Mitsubishi PQHY-P Y(S)HM-A, PQRY-P Y(S)HM-A DATA BOOK

AIR CONDITIONERS

MODEL

PQHY-P Y(S)HM-A

PQRY-P Y(S)HM-A

- For ground source application

DATA BOOK

Preface

DATABOOK describes the technical specifications of MITSUBISHI ELECTRIC Corp.'s CITYMULTI air conditioning system products.

In this DATABOOK for ground source application, information on water-cooled heat source unit PQHY-P Y(S)HM-A/ PQRY-P Y(S)HM-A, with the connection of standard CITY MULTI indoor unit series, Air to Water series, and Close Control PFD series are specified.

We recommend DATABOOK users to read carefully and take advantage of all the contents inside to design the CITY MULTI air conditioning system and/or to prepare documents for promotions.

Along with the DATABOOK, MITSUBISHI ELECTRIC provides a Design-Tool software to ensure the users to design the system correctly and simplify the calculations. Please contact your local distributor for this software.

Please be notified that specifications are subject to change without notice due to continual improvements of the product.

For any inquiries, please contact your local distributor.

i

Contents

I |

Brine information |

|

|

|

1. Brine freezing temperature ........................................................................................................ |

1 |

|

|

2. Capacity correction by brine concentration (For heat source unit) ...................................... |

2 |

|

|

3. Pressure drop correction by brine concentration (For heat source unit) ............................. |

3 |

|

II |

Heat source unit information |

|

|

|

1. General lineup of water-cooled heat source unit .................................................................... |

4 |

|

|

2. PQHY-P-Y(S)HM-A ...................................................................................................................... |

5 |

|

|

(1)Specification .............................................................................................................................................. |

5 |

|

|

(1)-1 Heat source units specification for standard combination |

|

|

|

|

(Standard CITY MULTI indoor units, PWFY-P100/200VM-E-AU) .................................................. |

5 |

|

(1)-2 System specification for closed control system (PFD-P250/500VM-E) ....................................... |

19 |

|

|

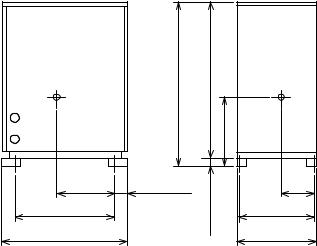

(2)External dimension .................................................................................................................................. |

21 |

|

|

(3)Center of gravity ...................................................................................................................................... |

24 |

|

|

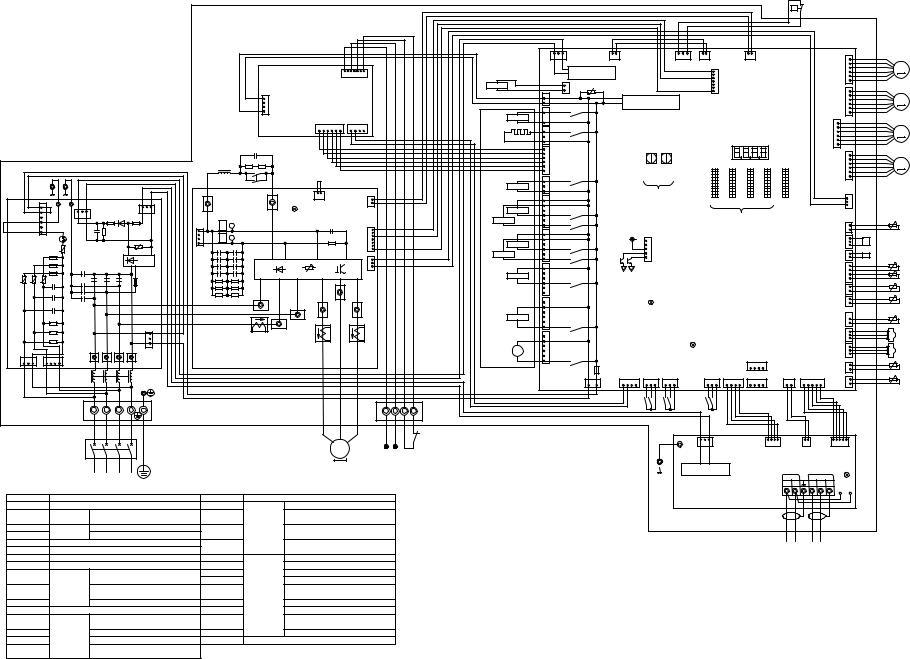

(4)Electrical wiring diagram .......................................................................................................................... |

25 |

|

|

(5)Sound levels ............................................................................................................................................ |

26 |

|

|

(6)Capacity tables with indoor units ............................................................................................................. |

30 |

|

|

(6)-1 Cooling capacity with standard indoor units ................................................................................. |

30 |

|

|

(6)-2 Heating capacity with standard indoor units ................................................................................. |

43 |

|

|

(7)Correction by total indoor ......................................................................................................................... |

44 |

|

|

(8)Correction by refrigerant piping length ..................................................................................................... |

46 |

|

|

(9)Correction by water temperature (For heat source unit) .......................................................................... |

49 |

|

|

(9)-1 Connection with standard CITY MULTI indoor units .................................................................... |

49 |

|

|

(9)-2 Connection with PWFY-P100/200VM-E-AU (HEX unit) ............................................................... |

49 |

|

|

(9)-3 |

Connection with PFD-P250/500VM-E .......................................................................................... |

50 |

|

(10)Correction by water flow rate (For heat source unit) .............................................................................. |

51 |

|

|

(10)-1 Connection with standard CITY MULTI indoor units .................................................................... |

51 |

|

|

(10)-2 Connection with PWFY-P100/200VM-E-AU (HEX unit) ............................................................... |

51 |

|

|

(10)-3 |

Connection with PFD-P250/500VM-E .......................................................................................... |

51 |

|

(11)Correction by indoor temperature .......................................................................................................... |

52 |

|

|

(11)-1 Connection with standard CITY MULTI indoor units .................................................................... |

52 |

|

|

(11)-2 Connection with PWFY-P100/200VM-E-AU (HEX unit) ............................................................... |

52 |

|

|

(11)-3 Connection with PFD-P250/500VM-E .......................................................................................... |

52 |

|

|

(12)Correction by water flow rate (For PWFY-P100/200VM-E-AU (HEX unit)) ............................................ |

53 |

|

|

(12)-1 Connection with PWFY-P100VM-E-AU (HEX unit) ...................................................................... |

53 |

|

|

(12)-2 Connection with PWFY-P200VM-E-AU (HEX unit) ...................................................................... |

53 |

|

|

(13)Water pressure drop correction by water volume ................................................................................. |

54 |

|

|

(13)-1 Heat source unit correction |

|

|

|

|

(Connection with Standard CITY MULTI indoor units, PWFY-P100/200VM-E-AU, |

|

|

|

PFD-P250/500VM-E) ................................................................................................................... |

54 |

|

(13)-2 HEX unit correction (Connection with PWFY-P100/200VM-E-AU) .............................................. |

54 |

|

|

(13)-3 Water pressure drop of strainer only (accessory for PWFY-P100/200VM-E-AU) ........................ |

54 |

|

|

(14)Operation temperature range ................................................................................................................ |

55 |

|

|

(14)-1 Connection with standard CITY MULTI indoor units .................................................................... |

55 |

|

|

(14)-2 Connection with PWFY-P100/200VM-E-AU (HEX unit) ............................................................... |

55 |

|

|

(14)-3 Connection with PFD-P250/500VM-E .......................................................................................... |

56 |

|

|

(15)Piping design ......................................................................................................................................... |

57 |

|

|

(15)-1 R410A Piping material .................................................................................................................. |

57 |

|

|

(15)-2 PQHY-P200-300YHM Piping |

|

|

|

|

(Connection with standard CITY MULTI indoor units, PWFY-P100/200VM-E-AU) ...................... |

58 |

|

(15)-3 PQHY-P400-600YSHM Piping |

|

|

|

|

(Connection with standard CITY MULTI indoor units, PWFY-P100/200VM-E-AU) ...................... |

59 |

|

(15)-4 PQHY-P650-900YSHM Piping |

|

|

|

|

(Connection with standard CITY MULTI indoor units, PWFY-P100/200VM-E-AU) ...................... |

60 |

|

(15)-5 PQHY-P250/P250+P250YHM |

|

|

|

|

(Connection with PFD indoor unit) ............................................................................................... |

61 |

|

(15)-6 Refrigerant charging calculation ................................................................................................... |

62 |

|

3. PQRY-P-Y(S)HM-A .................................................................................................................... |

63 |

(1)Specification ............................................................................................................................................ |

63 |

(1)-1 Heat source units specification for standard combination |

|

(Standard CITY MULTI indoor units, PWFY-P100VM-E-BU, PWFY-P100/200VM-E-AU) .......... |

63 |

(2)External dimension .................................................................................................................................. |

71 |

(3)Center of gravity ...................................................................................................................................... |

73 |

(4)Electrical wiring diagram .......................................................................................................................... |

74 |

(5)Sound levels ............................................................................................................................................ |

75 |

(6)Capacity tables with indoor units ............................................................................................................. |

77 |

(6)-1 Cooling capacity with standard indoor units ................................................................................. |

77 |

(6)-2 Heating capacity with standard indoor units ................................................................................. |

90 |

(7)Correction by total indoor ......................................................................................................................... |

91 |

(8)Correction by refrigerant piping length ..................................................................................................... |

92 |

(9)Correction by port counts of the BC controller ........................................................................................ |

93 |

(10)Correction by water temperature (For heat source unit) ........................................................................ |

94 |

(10)-1 Connection with standard CITY MULTI indoor units .................................................................... |

94 |

(10)-2 Connection with PWFY-P100/200VM-E-AU (HEX unit) ................................................................ |

94 |

(10)-3 Connection with PWFY-P100VM-E-BU (Booster unit) ................................................................. |

95 |

(10)-4 Connection with PWFY-P100VM-E-BU (Booster unit) + WCB Energy saving mode* ................. |

96 |

(11)Correction by water flow rate (For heat source unit) .............................................................................. |

97 |

(11)-1 Connection with standard CITY MULTI indoor units .................................................................... |

97 |

(11)-2 Connection with PWFY-P100/200VM-E-AU (HEX unit) ............................................................... |

97 |

(11)-3 Connection with PWFY-P100VM-E-BU (Booster unit) ................................................................. |

97 |

(12)Correction by indoor temperature .......................................................................................................... |

98 |

(12)-1 Connection with standard CITY MULTI indoor units .................................................................... |

98 |

(12)-2 Connection with PWFY-P100/200VM-E-AU (HEX unit) ............................................................... |

98 |

(12)-3 Connection with PWFY-P100VM-E-BU (Booster unit) ................................................................. |

98 |

(13)Correction by water flow rate |

|

(For PWFY-P100/200VM-E-AU (HEX unit) and PWFY-P100VM-E-BU (Booster unit) ........................... |

98 |

(13)-1 Connection with PWFY-P100VM-E-AU (HEX unit) ..................................................................... |

98 |

(13)-2 Connection with PWFY-P200VM-E-AU (HEX unit) ...................................................................... |

99 |

(13)-3 Connection with PWFY-P100VM-E-BU (Booster unit) ................................................................. |

99 |

(14)Water pressure drop correction by water volume ............................................................................... |

100 |

(14)-1 Heat source unit correction |

|

(Connection with Standard CITY MULTI indoor units, PWFY-P100/200VM-E-AU, |

|

PWFY-P100VM-E-BU) ............................................................................................................... |

100 |

(14)-2 Booster unit correction (Connection with PWFY-P100VM-E-BU) .............................................. |

100 |

(14)-3 HEX unit correction (Connection with PWFY-P100/200VM-E-AU) ............................................ |

100 |

(14)-4 Water pressure drop of strainer only |

|

(accessory for PWFY-P100VM-E-BU and PWFY-P100/200VM-E-AU) ..................................... |

101 |

(15)Operation temperature range .............................................................................................................. |

102 |

(15)-1 Connection with standard CITY MULTI indoor units .................................................................. |

102 |

(15)-2 Connection with PWFY-P100VM-E-BU (Booster unit) ............................................................... |

102 |

(15)-3 Connection with PWFY-P100/200VM-E-AU (HEX unit) ............................................................. |

103 |

(16)Piping design ....................................................................................................................................... |

104 |

(16)-1 R410A Piping material ................................................................................................................ |

104 |

(16)-2 PQRY-P200-300YHM Piping |

|

IF 16 ports or less are in use, i.e., if only one BC controller is in use with no sub BC controller |

|

(Connection with standard CITY MULTI indoor units, PWFY-P100VM-E-BU, |

|

PWFY-P100/200VM-E-AU) ........................................................................................................ |

105 |

(16)-3 PQRY-P200-300YHM Piping |

|

IF more than 16 ports are in use, or if there is more than one BC controller in use for |

|

one Heat source unit |

|

(Connection with standard CITY MULTI indoor units, PWFY-P100VM-E-BU, |

|

PWFY-P100/200VM-E-AU) ........................................................................................................ |

106 |

(16)-4 PQRY-P400YHM Piping |

|

IF more than 16 ports are in use, or if there is more than one BC controller in use for |

|

two heat source units |

|

(Connection with standard CITY MULTI indoor units, PWFY-P100VM-E-BU, |

|

PWFY-P100/200VM-E-AU) ........................................................................................................ |

107 |

(16)-5 Total piping length restrictions .................................................................................................... |

108 |

(16)-6 Refrigerant charging calculation ................................................................................................. |

109 |

I Brine information

1.Brine freezing temperature

Brine concentration is decided by the freezing temperature. First, it is necessary to decide the freezing temperature and find out brine concentration which will correspond to the freezing temperature.

Freezing Temperature [deg°C]

10

0

Propylene Glycol

-10

-20

Ethylene Glycol

-30

-40

-50

0 |

10 |

20 |

30 |

40 |

50 |

60 |

70 |

80 |

90 |

100 |

Brine concentration [wt%]

Note;

The graph was referred from chemical company data.

But Freezing Temperature condition will be slightly different based on each company. Please confirm detail data to the chemical company directly.

It is recommended to set the brine concentration to a percentage that will keep the freezing temperature at -15deg°C or less.

- 1 -

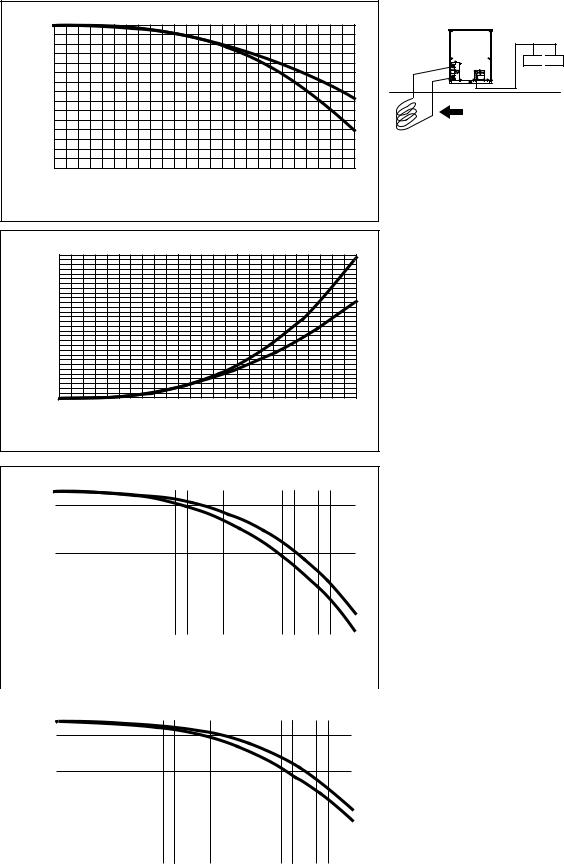

2.Capacity correction by brine concentration (For heat source unit)

Depending on the freezing temperature and brine concentration, the ratio of unit capacity will change. As shown in the line diagram, higher the brine concentration, the lower the ratio of capacity becomes.

Cooling

|

1 |

|

|

|

|

PQHY |

|

|

|

|

|

PQRY |

|

capacity |

|

|

|

|

Ethylene Glycol |

|

0.95 |

|

Propylene Glycol |

|

|

||

|

|

|

|

|||

cooling |

|

|

|

|

||

0.9 |

|

|

|

|

|

|

Ratio of |

|

|

|

|

|

|

0.85 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0% |

20% |

40% |

60% |

80% |

100% |

|

|

|

Brine concentration [wt%] |

|

||

|

1.30 |

|

|

|

|

|

input |

1.25 |

|

|

|

|

|

1.20 |

|

|

|

|

|

|

cooling |

1.15 |

|

Propylene Glycol |

|

|

|

|

|

|

|

|||

of |

1.10 |

|

|

|

||

|

|

|

|

|

||

Ratio |

1.05 |

|

|

|

Ethylene Glycol |

|

|

1.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

0% |

20% |

40% |

60% |

80% |

100% |

|

|

|

Brine concentration [wt%] |

|

||

Heating

|

1.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

capacity |

0.95 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ethylene |

Glycol |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

0.90 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

heating |

0.80 |

|

|

|

|

|

|

|

|

|

|

|

|

Propylene |

|

Glycol |

|

|

|

|

|

|

|

|

|

|||

of |

0.85 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ratio |

0.75 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.70 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

0% |

20% |

40% |

|

|

|

60% |

80% |

100% |

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Brine concentration [wt%] |

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

input |

0.95 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ethylene |

Glycol |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

heatingof |

0.9 |

|

|

|

|

|

|

|

|

|

|

|

Propylene |

|

Glycol |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ratio |

0.85 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

0.8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

0% |

20% |

40% |

|

|

|

|

60% |

|

80% |

|

100% |

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Brine concentration [wt%] |

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IU

IU

IU

- 2 -

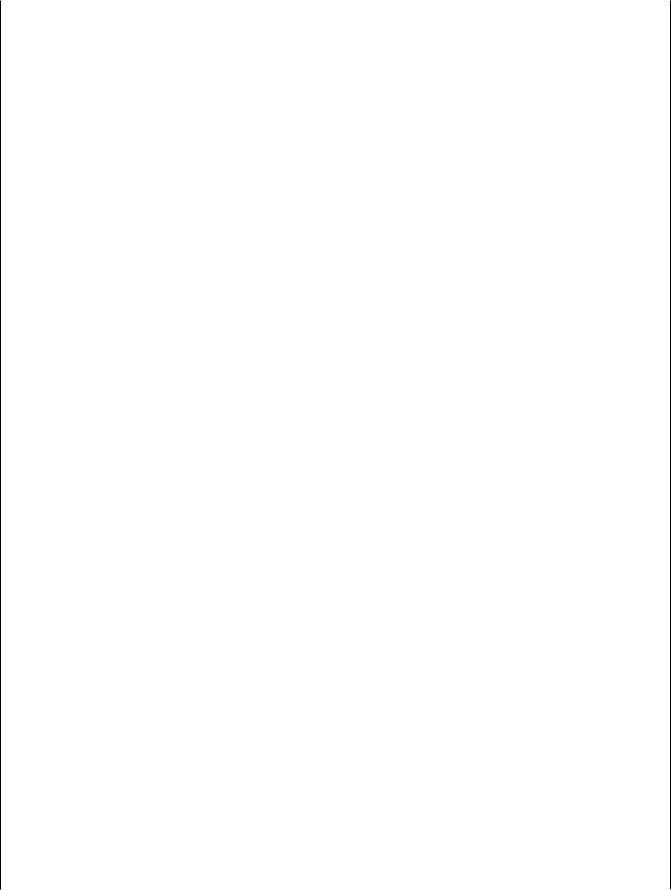

3.Pressure drop correction by brine concentration (For heat source unit)

Also, water pump is selected by the ratio of pressure drop of depending on the brine concentration.

Cooling

Ratio of pressure drop

8.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inlet-water temp. [°C] |

|||||||

7.0 |

|

|

|

Ethylene |

Glycol |

(cooling) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-5°C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0°C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5°C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10°C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0% |

20% |

40% |

|

60% |

|

|

80% |

100% |

||||||||||||||

|

|

|

|

|

|

Brine concentration [wt%] |

|

|

|

|

|

|

|

|

||||||||

Ratio of pressure drop

8.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inlet-water temp. [°C] |

|||||||

7.0 |

|

|

|

Propylene |

|

Glycol |

|

(cooling) |

|

|

|

|

|

|

|

|

|

|

|

|

|

-5°C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

6.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0°C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5°C |

|

5.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10°C |

|

4.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0% |

20% |

40% |

60% |

80% |

100% |

Brine concentration [wt%]

Heating

Ratio of pressure drop

26.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Inlet-water temp. [°C] |

|

|||||||

21.0 |

|

|

|

Ethylene |

|

Glycol |

(heating) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-5°C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

6.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0°C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5°C |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10°C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0% 20% 40% 60% 80% 100%

Brine concentration [wt%]

Ratio of pressure drop

26.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inlet-water temp. [°C] |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-5°C |

21.0 |

|

|

|

Propylene |

|

Glycol |

|

(heating) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0°C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

16.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5°C |

|

11.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10°C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

6.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0% |

20% |

40% |

|

60% |

|

|

80% |

100% |

||||||||||||||

Brine concentration [wt%]

* Please supply strainer on site.

- 3 -

II Heat source unit information

1.General lineup of water-cooled heat source unit

WY (Heat Pump) Series (8HP-36HP)

PQHY-P YHM-A

PQHY-P YSHM-A

Model |

8HP |

10HP |

12HP |

16HP |

|

|

|

|

|

Model Name |

PQHY-P200YHM-A |

PQHY-P250YHM-A |

PQHY-P300YHM-A |

PQHY-P400YSHM-A |

|

|

|

|

|

|

|

|

|

|

Model |

18HP |

20HP |

22HP |

24HP |

|

|

|

|

|

Model Name |

PQHY-P450YSHM-A |

PQHY-P500YSHM-A |

PQHY-P550YSHM-A |

PQHY-P600YSHM-A |

|

|

|

|

|

|

|

|

|

|

Model |

26HP |

28HP |

30HP |

32HP |

|

|

|

|

|

Model Name |

PQHY-P650YSHM-A |

PQHY-P700YSHM-A |

PQHY-P750YSHM-A |

PQHY-P800YSHM-A |

|

|

|

|

|

|

|

|

|

|

Model |

34HP |

36HP |

|

|

|

|

|

|

|

Model Name |

PQHY-P850YSHM-A |

PQHY-P900YSHM-A |

|

|

|

|

|

|

|

WR2 (Heat Recovery) Series (8HP-24HP)

PQRY-P YHM-A

PQRY-P YSHM-A

Model |

8HP |

10HP |

12HP |

16HP |

|

|

|

|

|

Model Name |

PQRY-P200YHM-A |

PQHRY-P250YHM-A |

PQRY-P300YHM-A |

PQRY-P400YSHM-A |

|

|

|

|

|

|

|

|

|

|

Model |

18HP |

20HP |

22HP |

24HP |

|

|

|

|

|

Model Name |

PQRY-P450YSHM-A |

PQRY-P500YSHM-A |

PQRY-P550YSHM-A |

PQRY-P600YSHM-A |

|

|

|

|

|

- 4 -

2.PQHY-P-Y(S)HM-A

(1)Specification

(1)-1 Heat source units specification for standard combination (Standard CITY MULTI indoor units, PWFY-P100/200VM-E-AU)

Model |

|

|

|

|

|

PQHY-P200YHM-A(For Ground source) |

Power source |

|

|

|

|

|

3-phase 4-wire 380-400-415V 50/60Hz |

Cooling capacity |

*1 |

kW |

22.4 |

|||

(Nominal) |

*1 |

kcal / h |

19,300 |

|||

|

*1 |

BTU / h |

76,400 |

|||

|

|

Power input |

kW |

3.92 |

||

|

|

Current input |

A |

6.6-6.2-6.0 |

||

|

|

COP |

kW / kW |

5.71 |

||

Temp. range of |

|

Indoor |

W.B. |

|

15.0~24.0°C(59~75°F) |

|

cooling |

|

Circulating water |

°C |

|

-5.0~45.0°C(23~113°F) |

|

Heating capacity |

|

*2 |

kW |

25.0 |

||

(Nominal) |

*2 |

kcal / h |

21,500 |

|||

|

*2 |

BTU / h |

85,300 |

|||

|

|

Power input |

kW |

4.12 |

||

|

|

Current input |

A |

6.9-6.6-6.3 |

||

|

|

COP |

kW / kW |

6.06 |

||

Temp. range of |

|

Indoor |

D.B. |

|

|

15.0~27.0°C(59~81°F) |

heating |

|

Circulating water |

°C |

|

-5.0~45.0°C(23~113°F) |

|

Indoor unit |

|

Total capacity |

|

|

|

50~130 % of heat source unit capacity |

connectable |

|

Model / Quantity |

|

|

|

P15~P250 / 1~17 |

Sound pressure level (measured in anechoic room) |

dB <A> |

47 |

||||

Refrigerant |

|

Liquid pipe |

mm(in.) |

|

9.52(3/8) Brazed |

|

piping diameter |

|

Gas pipe |

mm(in.) |

|

19.05(3/4) Brazed |

|

Circulating |

|

Water flow rate |

m3 / h |

5.76 |

||

water |

|

|

L/min |

96 |

||

|

|

|

cfm |

3.4 |

||

|

|

Pressure drop |

kPa |

|

17 |

|

|

|

Operating volume range |

m3 / h |

|

4.5 ~ 7.2 |

|

Compressor |

|

Type x Quantity |

|

|

|

Inverter scroll hermetic compressor |

|

|

Manufacture |

|

|

|

AC&R Works, MITSUBISHI ELECTRIC CORPORATION |

|

|

Starting method |

|

|

|

Inverter |

|

|

Motor output |

kW |

|

4.6 |

|

|

|

Case heater |

kW |

|

0.035(240 V) |

|

|

|

Lubricant |

|

|

|

MEL32 |

External finish |

|

|

|

|

|

Acrylic painted steel plate |

External dimension HxWxD |

mm |

|

1,160(1,100 without legs) x 880 x 550 |

|||

|

|

|

in. |

|

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16 |

|

Protection |

|

High pressure protection |

|

High pressure sensor, High pressure switch at 4.15MPa (601 psi) |

||

devices |

|

Inverter circuit (COMP.) |

|

Over-heat protection, Over-current protection |

||

|

|

Compressor |

|

|

|

Over-heat protection |

Refrigerant |

|

Type x original charge |

|

R410A x 5.0kg (12lbs) |

||

|

|

Control |

|

|

|

Indoor LEV and BC controller |

Net weight |

|

|

kg(lbs) |

195(430) |

||

Heat exchanger |

|

|

|

|

|

plate type |

|

|

Water volume in plate |

l |

|

5.0 |

|

|

|

Water pressure Max. |

MPa |

|

1.0 |

|

HIC circuit (HIC: Heat Inter-Changer) |

- |

|||||

Drawing |

|

External |

|

|

|

KB94T222 |

|

|

Wiring |

|

|

|

KE94C317 |

Standard attachment |

Document |

|

|

|

Installation Manual |

|

|

|

Accessory |

|

|

|

Refrigerant conn. pipe |

Optional parts |

|

|

|

|

|

Joint: CMY-Y102S-G2 |

|

|

|

|

|

|

Header: CMY-Y104/108/1010-G |

Remarks

●Turn DipSW 3-9 ON before power ON.

●Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be referred to the Installation Manual. ●Due to continuing improvement, above specifications may be subject to change without notice.

●The ambient temperature of the heat source unit needs to be kept below 40°C D.B. ●The ambient relative humidity of the heat source unit needs to be kept below 80%. ●The heat source unit should not be installed at outdoor.

●Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit. ●Be sure to provide interlocking for the unit operation and water circuit.

●Add brine to circulating water when a unit is operating at water temperature below 10°C.

Notes: |

|

|

Unit converter |

1.<Standard CITY MULTI indoor unit> |

Nominal heating conditions(subject to JIS B8615-1) |

kcal |

=kW x 860 |

Nominal cooling conditions(subject to JIS B8615-1) |

BTU/h =kW x 3,412 |

||

Indoor:27°CDB/19°CWB(81°FDB/66°FWB) |

Indoor:20°CDB(68°FDB) |

cfm |

=m3/min x 35.31 |

Water temperature:30°C(86°F) |

Water temperature:20°C(68°F) |

||

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.) |

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.) |

lb |

=kg / 0.4536 |

Brine concentration 0% |

Brine concentration 0% |

|

|

2.<PWFY-P100/200VM-E-AU> |

Nominal heating conditions |

|

|

Nominal cooling conditions |

|

|

|

Circulating water Temp. : 30°C (86°F) |

Circulating water Temp. : 20°C (68°F) |

|

|

Pipe length : 7.5 m (24-9/16 ft) |

Pipe length : 7.5 m (24-9/16 ft) |

|

|

Level difference : 0m (0ft) |

Level difference : 0m (0ft) |

|

|

Inlet water Temp 23°C |

Inlet water Temp 30°C |

*The specification data is |

|

Water flow rate : 1.93m3/h (P100) / 3.86m3/h (P200) |

Water flow rate : 2.15m3/h (P100) / 4.30m3/h (P200) |

||

Brine concentration 0% |

Brine concentration 0% |

subject to rounding variation. |

|

- 5 -

Model |

|

|

PQHY-P250YHM-A(For Ground source) |

Power source |

|

|

3-phase 4-wire 380-400-415V 50/60Hz |

Cooling capacity |

*1 |

kW |

28.0 |

(Nominal) |

*1 |

kcal / h |

24,100 |

|

*1 |

BTU / h |

95,500 |

|

Power input |

kW |

5.45 |

|

Current input |

A |

9.2-8.7-8.4 |

|

COP |

kW / kW |

5.13 |

Temp. range of |

Indoor |

W.B. |

15.0~24.0°C(59~75°F) |

cooling |

Circulating water |

°C |

-5.0~45.0°C(23~113°F) |

Heating capacity |

*2 |

kW |

31.5 |

(Nominal) |

*2 |

kcal / h |

27,100 |

|

*2 |

BTU / h |

107,500 |

|

Power input |

kW |

5.80 |

|

Current input |

A |

9.7-9.3-8.9 |

|

COP |

kW / kW |

5.43 |

Temp. range of |

Indoor |

D.B. |

15.0~27.0°C(59~81°F) |

heating |

Circulating water |

°C |

-5.0~45.0°C(23~113°F) |

Indoor unit |

Total capacity |

|

50~130 % of heat source unit capacity |

connectable |

Model / Quantity |

|

P15~P250 / 1~21 |

Sound pressure level (measured in anechoic room) |

dB <A> |

49 |

|

Refrigerant |

Liquid pipe |

mm(in.) |

9.52(3/8) Brazed (12.7(1/2) Brazed,total length >= 90m) |

piping diameter |

Gas pipe |

mm(in.) |

22.2(7/8) Brazed |

Circulating |

Water flow rate |

m3 / h |

5.76 |

water |

|

L/min |

96 |

|

|

cfm |

3.4 |

|

Pressure drop |

kPa |

17 |

|

Operating volume range |

m3 / h |

4.5 ~ 7.2 |

Compressor |

Type x Quantity |

|

Inverter scroll hermetic compressor |

|

Manufacture |

|

AC&R Works, MITSUBISHI ELECTRIC CORPORATION |

|

Starting method |

|

Inverter |

|

Motor output |

kW |

6.3 |

|

Case heater |

kW |

0.035(240 V) |

|

Lubricant |

|

MEL32 |

External finish |

|

|

Acrylic painted steel plate |

External dimension HxWxD |

mm |

1,160(1,100 without legs) x 880 x 550 |

|

|

|

in. |

45-11/16(43-5/16 without legs) x 34-11/16 x 21-11/16 |

Protection |

High pressure |

protection |

High pressure sensor, High pressure switch at 4.15MPa (601 psi) |

devices |

Inverter circuit (COMP.) |

Over-heat protection, Over-current protection |

|

|

Compressor |

|

Over-heat protection |

Refrigerant |

Type x original charge |

R410A x 5.0kg (12lbs) |

|

|

Control |

|

Indoor LEV and BC controller |

Net weight |

|

kg(lbs) |

195(430) |

Heat exchanger |

|

|

plate type |

|

Water volume in plate |

l |

5.0 |

|

Water pressure Max. |

MPa |

1.0 |

HIC circuit (HIC: Heat |

Inter-Changer) |

|

- |

Drawing |

External |

|

KB94T222 |

|

Wiring |

|

KE94C317 |

Standard attachment |

Document |

|

Installation Manual |

|

Accessory |

|

Refrigerant conn. pipe |

Optional parts |

|

|

Joint: CMY-Y102S-G2, CMY-Y102L-G2 |

|

|

|

Header: CMY-Y104/108/1010-G |

Remarks

●Turn DipSW 3-9 ON before power ON.

●Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be referred to the Installation Manual. ●Due to continuing improvement, above specifications may be subject to change without notice.

●The ambient temperature of the heat source unit needs to be kept below 40°C D.B. ●The ambient relative humidity of the heat source unit needs to be kept below 80%. ●The heat source unit should not be installed at outdoor.

●Be sure to mount a strainer (more than 50 meshes) at the water inlet piping of the unit. ●Be sure to provide interlocking for the unit operation and water circuit.

●Add brine to circulating water when a unit is operating at water temperature below 10°C.

Notes: |

|

|

Unit converter |

1.<Standard CITY MULTI indoor unit> |

|

kcal |

=kW x 860 |

Nominal cooling conditions(subject to JIS B8615-1) |

Nominal heating conditions(subject to JIS B8615-1) |

BTU/h =kW x 3,412 |

|

Indoor:27°CDB/19°CWB(81°FDB/66°FWB) |

Indoor:20°CDB(68°FDB) |

cfm |

=m3/min x 35.31 |

Water temperature:30°C(86°F) |

Water temperature:20°C(68°F) |

||

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.) |

Pipe length:7.5m(24-9/16ft.), Level difference:0m(0ft.) |

lb |

=kg / 0.4536 |

Brine concentration 0% |

Brine concentration 0% |

|

|

2.<PWFY-P100/200VM-E-AU> |

Nominal heating conditions |

|

|

Nominal cooling conditions |

|

|

|

Circulating water Temp. : 30°C (86°F) |

Circulating water Temp. : 20°C (68°F) |

|

|

Pipe length : 7.5 m (24-9/16 ft) |

Pipe length : 7.5 m (24-9/16 ft) |

|

|

Level difference : 0m (0ft) |

Level difference : 0m (0ft) |

|

|

Inlet water Temp 23°C |

Inlet water Temp 30°C |

*The specification data is |

|

Water flow rate : 1.93m3/h (P100) / 3.86m3/h (P200) |

Water flow rate : 2.15m3/h (P100) / 4.30m3/h (P200) |

||

Brine concentration 0% |

Brine concentration 0% |

subject to rounding variation. |

|

- 6 -

Model |

|

|

PQHY-P300YHM-A(For Ground source) |

|||

Power source |

|

|

3-phase 4-wire 380-400-415V 50/60Hz |

|||

Cooling capacity |

*1 |

kW |

33.5 |

|

|

|

(Nominal) |

*1 |

kcal / h |

28,800 |

|

|

|

|

*1 |

BTU / h |

114,300 |

|

|

|

|

Power input |

kW |

7.36 |

|

|

|

|

Current input |

A |

12.4-11.8-11.3 |

|

|

|

|

COP |

kW / kW |

4.55 |

|

|

|

Temp. range of |

Indoor |

W.B. |

15.0~24.0°C(59~75°F) |

|

||

cooling |

Circulating water |

°C |

-5.0~45.0°C(23~113°F) |

|

||

Heating capacity |

*2 |

kW |

37.5 |

|

|

|

(Nominal) |

*2 |

kcal / h |

32,300 |

|

|

|

|

*2 |

BTU / h |

128,000 |

|

|

|

|

Power input |

kW |

8.15 |

|

|

|

|

Current input |

A |

13.7-13.0-12.5 |

|

|

|

|

COP |

kW / kW |

4.60 |

|

|

|

Temp. range of |

Indoor |

D.B. |

15.0~27.0°C(59~81°F) |

|||

heating |

Circulating water |

°C |

-5.0~45.0°C(23~113°F) |

|||

Indoor unit |

Total capacity |

|

50~130 % of heat source unit capacity |

|||

connectable |

Model / Quantity |

|

P15~P250 / 1~26 |

|||

Sound pressure level (measured in anechoic room) |

dB <A> |

50 |

|

|

|

|

Refrigerant |

Liquid pipe |

mm(in.) |

9.52(3/8) Brazed (12.7(1/2) Brazed,total length >= 40m) |

|||

piping diameter |

Gas pipe |

mm(in.) |

22.2(7/8) Brazed |

|

||

Circulating |

Water flow rate |

m3 / h |

5.76 |

|

|

|

water |

|

L/min |

96 |

|

|

|

|

|

cfm |

3.4 |

|

|

|

|

Pressure drop |

kPa |

17 |

|

|

|

|

Operating volume range |

m3 / h |

4.5 ~ 7.2 |

|

|

|

Compressor |

Type x Quantity |

|

Inverter scroll hermetic compressor |

|

||

|

Manufacture |

|

AC&R Works, MITSUBISHI ELECTRIC CORPORATION |

|

||

|

Starting method |

|

Inverter |

|

||

|

Motor output |

kW |

7.4 |

|

|

|

|

Case heater |

kW |

0.035(240 V) |

|

||

|

Lubricant |

|

MEL32 |

|

||

External finish |

|

|

Acrylic painted steel plate |

|

||

External dimension HxWxD |

mm |

1,160(1,100 without legs) x 880 x 550 |

|

|||

|

|