Page 1

LPOR-304 Operating Instructions Revision A

LPOR-304

Dual Redundant Return

Band Receiver

Operating Manual

TEL: (209) 586-1022

USA: (800) 545-1022

FAX: (209) 586-1026

E-Mail: salessupport@ olson te c h.c om

www.olsonte ch.com

PAG E 1 o f

10

4 June 2006

Page 2

LPOR-304 Operating Instructions Revision A

Contents

DESCRIPTION ........................................................................................... 3

Front Panel .............................................................................................3

Figure 1 – LPOR-304 Front Panel ................................................................. 3

Rear Panel ..............................................................................................3

Figure 2 – LPOR-304 Rear Panel .................................................................. 3

Internal Adjustments................................................................................4

Figure 3 – Jumper Access Points .................................................................4

Control Board Layout................................................................................4

Figure 4 – Control Board Layout.................................................................. 4

Fuse.......................................................................................................5

Optical Input Chart...................................................................................5

Table 1 – Optical Input Chart.....................................................................5

LPOR-304 OPERATION OVERVIEW............................................................ 6

INSTALLATION ......................................................................................... 6

Table 2 – DIP Switch Settings .....................................................................6

OPTICAL BEHAVIOR .................................................................................7

Table 3 – Optical Thresholds......................................................................7

Function Switch .......................................................................................7

INDEPENDENT MODE DETAILED OPERATION............................................ 8

Rx1 and Rx2 LEDs (Independent)...............................................................8

Table 4 – Independent Rx1 and Rx2 LED Conditions ..........................................8

Mode LED (Independent) ..........................................................................8

REDUNDANT MODE DETAILED OPERATION ............................................... 8

Rx1 and Rx2 LEDs (Redundant) .................................................................8

Table 5 – Redundant Rx1 and Rx2 LED Conditions............................................. 8

Mode LED (Redundant).............................................................................8

Table 6 – Redundant Rx Mode LED Conditions .................................................8

OPTICAL POWER TEST POINTS ................................................................. 9

TEST POINT SELECT SWITCH .................................................................... 9

Table 7 – Test Point Select Switch Settings ....................................................9

I2C DISABLE LINES................................................................................... 9

SUMMARY ALARM RELAY .......................................................................... 9

Figure 5 – Microprocessor Block Diagram ..................................................... 10

PAG E 2 o f

10

4 June 2006

Page 3

LPOR-304 Operating Instructions Revision A

DESCRIPTION

The LP-OR-304 has dual, redundant return band receivers in a single module. The receivers have an

extended bandwidth of 300 MHz to allow the use of spectrum multiplication. Individual receivers in the

module can be disabled.

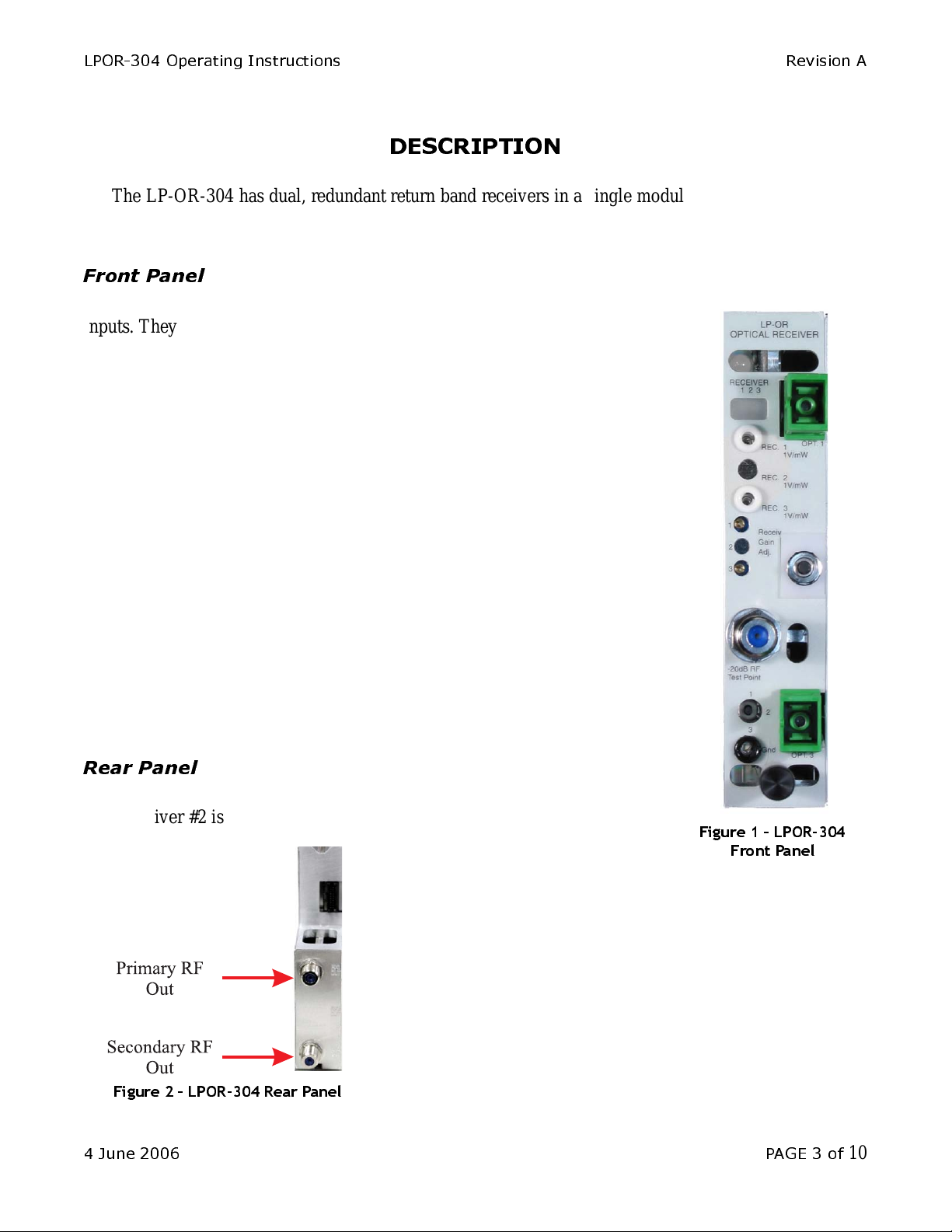

Front Panel

The two rectangular red/green status LEDs monitor the receivers’ optical

inputs. They are normally green and change to red on a low or missing optical

input. Any red LED causes a module alar m and a chassis summary alarm. The

two DC test points monitor the receivers’ optical inputs. One (1) mW ( 0 dBm)

is 1 V at the test point. Only high impedance meters should be used. Use the

ground test point at the bottom of the module, not chassis ground.

The two multi-turn potentiometers set the receivers’ gains. Setting any gain

control fully counter-clockwise will disable that receiver. A disabled receiver

will never generate an alarm.

The -20dB RF test point monitors the RF output of any single receiver. It

does not require termination.

The two position toggle switch selects which receiver’s output appears at

the test point. Ensure that this switch is in the correct position before using the

test point to set the RF gain.

The ground test point should be used when checking optical input levels.

The SC/APC optical input connectors are on the right of the front panel,

with optional FC/APC connectors available.

Rear Panel

The RF output connectors are on the rear of the unit. Receiver #1 is on the

top. Receiver #2 is on the bottom.

Figure 1 – LPOR-304

Front Panel

Figure 2 – LPOR-30 4 Rear Panel

4 June 2006 PAG E 3 of

10

Page 4

LPOR-304 Operating Instructions Revision A

Internal Adjustments

There are two jumpers that are accessible from the side that are used to set the receiver input range.

The jumpers can be changed with tweezers or needle nosed pliers. The nominal level for changing jumper

positions is -3 dBm.

Figure 3 – Jumper Acc ess Points

Control Board Layout

Figure 4 shows the locations of LPOR-304’s primary and secondary responsivity trim pots, the

programming DIP switch, and the fuse.

PAG E 4 o f

10

Figure 4 – Cont rol B oa rd Layou t

4 June 2006

Page 5

LPOR-304 Operating Instructions Revision A

Fuse

The module has an internal miniature 3A SB fuse in a holder. The Littelfuse part number is 0454003.

The Olson Technology P/N is 286-000009. See Figure 4, page 4 for fuse location.

Optical Input Chart

The following chart shows the test point readings versus optical input levels.

Table 1 – Optical Input Chart

T.P. Vo l ts

3.02 3.02 4.8

2.51 2.51 4

2.00 2.00 3

1.58 1.58 2

1.26 1.26 1

1.00 1.00 0

0.79 0.79 -1

0.63 0.63 -2

0.50 0.50 -3

0.40 0.40 -4

0.32 0.32 -5

0.25 0.25 -6

0.20 0.20 -7

0.16 0.16 -8

0.13 0.13 -9

0.10 0.10 -10

0.08 0.08 -11

0.06 0.06 -12

0.05 0.05 -13

0.04 0.04 -14

0.03 0.03 -15

Optical In pu t

(mW)

Optical In pu t

(dBm)

4 June 2006 PAG E 5 of

10

Page 6

LPOR-304 Operating Instructions Revision A

LPOR-304 OPERATION OVERVIEW

The LPOR-304 redundant receiver consists of two receiver boards, a switch board, and a status/

control board. The upper three LEDs are tri-color ones. The redundancy mode LED is visible through a

vent hole next to the Rx status LEDs. The unit can function as a redundant receiver or as dual

independent receivers.

A single pushbutton switch and an 8-position DIP switch control the major functions. See Figure 4,

page 4 for the switch location. The receiver gain controls will disable their receiver if fully turned CCW.

The status board has a microprocessor and two ADCs to monitor the optical input levels. The

microprocessor stores different responsivities for 1310 nm operation and 1550 nm operation. The voltage

read will be proportional to the optical power in mW. The microprocessor performs a 10*LOG10 function

to convert the mW value to dB m. All alarms and transfer decisions are based upon dBm levels. An 8position DIP switch, which is accessed by removing the left cover, sets all configurable parameters. All

alarm and display logic would be handled by the microprocessor. The user can select one of eight optical

switching thresholds via the DIP switch.

The microprocessor switches from the PRIMARY to the SECONDARY receiver in 50 ms or less

when the primary receiver indicates that it has insufficient light. The microprocessor also drives two

analog test points on the front panel via PWM outputs.

In the redundant mode, Rx1 is the PRIMARY receiver and Rx2 is the SECONDARY or BACKUP

receiver. In order to swap the fiber priority, the user must swap the input fibers.

INSTALLATION

The user must first set the DIP switches (SW1 on the 714 board) for the specific application (see

Figure 4, page 4 for location). The default factory shipping position for all switches is OFF. These

switches are read at least twice per second and updated when changes are sensed. T he eight switches

function as follows:

Table 2 – DIP Switch Settings

Switch

Number

1 Unit Mode Redundant Independent

2 Primary Input Wavelength 1310 nm 1550 nm

3 Secondary Input Wavelength 1310 nm 1550 nm

4 Optical Level Hysteresis Loose (3dB) Tight (1dB)

5 Restore Delay Instantaneous Delayed (60 Seconds)

6

7

8

Sets the Optical Switching Threshold in

the High to Low Direction

FUNCTION OFF ON

000 = -19 dBm

001 = -17 dBm

010 = -15 dBm

100 = -10 dBm

101 = -7 dBm

11 0 = -4 dBm

PAG E 6 o f

10

011 = -13 dBm

111 = -1 dBm

4 June 2006

Page 7

LPOR-304 Operating Instructions Revision A

OPTICAL BEHAVIOR

Six of the eight DIP switches (2, 3, 4, 6, 7, and 8) control the optical behavior of the unit. Switches 2

and 3 are used to set the wavelength of the two receivers. The user can select either 1310 nm or 1550 nm

independently for each channel. Switches 4, 6, 7, and 8 determine the optical input levels where the

receiver alarms switch. See Table 3 for details.

Table 3 – Optical Thresholds

Switch 6 Switch 7 S wi tch 8 Switch 4 Green to Red Thresho ld

OFF OFF OFF OFF -19 dBm -16 dBm

OFF OFF OFF ON -19 dBm -18 dBm

OFF OFF ON OFF -17 dBm -14 dBm

OFF OFF ON ON -17 dBm -16 dBm

OFF ON OFF OFF -15 dBm -12 dBm

OFF ON OFF ON -15 dBm -14 dBm

OFF ON ON OFF -13 dBm -10 dBm

OFF ON ON ON -13 dBm -12 dBm

ON OFF OFF OFF -10 dBm -7 dBm

ON OFF OFF ON -10 dBm -9 dBm

ON O FF ON OFF -7 dBm -4 dBm

ON O FF ON ON -7 dB m -6 dBm

ON ON OFF OFF -4 dBm -1 dBm

ON ON OFF ON -4 dB m -3 dBm

ON ON ON OFF -1 dBm +2 dBm

ON ON ON O N -1 dB m 0 dBm

Red to Green

Threshold

Function Switch

The pushbutton cycles through the following states by holding the button down for 0.5 second or

more:

• Automatic Mode (Redundant with Automatic Switchover)

• Force PRIMARY Rx Active

• Force SECONDARY Rx Active

(then cycle back to Automatic Mode)

The current state of the unit is stored in E2PROM in case of power failure. If power does fail, the last

valid state will be restored when power is restored.

4 June 2006 PAG E 7 of

10

Page 8

LPOR-304 Operating Instructions Revision A

INDEPENDENT MODE DETAILED OPERATION

Rx1 and Rx2 LEDs (Independent)

In the independent mode, the indivi dual receiver L EDs have three di splay sta tes. They will never be

orange.

Table 4 – Independent Rx1 and Rx2 LED Conditions

DISPLAY CONDITION

OFF Rx disabled

GREEN Rx input OK. Unit output from this Rx.

RED Rx input fault (Optical input is below preset threshold)

Mode LED (Independent)

In the independent mode, the mode LED blinks green for 0.25 second every 3 seconds to give an

indication that the unit is powered.

REDUNDANT MODE DETAILED OPERATION

Rx1 and Rx2 LEDs (Redundant)

The individual receiver LEDs have four display states. They blink to indicate an unacknowledged

fault on that input.

Table 5 – Redundant Rx1 and Rx2 LED Conditions

DISPLAY CONDITION

Off Rx Disable d v ia g ain c ontrol (Will nev er blin k )

Green Rx input Ok. Unit output from this Rx.

Orange Rx input Ok. Unit output from other Rx.

Red Rx input fault (Optical input is below preset threshold)

Mode LED (Redundant)

When operating as a redundant receiver, the mode LED has three display states. It is never turned off.

Table 6 – Redundant Rx Mode LED Conditions

DISPLAY CONDITION NOTES

Green

Primary Rx Input OK. Redundant

Operation Enabled.

Both receivers must be enabled. This state is

independent of the presence of backup optical input.

This can be from one of two causes:

Orange Redundant Operation Disabled

Red Redundant Operation Enabled

PAG E 8 o f

10

Either one or both receivers disabled with gain control.

Non-redundant operation selected with function switch.

Automatic transfer has occurred. Output of unit is

backup input whether or not optical signal is present on

this input.

4 June 2006

Page 9

LPOR-304 Operating Instructions Revision A

OPTICAL POWER TEST POINTS

The unit has two analog test points on the front panel, labeled REC.1 (T P1) and R EC.2 (TP2). These

voltages are generated by PWM outputs of the microprocessor. T he scale factor is such that the test points

give 1 Volt/mW of input light. Note that the microprocessor takes into account the wavelength in

generating these voltages. The wavele ngth causes the responsivity to va ry, changing the internal scaling

factor. Also note that these test points are in mW where other optical measurements mentioned herein are

in dBm. The step size for these outputs is approximately 33 µW.

TEST POINT SELECT SWITCH

This switch selects the RF monitor test point directly, not through the microprocessor. This switch

does not affect the output source of the unit. It has the same effect in redundant and independent modes.

Table 7 – Test Point Select Switch Settings

POSITION TEST POINT SOURCE

UP Rx1 (primary)

DOWN Rx2 (secondary)

I2C DISABLE LINES

There are two input lines from the I2C alarm circuit that are read at least twice per second. The inputs

and their function are as follows;

1) Alarm5 - This input (P2.2) determines if the Primary receiver is enabled. If Alarm5 is “OFF”, then

the Primary receiver is enabled. If Alarm5 is “1”, then the Primary receiver is disabled and the

Rx1 LED (D3) is turned off.

2) Alarm6 - This input ( P2.3) determines if the Seconda ry r eceiver is e nabled. If Alarm6 is “OFF”,

then the Secondary receiver is enabled. If Alarm6 is “1”, then the Secondary receiver is disabled

and the Rx2 LED (D4) is turned off.

SUMMARY ALARM RELAY

The P2.0 output of the microprocessor is used to drive a Summa ry Alarm Relay. When there are no

alarms and no receivers are disabled, this output s hould be a “OFF”. When there ar e any alarms and or

either receiver is disabled, this output should be a “1”.

Figure 5, page 10, shows a block diagram of all the microprocessor functions.

4 June 2006 PAG E 9 of

10

Page 10

LPOR-304 Operating Instructions Revision A

PAG E 1 0 of

10

Figure 5 – Microprocessor Block Diagram

END OF OPERATING MANUAL

4 June 2006

Loading...

Loading...