Omron GT1, DeviceNet MULTIPLE I/O TERMINAL, DeviceNet Slaves User Manual

Cat. No. W348-E1-05

DRT1-COM

GT1 Series

DeviceNet

MULTIPLE I/O TERMINAL

OPERATION MANUAL

DRT1-COM

GT1 Series

DeviceNet

MULTIPLE I/O TERMINAL

Operation Manual

Revised May 2003

iv

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means “word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of information.

Note Indicates information of particular interest for efficient and convenient operation of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

Trademarks and Copyrights

COMBICON is a registered trademark of Phoenix Contact K.K.

DeviceNet is a registered trademark of the Open DeviceNet Vendor Association, Inc.

PowerTap is a registered trademark of the Allen-Bradley Company, Inc.

OMRON, 1998

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

v

vi

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xi |

|

1 |

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xii |

2 |

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xii |

3 |

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xii |

4 |

Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xii |

5 |

Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xiii |

6 |

EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xv |

SECTION 1 |

|

|

MULTIPLE I/O TERMINAL . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

|

1-1 |

MULTIPLE I/O TERMINAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

1-2 |

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

SECTION 2 |

|

|

Hardware Setup and Operational Check. . . . . . . . . . . . . . . |

19 |

|

2-1 |

Basic Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

2-2 |

Specific Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

21 |

SECTION 3 |

|

|

Sample Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

27 |

|

3-1 |

Examples of Counter Unit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

SECTION 4 |

|

|

Basic I/O Unit Specifications . . . . . . . . . . . . . . . . . . . . . . . . . |

35 |

|

4-1 |

Communications Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

36 |

4-2 |

Specifications Common to All Basic I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

40 |

4-3 |

Transistor Input Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

44 |

4-4 |

Transistor Output Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

66 |

4-5 |

Relay Output Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

90 |

SECTION 5 |

|

|

Special I/O Unit Specifications . . . . . . . . . . . . . . . . . . . . . . . |

97 |

|

5-1 |

Analog Input Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

98 |

5-2 |

Analog Output Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

124 |

5-3 |

GT1-TS04T and GT1-TS04P Temperature Input Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

148 |

5-4 |

GT1-CT01 Counter Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

172 |

SECTION 6 |

|

|

Communications Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

189 |

|

6-1 |

Remote I/O Communications Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

190 |

SECTION 7 |

|

|

Troubleshooting and Maintenance . . . . . . . . . . . . . . . . . . . . |

195 |

|

7-1 |

Normal Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

196 |

7-2 |

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

197 |

7-3 |

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

204 |

Appendices |

|

|

A |

Slave Device Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

209 |

B |

Connectable Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

215 |

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

221 |

|

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

223 |

|

vii

About this Manual:

This manual describes the operation of the DeviceNet MULTIPLE I/O TERMINAL and includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before attempting to operate the MULTIPLE I/O TERMINAL.

Section 1 provides an overview of the MULTIPLE I/O TERMINAL, including its features and functions.

Section 2 provides the basic procedure for operation and includes an actual example.

Section 3 provides some examples of programs used with the Counter Unit.

Section 4 provides the basic specifications for the I/O Units including Communications Units, Transistor Input and Output Units, and Relay Output Units.

Section 5 provides the specifications for Special I/O Units, including the Analog Input Unit, the Analog Output Unit, the Temperature Input Unit, and the Counter Unit. Setting procedures for a Configurator are also provided.

Section 6 provides characteristics for communications in the DeviceNet Unit and describes how to calculate the times required for communications between Units.

Section 7 provides procedures for dealing with errors as well as basic maintenance procedures.

The Appendices provide Slave device profiles and lists of connectable devices.

!WARNING Failure to read and understand the information provided in this manual may result in personal injury or death, damage to the product, or product failure. Please read each section in its entirety and be sure you understand the information provided in the section and related sections before attempting any of the procedures or operations given.

ix

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PC) Systems and related devices.

The information contained in this section is important for the safe and reliable application of PC Systems. You must read this section and understand the information contained before attempting to set up or operate a PC System.

1 |

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xii |

2 |

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xii |

3 |

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xii |

4 |

Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xii |

5 |

Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xiii |

6 |

EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xv |

xi

Intended Audience |

1 |

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

•Personnel in charge of installing FA systems.

•Personnel in charge of designing FA systems.

•Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the manual or applying the product to nuclear control systems, railroad systems, aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are sufficient for the systems, machines, and equipment, and be sure to provide the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating OMRON PC Systems. Be sure to read this manual before attempting to use the software and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PC System and all PC Units be used for the specified purpose and under the specified conditions, especially in applications that can directly or indirectly affect human life. You must consult with your OMRON representative before applying a PC System to the abovementioned applications.

3 Safety Precautions

!WARNING Never attempt to disassemble any Units while power is being supplied. Doing so may result in serious electrical shock or electrocution.

!WARNING Never touch any of the terminals while power is being supplied. Doing so may result in serious electrical shock or electrocution.

4 Operating Environment Precautions

Do not operate the control system in the following places.

•Locations subject to direct sunlight.

•Locations subject to temperatures or humidity outside the range specified in the specifications.

•Locations subject to condensation as the result of severe changes in temperature.

•Locations subject to corrosive or flammable gases.

•Locations subject to dust (especially iron dust) or salts.

•Locations subject to shock or vibration.

•Locations subject to exposure to water, oil, or chemicals.

xii

Application Precautions |

5 |

•Take appropriate and sufficient countermeasures when installing systems in the following locations.

•Locations subject to static electricity or other forms of noise.

•Locations subject to strong electromagnetic fields.

•Locations subject to possible exposure to radioactivity.

•Locations close to power supplies.

!Caution The operating environment of the PC System can have a large effect on the longevity and reliability of the system. Improper operating environments can lead to malfunction, failure, and other unforeseeable problems with the PC System. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life of the system.

5 Application Precautions

Observe the following precautions when using the MULTIPLE I/O TERMINAL.

!WARNING Failure to abide by the following precautions could lead to serious or possibly fatal injury. Always heed these precautions.

• Always ground the system to 100 Ω or less when installing the system to protect against electrical shock.

•Always turn OFF the power supply to the system before attempting any of the following. Performing any of the following with the power supply turned ON may lead to electrical shock:

•Mounting or removing any Units (e.g., Power Supply Unit, I/O Units, CPU Unit, etc.) or memory cassettes.

•Assembling any devices or racks.

•Connecting or disconnecting any cables, connectors, or wiring.

!Caution Failure to abide by the following precautions could lead to faulty operation of or damage to the MULTIPLE I/O TERMINAL. Always heed these precautions.

•Use the Units only with the power supplies and voltages specified in the operation manuals. Other power supplies and voltages may damage the Units.

•Take measures to stabilize the power supply to conform to the rated supply if it is not stable.

•Provide circuit breakers and other safety measures to provide protection against shorts in external wiring.

•Do not apply voltages exceeding the rated input voltage to Input Units. The Input Units may be destroyed.

•Do not apply voltages exceeding the maximum switching capacity to Output Units. The Output Units may be destroyed.

•Always disconnect the LG terminal when performing withstand voltage tests.

•Install all Units according to instructions in the operation manuals. Improper installation may cause faulty operation.

•Be sure to tighten Backplane screws, terminal screws, and cable connector screws securely.

•Do not attempt to take any Units apart, to repair any Units, or to modify any Units in any way.

xiii

Application Precautions |

5 |

•Do not use communications cables or I/O cables in parallel to or close to high-tension, high-rate current carrying lines. Doing so may cause faulty operation.

•Be sure to install the MULTIPLE I/O TERMINAL in the proper direction. Not doing so may cause faulty operation.

•When attaching Units to the DIN track, be sure to attach them securely. Not doing so may cause the Units to be damaged.

•Use this product within the specified ranges for communications distances and connection distances. Not doing so may lead to faulty operation.

•Use the specified cables when making communications connections. Not doing so may cause faulty operation.

•Be sure to wire the communications paths, the communications power supplies, the internal power supplies, and the I/O power supplies correctly. Use voltages for the power supplies that are within the specified ranges. Not doing so may cause malfunction.

•Do not, under any circumstances, use this product with loads exceeding the contact rating values. Doing so may cause deterioration of insulation and damage.

•The life-expectancy of the relays depends greatly on the switching conditions. Before practical use of the product, perform a trial operation of the product in the actual conditions in which it will be used. Use the product at a switching frequency that will allow efficient operation. Continued use of the product in conditions causing reduced efficiency will cause deterioration of insulation and damage.

•Connection Cables

•Before switching ON power supplies, check that the connectors are mounted securely.

•Check that the connectors for the I/O Unit interfaces are securely locked.

•Tightening Torques

Check that all the screws for the Units are tightened to the correct torque. Not doing so may cause faulty operation.

•Internal power supplies, I/O power supplies, terminal screws:

0.3to 0.5 N • m

•Communications cable, communications connector screws:

0.25to 0.35 N • m

•High-density I/O Unit connector screws: 0.25 to 0.35 N • m

•Cleaning

•Do not used thinner-based products for cleaning. Doing so may dissolve attachment areas or cause discoloration.

•Power Supply

•Use separate power supplies for communications power supplies, internal power supplies, I/O power supplies, load power supplies, and encoder power supplies. Not doing so may lead to faulty operation.

!Caution The following precautions are necessary to ensure the general safety of the system. Always heed these precautions.

•Provide double safety mechanisms to handle incorrect signals that can be generated by broken signal lines or momentary power interruptions.

•Provide external interlock circuits, limit circuits, and other safety circuits in addition to any provided within the PC System to ensure safety.

xiv

EC Directives |

6 |

6 EC Directives

The MULTIPLE I/O TERMINAL conforms to EMC as follows:

EMC Directives

OMRON devices that comply with EC Directives also conform to the related EMC standards so that they can be more easily built into other devices or the overall machine. The actual products have been checked for conformity to EMC standards (see the following note). Whether the products conform to the standards in the system used by the customer, however, must be checked by the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of the equipment or control panel on which the OMRON devices are installed. The customer must, therefore, perform the final check to confirm that devices and the overall machine conform to EMC standards.

The MULTIPLE I/O TERMINAL products that comply with EC Directives must be installed as follows:

1,2,3... 1. MULTIPLE I/O TERMINAL products are designed for installation inside control panels. All MULTIPLE I/O TERMINAL products must be installed within control panels.

2.Used reinforced insulation or double insulation for the DC power supplies used for the communications power supply, internal circuit power supply, and the I/O power supplies.

3.MULTIPLE I/O TERMINAL products that meet EC Directives also meet the Common Emission Standard (EN50081-2). However, radiated emission (at 10 m) will vary with the overall configuration of the control panel, other devices connected to the control panel, and other conditions. You must therefore confirm that EC Directives are satisfied for the overall machine or device.

4.MULTIPLE I/O TERMINAL products that meet EC Directives have configurations with less than 30 m of I/O wiring, and less than 10 m of power supply wiring.

The following examples show means of reducing noise.

1,2,3... 1. Noise from the communications cable can be reduced by installing a ferrite core on the communications cable within 10 cm of the DeviceNet Master Unit.

Ferrite Core (Data Line Filter): LF130B (Manufactured by Easy Magnet Co.)

Impedance specifications 25 MHZ: 105 Ω

100 MHZ: 190 Ω

|

|

30 mm |

|

|

|

32 mm |

|

|

|

|

|

|

|

13 mm |

|

31.5 mm |

|

|

||

2.Wire the control panel with cables as thick and short as possible and ground to 100 Ω min.

xv

EC Directives |

6 |

3.Keep DeviceNet communications cables as short as possible and ground to 100 Ω min.

xvi

SECTION 1

MULTIPLE I/O TERMINAL

This section provides an overview of the MULTIPLE I/O TERMINAL, including its features and functions.

1-1 |

MULTIPLE I/O TERMINAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

|

1-1-1 |

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

1-1-2 |

System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

1-1-3 |

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

|

1-1-4 Communications Units and I/O Units . . . . . . . . . . . . . . . . . . . . . . . |

4 |

|

|

1-1-5 |

List of Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

1-2 |

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

|

|

1-2-1 I/O Unit Interface Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

|

|

1-2-2 |

Exchanging Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

|

1-2-3 |

Allocating I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

|

1-2-4 I/O Unit Interface Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

|

|

1-2-5 |

I/O Configuration Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

17 |

1

MULTIPLE I/O TERMINAL |

Section 1-1 |

1-1 MULTIPLE I/O TERMINAL

1-1-1 Overview

A MULTIPLE I/O TERMINAL is a building-block DeviceNet Slave that consists of a Communications Unit that interfaces one or more I/O Units. The I/O Unit interface supports up to 8 I/O Units and a total of up to 1,024 I/O points. I/O Units are connected using simple snap-on connections via I/O Unit Connecting Cables. Allocation and address settings on the I/O Unit interface are not required, enabling simple, flexible distributed I/O control.

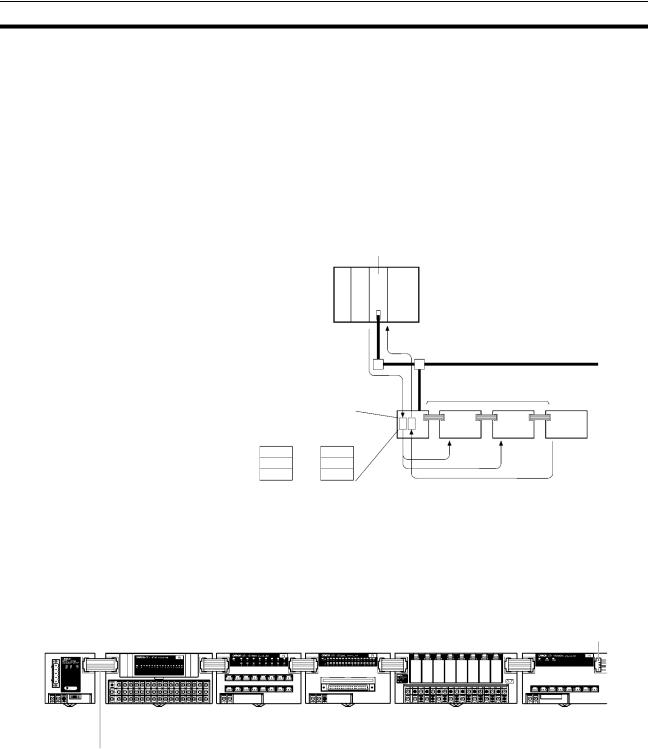

1-1-2 System Configuration

DeviceNet Master Unit

DeviceNet Network

I/O Unit Connecting Cable

Communications |

I/O Units |

Unit |

|

I/O Unit interface

Maximum of 8 Units; total length: 3 m, 1 m max. between Units

Total number of points (inputs + outputs): 1,024 points

The total number of points must be within the maximum number supported by the Master.

Example: With C200HW-DRM21-V1 Master, 512 inputs/512 outputs

2

MULTIPLE I/O TERMINAL |

Section 1-1 |

1-1-3 Features

Simple Connections

Automatic Recognition of

I/O Units

Status Notification

Many Types of I/O Unit

An I/O-intensive System Can be Built at Low Cost

Range Setting by

Configurator

The Communications Unit and the I/O Units are separate, and the Communications Unit and the I/O Units are connected by an I/O Unit interface. I/O can be expanded simply by connecting additional I/O Units to the I/O Unit interface.

When the power to the Communications Unit is turned ON, the models of the I/O Units on the I/O Unit interface are automatically recognized, and the number of remote I/O communications points with the DeviceNet Master Unit is automatically determined. This enables I/O to be increased or decreased simply by connecting or disconnecting I/O Units.

Status information about the I/O Unit interface can be transmitted as inputs to the DeviceNet Master Unit (two words).

The following I/O Units are available.

•16or 32-point Transistor Input Units (terminal block, connector, 25-pin D- sub connector, or high-density connector)

•16or 32-point Transistor Output Units (terminal block, connector, 25-pin D-sub connector, or high-density connector)

•8-point/16-point Relay Output Unit (16-point Unit)

•4- or 8-point Analog Input Unit (terminal block or connector)

•4-point Analog Output Unit (terminal block or connector)

•1-point Pulse Input Unit (high-speed counter)

•4-point Temperature Input Unit

Compared with fixed I/O Terminals, a high cost-performance ratio can be achieved if I/O Units are used.

The input and output ranges for the Analog Input, Analog Output, and Temperature Input Units can be set for each point using the Configurator (with version 1.11 or later). Using DIP switches, ranges can be set in 2-point units for the Analog Input and Analog Output Units, and in 4-point units for the Temperature Input Unit.

3

MULTIPLE I/O TERMINAL Section 1-1

1-1-4 Communications Units and I/O Units

Communications Unit The Communications Unit interfaces the I/O Units to the DeviceNet.

•It controls the I/O Units in response to I/O refresh requests from the DeviceNet Master.

•It automatically recognizes the configuration of the I/O Units when the I/O Unit interface is initialized.

•It notifies the connection status or the status information for the I/O Units to the DeviceNet Master Unit.

•It provides a DIP switch to set the node number and baud rate of the MULTIPLE I/O TERMINAL as a DeviceNet Slave.

DeviceNet Master Unit

Output area |

Input area |

||

(Master → |

Commu- (Communications |

||

nications Unit) |

Unit → |

Master) |

|

|

0 |

Status |

|

|

1 |

|

2 |

DeviceNet Network

I/O Unit interface

0 |

1 |

2 |

Example: |

Example: |

Example: |

Outputs |

Outputs |

Inputs |

I/O Units |

There are various I/O Units that can be connected to the I/O Unit interface. |

•I/O Units are connected to the Communications Unit using an I/O Unit Connecting Cable (included with the I/O Unit, a 1-m I/O Unit Connecting Cable (GCN1-100) is also available).

•No address or baud rate settings are required.

•The connection order of I/O Units is flexible.

|

Units with Connectors |

|

|

|

Communications Unit |

Transistor Input Unit |

|

End connector |

|

Transistor Output Unit |

Relay Output Unit |

|||

|

|

Units with Terminal Blocks |

Units with High-density |

Analog Input Unit |

|

Transistor Input Unit |

Connectors |

Analog Output Unit |

|

Transistor Output Unit |

Transistor Input Unit |

|

I/O Unit Connecting Cables |

Transistor Output Unit |

|

|

|

|

||

Included with Unit: 40 mm |

|

|

|

GCN1-100: |

1 m (sold separately) |

|

|

4

MULTIPLE I/O TERMINAL Section 1-1

1-1-5 |

List of Models |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Unit |

I/O |

Words allocated |

I/O |

Unit |

Installa- |

Model number |

Remarks |

||

|

|

|

points |

in PC memory |

connections |

power |

tion |

|

|

|

|

|

|

|

|

|

|

supply |

|

|

|

|

|

|

|

Input |

Output |

|

|

|

|

|

|

|

|

|

|

voltage |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Communications Unit |

None |

Status |

0 words |

None |

24 VDC |

DIN track |

DRT1-COM |

--- |

|

|

|

|

|

two |

|

|

(sup- |

|

|

|

|

|

|

|

words |

|

|

plied |

|

|

|

|

|

|

|

|

|

|

from out- |

|

|

|

|

Basic I/O |

Transistor |

16 |

1 word |

0 words |

M3 terminal |

|

GT1-ID16 |

NPN |

|

|

side) |

|

||||||||

|

Units |

Input Units |

inputs |

|

|

block |

|

GT1-ID16-1 |

PNP |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

1 word |

0 words |

Connectors |

|

|

GT1-ID16MX |

NPN |

|

|

|

inputs |

|

|

(made by |

|

|

GT1-ID16MX-1 |

PNP |

|

|

|

|

|

|

MOLEX) |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

1 word |

0 words |

Connectors |

|

|

GT1-ID16ML |

NPN |

|

|

|

inputs |

|

|

(made by |

|

|

(See note 2.) |

|

|

|

|

|

|

|

FUJITSU) |

|

|

GT1-ID16ML-1 |

PNP |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

(See note 2.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

1 word |

0 words |

Connectors |

|

|

GT1-ID16DS |

NPN |

|

|

|

inputs |

|

|

(25-pin D- |

|

|

(See note 2.) |

|

|

|

|

|

|

|

sub connec- |

|

|

GT1-ID16DS-1 |

PNP |

|

|

|

|

|

|

tors) |

|

|

||

|

|

|

|

|

|

|

|

(See note 2.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

32 |

2 words |

0 words |

High-density |

|

|

GT1-ID32ML |

NPN |

|

|

|

inputs |

|

|

connector |

|

|

GT1-ID32ML-1 |

PNP |

|

|

|

|

|

|

(made by |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FUJITSU) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Transistor |

16 out- |

0 words |

1 word |

M3 terminal |

|

|

GT1-OD16 |

NPN |

|

|

Output |

puts |

|

|

block |

|

|

GT1-OD16-1 |

PNP |

|

|

Units |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

16 out- |

0 words |

1 word |

Connectors |

|

|

GT1-OD16MX |

NPN |

|

|

|

|

|

|

||||||

|

|

|

puts |

|

|

(made by |

|

|

GT1-OD16MX-1 |

PNP |

|

|

|

|

|

|

MOLEX) |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 out- |

0 words |

1 word |

Connectors |

|

|

GT1-OD16ML |

NPN |

|

|

|

puts |

|

|

(made by |

|

|

(See note 2.) |

|

|

|

|

|

|

|

FUJITSU) |

|

|

GT1-OD16ML-1 |

PNP |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

(See note 2.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 out- |

0 words |

1 word |

Connectors |

|

|

GT1-OD16DS |

NPN |

|

|

|

puts |

|

|

(25-pin D- |

|

|

(See note 2.) |

|

|

|

|

|

|

|

sub connec- |

|

|

GT1-OD16DS-1 |

PNP |

|

|

|

|

|

|

tors) |

|

|

||

|

|

|

|

|

|

|

|

(See note 2.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

32 out- |

0 words |

2 words |

High-density |

|

|

GT1-OD32ML |

NPN |

|

|

|

puts |

|

|

connector |

|

|

GT1-OD32ML-1 |

PNP |

|

|

|

|

|

|

(made by |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FUJITSU) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Relay Out- |

8 out- |

0 words |

1 word |

M3 terminal |

|

|

GT1-ROP08 |

--- |

|

|

put Units |

puts |

|

|

block |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 out- |

0 words |

1 word |

M3 terminal |

|

|

GT1-ROS16 |

--- |

|

|

|

puts |

|

|

block |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5

MULTIPLE I/O TERMINAL |

|

|

|

|

Section 1-1 |

||||

|

|

|

|

|

|

|

|

|

|

Unit |

I/O |

Words allocated |

I/O |

Unit |

Installa- |

Model number |

Remarks |

||

|

|

points |

in PC memory |

connections |

power |

tion |

|

|

|

|

|

|

|

|

|

supply |

|

|

|

|

|

|

Input |

Output |

|

|

|

|

|

|

|

|

|

voltage |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Special I/ |

Analog |

4 inputs |

4 words |

0 word |

M3 terminal |

24 VDC |

DIN track |

GT1-AD04 |

Inputs: |

O Units |

Input Units |

|

|

|

block |

(sup- |

|

(See note 2.) |

4 to |

(See |

|

|

|

|

|

plied |

|

|

20 mA, 0 |

note.) |

|

|

|

|

|

from out- |

|

|

to 20 mA, |

|

|

8 inputs |

8 words |

0 word |

Connectors |

side) |

|

GT1-AD08MX |

0 to 5 V, |

|

|

|

|

|

(made by |

|

|

|

1 to 5 V, |

|

|

|

|

|

MOLEX) |

|

|

|

0 to 10 V, |

|

|

|

|

|

|

|

|

|

–10 to |

|

|

|

|

|

|

|

|

|

10 V |

|

|

|

|

|

|

|

|

|

|

|

Analog |

4 out- |

0 words |

4 words |

M3 terminal |

|

|

GT1-DA04 |

Outputs: |

|

Output |

puts |

|

|

block |

|

|

(See note 2.) |

4 to |

|

Units |

|

|

|

|

|

|

|

20 mA, |

|

|

|

|

|

|

|

|

|

0 to 5 V, |

|

|

|

|

|

|

|

|

|

1 to 5 V, |

|

|

|

|

|

|

|

|

|

0 to 10 V, |

|

|

|

|

|

|

|

|

|

–10 to |

|

|

|

|

|

|

|

|

|

10 V |

|

|

|

|

|

|

|

|

|

|

|

|

4 out- |

0 words |

4 words |

Connectors |

|

|

GT1-DA04MX |

Outputs: |

|

|

puts |

|

|

(made by |

|

|

|

0 to 5 V, |

|

|

|

|

|

MOLEX) |

|

|

|

1 to 5 V, |

|

|

|

|

|

|

|

|

|

0 to 10 V, |

|

|

|

|

|

|

|

|

|

–10 to |

|

|

|

|

|

|

|

|

|

10 V |

|

|

|

|

|

|

|

|

|

|

|

Tempera- |

4 inputs |

4 words |

0 words |

M3 terminal |

|

|

GT1-TS04T |

Inputs: |

|

ture Input |

|

(8 words |

|

block |

|

|

|

R, S, K, J, |

|

Units |

|

depend- |

|

|

|

|

|

T, B, L |

|

|

|

ing on |

|

|

|

|

|

|

|

|

|

|

|

|

|

GT1-TS04P |

Inputs: |

|

|

|

|

mode) |

|

|

|

|

||

|

|

|

|

|

|

|

|

Pt100, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

JPt100 |

|

|

|

|

|

|

|

|

|

|

|

Counter |

1 input |

3 words |

3 words |

M3 terminal |

|

|

GT1-CT01 |

1 external |

|

Unit |

|

|

|

block |

|

|

|

input |

|

|

|

|

|

|

|

|

|

2 external |

|

|

|

|

|

|

|

|

|

outputs |

|

|

|

|

|

|

|

|

|

|

Note The front-panel indicators and other parts of Analog Input Units, Analog Output Units, Temperature Input Units, and Counter Units differ from those of other I/O Units. These Units belong to a group called Special I/O Units.

An end connector is attached to the Communications Unit, and a 40-mm I/O Unit Connecting Cable is included with each I/O Unit. A 1-m I/O Unit Connecting Cable (GCN1-100) is also available.

1 m

6

MULTIPLE I/O TERMINAL |

|

|

|

|

Section 1-1 |

|

Applicable Connectors |

The applicable connectors are shown in the following table. |

|

||||

|

|

|

|

|

|

|

|

|

Connector |

|

Model number |

|

Remarks |

|

|

|

|

|

|

|

|

Connec- |

Pressure- |

Housing |

52109-0390 |

|

For AWG#24 |

|

tors made |

welded |

|

|

|

|

|

by MOLEX |

|

|

|

|

|

|

Crimp |

Housing |

51030-0330 |

|

|

|

|

|

|

|

|||

|

|

|

|

(See note.) |

|

|

|

|

|

|

|

|

|

|

|

|

Reeled con- |

50083-8014 |

|

For AWG#24 to 30 |

|

|

|

tacts |

|

|

|

|

|

|

50084-8014 |

|

For AWG#22 to 24 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Loose con- |

50083-8114 |

|

For AWG#24 to 30 |

|

|

|

tacts |

(See note.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

50084-8114 |

|

For AWG#22 to 24 |

|

|

|

|

|

|

|

|

|

|

Crimping tool |

57036-5000 |

|

For AWG#22 to 26 |

|

|

|

|

|

|

|

|

|

|

|

57037-5000 |

|

For AWG#24 to 30 |

|

|

|

|

(See note.) |

|

|

|

|

|

|

|

|

|

|

Connec- |

Soldered |

|

FCN361J024-AU |

|

|

|

tors made |

|

|

|

|

|

|

by |

|

|

|

|

|

|

Pressure-welded |

FCN367J024-AU/F |

|

|

||

|

FUJITSU |

|

|

|||

|

correspond- |

|

|

|

|

|

|

ing to 16- |

|

|

|

|

|

|

Crimp |

|

FCN363J024-AU |

|

|

|

|

point con- |

|

|

|

||

|

|

|

|

|

|

|

|

nectors |

|

|

|

|

|

|

|

|

|

|

|

|

|

Recom- |

Hood |

|

XW2S-2513 |

|

OMRON |

|

mended |

|

|

|

|

|

|

connectors |

|

|

|

|

|

|

correspond- |

|

|

|

|

|

|

Plug |

|

XW2A-2501 |

|

OMRON |

|

|

ing to 25- |

|

|

|

|

|

|

pin D-sub |

|

|

|

|

|

|

connectors |

|

|

|

|

|

|

|

|

|

|

|

|

|

Connec- |

Soldered |

|

FCN361J040-AU |

|

|

|

tors made |

|

|

|

|

|

|

by |

|

|

|

|

|

|

Pressure-welded |

FCN367J040-AU/F |

|

|

||

|

FUJITSU |

|

|

|||

|

correspond- |

|

|

|

|

|

|

ing to high- |

|

|

|

|

|

|

Crimp |

|

FCN363J040-AU |

|

|

|

|

density |

|

|

|

||

|

|

|

|

|

|

|

|

connectors |

|

|

|

|

|

|

|

|

|

|

|

|

Note Refer to page 219, High-density Connector Cables for MULTIPLE I/O TERMINALs for details.

7

Functions Section 1-2

1-2 |

Functions |

|

|

|

1-2-1 |

I/O Unit Interface Specifications |

|

||

|

|

|

|

|

|

|

Item |

Specification |

|

|

|

|

|

|

|

|

Communications method |

Special protocol |

|

|

|

|

|

|

|

|

Number of I/O Units |

|

8 Units max. |

|

|

|

|

|

|

|

Maximum number of points |

Total inputs/outputs: 1,024 points (bits) |

|

|

|

|

|

|

|

|

Communications dis- |

Total length |

3 m max. |

|

|

tance |

|

|

|

|

Between Units |

1 m max. (Cable included with Unit is |

|

|

|

|

||

|

|

|

|

40 mm.) |

|

|

|

|

|

|

|

Communications power supply |

Supplied from the Communications |

|

|

|

|

|

Unit to the I/O Unit (0.4 A max.) |

|

|

|

|

|

|

|

Relationship to DeviceNet |

After the I/O Unit interface is estab- |

|

|

|

|

|

lished, DeviceNet communications con- |

|

|

|

|

tinue normally, even if an error occurs |

|

|

|

|

on the I/O Unit interface. |

|

|

|

|

|

|

|

Addresses |

|

Automatically recognized when the |

|

|

|

|

power to the Communications Unit is |

|

|

|

|

turned ON. |

|

|

|

|

|

|

|

I/O configuration |

|

Automatically recognized when the |

|

|

|

|

power to the Communications Unit is |

|

|

|

|

turned ON. If the configuration is |

|

|

|

|

changed while the power supply is ON, |

|

|

|

|

a configuration error will occur. |

|

|

|

|

|

|

|

Self-diagnostic func- |

Configuration errors |

The I/O Unit configuration is constantly |

|

|

tions |

|

checked while power is supplied. If a |

|

|

|

|

mismatch occurs while the power is |

|

|

|

|

turned ON, I/O refreshing for all I/O |

|

|

|

|

Units is stopped. |

|

|

|

|

|

|

|

|

Special I/O Unit |

Errors are detected in the Special I/O |

|

|

|

errors |

Units (Analog Input Units, Analog Out- |

|

|

|

|

put Units, Temperature Input Units, and |

|

|

|

|

Counter Units) on the I/O Unit interface. |

|

|

|

|

|

|

|

|

I/O Unit interface |

Communications stop when there is no |

|

|

|

errors |

communications response from an I/O |

|

|

|

|

Unit. |

|

|

|

|

Communications stop when there is no |

|

|

|

|

specific response from the last I/O Unit |

|

|

|

|

(terminator). |

|

|

|

|

Communications stop when nine or |

|

|

|

|

more I/O Units are connected. |

|

|

|

|

|

|

|

|

Power supply over- |

The power supply to the I/O Units and I/ |

|

|

|

load to I/O Units |

O refreshing for all I/O Units are |

|

|

|

|

stopped when the power supply to the |

|

|

|

|

I/O Units through the Communications |

|

|

|

|

Unit exceeds 0.4 A. |

|

|

|

|

|

|

|

Error detection |

|

Frame error check; CRC-CCITT check |

|

|

|

|

|

8

Functions |

Section 1-2 |

I/O Interface Current

Consumption

I/O Unit Interface

Addresses

Checking the I/O Unit

Interface Status

Make sure that the power supply from the Communications Unit to the I/O Units is less than the total rated output current (400 mA). The I/O interface current consumption for each I/O Unit is shown in the following table.

I/O Unit |

I/O interface current consumption |

|

|

GT1-ID16(-1) |

35 mA max. |

|

|

GT1-ID16MX(-1) |

35 mA max. |

|

|

GT1-ID16ML(-1) |

35 mA max. |

|

|

GT1-ID16DS(-1) |

35 mA max. |

|

|

GT1-ID32ML(-1) |

55 mA max. |

|

|

GT1-OD16(-1) |

35 mA max. |

|

|

GT1-OD16MX(-1) |

35 mA max. |

|

|

GT1-OD16ML(-1) |

35 mA max. |

|

|

GT1-OD16DS(-1) |

35 mA max. |

|

|

GT1-OD32ML(-1) |

65 mA max. |

|

|

GT1-ROP08 |

40 mA max. |

|

|

GT1-ROS16 |

50 mA max. |

|

|

GT1-AD04 |

50 mA max. |

|

|

GT1-AD08MX |

50 mA max. |

|

|

GT1-DA04 |

50 mA max. |

|

|

GT1-DA04MX |

50 mA max. |

|

|

GT1-TS04T |

50 mA max. |

|

|

GT1-TS04P |

50 mA max. |

|

|

GT1-CT01 |

90 mA max. |

|

|

Calculation Example

When five GT1-ID32ML Input Units and three GT1-OD16 Output Units are used, the total current consumption is calculated as follows:

(GT1-ID32ML current consumption) x 5 Units + (GT1-OD16 current consumption) x 3 Units = 55 mA x 5 + 35 mA x 3 = 380 mA ≤ 400 mA

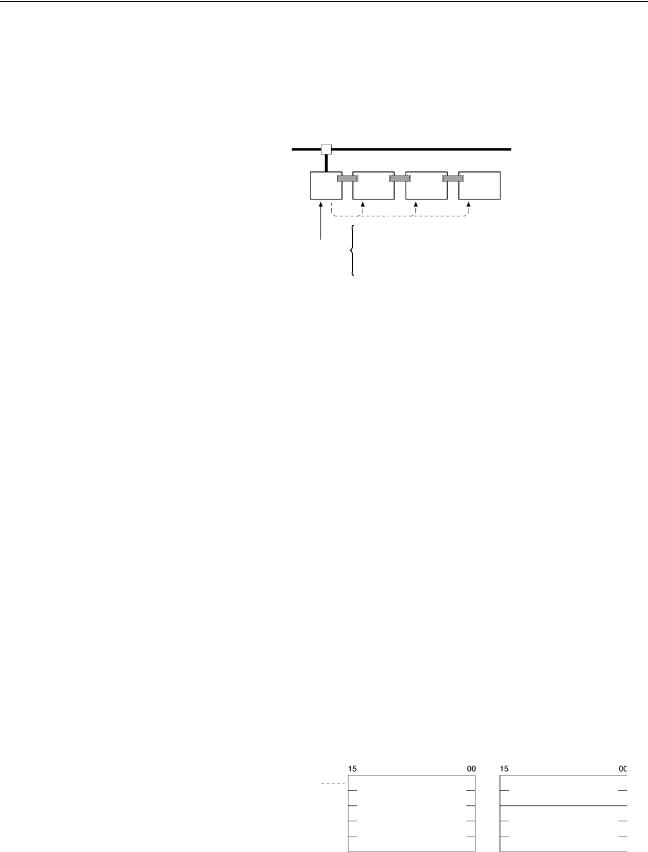

The addresses of the I/O Units on the I/O Unit interface are automatically set when the Communications Unit is started. The addresses are from 0 to 7 in ascending order from the I/O Units closest to the Communications Unit.

DeviceNet Master Unit

DeviceNet Network

I/O Unit interface |

|

Communica- I/O Unit I/O Unit |

I/O Unit |

tions Unit |

|

The following two methods are used to check the I/O Unit interface status:

•Checking the Communications Unit and I/O Unit indicators

•Checking the status of the Communications Unit

9

Functions |

Section 1-2 |

Indicators |

|

DeviceNet |

TS indicator |

Network |

Communica- I/O Unit I/O Unit tions Unit

Unit |

Normal |

Error |

|

|

|

|

|

Communications |

TS Indicator: |

TS indicator |

|

Unit |

Lit green |

I/O Unit interface error: |

Lit red |

|

|

Special I/O Unit error: |

Flashing green |

|

|

Maximum power supply |

|

|

|

overload to I/O Units: |

Not lit |

|

|

|

|

I/O Units |

TS indicator: |

TS indicator |

|

|

Lit green |

I/O Unit interface error: |

Lit red |

|

U.ERR indica- |

U.ERR indicator |

|

|

tor: Not lit |

Special I/O Unit error: |

Lit red |

|

PWR indicator: |

PWR indicator |

|

|

Lit green |

No internal power supply: |

Not lit |

|

|

|

|

For details, refer to page 199, Troubleshooting via Indicators.

Checking the I/O Unit Interface Status

The first two words of the CPU Unit allocation input area are always allocated to the status of the I/O Unit interface via the DeviceNet.

DeviceNet Master Unit

Output Input area area

0 wd

+1 wd

Status, two words

I/O Unit connection information

Error slaves |

Registered slaves |

For details, see page 15.

DeviceNet Network

|

|

Communica- I/O Unit I/O Unit |

|

|

tions Unit |

1-2-2 |

Exchanging Data |

|

Initialization |

When the Communications Unit is started, it automatically recognizes the |

|

|

|

configuration of the I/O Units and registers this status as the normal configu- |

|

|

ration (in RAM memory). At the same time, addresses 0 to 7 are allocated to |

|

|

the I/O Units in ascending order from the I/O Unit closest to the Communica- |

|

|

tions Unit. These processes are performed each time the power is turned ON. |

10

Functions |

Section 1-2 |

Remote I/O communications with the DeviceNet Master Unit are carried out by a MULTIPLE I/O TERMINAL based on the registered configuration. When the power to the Communications Unit is turned ON, the bits allocated to the I/ O Units can be used to check the status (bits 0 to 7 of the first word) of the Communications Unit.

DeviceNet Network

Communica- |

I/O Unit I/O Unit |

I/O Unit |

|

tions Unit |

Automatically recognizes the configuration of the |

||

|

|||

At startup |

I/O Units |

|

|

Communications with the DeviceNet Master Unit |

|||

|

|||

|

based on this I/O configuration |

||

Note |

1. |

If the configuration of the I/O Units is to be changed, a number of precau- |

|

|

tions must be noted. For details, see 1-2-5 I/O Configuration Changes. |

|

2. |

For details of data exchange timing, see 6-1-1 I/O Response Time. |

Error Processing |

Even if an error occurs in the I/O Unit interface after initialization is completed, |

|

|

DeviceNet communications will continue normally. Therefore, an error pro- |

|

|

cessing program section must be included in the CPU Unit to check the status |

|

|

of the Communications Unit for errors that have occurred and to identify the |

|

|

error type and location. |

|

1-2-3 |

Allocating I/O |

|

|

|

|

This section explains how words for a MULTIPLE I/O TERMINAL are allo- |

|

|

|

cated in the output area and input area of the Master. For details of remote I/O |

|

|

|

functions in the output area and input area of the Master such as word specifi- |

|

|

|

cation, fixed allocation, and user-set allocation, refer to the DeviceNet Opera- |

|

|

|

tion Manual (W267). |

|

Fixed Allocation |

The output area and input area corresponding to the Communications Unit |

||

|

|

node number for a MULTIPLE I/O TERMINAL are as shown in the following |

|

|

|

diagram. |

|

|

|

Output Area |

|

|

|

The output area contains output bits in the order that I/O Units are connected |

|

|

|

on the I/O Unit interface. |

|

|

|

Input Area |

|

|

|

The input area contains the Communications Unit status (two words), and |

|

|

|

input bits in the order that I/O Units are connected on the I/O Unit interface. |

|

|

|

Output area |

Input area |

Area corresponding to

Communications Unit

node number Output bits on the I/O Unit

interface

I/O Unit interface status

Input bits on the I/O Unit interface

The input and output bits for the I/O Unit interface are allocated in the DeviceNet input and output areas in 16-point (one word) increments. With 8- point I/O Units, these bits are allocated using the rightmost byte (bits 0 to 7), and the leftmost byte (bits 8 to 15) will be 00 Hex.

11

Functions |

Section 1-2 |

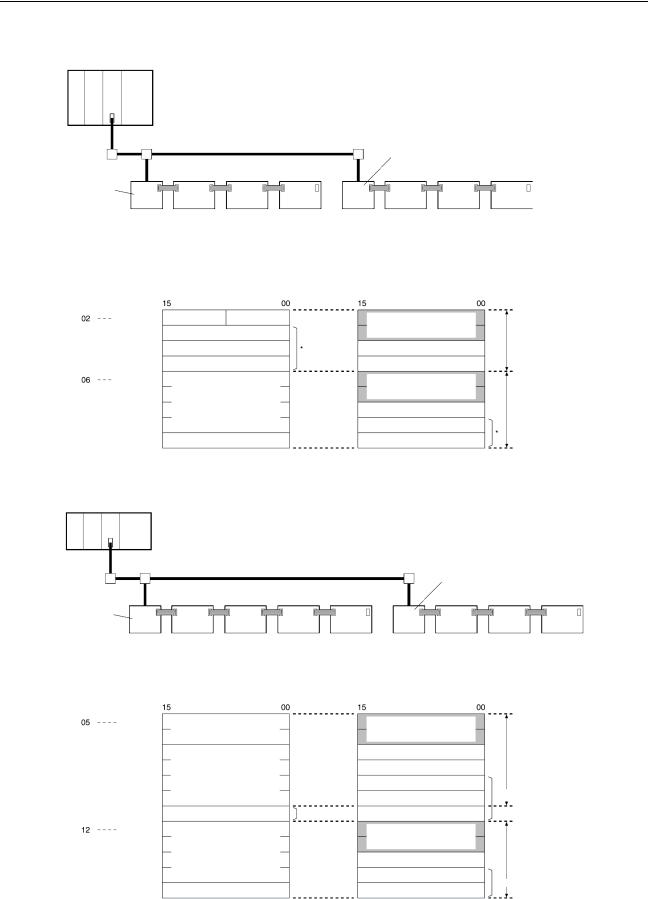

Example: CVM1/CV Series

DeviceNet Network

Communications Unit

node number 06

Communications Unit node number 02

I/O Unit |

#0 |

#1 |

#2 |

#0 |

#1 |

#2 |

|

addresses |

|||||||

16 inputs |

8 outputs |

16 inputs |

16 inputs |

4-point |

16 outputs |

||

|

|||||||

|

|

|

|

|

Analog |

|

|

|

|

|

|

|

Output |

|

|

|

|

|

|

|

Unit |

|

Communications Unit |

Output area |

|

Input area |

|

node number |

|

|||

CIO 1902 |

00 Hex |

8 output bits for |

CIO 2002 |

I/O Unit interface status |

Unit #1 |

||||

CIO 1903 |

Unused |

CIO 2003 |

for node number 02 |

|

|

||||

CIO 1904 |

Unused |

CIO 2004 16 input bits for Unit #0 |

||

CIO 1905 |

Unused |

CIO 2005 |

16 input bits for Unit #2 |

|

CIO 1906 |

|

|

CIO 2006 |

I/O Unit interface status |

CIO 1907 |

4 analog |

CIO 2007 |

for node number 06 |

|

CIO 1908 |

outputs for |

CIO 2008 16 input bits for Unit #0 |

||

Unit #1 |

||||

CIO 1909 |

|

|

CIO 2009 |

Unused |

CIO 1910 16 output bits for Unit #2 |

CIO 2010 |

Unused |

||

The unused words can be used as work bits.

Example: C200HX/HG/HE

Area allocated to Communications Unit for node number 02

Area allocated to Communications Unit for node number 06

DeviceNet Network |

Communications Unit |

|

node number 12 |

Communications Unit node number 05

I/O Unit |

|

|

|

|

|

addresses |

#0 |

#1 |

#2 |

#3 |

#0 |

|

32 outputs |

4-point |

16 inputs |

16 inputs |

16 inputs |

|

|

Analog |

|

|

|

|

|

Output Unit |

|

|

|

Communications Unit |

|

|

|

|

node number |

Output area |

|

|

Input area |

|

|

|

||

CIO 55 |

32 output bits for |

|

CIO 355 |

I/O Unit interface status |

CIO 56 |

Unit #0 |

|

CIO 356 |

for node number 05 |

|

|

|||

CIO 57 |

|

|

CIO 357 |

16 input bits for Unit #2 |

CIO 58 |

4 analog outputs |

|

CIO 358 |

16 input bits for Unit #3 |

CIO 59 |

for Unit #1 |

|

CIO 359 |

Unused |

|

|

|||

CIO 60 |

|

|

CIO 360 |

Unused |

CIO 61 |

Unused |

(See |

CIO 361 |

Unused |

note 1.) |

||||

CIO 62 |

|

|

CIO 362 |

I/O Unit interface status |

|

|

|

|

|

CIO 63 |

4 analog outputs |

|

CIO 363 |

for node number 12 |

|

|

|

|

|

CIO 64 |

for Unit #1 |

|

CIO 364 |

16 input bits for Unit #0 |

CIO 65 |

|

|

CIO 365 |

Unused |

CIO 66 16 output bits for Unit #2 |

|

CIO 366 |

Unused |

|

#1 |

#2 |

4-point |

32 outputs |

Analog |

|

Output Unit

Area allocated to Communications Unit for node number 05

(See note 1.)

Area allocated to Communications Unit for node number 12

(See note 2.)

Note 1. The unused words between I/O areas that are used cannot be used as work bits. 2. The unused words (not between I/O areas that are used) can be used as work bits.

12

Functions |

Section 1-2 |

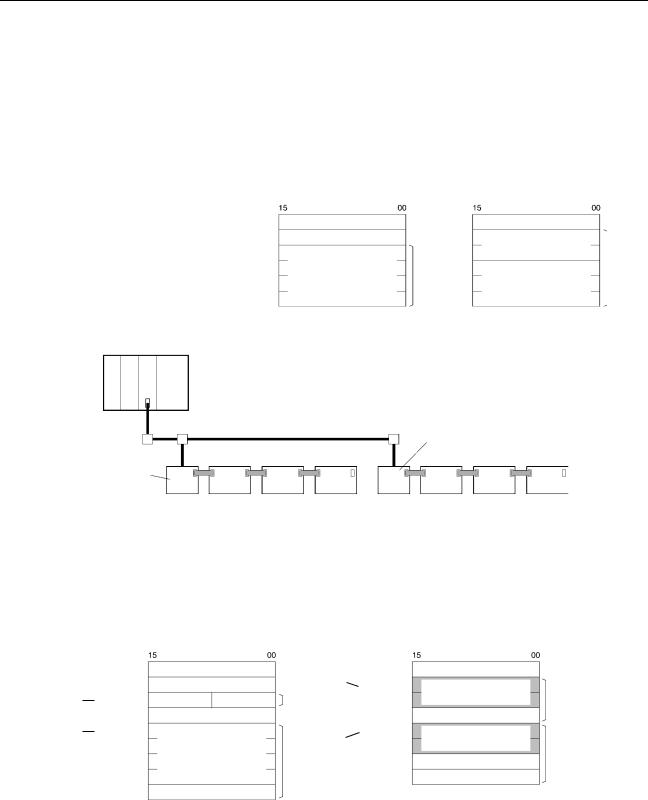

User-set Allocation |

The Configurator can be used to set the Communications Unit node number, |

|

first word, and number of bytes to allocate (allocation size) for input block 1 |

|

and 2 and for output block 1 and 2, as shown in the following diagram. |

Output block 1 or 2:

Output bits in the order I/O Units are connected on the I/O Unit interface

Input block 1 or 2:

I/O Unit interface status (two words), and input bits in the order I/O Units are connected on the I/O Unit interface

Output block 1 or 2 |

Input block 1 or 2 |

|

First word |

I/O Unit interface |

|

|

size |

||

First word |

status |

||

|

|||

Output bits on the |

Allocation |

Input bits on the |

|

I/O Unit interface |

|||

|

|

I/O Unit interface |

Allocation size

Example: CVM1/CV Series

DeviceNet Network

Communications Unit node number 06

Communications Unit node number 02

I/O Unit |

#0 |

#1 |

# 2 |

#0 |

#1 |

#2 |

addresses |

||||||

|

16 inputs |

8 outputs |

16 inputs |

16 inputs |

4-point |

16 outputs |

Analog

Output Unit

Allocation settings for node number 02

First word: |

CIO 1952 |

Allocation size: |

2 bytes (1 word) |

Allocation settings for node number 06

First word: |

CIO 1954 |

Allocation size: |

10 bytes (5 words) |

Allocation settings for node number 02 First word: CIO 1904

Allocation size: 8 bytes (4 words)

Allocation settings for node number 06 First word: CIO 1901

Allocation size: 6 bytes (3 words)

Output block 2

CIO 1950

CIO 1951

First word |

CIO 1952 |

00 Hex |

8output bits for |

|

of node |

Unit #1 |

|||

number 02 |

CIO 1953 |

|

|

|

First word |

CIO 1954 |

|

|

|

|

|

|

||

of node |

CIO 1955 |

4 analog outputs |

||

number 06 |

CIO 1956 |

|||

for Unit #1 |

||||

|

||||

|

CIO 1957 |

|

|

|

|

CIO 1958 |

16 input bits for Unit #2 |

||

First word |

|

Input block 1 |

of node |

CIO 1900 |

|

number 06 |

|

|

|

CIO 1901 |

I/O Unit interface status |

Size of node |

CIO 1902 |

for node number 06 |

|

||

number 02 |

CIO 1903 |

16 input bits for Unit #0 |

First word |

CIO 1904 |

I/O Unit interface status |

of node |

|

|

CIO 1905 |

for node number 02 |

|

number 02 |

|

|

Size of node |

CIO 1906 16 input bits for Unit #0 |

|

number 06 |

CIO 1907 16 input bits for Unit #2 |

|

Size of node number 06

Size of node number 02

13

Functions |

Section 1-2 |

Example: C200HX/HG/HE Series

|

DeviceNet Network |

|

|

Communications Unit |

|||

|

|

|

|

|

|

node number 12 |

|

Communications Unit |

|

|

|

|

|

|

|

node number 05 |

|

|

|

|

|

|

|

I/O Unit |

|

|

|

|

|

|

|

addresses |

#0 |

#1 |

#2 |

# 3 |

#0 |

#1 |

#2 |

|

32 outputs 4-point |

16 outputs |

16 inputs |

16 outputs 4-point |

16 outputs |

||

|

|

Analog |

|

|

|

Analog |

|

|

|

Output Unit |

|

|

Output Unit |

||

|

Allocation settings for node number 05 |

Allocation settings for node number 05 |

|||||

|

First word: |

CIO 50 |

|

First word: |

|

CIO 360 |

|

|

Allocation size: |

12 bytes (6 words) |

Allocation size: |

3 bytes (4 words) |

|

||

|

Allocation settings for node number 12 |

Allocation settings for node number 12 |

|||||

|

First word: |

CIO 120 |

|

First word: |

|

CIO 363 |

|

|

Allocation size: |

10 bytes (5 words) |

Allocation size: |

8 bytes (3 words) |

|

||

First word |

|

Output block 1 |

First word |

|

Input block 1 |

|

|

CIO 50 |

|

of node |

CIO 360 |

|

|

||

of node |

|

32 output bits for |

I/O Unit interface status |

|

|||

|

|

||||||

number 05 |

CIO 51 |

Unit #0 |

number 05 |

CIO 361 |

for node number 05 |

Size of node |

|

|

|

CIO 52 |

|

Size of node |

CIO 362 |

16 input bits for Unit #2 |

number 05 |

|

|

|

|

||||

|

|

CIO 53 |

4 analog outputs |

number 05 |

CIO 362 |

16 input bits for Unit #3 |

|

|

|

|

|

||||

|

|

CIO 54 |

for Unit #1 |

First word |

CIO 363 |

I/O Unit interface status |

Size of node |

|

|

CIO 55 |

|

of node |

CIO 364 |

for node number 12 |

|

|

|

|

number 12 |

|

number 12 |

||

|

|

|

|

CIO 365 16 input bits for Unit #0 |

|||

|

|

|

|

|

|

||

|

|

CIO 120 |

Output block 2 |

|

|

|

|

|

|

|

|

|

|

|

|

First word |

|

|

|

|

|

||

|

|

|

|

|

|

||

of node |

CIO 121 |

4 analog outputs |

|

|

|

|

|

number 12 |

CIO 122 |

for Unit #1 |

Size of node |

|

|

|

|

|

|

|

|

|

|||

CIO 123 |

number 12 |

|

|

CIO 124 |

16 output bits for Unit #2 |

14

Functions |

Section 1-2 |

Allocation Precautions Note the following precautions when starting the DeviceNet Network.

Limits on the Total Number of Input and Output Points for a Master Unit

A maximum of 1,024 inputs and outputs can be controlled by one Communications Unit (DRT1-COM). The number of I/O points for each node, however, depends on the Master Unit. For example, with the CV-series Master Unit (CVM1-DRM21-V1) or the C200HX/HG/HE and C200HS Master Unit (C200HW-DRM21-V1), up to 512 inputs and up to 512 outputs can be used at each node. Therefore, connect I/O Units within a range that does not exceed the number of I/O points for each Master Unit node. The following table shows the I/O size of each Unit.

Unit model |

Number of |

Number of |

|

inputs |

outputs |

|

|

|

DRT1-COM |

32 points |

0 point |

|

|

|

GT1-ID16(-1), GT1-ID16MX(-1), GT1-ID16ML(-1)*, |

16 points |

0 point |

GT1-ID16DS(-1)* |

|

|

|

|

|

GT1-OD16(-1), GT1-OD16MX(-1), GT1-OD16ML(-1)*, |

0 points |

16 points |

GT1-OD16DS(-1)*, GT1-ROS16, GT1-ROP08 |

|

|

|

|

|

GT1-ID32ML(-1) |

32 points |

0 point |

|

|

|

GT1-OD32ML(-1) |

0 points |

32 points |

|

|

|

GT1-AD04* |

64 points |

0 points |

|

|

|

GT1-AD08MX (With 8-input mode) |

128 points |

0 points |

|

|

|

GT1-AD08MX (With 4-input mode) |

64 points |

0 points |

|

|

|

GT1-DA04*, GT1-DA04MX |

0 points |

64 points |

|

|

|

GT1-TS04T, GT1-TS04P (With Normal Mode) |

64 points |

0 points |

|

|

|

GT1-TS04T, GT1-TS04P (With 2-decimal-place Mode) |

128 points |

0 points |

|

|

|

GT1-CT01 |

48 points |

48 points |

|

|

|

The GT1-ROP08 (Relay Output Unit with Power Relay) has 8 actual outputs but, as a MULTIPLE I/O TERMINAL, the number of outputs allocated to the Master Unit is 16.

Calculation Example

When one GT1-DA04MX Analog Output Unit and three GT1-AD08 Analog Input Units are used, the total number of input points and output points is calculated as follows:

Total Number of Input Points:

Communications Unit (Status) + Analog Input Units x 3 = 32 points + 128 points x 3 = 416 points

Total Number of Output Points: Analog Output Units x 1 = 64 points

Reference

For information on dealing with other problems concerning the MULTIPLE I/O TERMINAL, refer to SECTION 7 Troubleshooting and Maintenance. For information on problems concerning the DeviceNet, refer to DeviceNet Operation Manual (W267).

1-2-4 I/O Unit Interface Status

The following I/O Unit interface status is maintained in the CPU Unit.

•I/O Unit connection information (I/O Unit interface status)

•Registered I/O Unit addresses

15

Functions Section 1-2

• Error I/O Unit addresses

As shown in the following diagram, the status consists of two words. The first two words of the Communications Unit allocation input area in the CPU Unit are allocated for this status. Include a program section in the CPU Unit to check this status and perform error processing.

0 wd |

I/O Unit connection information |

|

+1 wd |

Error I/O Unit addresses |

Registered I/O Unit addresses |

I/O Unit Connection Information

|

Bit |

0 wd |

|

1: Error (OR of bits 0 to 4) |

1: Special I/O Unit Error |

1: Refreshing I/O |

1: Configuration Error |

1: I/O Unit Interface Error |

|

|

1: I/O Unit Power Supply Overload |

|

1: High-density I/O Unit Error |

Bit |

Flag name |

Meaning |

Content |

|

|

|

|

15 |

Refreshing I/O |

Refreshing I/O |

1: Communications between the |

|

|

|

Communications Unit and I/O Units |

|

|

|

is normal. |

|

|

|

0: Communications error (no |

|

|

|

response is received from an I/O |

|

|

|

Unit) |

|

|

|

|

14 |

Error |

OR of bits 0 to 4 |

1: Any one of bits 0 to 4 is ON |

|

|

|

0: Bits 0 to 4 are all OFF |

|

|

|

|

4 |

High-density |

A high-density I/O Unit error was |

1: Unit error |

|

I/O Unit Error |

detected. |

0: Unit normal |

|

|

|

|

|

|

|

|

3 |

I/O Unit Power |

An overcurrent to an I/O Unit |

1: Overcurrent detected |

|

Supply Over- |

was detected. |

0: Normal |

|

load |

|

|

|

|

|

|

|

|

|

|

2 |

I/O Unit Inter- |

An I/O Unit interface error was |

1: I/O Unit interface error |

|

face Error |

detected. |

0: Normal |

|

|

Data Transfer Error: |

|

|

|

|

|

|

|

In the I/O Unit interface, there |

|

|

|

was no response to a com- |

|

|

|

mand after the fixed time has |

|

|

|

elapsed. Alternatively, the |

|

|

|

response expected to be |

|

|

|

returned from the end I/O Unit |

|

|

|

(terminator) was not received. |

|

|

|

Too many I/O Units: |

|

|

|

Nine or more I/O Units are |

|

|

|

connected. |

|

|

|

|

|

1 |

Configuration |

The I/O configuration was |

1: I/O configuration change during |

|

Error |

changed when the Communica- |

startup |

|

|

tions Unit was started. |

0: No I/O configuration change during |

|

|

|

|

|

|

|

startup |

|

|

|

|

0 |

Special I/O |

An error occurred in a Special |

1: Special I/O Unit error |

|

Unit Error |

I/O Unit. |

0: Special I/O Unit normal |

|

|

|

|

|

|

|

|

16

Functions |

Section 1-2 |

Abnormal I/O Unit Addresses and Registered I/O Unit Addresses

+1 wd

The bits corresponding to I/O Unit with errors are turned ON. Bits 8 to 15 correspond to addresses 0 to 7.

1: Error

0: No error, or not part of network