Philips EMERSON LF501EM4, MAGNAVOX 50ME313V/F7 Schematic

50” LCD TV

chassis FL13.16

© 2013 Funai Electric Co., Ltd.

All rights reserved. No part of this manual may be reproduced, copied, transmitted, disseminated, transcribed,

downloaded or stored in any storage medium, in any form or for any purpose without the express prior written

consent of Funai. Furthermore, any unauthorized commercial distribution of this manual or any revision hereto

is strictly prohibited.

Information in this document is subject to change without notice. Funai reserves the right to change the content

herein without the obligation to notify any person or organization of such changes.

with the design is a registered trademark of Funai Electric Co., Ltd and may not be used in any way

without the express written consent of Funai. All other trademarks used herein remain the exclusive property of

their respective owners. Nothing contained in this manual should be construed as granting, by implication or

otherwise, any license or right to use any of the trademarks displayed herein. Misuse of any trademarks or any

other content in this manual is strictly prohibited. Funai shall aggressively enforce its intellectual property rights

to the fullest extent of the law.

SERVICE MANUAL

Contents

This service manual contains information of different types of models.

Make sure to refer to the section describing your model.

TYPE A

LF501EM4 EMERSON (Serial No.: DS1)

50ME313V/F7 MAGNAVOX (Serial No.: DS1)

TYPE B

50ME313V/F7 MAGNAVOX (Serial No.: DS2)

LF501EM4 EMERSON (Serial No.: DS2)

130327

IMPORTANT SAFETY NOTICE

Proper service and repair is important to the safe, reliable operation of all

Funai Equipment. The service procedures recommended by Funai and

described in this service manual are effective methods of performing

service operations. Some of these service special tools should be used

when and as recommended.

It is important to note that this service manual contains various CAUTIONS

and NOTICES which should be carefully read in order to minimize the risk

of personal injury to service personnel. The possibility exists that improper

service methods may damage the equipment. It also is important to

understand that these CAUTIONS and NOTICES ARE NOT EXHAUSTIVE.

Funai could not possibly know, evaluate and advice the service trade of all

conceivable ways in which service might be done or of the possible

hazardous consequences of each way. Consequently, Funai has not

undertaken any such broad evaluation. Accordingly, a servicer who uses a

service procedure or tool which is not recommended by Funai must first

use all precautions thoroughly so that neither his safety nor the safe

operation of the equipment will be jeopardized by the service method

selected.

The LCD panel is manufactured to provide many years of useful life.

Occasionally a few non active pixels may appear as a tiny spec of color.

This is not to be considered a defect in the LCD screen.

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Standard Notes for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Cabinet Disassembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Electrical Adjustment Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

How to Initialize the LCD TV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Firmware Renewal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Block Diagrams [TYPE A] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[TYPE B] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Schematic Diagrams / CBA and Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Wiring Diagram [TYPE A] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

[TYPE B] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Exploded Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

1-1 FL13.16SP

SPECIFICATIONS

< TUNER / NTSC >

ANT. Input ---------------------- 75 Ω Unbal., F type

< TUNER / ATSC >

< LCD PANEL >

< VIDEO >

< AUDIO >

All items are measured across 8 Ω load at speaker output terminal with L.P.F.

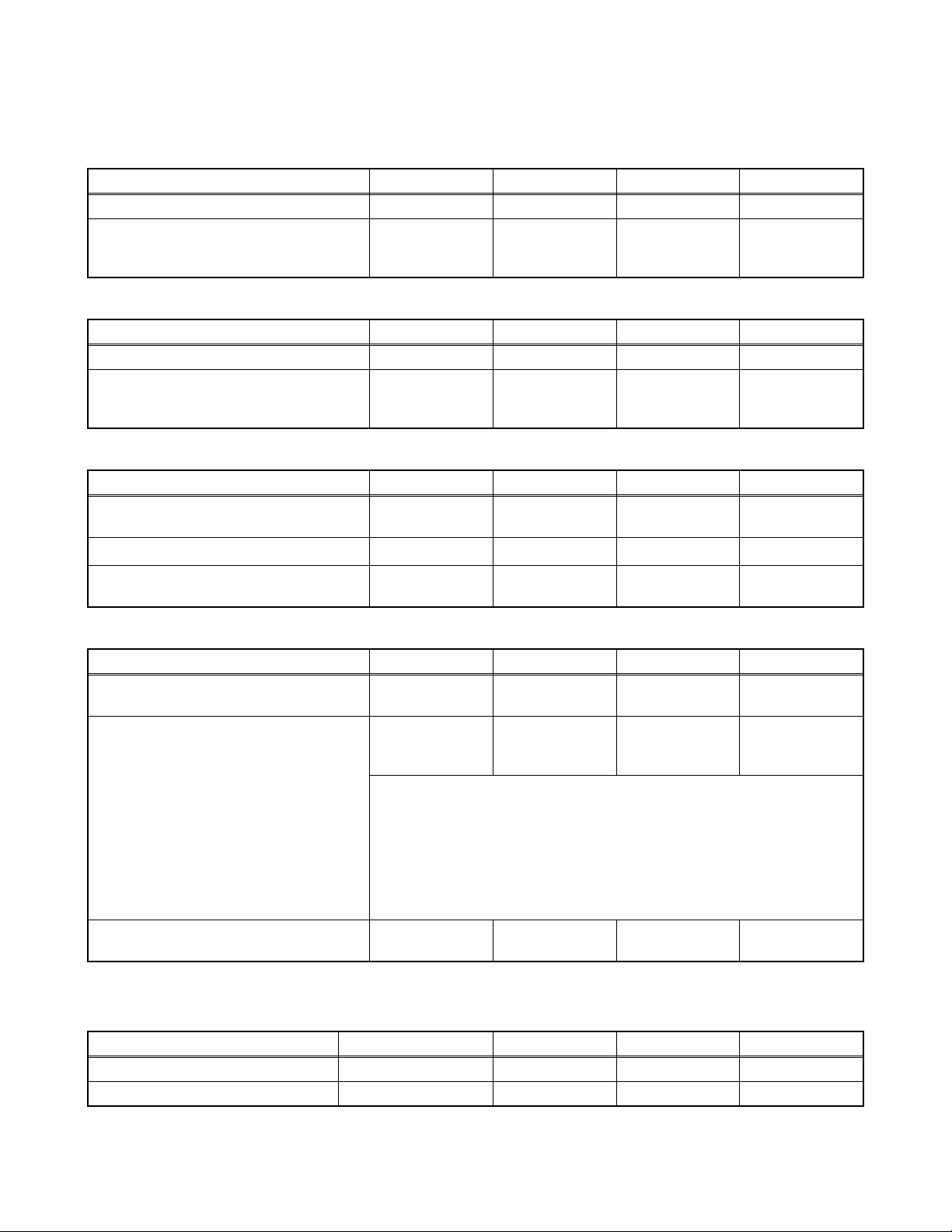

Description Condition Unit Nominal Limit

1. AFT Pull-In Range --- MHz ±2.3 ±2.1

2. Synchronizing Sens.

TV.ch.4

CA.ch.31

CA.ch.87

dBµV

dBµV

dBµV

18

18

18

20

20

23

Description Condition Unit Nominal Limit

1. Received Freq. Range (-28dBm) --- kHz --- ±100

2. ATSC Dynamic Range (min / max)

ch.4

ch.10

ch.41

dBm

dBm

dBm

---

---

---

-76/0

-76/0

-76/+4

Description Condition Unit Nominal Limit

1. Native Pixel Resolution

Horizontal

Verti cal

pixels

pixels

1920

1080

---

---

2. Brightness (w / filter) ---

cd/m

2

270 ---

3. Viewing Angle

Horizontal

Verti cal

°

°

-88 to 88

-88 to 88

---

---

Description Condition Unit Nominal Limit

1. Over Scan

Horizontal

Verti cal

%

%

5

5

5±5

5±5

2. Color Temperature

---

x

y

°K 12000

0.272

0.278

---

±3%

±3%

<Measurement condition>

Input signal: HDMI1 Raster (40/80IRE) 1080i@60

Measurement point: Screen center

Measuring instrument:

Made of KONICA MINOLTA Luminance meter CA-310

Aging time: 60min. (Retail MODE / 100IRE Raster HDMI

1080i@60)

MODE setting of TV: Shipment setting / Retail MODE

Ambient temperature: 25°C ±5°C

3. Resolution (composite video)

Horizontal

Verti cal

line

line

400

350

---

---

Description Condition Unit Nominal Limit

1.

Audio MAX Output (ATSC 0dBfs)

Lch/Rch W 10.0/10.0 9.0/9.0

2. Audio Distortion (NTSC) 500mW: Lch/Rch % 0.5/0.5 2.0/2.0

2-1 LTVN_ISP

IMPORTANT SAFETY PRECAUTIONS

Prior to shipment from the factory, our products are strictly inspected for recognized product safety and electrical

codes of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally

important to implement the following precautions when a set is being serviced.

Safety Precautions for LCD TV

Circuit

1. Before returning an instrument to the

customer, always make a safety check of the

entire instrument, including, but not limited to, the

following items:

a. Be sure that no built-in protective devices are

defective and have been defeated during

servicing. (1) Protective shields are provided

on this chassis to protect both the technician

and the customer. Correctly replace all missing

protective shields, including any removed for

servicing convenience. (2) When reinstalling

the chassis and/or other assembly in the

cabinet, be sure to put back in place all

protective devices, including but not limited to,

nonmetallic control knobs, insulating

fishpapers, adjustment and compartment

covers/shields, and isolation resistor/capacitor

networks. Do not operate this instrument or

permit it to be operated without all

protective devices correctly installed and

functioning. Servicers who defeat safety

features or fail to perform safety checks

may be liable for any resulting damage.

b. Be sure that there are no cabinet openings

through which an adult or child might be able to

insert their fingers and contact a hazardous

voltage. Such openings include, but are not

limited to, (1) spacing between the Liquid

Crystal Panel and the cabinet mask, (2)

excessively wide cabinet ventilation slots, and

(3) an improperly fitted and/or incorrectly

secured cabinet back cover.

c. Antenna Cold Check - With the instrument AC

plug removed from any AC source, connect an

electrical jumper across the two AC plug

prongs. Place the instrument AC switch in the

on position. Connect one lead of an ohmmeter

to the AC plug prongs tied together and touch

the other ohmmeter lead in turn to each tuner

antenna input exposed terminal screw and, if

applicable, to the coaxial connector. If the

measured resistance is less than 1.0 megohm

or greater than 5.2 megohm, an abnormality

exists that must be corrected before the

instrument is returned to the customer. Repeat

this test with the instrument AC switch in the off

position.

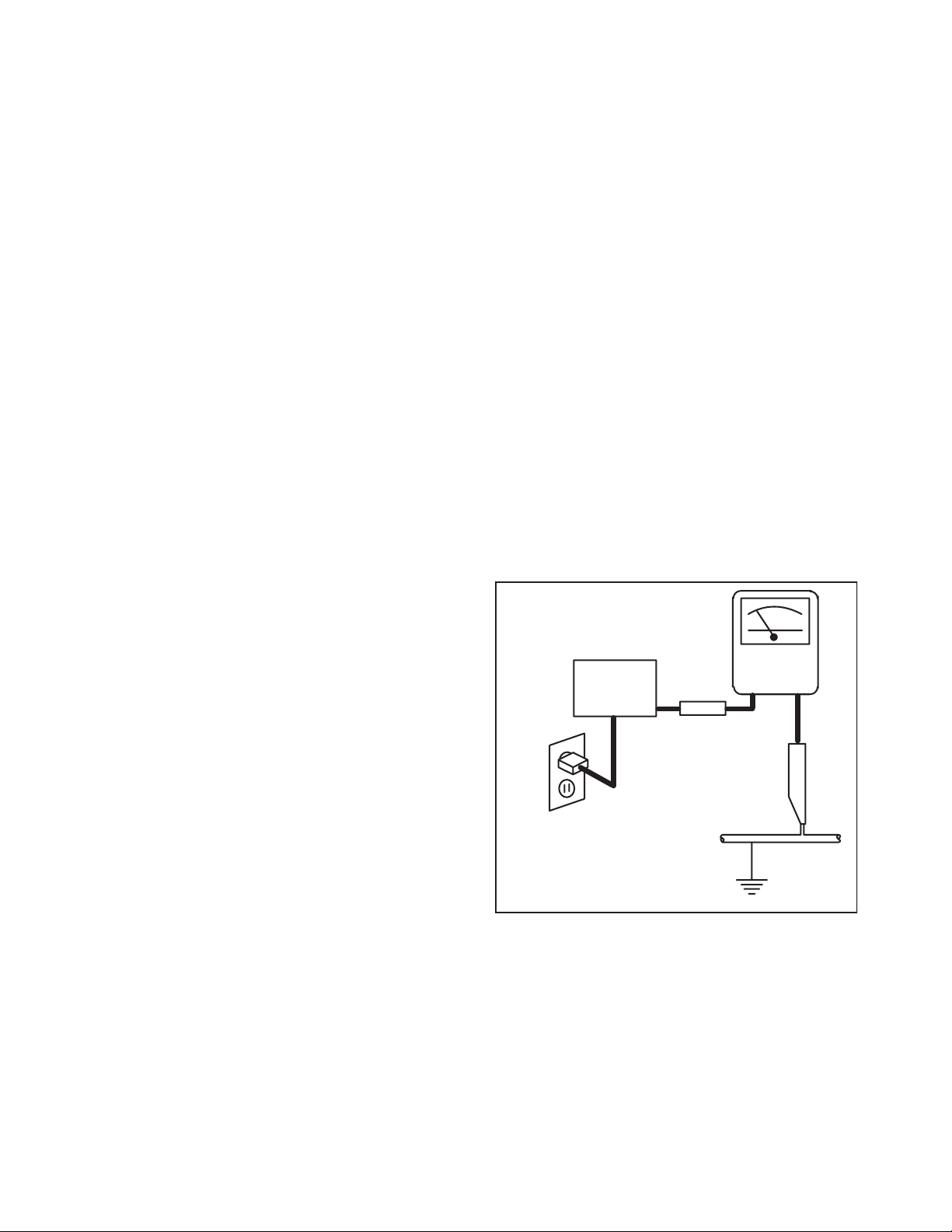

d. Leakage Current Hot Check - With the

instrument completely reassembled, plug the

AC line cord directly into a 120 V AC outlet. (Do

not use an isolation transformer during this

test.) Use a leakage current tester or a

metering system that complies with American

National Standards Institute (ANSI) C101.1

Leakage Current for Appliances and

Underwriters Laboratories (UL) 1410, (50.7).

With the instrument AC switch first in the on

position and then in the off position, measure

from a known earth ground (metal water pipe,

conduit, etc.) to all exposed metal parts of the

instrument (antennas, handle brackets, metal

cabinet, screw heads, metallic overlays, control

shafts, etc.), especially any exposed metal

parts that offer an electrical return path to the

chassis. Any current measured must not

exceed 0.5 milli-ampere. Reverse the

instrument power cord plug in the outlet and

repeat the test.

ANY MEASUREMENTS NOT WITHIN THE

LIMITS SPECIFIED HEREIN INDICATE A

POTENTIAL SHOCK HAZARD THAT MUST

BE ELIMINATED BEFORE RETURNING THE

INSTRUMENT TO THE CUSTOMER OR

BEFORE CONNECTING THE ANTENNA OR

ACCESSORIES.

2. Read and comply with all caution and safety-

related notes on or inside the receiver cabinet, on

the receiver chassis, or on the Liquid Crystal

Panel.

ALSO TEST WITH

PLUG REVERSED

USING AC

ADAPTER PLUG

AS REQUIRED

TEST ALL EXPOSED

METAL SURFACES

READING SHOULD

NOT BE ABOVE 0.5 mA

EARTH

GROUND

_

DEVICE

LEAKAGE

CURRENT

TESTER

+

BEING

TESTED

2-2 LTVN_ISP

3. Design Alteration Warning - Do not alter or add

to the mechanical or electrical design of this TV

receiver. Design alterations and additions,

including, but not limited to circuit modifications

and the addition of items such as auxiliary audio

and/or video output connections, might alter the

safety characteristics of this receiver and create a

hazard to the user. Any design alterations or

additions will void the manufacturer's warranty and

may make you, the servicer, responsible for

personal injury or property damage resulting

therefrom.

4. Hot Chassis Warning -

a. Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord and maybe safety-serviced without

an isolation transformer only if the AC power

plug is inserted so that the chassis is

connected to the ground side of the AC power

source. To confirm that the AC power plug is

inserted correctly, with an AC voltmeter,

measure between the chassis and a known

earth ground. If a voltage reading in excess of

1.0 V is obtained, remove and reinsert the AC

power plug in the opposite polarity and again

measure the voltage potential between the

chassis and a known earth ground.

b. Some TV receiver chassis normally have 85V

AC(RMS) between chassis and earth ground

regardless of the AC plug polarity. This chassis

can be safety-serviced only with an isolation

transformer inserted in the power line between

the receiver and the AC power source, for both

personnel and test equipment protection.

c. Some TV receiver chassis have a secondary

ground system in addition to the main chassis

ground. This secondary ground system is not

isolated from the AC power line. The two

ground systems are electrically separated by

insulation material that must not be defeated or

altered.

5. Observe original lead dress. Take extra care to

assure correct lead dress in the following areas: a.

near sharp edges, b. near thermally hot parts-be

sure that leads and components do not touch

thermally hot parts, c. the AC supply, d. high

voltage, and, e. antenna wiring. Always inspect in

all areas for pinched, out of place, or frayed wiring.

Check AC power cord for damage.

6. Components, parts, and/or wiring that appear to

have overheated or are otherwise damaged

should be replaced with components, parts, or

wiring that meet original specifications.

Additionally, determine the cause of overheating

and/or damage and, if necessary, take corrective

action to remove any potential safety hazard.

7. Product Safety Notice - Some electrical and

mechanical parts have special safety-related

characteristics which are often not evident from

visual inspection, nor can the protection they give

necessarily be obtained by replacing them with

components rated for higher voltage, wattage, etc.

Parts that have special safety characteristics are

identified by a # on schematics and in parts lists.

Use of a substitute replacement that does not

have the same safety characteristics as the

recommended replacement part might create

shock, fire, and/or other hazards. The product's

safety is under review continuously and new

instructions are issued whenever appropriate.

Prior to shipment from the factory, our products

are strictly inspected to confirm they comply with

the recognized product safety and electrical codes

of the countries in which they are to be sold.

However, in order to maintain such compliance, it

is equally important to implement the following

precautions when a set is being serviced.

2-3 LTVN_ISP

Precautions during Servicing

A. Parts identified by the # symbol are critical for

safety.

Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations

applying to spurious radiation. These must also be

replaced only with specified replacements.

Examples: RF converters, RF cables, noise

blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulation Tape

2) PVC tubing

3) Spacers

4) Insulators for transistors.

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before

soldering.

F. Observe that the wires do not contact heat

producing parts (heat sinks, oxide metal film

resistors, fusible resistors, etc.)

G. Check that replaced wires do not contact sharp

edged or pointed parts.

H. When a power cord has been replaced, check that

11~13 lb (5~6 kg) of force in any direction will not

loosen it.

I. Also check areas surrounding repaired locations.

J. Use care that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

K. When connecting or disconnecting the internal

connectors, first, disconnect the AC plug from the

AC supply outlet.

L. When installing parts or assembling the cabinet

parts, be sure to use the proper screws and

tighten certainly.

2-4 LTVN_ISP

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and

wires have been returned to original positions. Afterwards, perform the following tests and confirm the specified

values in order to verify compliance with safety standards.

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d') between

soldered terminals, and between terminals and

surrounding metallic parts. (See Fig. 1)

Table 1: Ratings for selected area

Note: This table is unofficial and for reference only. Be

sure to confirm the precise values.

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals,

antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.) is

lower than or equal to the specified value in the table

below.

Measuring Method: (Power ON)

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accessible parts. Use an AC

voltmeter to measure across both terminals of load Z.

See Fig. 2 and following table.

Table 2: Leakage current ratings for selected areas

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

AC Line Voltage Region

Clearance

Distance (d), (d’)

110 to 130 V

U.S.A. or

Canada

≥ 3.2 mm

(0.126 inches)

AC Line Voltage Region Load Z Leakage Current (i) Earth Ground (B) to:

110 to 130 V

U.S.A. or

Canada

0.15 µF CAP. & 1.5 kΩ

RES. Connected in parallel

i ≤ 0.5 mA rms

Exposed accessible

parts

Chassis or Secondary Conductor

Primary Circuit

Fig. 1

d' d

AC Voltmeter

(High Impedance)

Exposed Accessible Part

B

Earth Ground

Power Cord Plug Prongs

Z

Fig. 2

3-1 TVN_SN

STANDARD NOTES FOR SERVICING

Circuit Board Indications

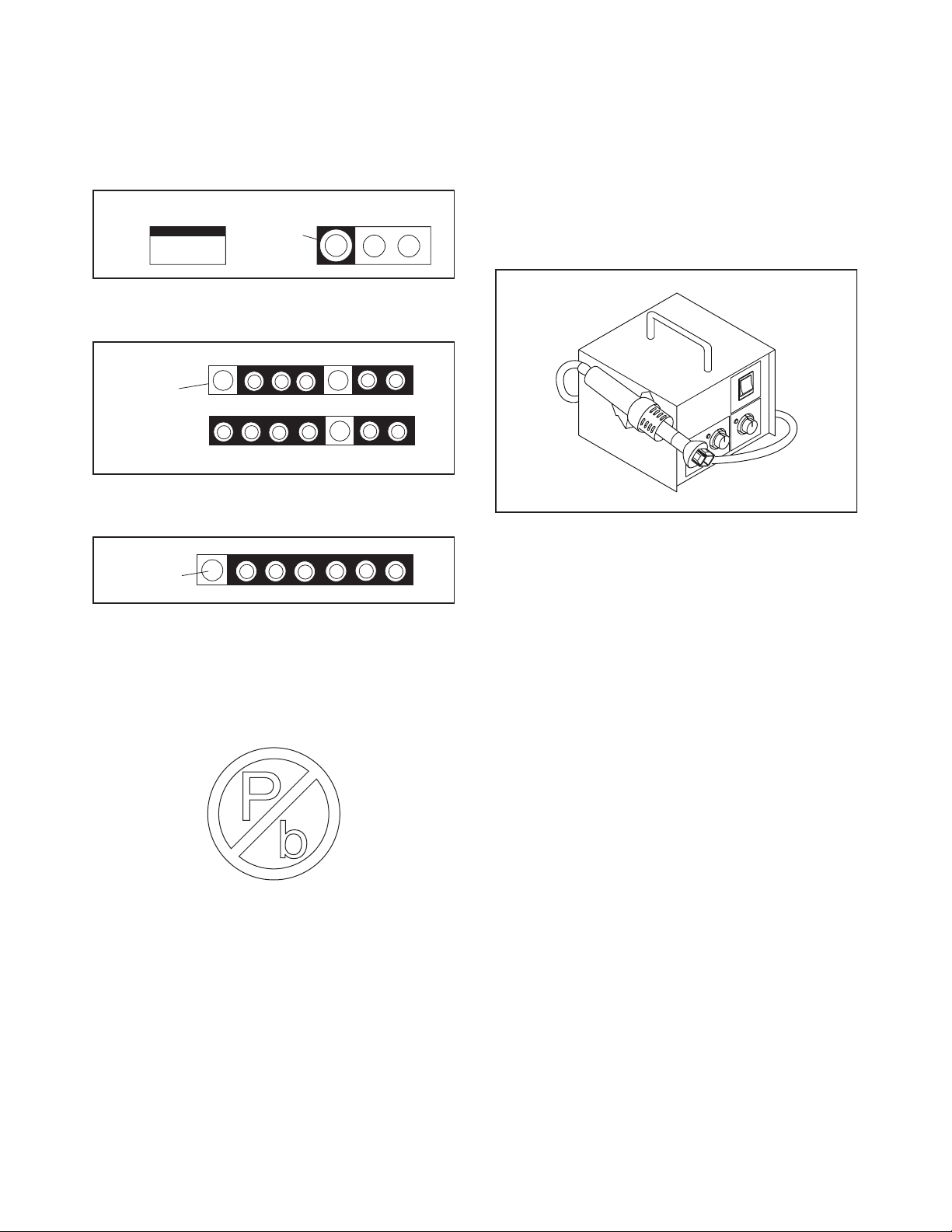

1. The output pin of the 3 pin Regulator ICs is

indicated as shown.

2. For other ICs, pin 1 and every fifth pin are

indicated as shown.

3. The 1st pin of every male connector is indicated as

shown.

Pb (Lead) Free Solder

Pb free mark will be found on PCBs which use Pb

free solder. (Refer to figure.) For PCBs with Pb free

mark, be sure to use Pb free solder. For PCBs

without Pb free mark, use standard solder.

How to Remove / Install Flat Pack-IC

1. Removal

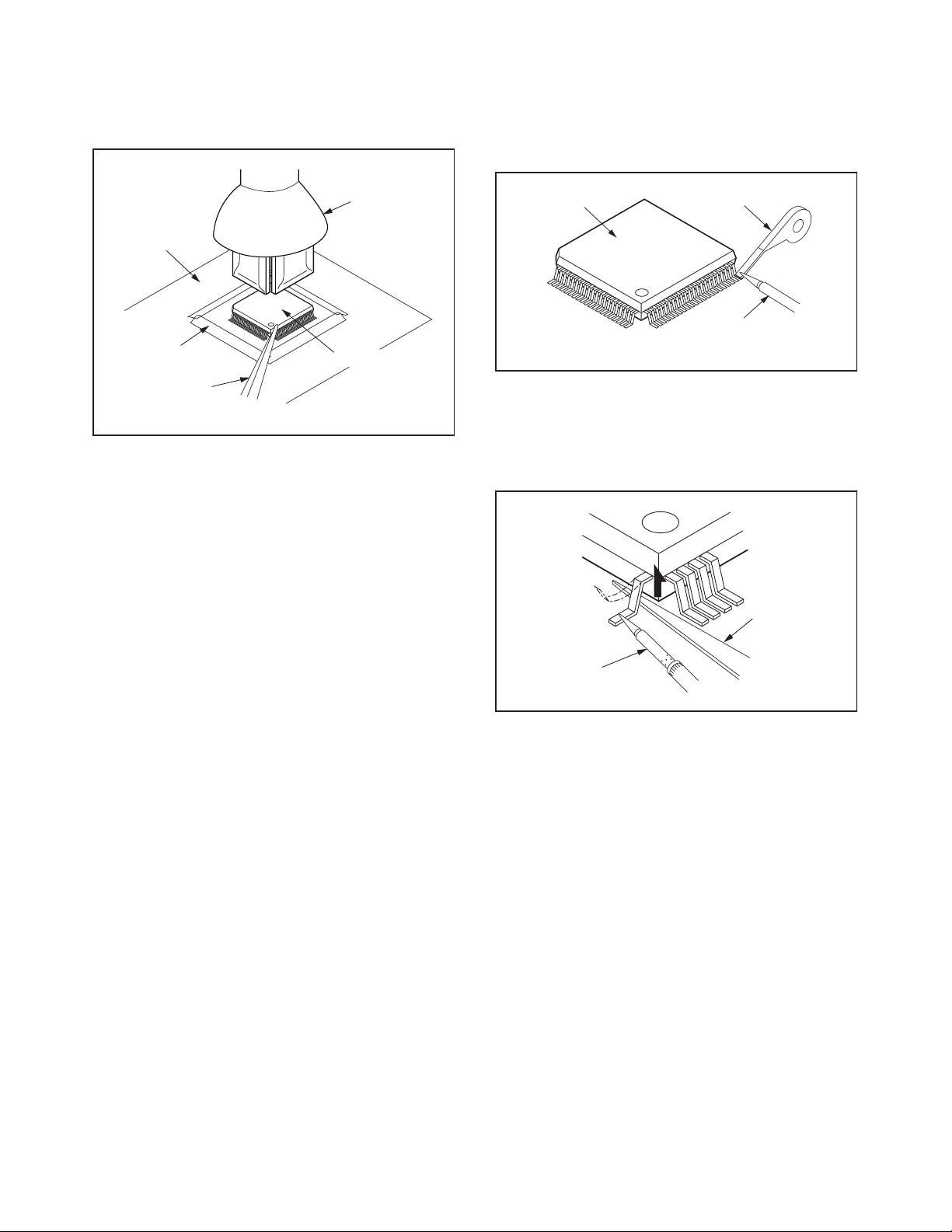

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

2. Remove the flat pack-IC with tweezers while

applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

Top View

Out

In

Bottom View

Input

5

10

Pin 1

Pin 1

Pb free mark

Fig. S-1-1

3-2 TVN_SN

3. The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when

removing it.

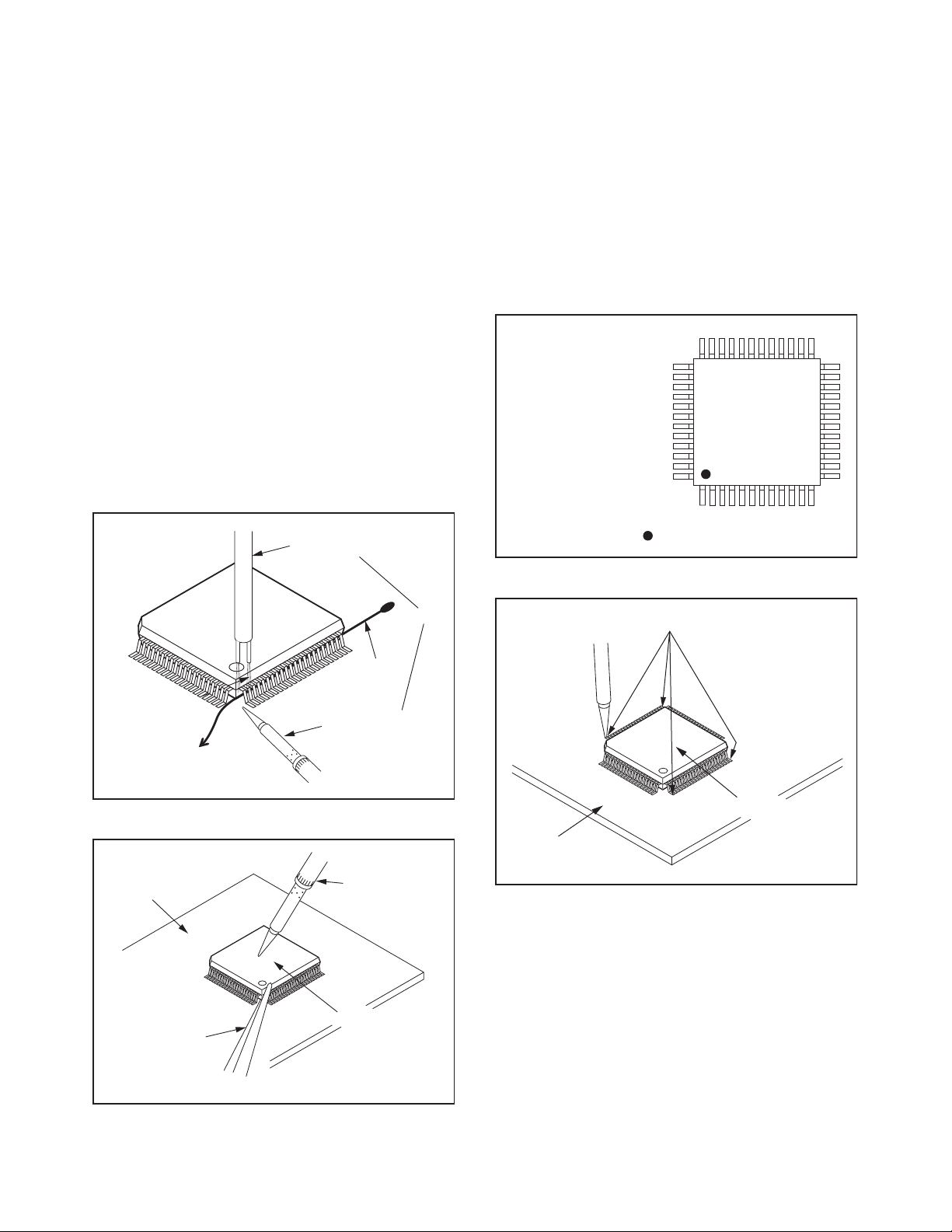

With Soldering Iron:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Hot-air

Flat Pack-IC

Desoldering

Machine

CBA

Flat Pack-IC

Tweezers

Masking

Tape

Fig. S-1-2

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

Fine Tip

Soldering Iron

Sharp

Pin

Fig. S-1-4

3-3 TVN_SN

With Iron Wire:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

3. While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA

contact pads as shown in Fig. S-1-5.

4. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

5. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Note: When using a soldering iron, care must be

taken to ensure that the flat pack-IC is not

being held by glue. When the flat pack-IC is

removed from the CBA, handle it gently

because it may be damaged if force is applied.

2. Installation

1. Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replacement flat pack-IC more

easily.

2. The “ I ” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the

pin 1 on the PCB when positioning for installation.

Then presolder the four corners of the flat pack-IC.

(See Fig. S-1-8.)

3. Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

To Solid

Mounting Point

Soldering Iron

Iron Wire

or

Hot Air Blower

Fig. S-1-5

Fine Tip

Soldering Iron

CBA

Flat Pack-IC

Tweezers

Fig. S-1-6

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

Presolder

CBA

Flat Pack-IC

Fig. S-1-8

3-4 TVN_SN

Instructions for Handling Semi-

conductors

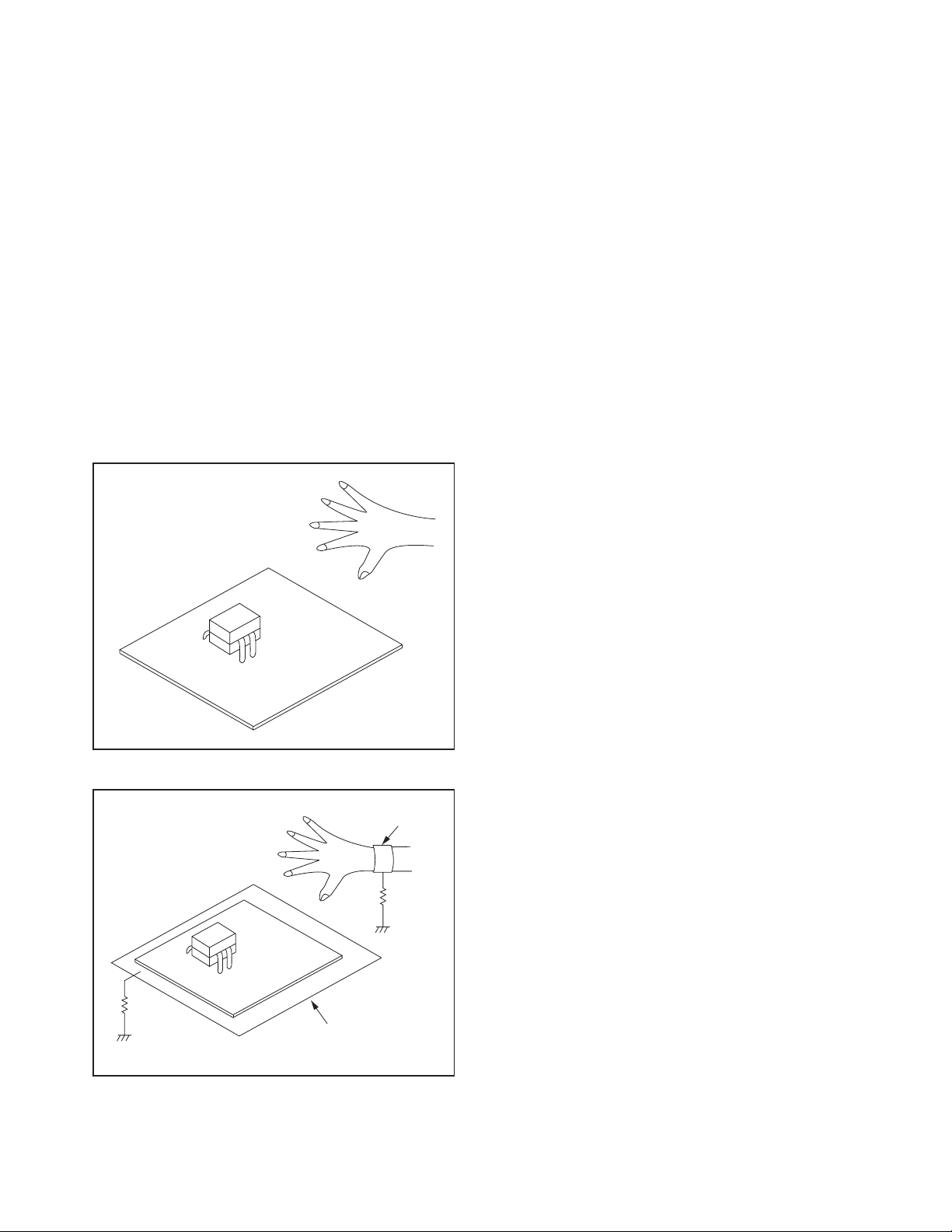

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 MΩ) that is

properly grounded to remove any static electricity that

may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1 MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape through the body grounding

band, be careful to avoid contacting semi-conductors

with your clothing.

<Incorrect>

CBA

Grounding Band

Conductive Sheet or

Copper Plate

1MΩ

1MΩ

<Correct>

CBA

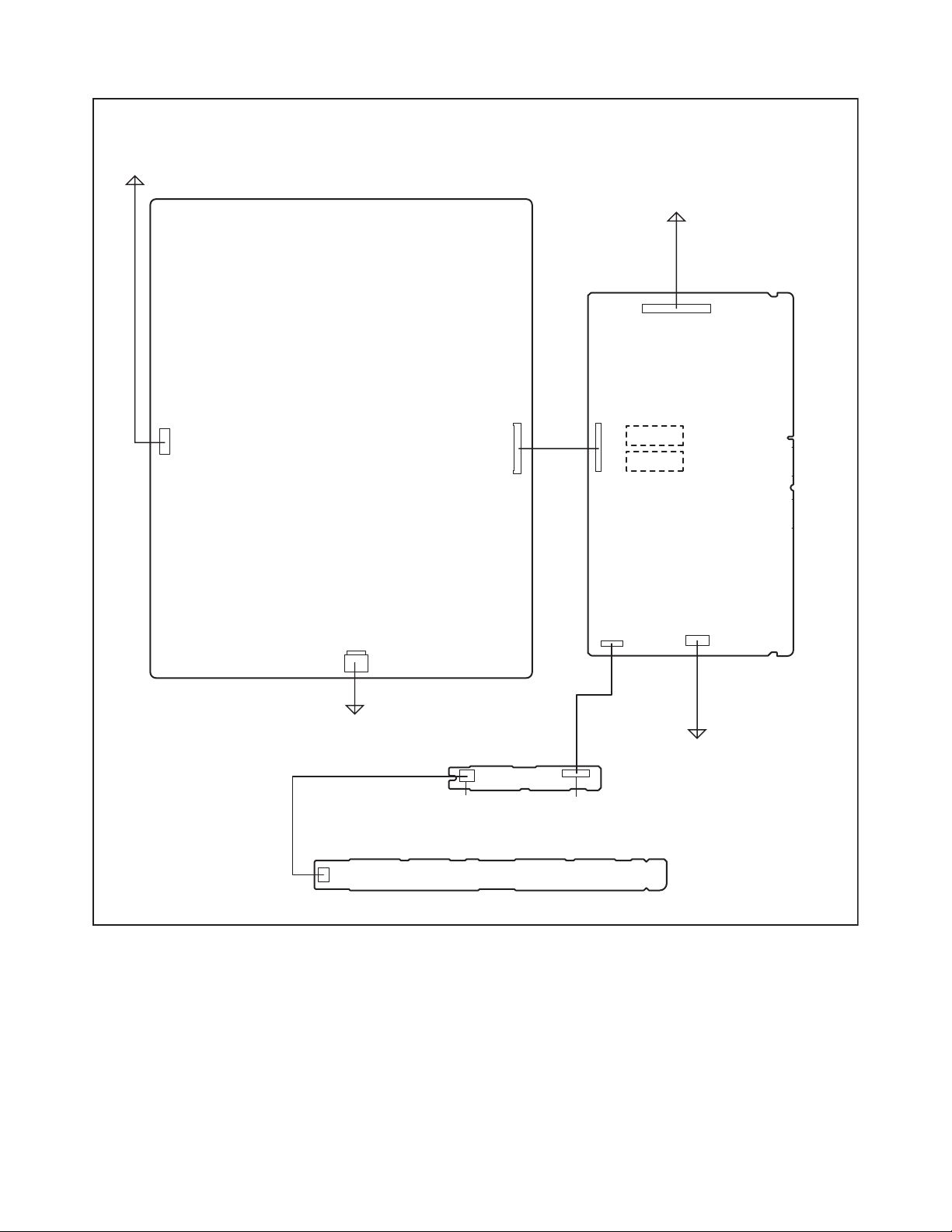

4-1 FL13.16-A_DC

CABINET DISASSEMBLY INSTRUCTIONS

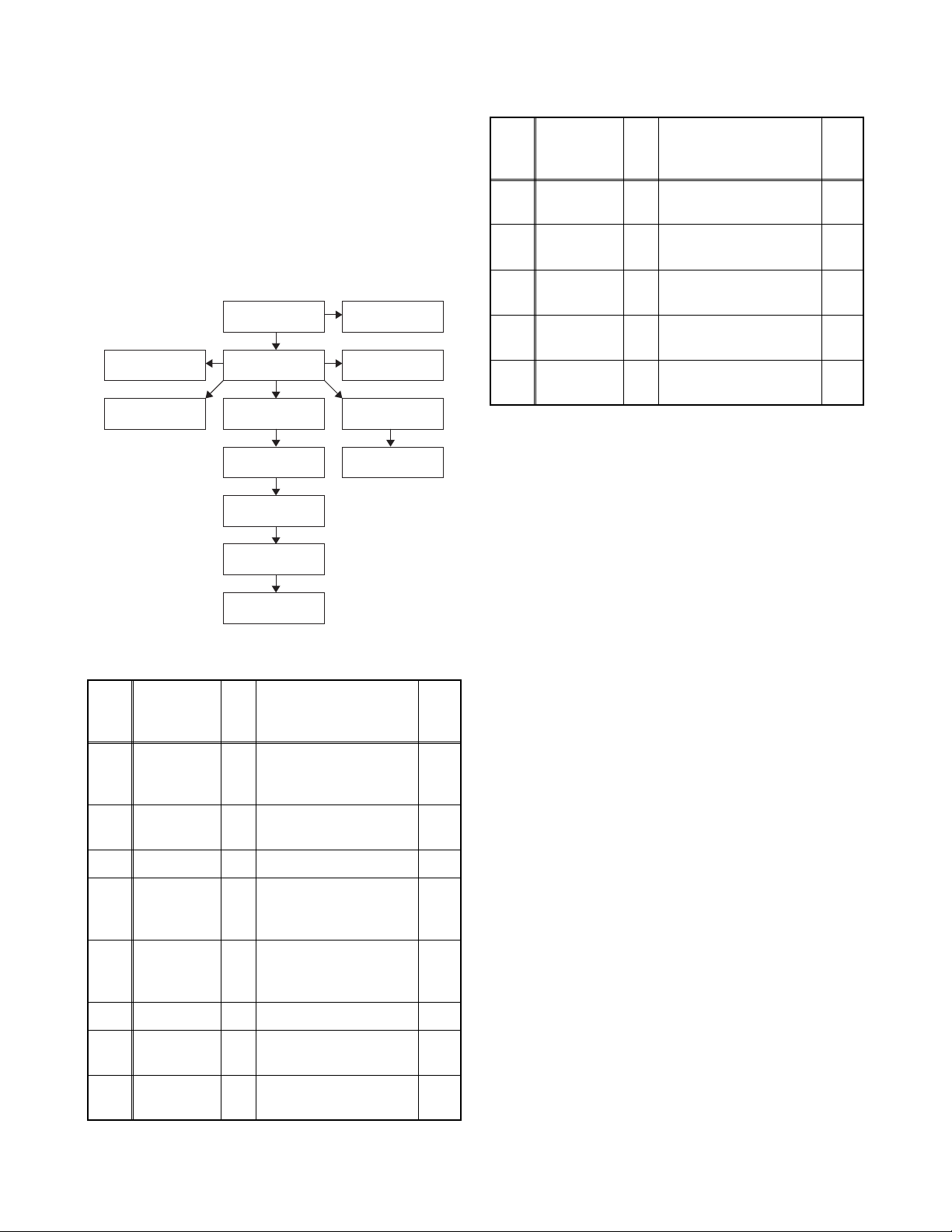

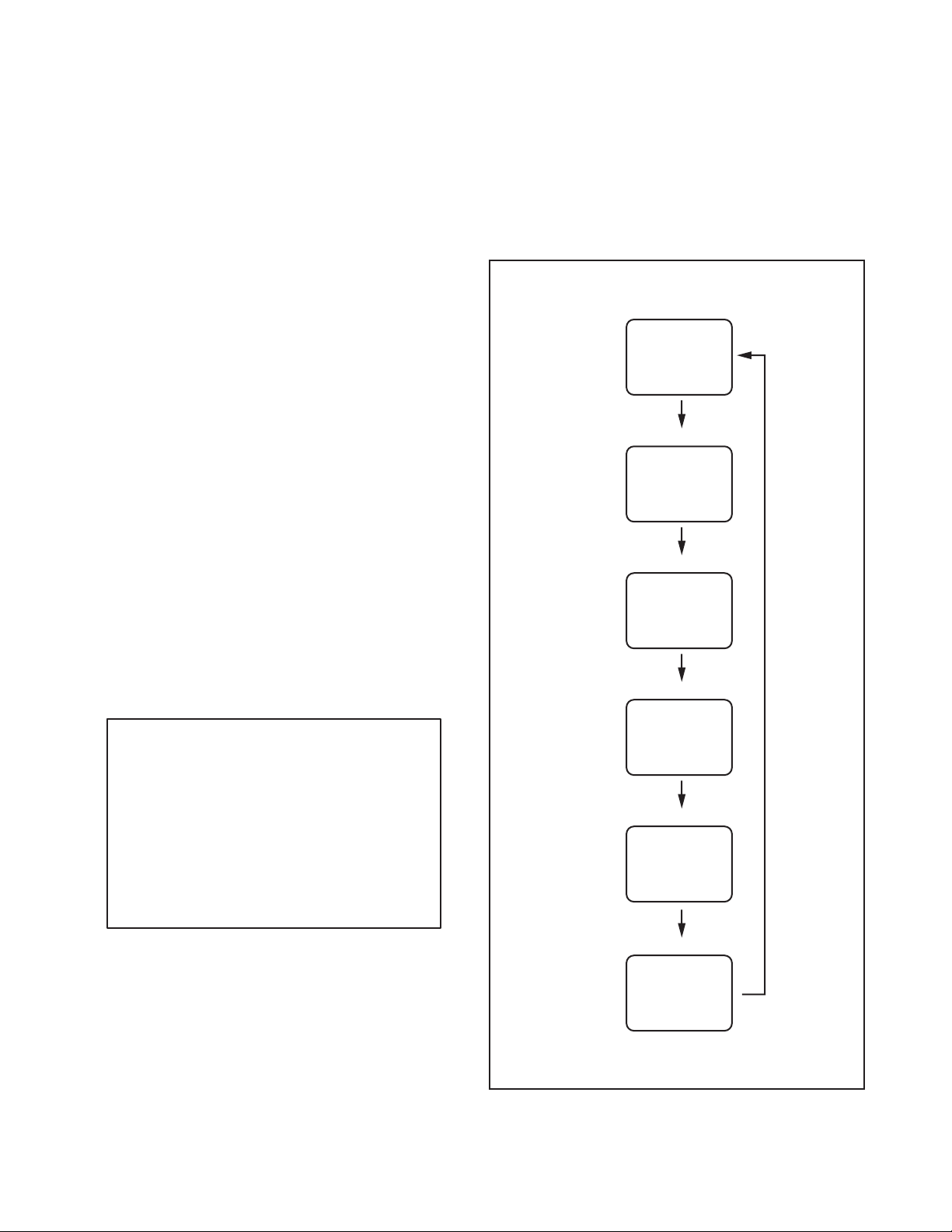

1. Disassembly Flowchart

This flowchart indicates the disassembly steps for the

cabinet parts and the CBA in order to gain access to

items to be serviced. When reassembling, follow the

steps in reverse order. Bend, route and dress the

cables as they were.

2. Disassembly Method

Note:

(1) Order of steps in procedure. When reassembling,

follow the steps in reverse order. These numbers

are also used as the Identification (location) No. of

parts in figures.

(2) Parts to be removed or installed.

(3) Fig. No. showing procedure of part location

(4) Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

P = Spring, L = Locking Tab, S = Screw,

H = Hex Screw, CN = Connector

e.g. 2(S-2) = two Screws of (S-2),

2(L-2) = two Locking Tabs of (L-2)

(5) Refer to the following “Reference Notes in the

Ta bl e .”

Precautions concerning the LCD Panel

Assembly:

1. When you disassemble/re-assemble the Front

Cabinet

• Do not pull the FFC Cable and Board Cable

forcefully when you re-assemble.

• Be careful not to scratch the display panel when

assembling.

• The screw tightening torque must be 6kgf·cm

(5.2lb·in).

• Make sure to replace the Sensor Lens to a new one

when replacing the Front Cabinet.

• Be careful not to scratch the rear frame when

disassembling/re-assembling or when tightening the

screws.

Step/

Loc.

No.

Part

Fig.

No.

Removal Note

[1]

Stand

Hinge

Assembly

D1 4(S-1), 4(S-2) ---

[2]

Stand Base

Assembly

D1 --------------- ---

[3] Rear Cover D1 5(S-3), 6(S-4) ---

[4]

Power

Supply

CBA

D2

D5

4(S-5), CN501,

CN601, CN1001

---

[5]

Digital Main

CBA Unit

D2

D5

4(S-6), CN3013,

CN3101, CN3801,

Jack Holder

---

[6] Speaker D3 --------------- ---

[7]

Bottom

Cover L

D3 2(S-7), (S-8) ---

[8]

Bottom

Cover R

D3

2(S-9), (S-10),

Function Knob

---

[1] Stand Hinge

Assembly

[3] Rear Cover

[9] Function

CBA Unit

[10] Stand Bracket

[11] LCD Panel

Assembly

[6] Speaker

[13] Front Cabinet

[2] Stand Base

Assembly

[4] Power Supply

CBA

[7] Bottom

Cover L

[8] Bottom

Cover R

[12] IR Sensor

CBA Unit

[5] Digital Main

CBA Unit

[9]

Function

CBA Unit

D3

D5

CN4001 2

[10]

Stand

Bracket

D3 4(S-11) ---

[11]

LCD Panel

Assembly

D3 --------------- ---

[12]

IR Sensor

CBA Unit

D4 Sensor Plate 2

[13]

Front

Cabinet

D4

11(S-12), Blind Label,

Sensor Lens

1

↓

(1)

↓

(2)

↓

(3)

↓

(4)

↓

(5)

Step/

Loc.

No.

Part

Fig.

No.

Removal Note

4-2 FL13.16-A_DC

2. When you disassemble/re-assemble the

Function CBA Unit or the IR Sensor CBA Unit

• Be careful not to break the hooks. If you pull with too

much force, the hooks may be damaged.

• Make sure the hooks are securely in place when

assembling.

• The Function CBA Unit and Function Knob are fixed

in place by the hooks. Make sure these hooks are

not damaged. Make sure the Function CBA Unit and

Function Knob are securely in place when re-

assembling.

• The IR Sensor CBA Unit and Sensor Plate are fixed

in place by the hooks. Make sure these hooks are

not damaged. Make sure the IR Sensor CBA Unit

and Sensor Plate are securely in place when re-

assembling.

• When assembling the IR Sensor CBA Unit, make

sure the Sensor Plate is properly set so that it

contacts the LCD Panel Assembly.

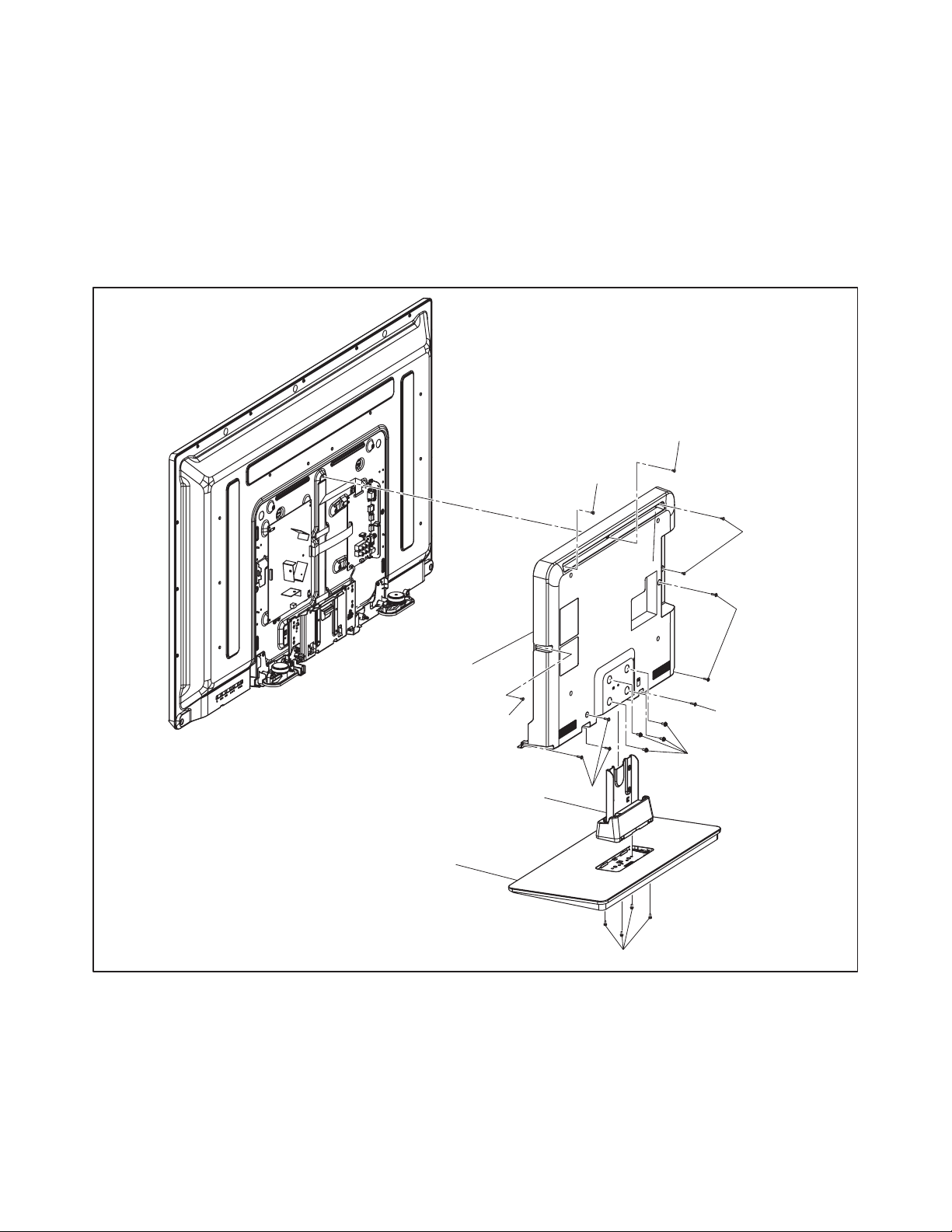

[3] Rear Cover

(S-3)

(S-3)

(S-3)

(S-3)

(S-2)

(S-1)

(S-4)

(S-4)

(S-4)

[1] Stand Hinge Assembly

[2] Stand Base Assembly

Fig. D1

4-3 FL13.16-A_DC

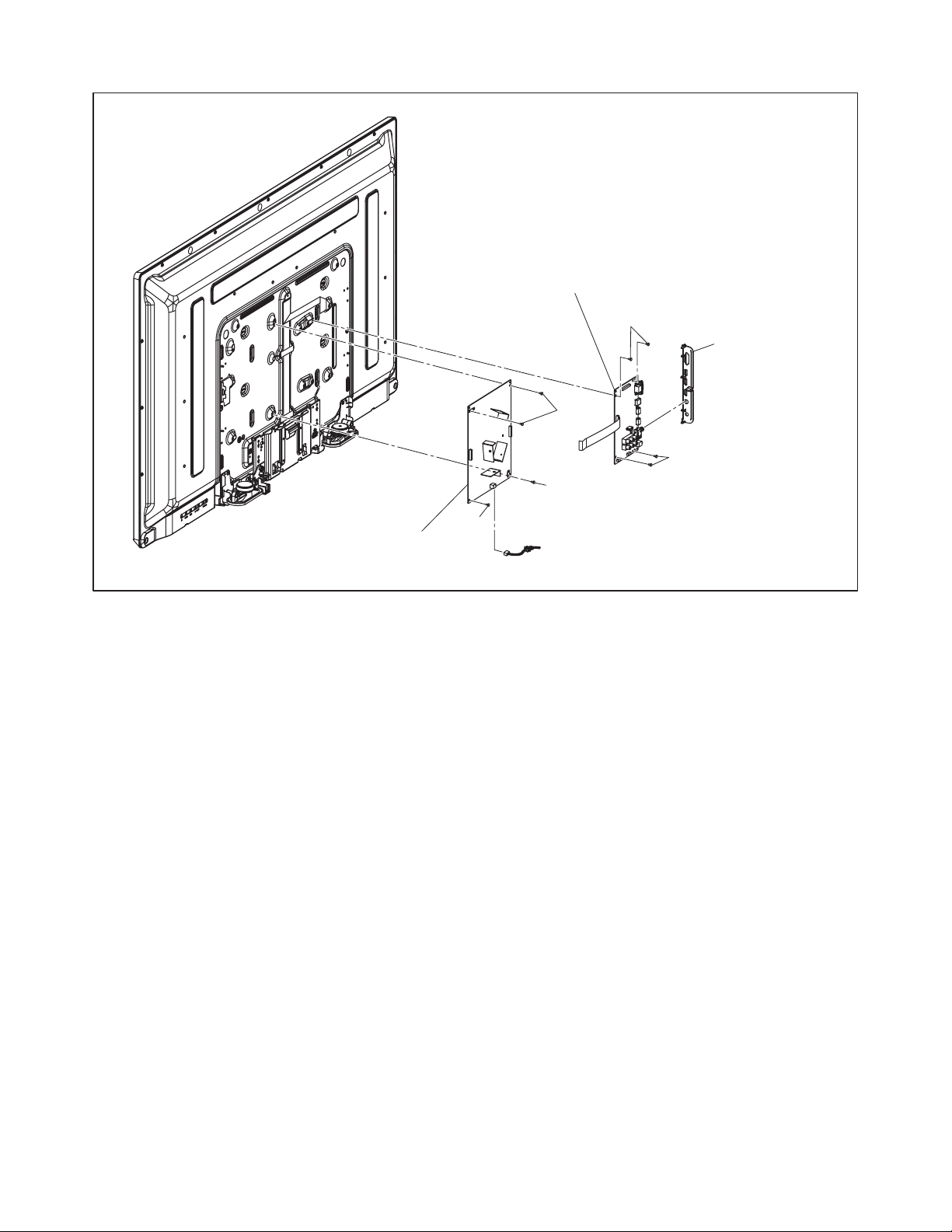

[5] Digital Main CBA Unit

[4] Power Supply CBA

(S-6)

(S-6)

Jack Holder

(S-5)

(S-5)

(S-5)

Fig. D2

4-4 FL13.16-A_DC

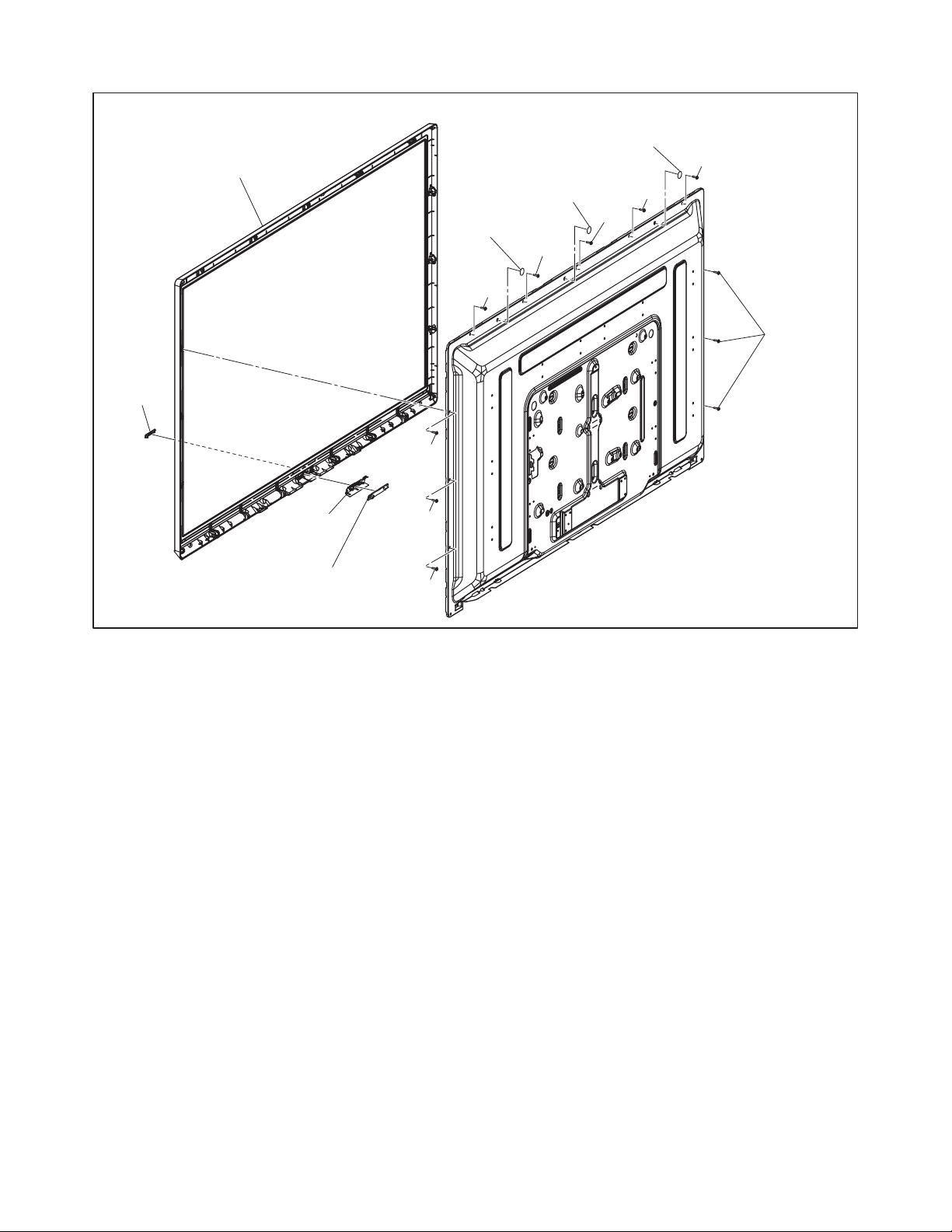

[6] Speaker

[6] Speaker

[10] Stand Bracket

[7] Bottom Cover L

[8] Bottom Cover R

[9] Function CBA Unit

*

2

[11] LCD Panel Assembly

(S-11)

(S-11)

Function Knob

(S-7)

(S-9)

(S-10)

(S-8)

Fig. D3

*

2

: Make sure to read all the precautions on page 4-2 when you disassemble/re-assemble the

Function CBA Unit.

4-5 FL13.16-A_DC

[12] IR Sensor CBA Unit

*

2

Sensor Plate

Blind Label

Blind Label

Blind Label

[13] Front Cabinet

*

1

(S-12)

(S-12)

(S-12)

(S-12)

(S-12)

(S-12)

(S-12)

(S-12)

(S-12)

Sensor

Lens

Fig. D4

*

1

: Make sure to read all the precautions on page 4-1 when you disassemble/re-assemble the

Front Cabinet.

*

2

: Make sure to read all the precautions on page 4-2 when you disassemble/re-assemble the IR

Sensor CBA Unit.

4-6 FL13.16-A_DC

TV Cable Wiring Diagram

Power Supply CBA

Function CBA Unit

IR Sensor CBA Unit

To LCD Panel

Assembly

To LCD Panel

Assembly

To AC Cord

To Speaker

Digital Main

CBA Unit

CN3801

CN4001

CN4051 CN4052

CN1001

CN601

CN501

CN3013

CN3101

CN3701

CN3602

*1

*2

Fig. D5

*1: TYPE A

*2: TYPE B

5-1 FL13.16EA

ELECTRICAL ADJUSTMENT INSTRUCTIONS

General Note: “CBA” is abbreviation for

“Circuit Board Assembly.”

Note: Electrical adjustments are required after

replacing circuit components and certain

mechanical parts. It is important to perform

these adjustments only after all repairs and

replacements have been completed.

Also, do not attempt these adjustments unless

the proper equipment is available.

Test Equipment Required

1. Remote control unit

2. Color Analyzer,

CA-310 (KONICA MINOLTA Luminance meter) or

measuring instrument as good as CA-310.

How to set up the service mode:

Service mode:

1. Turn the power on.

2. Press [MENU] button to display Setup menu.

3. Select “Features”.

4. Select “Software Upgrade”.

5. Select “Current Software Info”.

6. Press [0], [4], [2], [5], [7], [4] and [INFO] buttons on

the remote control unit in this order. The following

screen appears.

1. Purity Check Mode

This mode cycles through full-screen displays of red,

green, blue, and white to check for non-active pixels.

1. Enter the service mode.

2. Each time the [7] button on the remote control unit

is pressed, the display changes as follows.

3. To cancel or to exit from the Purity Check Mode,

press [CH RETURN] or [PREV CH] button.

Code:

Pic code:

Panel-Option code:

MIPS:

Press "POWER" key to exit.

*******-**-**-****-**

**-***-**-*****-***

**-***-***-***-***

**

Safety:

HDMI EDID:

HDMI UART:

Touch Sensor Ver:

Safety_Non

**

OFF

-.-- / ---

Total Watch Time:

Lightsensor:

*****

**

"

*

" differs depending on the models.

[7] button

Note:

When entering this mode, the default setting is White mode.

Purity Check Mode

[7] button

White 50% mode

Red, Green, Blue mode

V-ramp mode

Black mode

[7] button

White mode

[7] button

[7] button

White 20% mode

[7] button

5-2 FL13.16EA

The White Balance Adjustment should be

performed when replacing the LCD Panel

or Digital Main CBA.

2. White Balance Adjustment

Purpose: To mix red and blue beams correctly for

pure white.

Symptom of Misadjustment: White becomes bluish

or reddish.

1. Operate the unit for more than 60 minutes.

2. Enter the service mode.

3. Press [VOLUME DOWN] button three times on the

remote control unit to select “Drive setting” mode.

“Drive” appears in the screen.

4. Set the color analyzer at the CHROMA mode and

zero point calibration. Bring the optical receptor

pointing at the center of the LCD-Panel.

Note: The optical receptor must be set

perpendicularly to the LCD Panel surface.

5. Press [3] button to select the “HDB” for High Drive

Blue adjustment. (“HDB” appears in the screen.)

6. Press [MENU] button. The internal Raster signal

appears in the screen. (“Internal (Single)” appears

in the upper right of the screen as shown below.)

7. Press [CHANNEL UP/DOWN] buttons to adjust

the color temperature becomes 12000°K

(x

=

0.272 / y

=

0.278 ± 0.003).

8. Press [1] button to select the “HDR” for High Drive

Red adjustment (“HDR” appears in the screen.)

and press [CHANNEL UP/DOWN] buttons to

adjust the color temperature.

9. If necessary, adjust the “HDB” or “HDR” again.

10. Press [6] button to select the “LDB” for Low Drive

Blue adjustment (“LDB” appears in the screen.)

and press [CHANNEL UP/DOWN] buttons to

adjust the color temperature.

11. Press [4] button to select the “LDR” for Low Drive

Red adjustment (“LDR” appears in the screen.)

and press [CHANNEL UP/DOWN] buttons to

adjust the color temperature.

12. If necessary, adjust the “LDB” or “LDR” again.

13. Press [VOLUME DOWN] button to shift to the

“Debugging Message” mode.

If there is no message under “[WB]” section, this

adjustment completes.

If “Drive settings are NG. Retry again.” is

displayed, repeat above steps from 5. to 12. Then

check “Debugging Message” again. If “Drive

settings are NG. Retry again.” is displayed, replace

the LCD Panel or Digital Main CBA.

14. To cancel or to exit from the White Balance

Adjustment, press [CH RETURN] or [PREV CH]

button.

ITEM

SPECIFICATION

Color temperature

x= 0.272 ± 0.003

y= 0.278 ± 0.003

Input Signal

Internal pattern

(40/80% raster)

Measurement point Screen center

M. EQ.

CA-310 (KONICA MINOLTA

Luminance meter) or

measuring instrument as

good as CA-310.

Aging time

60min.

(Retail MODE/100IRE Raster

HDMI 1080i@60)

MODE setting of TV

Shipment setting/

Retail MODE

Ambient

temperature

25°C ± 5°C

Color Analyzer

Perpendicularity

To avoid interference from ambient

light, this adjustment should be

performed in a dark room.

Internal (Single)

HDB 0

Internal (Single)

LDB 0

6-1 FL13.16INT

HOW TO INITIALIZE THE LCD TV

The purpose of initialization is to place the set in a new out of box condition. The customer will be prompted to

select a language and program channels after the set has been initialized.

To put the program back at the factory-default, initialize the LCD TV using the following procedure.

1. Turn the power on.

2. Enter the service mode.

- To cancel the service mode, press [ ] button on

the remote control unit.

3. Press [BACK] button to enter the Control Panel

Key Confirmation Menu.

4. Press any button on the control panel.

5. Press [INFO] button to proceed with the self check

mode.

6. Make sure to confirm the "INITIALIZED FINISH"

appears in the green screen.

7. Unplug the AC Cord and plug it back on again.

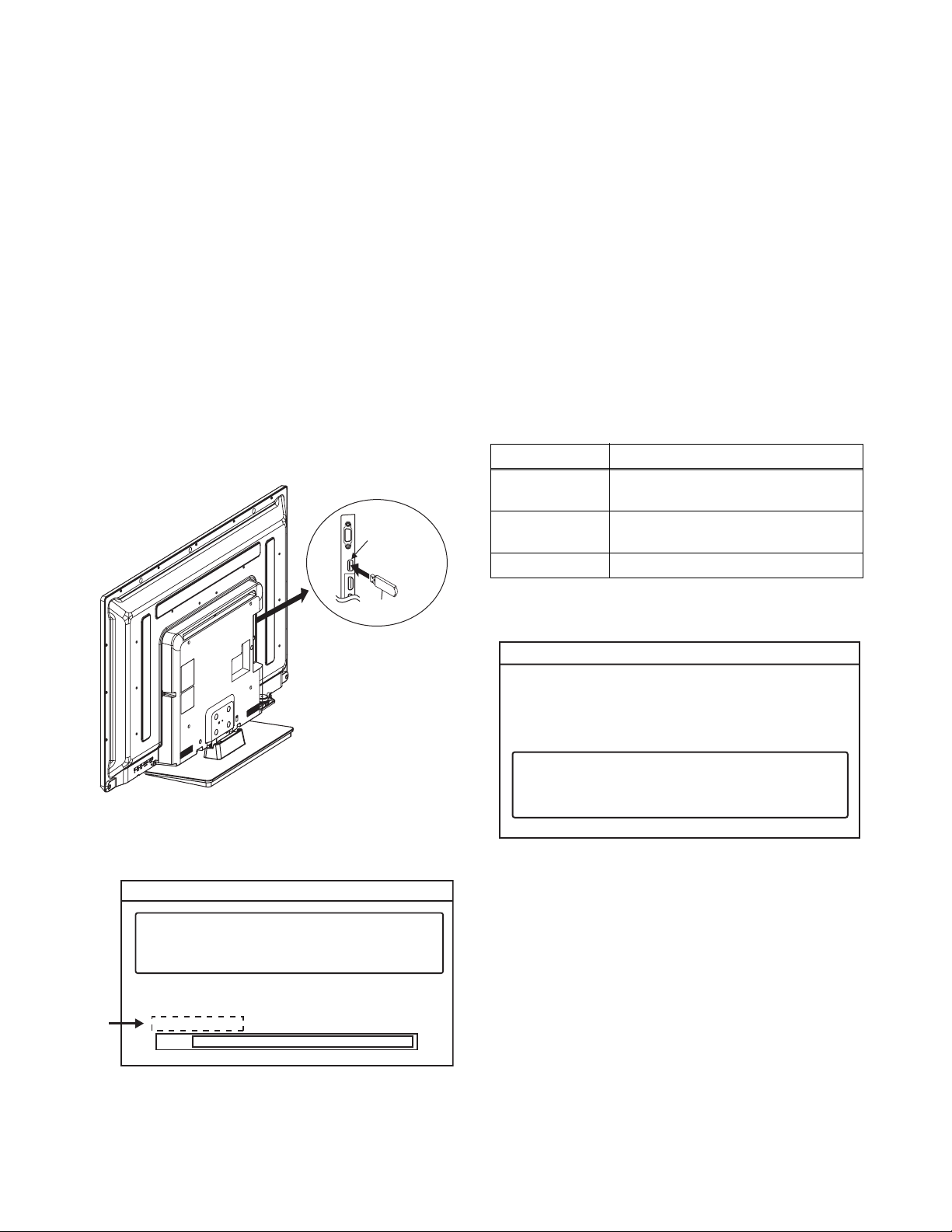

7-1 FL13.16FW

FIRMWARE RENEWAL MODE

Equipment Required

a. USB storage device

b. Remote Control Unit

Firmware Update Procedure

User Upgrade (Filename example: TVNB012_00_UF_XX91_BC.ecc or TVNB1012_00_UG_XX91_BA0.bin)

Upgrade the firmware only. The setting values will not be initialized.

The User Upgrade and the Firmware Upgrade (Factory Upgrade) will be done by the same file. If you want to

upgrade the firmware and initialize the setting values also, add “FACT_” at the beginning of the filename.

If you want to upgrade the firmware only and leave the setting values as they are, eliminate the “FACT_” from the

filename.

Update procedure

1. Turn the power on.

2. Press [MENU] button to display Menu.

3. Select “Features”.

4. Select “Software Upgrade”.

5. Select “Upgrade” to display Upgrade screen.

6. Press [OK] button to display Software Upgrade

screen.

7. Select “USB” and press [OK] button.

8. Insert the USB storage device to the USB port as

shown below.

9. Select “Check” and press [OK] button.

10. Select “Upgrade” and press [OK] button to start

software upgrade.

11. The update will start and the following will appear

in the screen.

Note: If the above screen isn’t displayed, repeat from

step 1.

The appearance shown in *1 is described as follows.

12. When the firmware update is completed, the

following will appear in the screen.

Remove the USB storage device from the USB

port.

Turn the power off and turn the power on again.

USB port

USB storage

device

Rear Cabinet

Appearance State

Downloading...

Downloading the firmware from

the USB storage device.

Writing...

Writing the downloaded firmware

in flash memory.

Checking... Checking the new firmware.

Software upgrade in progress. Please wait.

Do not remove the USB storage device or

turn the TV off while upgrade is in progress.

Software Upgrade

Downloading...

Current Version:

New Version:

*******-***-*-***-****

*******-***-*-***-****

0%

*1

"

*

" differs depending on the models.

Software Upgrade

The software upgrade is completed.

Remove USB storage device, turn TV off then on again.

7-2 FL13.16FW

Factory Upgrade (Firmware Upgrade/Flash Upgrade)

Firmware Upgrade

(Filename example: FACT_TVNB012_00_UF_XX91_BC.ecc or FACT_TVNB1012_00_UG_XX91_BA0.bin)

Upgrade the firmware and initialize the setting values.

The User Upgrade and the Firmware Upgrade (Factory Upgrade) will be done by the same file. If you want to

upgrade the firmware and initialize the setting values also, add “FACT_” at the beginning of the filename.

If you want to upgrade the firmware only and leave the setting values as they are, eliminate the “FACT_” from the

filename.

Flash Upgrade

(Filename example: ALL_TVNB012_00_UF_XX91_BC.ecc or ALL_TVNB1012_00_UG_XX91_BA0.bin)

Upgrade the firmware and initialize the setting values along with the factory default such as White Balance, etc.

Before the upgrade, you will need to make a note of all the factory default so you will be able to set it back on the

TV after the initialization.

The Flash Upgrade will be done by it's unique file.

The User Upgrade/Firmware Upgrade (Factory Upgrade) file cannot be used for this upgrade.

Update procedure

1. Turn the power off.

2. Insert the USB storage device to the USB port as

shown below.

3. Turn the power on.

4. The update will start and the following will appear

in the screen.

Note: If the above screen isn’t displayed, repeat from

step 1.

The appearance shown in *1 is described as follows.

5. When the firmware update is completed, the

following will appear in the screen.

Remove the USB storage device from the USB

port.

Turn the power off and turn the power on again.

Service mode initial screen with a word

“INITIALIZED” will appear in the screen. The color

of the word “INITIALIZED” will change from red to

green when initialization is completed.

USB port

USB storage

device

Rear Cabinet

Software upgrade in progress. Please wait.

Do not remove the USB storage device or

turn the TV off while upgrade is in progress.

Software Upgrade

Downloading...

Current Version:

New Version:

*******-***-*-***-****

*******-***-*-***-****

0%

*1

"

*

" differs depending on the models.

Appearance State

Downloading...

Downloading the firmware from

the USB storage device.

Writing...

Writing the downloaded firmware

in flash memory.

Checking... Checking the new firmware.

Software Upgrade

The software upgrade is completed.

Remove USB storage device, turn TV off then on again.

Loading...

Loading...