Panasonic PM2-LF10 Installation Manual

INSTRUCTION MANUAL

Photoelectric Sensor Micro-photosensor

PM2 Series

Thank you very much for using SUNX products. Please read this Instruction Manual carefully and thoroughly for the correct and optimum use of this product. Kindly keep this manual in a convenient place for quick reference.

Never use this product as a sensing device for personnel protection.

In case of using sensing devices for personnel protection, use products which meet standards, such as OSHA, ANSI or IEC etc., for personnel protection appli-

WARNING cable in each region or country.

1 SPECIFICATIONS

|

Type |

Top sensing |

Front sensing |

L type (Top sensing) |

||

Model |

Connector type |

PM2-LH10 PM2-LH10B |

PM2-LF10 |

PM2-LF10B |

PM2-LL10 |

PM2-LL10B |

Item No. |

Cable type |

PM2-LH10-C1 PM2-LH10B-C1 PM2-LF10-C1 PM2-LF10B-C1 PM2-LL10-C1 PM2-LL10B-C1 |

||||

Sensing range |

2.5 to 8mm (Convergent point 5mm) with white non-glossy paper (15 15mm) (Note 1) |

|||||

Supply voltage |

5 to 24V DC 10% Ripple P-P 5% or less |

|

||||

Current consumption |

Average: 25mA or less, Peak: 80mA or less |

|

||||

NPN open-collector transistor

Output

Maximun sink current: 100mA

Applied voltage: 30V DC or less (between output and 0V)

Residual voltage: 1V or less (at 100mA sink current), 0.4V or less (at 16mA sink current)

|

Output operation |

Light-ON |

Dark-ON |

Light-ON |

Dark-ON |

Light-ON |

Dark-ON |

|

Over current protection |

|

|

Incorporated |

|

|

|

Response time |

|

|

0.8ms or less |

|

|

||

Ambient temperature |

-10 to +55 (No dew condensation or icing allowed), Storage: -25 to +80 |

|

|||||

Ambient humidity |

|

|

45 to 85% RH, Storage: 45 to 85% RH |

|

|

||

Cable |

|

0.2mm2 3-core cabtyre cable, 1m long (Cable type only) (Note 2) |

|

||||

Material |

Enclosure: Polycarbonate, terminal part (Connector type only): HSM (Ag plated) |

||||||

Cable fixing part (Cable type only): PBT |

|

|

|

||||

|

|

|

|

|

|||

Notes: 1) Take care that, depending on the product, the sensing range may extend to 12.5mm maximum with white non-glossy paper.

2) The cable cannot be extended.

2 CAUTIONS

A reverse supply protection circuit and output short-circuit protection circuit are not incorporated. Since wrong wiring may cause malfunction, make sure to check the terminal arrangement, cable wiring and power supply area before wiring. Make sure that the power supply is off while wiring. Verify that the supply voltage variation is within the rating.

If power is supplied from a commercial switching regulator, ensure that the frame ground (F.G.) terminal of the power supply is connected to an actual ground.

Do not use during the initial transient time (50ms) after the power supply is switched on.

Do not run the wires together with high-voltage lines or power lines or put them in the same raceway. This can cause malfunction due to induction. For the connector type, the cable length must be 2m, or less, with 0.3mm2, or more, cable. If the cable is extended for more than 2m, connect a capacitor of 10 F approx. between +V and 0V terminals. Further, the cable type cannot be extended.

Avoid dust, dirt, and steam.

Take care that the sensor does not come in direct contact with water, oil, grease, or organic solvents, such as, thinner etc.

Take care that the sensor is not directly exposed to fluorescent lamp from a rapid-starter lamp or a high frequency lighting device, as it may affect the sensing performance.

If there is a reflective object (conveyor, etc.) in the background, since it may affect the sensing, use by keeping enough distance from the reflective object.

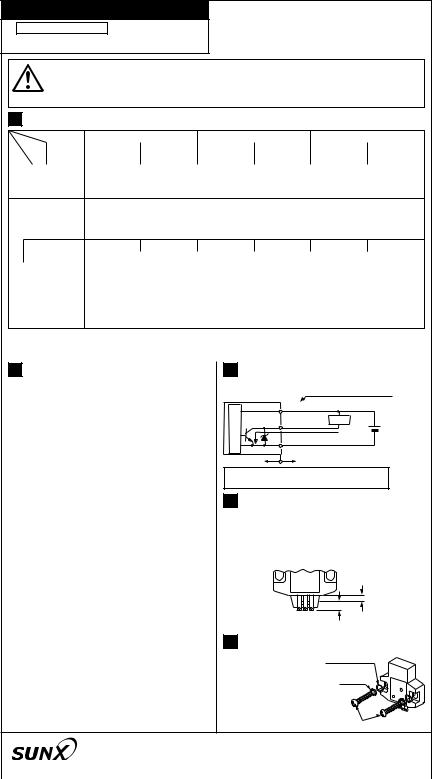

3 I/O CIRCUIT DIAGRAMS

|

|

|

Color code of cable type |

||

|

|

|

and mainting cable |

|

|

circuit |

|

|

(Brown) +V |

|

|

Tr |

|

(Black) Output Load |

+ |

5 to 24V DC |

|

Sensor |

|

ZD |

100mA max. |

- |

10% |

|

|

||||

|

|

|

|||

|

|

|

(Blue) 0V |

|

|

Internal circuit |

|

Users' circuit |

|

|

|

Symbols...ZD : Surge absorption zener diode Tr : NPN output transistor

4 SOLDERING (Connector type only)

If soldering is done directly on the terminals, strictly adhere to the conditions given below. Soldering temperature: 260 or less

Soldering time: 10 sec. or less

Soldering position: 1.5mm, or more, away from the sensor body.

|

|

1.5mm |

|

|

0V OUT V |

|

|

||

|

Soldering position |

|

||

5 MOUNTING |

Plain washer |

|

||

When fixing the sensor |

(Outer dia 6mm) |

|

||

with screws, use |

M3 |

|

||

Spring |

|

|||

screws and the tight- |

|

|||

washer |

|

|||

ening torque should be |

|

|||

PM2 |

|

|||

0.49N m or less. |

|

0V O |

|

|

Furthermore, |

use |

+ |

||

|

||||

|

|

|||

small, round type plain washers ( 6mm).

|

Head office: 2431-1 Ushiyam-cho, Kasugai-shi, Aichi, 486-0901,Japan |

|

|

|

Phone: +81-(0)568-33-7211 Fax: +81-(0)568-33-2631 |

|

|

SUNX Limited |

Overseas Sales Dept.: Phone: +81-(0)568-33-7861 Fax: +81-(0)568-33-8591 |

||

Internet homepage: http://www.sunx.co.jp/ |

|

||

|

|

|

|

|

|

PRINTED IN JAPAN |

|

This bag is a product made from polyethylene. Even if it burns, harmful gas is not generated. |

|

||

Loading...

Loading...