Page 1

be certain.

m

Bionix® EnviroBath™

Biomedical Environmental Chamber

100-209-141 A

Page 2

Copyright information © 2009 MTS Systems Corporation. All rights reserved.

Trademark information MTS, Bionix, Insight, Landmark, and QTest are registered trademarks of MTS

Systems Corporation; Alliance, EnviroBath, and Synergie are trademarks of

MTS Systems Corporation within the United States. These trademarks may be

protected in other countries.

Publication information

MANUAL PART NUMBER PUBLICATION DATE

100-209-141 A February 2009

Page 3

Contents

Technical Support 5

How to Get Technical Support 5

Before You Contact MTS 5

If You Contact MTS by Phone 7

Problem Submittal Form in MTS Manuals 8

Preface 9

Before You Begin 9

Conventions 10

Documentation Conventions 10

Introduction 13

About the Bionix EnviroBath Chamber 13

Bionix EnviroBath Chamber Specifications 15

Safety Information 17

Installation 19

General Installation Guidelines 19

Saline Distribution Assembly 19

Serum Distribution Assembly 20

Bionix EnviroBath 1 Chamber Common Vertical Mounting Configurations 22

Bionix EnviroBath 6 Chamber Common Mounting Configurations 25

Bionix EnviroBath 10 Chamber Common Mounting Configurations 28

Horizontal Mounting Configurations 31

Universal Adapters 33

Bionix® EnviroBath™ Chamber Contents

3

Page 4

Operation 35

Maintenance 37

4

Contents

Bionix® EnviroBath™ Chamber

Page 5

Technical Support

How to Get Technical Support

Start with your

manuals

Technical support

methods

MTS web site

www.mts.com

E-mail techsupport@mts.com

Telephone MTS Call Center 800-328-2255

Fax 952-937-4515

The manuals supplied by MTS provide most of the information you need to use

and maintain your equipment. If your equipment includes MTS software, look

for online help and README files that contain additional product information.

If you cannot find answers to your technical questions from these sources, you

can use the internet, e-mail, telephone, or fax to contact MTS for assistance.

MTS provides a full range of support services after your system is installed. If

you have any questions about a system or product, contact MTS in one of the

following ways.

The MTS web site gives you access to our technical support staff by means of a

Technical Support link:

www.mts.com > Contact Us > Service & Technical Support

Weekdays 7:00 A.M. to 5:00 P.M., Central Time

Please include “Technical Support” in the subject line.

Before You Contact MTS

MTS can help you more efficiently if you have the following information

available when you contact us for support.

Know your site

number and system

number

Bionix® EnviroBath™ Chamber Technical Support

The site number contains your company number and identifies your equipment

type (material testing, simulation, and so forth). The number is usually written on

a label on your MTS equipment before the system leaves MTS. If you do not

have or do not know your MTS site number, contact your MTS sales engineer.

Example site number: 571167

When you have more than one MTS system, the system job number identifies

which system you are calling about. You can find your job number in the papers

sent to you when you ordered your system.

Example system number: US1.42460

5

Page 6

Know information from

prior technical

If you have contacted MTS about this problem before, we can recall your file.

You will need to tell us the:

assistance

• MTS notification number

• Name of the person who helped you

Identify the problem Describe the problem you are experiencing and know the answers to the

following questions:

• How long and how often has the problem been occurring?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the

problem started?

• What are the model numbers of the suspect equipment?

• What model controller are you using (if applicable)?

• What test configuration are you using?

Know relevant

computer information

Know relevant

software information

If you are experiencing a computer problem, have the following information

available:

• Manufacturer’s name and model number

• Operating software type and service patch information

• Amount of system memory

• Amount of free space on the hard drive in which the application resides

• Current status of hard-drive fragmentation

• Connection status to a corporate network

For software application problems, have the following information available:

• The software application’s name, version number, build number, and if

available, software patch number. This information is displayed briefly

when you launch the application, and can typically be found in the “About”

selection in the “Help” menu.

• It is also helpful if the names of other non-MTS applications that are

running on your computer, such as anti-virus software, screen savers,

keyboard enhancers, print spoolers, and so forth are known and available.

Technical Support

6

Bionix® EnviroBath™ Chamber

Page 7

If You Contact MTS by Phone

Your call will be registered by a Call Center agent if you are calling within the

United States or Canada. Before connecting you with a technical support

specialist, the agent will ask you for your site number, name, company, company

address, and the phone number where you can normally be reached.

If you are calling about an issue that has already been assigned a notification

number, please provide that number. You will be assigned a unique notification

number about any new issue.

Identify system type To assist the Call Center agent with connecting you to the most qualified

technical support specialist available, identify your system as one of the

following types:

• Electromechanical materials test system

• Hydromechanical materials test system

• Vehicle test system

• Vehicle component test system

• Aero test system

Be prepared to

troubleshoot

Write down relevant

information

After you call MTS logs and tracks all calls to ensure that you receive assistance and that action

Prepare yourself for troubleshooting while on the phone:

• Call from a telephone when you are close to the system so that you can try

implementing suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an

experienced user nearby to assist you.

Prepare yourself in case we need to call you back:

• Remember to ask for the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions to be followed, such as data recording

or performance monitoring.

is taken regarding your problem or request. If you have questions about the status

of your problem or have additional information to report, please contact MTS

again and provide your original notification number.

Bionix® EnviroBath™ Chamber Technical Support

7

Page 8

Problem Submittal Form in MTS Manuals

Use the Problem Submittal Form to communicate problems you are experiencing

with your MTS software, hardware, manuals, or service which have not been

resolved to your satisfaction through the technical support process. This form

includes check boxes that allow you to indicate the urgency of your problem and

your expectation of an acceptable response time. We guarantee a timely

response—your feedback is important to us.

The Problem Submittal Form can be accessed:

• In the back of many MTS manuals (postage paid form to be mailed to MTS)

• www.mts.com > Contact Us > Problem Submittal Form (electronic form to

be e-mailed to MTS)

Technical Support

8

Bionix® EnviroBath™ Chamber

Page 9

Preface

Before You Begin

Safety first! Before you attempt to use your MTS product or system, read and understand the

Safety manual and any other safety information provided with your system.

Improper installation, operation, or maintenance of MTS equipment in your test

facility can result in hazardous conditions that can cause severe personal injury or

death and damage to your equipment and specimen. Again, read and understand

the safety information provided with your system before you continue. It is very

important that you remain aware of hazards that apply to your system.

Other MTS manuals In addition to this manual, you may receive additional MTS manuals in paper or

electronic form.

If you have purchased a test system, it may include an MTS System

Documentation CD. This CD contains an electronic copy of the MTS manuals

that pertain to your test system, including hydraulic and mechanical component

manuals, assembly drawings and parts lists, and operation and preventive

maintenance manuals. Controller and application software manuals are typically

included on the software CD distribution disc(s).

Bionix® EnviroBath™ Chamber Preface

9

Page 10

Conventions

DANGER

WARNING

CAUTION

Conventions

Documentation Conventions

The following paragraphs describe some of the conventions that are used in your

MTS manuals.

Hazard conventions As necessary, hazard notices may be embedded in this manual. These notices

contain safety information that is specific to the task to be performed. Hazard

notices immediately precede the step or procedure that may lead to an associated

hazard. Read all hazard notices carefully and follow the directions that are given.

Three different levels of hazard notices may appear in your manuals. Following

are examples of all three levels.

Note For general safety information, see the safety information provided with

your system.

Danger notices indicate the presence of a hazard with a high level of risk which,

if ignored, will result in death, severe personal injury, or substantial property

damage.

Warning notices indicate the presence of a hazard with a medium level of risk

which, if ignored, can result in death, severe personal injury, or substantial

property damage.

Caution notices indicate the presence of a hazard with a low level of risk which,

if ignored, could cause moderate or minor personal injury, equipment damage, or

endanger test integrity.

Notes Notes provide additional information about operating your system or highlight

easily overlooked items. For example:

Note Resources that are put back on the hardware lists show up at the end of

the list.

Special terms The first occurrence of special terms is shown in italics.

Illustrations Illustrations appear in this manual to clarify text. It is important for you to be

aware that these illustrations are examples only and do not necessarily represent

your actual system configuration, test application, or software.

Electronic manual

conventions

This manual is available as an electronic document in the Portable Document

File (PDF) format. It can be viewed on any computer that has Adobe Acrobat

Reader installed.

10

Preface

Bionix® EnviroBath™ Chamber

Page 11

Conventions

Hypertext links The electronic document has many hypertext links displayed in a blue font. All

blue words in the body text, along with all contents entries and index page

numbers, are hypertext links. When you click a hypertext link, the application

jumps to the corresponding topic.

Bionix® EnviroBath™ Chamber Preface

11

Page 12

Conventions

12

Preface

Bionix® EnviroBath™ Chamber

Page 13

Introduction

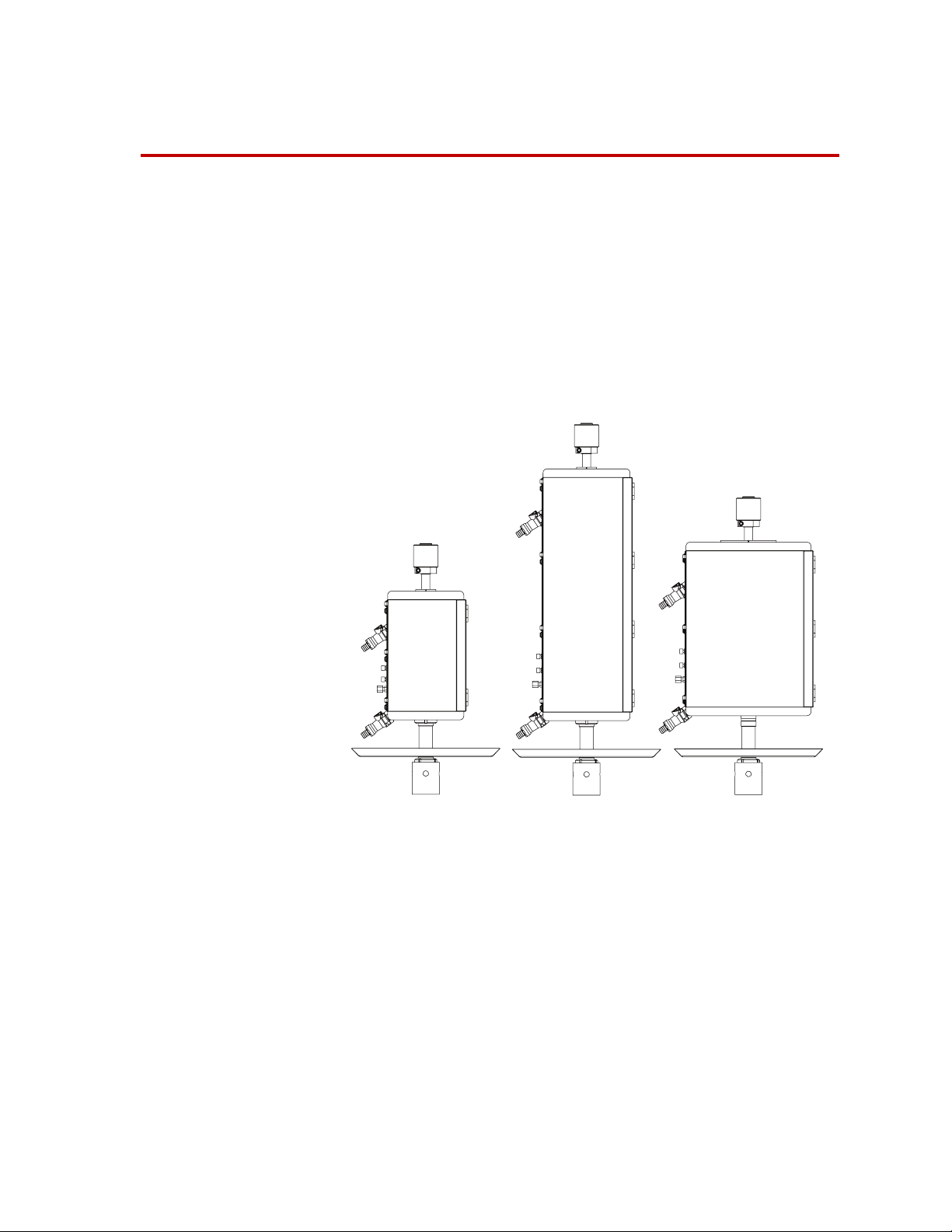

1 liter

10 liter

6 liter

About the Bionix EnviroBath Chamber

The MTS Bionix EnviroBath chamber is engineered for compatibility with MTS

Landmark and MTS Insight load frames. The Bionix EnviroBath chamber is also

compatible with the MTS Model 810, Model 858, Mini Bionix load frames, and

legacy EM load frames (such as Alliance, QTest and Synergie). It has an acrylic

chamber and its transparent walls allow easy viewing when non-opaque fluids

are employed in the test. The walls are compatible with the relatively moderate

temperatures typically employed in simulating the biomaterials service

environment.

The Bionix EnviroBath chamber facilitates accurate and efficient mechanical

testing of medical devices and biomaterial specimens in fluids heated to body

temperatures. Engineered for biomedical and general material test applications,

the Bionix EnviroBath chamber is easy to set up, operate, and maintain. It is

available in a range of volume configurations to accommodate a broad variety of

test specimens. A universal adapter design ensures full compatibility with all

MTS electromechanical and servohydraulic load frame systems, as well as other

electromechanical test systems.

Bionix® EnviroBath™ Chamber Introduction

13

Page 14

Features include:

• Variety of volume configurations: 1 liter, 6 liters, 10 liters

• Supports saline and protein-based fluids

• Utilizes a wide selection of Bionix grips and fixtures

• Reliable fluid temperature control mechanism

• Optional protein-based fluid system

The designs accommodate a variety of fixture and specimen heights and provide

easy access for specimen and fixture attachment.

Mounting of the Bionix EnviroBath chamber uses an attachment kit that installs

directly onto the system load cell (servohydraulic) or the baseplate clevis adapter

(electromechanical). In addition, the 10 liter EnviroBath chamber has column

clamps for servohydraulic applications.

Constant temperature control is regulated by an external circulator bath. Low

level fluid sensors shut the system down if the fluid drops unexpectedly to preset

minimum levels.

The standard Bionix EnviroBath chamber system includes a chamber,

recirculating heating system, and lower attachment kit.

Optional pull-rods are used inside the environmental chamber. For some

configurations, a flexible bellows tightly seals these rods. The pull-rods are easily

attached to the load cell (mounted on the base plate of the load frame) and to the

crosshead.

The chamber works with both axial and axial-torsion grips designed by MTS to

withstand the corrosive environment of the chamber. For supported grips and

fixtures, see the “Compatibility Matrix” on page 16.

14

Introduction

Bionix® EnviroBath™ Chamber

Page 15

Bionix EnviroBath Chamber Specifications

General Specifications

T

EMPERATURE

Range 5°C above ambient to 40°C

(40°F above ambient to 104°F)

Stability ±2°C at 37°C (±3.6°F at 98.6°F)

POWER (V AC, HZ, A)

120 V AC, 50/60 Hz, 11 A

240 V AC, 50 Hz, 10 A

Capacity and Dimensions

M

ODEL VOLUME AXIAL FORCE TORSIONAL FORCE INTERNAL DIMENSIONS

*

1 1 liter 2.4 kN

(540 lbf)

6 6 liters 2.4 kN

(540 lbf)

10 10 liters 10 kN

(2248 lbf)

* Width x Height x Depth

28 N·m

(20.6 lbf·ft)

28 N·m

(20.6 lbf·ft)

100 N·m

(73.7 lbf·ft)

X H X D)

(W

100 x 200 x 56 mm

4 x 8 x 2.2 in

130 x 480 x 100 mm

5 x 19 x 3.9 in

215 x 305 x 150 mm

8.5 x 12 x 5.8 in

Options

1610

Mister/Spray Option XX

Protein-Based Fluid XXX

Horizontal XX

Digital Temperature Monitor XXX

EXTERNAL DIMENSIONS

(W

X H X D)

180 x 295 x 95 mm

7 x 11.5 x 3.65 in

205 x 575 x 140 mm

8 x 22.5 x 5.5 in

295 x 395 x 190 mm

11.5 x 15.5 x 7.4 in

*

Bionix® EnviroBath™ Chamber Introduction

15

Page 16

Compatibility Matrix

G

RIPS AND FIXTURES 1610PART NUMBER

Bionix Vise Action Grips, 100 N XXX 100-186-411

Model 642.01 Bend Fixture XXX 100-201-458 (EM)

100-201-456 (SH)

Manual Thumb Screw XXX 100-167-987

Bionix Stainless Steel Compression Platens, 40 mm XXX100-203-455

Bionix Spring Action Grips XX 056-077-50x

Bionix Stainless Steel Compression Platens, 50 mm XX 100-182-229

Model 684.01A-42 Titanium Cam Action Grips XX 049-008-701

Bionix Vise Action Grips, 2 kN XX 100-174-783

Bionix Roller Action Grips, 1 kN XX 100-185-262

Model 642.01 Bend Fixture X 100-203-453 (EM)

100-203-454 (SH)

Bionix Stainless Steel Compression Platens, 100 mm X 100-182-227

Model 686.01A-42 Axial Torsional Grips X 051-882-2xx

Note: EnviroBath 10 chamber is compatible with customer-supplied spinal fixture per ASTM F1717-01.

Electromechanical Load Frames

1610

MTS Insight 1 & 2 standard length XX

MTS Insight 1 & 2 extended length XXX

MTS Insight 5 - 300 standard and extended length XXX

Legacy MTS load frames and Instron EM Load Frames Consult MTS

Servohydraulic Load Frames

1610

Bionix Tabletop Axial or Axial/Torsional

MTS Landmark

Legacy MTS load frames

‡

‡

* Additional adapter required.

† Extended columns required.

‡ Crosshead mounted actuator.

*

X

XXX

Consult MTS

*†

X

X

16

Introduction

Bionix® EnviroBath™ Chamber

Page 17

Safety Information

Hazard placard

placement

Hazard placards contain specific safety information and are affixed directly to the

system so they are plainly visible.

Each placard describes a system-related hazard. When possible, international

symbols (icons) are used to graphically indicate the type of hazard and the

placard label indicates its severity. In some instances, the placard may contain

text that describes the hazard, the potential result if the hazard is ignored, and

general instructions about how to avoid the hazard.

Know system limits Never rely on system limits such as mechanical limits or software limits to

protect you or any personnel. Limits are designed to minimize the chance of

accidental damage to test specimens or to equipment. Test all limits for proper

operation immediately before a test. Always use these limits and adjust them

properly.

High temperature

hazards

Toxicity of process

Instructions in setting up the heating circulator bath can be found in the vendor

documentation. The customer is responsible for ensuring that the process

temperature is set below the boiling point of the process fluid. Perform

overtemperature interlock testing as recommended by the heating circulator bath

documentation.

Be sure to follow the safety warnings in the MSDS for the process fluids.

fluid

Bionix® EnviroBath™ Chamber Safety Information

17

Page 18

Safety Information

18

Bionix® EnviroBath™ Chamber

Page 19

Installation

POSITIVE HEAD REQUIRED.

CHAMBER MUST BE ABOVE

PUMP AND CONNECT TUBING

FOR PROPER CIRCULATION AND DRAIN.

RESERVOIR WITH ACTIVE TEMP CONTROL FUNCTION

USE 1/2 INCH ID

(0.9% SALINE, MAX)

SILICONE EXTENSION TUBING

BIONIX CHAMBER

COUPLING

COUPLING

4.

FOR ALL CONNECTIONS

PRESSURE OF 1.6M [66"] (APPROX.)

QUICK

HEATER/CIRCULATOR

QUICK

THE CIRCULATION PUMP HAS LIMITED HEAD PRESSURE/FLOW PERFORMANCE. ZERO FLOW WILL OCCUR AT HEAD A

SPEED SETTING UNLESS A SAFE STEADY-STATE

FLUID LEVEL CAN BE ESTABLISHED.

IMPORTANT OPERATIONAL TIPS

:

GRAVITY DRAIN SYSTEM:

TUBE ROUTING FROM UPPER QUICK COUPLING MUST BE GENERALLY DOWNWARD. 1.

LOWER QUICK COUPLING MUST BE ABOVE RESERVOIR FOR CHAMBER TO DRAIN COMPLETELY WHEN PUMP IS SWITCHED 2.

OFF.

BEWARE OF OVER FILLING CHAMBER

: UNDER STEADY-STATE CIRCULATION CHAMBER FLUID LEVEL WILL TYPICALLY BE 2-4 3.

CM (3/4"-1-1/2") ABOVE UPPER QUICK COUPLING PORT.

DO NOT ALLOW IT TO REACH THE UPPER SURFACE OF THE

SAMPLE COMPARTMENT. THE CIRCULATION PUMP HAS "HIGH" AND "LOW" SPEED SETTING. DO NOT OPERATE AT HIGH

GLASS

THERMOMETER

3-WAY VALVE

CHECK VALVE

This section provides general installation guidelines and illustrations for the most

common mounting configurations.

General Installation Guidelines

Tubing and connector

requirements

Because of the variety of process fluids that can be used, MTS recommends

using only MTS supplied tubing and connectors. Use of improper tubing and

connectors could void any warranty.

Saline Distribution Assembly

The following illustration shows a typical setup using a saline distribution

system.

Bionix® EnviroBath™ Chamber Installation

19

Page 20

Serum Distribution Assembly

USE ONLY I/P-82 PUMP TUBING

AT SUCTION LINE

COUPLING

TEMP CONTROL FUNCTION

EXCEPT AT TUBE PUMP

(USE DEMINERALIZED WATER)

(1/2 INCH ID)

USE 1/2 INCH ID

THERMOMETER

USE 1/2 INCH ID

19L RESERVOIR - PROTEIN SERUM

FOR ALL CONNECTIONS

SILICONE EXTENSION TUBING

HEATER/CIRCULATOR

SILICONE EXTENSION TUBING

QUICK

QUICK

TUBE PUMP

BIONIX CHAMBER

COUPLING

COUPLING

QUICK

COUPLING

QUICK

28L RESERVOIR WITH ACTIVE

GLASS

AT PUMP

3-WAY VALVE

LOSS AND FLUID EVAPORATION.

IMPORTANT OPERATIONAL TIPS

:

GRAVITY DRAIN SYSTEM:

TUBING ROUTING FROM UPPER QUICK COUPLING MUST 1.

BE GENERALLY DOWNWARD.

LOWER QUICK COUPLING MUST BE ABOVE RESERVOIR 2.

FOR CHAMBER TO DRAIN COMPLETELY WHEN PUMP IS

SWITCHED OFF.

BEWARE OF OVER FILLING CHAMBER: UNDER STEADY-3.

STATE CIRCULATION CHAMBER FLUID LEVEL WILL

TYPICALLY BE 2-4 CM (3/4"-1-1/2") ABOVE UPPER QUICK

COUPLING PORT. DO NOT ALLOW IT TO REACH THE

UPPER SURFACE OF THE SAMPLE COMPARTMENT.

THE TUBING PUMP HAS A VARIABLE SPEED SETTING.4.

DETERMINE A PUMP SPEED WHICH RESULTS IN A SAFE

STEADY-STATE FLUID LEVEL.

DUAL RESERVOIR HEAT EXCHANGER

DUE TO LOSSES THROUGHOUT THE HEAT 5.

EXCHANGE SYSTEM, HEATER SET POINT

TEMPERATURE MAY NEED TO BE 5

C TO 10 C

ABOVE DESIRED TEST FLUID TEMPERATURE.

EXAMPLE: FOR A 37

C TEST FLUID TEMPERATURE

START WITH A HEATER SET POINT OF 47

C. ADJUST

AS NEEDED.

FOR BEST MEASUREMENT ACCURACY MAINTAIN 6.

125MM IMMERSION DEPTH FOR GLASS

THERMOMETER.

PLACE FOAM INSULATION AROUND CARBOY 7.

AND OVER HEATER RESERVOIR TO MINIMIZE HEAT

The following illustration shows a typical setup using a serum distribution

system. The illustration uses the EnviroBath 6/10 chamber as an example; the

setup for an EnviroBath 1 chamber would be similar.

Connect the hoses Cut tubing to the appropriate length and push the tubing onto the quick coupling.

20

Installation

Bionix® EnviroBath™ Chamber

Connect the quick coupling connectors to the circulating bath and EnviroBath

chamber connectors.

Page 21

Position the

circulating system

relative to the chamber

Determine the height at which the circulating system is placed relative to the

EnviroBath chamber to ensure proper fluid circulation and drain. Proper

orientation also minimizes the chance of fluid leaking from the top of the

chamber.

Head is the measure of the distance between the fluid out coupling on the

circulating bath and the bottom of the EnviroBath chamber. A positive head is

required for proper circulation and drain; the tubing routing from the upper quick

coupling to the circulating system should be generally downward. The lower

quick coupling must be above the reservoir for the chamber to drain completely

when the pump is switched to OFF.

Also consider head distance when setting up the system. The circulating pump

has limited head pressure/flow performance. Zero flow will occur at a head of

approximately 1.6 m (66 in).

Rate of process fluid

flow

Do not overfill the chamber. Under steady-state circulation, the chamber fluid

typically is 2–4 cm (0.75–1.5 in) above the upper quick coupling port. Do not

allow the fluid to reach the upper surface of the sample compartment. The

circulating pump has a high and low speed setting. Do not operate at high speed

setting unless a safe steady-state fluid level can be established.

Bionix® EnviroBath™ Chamber Installation

21

Page 22

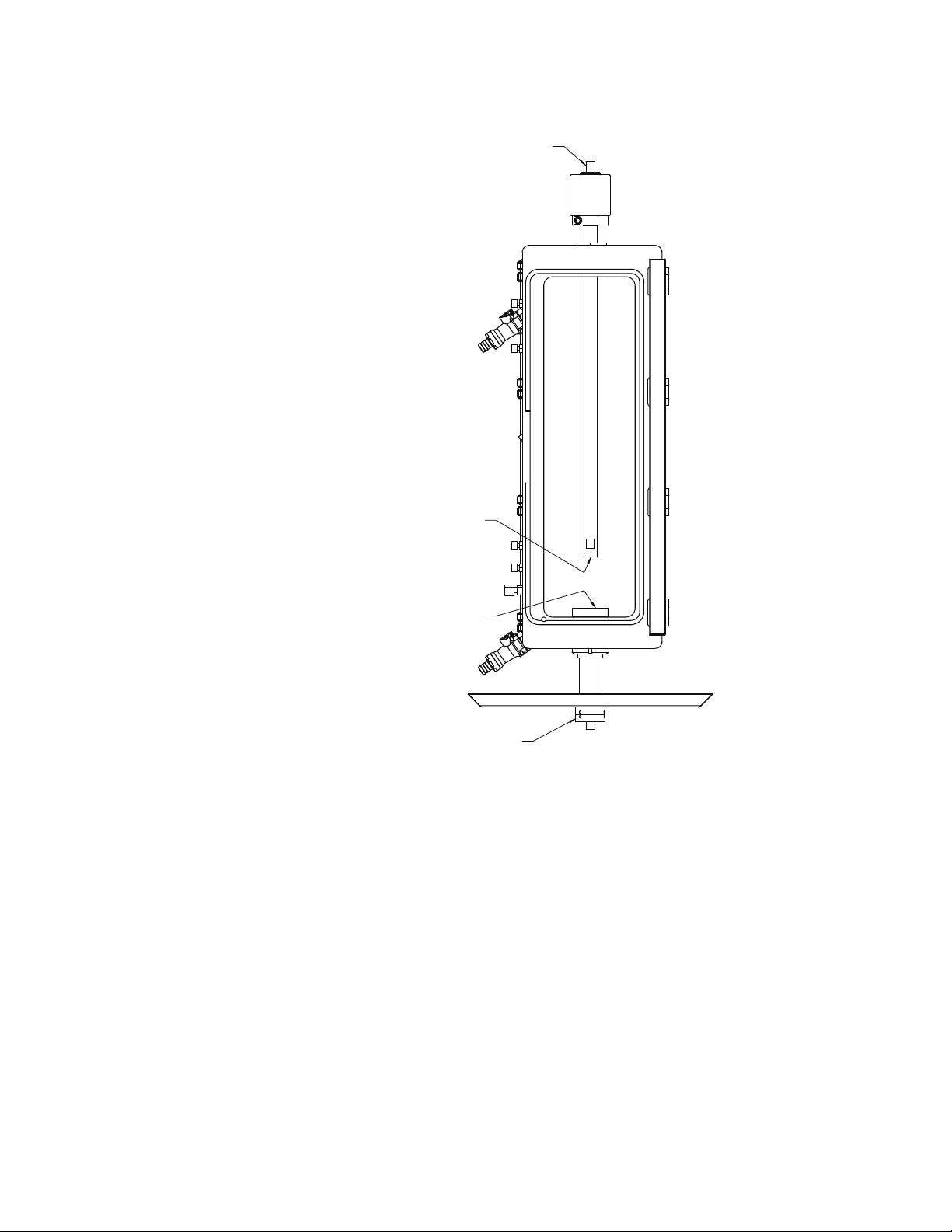

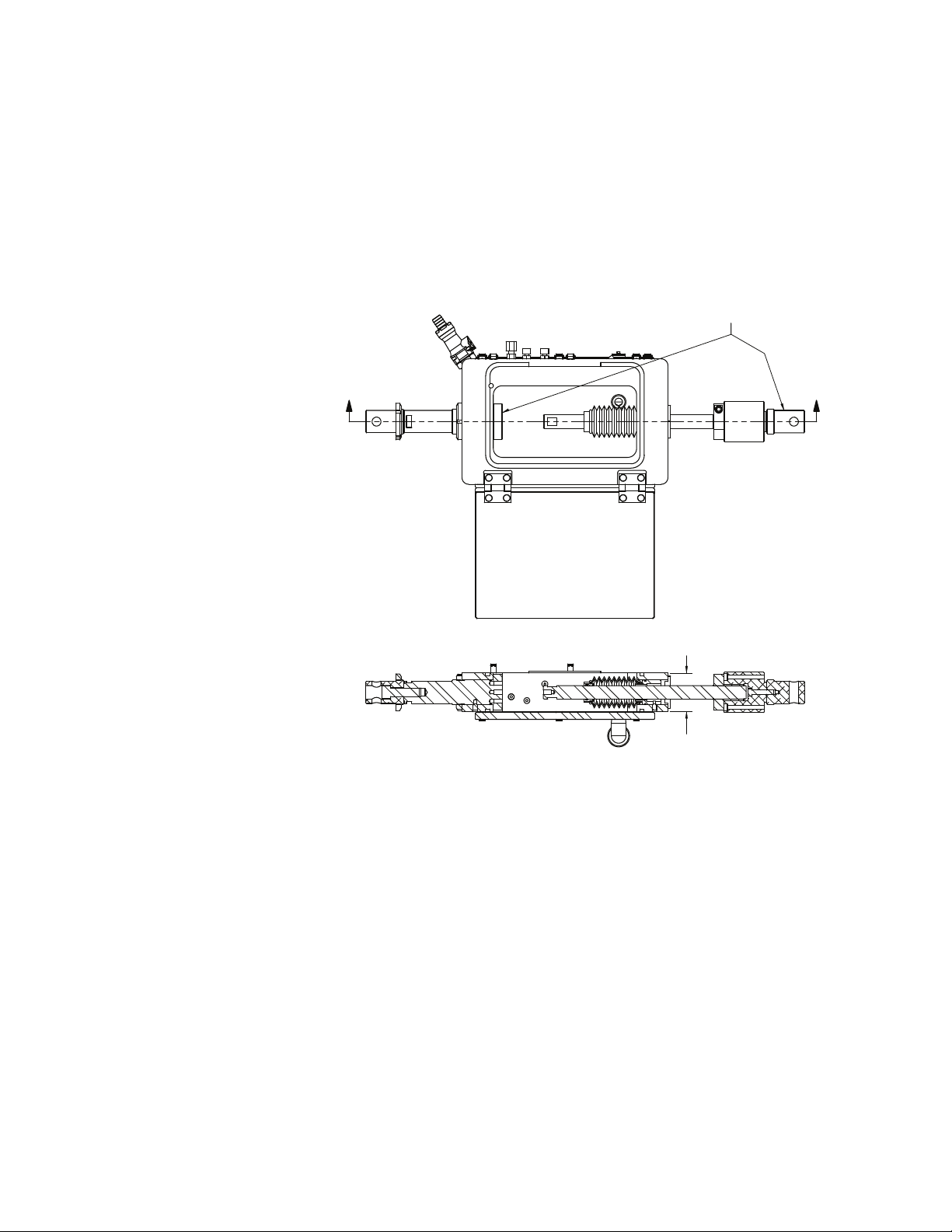

Bionix EnviroBath 1 Chamber Common Vertical Mounting Configurations

Note Adapters (for example “B”, “C”, “D”) referenced in the following

illustration are detailed in “Universal Adapters” on page 33.

Electromechanical,

2.4 kN (550 lb)

MALE UNIVERSAL ADPTR

"B", "C", "D"

4.000

7.500

1.970

.750

ACCESSORY MOUNT-UPPER

C

M6X1 ON

L

ACCESSORY MOUNTING-LOWER

C

M6 AT

L

4X M5X.8 ON A 1.688BC

COUPLING ASSY

MALE "D"

22

Installation

Bionix® EnviroBath™ Chamber

Page 23

Servohydraulic, axial,

2.4 kN (550 lb)

LOAD FRAME ATTACHMENT:

M12 SCREW ON

C

L

ACCESSORY MOUNT-UPPER

M6X1 ON

ACCESSORY MOUNTING-LOWER

M6 AT

4X M5X.8 ON A 1.688BC

C

L

C

L

LOAD FRAME ATTACHMENT

M12X1.25 STUD AND

SPIRAL WASHER SET ON

C

L

Bionix® EnviroBath™ Chamber Installation

23

Page 24

Servohydraulic.

4X M5X.8 ON A 1.688BC

M6 ON

ACCESSORY MOUNTING:

C

L

4X M5 SCREW ON A 1.688BC

C

L

M12 SCREW ON

LOAD FRAME ATTACHMENT:

8X M8 SCREW ON A 3.100 BC

LOAD FRAME ATTACHMENT:

PILOT

2.200

PILOT

1.125

1.980

axial/torsional

2.4 kN (550 lb)/

28 N·m (250 in-lb)

24

Installation

Bionix® EnviroBath™ Chamber

Page 25

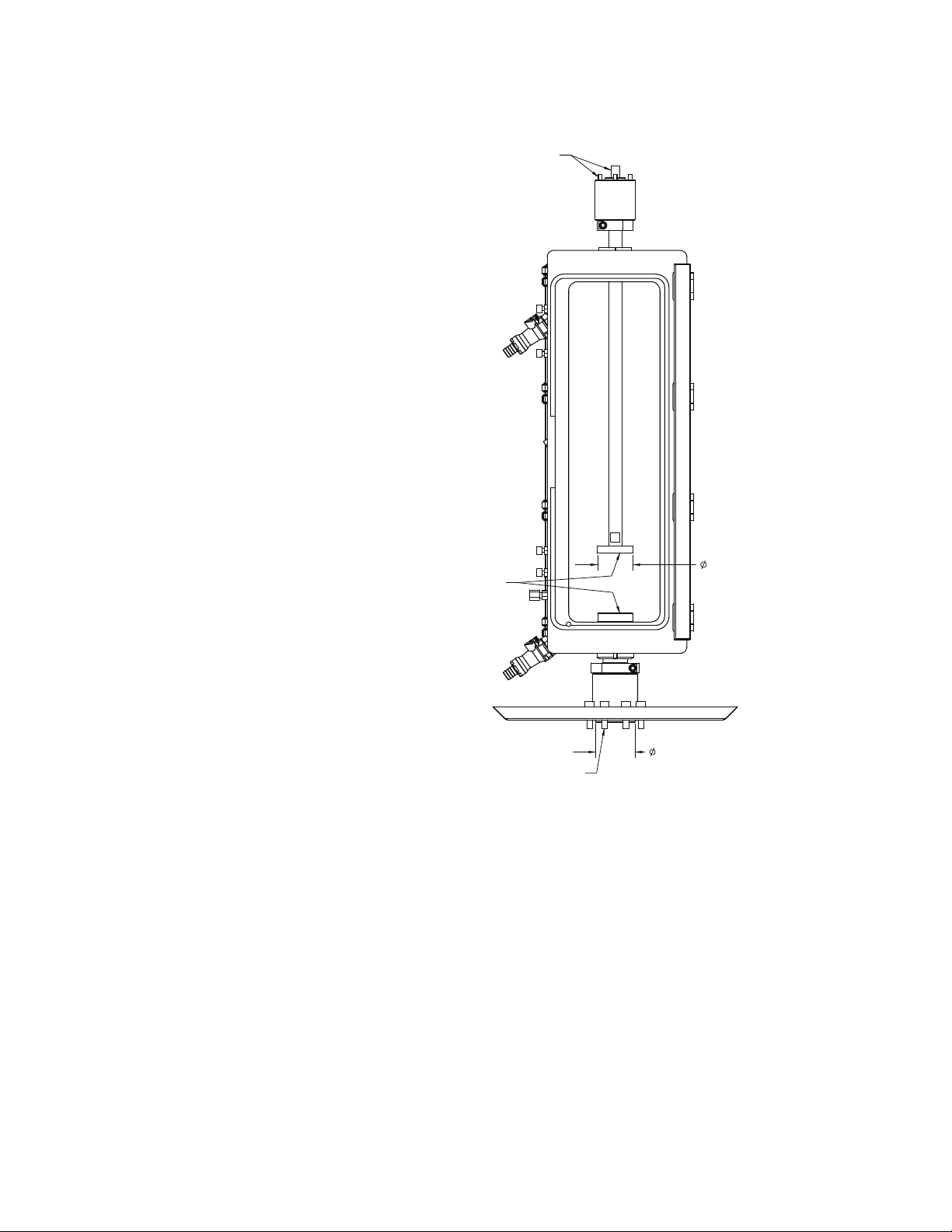

Bionix EnviroBath 6 Chamber Common Mounting Configurations

M6 AT

LOWER

ADAPTER

C

L

M6X1 ON

UNIVERSAL

C

L

MOUNT-UPPER

COUPLING ASSY

4X M5X.8 ON A 1.688BC

"B", "C", "D"

MALE

MALE "D"

ACCESSORY MOUNTING-

ACCESSORY

1.970

.750

18.500

5.100

Note Adapters (for example “B”, “C”, “D”) referenced in the following

illustration are detailed in “Universal Adapters” on page 33.

Electromechanical,

vertical, 2.4 kN (550 lb)

Bionix® EnviroBath™ Chamber Installation

25

Page 26

Servohydraulic, axial,

2.4 kN (550 lb)

LOAD FRAME ATTACHMENT:

M12 SCREW ON

ACCESSORY

MOUNT-UPPER

M6X1 ON

C

L

C

L

ACCESSORY

MOUNTING-LOWER

4X M5X.8 ON A

LOAD FRAME ATTACHMENT

M12X1.25 STUD AND

SPIRAL WASHER SET ON

M6 AT

1.688BC

C

L

C

L

26

Installation

Bionix® EnviroBath™ Chamber

Page 27

Servohydraulic.

LOAD FRAME ATTACHMENT:

8X M8 SCREW ON A 3.100 BC

1.688BC

4X M5X.8 ON A

C

L

4X M5 SCREW ON A 1.688BC

C

L

LOAD FRAME ATTACHMENT:

M12 SCREW ON

ACCESSORY

MOUNTING:

M6 ON

2.200

1.980

axial/torsional

2.4 kN (550 lb)/

28 N·m (250 in-lb)

Bionix® EnviroBath™ Chamber Installation

27

Page 28

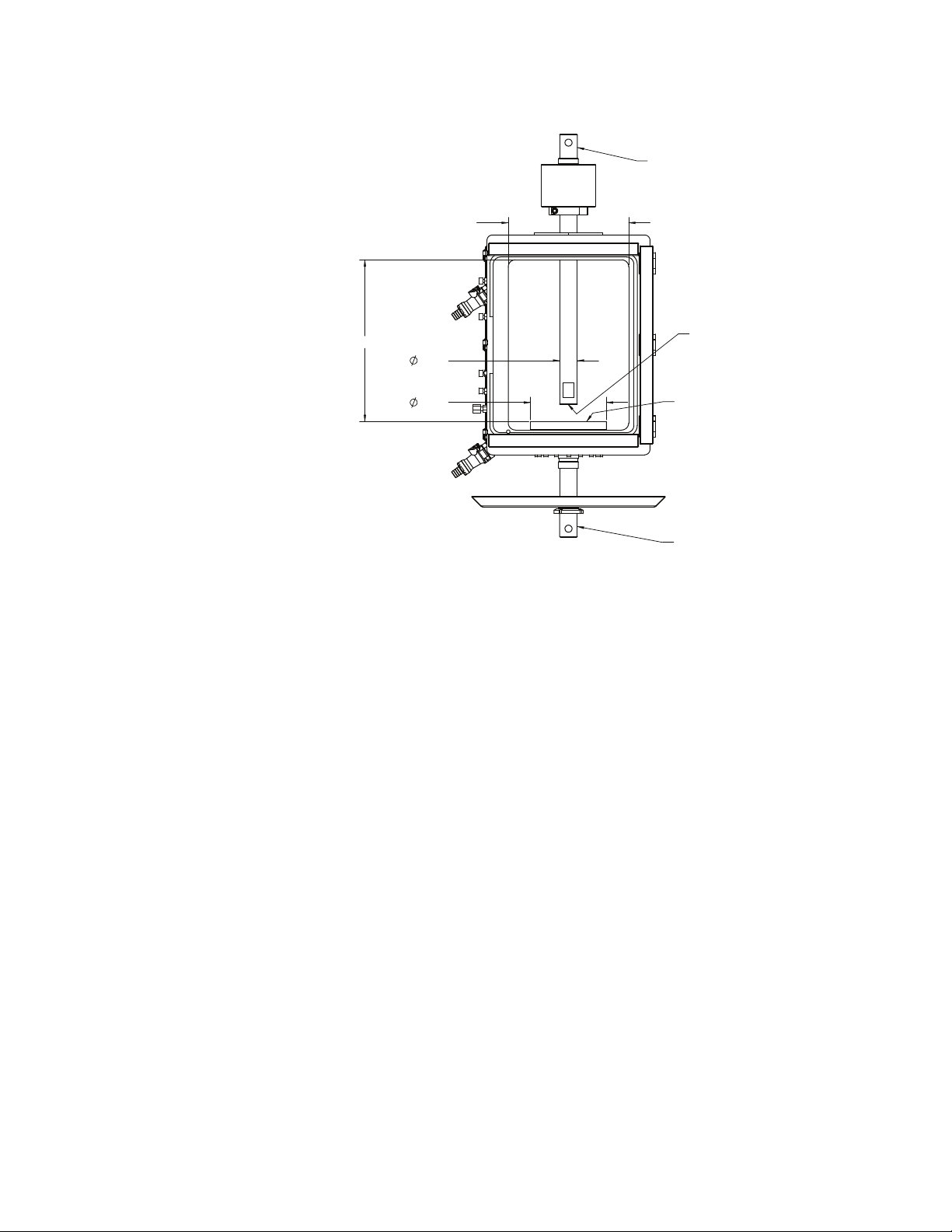

Bionix EnviroBath 10 Chamber Common Mounting Configurations

"B", "C", "D"

MALE UNIVERSAL ADPTR

MALE UNIVERSAL ADAPTER

"D"

.750

B

B

C

L

4X M5X.8 ON A 1.688BC

M6X1 ON

ACCESSORY MOUNT-LOWER

M12X1.25 ON

C

L

ACCESSORY MOUNT-UPPER

SECTION B-B

M6X1 ON

C

L

5.750

Note Adapters (for example “B”, “C”, “D”) referenced in the following

illustration are detailed in “Universal Adapters” on page 33.

Electromechanical,

2.4 kN (550 lb)

28

Installation

Bionix® EnviroBath™ Chamber

Page 29

Electromechanical,

10 kN (2.2 kip)

8.500

MALE UNIVERSAL ADAPTER

"D"

11.400

1.250

5.350

ACCESSORY MOUNT-UPPER

M12X1.25 ON

ACCESSORY MOUNT-LOWER

M12X1.25 ON

M6X1 ON

4X M5X.8 ON A 1.688BC

MALE UNIVERSAL ADAPTER

"D"

C

L

C

L

C

L

Bionix® EnviroBath™ Chamber Installation

29

Page 30

Servohydraulic,

22.3

[661.19 AXIAL XDCR]

23.7

27.4

[662.20X-05 A/T XDCR]

[662.20X-03/-04 A/T XDCR]

MNT

3.00

COLUMN

T-SLOT TABLE SURFACE

21.110

A

A

8X M8X1.25 ON A 3.100BC

ON A 3.100BC

C

L

5/16-18UNC

ON A 3.100BC

ACCESSORY MOUNTING:

4X M5X.8 ON A 1.688BC

M12 ON

SECTION A-A

8X M8X1.25 OR

5/16-18UNC

C

L

M12X1.25 AT

LOAD FRAME ATTACHMENT:

LOAD FRAME ATTACHMENT:

M12X1.25 AT

C

L

8X M8X1.25 OR

3.930

1.000

2.201

11.200 MAX

10 kN (2.2 kip)

30

Installation

Bionix® EnviroBath™ Chamber

Page 31

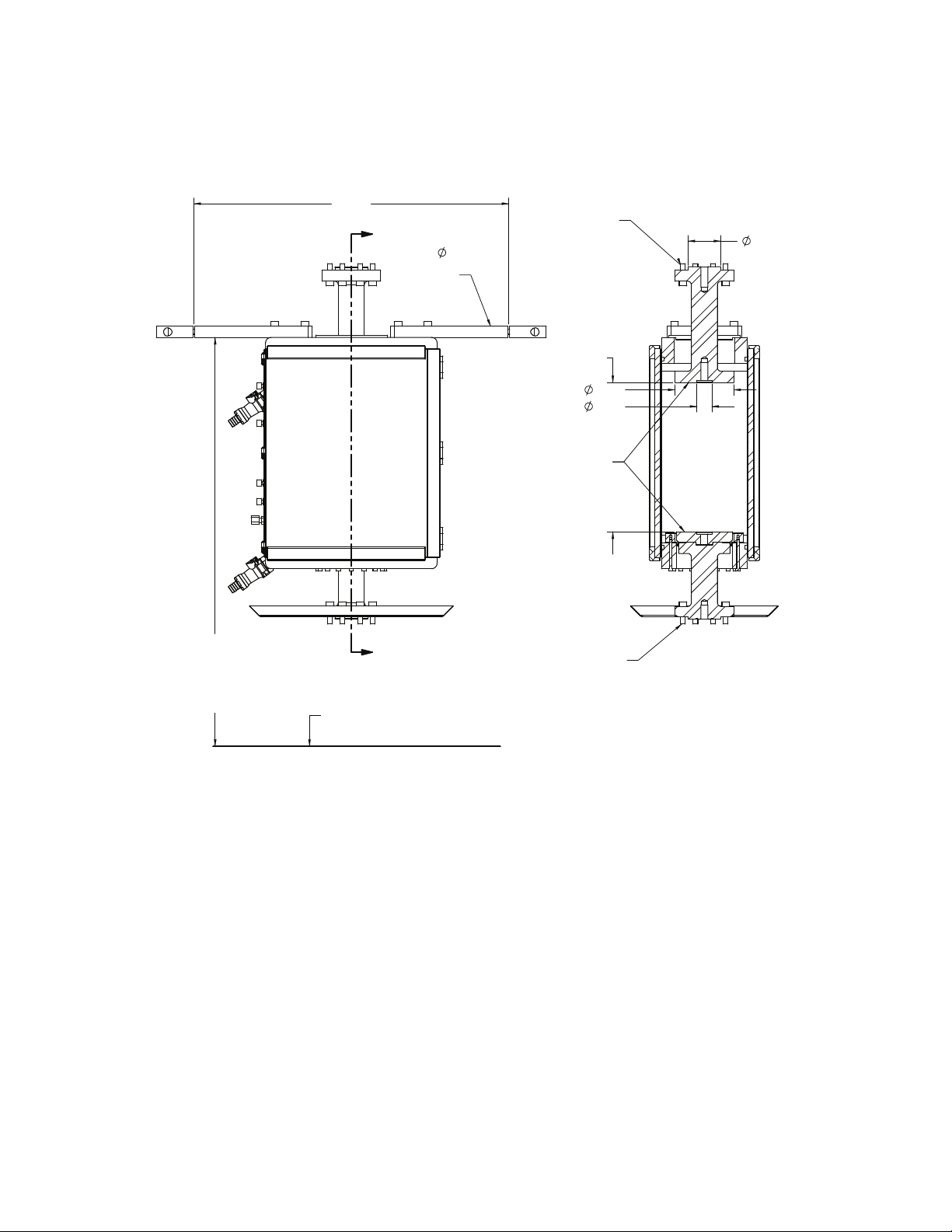

Horizontal Mounting Configurations

AS VERTICAL

MOUNTINGS SAME

LOAD FRAME AND ACCESSORY

A

A

SECTION A-A

2.150

TOP VIEW

The Bionix EnviroBath 1 chamber and Bionix EnviroBath 6 chamber can be

horizontally mounted in the MTS Insight 1 kN and 2 kN single column load

frames.

Note Adapters (for example “B”, “C”, “D”) referenced in the following

illustration are detailed in “Universal Adapters” on page 33.

Horizontal, Bionix

EnviroBath 1,

Electromechanical,

2.4 kN (550 lb)

Bionix® EnviroBath™ Chamber Installation

31

Page 32

Horizontal, Bionix

AS E/M VERTICAL

MOUNTINGS SAME

LOAD FRAME AND ACCESSORY

TOP VIEW

EnviroBath 6,

Electromechanical,

2.4 kN (550 lb)

32

Installation

Bionix® EnviroBath™ Chamber

Page 33

Universal Adapters

Clevis Pin

Connection Type

Attachment

CLEVIS PIN CONNECTION TYPE TYPE BTYPE CTYPE D

Load Up to 10 N Up to 200 N Up to 150 kN

Clevis Diameter (X) 0.50 in 0.625 in 1.25 in

Pin Diameter (Y) 0.187 in 0.25 in 0.50 in

Upper Grip Connection (male) Bm Cm Dm

Lower Grip Connection (male) Dm Dm Dm

Upper Load Frame Connection (female) Bf Cf Df

Lower Load Frame Connection (female) Df Df

Df

Bionix® EnviroBath™ Chamber Installation

33

Page 34

34

Installation

Bionix® EnviroBath™ Chamber

Page 35

Operation

Bionix EnviroBath

chamber

Heating circulator

bath operation

Other than the hose connections and closing and latching the door before filling

the chamber with fluid, all operation is performed using the heating circulator

bath.

A manual describing operation of the heating circulator bath is provided by the

vendor.

Process fluids Use only recommended fluids:

• Water

• Saline

• Protein serum

Set limits before

testing

Limits should be set such that grips and fixtures cannot damage the EnviroBath

chamber during setup and testing.

For electromechanical test frames, limits are usually set by positioning physical

switches to stop crosshead travel when the limit is reached. For more

information, see the individual frame product manual.

For servohydraulic test frames, limits are usually set in the control software. For

more information, see setting detectors in the controller software manual for

additional information.

Elevated temperature

operation

For elevated temperature operation information, see circulating bath vendor

documentation

Fluids used in the EnviroBath chamber can reach boiling point.

Boiling fluid can cause personal injury and equipment damage.

When operating the EnviroBath chamber at elevated temperature, it is the

customer’s responsibility to ensure the temperature set point is below the boiling

point of the process fluid.

Bionix® EnviroBath™ Chamber Operation

35

Page 36

Resonant frequency

The drip pan has a resonant frequency of about 10 Hz and vibrates if the

system is operated around that frequency.

A vibrating drip pan can cause fluid spills. Vibration over time can result in

equipment damage.

Do not operate the system at approximately 10 Hz.

36

Operation

Bionix® EnviroBath™ Chamber

Page 37

Maintenance

Periodic cleaning Maintenance of the Bionix EnviroBath chamber consists of periodic cleaning and

seal inspection.

Before cleaning, disassemble the chamber and extension rod feed-thru seals to

the extent necessary to inspect for build-up of deposits.

To clean the unit, use a mild detergent and a clean, lint-free cloth. Rinse

thoroughly to remove detergent deposits and dry with a clean, lint-free cloth.

Seal inspection O-ring seals, fittings, and pipe thread sealant should be inspected at each use and

replaced if leakage is noticed. When replacing seals, ensure that the seam is at the

top. The seals can be removed by pulling them out of the channel. The seals can

be installed by starting with one end top center, and pushing the seal into the

groove with a thumb or finger. Never use a sharp objects to install seals.

Heating circulator

bath operation

A manual describing maintenance of the heating circulator bath is provided by

the vendor.

Bionix® EnviroBath™ Chamber Maintenance

37

Page 38

38

Maintenance

Bionix® EnviroBath™ Chamber

Page 39

Page 40

m

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255

(within the U.S. or Canada)

Phone: 952-937-4000

(outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

Internet: www.mts.com

ISO 9001 Certified QMS

Loading...

Loading...