Page 1

m

be certain.

Advantage™ Pneumatic Grips

Product Information

100-013-660 L

Page 2

Copyright information © 2012 MTS Systems Corporation. All rights reserved.

Trademark information MTS is a registered trademark of MTS Systems Corporation within the United

States. These trademarks may be protected in other countries.

Molykote is a registered trademark of Carleton-Stuart Corporation. Surfalloy is a

trademark of Alloying Surfaces Incorporated. Scotch-Brite is a trademark of 3M.

All other trademarks or service marks are property of their respective owners.

Publication information

Manual Part Number Publication Date

100-013-660 A October 2000

100-013-660 B December 2000

100-013-660 C January 2001

100-013-660 D June 2001

100-013-660 E June 2001

100-013-660 F September 2001

100-013-660 G October 2004

100-013-660 H November 2004

100-013-660 J February 2005

100-013-660 K November 2009

100-013-660 L August 2012

2

Advantage™ Pneumatic Grips

Page 3

Contents

Technical Support 5

How to Get Technical Support 5

Before You Contact MTS 6

If You Contact MTS by Phone 7

Problem Submittal Form in MTS Manuals 8

Preface 11

Before You Begin 11

Conventions 12

Documentation Conventions 12

Introduction 15

Functional Description 17

Specifications 20

Safety Information 21

General Safety Practices: Grips and Fixtures 21

Hazard Placard Placement 27

Power Loss Consideration 27

Installation 29

Installation Using the Mounting Pin 30

Installation Without Using the Mounting Pin 32

Connecting the Air Supply 35

Advantage™ Pneumatic Grips Contents

3

Page 4

Operation 39

Selecting Face Surfaces 40

Grip Faces for the 10 N Grips 41

Grip Faces for the 200 N and 2000 N Grips 42

Grip Faces for the 10,000 N Grips 45

Changing Face Surfaces 47

Changing Wedges 48

Installing a Specimen 50

Adjusting the Air Supply Pressure 53

Maintenance 55

4

Contents

Advantage™ Pneumatic Grips

Page 5

Technical Support

How to Get Technical Support

Start with your

manuals

Technical support

methods

The manuals supplied by MTS provide most of the information you need to use

and maintain your equipment. If your equipment includes software, look for

online help and README files that contain additional product information.

If you cannot find answers to your technical questions from these sources, you

can use the Internet, e-mail, telephone, or fax to contact MTS for assistance.

MTS provides a full range of support services after your system is installed. If

you have any questions about a system or product, contact Technical Support in

one of the following ways.

www.mts.com The web site provides access to our technical support staff by means of an

onlineform:

www.mts.com > Contact MTS > Service & Technical Support button

E-mail tech.support@mts.com

Telephone MTS Call Center 800-328-2255

Weekdays 7:00 A.M. to 5:00 P.M., Central Time

Fax 952-937-4515

Please include “Technical Support” in the subject line.

Outside the U.S. For technical support outside the United States, contact your local sales and

service office. For a list of worldwide sales and service locations and contact

information, use the Global MTS link at the MTS web site:

www.mts.com > Global MTS > (choose your region in the right-hand

column) > (choose the location closest to you)

Advantage™ Pneumatic Grips Technical Support

5

Page 6

Before You Contact MTS

MTS can help you more efficiently if you have the following information

available when you contact us for support.

Know your site

number and system

number

Know information from

prior technical

The site number contains your company number and identifies your equipment

type (such as material testing or simulation). The number is typically written on a

label on your equipment before the system leaves MTS. If you do not know your

MTS site number, contact your sales engineer.

Example site number: 571167

When you have more than one MTS system, the system job number identifies

your system. You can find your job number in your order paperwork.

Example system number: US1.42460

If you have contacted MTS about this problem before, we can recall your file

based on the:

assistance

• MTS notification number

• Name of the person who helped you

Identify the problem Describe the problem and know the answers to the following questions:

• How long and how often has the problem occurred?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the

problem started?

Technical Support

6

• What are the equipment model numbers?

• What is the controller model (if applicable)?

• What is the system configuration?

Advantage™ Pneumatic Grips

Page 7

Know relevant

computer information

For a computer problem, have the following information available:

• Manufacturer’s name and model number

• Operating software type and service patch information

• Amount of system memory

• Amount of free space on the hard drive where the application resides

• Current status of hard-drive fragmentation

• Connection status to a corporate network

Know relevant

For software application problems, have the following information available:

software information

• The software application’s name, version number, build number, and (if

available) software patch number. This information can typically be found

in the About selection in the Help menu.

• The names of other applications on your computer, such as:

– Anti-virus software

– Screen savers

– Keyboard enhancers

– Print spoolers

– Messaging applications

If You Contact MTS by Phone

A Call Center agent registers your call before connecting you with a technical

support specialist. The agent asks you for your:

• Site number

• Name

• Company name

• Company address

• Phone number where you can be reached

If your issue has a notification number, please provide that number. A new issue

will be assigned a unique notification number.

Advantage™ Pneumatic Grips Technical Support

7

Page 8

Identify system type To enable the Call Center agent to connect you with the most qualified technical

support specialist available, identify your system as one of the following types:

• Electromechanical material test system

• Hydromechanical material test system

• Vehicle test system

• Vehicle component test system

• Aero test system

Be prepared to

Prepare to perform troubleshooting while on the phone:

troubleshoot

• Call from a telephone close to the system so that you can implement

suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an

experienced user nearby to assist you.

Write down relevant

In case Technical Support must call you:

information

• Verify the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions.

After you call MTS logs and tracks all calls to ensure that you receive assistance for your

problem or request. If you have questions about the status of your problem or

have additional information to report, please contact Technical Support again and

provide your original notification number.

Problem Submittal Form in MTS Manuals

Use the Problem Submittal Form to communicate problems with your software,

hardware, manuals, or service that are not resolved to your satisfaction through

the technical support process. The form includes check boxes that allow you to

indicate the urgency of your problem and your expectation of an acceptable

response time. We guarantee a timely response—your feedback is important to

us.

Technical Support

8

Advantage™ Pneumatic Grips

Page 9

Access the Problem Submittal Form:

• In the back of many MTS manuals (postage paid form to be mailed to MTS)

• www.mts.com > Contact Us > Problem Submittal Form button (electronic

form to be e-mailed to MTS)

Advantage™ Pneumatic Grips Technical Support

9

Page 10

Technical Support

10

Advantage™ Pneumatic Grips

Page 11

Preface

Before You Begin

Safety first! Before you use your MTS product or system, read and understand the Safety

manual and any other safety information provided with your system. Improper

installation, operation, or maintenance can result in hazardous conditions that can

cause severe personal injury or death, or damage to your equipment and

specimen. Again, read and understand the safety information provided with your

system before you continue. It is very important that you remain aware of

hazards that apply to your system.

Other MTS manuals In addition to this manual, you may receive additional manuals in paper or

electronic form.

You may also receive an MTS System Documentation CD. It contains an

electronic copy of the manuals that pertain to your test system, such as:

• Hydraulic and mechanical component manuals

• Assembly drawings

• Parts lists

• Operation manual

• Preventive maintenance manual

Controller and application software manuals are typically included on the

software CD distribution disc(s).

Advantage™ Pneumatic Grips Preface

11

Page 12

Conventions

DANGER

WARNING

CAUTION

Conventions

Documentation Conventions

The following paragraphs describe some of the conventions that are used in your

MTS manuals.

Hazard conventions Hazard notices may be embedded in this manual. These notices contain safety

information that is specific to the activity to be performed. Hazard notices

immediately precede the step or procedure that may lead to an associated hazard.

Read all hazard notices carefully and follow all directions and recommendations.

Three different levels of hazard notices may appear in your manuals. Following

are examples of all three levels.

Note For general safety information, see the safety information provided with

your system.

Danger notices indicate the presence of a hazard with a high level of risk which,

if ignored, will result in death, severe personal injury, or substantial property

damage.

12

Warning notices indicate the presence of a hazard with a medium level of risk

which, if ignored, can result in death, severe personal injury, or substantial

property damage.

Caution notices indicate the presence of a hazard with a low level of risk which,

if ignored, could cause moderate or minor personal injury or equipment damage,

or could endanger test integrity.

Notes Notes provide additional information about operating your system or highlight

easily overlooked items. For example:

Note Resources that are put back on the hardware lists show up at the end of

the list.

Special terms The first occurrence of special terms is shown in italics.

Preface

Advantage™ Pneumatic Grips

Page 13

Conventions

Illustrations Illustrations appear in this manual to clarify text. They are examples only and do

not necessarily represent your actual system configuration, test application, or

software.

Electronic manual

conventions

This manual is available as an electronic document in the Portable Document

File (PDF) format. It can be viewed on any computer that has Adobe Acrobat

Reader installed.

Hypertext links The electronic document has many hypertext links displayed in a blue font. All

blue words in the body text, along with all contents entries and index page

numbers, are hypertext links. When you click a hypertext link, the application

jumps to the corresponding topic.

Advantage™ Pneumatic Grips Preface

13

Page 14

Conventions

14

Preface

Advantage™ Pneumatic Grips

Page 15

Introduction

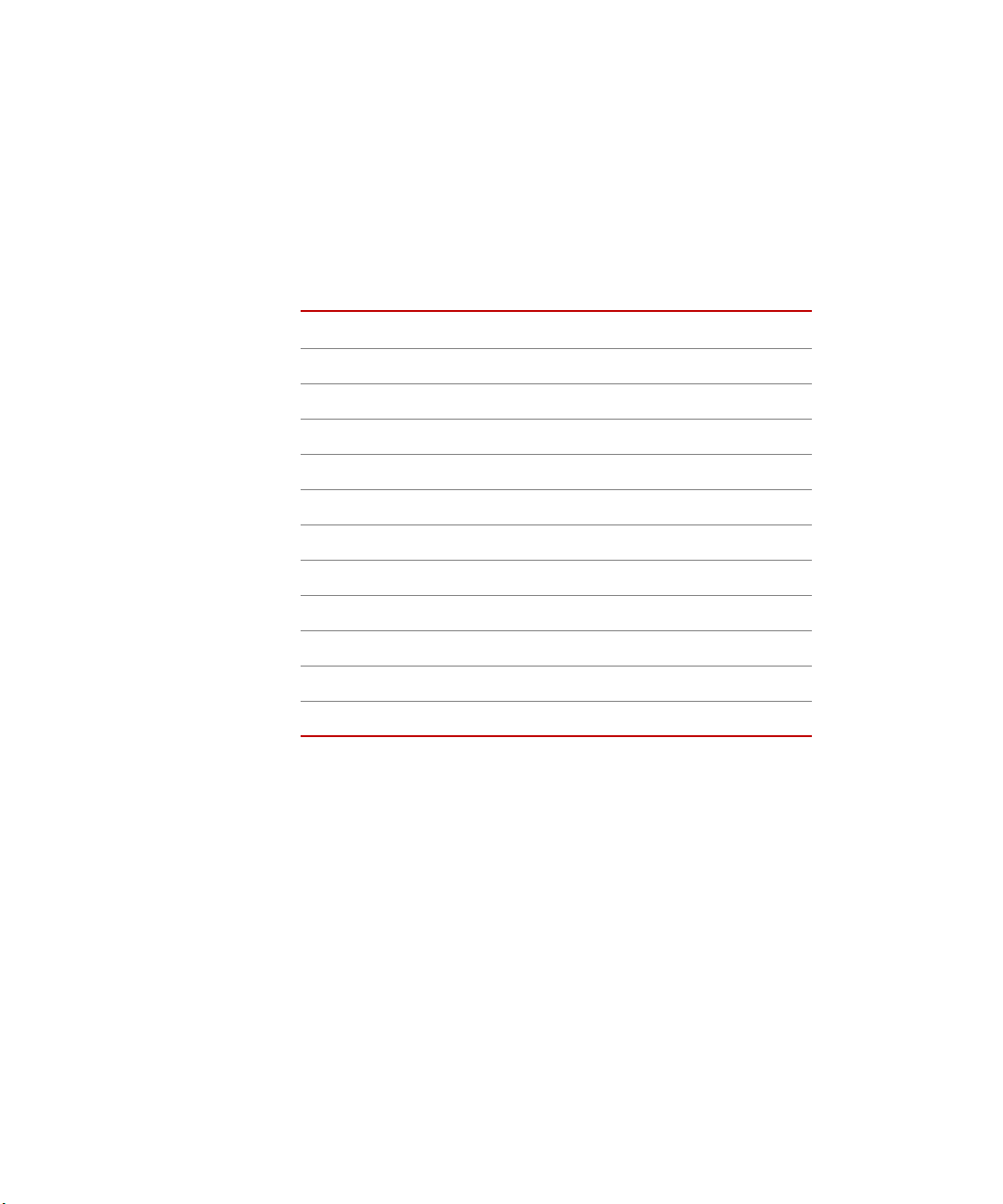

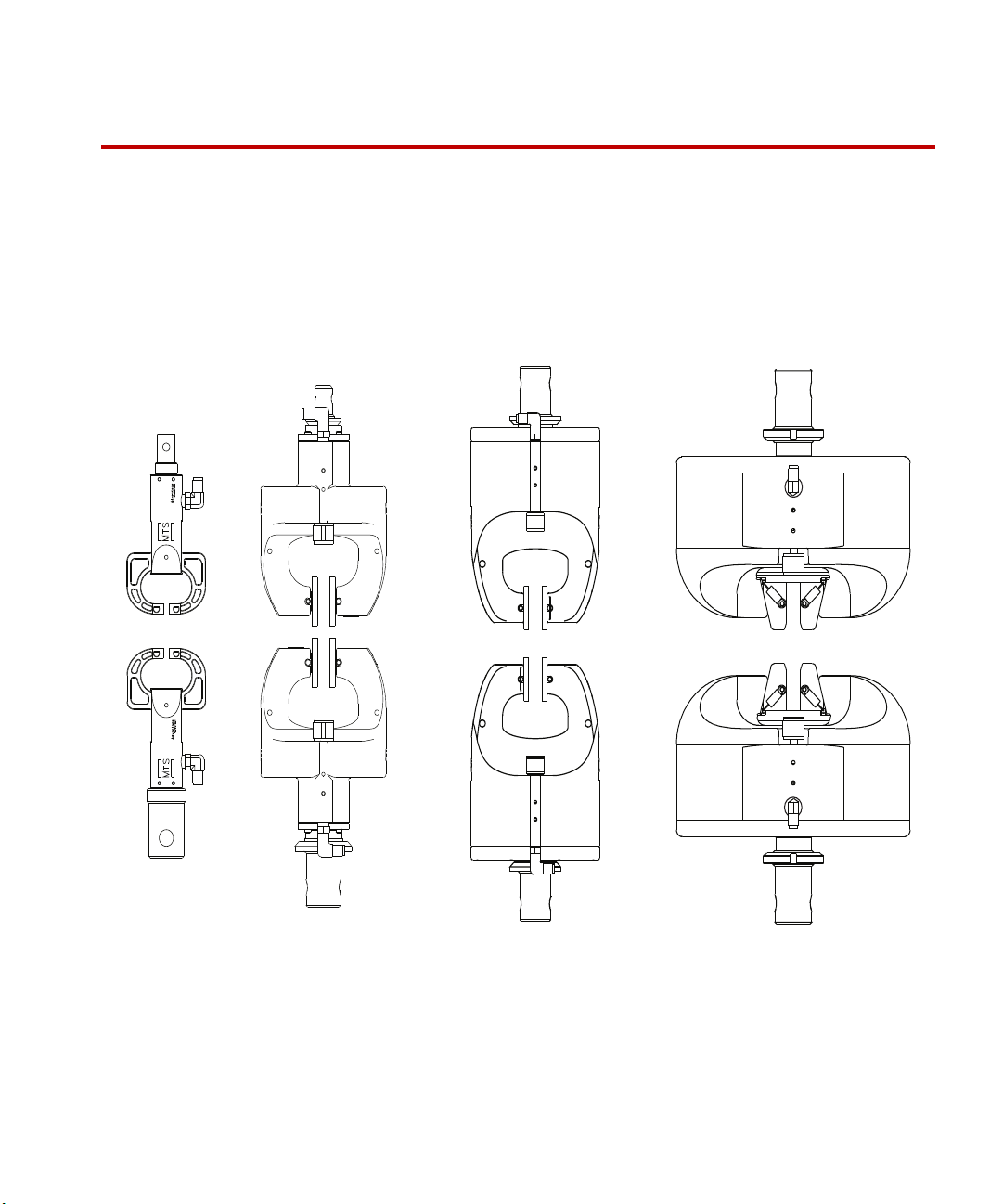

10 N 200 N 2000 N 10,000 N

Contents Functional Description 17

The Advantage™ Pneumatic Grips hold a test specimen in a load unit for static

tension testing. Most of the grips accommodate flat-surfaced specimens only, the

10,000 N high tensile grip can clamp flat and round specimens.

Specifications 20

Advantage Pneumatic Grip Family

Advantage™ Pneumatic Grips Introduction

15

Page 16

What you need to

know

This manual assumes that you know how to use your controller. See the

appropriate manual for information about performing any controller-related step

in this manual’s procedures. You are expected to know how to:

• Turn main power on and off (electromechanical systems) or turning

hydraulic pressure on and off (servohydraulic systems)

• Manually adjust the actuator or crosshead position

• Adjust the air supply pressure

• Use the air controller clamping controls (if available)

16

Introduction

Advantage™ Pneumatic Grips

Page 17

Functional Description

The Advantage Pneumatic Grips are designed for static tension testing. The

pneumatic grips require an external air supply to provide filtered, dry air to the

grips. Applying air to the grips cause them to clamp and removing the air causes

them to release. There are a variety of ways to control the air to the grips. The

grips can be installed in an electromechanical load frame or a servohydraulic load

unit with the appropriate adapter kit.

Functional Description

Advantage 10 N

applications

Advantage

200 N/2000 N

applications

The 10 N (2 lbf) capacity pneumatic grips are designed for low tensile

applications and testing thin specimens with low breaking strengths like the gold

wire in electronics, tungsten wire, thermocouples, gels, and plastic films.

These grips feature dual acting, swivel faces that simultaneously move to the

centerline of the grip and eliminate the bending strains on your specimen that can

invalidate your test results. The ability to swivel lets these faces conform to any

variations in your specimen’s geometry. The grip also has a self-aligning feature

which allows the grips to maintain alignment while actuated.

The 200 N (40 lbf) and 2000 N (400 lbf) capacity pneumatic grips can be used to

test a variety of thin films, sheets, and tapes.

The low and medium tensile models feature dual acting grip faces that

simultaneously move to the centerline of the grip. This assures correct specimen

alignment and removes the bending strains that can invalidate test results.

The design of these grips let you quickly and easily load and align your

specimens. They also feature an area above the grip faces that is large enough for

you to load the specimens while holding them with your fingers.

The weight of the 200 N grip is low enough to allow it to be used with 100 N

force transducers.

Advantage™ Pneumatic Grips Introduction

17

Page 18

Functional Description

Advantage 10,000 N

applications

Grip faces

and wedges

The 10,000 N (2,200 lbf) capacity pneumatic grips are designed for performing

tensile tests on a variety of materials including elastomers, plastics, rigid and

semi-rigid films, and sheets. These grips can use a variety of flat, round, and veeshaped wedges. They feature dual acting grip faces that simultaneously move to

the centerline of the grip.

The grips offer quick and easy specimen insertion. This model also features a

constant clamping load to protect your specimens from damage due to slippage.

The weight of the 10,000 N grip is low enough to allow it to be used with 5,000

N force transducers.

The 10 N, 200 N, and 2000 N grips use grip faces to contact and hold a specimen.

The 10,000 N grips use wedges to contact and hold a specimen. Several surfaces

are available for the faces and grips (not all surfaces are available for all grips).

• Corrugated for gripping smooth and flexible specimens

• Serrated for gripping soft material

• Smooth rubber coating for extra gripping protection of thin delicate

specimens (in some cases the smooth faces will slip below the rated capacity

of the grip)

• Matte rubber coating for more gripping power than smooth rubber coated

faces

Electromechanical

Servohydraulic

Introduction

18

systems

systems

• Corrugated rubber coating for more gripping power than the matte rubber

coated faces

• Diamond tipped for more aggressive gripping needs

• Grab test for gripping fabric specimens

• Line contact for gripping rubber, latex, and cable sheath

Installing the grips in an electromechanical system involves mounting one grip to

the base of the load frame and the other grip to the crosshead of the load frame.

Standard mounting pins are used.

Installing the grips in a servohydraulic system involves attaching one grip onto

the end of the load unit actuator rod and one grip to the load unit force transducer.

The standard mounting pin can be removed so the grip can be bolted directly to

the actuator or load transducer.

Advantage™ Pneumatic Grips

Page 19

Functional Description

Adapters Each grip assembly includes a set of standard mounting pins. Some grip

assemblies include different size mounting pins for the upper and lower grips.

Optional adapters are available to install the grips in some specific load frames or

load units.

Optional mounting adapters allow the grips to be installed on an actuator and

load transducer of a servohydraulic load unit. The adapter allows the use of the

standard mounting pin in servohydraulic systems.

Advantage™ Pneumatic Grips Introduction

19

Page 20

Specifications

WARNING

Specifications

This section lists the specifications for the Advantage Pneumatic Grips.

General Specifications

P

ARAMETER SPECIFICATION

Temperature range

Air supply must provide clean dry air at 5.5 bar (80 psi)

* Between -40°C and 0°C moisture will accumulate on exposed parts and freeze.

Moisture compromises the functionality of the grips at this temperature range. Use

an external clamp/release switch for this temperature range.

You can burn yourself if you touch the clamping knobs on the grips when

they are hotter than 55°C (130°F)

Use protective gloves if it is necessary to manually clamp or unclamp the grips at

elevated temperatures. Or add remote clamping control to the grips (see “Air

connection kits” on page 36).

°C to 200°C (-40°F to 400°F)

-40

*

Model Specific Specifications

Model Capacity

Clamping Force

*

Upper Grip Weight Max Specimen

Thickness

10 N 10 N (2 lbf) ~31 N (7 lbf) ~0.27 kg (0.6 lb) 5 mm (0.2 in)

200 N 200 N (40 lbf) ~623 N (140 lbf) ~0.91 kg (2 lb) 10 mm (0.39 in)

2000 N 2000 N (400 lbf) ~7100 N (1600 lbf) ~2.7 kg (6 lb) 12 mm (0.47 in)

10,000 N 10 kN (2200 lbf) ~17 kN (4000 lbf) ~6.8 kg (15 lb) 25 mm (1 in)

* At 5.5 bars (80 psi).

20

Introduction

Advantage™ Pneumatic Grips

Page 21

Safety Information

General Safety Practices: Grips and Fixtures

Typically, grips and fixtures are part of equipment used in MTS testing systems.

This section provides general information about safety issues that pertain to

systems that use grips and fixtures. These issues include statements to the

intended use and foreseeable misuse of the system and definition for the

graphical hazard labeling that is affixed to your product, and other (more general)

safety information that relates to the high-pressure and high-performance

characteristics of MTS servohydraulic and electromechanical systems.

When you prepare to operate a system that includes grips or fixtures, ensure the

following:

• Do not use or allow personnel to operate the system who are not

experienced, trained, or educated in the inherent dangers associated with

high-performance servo hydraulics and who are not experienced, trained, or

educated with regard to the intended operation as it applies to this test

system.

• Do not disable safety components or features (including limit detectors,

light curtains, or proximity switches/detectors).

• Do not attempt to operate the system without appropriate personal safety

gear (for example, hearing, hand, and eye protection).

• Do not modify the system or replace system components using parts that are

not MTS component parts or effect repairs using parts or components that

are not manufactured to MTS specifications.

• Do not operate the grips or fixtures in an explosive atmosphere.

• Do not use the system in a test area where uncontrolled access to the test

system is allowed when the system is in operation.

• For servohydraulic systems, do not operate the system unless an interlock is

installed to monitor supply pressure into the HSM and initiate a system

interlock if a low or no pressure event occurs.

If you have system related responsibilities (that is, if you are an operator, service

engineer, or maintenance person), you should study safety information carefully

before you attempt to perform any test system procedure.

Advantage™ Pneumatic Grips Safety Information

21

Page 22

You should receive training on this system or a similar system to ensure a

thorough knowledge of your equipment and the safety issues that are associated

with its use. In addition, you should gain an understanding of system functions

by studying the other manuals supplied with your test system. Contact MTS for

information about the content and dates of training classes that are offered.

It is very important that you study the following safety information to ensure that

your facility procedures and the system’s operating environment do not

contribute to or result in a hazardous situation. Remember, you cannot eliminate

all the hazards associated with this system, so you must learn and remain aware

of the hazards that apply to your system at all times. Use these safety guidelines

to help learn and identify hazards so that you can establish appropriate training

and operating procedures and acquire appropriate safety equipment (such as

gloves, goggles, and hearing protection).

Each test system operates within a unique environment which includes the

following known variables:

• Facility variables (facility variables include the structure, atmosphere, and

utilities)

• Unauthorized customer modifications to the equipment

• Operator experience and specialization

• Test specimens

Because of these variables (and the possibility of others), your system can

operate under unforeseen circumstances that can result in an operating

environment with unknown hazards.

Improper installation, operation, or maintenance of your system can result in

hazardous conditions that can cause death, personal injury, or damage to the

equipment or to the specimen. Common sense and a thorough knowledge of the

system’s operating capabilities can help to determine an appropriate and safe

approach to its operation.

Read all manuals Study the contents of this manual and the other manuals provided with your

system before attempting to perform any system function for the first time.

Procedures that seem relatively simple or intuitively obvious may require a

complete understanding of system operation to avoid unsafe or dangerous

situations.

Safety Information

22

Advantage™ Pneumatic Grips

Page 23

Avoid pinch/crush

points

Pinch points exist between the parts of the grip or fixture that contact the

specimen. Be aware of these pinch points when installing a specimen or working

around the grip or fixture during test setup. High forces generated when grip

pressure is activated can pinch, cut, or crush anything in the path of the grip/

fixture specimen contact area and cause serious injury. Stay clear of any potential

pinch points.

A crush point exists between the grips. Whenever possible, use tongs or similar

tool when handling the specimen during specimen installation. Never allow any

part of your body to enter the path of machine movement or to touch moving

machinery, linkages, hoses, cables, specimens, and so forth. These present

serious crush points or pinch points.

Locate and read

hazard placards/labels

Know facility safe

procedures

Find, read, and follow the hazard placard instructions located on the equipment.

These placards are placed strategically on the equipment to call attention to areas

such as known crush points, electrical voltage, and high pressure hazards.

Most facilities have internal procedures and rules regarding safe practices within

the facility. Be aware of these safe practices and incorporate them into your daily

operation of the system.

Know controls Before you operate the system for the first time, make a trial run through the

operating procedures with the power off. Locate all hardware and software

controls and know what their functions are and what adjustments they require. If

any control function or operating adjustment is not clear, review the applicable

information until you understand it thoroughly.

Know specimen

properties

Advantage™ Pneumatic Grips Safety Information

The user is responsible for understanding the characteristics of the test specimen.

Be sure to use appropriate personal protective equipment (clothing, hand gloves,

eye protection etc.).

Use protective guards such as cages, enclosures, and special laboratory layouts

when you work with hazardous test specimens (for example, brittle or

fragmenting materials or materials that are internally pressurized).

23

Page 24

Have first aid available Accidents can happen even when you are careful. Arrange your operator

schedules so that a properly trained person is always close by to render first aid.

In addition, ensure that local emergency contact information is posted clearly and

in sight of the system operator.

Be aware of

component movement

with hydraulics off

Keep bystanders

safely away

The actuator rod can also drift down when hydraulics are turned off hitting

anything in its path. This uncommanded movement is because of oil movement

between the pressure/return ports and oil blow by across the piston hub. Be aware

that this can happen and clear the area around the actuator rod when hydraulics

are turned off.

Keep bystanders at a safe distance from all equipment. Never allow bystanders to

touch specimens or equipment while the test is running.

Wear proper clothing Do not wear neckties, shop aprons, loose clothing or jewelry, or long hair that

could get caught in equipment and result in an injury. Remove loose clothing or

jewelry and restrain long hair.

Remove flammable

fluids

Check bolt ratings and

torques

Remove flammable fluids from their containers or from components before you

install the container or component. If desired, you can replace the flammable

fluid with a non-flammable fluid to maintain the proper proportion of weight and

balance.

To ensure a reliable product, fasteners (such as bolts and tie rods) used in MTSmanufactured systems are torqued to specific requirements. If a fastener is

loosened or the configuration of a component within the system is modified, refer

to information in this product manual to determine the correct fastener, fastener

rating, and torque. Overtorquing or undertorquing a fastener can create a

hazardous situation due to the high forces and pressures present in MTS test

systems.

Practice good

housekeeping

Do not exceed the

Maximum Supply

Safety Information

24

Pressure

On rare occasions, a fastener can fail even when it is correctly installed. Failure

usually occurs during torquing, but it can occur several days later. Failure of a

fastener can result in a high velocity projectile. Therefore, it is a good practice to

avoid stationing personnel in line with or below assemblies that contain large or

long fasteners.

Keep the floors in the work area clean. Hydraulic fluid that is spilled on any type

of floor can result in a dangerous, slippery surface. Do not leave tools, fixtures,

or other items not specific to the test, lying about on the floor, system, or decking.

For hydraulic grips and fixtures. make sure that the hydraulic supply pressure is

limited to the maximum pressure defined by the grip or fixture identification (ID)

tag.

Advantage™ Pneumatic Grips

Page 25

Do not disable safety

devices

Your system may have active or passive safety devices installed to prevent

system operation if the device indicates an unsafe condition. Do not disable such

devices as it may result in unexpected system motion.

Provide adequate

lighting

Provide means to

access out-of-reach

components

Wear appropriate

personal protection

Handle chemicals

safely

Ensure adequate lighting to minimize the chance of operation errors, equipment

damage, and personal injury. You need to see what you are doing.

Make sure you can access system components that might be out of reach while

standing on the floor. For example, ladders or scaffolding might be required to

reach load cell connectors on tall load units.

Wear eye protection when you work with high-pressure hydraulic fluid,

breakable specimens, or when anything characteristic to the specimen could

break apart.

Wear ear protection when you work near electric motors, pumps, or other devices

that generate high noise levels. Some systems can create sound pressure levels

that exceed 70 dbA during operation.

Wear appropriate personal protection equipment (gloves, boots, suits, respirators)

whenever you work with fluids, chemicals, or powders that can irritate or harm

the skin, respiratory system, or eyes.

Whenever you use or handle chemicals (for example, cleaning fluids, hydraulic

fluid, batteries, contaminated parts, electrical fluids, and maintenance waste),

refer to the appropriate MSDS documentation for that material and determine the

appropriate measures and equipment required to handle and use the chemical

safely. Ensure that the chemical is disposed of appropriately.

Know system

interlocks

Interlock devices should always be used and properly adjusted. Interlock devices

are designed to minimize the chance of accidental damage to the test specimen or

the equipment. Test all interlock devices for proper operation immediately before

a test. Do not disable or bypass any interlock devices as doing so could allow

hydraulic pressure to be applied regardless of the true interlock condition. The

Reset/Override button is a software function that can be used to temporarily

override an interlock while attempting to gain control of the system.

Know system limits Never rely on system limits such as mechanical limits or software limits to

protect you or any personnel. System limits are designed to minimize the chance

of accidental damage to test specimens or to equipment. Test all limits for proper

operation immediately before a test. Always use these limits and adjust them

properly.

Advantage™ Pneumatic Grips Safety Information

25

Page 26

Do not disturb sensors Do not bump, wiggle, adjust, disconnect, or otherwise disturb a sensor (such as

an accelerometer or extensometer) or its connecting cable when hydraulic

pressure is applied.

Ensure secure cables Do not change any cable connections when electrical power or hydraulic pressure

is applied. If you attempt to change a cable connection while the system is in

operation, an open control loop condition can result. An open control loop

condition can cause a rapid, unexpected system response which can result in

severe personal injury, death, or damage to equipment. Also, ensure that all

cables are connected after you make any changes in the system configuration.

Stay alert Avoid long periods of work without adequate rest. In addition, avoid long periods

of repetitious, unvarying, or monotonous work because these conditions can

contribute to accidents and hazardous situations. If you are too familiar with the

work environment, it is easy to overlook potential hazards that exist in that

environment.

Contain small leaks Do not use your fingers or hands to stop small leaks in hydraulic or pneumatic

hoses. Substantial pressures can build up, especially if the hole is small. These

high pressures can cause the oil or gas to penetrate your skin, causing painful and

dangerously infected wounds. Turn off the hydraulic supply and allow the

hydraulic pressure to dissipate before you remove and replace the hose or any

pressurized component.

Stay clear of moving

equipment/avoid crush

points

Know the causes of

unexpected actuator

motions

Safety Information

26

Stay clear of mechanical linkages, connecting cables, and hoses that move

because you can get pinched, crushed, tangled, or dragged along with the

equipment. High forces generated by the system can pinch, cut, or crush anything

in the path of the equipment and cause serious injury. Stay clear of any potential

crush points. Most test systems can produce sudden, high-force motion. Never

assume that your reactions are fast enough to allow you to escape injury when a

system fails.

The high force and velocity capabilities of MTS actuators can be destructive and

dangerous (especially if actuator motion is unexpected). The most likely causes

of unexpected actuator response are operator error and equipment failure due to

damage or abuse (such as broken, cut, or crushed cables and hoses; shorted wires;

overstressed feedback devices; and damaged components within the servocontrol

loop). Eliminate any condition that could cause unexpected actuator motion.

Advantage™ Pneumatic Grips

Page 27

Hazard Placard Placement

Hazard placards contain specific safety information and are affixed directly to the

system so they are plainly visible. Each placard describes a system-related

hazard. When possible, international symbols (icons) are used to graphically

indicate the type of hazard and the placard label indicates its severity. In some

instances, the placard can contain text that describes the hazard, the potential

result if the hazard is ignored, and general instructions about how to avoid the

hazard.

The following label is typically located on the grips.

Hand crush hazard from the sides. Use

caution when working near the grips

when pneumatic pressure to the grips is

enabled.

Model identification label. Includes

product name, part number, force

capacity, temperature range, and air

pressure requirements.

Power Loss Consideration

If power to the MTS air controller fails, grip pressure will be lost. Typically,

specimens gripped by pneumatic grips are relatively small and light weight.

Consequently, any chance of specimen or equipment damage is slight. As an

added precaution, a controller force detector could be set to detect load drop-off

and generate an interlock to stop program command.

Advantage™ Pneumatic Grips Safety Information

27

Page 28

Safety Information

28

Advantage™ Pneumatic Grips

Page 29

Installation

Contents Installation Using the Mounting Pin 30

This section describes how to install the Advantage Pneumatic Grips into a load

frame of an electromechanical test system or a load unit of a servohydraulic test

system.

Installation Without Using the Mounting Pin 32

Connecting the Air Supply 35

Advantage™ Pneumatic Grips Installation

29

Page 30

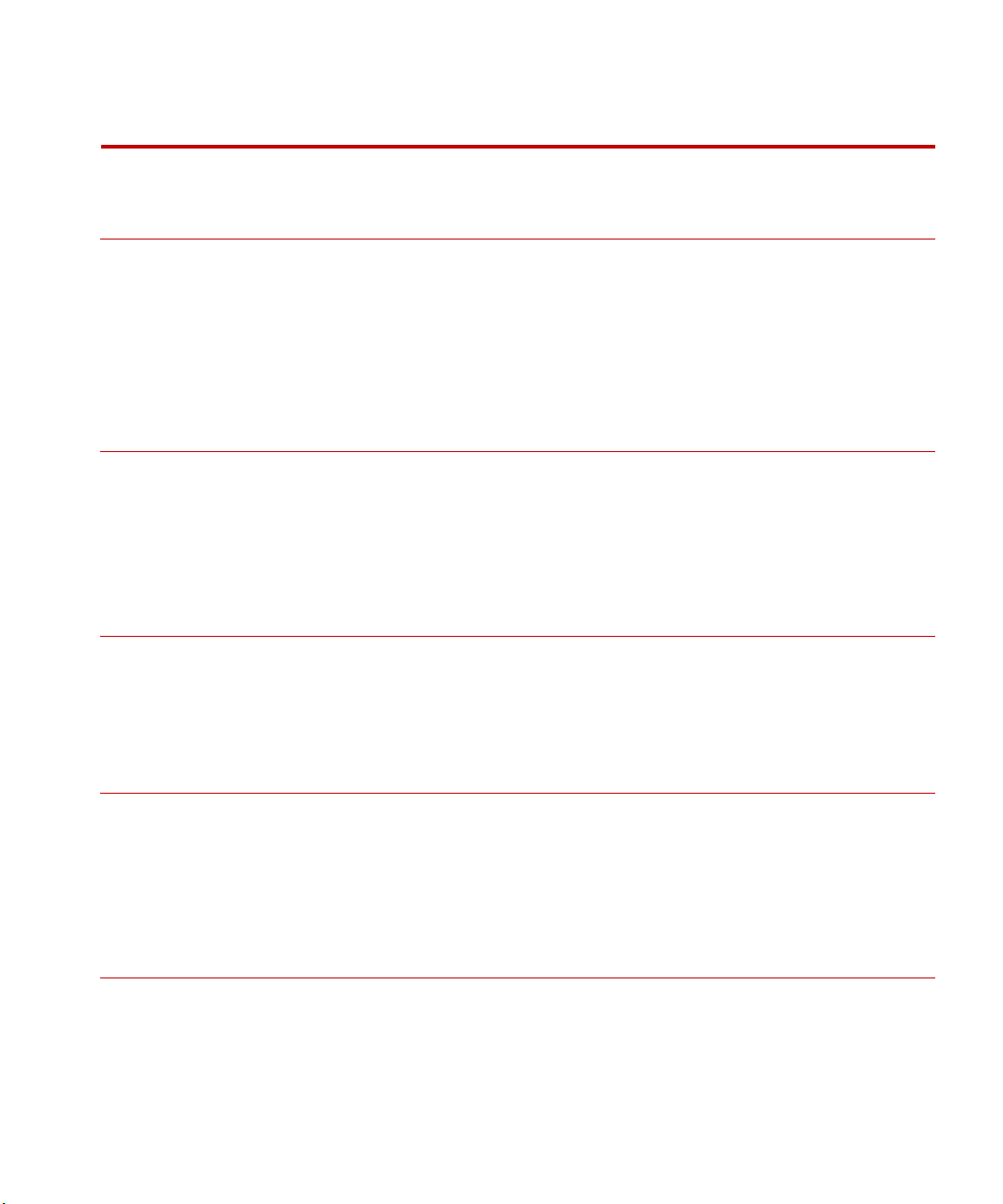

Installation Using the Mounting Pin

Mounting Dowel

Mounting Pin

Locking Collar

Grip Assembly

Load Unit Mounting Adapter

10 N 200 N/2000 N 10,000 N

Installation Using the Mounting Pin

This section describes how to install of the Advantage Pneumatic Grips using the

standard mounting pin.

Installation Components Using the Mounting Pin

Servohydraulic

adapter

Installation

30

If you are installing the grips on a

servohydraulic load unit and want to use the

standard mounting pins, you must install a

load unit mounting adapter on the actuator

and on the force transducer.

Advantage™ Pneumatic Grips

Page 31

Installation Using the Mounting Pin

1. Set up the load frame.

A. Turn on the power to the load frame.

B. Adjust the crosshead position as necessary to allow adequate room to

install the grips.

C. Turn the load frame power off.

D. Clean all of the surfaces that will contact each other (such as the

mounting pin and the load frame mounting adapter) and lubricate them

with Magnalube

®

-G.

2. Mount the grip assemblies to the load frame.

A. Install the mounting pin into the load frame mounting adapter.

B. Align the holes of the mounting pin with the load frame mounting

adapter.

C. Install the mounting dowel to attach the grip assembly to the load

frame.

D. When both grips are mounted to the load frame, align the upper and

lower grips to each other and tighten the locking collars to remove any

slack.

3. Connect the air supply.

The grips can be controlled with air valve knobs on the grip, optional in-line

air control switches, or a remote air grip controller. Go to “Connecting the

Air Supply” on page 35 to connect the air control system for your

application.

4. Install the faces or wedges.

The 10 N, 200 N, and 2000 N grips use grip faces and the 10,000 N grips

use grip wedges. See “Selecting Face Surfaces” on page 40 then:

• Go to “Changing Face Surfaces” on page 47 to install the grip faces.

• Go to “Changing Wedges” on page 48 to install wedges into the grips.

This completes the installation of the grips.

Advantage™ Pneumatic Grips Installation

31

Page 32

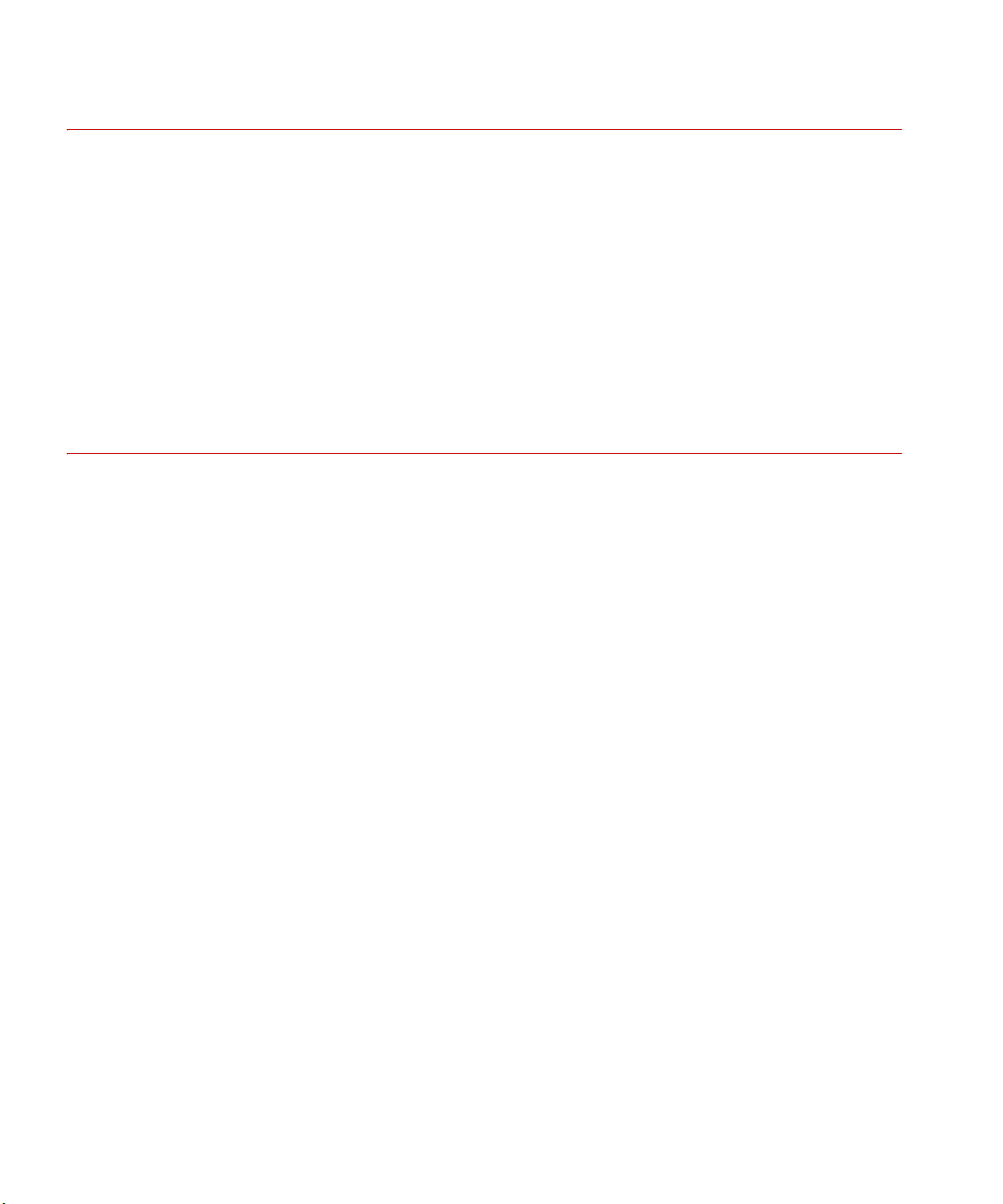

Installation Without Using the Mounting Pin

End Cap

Cap Screw

Grip Assembly

Air Fitting

Actuator

Spacer

10 N 200 N/2000 N 10,000 N

Spring Pin

Threaded

Adapter

Jam Nuts

Was he r

Installation Without Using the Mounting Pin

This section describes how to install the Advantage Pneumatic Grips by bolting

them directly to a load unit actuator and force transducer (usually in a

servohydraulic test system).

Note You will need the appropriate attachment kit to install the grips in a

servohydraulic load unit.

Installation

32

Non-pinned Installation Components

Advantage™ Pneumatic Grips

Page 33

Installation Without Using the Mounting Pin

WARNING

1. Set up the load unit.

A. Turn on the system hydraulic pressure.

B. Adjust the actuator and crosshead positions as necessary to allow

adequate room to install the grips. Lock the crosshead if you reposition

it.

C. Turn the hydraulic pressure off.

Installing the grip puts your hands in a crush zone.

Your fingers and hands could get crushed.

Make sure you have locked the crosshead, and that you have removed hydraulic

pressure from the load unit.

D. Clean all of the surfaces that will contact each other (such as screw

threads and adapters) and lubricate them with Magnalube-G.

Note Depending on the attachment kit needed for the installation, you might

need to install a threaded insert into the actuator or force transducer.

2. Remove the mounting pin.

The grips normally have the mounting pin installed when they are

manufactured. The mounting pin must be removed so the grip can be bolted

to the actuator or force transducer.

10 N only Remove the spring pins to remove the end cap from the grip assembly.

Remove the cap screw that secures the mounting pin to the end cap.

200 N/2000 N only Remove the end cap from the grip assembly. Remove the cap screw that

secures the mounting pin to the end cap.

10,000 N only If installed, remove the wedges (see “Changing Wedges” on page 48).

Remove the socket head screw from the mounting pin (access the screw

through the top of the grip).

Advantage™ Pneumatic Grips Installation

33

Page 34

Installation Without Using the Mounting Pin

Air Port

3. Mount the grips to the load unit.

Mount one grip to the actuator and the other to the force transducer.

10 N only An installation kit (MTS part number 100-044-042) is required for the 10 N

grip. Replace the cap screw with the longer one from the installation kit.

Replace the O-ring from the end cap with the washer from the kit. Insert the

cap screw through the end cap and secure it with one jam nut. Attach the

grip assembly to the end cap with the spring pins. Thread second jam nut on

the cap screw and thread the entire grip assembly into the actuator or force

transducer. Use the second jam nut to align the two grips and tighten the

second jam nut to secure the grip in place.

200 N/2000 N only Use the socket head screw to attach the end cap and

spacer to the actuator or force transducer. Ensure

the two end caps are aligned with each other and

that the air port will be aligned with the front of the

grip assembly (the side with the air fitting) before

you tighten the cap screw. Attach the grip assembly

to the end cap.

10,000 N only Align the grip assembly over the actuator or force transducer and thread the

socket head screw into the actuator (access the screw through the top of the

grip). Align the two grip assemblies and torque the socket head screw to 97

N•m (72 ft-lb).

34

Installation

4. Connect the air supply.

The grips can be controlled with the air valve knobs on the grip, remotely

through a grip controller, or with a remote switch assembly. Go to

“Connecting the Air Supply” on page 35 to connect the air control system

for your application.

5. Install the faces or wedges.

The 10 N, 200 N, and 2000 N grips use grip faces and the 10,000 N grips

use grip wedges. See “Selecting Face Surfaces” on page 40 then proceed to

one of the following:

• Go to “Changing Face Surfaces” on page 47 to install the grip faces.

• Go to “Changing Wedges” on page 48 to install wedges into the grips.

Advantage™ Pneumatic Grips

Page 35

Connecting the Air Supply

An external air supply is required to operate the grips. The air supply must

produce clean dry air. Different grip control options are available.

• The most basic configuration consists of connecting the two grips directly

to the air supply using the supplied fixtures and tubing. This requires the

grips to be controlled manually using the air valve knob on each grip (the

10 N grip requires remote, in line, air switches).

• Optional air switches allow each grip to be independently clamped and

released.

• The optional Advantage Pneumatic Grip Controller allows each grip to

be independently clamped and released using two configurable foot

switches.

Connecting the Air Supply

Advantage™ Pneumatic Grips Installation

35

Page 36

Connecting the Air Supply

Air connection kits The following list the kits which can be used individually or in

combinations of each other:

KIT MTS PART NUMBER DESCRIPTION

Standard Fittings

(included with all grips)

Filter/Regulator Kit

(Optional)

Remote Switch Kit

(Included with the

10000 N grip)

Quick Attachment Kit

(Optional)

Air Controller

(Optional)

100-041-200 The grips include mating connectors to the grips air

fixtures, a “Y” fitting, and 3 m of tubing. These

components can be used to connect both grips to a

common air source.

100-041-199 Includes a filter, regulator, air gage, and a valve to

adjust the air pressure, and 3 m of tubing.

100-041-201 Includes two, in line air toggle switches, and

3 m of tubing. This allows you to use the toggle

switches to clamp and release each grip

independently.

100-041-202 Includes two quick disconnect fittings and 3 m of

tubing.

213-0001 The Advantage Pneumatic Grip Controller kit

includes a filter, regulator, air gage, and a valve to

adjust the air pressure. It can also turn the air on

(clamp) and off (release) to each grip.

36

Installation

Advantage™ Pneumatic Grips

Page 37

Quick

Attachment

MTS P/N

100-041-202

Air Controller

MTS P/N

100-053-233

To Air

Supply

To Air

Supply

Standard

Fittings

MTS P/N

100-041-200

Filter/Regulator Assembly

MTS P/N 100-041-199

Alternate P/N 26.90018

Remote

Switches

MTS P/N

100-041-201

12

12

Connecting the Air Supply

Advantage™ Pneumatic Grips Installation

Pneumatic Configurations

37

Page 38

Connecting the Air Supply

38

Installation

Advantage™ Pneumatic Grips

Page 39

Operation

WARNING

Contents Selecting Face Surfaces 40

Grip operation consists of selecting and changing face surfaces (or wedges), and

installing a specimen.

Changing Face Surfaces 47

Changing Wedges 48

Installing a Specimen 50

Adjusting the Air Supply Pressure 53

Clamping and

releasing the grips

Clamping and releasing the grips can be accomplished several ways:

• Manually – each grip has a knob (except the 10 N model) that controls an

air valve. Turn the knob clockwise to clamp the grip and counterclockwise

to release the grip.

• Foot switch– the optional Advantage Pneumatic Grip Controller allows you

to control each grip independently using a foot switch. It includes two foot

switches that can be configured to your preference.

• Toggle switch– an optional kit (MTS part number 100-041-201) provides a

pair of in line air toggle switches. Each switch can control the clamp and

release of one of the grips.

You can burn yourself if you touch the clamping knobs on the grips when

they are hotter than 55°C (130°F)

Use protective gloves if it is necessary to manually clamp or unclamp the grips at

elevated temperatures. Or add remote clamping control to the grips (see “Air

connection kits” on page 36).

Advantage™ Pneumatic Grips Operation

39

Page 40

Selecting Face Surfaces

Selecting Face Surfaces

A face is a type of surface attachment for the Advantage Pneumatic grips. There

are a variety of surface coatings to accommodate a variety of specimens. The

following tables will help you determine which face is suitable for a specific type

of specimen.

Note You are responsible for matching the appropriate face with the type of

specimen you intend to test.

Face Surface Usage Guidelines

Face Surface Usage

Corrugated

Gripping smooth specimens such as textile, fabrics, tissue, leather, and

other smooth materials.

Serrated

Gripping soft materials such as paper, board, aluminum, copper, steel

wire, and soft steels without causing failure.

Smooth rubber coated

Rubber matte

*

Offers extra protection for thin specimens such as plastic films.

Offers more gripping power than smooth rubber coated faces and are more

resistant to abrasive specimens.

Rubber corrugated

Offers more gripping power than smooth rubber matte faces and protects

thin flexible specimens.

Diamond tipped

Provides an aggressive gripping surface for gripping soft materials such as

soft steels, rigid plastic, and wood.

Grab test

Gripping fabrics such as leather and woven fabrics. The grab test face is

used in accordance with international ASTM D5034, ASTM D7683,

ASTM D2208, and ISO 5082.

Line contact

* In some cases the smooth faces will slip below the rated capacity of the grip.

Gripping rubber, latex, and cable sheath.

Once you have determined the grip surface, refer to the following to select the

proper face for your grip:

• Go to “Grip Faces for the 10 N Grips” on page 41.

40

Operation

• Go to “Grip Faces for the 200 N and 2000 N Grips” on page 42.

• Go to “Grip Faces for the 10,000 N Grips” on page 45.

Advantage™ Pneumatic Grips

Page 41

Grip Faces for the 10 N Grips

These grip faces are for the 10 N (2 lbf) Advantage Pneumatic Grips and

specimens from 0 to 5 mm thick.

Selecting Face Surfaces

15 mm x 8 mm

(0.6 in x 0.3 in)

Tab le 1:

Face Surface Part Number

Smooth 056-163-701

Serrated 056-163-702 38.00662

†

Rubber

* Obsolete part numbers are associated with older grips. Current part

† Rubber grip faces are for use only at room temperature.

numbers are direct replacements.

056-163-703 38.00401

Obsolete P/N

*

Advantage™ Pneumatic Grips Operation

41

Page 42

Selecting Face Surfaces

Grip Faces for the 200 N and 2000 N Grips

The faces for the 200 N (40 lbf) and the 2000 N (450 lbf) Advantage Pneumatic

Grips are compatible and the same as the ones used on MTS Screw Grips. The 25

x 25 mm (1.0 x 1.0 in) size is preferred for the 200 N grip; the 38 x 58 mm (1.5 x

2.28 in) size is preferred for the 2000 N grip.

12.5 mm x 25 mm

(0.5 in x 1 in)

25 mm x 25 mm

(1 in x 1 in)

Table 2:

Face Surface Part Number

Rubber (smooth)

* Obsolete part numbers are associated with older grips. Current part

numbers are direct replacements.

† Rubber grip faces are for use only at room temperature.

†

056-163-825

Obsolete P/N

Table 3:

Face Surface Part Number

Smooth 056-163-801

Corrugated 056-163-802 38.00689

Serrated 056-163-803 38.00690

Diamond Tip 056-163-804 38.00593

Rubber (matte)

Rubber (corrugated)

Rubber (smooth)

Line Contact r=4.75mm 056-163-808 38.00693

†

†

†

056-163-805 38.00692

056-163-806 38.00691

056-163-807 38.00424

Obsolete P/N

*

*

42

Operation

Line Contact w/Rubber

Opposite

Line Contact w/Rubber

Opposite

* Obsolete part numbers are associated with older grips. Current part

† Rubber grip faces are for use only at room temperature.

†

r=4.75mm

†

r=2.5mm

numbers are direct replacements.

056-163-826 none

056-163-829 38.00544

Advantage™ Pneumatic Grips

Page 43

Selecting Face Surfaces

25 mm x 75 mm

(1 in x 2.6 in)

25 mm x 150 mm

(1 in x 5.9 in)

Table 4:

Face Surface Part Number

Smooth 056-163-809

Corrugated 056-163-810 38.00695

Serrated 056-163-811 38.00696

Diamond Tip 056-163-812 38.00581

Rubber (matte)

Rubber (corrugated)

Rubber (smooth)

* Obsolete part numbers are associated with older grips. Current part

numbers are direct replacements.

† Rubber grip faces are for use only at room temperature.

†

†

†

056-163-813 38.00698

056-163-814 38.00697

056-163-815 38.00425

Obsolete P/N

Table 5:

Face Surface Part Number

Diamond 056-163-828

Rubber 056-163-830 38.00543

* Obsolete part numbers are associated with older grips. Current part

numbers are direct replacements.

Obsolete P/N

*

*

Advantage™ Pneumatic Grips Operation

43

Page 44

Selecting Face Surfaces

38 mm x 58 mm

(1.5 in x 2.3 in)

Table 6:

Face Surface Part Number

Smooth 056-163-816

Corrugated 056-163-817 38.00406

Serrated 056-163-818 38.00407

Diamond Tip 056-163-819 38.00408

Rubber (matte)

Rubber (corrugated)

Rubber (smooth-EPDM)

Line Contact (r=4.75mm) 056-163-823 38.00410

Line Contact (r=4.75mm) w/

Rubber Opposite

Grab Test 056-163-824 38.00412

* Obsolete part numbers are associated with older grips. Current part

numbers are direct replacements.

† Rubber grip faces are for use only at room temperature.

†

†

†

†

056-163-820 38.00700

056-163-821 38.00699

056-163-822 38.00409

056-163-827 38.00701

Obsolete P/N

*

44

Operation

Advantage™ Pneumatic Grips

Page 45

Grip Faces for the 10,000 N Grips

These grip faces are wedges for the high tensile grips rated at 10,000 N (2000

lbf). The usable width of these wedges is 25 mm (1 in) or 50 mm (2 in), the

insertion depth is 38 mm (1.5 in), and the temperature range is -40°C to 177°C (40°F to 350°F). They are sold in matched sets of four.

Flat 25 mm (1 in)

wedges

Surface Specimen Thickness Part Number

90° Diamond 0–7.1 mm (0–0.28 in) 50507906

90° Diamond 7.1–14.4 mm (0.28–0.57 in) 50507907

Surfalloy 0–7.1 mm (0–0.28 in) 50507917

Surfalloy 7.2–14.4 mm (0.28–0.57 in) 50507918

Serrated 0–7.1 mm (0–0.28 in) 50507919

Serrated 7.1–14.4 mm (0.28–0.57 in) 50507920

Smooth 0–7.1 mm (0–0.28 in) 50507924

Smooth 7.1–14.4 mm (0.28–0.57 in) 50507925

Corrugated 0–7.1 mm (0–0.28 in) 50507929

Corrugated 7.1–14.4 mm (0.28–0.57 in) 50507930

Selecting Face Surfaces

Flat 50 mm (2 in)

wedges

Advantage™ Pneumatic Grips Operation

Surface Specimen Thickness Part Number

90° Diamond 0–7.1 mm (0–0.28 in) 54585001

90° Diamond 7.1–14.4 mm (0.28–0.57 in) 54585002

Surfalloy 0–7.1 mm (0–0.28 in) 54585005

Surfalloy 7.2–14.4 mm (0.28–0.57 in) 54585006

Serrated 0–7.1 mm (0–0.28 in) 54507909

Serrated 7.1–14.4 mm (0.28–0.57 in) 54507910

Smooth 0–7.1 mm (0–0.28 in) 54507913

Smooth 7.1–14.4 mm (0.28–0.57 in) 54507914

Corrugated 0–7.1 mm (0–0.28 in) 54507917

Corrugated 7.1–14.4 mm (0.28–0.57 in) 54507918

45

Page 46

Selecting Face Surfaces

Round wedges

Surface Specimen Diameter Part Number

Surfalloy 10 mm 50507912

Surfalloy 15 mm 50507913

Surfalloy 25 mm 50507914

Surfalloy 0.5 in 50507915

Surfalloy 1 in 50507916

Vee-shaped wedges

The vee wedge specimen diameter specification represents the diameter range if

the specimen is installed from the side of the grips (the widest opening). The

specimen diameter also lists the maximum specimen diameter if the specimen is

installed from the top of the grips.

Surface

Serrated 3.0–8.1/9.4 mm (0.12–0.32/0.37 in) 50507908

Serrated 8.9–10.9/15.2 mm (0.35–0.43/0.60 in) 50507909

Serrated 14.0–18.0/20.8 mm (0.55–0.71/0.82 in) 50507910

Serrated 20.1–22.9/27.2 mm (0.79–0.90/1.07 in) 50507911

* The specification has a diameter range for installing the specimen from the side of

the grips. The second specification is the maximum diameter if the specimen is

installed from the top of the grips.

Specimen Diameter

*

Part Number

46

Operation

Advantage™ Pneumatic Grips

Page 47

Changing Face Surfaces

O-ring

Grip Face Pin

Grip Face

Grip Coupling

PullPull

Upper

Lower

Serrated Faces

Grip faces for the 10 N, 200 N, and 2000 N grips are held in the grip assemblies

with grip face pins. These pins have a tiny O-ring on one end of it to prevent the

grip face pin from working its way out of the grip assembly.

Note Serrated grip faces must be orientated as

shown. Each grip face has an arrow that

indicates the direction the face should be pulled.

When the faces are installed the arrows point

towards the grip.

Changing Face Surfaces

Perform the following procedure to change the grip

faces:

1. Remove any specimen installed in the grips. Leave

the grip controls in the release position.

2. Adjust the load frame as necessary for convenient

access to the grip faces.

3. Turn off the grip air supply pressure.

4. Remove the grip face pin. Twist the grip face pin while pulling it from out of

the grip coupling.

5. Slide the grip face out of the “U” shaped grip coupling in the grip assembly.

6. Install a new grip face into the grip coupling and insert the grip face pin.

Advantage™ Pneumatic Grips Operation

47

Page 48

Changing Wedges

Unhook the top

of the spring

Spring

Anchor

Piston

Spring

Wedges

Chamber

Changing Wedges

Several types of wedges are available for the grips:

• Narrow flat wedges are used for flat specimens

• Round wedges are used for round specimens

• Vee-notched wedges are used for round specimens

• Optional wide wedges are available for flat, full width specimens

The following figure shows the components involved with changing the wedges.

Required equipment You might need the following supplies to change wedges:

48

Operation

Wedge Component Identification

• A utility hook (provided in the tool kit supplied with the grip)

• Replacement extension springs, if necessary

• Magnalube lubricant

Advantage™ Pneumatic Grips

Page 49

Changing Wedges

Procedure Perform the following procedure to replace one wedge with a different wedge.

Note Each wedge is labeled with the wedge part number and manufacturing

date code. Ensure that replacement wedges are a matched set before

attempting to install the wedges into the grip.

1. Remove any specimen installed in the grips. Leave the grip controls in the

release position.

• Position the load frame as necessary for convenient access to the grip

wedges.

• Remove the grip air supply pressure.

• For servohydraulic systems remove the hydraulic pressure from the

load unit.

2. Using the utility packing hook, disconnect both springs from the spring

posts on the corresponding wedge. It is not necessary to remove the springs

from the spring anchors.

3. Inspect the springs and replace them, if necessary.

4. Remove the wedge by sliding it towards the center of the grip and then

lifting it out of the grip.

5. Repeat Steps 2 and 3 for the remaining wedges.

6. Apply a thin coat of Magnalube lubricant to the edges of the wedge which

contact the chamber and piston.

7. Place the wedge into the center of the grip and then slide it towards the

chamber.

8. Using the utility packing hook, connect the springs from the spring anchor

on the grip piston to the spring post on the corresponding wedge.

9. Repeat Steps 6 and 7 for the remaining wedges.

Advantage™ Pneumatic Grips Operation

49

Page 50

Installing a Specimen

CAUTION

W

W

H

H

Large contact area

recommended

Small contact area can

cause premature wear

and damage the grips

Wedge face

Contact area

Bottom gap

specification

(3-6 mm)

(H x W)

Installing a Specimen

The following procedure describes how to install a specimen in the Advantage

Pneumatic Grips. This procedure assumes the proper set of face surfaces has

been selected and properly installed.

The contact area between the grip face and specimen should be as large as

possible.

A small contact area between the grip face and specimen can cause

premature wear to the grip face surface.

MTS recommends that specimens should be machined to provide the largest

possible surface contact area between the grip face and the specimen

50

Operation

Advantage™ Pneumatic Grips

Page 51

Installing a Specimen

CAUTION

CAUTION

Improper specimen installation can damage the grip faces.

To prevent damage to the grips, install the grip faces precisely as specified in the

following steps.

1. Adjust the grip pressure to the maximum level as determined in “Adjusting

the Air Supply Pressure” on page 53.

2. Apply power to the load frame or load unit.

3. Release the upper and lower grips.

Note If you are using flat wedges in the 10,000 N grips, loosen the cap screws

securing the specimen guides on the wedges. Adjust the specimen

guides so as to allow the specimen to be centered in the grip. Tighten the

socket head cap screws.

4. Place the specimen in the lower grip allowing a space of at least 3 mm (0.12

in) but not greater than 6 mm (0.25 in) between the bottom of the specimen

and the bottom inner edges of the lower grip wedges. Lock the lower grip.

5. Lower the crosshead or extend the actuator until the specimen is positioned

in the upper grip allowing a space of at least 3 mm (0.12 in) but not greater

than 6 mm (0.25 in) between the top of the specimen and the inner top edges

of the wedges. Lock the upper grip.

Specimen slippage during the test can damage the grips.

Specimen slippage typically occurs when:

• Insufficient grip pressure is used to securely grip the specimen

• Grip faces or wedges with rounded or flattened serrations are used

• A specimen is harder than the wedge or face material

Do not exceed the maximum pressure rating of the grip. Increasing the pressure

setting to hold round specimens can reduce the life of the vee-notched wedges.

Advantage™ Pneumatic Grips Operation

51

Page 52

Installing a Specimen

6. If specimen slippage occurs which exceeds the specifications in Step 4 and

Step 5, reinstall the specimen and increase the grip pressure. Note the

caution above.

52

Operation

Advantage™ Pneumatic Grips

Page 53

Adjusting the Air Supply Pressure

CAUTION

P

1.04 L×

A

--------------------

=

The output pressure of the air supply determines the gripping force applied to the

specimen by the grip faces. The optimum gripping force is great enough to

securely grip the specimen, yet low enough to minimize specimen deformation or

prevent specimen slippage.

The grips can be damaged if operated with incorrect air pressure.

Insufficient air pressure can cause the wedges to separate from the piston.

Ensure you calculate the minimum required air pressure and set the air supply

above the calculated value and below 5.5 bar (80 psi).

Excessive air pressure can damage the piston seals.

Clamping force Use the following formulas to determine the approximate clamping force of a

given air pressure:

Adjusting the Air Supply Pressure

Model Formula

10 N

200 N

2000 N

10,000 N

* At 5.5 bar (80 psi).

† Calculate a minimum operating pressure.

N

≈ bar x 5.6

lbf

≈ psi x 0.875

N

≈ bar x 113.2

lbf

≈ psi x 1.75

N

≈ bar x 1290.9

lbf

≈ psi x 20

†

kN

≈ bar x 3.23

lbf

≈ psi x 50

Clamping Force

31 N

7 lbf

623 N

140 lbf

7100 N

1600 lbf

18 kN

4000 lbf

Minimum pressure The 10,000 N grips require a minimum operating air pressure

for any given gripping force. Use the formula to calculate the

minimum air pressure for the 10,000 N grip.

Advantage™ Pneumatic Grips Operation

*

53

Page 54

Adjusting the Air Supply Pressure

Where:

2

A = Area of the piston is 215 cm

(33.3 in2)

L = Maximum axial load applied to the specimen (kN or lb)

P = Grip supply pressure (MPa or psi)

54

Operation

Advantage™ Pneumatic Grips

Page 55

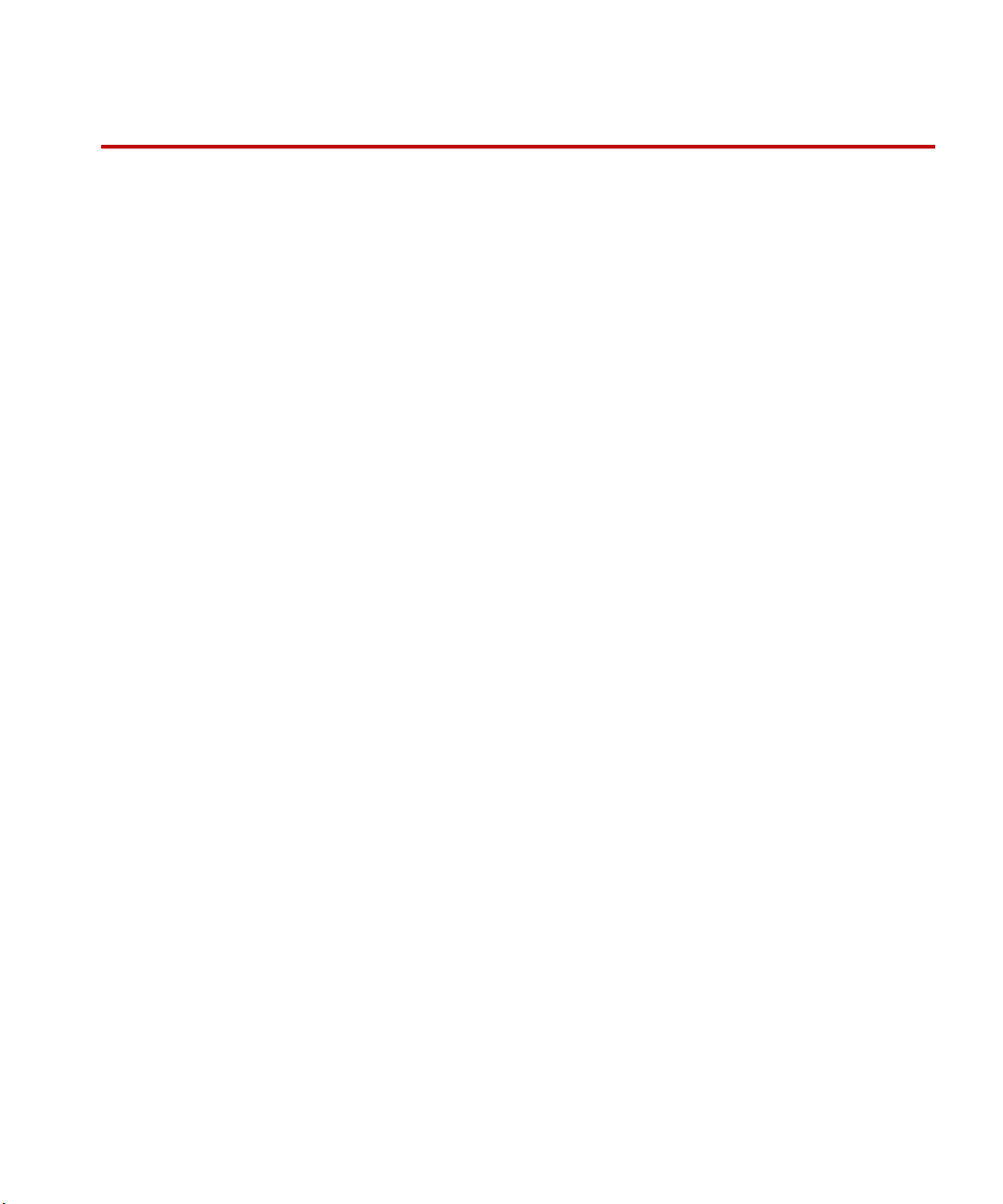

Maintenance

Lever spring

Lever arm

Bearing ring

Piston

Piston seal

Endcap

Socket head

cap screws

Adapter kit

Grip face

assembly

Pushrod

Piston roller

Piston spring

Grip body

Gasket

This section provides information on Advantage Pneumatic Grip maintenance.

Also provided is a table listing spare parts kits.

Advantage™ Pneumatic Grips Maintenance

55

Page 56

Cleaning face surfaces Periodically check the face surfaces for debris buildup. Clean them if necessary.

CAUTION

Face surfaces will wear out eventually and need to be replaced. Use only MTS

replacement parts. See “Selecting Face Surfaces” on page 40 for replacement

parts.

Do not use oil or alcohol based solvents or abrasive material to clean rubber

face surfaces.

Using oil or alcohol based solvents or abrasive material such as Scotch-Brite™ on

rubber face surfaces can cause product damage.

Rubber face surfaces should be cleaned using a clean soft cloth dampened with a

water based solvent. Do not use oil or alcohol based solvents or abrasive material

such as Scotch-Brite™.

Metal face surfaces can be cleaned using an oil or alcohol based solvent and a

soft wire brush. Be sure to brush parallel with the grooves.

Spare parts kits The spare parts kits include seals, gaskets, washers and grip face pins and the

lubricant necessary for grip maintenance.

56

Maintenance

Model MTS Part Number

10 N 100-044-618

200 N 100-044-616

2000 N 100-044-617

10,000 N 100-044-619

Advantage™ Pneumatic Grips

Page 57

Page 58

m

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255

(within the U.S. or Canada)

Phone: 952-937-4000

(outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

Internet: www.mts.com

ISO 9001 Certified QMS

Loading...

Loading...