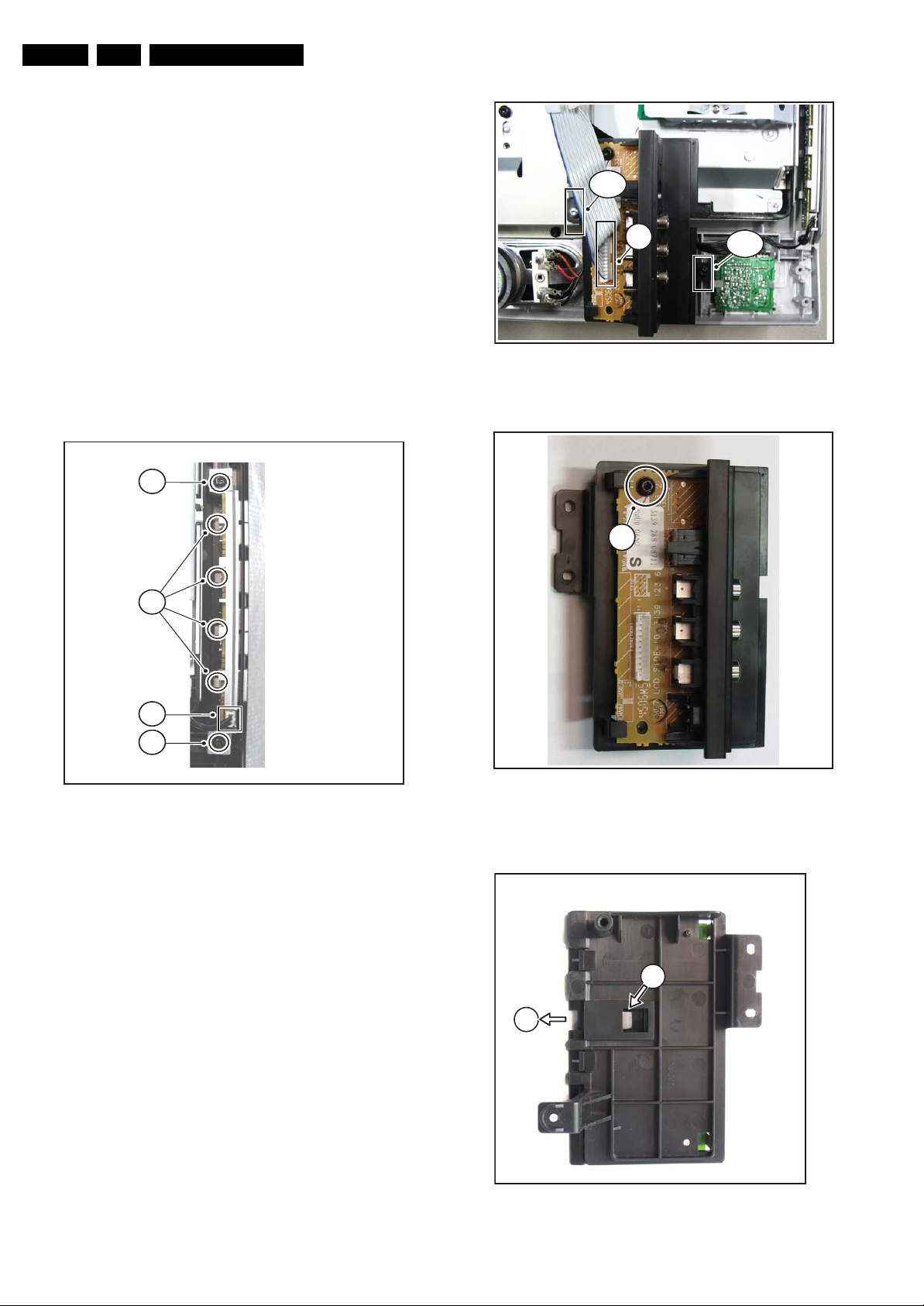

4.3.2 Keyboard Control Panel

1. Remove the rear cover, as described earlier.

2. Refer to fig. “Keyboard control panel” below.

3. Remove the T10 parker screws [1].

4. Unplug connector [2].

5. Remove the unit.

6. Release clips [3] and remove the board.

When defective, replace the whole unit.

1

Mechanical Instructions

b (1x)

a

Figure 4-9 Side I/O module

b (1x)

G_16860_066.ep

01020

3

2

1

Figure 4-8 Keyboard control panel

4.3.3 Side I/O Panel

1. Remove the rear cover, as described earlier.

2. Unplug connector [a].

3. Remove screws [b] and remove the complete module. One

of the screws is T10 tapping, the other one is T10 parker.

See fig. “Side I/O module”.

4. Remove T10 parker screw [c]. See fig. “Side I/O panel 1”.

5. Push catch [d] (located at the underside of the bracket) and

slide the unit to the right from its bracket [e]. See fig. “Side

I/O panel 2”.

6. To remove the PWB from its bracket, you have to lift the

catch [f] located on top of the headphone connector. At the

same time, slide the PWB out of its bracket [g]. See fig.

“Side I/O panel 3”.

When defective, replace the whole unit.

G_16850_007.eps

310707

c

Figure 4-10 Side I/O panel [1/3] top side

2d

2e

G_16860_075.eps

010207

G_16860_076.eps

010207

Figure 4-11 Side I/O panel [2/3] bottom side

Mechanical Instructions

4.3.5 Mid-range Speakers

1. Remove the rear cover, as described earlier.

2. Refer to fig. “Mid-range speakers” below.

3. Unplug connectors [1].

4. Remove T10 parker screws [2].

EN 13LC7.1L LA 4.

g

2

f

Figure 4-12 Side I/O panel [3/3]

4.3.4 IR/LED Panel

1. Remove the rear cover, as described earlier.

2. Refer to fig. “IR/LED panel” below.

3. Unplug connector(s) [1].

4. Release clip [2] and remove the board.

When defective, replace the whole unit.

1

G_16860_077.eps

010207

2 1 2

Figure 4-14 Mid-range speakers

4.3.6 Tweeters

1. Remove the rear cover, as described earlier.

2. Refer to fig. “Tweeters” below.

3. Unplug connectors [1].

4. Remove T10 parker screws [2].

2 1

Figure 4-15 Tweeters

G_16850_010.eps

110107

G_16850_011.eps

110107

2

Figure 4-13 IR/LED panel

G_16850_009.eps

110107

EN 14 LC7.1L LA4.

Mechanical Instructions

4.3.7 1080p Panel

1. Refer to next figure(s).

2. Unplug cables [a]. Be careful with the LVDS connectors as

they are very fragile.

3. Remove the fixation screws [b].

4. Take the board out (it hinges at the lower side).

5. Remove the screws [c] that fixate the top and bottom

shieldings, and remove the shieldings.

Note: Pay special attention not to damage the EMC foams.

Ensure that EMC foams are mounted correctly, especially

notice the large EMC foam “block” [d] at the bottom shielding.

b

c

a

c

c

b

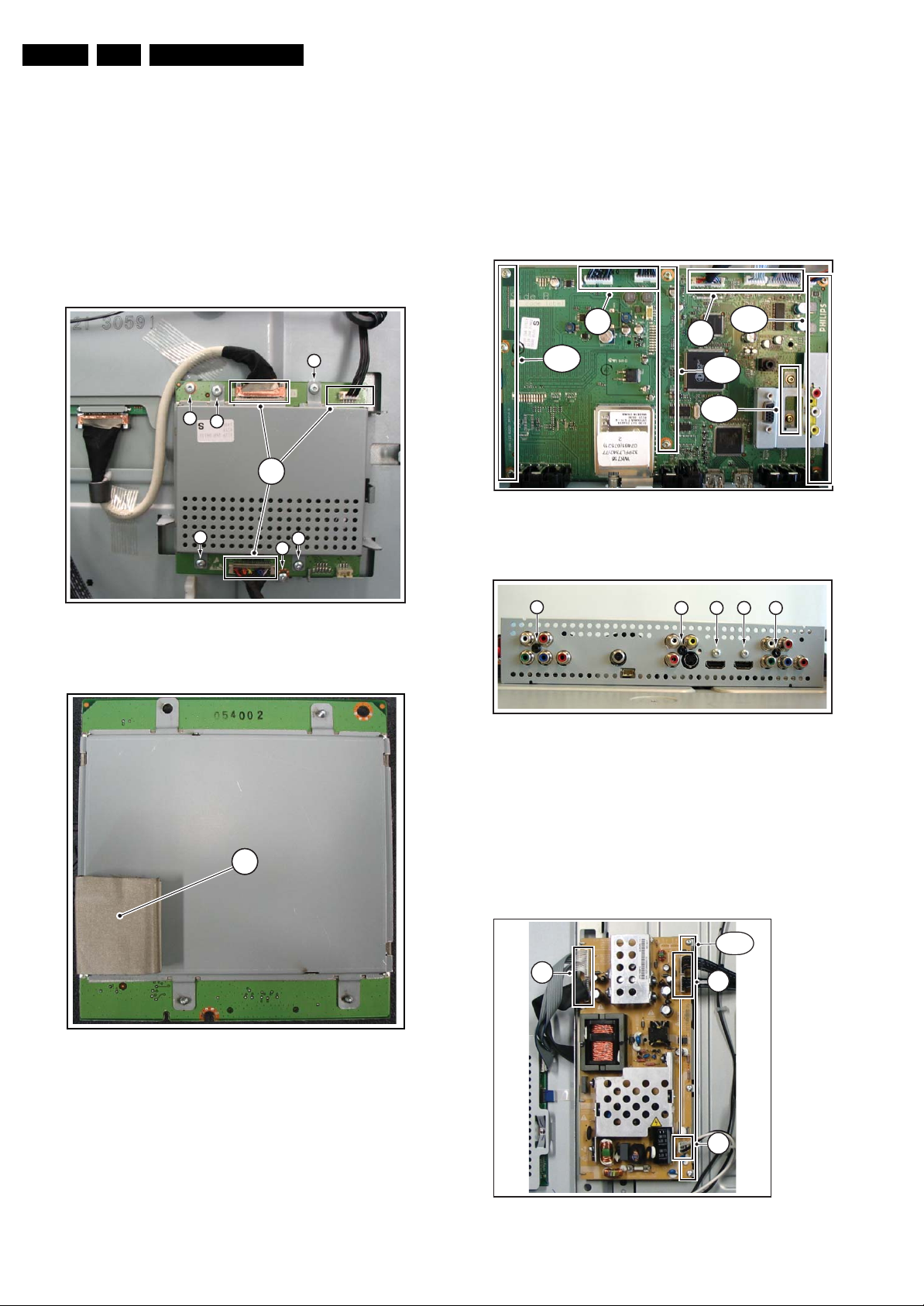

4.3.8 Small Signal Board (SSB)

1. Remove the rear cover, as described earlier.

2. Refer to figures “SSB removal” below.

3. Disconnect all cables [a] on the SSB.

4. Remove the T10 tapping screws [b] that hold the SSB. See

Figure “SSB removal”.

5. Remove the screws that hold the CINCH and HDMI

connectors at the connector panel.

6. Lift the SSB from the set.

a

c

b (3x)

b (3x)

a

b (2x)

b (2x)

H_17260_036.eps

050707

Figure 4-18 SSB removal -1-

Figure 4-16 1080p panel

d

G_16860_089.eps

150307

G_16860_088.eps

150307

b

Figure 4-19 SSB removal -2-

4.3.9 Main Supply Panel

1. Remove the rear cover, as described earlier.

2. Refer to fig. “Main supply panel” below.

3. Unplug cables [a].

4. Remove the fixation screws [b].

5. Take the board out (it hinges at the left side).

a

b bb b

H_17260_037.eps

b (3×)

a

050707

Figure 4-17 Bottom shielding 1 080p panel

a

G_16860_065.eps

Figure 4-20 Main supply panel

010207

Mechanical Instructions

EN 15LC7.1L LA 4.

4.3.10 LCD Panel

1. Remove the rear cover, as described earlier.

2. Refer to fig. “LCD panel” below.

3. Unplug the connectors on the Main Supply Panel [a] and

the LED & IR board [c].

4. Unplug the outer connectors [d] from the mid-range

loudspeakers.

5. Do NOT forget to unplug the LVDS connector [e] from the

SSB. Important: Be careful, as this is a very fragile

connector!

f (1x)

g (2x)

a

6. Remove T10 parker screw [b] that holds the Side I/O

module bracket.

7. Remove T10 parker screws [f] of the central sub-frame.

8. Remove LCD panel fixation screws [g] and lift the complete

central sub-frame from the set (including the PSU, SSB,

and Side I/O boards and wiring).

9. Lift the LCD panel [7] from the front cabinet.

e

g (2x)

f (3x)

b

d

f (2x)

d

c (1x)

G_16860_067.eps

310107

Figure 4-21 LCD panel [1/2]

4.4 Set Re-assembly

To re-assemble the whole set, execute all processes in reverse

order.

7

Notes:

• While re-assembling, make sure that all cables are placed

and connected in their original position. See figure “Cable

dressing”.

• Pay special attention not to damage the EMC foams.

Ensure that EMC foams are mounted correctly (one is

located above the LVDS connector on the display, between

the LCD display and the metal sub-frame).

Figure 4-22 LCD panel [2/2]

G_16850_015.eps

110107

EN 16 LC7.1L LA5.

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

Index of this chapter:

5.1 Test Points

5.2 Service Modes

5.3 Service Tools

5.4 Error Codes

5.5 The Blinking LED Procedure

5.7 Fault Finding and Repair Tips

5.1 Test Points

In the chassis schematics and layout overviews, the test points

(Fxxx) are mentioned. In the schematics, test points are

indicated with a rectangular box around “Fxxx” or “Ixxx”, in the

layout overviews with a “half-moon” sign.

As most signals are digital, it will be difficult to measure

waveforms with a standard oscilloscope. Several key ICs are

capable of generating test patterns, which can be controlled via

ComPair. In this way it is possible to determine which part is

defective.

Perform measurements under the following conditions:

• Service Default Mode.

• Video: Color bar signal.

• Audio: 3 kHz left, 1 kHz right.

5.2 Service Modes

The Service Mode feature is split into four parts:

• Service Default Mode (SDM).

• Service Alignment Mode (SAM).

• Customer Service Mode (CSM) and Digital Customer

Service Mode (DCSM).

• Computer Aided Repair Mode (ComPair).

SDM and SAM offer features, which can be used by the Service

engineer to repair/align a TV set. Some features are:

• A pre-defined situation to ensure measurements can be

made under uniform conditions (SDM).

• Activates the blinking LED procedure for error identification

when no picture is available (SDM).

• The possibility to overrule software protections when SDM

was entered via the Service pins.

• Make alignments (e.g. white tone), (de)select options,

enter options codes, reset the error buffer (SAM).

• Display information (“SDM” or “SAM” indication in upper

right corner of screen, error buffer, software version,

operating hours, options and option codes, submenus).

The (D)CSM is a Service Mode that can be enabled by the

consumer. Instructions on how to enable the CSM can be given

by telephone by either the dealer or the P3C (Philips Customer

Care Center). The CSM displays diagnosis information, which

the customer can forward to the dealer/P3C. In CSM mode,

“CSM”, is displayed in the top right corner of the screen.

The information provided in CSM and the purpose of CSM is to:

• Increase the home repair hit rate

• Decrease the number of nuisance calls

• Solved customers' problem without home visit

ComPair Mode is used for communication between a computer

and a TV on I2C /UART level and can be used by a Service

engineer to quickly diagnose the TV set by reading out error

codes, read and write in NVMs, communicate with ICs and the

uP (PWM, registers, etc.), and by making use of a faultfinding

database. It will also be possible to up and download the

software of the TV set via I2C with help of ComPair. To do this,

ComPair has to be connected to the TV set via the ComPair

connector, which will be accessible through the rear of the set

(without removing the rear cover).

5.2.1 General

Some items are applicable to all Service Modes or are general.

These are listed below.

Life Timer

During the life time cycle of the TV set, a life timer is kept. This

life timer counts the normal operation hours, but not the Standby hours. The actual value of the life timer is displayed in SDM

and CSM in a decimal value. Every two soft-resets should

increase the hour by +1. Minimal five digits are displayed.

Software Identification, Version, and Cluster

The software identification, version, and cluster will be shown

in the main menu display of SDM, SAM, and CSM.

The screen will show: “AAAABCD X.YY”, where:

• AAAA is the chassis name: LC71 for analogue range (nonDVB), LC72 for digital range (DVB).

• B is the region indication: E= Europe, A= AP/China, U=

NAFTA, L= LATAM.

• C is the display indication: L= LCD, P= Plasma.

• D is the language/features indication: 1= standard, H=

1080p full HD.

• X is the main version number: The main version number is

updated with a major change of specification (incompatible

with the previous software version). Numbering will go from

1 - 9 then from A - Z.

– If the main version number changes, the new version

number is written in the NVM

– If the main version number changes, the default

settings are loaded

• YY is the sub version number: The sub version number is

updated with a minor change (backwards compatible with

the previous versions) Numbering will go from 00 - 99.

– If the sub version number changes, the new version

number is written in the NVM

– If the NVM is fresh, the software identification, version,

and cluster will be written to NVM

Display Option Code Selection

When after a display exchange, the display option code is not

properly set, it will result in a TV with “no display”. Therefore, it

is required to set this display option code after such a repair.

To do so, press the following key sequence on a standard RC

transmitter: “062598” directly followed by MENU and “xxx”,

where “xxx” is a 3 digit decimal value of the panel type (see first

column in table “Option codes OP1...OP7” in Chapter

“Alignments” or sticker on the side/bottom of the cabinet).

When the value is properly accepted and stored in NVM, the

set will switch to Stand-by, to indicate that the process has

been completed successfully.

Display Option

Code

39mm

040

PHILIPS

MODEL:

32PF9968/10

27mm

PROD.SERIAL NO:

AG 1A0620 000001

(CTN Sticker)

Figure 5-1 Location of Display Option Code sticker

E_06532_038.eps

290107

Service Modes, Error Codes, and Fault Finding

s

7

During this algorithm, the NVM-content must be filtered,

because several items in the NVM are TV-related and not SSBrelated (e.g. Model and Prod. S/N). Therefore, “Model” and

“Prod. S/N” data is changed into “See Type Plate”.

In case a call centre or consumer reads “See Type Plate” in

CSM mode, he needs to look to the side/bottom sticker to

identify the set, for further actions.

EN 17LC7.1L LA 5.

5.2.2 Service Default Mode (SDM)

Purpose

Set the TV in SDM mode in order to be able to:

• Create a predefined setting for measurements to be made.

• Override software protections.

• Start the blinking LED procedure.

• Read the error buffer.

• Check the life timer.

Specifications

Table 5-1 SDM default settings

Region Frequency (MHz) Default system

Europe (except France),

475.25 PAL B/G

AP-PAL/-Multi

France SECAM L

NAFTA, AP-NTSC 61.25 (channel 3) NTSC M

LATAM PAL M

• Set linear video and audio settings to 50%, but volume to

25%. Stored user settings are not affected.

• All service-unfriendly modes (if present) are disabled, since

they interfere with diagnosing/repairing a set. These

service unfriendly modes are:

– (Sleep) timer.

– Blue mute/Wall paper.

– Auto switch “off” (when there is no “ident” signal).

– Hotel or hospital mode.

– Child lock or parental lock (manual or via V-chip).

– Skipping, blanking of “Not favorite”, “Skipped” or

“Locked” presets/channels.

– Automatic storing of Personal Preset or Last Status

settings.

– Automatic user menu time-out (menu switches back/

OFF automatically.

– Auto Volume levelling (AVL).

How to Activate

To activate SDM, use one of the following methods:

• Press the following key sequence on the remote control

transmitter: “062596” directly followed by the MENU button

(do not allow the display to time out between entries while

keying the sequence).

• Short one of the “Service” jumpers on the TV board during

cold start (see Figures “Service jumper”). Then press the

mains button (remove the short after start-up). Caution:

Activating SDM by shorting “Service” jumpers will override

the DC speaker protection (error 1), the General I2C error

(error 4), and the Trident video processor error (error 5).

When doing this, the service-technician must know exactly

what he is doing, as it could damage the television set.

SDMSDM

H_17270_016.eps

060707

Figure 5-2 Service jumper (SSB component side)

On Screen Menu

After activating SDM, the following screen is visible, with SDM

in the upper right corner of the screen to indicate that the

television is in Service Default Mode.

HHHHH A A A A B C D- X . Y Y

ERR XX XX XX XX XX

O P X X X X X X X X X X X X X X X X X X

SDM

G_16860_030.ep

26010

Figure 5-3 SDM menu

Menu explanation:

• HHHHH: Are the operating hours (in decimal).

• AAAABCD-X.YY: See paragraph “Service Modes” ->

“General” -> “Software Identification, Version, and Cluster”

for the SW name definition.

• SDM: The character “SDM” to indicate that the TV set is in

Service mode.

• ERR: Shows all errors detected since the last time the

buffer was erased. Five errors possible.

• OP: Used to read-out the option bytes. See “Options” in the

Alignments section for a detailed description. Seven codes

are possible.

How to Navigate

As this mode is read only, there is not much to navigate. To

switch to other modes, use one of the following methods:

• Command MENU from the user remote will enter the

normal user menu (brightness, contrast, color, etc...) with

“SDM” OSD remaining, and pressing MENU key again will

return to the last status of SDM again.

• To prevent the OSD from interfering with measurements in

SDM, command “OSD” (“STATUS” for NAFTA and

LATAM) from the user remote will toggle the OSD “on/off”

with “SDM” OSD remaining always “on”.

• Press the following key sequence on the remote control

transmitter: “062596” directly followed by the OSD/i+

button to switch to SAM (do not allow the display to time out

between entries while keying the sequence).

EN 18 LC7.1L LA5.

Service Modes, Error Codes, and Fault Finding

How to Exit

Switch the set to STANDBY by pressing the mains button on

the remote control transmitter or on the television set.

If you switch the television set “off” by removing the mains (i.e.,

unplugging the television), the television set will remain in SDM

when mains is re-applied, and the error buffer is not cleared.

The error buffer will only be cleared when the “clear” command

is used in the SAM menu.

Note:

• If the TV is switched “off” by a power interrupt while in SDM,

the TV will show up in the last status of SDM menu as soon

as the power is supplied again. The error buffer will not be

cleared.

• In case the set is in Factory mode by accident (with “F”

displayed on screen), by pressing and hold “VOL-” and

“CH-” together should leave Factory mode.

5.2.3 Service Alignment Mode (SAM)

Purpose

• To change option settings.

• To display / clear the error code buffer.

• To perform alignments.

Specifications

• Operation hours counter (maximum five digits displayed).

• Software version, error codes, and option settings display.

• Error buffer clearing.

• Option settings.

• Software alignments (Tuner, White Tone and Audio).

• NVM Editor.

• ComPair Mode switching.

• Set the screen mode to full screen (all contents on screen

are viewable).

How to Activate

To activate SAM, use one of the following methods:

• Press the following key sequence on the remote control

transmitter: “062596” directly followed by the OSD/

STATUS/INFO/i+ button (it depends on region which

button is present on the RC). Do not allow the display to

time out between entries while keying the sequence.

• Or via ComPair.

After entering SAM, the following screen is visible, with SAM in

the upper right corner of the screen to indicate that the

television is in Service Alignment Mode.

LLLL L A AAABCD- X. YY

ERR XX XX XX XX XX

O P X X X X X X X X X X X X X X X X X X

C l e a r > Y e s

O p t i o n s >

T u n e r >

R G B A l i g n >

N V M E d i t o r >

C o m p a i r >

S W E V E N T S >

Figure 5-4 SAM menu

Menu explanation:

1. LLLLL. This represents the run timer. The run timer counts

normal operation hours, but does not count Stand-by

hours.

2. AAAABCD-X.YY. See paragraph “Service Modes” ->

“General” -> “Software Identification, Version, and Cluster”

for the SW name definition.

3. SAM. Indication of the Service Alignment Mode.

4. ERR (ERRor buffer). Shows all errors detected since the

last time the buffer was erased. Five errors possible.

SAM

G_16860_031.eps

260107

5. OP (Option Bytes). Used to read-out the option bytes. See

“Options” in the Alignments section for a detailed

description. Seven codes are possible.

6. Clear. Erases the contents of the error buffer. Select the

CLEAR menu item and press the MENU RIGHT key. The

content of the error buffer is cleared.

7. Options. Used to set the option bits. See “Options” in the

“Alignments” chapter for a detailed description.

8. Tuner. Used to align the tuner. See “Tuner” in the

“Alignments” chapter for a detailed description.

9. RGB Align. Used to align the White Tone. See “White

Tone” in the “Alignments” chapter for a detailed

description.

10. NVM Editor. Can be used to change the NVM data in the

television set. See also paragraph “Fault Finding and

Repair Tips” further on.

11. ComPaIr. Can be used to switch the television to “In

Application Programming” mode (IAP), for software

uploading via ComPair. Read paragraph “Service Tools” > “ComPair”. Caution: When this mode is selected without

ComPair connected, the TV will be blocked. Remove the

AC power to reset the TV.

12. SW Events. Only to be used by development to monitor

SW behavior during stress test.

How to Navigate

• In the SAM menu, select menu items with the MENU UP/

DOWN keys on the remote control transmitter. The

selected item will be indicated. When not all menu items fit

on the screen, use the MENU UP/DOWN keys to display

the next / previous menu items.

• With the MENU LEFT/RIGHT keys, it is possible to:

– Activate the selected menu item.

– Change the value of the selected menu item.

– Activate the selected submenu.

• When you press the MENU button twice while in top level

SAM, the set will switch to the normal user menu (with the

SAM mode still active in the background). To return to the

SAM menu press the MENU button.

• Command “OSD/i+” key from the user remote will toggle

the OSD “on/off” with “SAM” OSD remaining always “on”.

• Press the following key sequence on the remote control

transmitter: “062596” directly followed by the MENU button

to switch to SDM (do not allow the display to time out

between entries while keying the sequence).

How to Store SAM Settings

To store the settings changed in SAM mode (except the

OPTIONS settings), leave the top level SAM menu by using the

POWER button on the remote control transmitter or the

television set.

How to Exit

Switch the set to STANDBY by pressing the mains button on

the remote control transmitter or the television set.

Note:

• When the TV is switched “off” by a power interrupt while in

SAM, the TV will show up in “normal operation mode” as

soon as the power is supplied again. The error buffer will

not be cleared.

• In case the set is in Factory mode by accident (with “F”

displayed on screen), by pressing and hold “VOL-” and

“CH-” together should leave Factory mode.

Service Modes, Error Codes, and Fault Finding

EN 19LC7.1L LA 5.

5.2.4 Customer Service Mode (CSM)

Purpose

The Customer Service Mode shows error codes and

information on the TV’s operation settings. A call centre can

instruct the customer (by telephone) to enter CSM in order to

identify the status of the set. This helps them to diagnose

problems and failures in the TV before making a service call.

The CSM is a read-only mode; therefore, modifications are not

possible in this mode.

Specifications

• Ignore “Service unfriendly modes”.

• Line number for every line (to make CSM language

independent).

• Set the screen mode to full screen (all contents on screen

are viewable).

• After leaving the Customer Service Mode, the original

settings are restored.

• Possibility to use “CH+” or “CH-” for channel surfing, or

enter the specific channel number on the RC.

How to Activate

To activate CSM, press the following key sequence on the

remote control transmitter: “123654” (do not allow the display

to time out between entries while keying the sequence).

Upon entering the Customer Service Mode, the following

screen will appear:

1 M O D E L : 3 2 P F L 5 5 2 2 D / 1

2 P R O D S / N : AG1A0712123456

3 S W I D : L C 7 1 E L 1 - 1 . x x

4 O P : X X X X X X X X X X X X X X X X X X X X X

5 C O D E S : X X X X X X X X X X

6 S S B : 3 1 39 127 12341

7 N V M : X X X X X X X X

8 F l a s h D a t a : X X . X X . X X . X X

9 L I F E T I M E R : L L L L L

1 0 T U N E R : W E A K / G O O D / S T R O N G

1 1 S Y S T E M : P A L / N T S C / S E C A M

1 2 S O U N D : M O N O / S T E R E O / N I C A M

1 3 H D A U : Y E S / N O

1 4 F O R M A T : X X X X X X X X

0

Figure 5-5 CSM menu

Menu Explanation

1. MODEL. Type number, e.g. 32PFL5522D/10. (*)

2. PROD S/N. Product serial no., e.g. AG1A0712123456. (*)

3. SW ID. Software cluster and version is displayed.

4. OP. Option code information.

5. CODES. Error buffer contents.

6. SSB. Indication of the SSB factory identification code

(12nc). (*)

7. NVM. The NVM software version no.

8. Flash Data. PQ (picture quality) and AQ (audio quality)

data version. This is a sub set of the main SW.

9. LIFE TIMER. Operating hours indication.

10. TUNER. Indicates the tuner signal condition: “Weak” when

signal falls below threshold value, “Medium” when signal is

at mid-range, and “Strong” when signal falls above

threshold value.

11. SYSTEM. Gives information about the video system of the

selected transmitter (PAL/SECAM/NTSC).

12. SOUND. Gives information about the audio system of the

selected transmitter (MONO/STEREO/NICAM).

13. HDAU. HDMI audio stream detection. “YES” means audio

stream detected. “NO” means no audio stream present.

Only displayed when HDMI source is selected.

14. FORMAT. Gives information about the video format of the

selected transmitter (480i/480p/720p/1080i).

15. HD SW ID. Software version of the 1080p full HD module

(when present).

16. Reserved.

17. Reserved.

18. Reserved.

CS M

G_16860_032.eps

210207

(*) If an NVM IC is replaced or initialized, this data must be rewritten to the NVM. ComPair will foresee in a possibility to do

this.

How to Exit

To exit CSM, use one of the following methods:

• Press the MENU button twice, or POWER button on the

remote control transmitter.

• Press the POWER button on the television set.

5.3 Service Tools

5.3.1 ComPair

Introduction

ComPair (Computer Aided Repair) is a Service tool for Philips

Consumer Electronics products. and offers the following:

1. ComPair helps you to quickly get an understanding on how

to repair the chassis in a short and effective way.

2. ComPair allows very detailed diagnostics and is therefore

capable of accurately indicating problem areas. You do not

have to know anything about I2C or UART commands

yourself, because ComPair takes care of this.

3. ComPair speeds up the repair time since it can

automatically communicate with the chassis (when the uP

is working) and all repair information is directly available.

4. ComPair features TV software upgrade possibilities.

Specifications

ComPair consists of a Windows based fault finding program

and an interface box between PC and the (defective) product.

The (new) ComPair II interface box is connected to the PC via

an USB cable. For the TV chassis, the ComPair interface box

and the TV communicate via a bi-directional cable via the

service connector(s).

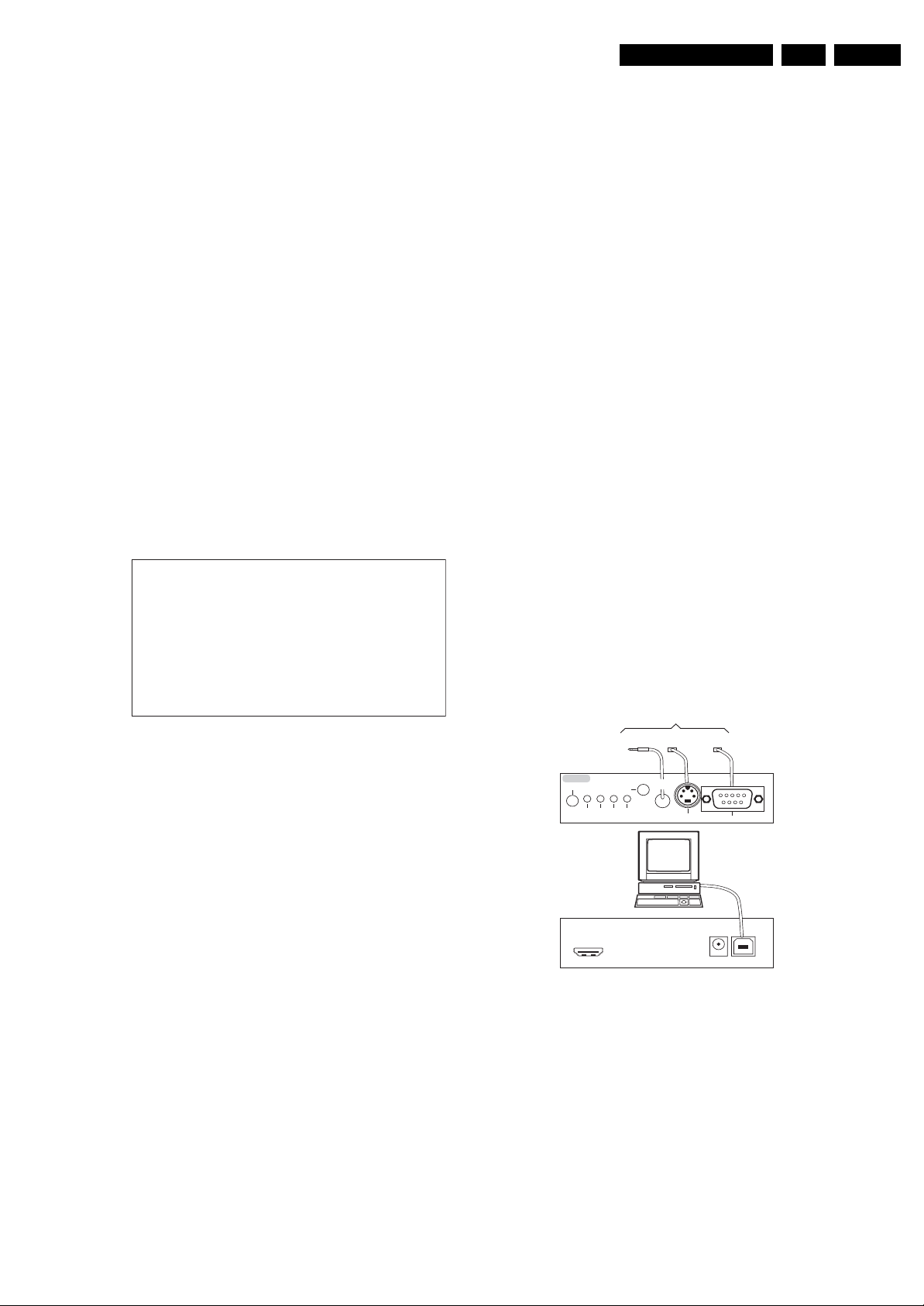

How to Connect

This is described in the ComPair chassis fault finding database.

TO TV

TO

UART SERVICE

I2C SERVICE

CONNECTOR

CONNECTOR

2

C

I

PC

ComPair II Developed by Philips Brugge

Optional power

5V DC

TO

RS232 /UART

G_06532_036.eps

240807

TO

UART SERVICE

CONNECTOR

ComPair II

RC in

Optional

Switch

Power ModeLink/

Activity

HDMI

2

I

C only

RC out

Multi

function

Figure 5-6 ComPair II interface connection

Caution: It is compulsory to connect the TV to the PC as

shown in the picture above (with the ComPair interface in

between), as the ComPair interface acts as a level shifter. If

one connects the TV directly to the PC (via UART), ICs will be

blown!

EN 20 LC7.1L LA5.

Service Modes, Error Codes, and Fault Finding

How to Order

ComPair II order codes:

• ComPair II interface: 3122 785 91020.

• ComPair32 CD (update): 3122 785 60160.

•ComPair I

with chassis L01, A02, A10, EMx, TPM1.xA, etc...).

•ComPair I

2

C interface cable: 3122 785 90004 (to be used

2

C interface extension cable: 3139 131 03791 (to

be used with chassis L01, A02, A10, L04, LC4, LC7.1,

LC7.2).

• ComPair UART interface cable: 3122 785 90630 (to be

used with chassis LC4, EJ3, BJ2, BL2, BP2,...).

• ComPair RS232 cable: 3104 311 12742 (to be used with

chassis Q52x).

•ComPair I

2

C interface cable (3.5 mm Jack-to-SVHS plug):

9965 100 07325 (to be used with chassis LC7.5).

Note: For I2C it is compulsory to use this particular cable.

• ComPair UART interface cable (3.5 mm Jack-to-Jack):

3138 188 75051 (to be used with chassis LC7.5).

Note: For UART it is also allowed to use a standard “Jackto-Jack” cable.

Note: If you encounter any problems, contact your local

support desk.

5.3.2 LVDS Tool

Support of the LVDS Tool has been discontinued.

5.4 Error Codes

5.4.1 Introduction

Error codes are required to indicate failures in the TV set. In

principle a unique error code is available for every:

• Activated protection.

• Failing I2C device.

• General I2C error.

• SDRAM failure.

The last five errors, stored in the NVM, are shown in the

Service menu’s. This is called the error buffer.

The error code buffer contains all errors detected since the last

time the buffer was erased. The buffer is written from left to

right. When an error occurs that is not yet in the error code

buffer, it is displayed at the left side and all other errors shift one

position to the right.

An error will be added to the buffer if this error differs from any

error in the buffer. The last found error is displayed on the left.

An error with a designated error code may never lead to a

deadlock situation. This means that it must always be

diagnosable (e.g. error buffer via OSD or blinking LED

procedure, ComPair to read from the NVM).

In case a failure identified by an error code automatically

results in other error codes (cause and effect), only the error

code of the MAIN failure is displayed.

Example: In case of a failure of the I2C bus (CAUSE), the error

code for a “General I2C failure” and “Protection errors” is

displayed. The error codes for the single devices (EFFECT) is

not displayed. All error codes are stored in the same error

buffer (TV’s NVM) except when the NVM itself is defective.

5.4.2 How to Read the Error Buffer

You can read the error buffer in 3 ways:

• On screen via the SAM/SDM/CSM (if you have a picture).

Example:

– ERROR: 0 0 0 0 0 : No errors detected

– ERROR: 6 0 0 0 0 : Error code 6 is the last and only

detected error

– ERROR: 9 6 0 0 0 : Error code 6 was detected first and

error code 9 is the last detected (newest) error

• Via the blinking LED procedure (when you have no

picture). See “The Blinking LED Procedure”.

•Via ComPair.

5.4.3 Error Codes

In case of non-intermittent faults, write down the errors present

in the error buffer and clear the error buffer before you begin

the repair. This ensures that old error codes are no longer

present.

If possible, check the entire contents of the error buffer. In

some situations, an error code is only the result of another error

and not the actual cause of the problem (for example, a fault in

the protection detection circuitry can also lead to a protection).

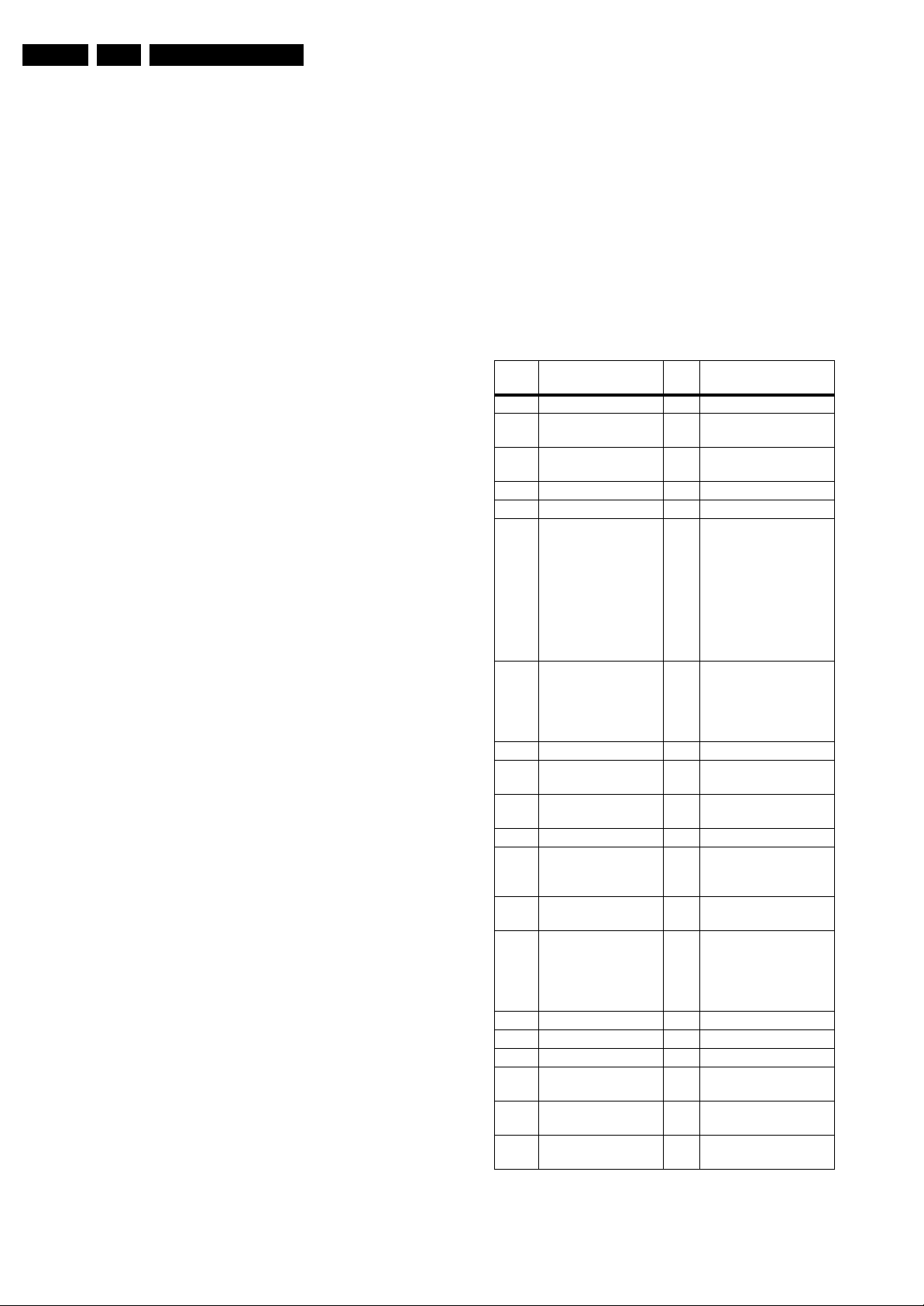

Table 5-2 Error code overview

Error

code

1)

Description

Item

no. Remarks

0 No error.

1 DC Protection of

speakers.

2 +12V protection

12V missing or “low”.

error.

3 Reserved.

4 General I2C error. note 2

5 Trident Video

Processor

communication error.

7202 When Trident IC is

defective, error 10 and

14 might also be

reported. Trident

communicates via

parallel bus, not via the

I2C bus. The I2C bus of

Trident is only used in

ComPair mode.

6 I2C error while

communicating with

the NVM.

7315 The TV will not start-up

due to critical data not

available from the

NVM, but the LED will

blink the error code.

7 I2C error Tuner. 1101

8 I2C error IF

7113

Demodulator.

9 I2C error Sound

7411

Processor.

10 SDRAM defective. 7204

11 I2C error while

7817

communicating with

the HDMI IC.

12 I2C error MOJO

7G00 if applicable

PNX8314.

13 DVB HW

communication error.

7F01

,

if applicable

7K00

,

7G00

14 SDRAM defective. 7205

15 Reserved.

16 Reserved.

17 I2C error FPGA

if applicable

AmbiLight module.

18 I2C error iBoard

if applicable

processor.

19 I2C error 1080p

if applicable

module.

Notes

1. Some of the error codes reported are depending on the

option code configurations.

Service Modes, Error Codes, and Fault Finding

EN 21LC7.1L LA 5.

2. This error means: no I2C device is responding to the

particular I2C bus. Possible causes: SCL/SDA shorted to

GND, SCL shorted to SDA, or SCL/SDA open (at uP pin).

The internal bus of the Trident platform should not cause

the entire system to halt as such an error can be reported.

5.4.4 How to Clear the Error Buffer

The error code buffer is cleared in the following cases:

• By using the CLEAR command in the SAM menu:

– To enter SAM, press the following key sequence on the

remote control transmitter: “062596” directly followed

by the OSD/i+ button (do not allow the display to time

out between entries while keying the sequence).

– Make sure the menu item CLEAR is selected. Use the

MENU UP/DOWN buttons, if necessary.

– Press the MENU RIGHT button to clear the error

buffer. The text on the right side of the “CLEAR” line will

change from “CLEAR?” to “CLEARED”

• If the contents of the error buffer have not changed for 50

hours, the error buffer resets automatically.

Note: If you exit SAM by disconnecting the mains from the

television set, the error buffer is not reset.

5.5 The Blinking LED Procedure

5.5.1 Introduction

The software is capable of identifying different kinds of errors.

Because it is possible that more than one error can occur over

time, an error buffer is available, which is capable of storing the

last five errors that occurred. This is useful if the OSD is not

working properly.

Errors can also be displayed by the blinking LED procedure.

The method is to repeatedly let the front LED pulse with as

many pulses as the error code number, followed by a period of

1.5 seconds in which the LED is “off”. Then this sequence is

repeated.

Example (1): error code 4 will result in four times the sequence

LED “on” for 0.25 seconds / LED “off” for 0.25 seconds. After

this sequence, the LED will be “off” for 1.5 seconds. Any RC5

command terminates the sequence. Error code LED blinking is

in red color.

Example (2): the content of the error buffer is “129600”

After entering SDM, the following occurs:

• 1 long blink of 5 seconds to start the sequence,

• 12 short blinks followed by a pause of 1.5 seconds,

• 9 short blinks followed by a pause of 1.5 seconds,

• 6 short blinks followed by a pause of 1.5 seconds,

• 1 long blink of 1.5 seconds to finish the sequence,

• The sequence starts again with 12 short blinks.

5.5.2 Displaying the Entire Error Buffer

5.6 TV Main Software Upgrade

For instructions on how to upgrade the TV Main software, refer

to ComPair.

5.7 Fault Finding and Repair Tips

Notes:

• It is assumed that the components are mounted correctly

with correct values and no bad solder joints.

• Before any fault finding actions, check if the correct options

are set.

5.7.1 NVM Editor

In some cases, it can be convenient if one directly can change

the NVM contents. This can be done with the “NVM Editor” in

SAM mode. With this option, single bytes can be changed.

Caution:

• Do not change the NVM settings without

understanding the function of each setting, because

incorrect NVM settings may seriously hamper the

correct functioning of the TV set!

• Always write down the existing NVM settings, before

changing the settings. This will enable you to return to the

original settings, if the new settings turn out to be incorrect.

Table 5-3 NVM editor overview

Hexadecimal Decimal Description

.ADR 0x000A 10 Existing value

.VAL 0x0000 0 New value

.Store Store?

5.7.2 Load Default NVM Values

It is possible to download default values automatically into the

NVM in case a blank NVM is placed or when the NVM first 20

address contents are “FF”. After the default values are

downloaded, it is possible to start-up and to start aligning the

TV set. To initiate a forced default download the following

action has to be performed:

1. Switch “off” the TV set with the mains cord disconnected

from the wall outlet (it does not matter if this is from

“Standby” or “Off” situation).

2. Short-circuit the SDM jumpers on the SSB (keep short

circuited).

3. Press “P+” or “CH+” on the local keyboard (and keep it

pressed).

4. Reconnect the mains supply to the wall outlet.

5. Release the “P+” or “CH+” when the set is “on” or blue LED

is blinking.

When the downloading has completed successfully, the set

should be into Standby, i.e. red LED on.

Additionally, the entire error buffer is displayed when Service

Mode “SDM” is entered. In case the TV set is in protection or

Stand-by: The blinking LED procedure sequence (as in SDMmode in normal operation) must be triggered by the following

RC sequence: “MUTE” “062500” “OK”.

In order to avoid confusion with RC5 signal reception blinking,

this blinking procedure is terminated when a RC5 command is

received.

To erase the error buffer, the RC command “MUTE” “062599

“OK” can be used.

Alternative method (1):

1. Go to SAM.

2. Select NVM Editor.

3. Select ADR (address) to 001 (dec).

4. Change the VAL (value) to 170 (dec).

5. Store the value.

6. Do a hard reset to make sure new default values took

place.

Alternative method (2):

It is also possible to upload the default values to the NVM with

ComPair in case the SW is changed, the NVM is replaced with

a new (empty) one, or when the NVM content is corrupted.

After replacing an EEPROM (or with a defective/no EEPROM),

default settings should be used to enable the set to start-up and

EN 22 LC7.1L LA5.

allow the Service Default Mode and Service Alignment Mode to

be accessed.

5.7.3 Replacing the SSB flash IC

When you have to replace the SSB flash IC (item 7310), refer

to the Spare Parts list for the correct order number. You will

then receive a pre-programmed flash IC which contains the

boot-loader firmware. Without this firmware, you cannot

program the TV with ComPair. Therefore you must order the

pre-programmed flash IC, which you will receive when using

the order number which is listed in the Spare Parts list.

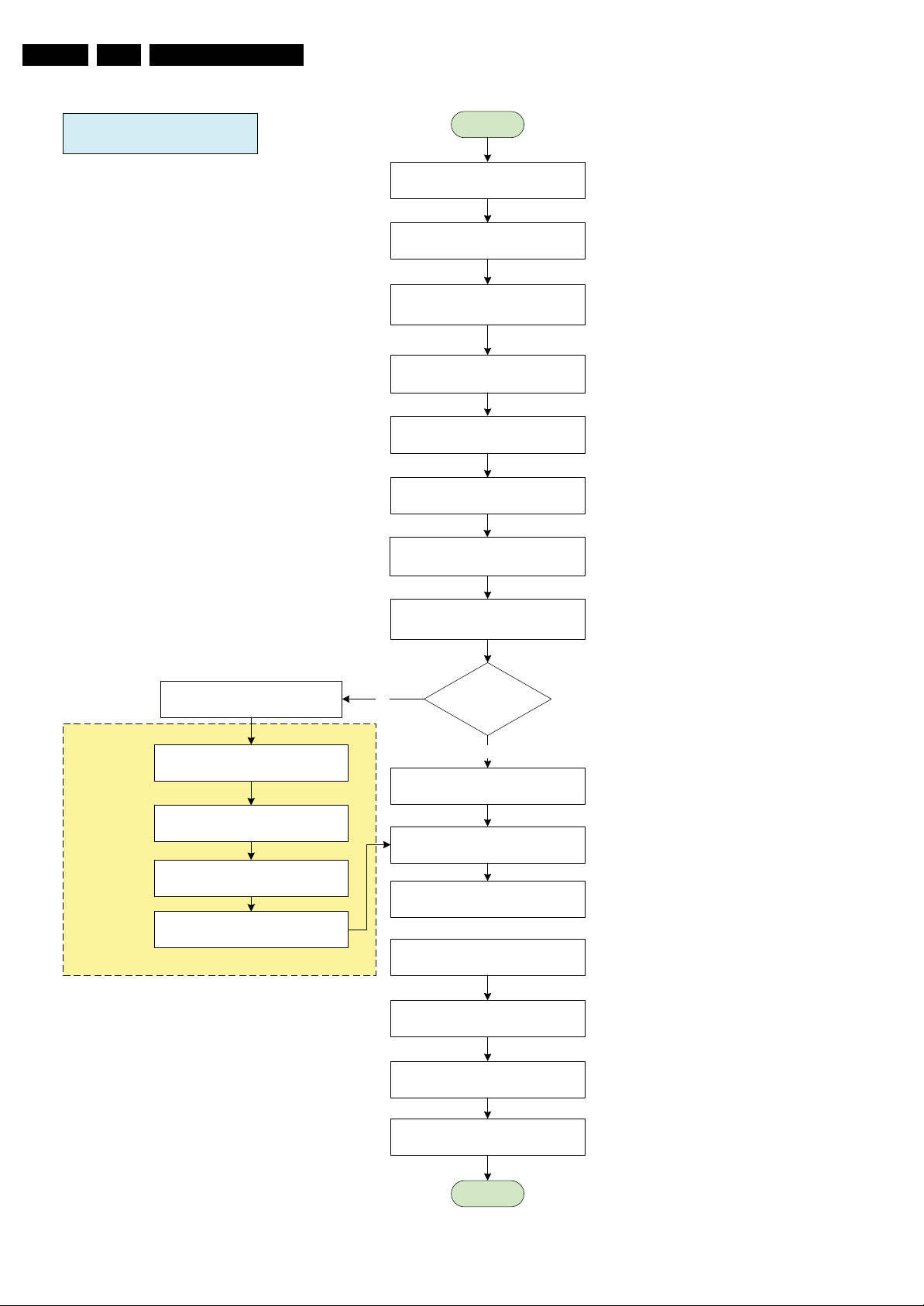

5.7.4 Start-up/Shut-down Flowcharts

Important note for DVB sets:

• When you put a DVB set into Stand-by mode with an RC,

the set will go to “Semi Stand-by” mode for 5 minutes. This,

to facilitate “Off the Air download” (OAD). If there is no

activity within these 5 minutes, the set will switch to Standby mode. In “Semi Stand-by” mode, the LCD backlight and

Audio Amplifier are turned “off” but other circuits still work

as normal. The customer might think the set is in Stand-by.

However, in real Stand-by mode, only the uP and the NVM

are alive and all other circuits are switched “off”.

• If you press the mains switch at the local key board in a

DVB set, the set will switch to Stand-by mode.

Service Modes, Error Codes, and Fault Finding

On the next pages you will find start-up and shut-down

flowcharts, which might be helpful during fault finding.

It should be noted, that some events are only related to PDP

sets, and therefore not applicable to this LCD chassis.

Start Up

Service Modes, Error Codes, and Fault Finding

AC ON

+5VSTBY & +3V3STBY Available (1)

RENEAS POR by +3VSTBY (2)

STANDBYn = LOW

InitCold Component:

1. Check SDM port.

- If SDM pin = LOW and NVM first 20Byte =

0xFF, reload Software default NVM value.

2. Check Panel port.

- If Panel Pin = LOW and check slave address

0x65 = 0xA5, Enter Panel Mode.

No

Last status is ON?

Yes

Read NVM completed.

STOP I²C activities.

LED = BLUE for Normal mode

LED = RED for Recording mode

BLOCK RC Key

M16C RST_H = HIGH

RST_HDMI = LOW

RST_AUD = LOW

RESET_n = LOW

LCD_PWR_ON = LOW

SDI PDP => CTRL_DISP1 = LOW

Error 6 - NVM

[Protection]

Standby Normal Mode

(RED LED)

Port Assignment in STANDBY

Wait for RC key or

Wake up event

160ms

(1) +5VSTBY to be measured

at PDTC114ET (item 7322)

(2) to be measured at pin 4

of BD45275G (item 7312)

User wake up the sets

in DVB recording mode

LCD_PWR_ON = HIGH

(Same function as CTRL-DISP2)

SDI PDP => CTRL_DISP1 = LOW

20ms

1000ms to

1500ms

Wait for 20 ms

Switch ON LVDS Signal

Init. Warm Component

(For software)

EN 23LC7.1L LA 5.

Error 2

[Protection]

Notes:

---------

1. LC07 TV software only start communication with IBOZ once

receive the INT message from IBOZ.

For DVB Sets only (Semistandby)

Recording mode

SDI PDP => CTRL_DISP1 = HIGH

Recording Mode finished

Software Shutdown:

WP for NVM

Port Assignment in STANDBY

Wait for 100ms

Time out = 2000ms

Yes

500ms

100ms

Error 7

Error 8

Error 9

Error 11

1700ms

Error 3

[Protection]

STANDBYn = HIGH

(Same function as CTRL-DISP3)

Wait for 500ms

Is Power Down =

No

BL_ADJ = HIGH (100% Duty Cycle)

HIGH?

Yes

Wait for 100ms

M16C RST_H to LOW

RST_HDMI = HIGH

RST_AUD = HIGH

RESET_n = HIGH

Enable Power Down INT

Enable DC_PROT INT

Initialise Tuner

Initialise IF Demodulator, Afric

TDA9886T

Initialise Micronas

Mute Audio

Initialise HDMI, Sil9023

Initialise Trident CX

DPTVInit( )

Initialise FHP Panel

* For FHP PDP Sets only

Initialise Bolt-ON

* For iTV, 1080P, Ambi Light

For LCD:

BL_ON_OFF = HIGH

* BL_ADJ keep 100% for 3000ms

before dimming.

Blank Picture

Picture Mode Setup & Detection

unBlank Picture &

UnMute Audio

No

Error 5 - Trident

[Protection]

Error 10 – SDRAM 7204

[Protection]

Error 14 – SDRAM 7205

[Protection]

Error 17 – AmbiLight

Error 18 – iTV iFace

End

For PDP:

3000ms delay

STANDBYn = LOW

Standby

Normal Mode

Enable RC Key

DVB recording mode

Figure 5-7 Start-up flowchart

Error 19 – 1080P

G_16860_070.eps

220207

EN 24 LC7.1L LA5.

Service Modes, Error Codes, and Fault Finding

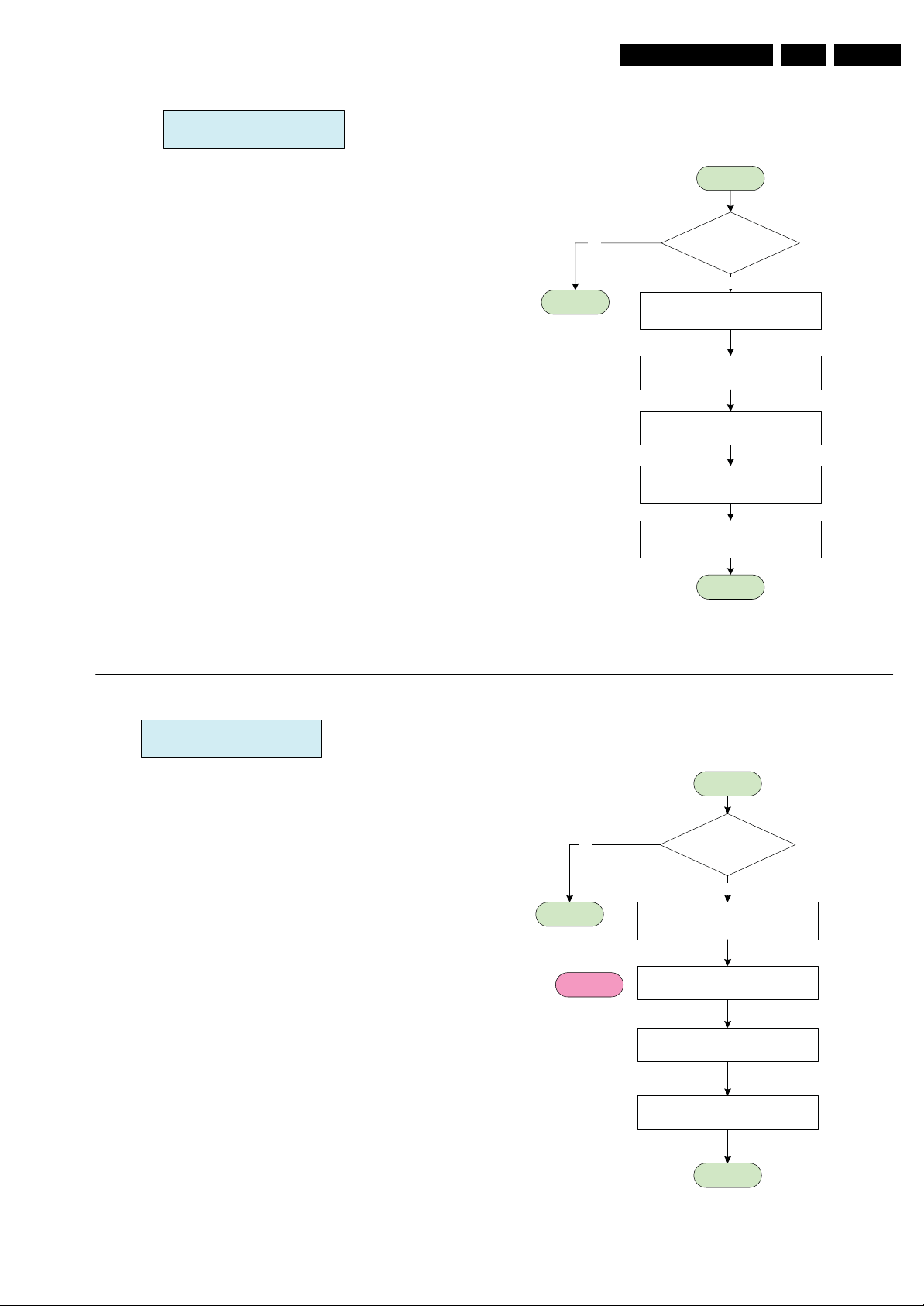

SEMISTANDBY/ STANDBY

300ms

20ms

Start

Mute Audio

BL_ADJ stop dimming

(PWM duty cycle 100%)

BL_ON_OFF = LOW

Wait 300ms

Switch OFF LVDS

Wait 20ms

LCD_PWR_ON = LOW

LED = RED No

For DVB Sets only (Semistandby)

Wait for 3000ms

Except power tact switch

SDI PDP => CTRL_DISP1 = HIGH

Off Air Downloading/ Recording Mode

IBOZ send shut down command

Software Shutdown:

Standby using

“power key”

Yes

LED = NO LED

for Standby soft mode

Disable Power Down INT &

DC_PROT_INT

BL_ADJ = LOW

(PWM duty cycle 0%)

WriteProtect for NVM

Port Assignment in STANDBY

Sets go to standby here

40ms

Total = 360ms

STANDBYn = LOW

Wait for 3000ms

End

Figure 5-8 Semi Stand-by/Stand-by flowchart

Blocking for the next start up to ensure

power supply discard properly.

G_16860_071.eps

220207

Service Modes, Error Codes, and Fault Finding

Power Down INT:

AC OFF or Transient INT

EN 25LC7.1L LA 5.

Start

Notes:

1. Power Down INT will be based on fall edge triggering

2. +3V3STBY will stay for 15ms, software must perform

WriteProtect for NVM within 15ms.

Avoid false trigger

No

End

Poll the Power Down

INT for 5 times

Yes

Mute Audio & VIdeo

WriteProtect for NVM

STANDBYn = LOW

Wait 5000 ms

Re-start: Start up

End

DC_PROT INT

Avoid false trigger

No

End

Error 1

[Protection]

Start

is DC_PROT = LOW

for 3 sec?

Yes

Mute Audio & VIdeo

Log Error Code

WriteProtect for NVM

STANDBYn = LOW

End

G_16860_072.eps

220207

Figure 5-9 Power Down & DC_PROT flowchart

EN 26 LC7.1L LA5.

Personal Notes:

Service Modes, Error Codes, and Fault Finding

E_06532_012.eps

131004

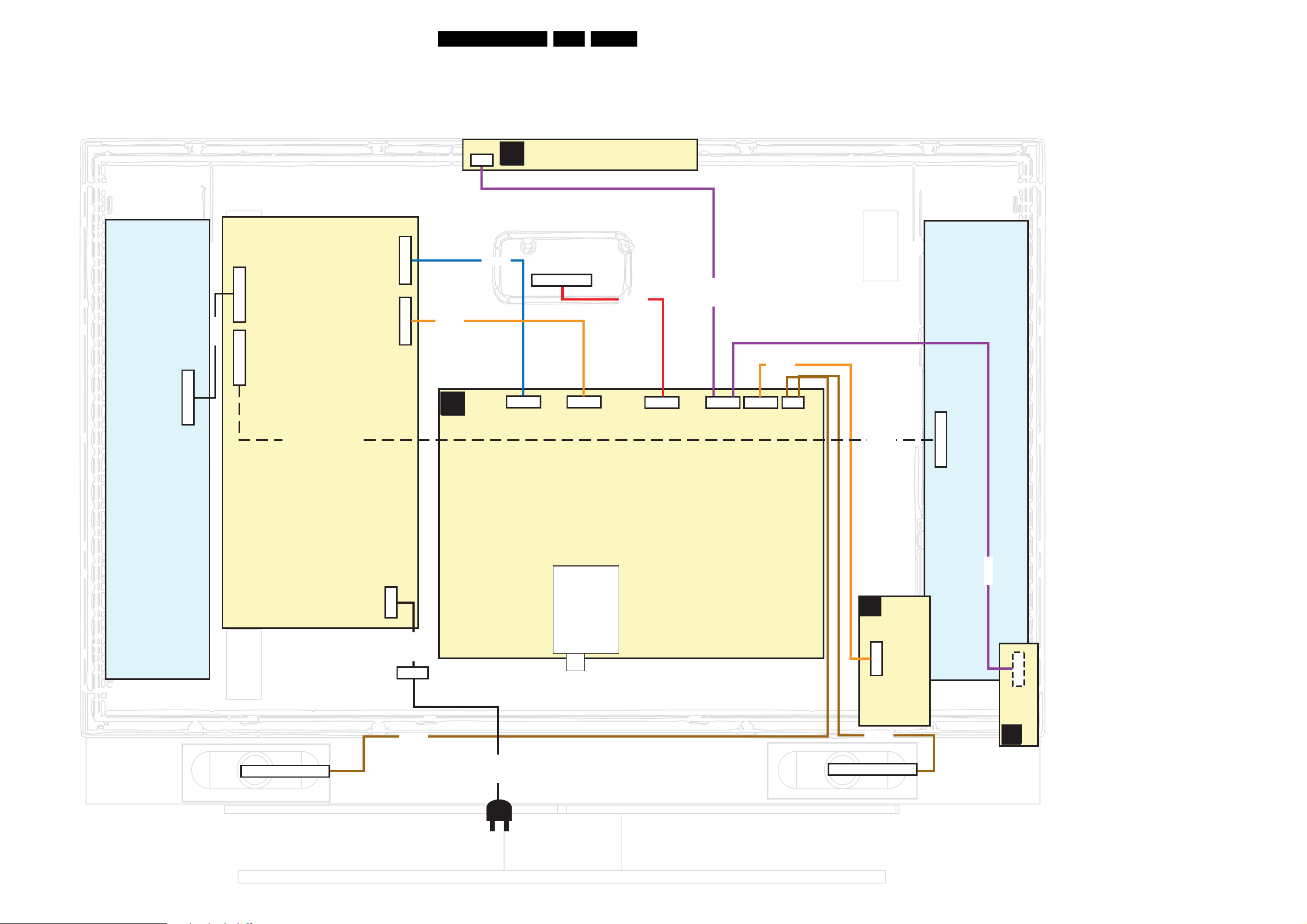

Block Diagrams, Test Point Overview, and Waveforms

6. Block Diagrams, Test Point Overview, and Waveforms

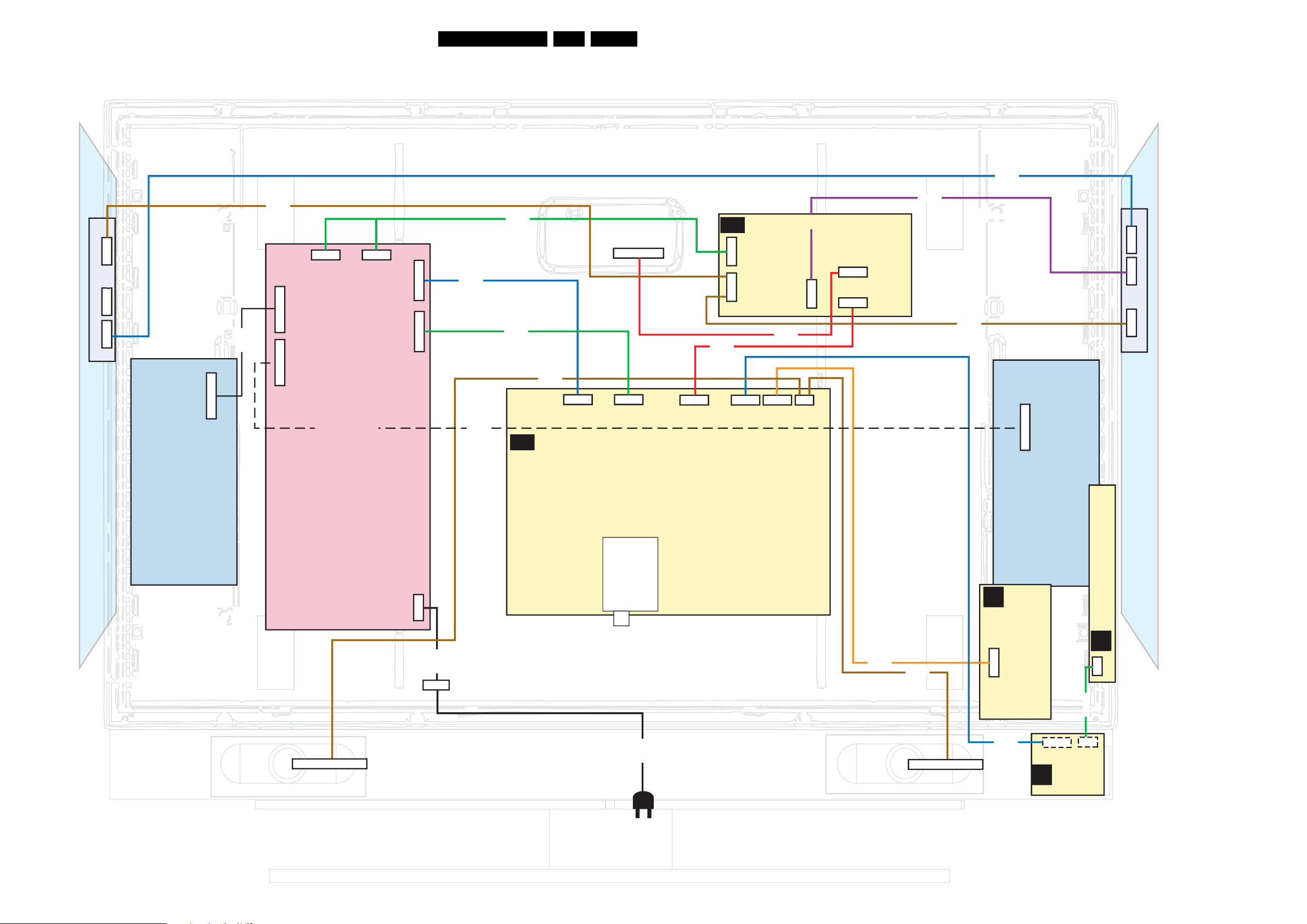

Wiring Diagram 26” (ME5P)

27LC7.1L LA 6.

WIRING 26”

INVERTER

(STYLING ME5P)

14P

CN2

8521

12P

CN3

14P

CN2

SUPPLY

(1005)

ONLY USED

FOR LPL PANELS

CN6

CN7

9P

8P

8P11

B

1684

3P

8C01

SSB

KEYBOARD CONTROL

E

(1114)

LCD DISPLAY

(1004)

LV DS

30P

8G51

9P

1C01

8P

1P11

30P

1G51

8M20

7P

1M20

11P

1304

8304

4P

1735

8520

INVERTER

ONLY FOR LPL

PANELS

12P

CN3

RIGHT SPEAKER

CN1

2P3

INLET

8735

8002

8191

TUNER

SIDE I/O

D

(1116)

11P

1304

8735

LEFT SPEAKER

8M20

6P

1870

IR/LED/LIGHT

SENSOR

(1112)

J

H_17260_014.eps

021007

Block Diagrams, Test Point Overview, and Waveforms

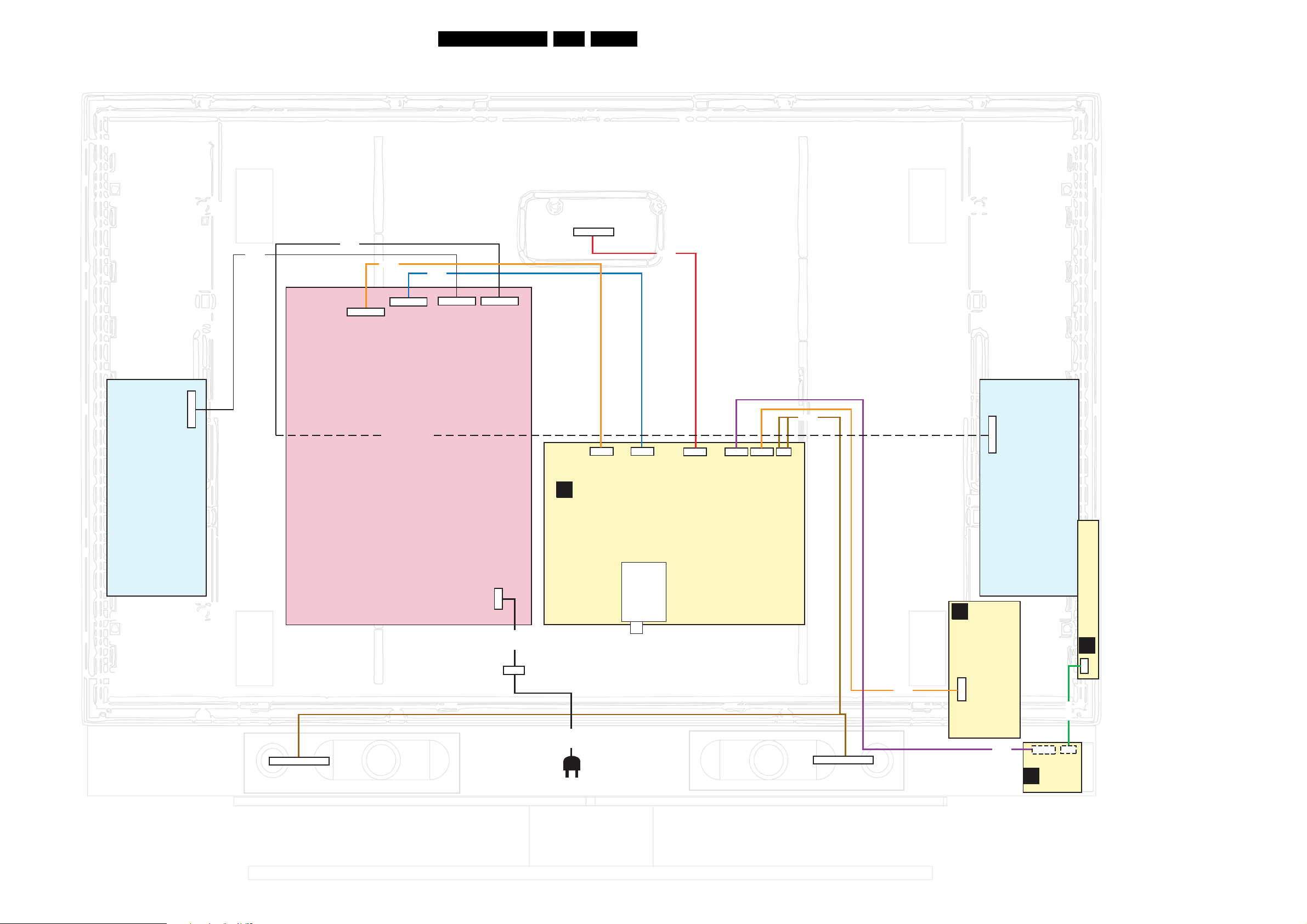

Wiring Diagram 26” - 32” (ME7)

WIRING 26”- 32” LCD

28LC7.1L LA 6.

(STYLING ME7)

CN2

DISPLAY SUPPLY

1. +24V

2. +24V

3. +2 4V

4. +24V

5. +24V

6. GND

7. GND

8. GN D

9. GND

10. GND

11. DIM

12. BL-ON

13. PWM

14. N.C.

CN3

DISPLAY SUPPLY

1. +24V

2. +24V

3. +2 4V

4. +24V

5. +24V

6. GND

7. GND

8. GN D

9. GND

10. GND

11. N.C.

12. N.C.

CN7

CONTROL:

1. -12VA

2. +12VA

3. GN D

4. 5.2VS

5. 5.2VS

6. 5.2VS

7. GND

8. GN D.

9. GND

14P

CN2

INVERTER

CN6

CONTROL:

1. BL-DIM

2. PG

3. BL-ON

4. GND

5. N.C.

6. PSON

7. N.C.

8. 12 V

8521

14P

CN2

12P

CN3

MAIN SUPPLY

(1005)

ONLY USED

FOR LPL PANEL

CN6

CN7

LCD DISPLAY

(1004)

LV DS

30P

9P

8P

8C01

8520

8P11

B

8735

SSB

9P

1C01

8P

1P11

8G51

30P

1G51

7P

1M20

11P

1304

4P

1735

12P

CN3

INVERTER

RIGHT SPEAKER

(5200)

CN1

2P3

INLET

8002

TUNER

8191

8192(UK)

8304

8735

LEFT SPEAKER

(5200)

D

11P

8M20

SIDE I/O

(1116)

1304

J

3P

7P

1M01

1M20

IR/LED/LIGHT

SENSOR

(1112)

G_16860_034.eps

8M01

021007

KEYBOARD CONTROL

3P

(1114)

E

1M01

Block Diagrams, Test Point Overview, and Waveforms

Wiring Diagram LCD with AmbiLight (ME7)

WIRING 32” LCD WITH AMBI-LIGHT (STYLING ME7)

29LC7.1L LA 6.

LCD DISPLAY

(1004)

8M82

1M09

1M59

1M82

4P

5P

7P

CN2

INVERTER

14P

8521

8402

CN4

14P

CN2

12P

CN3

SUPPLY

(1005)

FOR LPL PANEL

4P

ONLY USED

4P

CN5

CN6

CN7

9P

8P

8C01

8520

8401

8P11

B

8735

SSB

9P

1C01

8P

1P11

LV DS

30P

30P

1G51

8405

AMBIENT LIGHT

AL

DRIVER

9P

1115

8P

1116

8406

11P

7P

1304

1M20

4P

1735

5P

8404

7P

1M82

30P

1311

1310

1113

30P

8402

12P

CN3

5P

4P

1M59

1M09

INVERTER

(1175)

AMBI-LIGHT UNIT (IN BACK COVER)

RIGHT SPEAKER

(5200)

CN1

2P3

INLET

8002

TUNER

8191

8304

8735

LEFT SPEAKER

(5200)

D

11P

8M20

SIDE I/O

(1116)

1304

7P

1M20

IR/LED/LIGHT

J

SENSOR

(1112)

(1114)

KEYBOARD CONTROL

E

3P

1M01

8M01

3P

1M01

H_17270_001.eps

AMBI-LIGHT UNIT (IN BACK COVER)

021007

(1175)

Block Diagrams, Test Point Overview, and Waveforms

Wiring Diagram 37” - 42” LCD (ME7)

WIRING 37”- 42” LCD

(STYLING ME7)

8521

8520

8C01

8P11

30LC7.1L LA 6.

LCD DISPLAY

(1004)

LVD S

30P

8G51

9P

X412

8P

X406

14P

X404

12P

X403

MAIN SUPPLY

(1005)

14P

CN2

ONLY USED

FOR LPL PANEL

9P

INVERTER INVERTER

B

2P3

CN1

8002

1C01

SSB

8P

1P11

30P

1G51

7P

1M20

11P

1304

4P

1735

8735

D

SIDE I/O

(1116)

12P

CN3

KEYBOARD CONTROL

E

(1114)

RIGHT SPEAKER

INLET

8191

8192(UK)

LEFT SPEAKER

8304

11P

3P

1M01

1304

8M01

8M20

J

7P

1M01

1M20

IR/LED/LIGHT

SENSOR

(1112)

H_16940_012.eps

3P

180707

Loading...

Loading...