Mitsubishi PUH-P1.6VGA, PUH-P2VGA, PUH-P2.5VGA, PUH-P3VGA, PUH-P3YGA Service Manual

...

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

R407C

Outdoor unit

[model names]

[Service Ref.]

1999

No.OC180

REVISED EDITION-A

PUH-P1.6VGA PU-P1.6VGA

PUH-P1.6YGA

PUH-P2VGA PU-P2VGA

PUH-P2YGA

PUH-P2.5VGA PU-P2.5VGA

PUH-P2.5YGA

PUH-P3VGA PU-P3VGA

PUH-P3YGA PU-P3YGA

PUH-P4YGA PU-P4YGA

PUH-P5YGA PU-P5YGA

PUH-P6YGA PU-P6YGA

PUH-P1.6VGA PU-P1.6VGA

PUH-P1.6YGA

PUH-P2VGA PU-P2VGA

PUH-P2YGA

PUH-P2.5VGA PU-P2.5VGA

PUH-P2.5VGA

1 PU-P2.5VGA1

PUH-P2.5YGA

PUH-P2.5YGA

1

PUH-P3VGA PU-P3VGA

PUH-P3YGA PU-P3YGA

PUH-P4YGA PU-P4YGA

PUH-P5YGA PU-P5YGA

PUH-P6YGA PU-P6YGA

CONTENTS

1. SAFETY PRECAUTION··································3

2.

COMBINATION OF INDOOR AND OUTDOOR UNITS

3. PART NAMES AND FUNCTIONS··················5

4. SPECIFICATIONS···········································6

5. DATA·····························································12

6. OUTLINES AND DIMENSIONS····················15

7. WIRING DIAGRAM·······································19

8.

REFRIGERANT SYSTEM DIAGRAM

9. DISASSEMBLY PROCEDURE·····················25

10. PARTS LIST··················································29

11. OPTIONAL PARTS························Back cover

···5

·············23

Revision:

●PUH-P1.6YGA, -P2YGA, -P2.5YGA,

PUH-P2.5VGA1, -P2.5YGA1 and

PU-P1.6VGA, -P2VGA, -P2.5VGA,

PU-P3VGA, -P3YGA, -P4YGA, -P5YGA,

PU-P6YGA, -P2.5VGA1 added in

Revised Edition-A.

●Please destroy OC180.

1

SAFETY PRECAUTION

Cautions for using with the outdoor unit which adopts R407C refrigerant.

· Do not use the existing refrigerant piping.

-The old refrigerant and refrigerant oil in the existing piping contains a large amount of chlorine which may cause the refrigerant oil of the new unit to deteriorate.

· Do not use copper pipes which are broken, deformed or discolour .

In addition, be sure that the inner surfaces of the pipes are clean, free of hazardous sulphur and oxides, or have no dust /

dirt, shaving particles, oils, moisture or any other contamination.

-If there is a large amount of residual oil (hydraulic oil, etc.) inside the piping and joints, deterioration of the refrigerant oil will

result.

· Store the piping to be used during installation indoors and keep both ends of the piping sealed until just before

brazing. (Store elbows and other joints in a plastic bag.)

-If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and compressor trouble may result.

· Use ester oil, ether oil or alkyl benzene (small amount) as the refrigerant oil to coat flares and flange connections.

-The refrigerant oil will degrade if it is mixed with a large amount of mineral oil.

Use liquid refrigerant to fill the system.

-If gas refrigerant is used to fill the system, the composition of the refrigerant in the cylinder will change and performance

may drop.

· Do not use a refrigerant other than R407C.

-If another refrigerant (R22, etc.) is used, the chlorine in the refrigerant may cause the refrigerant oil to deteriorate.

· Use a vacuum pump with a reverse flow check valve.

-The vacuum pump oil may flow back into the refrigerant cycle and cause the refrigerant oil to deteriorate.

· Do not use the following tools that are used with conventional refrigerant.

(Gauge manifold , charge hose, gas leak detector, reverse flow check valve, refrigerant charge base, vacuum gauge,

refrigerant recovery equipment)

-If the conventional refrigerant and refrigerant oil are mixed in the R407C, the refrigerant may deteriorated.

-If water is mixed in the R407C, the refrigerant oil may deteriorate.

-Since R407C does not contain any chlorine, gas leak detectors for conventional refrigerant will not react to it.

· Do not use a charging cylinder.

-Using a charging cylinder may cause the refrigerant to deteriorate.

· Be especially careful when managing the tools.

-if dust, dirt, or water gets in the refrigerant cycle, the refrigerant may deteriorate.

· Do not use the drier which is sold in the field.

-The drier for R407C refrigerant is pre-attached to outdoor unit refrigerant circuit.

-Some drier in the field are not in conformity with R407C refrigerant.

3

Gravimeter

Unit

[1] Service tools

Use the below service tools as exclusive tools for R407C refrigerant.

No. Tool name Specifications

1 Gauge manifold ·Only for R407C.

·Use the existing fitting SPECIFICATIONS. (UNF7/16)

·Use high-tension side pressure of 3.43MPa·G or over.

2 Charge hose ·Only for R407C.

·Use pressure performance of 5.10MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R407C.

5 Adapter for reverse flow check. ·Attach on vacuum pump.

6 Refrigerant charge base.

7 Refrigerant cylinder. ·For R407C ·Top of cylinder (Brown)

·Cylinder with syphon

8 Refrigerant recovery equipment.

[2] Notice on repair service

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

[3] Refrigerant recharging

(1) Refrigerant recharging process

1Direct charging from the cylinder.

·R407C cylinder are available on the market has a syphon pipe.

·Leave the syphon pipe cylinder standing and recharge it.

(By liquid refrigerant)

(2) Recharge in refrigerant leakage case

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release the refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

4

2 COMBINATION OF INDOOR AND OUTDOOR UNITS

Air intake

Air outlet

(Expels warm air during cooling)

Air intake

Air outlet

Air intake

Air outlet

Air intake

Air outlet

Heat pump type

Outdoor unit

PUH-P

Cooling only type

PU-P

PLH-P

·KAH

PCH-P·GAH

PKH-P·GALH

PKH-P·FALH

PSH-P·GAH

PLA-P·KA

PCA-P·GA

PKA-P·GAL

PKA-P·FAL

PSA-P·GA

OC181

OC182

OC176

OC175

OC212

OC181

OC182

OC176

OC175

OC212

YGA

—

—

—

—

—

—

—

YGA

—

—

—

—

—

—

—

YGA

—

—

—

—

—

—

YGA

—

—

—

—

—

—

VGA

—

—

—

—

—

—

VGA(1)

—

—

—

—

—

—

—

VGA

—

—

—

—

—

—

—

VGA

—

—

—

—

—

—

—

—

YGA

—

—

—

—

YGA

—

—

—

—

YGA

—

—

YGA

—

—

VGA

—

—

VGA(1)

—

—

—

—

YGA(1)

—

—

—

—

YGA

—

—

—

—

VGA

—

—

—

—

VGA

—

—

—

—

—

—

YGA

—

—

—

—

—

—

Indoor unit

1.6Service

Manual No.

Service Ref.

2 2.5 3 4 5 6 1.6 2 2.5 3 4 5 6

Heat pump with

electric heater

Heat pump without

electric heater or

Cooling only

REVISED

EDITION-A

REVISED

EDITION-A

REVISED

EDITION-A

REVISED

EDITION-A

REVISED

EDITION-A

REVISED

EDITION-A

REVISED

EDITION-A

REVISED

EDITION-A

3 PART NAMES AND FUNCTIONS

CHARGELESS SYSTEM

PRE-CHARGED REFRIGERANT IS SUPPLIED FOR PIPING LENGTH AT SHIPMENT.(Max.30m)

PU(H)-P1.6VGA

PUH-P1.6YGA

PU(H)-P2VGA, PUH-P2YGA

PU(H)-P2.5VGA

(1), PUH-P2.5YGA(1)

PU(H)-P3VGA, PU(H)-P3YGA

The refrigerant circuit with LEV(Linear Expansion Valve) and a large accumulator always control the optimal refrigerant

level regardless of the length (30m max. and 5m min.) of piping. The additional refrigerant charging work during

installation often causes problems. Heretofore it is completely eliminated. This unique system improves the quality

and reliability of the work done.It also helps to speed up the installation time.

PU(H)-P4YGA

5

PU(H)-P5YGA

PU(H)-P6YGA

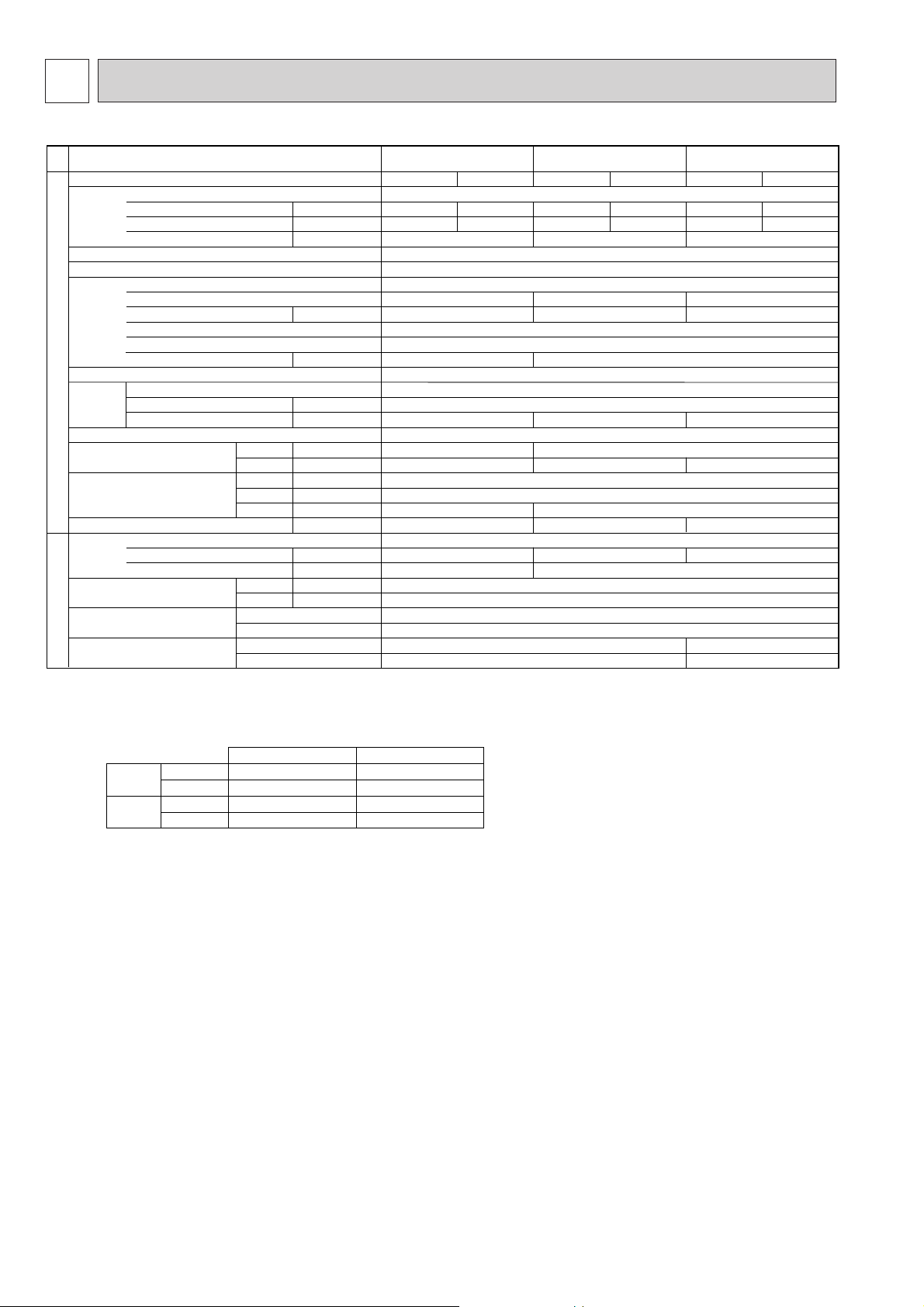

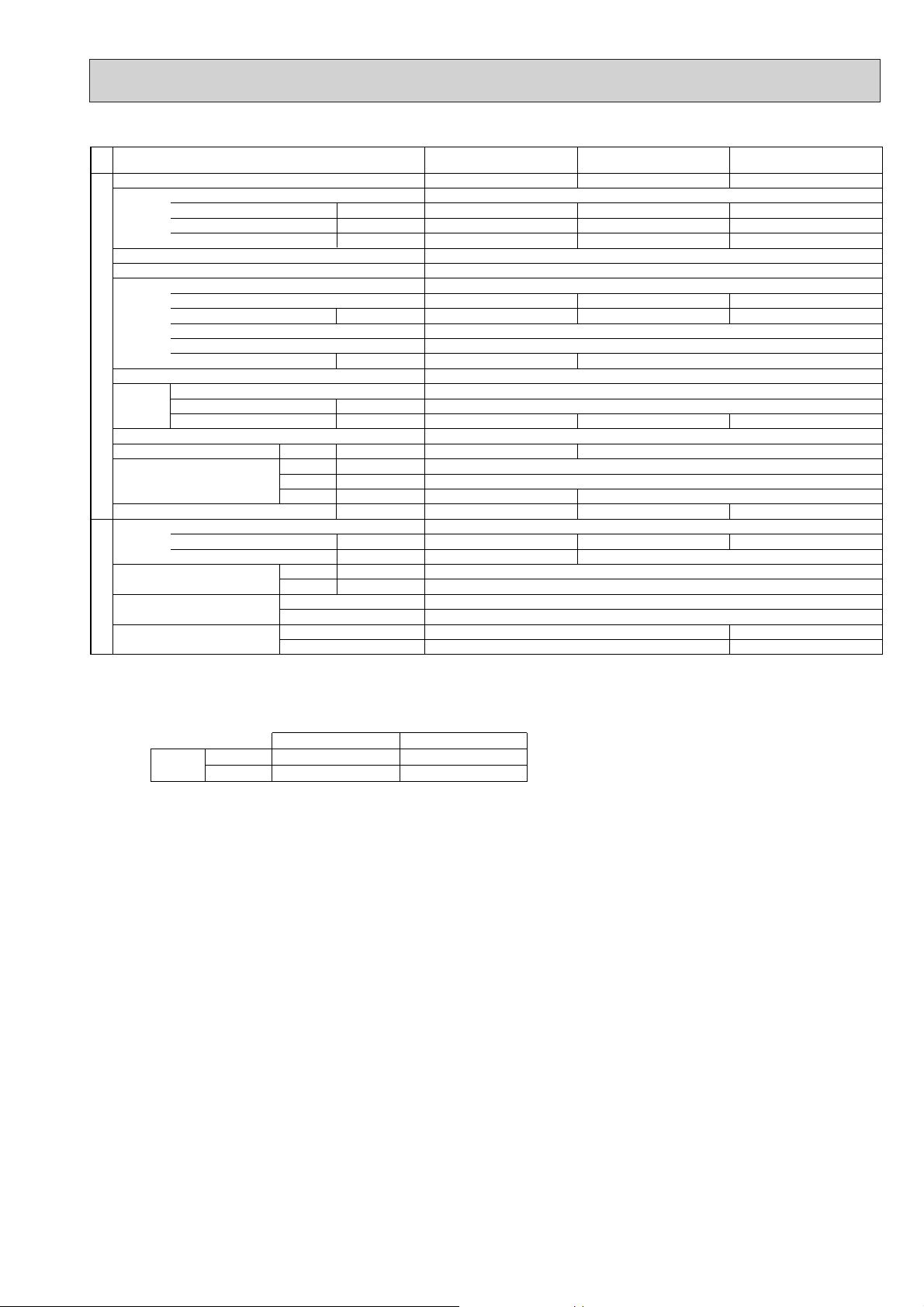

4 SPECIFICATIONS

kW

A

A

kW

W

kW

K

/min(CFM

)

dB

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

L

mm(in.)

mm(in.)

Function

Power supply (phase, cycle, voltage)

Input

Running current

Starting current

External finish

Refrigerant control

Compressor

Model

Motor output

Starter type

Protection devices

Crankcase heater

Heat exchanger

Fan Fan(drive) o No.

Fan motor output

Airflow

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Charge

Oil (Model)

Pipe size O.D.

Connection method

Between the indoor &

outdoor unit

OUTDOOR UNIT

REFRIGERANT PIPING

Cooling

Heating

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Notes1.Rating Conditions (ISO T1)

Cooling :Indoor : D.B. 27˚C(80˚F), W.B.19˚C (66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C (75˚F)

Heating :Indoor : D.B. 20˚C(68˚F) Outdoor : D.B. 7˚C(45˚F), W.B. 6˚C (43˚F)

Refrigerant piping length (one way) : 5m (16ft)

3. Above data based on indicated voltage

Indoor Unit 1 phase 240V 50Hz

Outdoor Unit 1 phase 240V 50Hz / 3 phase 415V 50Hz

2. Guaranteed operating range

Upper limit

Lower limit

Upper limit

Lower limit

Indoor

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

D.B. 28˚C

D.B. 17˚C

Outdoor

D.B. 46˚C

D.B. -5˚C

D.B. 24˚C, W.B. 18˚C

D.B. -11˚C, W.B. -12˚C

Cooling

Heating

Service Ref.

PUH-P1.6VGA / YGA PUH-P2VGA / YGA PUH-P2.5VGA

(1) / YGA(1)

Cooling

1.71

7.66 / 2.67

36 / 20

RE277VHSM / RE277YFKM

1.3

30

45(1,590)

46

48

650(25-5/8)

55(121)

2.6(5.7)

0.57 (Ester)MEL56

Single, 50Hz, 220-240V/3-ph, 50Hz, 380-415V(4wires)

74 / 30

Munsell 5Y 8/1

Linear Expansion Valve

Hermetic

NE38VMJM / NE38YEJM

1.7

Line start

Inner thermostat, HP switch, Discharge thermo. / Thermal relay, Discharge thermo, HP switch, Anti-phase protector.

Plate fin coil

Propeller (direct) o 1

0.07

55(1,940)

Reverse cycle

49

900(35-7/16)

330+20(13+3/4)

71(157)

R407C

3.1(6.8)

9.52(3/8)

15.88(5/8)

Flared

Flared

Heating

1.83

8.19 / 2.86

Cooling

2.63

11.78 / 4.11

38

48

855(33-5/8)

1.2 (Ester)MEL56

77 / 32

NE41VMJM / NE41YEJM

1.9

50(1,770)

50

82(181)

3.3(7.3)

Max. 50m

Max. 50m

Heating

2.58

11.55 / 4.03

Cooling

2.48

11.11 / 3.88

Heating

2.57

11.51 / 4.02

Max. 40m

Max. 40m

1.Heat pump

6

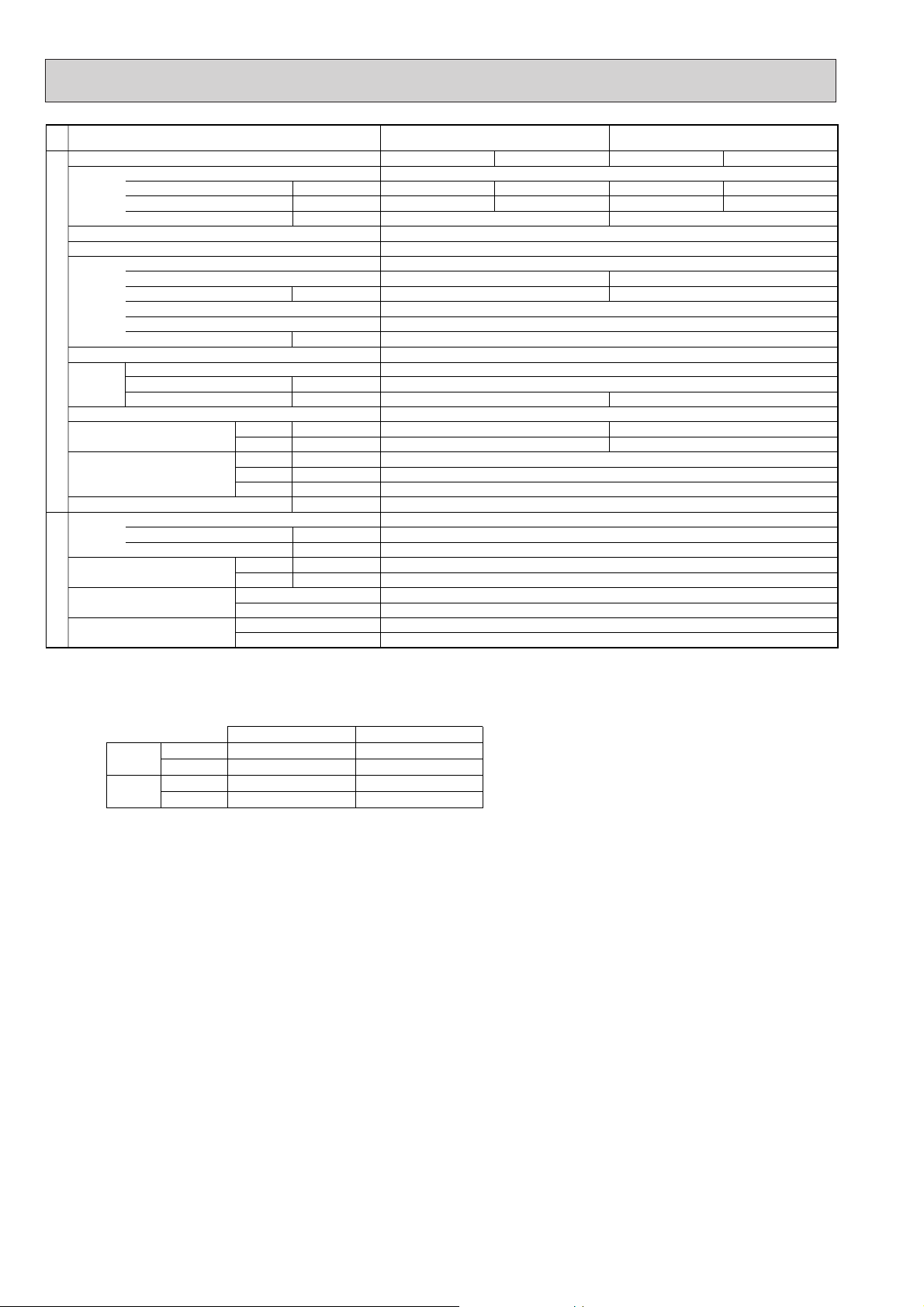

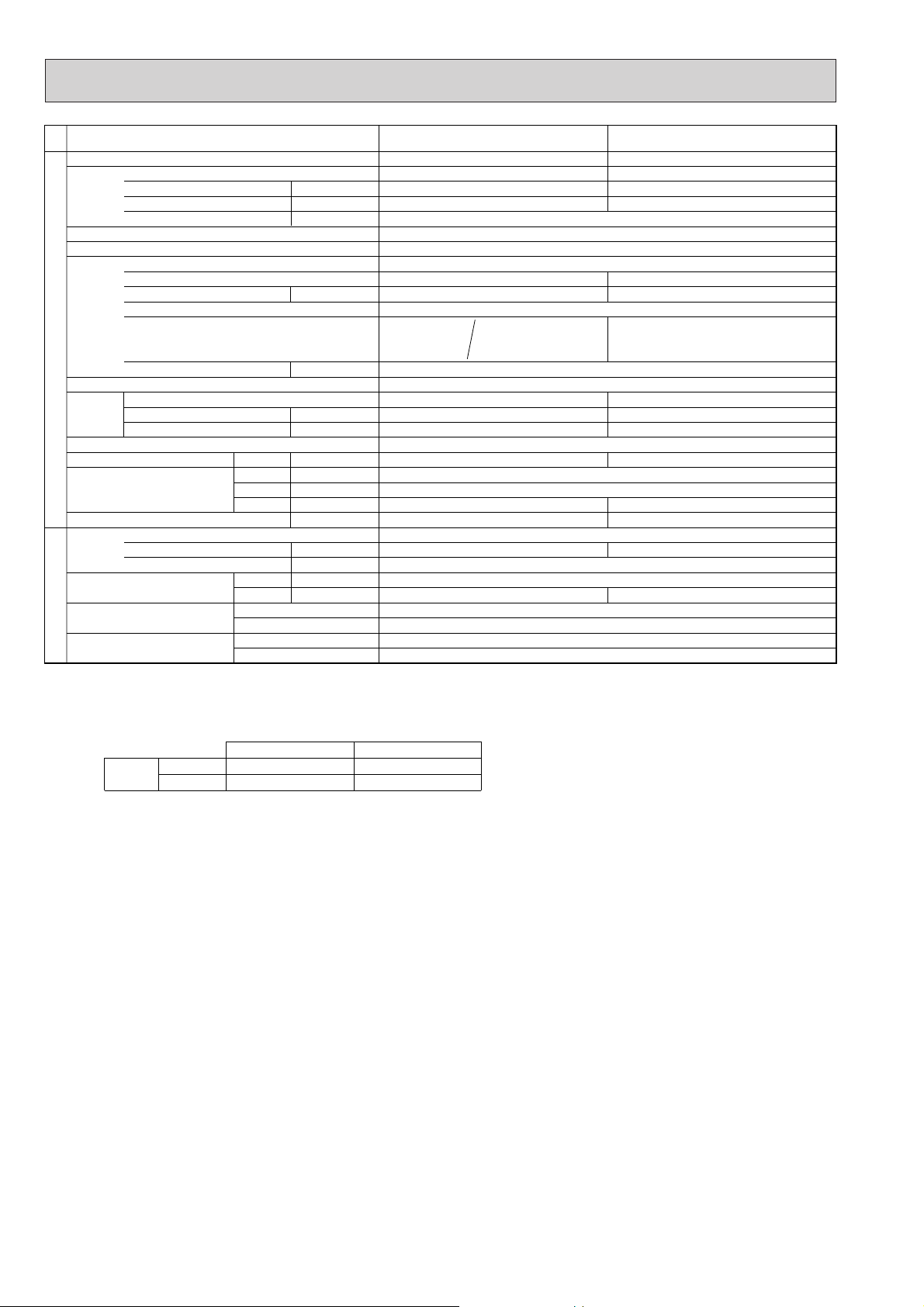

Service Ref.

Function

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

Heat exchanger

OUTDOOR UNIT

Fan Fan(drive) o No.

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor &

REFRIGERANT PIPING

outdoor unit

Notes1.Rating Conditions (ISO T1)

2. Guaranteed operating range

3. Above data based on indicated voltage

Input

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Crankcase heater

Fan motor output

Airflow

Cooling

Heating

W

D

H

Charge

Oil (Model)

Cooling :Indoor : D.B. 27˚C(80˚F), W.B. 19˚C(66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C(75˚F)

Heating :Indoor : D.B. 20˚C(68˚F) Outdoor : D.B. 7˚C(45˚F), W.B. 6˚C(43˚F)

Refrigerant piping length (one way) : 5m (16ft)

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

Indoor Unit 1 phase 240V 50Hz

Outdoor Unit 1 phase 240V 50Hz / 3 phase 415V 50Hz

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Indoor

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

D.B. 28˚C

D.B. 17˚C

kW

kW

kW

K

/min(CFM

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

mm(in.)

mm(in.)

A

A

W

dB

dB

L

Single, 50Hz, 220-240V/3-ph, 50Hz, 380-415V(4wires)

Internal thermostat

Discharge thermo

)

D.B. 46˚C

D.B. -5˚C

D.B. 24˚C, W.B. 18˚C

D.B. -11˚C, W.B. -12˚C

PUH-P3VGA / YGA PUH-P4YGA

Cooling

3.34

14.64 / 5.46

NE52VNJM / NE52YDJM

HP switch

Outdoor

93 / 41

Thermal relay

Discharge thermo, HP switch

Anti-phase protector

Propeller (direct) o 1

0.07

50(1,770)

855(33-5/8)

82(181)

3.7(8.2)

15.88(5/8)

Heating

3.52

15.43 / 5.76

2.5

49

51

Cooling

3-ph, 50Hz, 380-415V(4wires)

3.36

5.49

Munsell 5Y 8/1

Linear Expansion Valve

Hermetic

Line start

Anti-phase protector, Thermal relay

Discharge thermo, HP switch

38

Plate fin coil

Reverse cycle

900(35-7/16)

330+20(13+3/4)

R407C

1.6 (Ester)MEL56

9.52(3/8)

Flared

Flared

Max. 50m

Max. 50m

Heating

3.54

5.79

45

NE56YDJM

2.7

Propeller (direct) o 2

0.07+0.07

85(3,000)

51

53

1,260(49-5/8)

96(212)

4.0(8.8)

19.05(3/4)

7

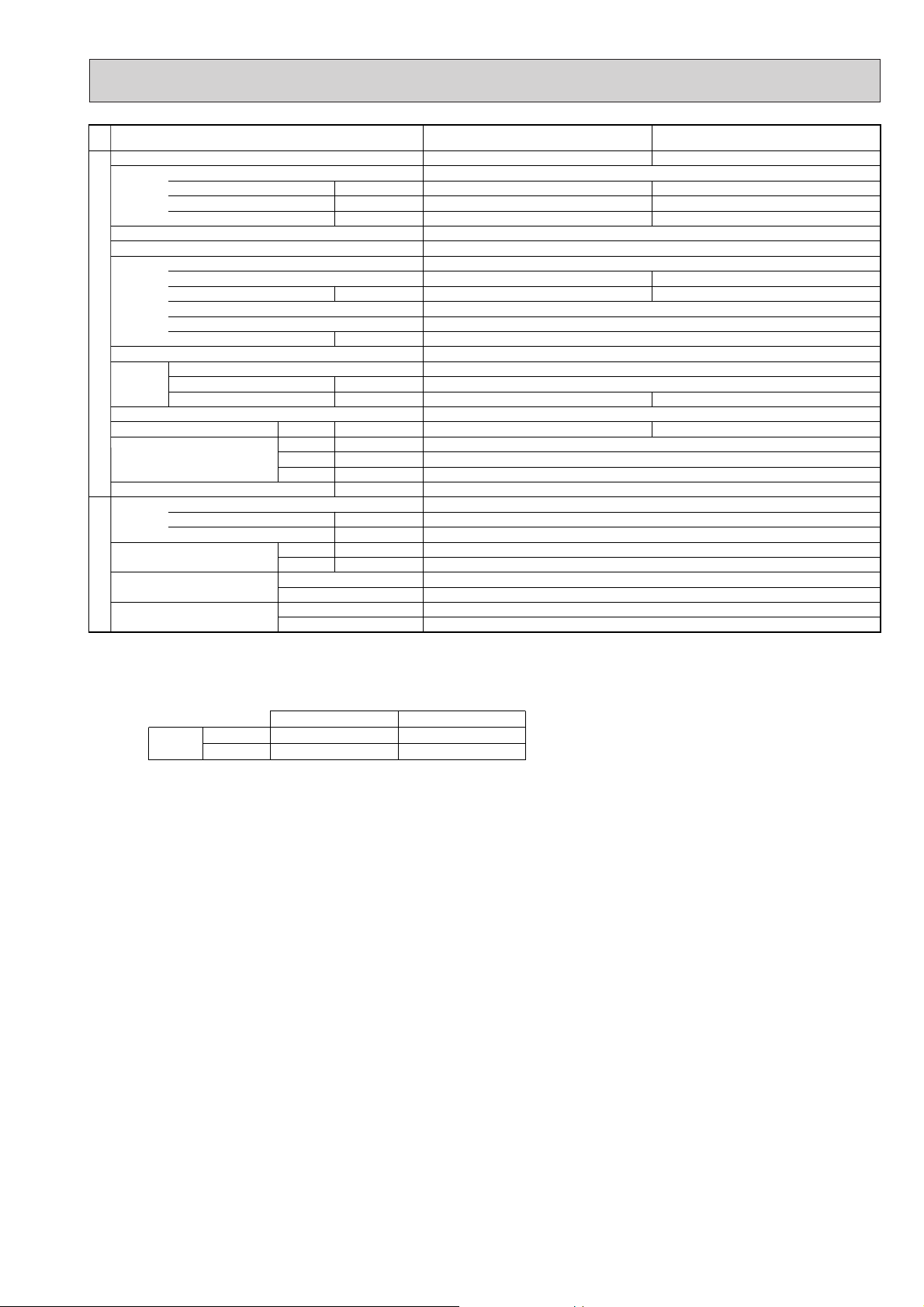

Service Ref.

Function

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

Heat exchanger

Fan Fan(drive) o No.

OUTDOOR UNIT

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor &

REFRIGERANT PIPING

outdoor unit

Notes1.Rating Conditions (ISO T1)

2. Guaranteed operating range

3. Above data based on indicated voltage

Input

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Crankcase heater

Fan motor output

Airflow

Cooling

Heating

W

D

H

Charge

Oil (Model)

Cooling :Indoor : D.B. 27˚C(80˚F), W.B. 19˚C (66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C (75˚F)

Heating :Indoor : D.B. 20˚C(68˚F) Outdoor : D.B. 7˚C(45˚F), W.B. 6˚C (43˚F)

Refrigerant piping length (one way) : 5m (16ft)

Cooling

Heating

Upper limit

Lower limit

Upper limit

Lower limit

Indoor Unit 1 phase 240V 50Hz

Outdoor Unit 3 phase 415V 50Hz

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Indoor

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

D.B. 28˚C

D.B. 17˚C

K

/min(CFM

dB(A)

dB(A)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

mm(in.)

mm(in.)

kW

A

A

kW

Internal thermostat, Anti-phase protector, thermal relay, HP switch, Discharge thermo, LP switch

W

kW

)

L

Outdoor

D.B. 46˚C

D.B. -5˚C

D.B. 24˚C, W.B. 18˚C

D.B. -11˚C, W.B. -12˚C

PUH-P5YGA PUH-P6YGA

Cooling

5.25

8.39

HE86YAA

95(3,360)

Heating

3-ph, 50Hz, 380-415V(4wires)

5.47

8.74

79

Linear Expansion Valve

4.3

53

55

Cooling

10.17

Munsell 5Y 8/1

Hermetic

Line start

38

Plate fin coil

Propeller (direct) o 2

0.075+0.075

Reverse cycle

1,050(41-5/16)

330+20(13+3/4)

1,260(49-5/8)

122(269)

R407C

5.8(12.8)

2.0 (Ester)MEL32

9.52(3/8)

19.05(3/4)

Flared

Flared

Max. 50m

Max. 50m

6.36

Heating

6.43

10.28

84

HE101YAA

5.1

100(3,530)

55

57

8

2. Cooling only type

Service Ref.

Function

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

OUTDOOR UNIT

Heat exchanger

Fan Fan(drive) o No.

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor &

REFRIGERANT PIPING

outdoor unit

Notes1.Rating Conditions (ISO T1)

Input

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Crankcase heater

Fan motor output

Airflow

Cooling

W

D

H

Charge

Oil (Model)

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Cooling :Indoor : 27˚C(80˚F)DB. 19˚C (66˚F)WB Outdoor : 35˚C(95˚F)DB. 24˚C (75˚F)WB

Refrigerant piping length (one way) : 5m (16ft)

kW

kW

kW

K

/min(CFM

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

mm(in.)

mm(in.)

A

A

W

)

dB

L

PU-P1.6VGA PU-P2VGA PU-P2.5VGA

Cooling

1.71

7.66

36

RE277VHSM

1.3

Inner thermostat, HP switch, Discharge thermo

30

45(1,590)

46

650(25-5/8)

55(121)

2.6(5.7)

0.57 (Ester)MEL56

Max. 40m

Max. 40m

Cooling

Single, 50Hz, 220-240V

2.48

11.11

74

Munsell 5Y 8/1

Linear Expansion Valve

Hermetic

NE38VMJM

1.7

Line start

Plate fin coil

Propeller (direct) o 1

0.07

55(1,940)

—

900(35-7/16)

330+20(13+3/4)

855(33-5/8)

71(157)

R407C

3.1(6.8)

1.2 (Ester)MEL56

9.52(3/8)

15.88(5/8)

Flared

Flared

(1)

Cooling

2.63

11.78

77

NE41VMJM

1.9

38

50(1,770)

48

82(181)

3.3(7.3)

Max. 50m

Max. 50m

2. Guaranteed operating range

Indoor

Cooling

3. Above data based on indicated voltage

Upper limit

Lower limit

Indoor Unit 1 phase 240V 50Hz

Outdoor Unit 1 phase 240V 50Hz

D.B. 35˚C, W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

Outdoor

D.B.

46˚C

D.B.

-5˚C

9

Service Ref.

Function

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

OUTDOOR UNIT

Heat exchanger

Fan Fan(drive) o No.

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor &

REFRIGERANT PIPING

outdoor unit

Notes1.Rating Conditions (ISO T1)

Input

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Crankcase heater

Fan motor output

Airflow

Cooling

W

D

H

Charge

Oil (Model)

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Cooling :Indoor : D.B. 27˚C(80˚F), W.B. 19˚C(66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C(75˚F)

Refrigerant piping length (one way) : 5m (16ft)

kW

kW

kW

K

/min(CFM

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

mm(in.)

mm(in.)

A

A

W

dB

L

Single, 50Hz, 220-240V/3-ph, 50Hz, 380-415V(4wires)

Internal thermostat

Discharge thermo

)

PU-P3VGA / YGA PU-P4YGA

Cooling

3.34

14.64/5.46

93/41

NE52VNJM / NE52YDJM

HP switch

Propeller (direct) o 1

2.5

Thermal relay

Discharge thermo, HP switch

Anti-phase protector

0.07

50(1,770)

49

855(33-5/8)

82(181)

3.7(8.2)

15.88(5/8)

3-ph, 50Hz, 380-415V(4wires)

Cooling

3.36

5.49

45

Munsell 5Y 8/1

Linear Expansion Valve

Hermetic

NE56YDJM

2.7

Line start

Anti-phase protector, thermal relay

Discharge thermo, HP switch

38

Plate fin coil

Propeller (direct) o 2

0.07+0.07

85(3,000)

—

51

900(35-7/16)

330+20(13+3/4)

1,260(49-5/8)

96(212)

R407C

4.0(8.8)

1.6 (Ester)MEL56

9.52(3/8)

19.05(3/4)

Flared

Flared

Max. 50m

Max. 50m

2. Guaranteed operating range

Indoor

Cooling

3. Above data based on indicated voltage

Upper limit

Lower limit

Indoor Unit 1 phase 240V 50Hz

Outdoor Unit 1 phase 240V 50Hz/3 phase 415V 50Hz

D.B. 35˚C , W.B. 22.5˚C

D.B. 19˚C, W.B. 15˚C

Outdoor

D.B. 46˚C

D.B. -5˚C

10

Service Ref.

Function

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

OUTDOOR UNIT

Heat exchanger

Fan Fan(drive) o No.

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor &

REFRIGERANT PIPING

outdoor unit

Notes1.Rating Conditions (ISO T1)

Input

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Crankcase heater

Fan motor output

Airflow

Cooling

W

D

H

Charge

Oil (Model)

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

Cooling :Indoor : D.B. 27˚C(80˚F), W.B. 19˚C(66˚F) Outdoor : D.B. 35˚C(95˚F), W.B. 24˚C(75˚F)

Refrigerant piping length (one way) : 5m (16ft)

kW

kW

kW

K

/min(CFM

dB

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

kg(lbs)

mm(in.)

mm(in.)

A

A

Internal thermostat, Anti-phase protector, thermal relay, HP switch, Discharge thermo, LP switch

W

)

L

PU-P5YGA PU-P6YGA

Cooling

3-ph, 50Hz, 380-415V(4wires)

5.25

8.39

79

HE86YAA

4.3

95(3,360)

53

Cooling

6.36

10.17

84

Munsell 5Y 8/1

Linear Expansion Valve

Hermetic

HE101YAA

5.1

Line start

38

Plate fin coil

Propeller (direct) o 2

0.075+0.075

100(3,530)

—

55

1,050(41-5/16)

330+20(13+3/4)

1,260(49-5/8)

122(269)

R407C

5.8(12.8)

2.0(Ester)MEL32

9.52(3/8)

19.05(3/4)

Flared

Flared

Max. 50m

Max. 50m

2. Guaranteed operating range

Indoor

Cooling

3. Above data based on indicated voltage

Upper limit

Lower limit

Indoor Unit 1 phase 240V 50Hz

Outdoor Unit 3 phase 415V 50Hz

D.B. 35˚C , W.B.22.5˚C

D.B. 19˚C, W.B. 15˚C

Outdoor

D.B.

46˚C

D.B.

-5˚C

11

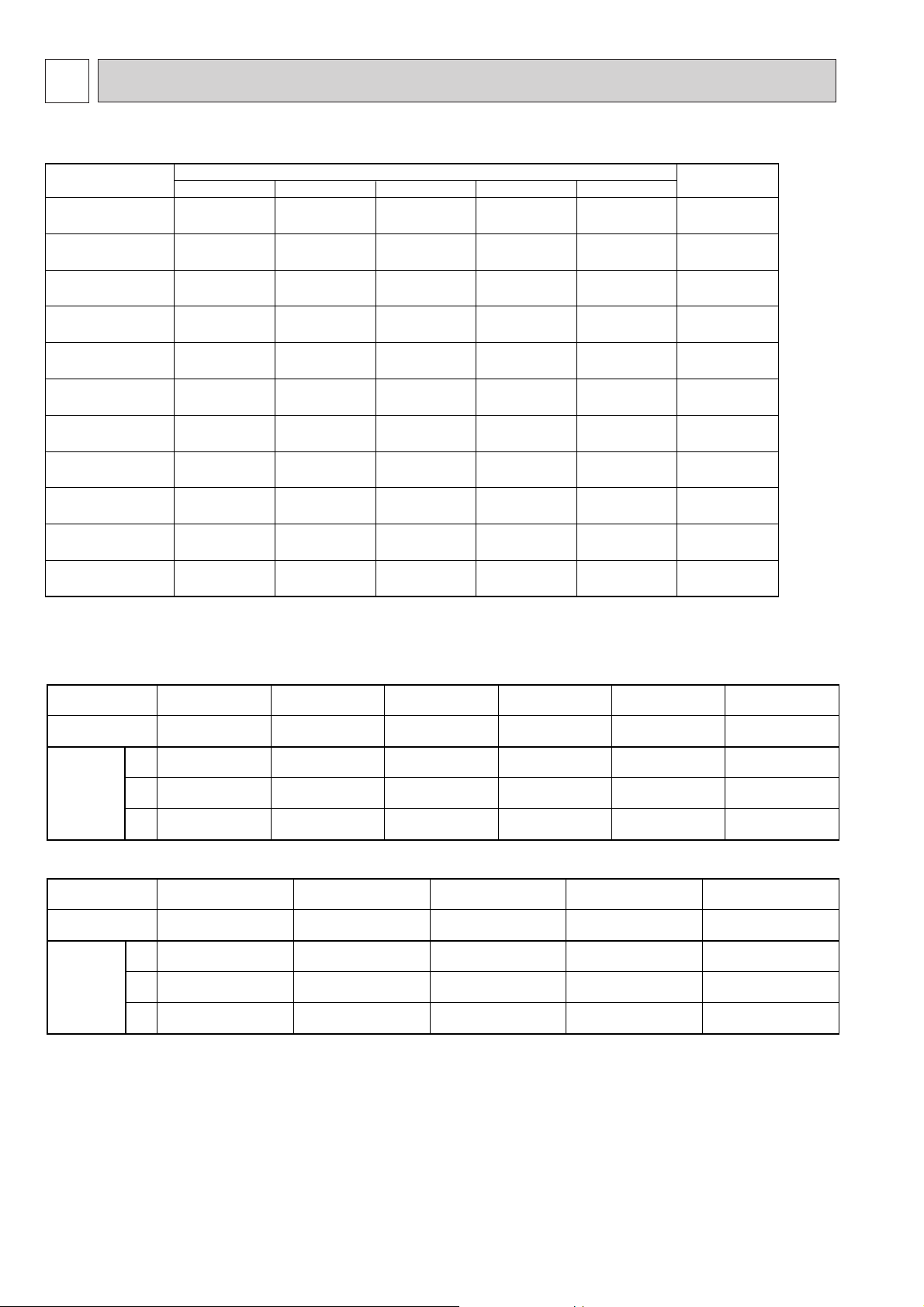

5 DATA

PUH-P1.6VGA

PU-P1.6VGA

PUH-P1.6YGA

PUH-P2VGA

PU-P2VGA

PUH-P2YGA

PUH-P2.5VGA(1)

PU-P2.5VGA(1)

PUH-P2.5YGA(1)

PUH-P3VGA

PU-P3VGA

PUH-P3YGA

PU-P3YGA

PUH-P4YGA

PU-P4YGA

PUH-P5YGA

PU-P5YGA

PUH-P6YGA

PU-P6YGA

Piping length (one way)

10m 20m 30m

40m

50m

Factory

charged

2.4

2.4

2.5

2.5

2.7

2.7

2.9

2.9

3.4

5.1

5.1

2.5

2.5

2.6

2.6

2.8

2.8

3.1

3.1

3.7

5.4

5.4

2.6

2.6

3.1

3.1

3.3

3.3

3.7

3.7

4.0

5.8

5.8

3.0

3.0

3.7

3.7

3.9

3.9

4.3

4.3

4.7

6.5

6.5

—

—

—

—

4.5

4.5

4.9

4.9

5.4

7.2

7.2

2.6

2.6

3.1

3.1

3.3

3.3

3.7

3.7

4.0

5.8

5.8

Service Ref.

Compressor model

Winding

Resistance

( " )

U-V

(R-C)

U-W

(S-C)

W-V

U-V

(R-C)

U-W

(S-C)

W-V

RE277VHSM RE277YFKM

Unit

PUH-P1.6VGA

PU-P1.6VGA

PUH-P1.6YGA

PUH-P2VGA

PU-P2VGA

PUH-P2.5VGA

(1)

PU-P2.5VGA(1)

NE38VMJM NE41VMJM

1.80

3.00

—

10.8

10.8

10.8

5.21

5.21

5.21

NE38YEJM

PUH-P2YGA

5.00

5.00

5.00

NE41YEJM

PUH-P2.5YGA

(1)

0.85

2.15

—

0.79

2.19

—

Unit

Compressor model

Winding

Resistance

( " )

PUH-P5YGA

PU-P5YGA

PUH-P6YGA

PU-P6YGA

HE86YAA HE101YAA

2.40

2.40

2.40

PUH-P4YGA

PU-P4YGA

NE56YDJM

3.20

3.20

3.20

PUH-P3VGA

PU-P3VGA

NE52VNJM

0.64

1.67

—

PUH-P3YGA

PU-P3YGA

NE52YDJM

3.70

3.70

3.70

2.20

2.20

2.20

1. REFILLING REFRIGERANT CHARGE (R407C : kg)

2. COMPRESSOR TECHNICAL DATA

at 20˚C

at 20˚C

12

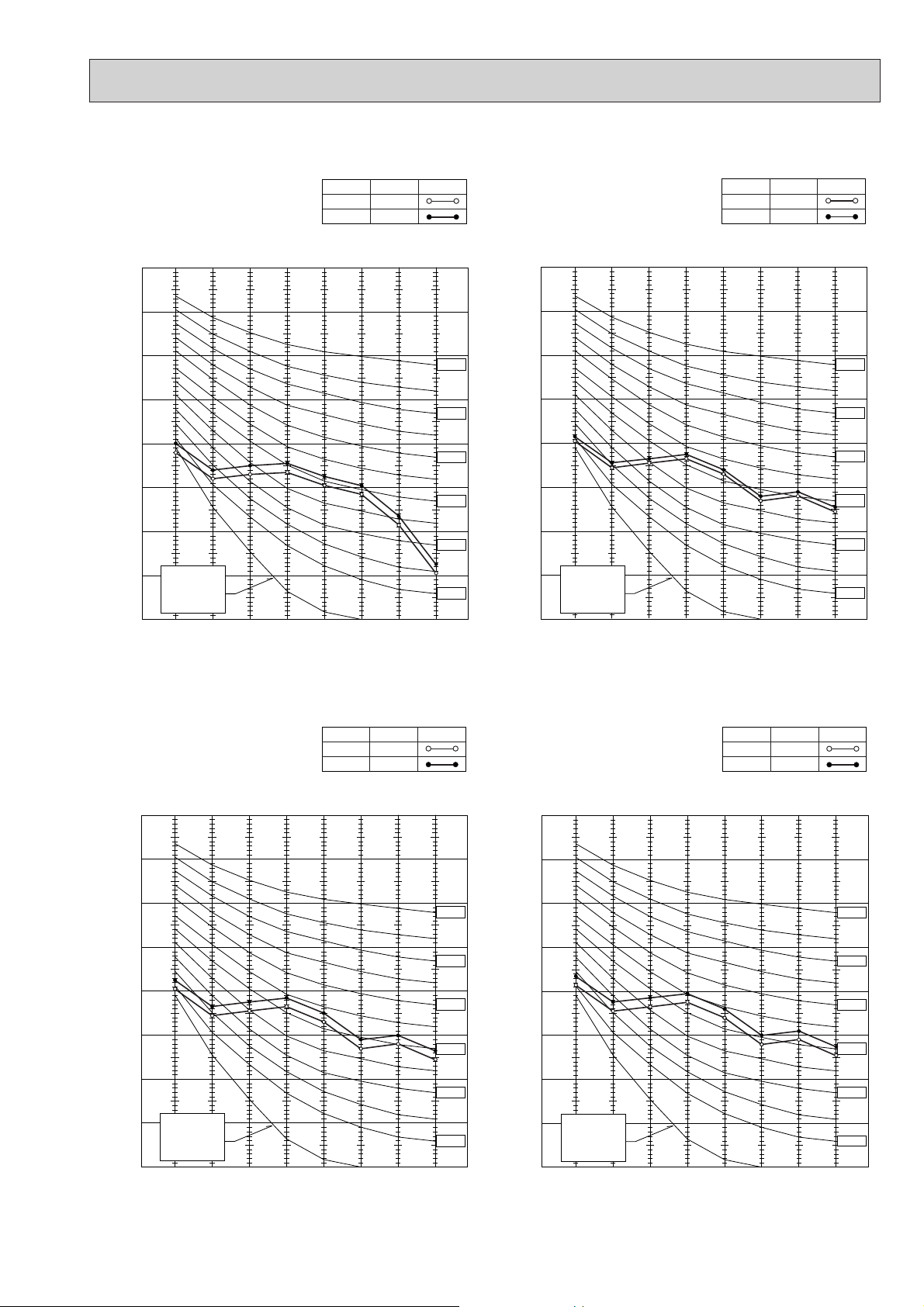

3. NOISE CRITERION CURVES

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROTIMATE

TERESHOLD OF

REARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

COOLING

NOTCH

HEATING

SPL(dB) LINE

PUH-P2VGA / YGA

PU-P2VGA

48

49

90

80

70

60

50

40

30

20

10

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

APPROTIMATE

TERESHOLD OF

REARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

COOLING

NOTCH

HEATING

SPL(dB) LINE

PUH-P2.5VGA(1) / YGA(1)

PU-P2.5VGA(1)

48

50

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROTIMATE

TERESHOLD OF

REARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

COOLING

NOTCH

HEATING

SPL(dB) LINE

49

51

PUH-P3VGA / YGA

PU-P3VGA / YGA

PUH-P1.6VGA / YGA

PU-P1.6VGA

90

80

NOTCH

COOLING

HEATING

SPL(dB)48LINE

46

70

60

50

40

30

APPROTIMATE

20

TERESHOLD OF

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

REARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

13

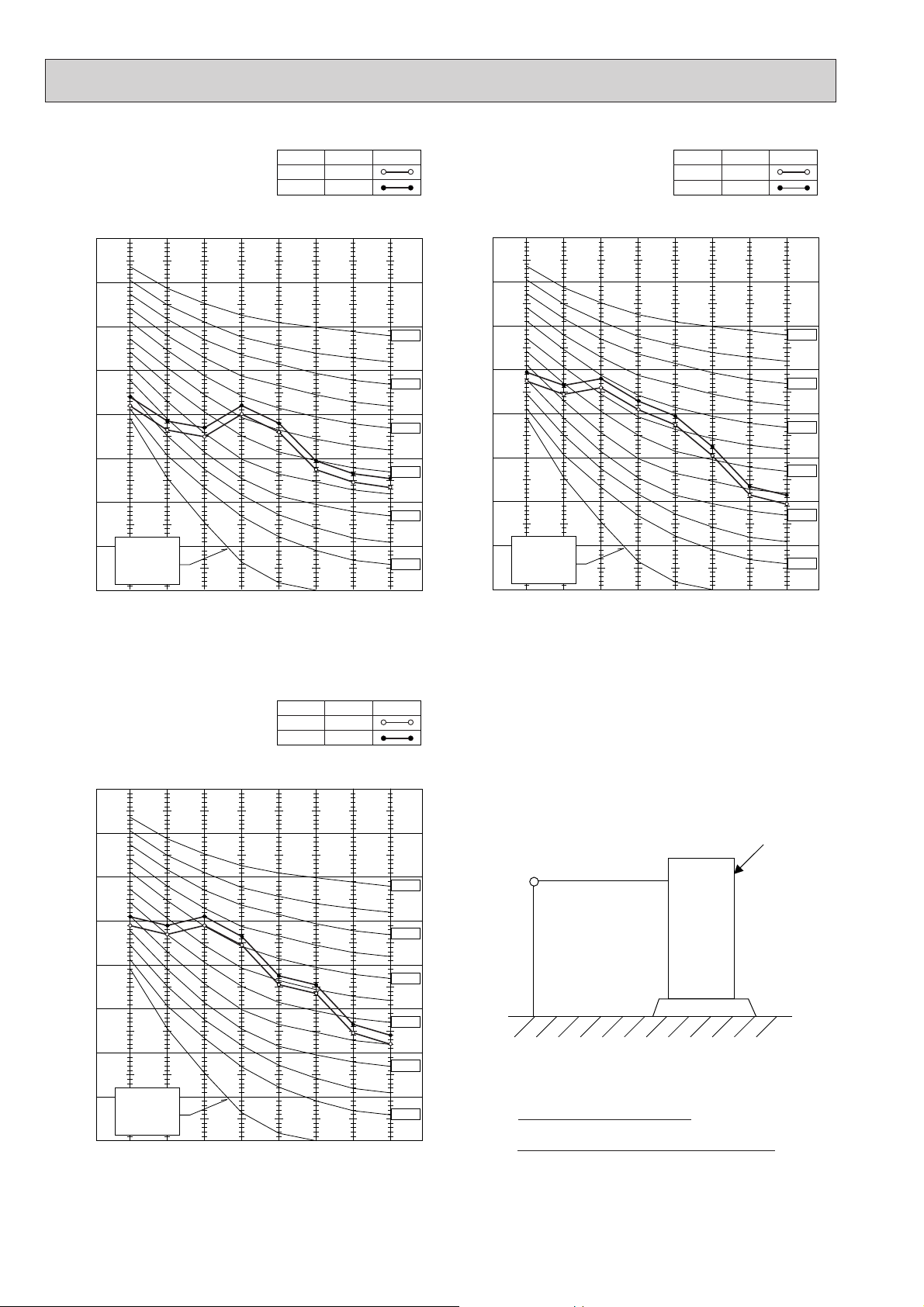

PUH-P4YGA

PU-P4YGA

NOTCH

COOLING

HEATING

SPL(dB) LINE

51

53

PUH-P5YGA

PU-P5YGA

NOTCH

COOLING

HEATING

SPL(dB) LINE

53

55

90

80

70

60

50

40

30

APPROTIMATE

20

TERESHOLD OF

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

REARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

90

80

70

60

50

40

30

APPROTIMATE

20

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

TERESHOLD OF

REARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

PUH-P6YGA

PU-P6YGA

90

80

70

60

50

40

30

APPROTIMATE

20

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

TERESHOLD OF

REARING FOR

CONTINUOUS

NOISE

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NOTCH

COOLING

HEATING

SPL(dB) LINE

55

57

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

UNIT

MICROPHONE

1m

1m

GROUND

Ambient temperature 27:

Test conditions are based on JIS Z8731

14

Loading...

Loading...