Mitsubishi PLK-E1010 Instruction Manual

MITSUBISHI

Industrial Sewing Machine

TECHNICAL MANUAL

MECHANICAL VERSION

Electronic Pattern Sewing Machine

Model PLK-E1010

A180E494P01

From the library of Superior Sewing Machine & Supply LLC • www.supsew.com

FOR YOUR SAFETY !

If you operate the sewing machine first time, please make sure to read the following

instructions for your safet y and proper oper ation.

In this technical manual, the notice CAUTION is mentioned at some paragraph to attract your

attention for the safety. Please keep it in mind whenever you work with the sewing machine.

CAUTION is used as the notice to warn a possible danger to cause a wound.

This technical manual explains the instructions how to operate and maintain the

sewing machine.

All information in this technical manual ar e subj ect to change without notice.

MITSUBISHI ELECTRIC CORPORATION

Reprinting the parts or all of this technical manual is not allowed without permission.

has all the copy rights on this technical manual.

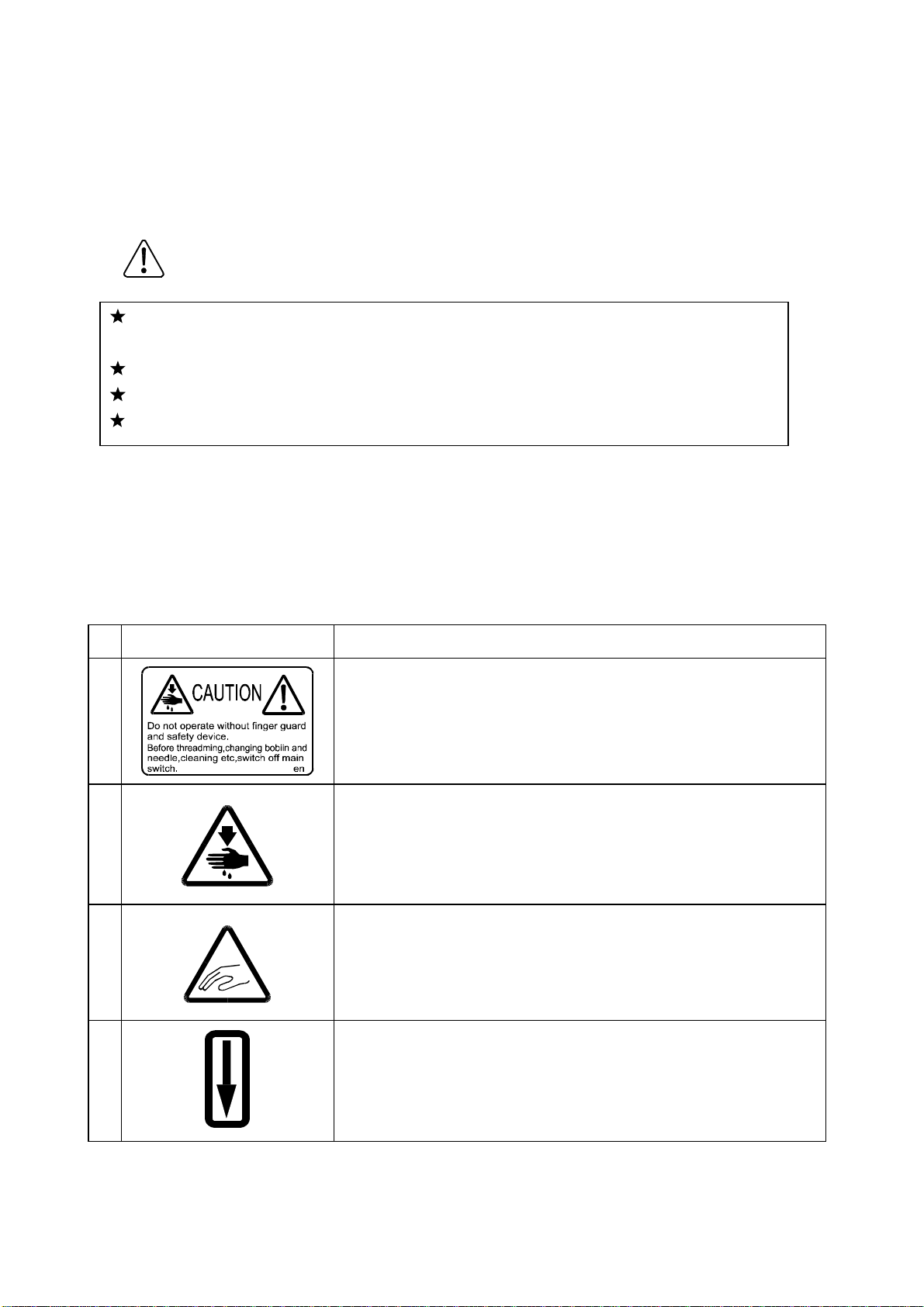

Explanations for the wa r ni ng signs

No Warning sign

1

Caution for sewing machine operation:

Warning to operate the sewing machine without safety

guards and to prohibit doing any operation except sewing

while the power is turned ON.

Meanings of warning sign

2

3

4

Caution for a wound on the fingers:

Warning to a possible danger to cause a wound on the

fingers under the specif ied oper at ion.

Caution for the fing er s to be caught in the machine:

Warning to a possible danger to be caught the fingers in the

machine under the specified operation.

Direction of pulley rotation:

Indicating the proper rotating direction of the sewing

machine pulley.

From the library of Superior Sewing Machine & Supply LLC • www.supsew.com

ENVIRONMENT STANDARD

For avoiding the sewing machine from the troubles, please do not operate the sewing

machine under the following conditions.

Caution

(1)

(a) During operating : The atmosphere temperature should not exceeded more 35ºC

(b) During transportation : The atmosphere temperature should not exceeded more

(2)

(a) In the atmosphere filled with dust or cor r osive g as.

(b) In the atmosphere filled with f lam mable or explosive gas.

(3)

(a) In the place where the power fluctuation exceeds more or less 10 % of the fixed

(b) In the place where the power source can not supply enough voltage to keep the

(4)

Temperature and humidity

(95ºF) or less 5ºC(41ºF).

55ºC (131ºF) or less -10ºC (18ºF) .

The relative humidity in the atmosphere should not exceeded more 85% or less 45%.

Atmosphere for the machine oper at ion

Power source voltage

power voltage.

motor running.

Power source voltage

(a) In the place where the power fluctuation exceeds more or less 10 % of the fixed

power voltage.

(b) In the place where the power source can not supply enough voltage to keep the

motor running.

(5)

Noise

(a) In the place near a high frequency tr ansm it t er or a high frequency welder.

(b) In the place filled with strong electrom agnetic radiation or magnetic field.

·

·

·

·

·

From the library of Superior Sewing Machine & Supply LLC • www.supsew.com

CONTENTS

1. STRUCTURE OF THE MACHINE ······································································

2. SPECIFICATION ··································································································

3. INSTALLATION ···································································································

1

2

3

3-1. Preparation of the table ··················································································

3-2. Preparation for the steel stand ········································································ 3

3-3. Installation of the motor ··················································································

3-4. Installation of the control box ·········································································· 3

3-5. Connection of the operation panel ·································································· 3

3-6. Installation of the power switch ······································································· 4

3-7. Connection of the foot switch ········································································· 4

3-8. Installation of the oil pan ················································································· 5

3-9. Installation of the sewing machine head ·························································

3-10. Putting across the V-belt ··············································································· 6

3-11. Connection of the electric cables ··································································

3-12. Installation of the belt cover ········································································· 8

3-13. Installation of the thread stand ······································································ 9

3-14. Functioning the work holder pedal ································································ 9

4. LUBRICATION ····································································································

3

3

5

7

10

5. PROPER OPERATION ······················································································

5-1. Loading the system software to the control box ············································· 11

5-2. Installation of the needle ················································································· 11

5-3 Threading the upper thread ············································································· 12

5-4. Winding the bobbin thread ············································································· 12

5-5. Setting the bobbin ··························································································· 14

5-6. Setting the bobbin case ·················································································· 14

6. PROPER SEWING ·······························································································

6-1. Operation of the halt switch ············································································

6-2. The sewing operation ····················································································· 16

6-3. Adjustment of the thread tension ···································································· 17

11

15

15

·

·

·

·

·

·

·

·

·

From the library of Superior Sewing Machine & Supply LLC • www.supsew.com

7. ST ANDARD ADJUSTMENT ···············································································

7-1. Adjustment of the needle bar position ····························································· 19

7-2. Adjustment of the position between the needle and the shuttle hook ·············· 20

7-3. Adjustment of the clearance between the shuttle hook and the needle ··········

7-4. Adjustment of the clearance between the driver and the needle ····················· 21

7-5. Adjustment of the thread guide ······································································· 22

7-6. Adjustment of the presser foot ········································································ 22

7-6-1. Adjustment of the presser foot position ················································

7-6-2. Adjustment of the presser foot lift during the sewing ····························

7-6-3. Adjustment of the presser foot timing ··················································· 25

7-7. Adjustment of the wiper ·················································································· 26

7-8. Adjustment of the bobbin winder ····································································· 27

7-9. Adjustment of the work holder ········································································

7-10. Adjustment of the trimmer cam follower ························································ 28

7-11. Adjustment of the position for movable knife point ········································ 28

7-12. Adjustment of the fixed knife position ···························································

7-13. Adjustment of the thread take up spring stroke ············································

7-14. Adjustment of the thread take up spring tension ··········································· 29

7-15. Adjustment of the thread tail after the trimming ············································

7-16. Cancellation of the trimming function ···························································· 30

7-17. Adjustment of the upper thread tension ························································ 30

7-18. Adjustment of the synchronizer ····································································· 31

7-19. Adjustment of the mechanical home position ················································ 32

7-19-1. Shifting the mechanical home position X direction ······························ 32

7-19-2. Shifting the mechanical home position Y direction ······························ 33

7-20. Adjustment of the X-Y contact pressure ······················································· 34

19

21

22

25

27

29

29

30

7-21. Adjustment of the X-Y timing belt tension ····················································· 34

7-21-1. Adjustment of the X timing belt tension ··············································· 34

7-21-1. Adjustment of the Y timing belt tension ··············································· 35

7-22. Adjustment of the V belt tension ··································································· 35

8. MAINTENANCE ·································································································

8-1. Cleaning ·········································································································

8-2. Disposing of oil waste ····················································································· 36

9. BAD SEWING CONDITION & ITS CAUSE AND REMEDY ···························

APPENDIX ··················································································································

Ref.1. Table cut out drawin g ···················································································· 41

Ref.2. Table & stand assembly ················································································ 41

Ref.3. St and components drawin gs ········································································

36

36

37

40

42

From the library of Superior Sewing Machine & Supply LLC • www.supsew.com

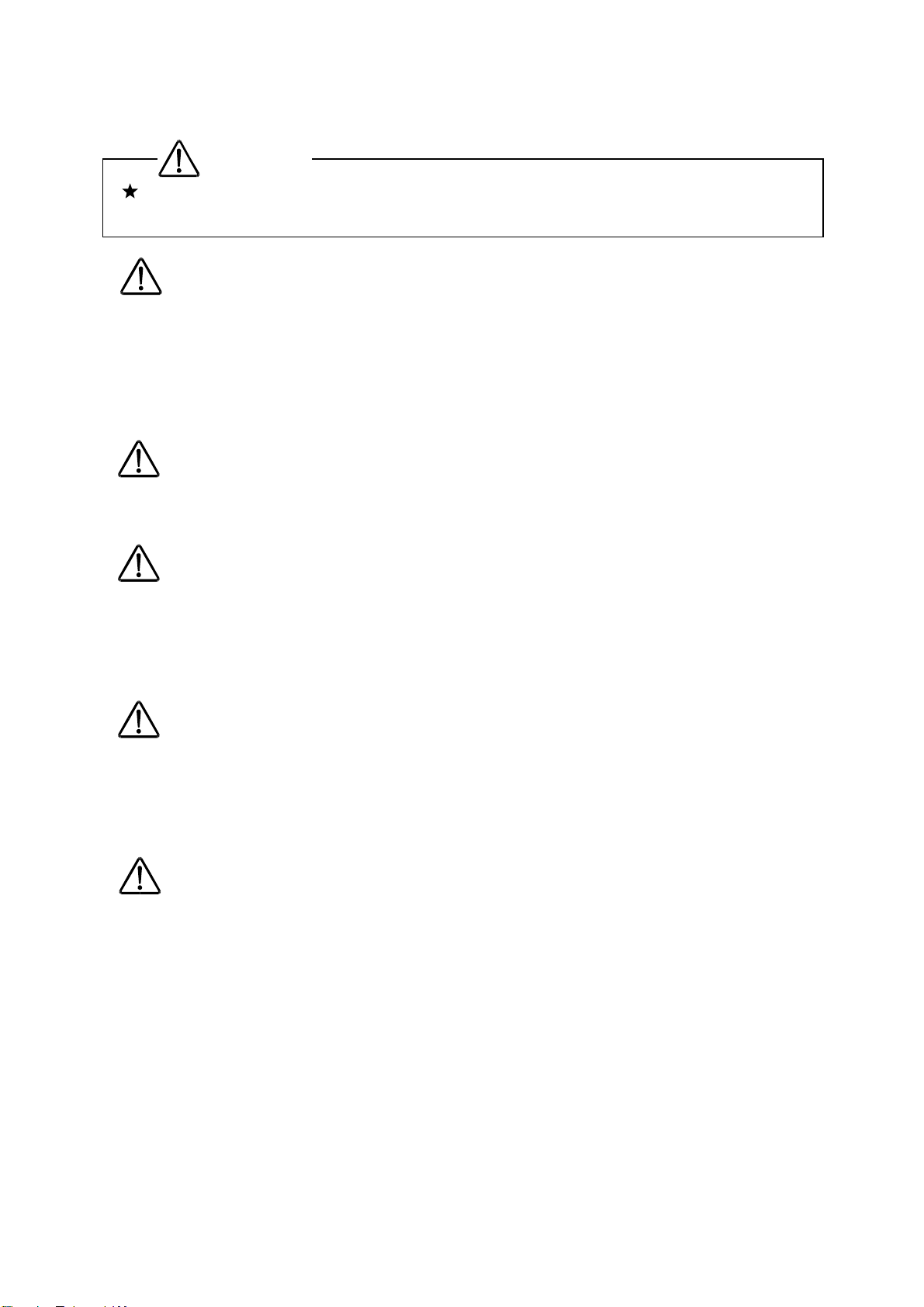

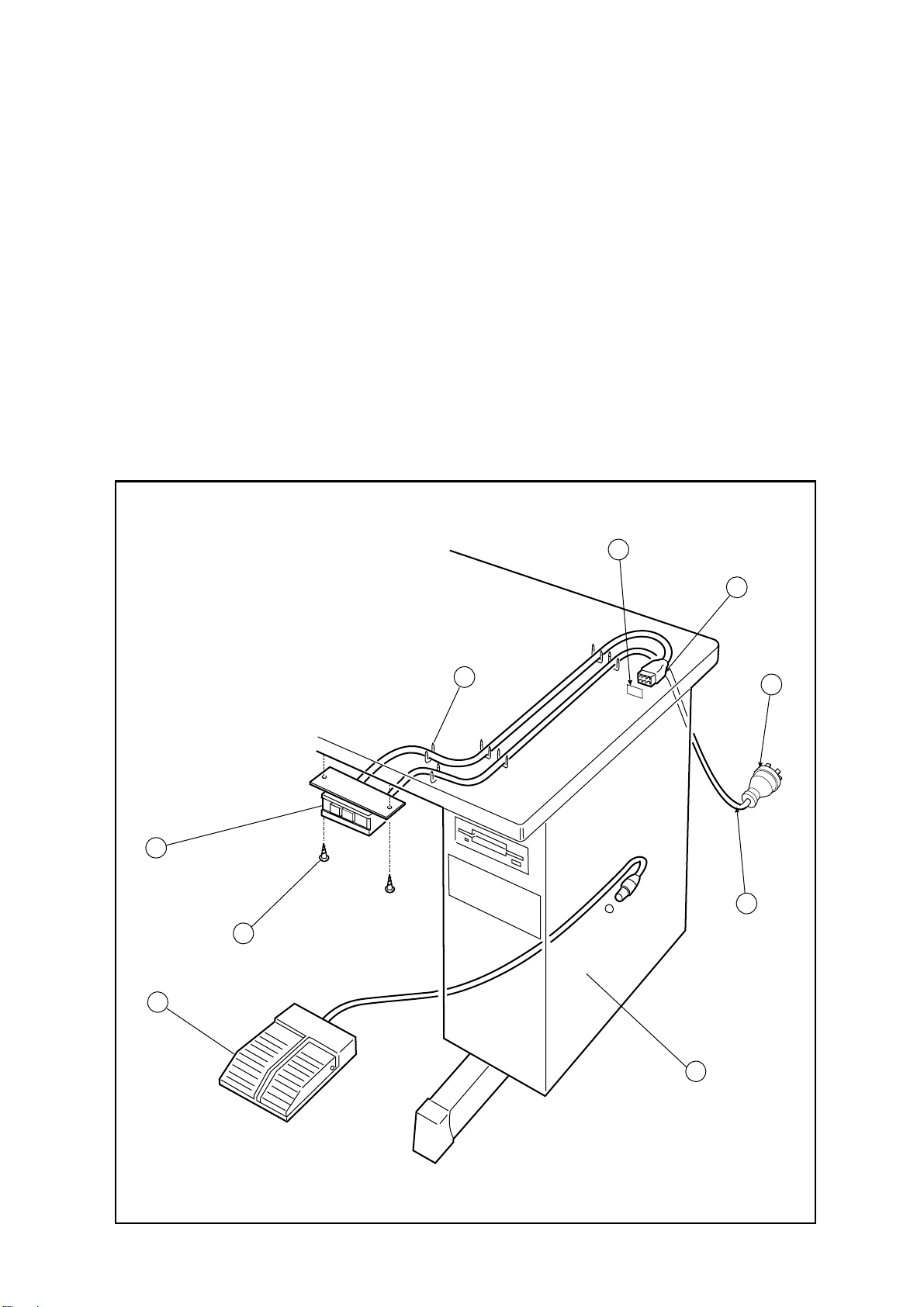

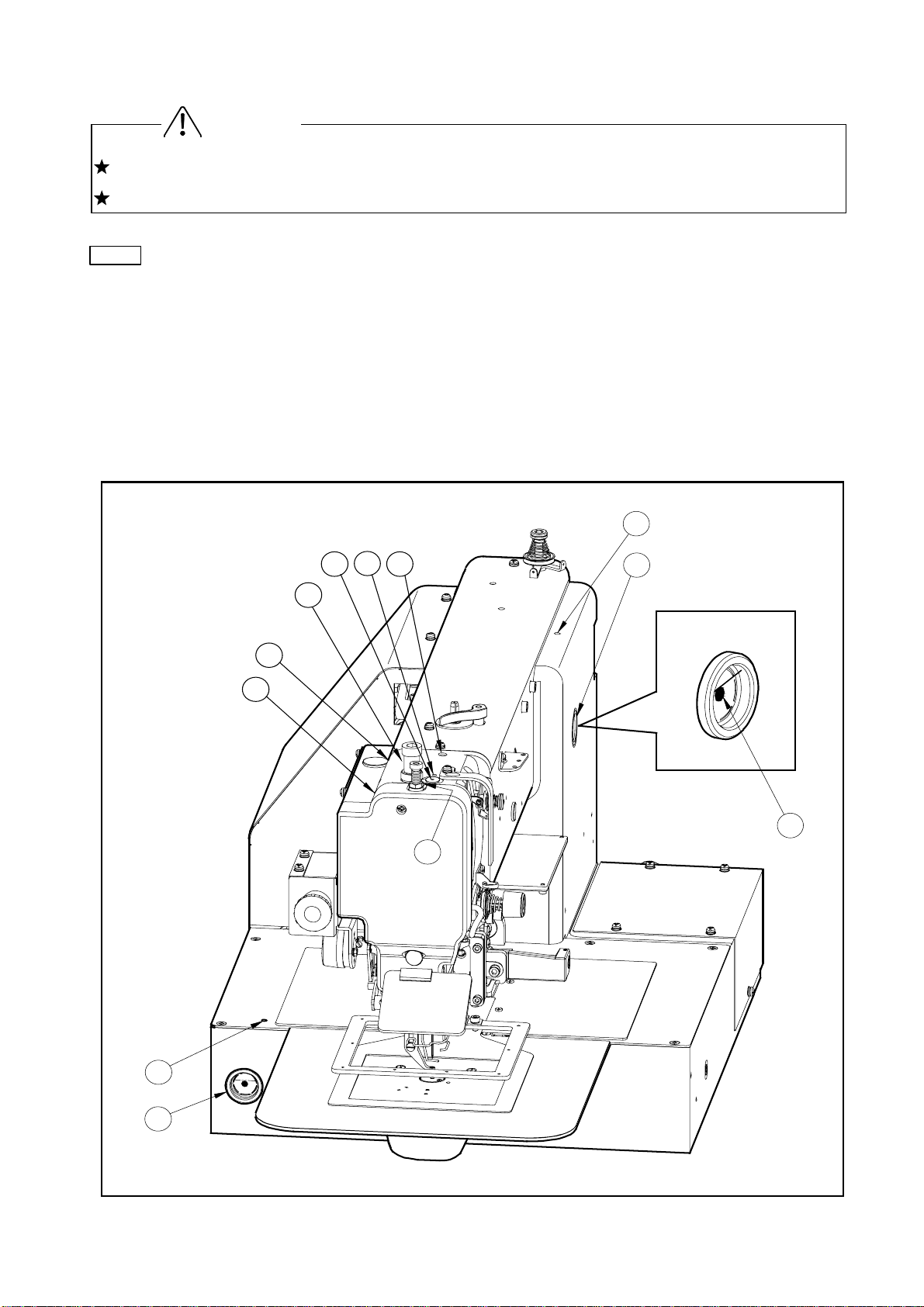

1. STRUCTURE OF THE SEWING MACHINE

PLK-E1010 electronic pattern sewing machine is constructed with the following main parts.

1

5

2

3

4

9

8

7

6

1

Sewing machine head 2Thread stand

6

Work holder foot switch 7 Start foot switch

*Limi-servo motor

3Operation Panel

8Work holder pedal 9Steel stand

1

4Control Unit

5Halt switch

From the library of Superior Sewing Machine & Supply LLC • www.supsew.com

2. SPECIFICATION

(1) Specification of mechanism

Sewing area : X-Direction (left/ right) Y-Direction (fore/backward)

: 100mm 100mm

Maximum sewing speed : 2500 rpm

Sewing speed : 10 steps variable from 200 to 2500 rpm

Stitch length : 0.1 to 12.7 mm

(Adjustable from 0.1mm to 12.7mm by 0.1mm resolution)

Stitch type : Single needle lock stitch

Needle bar stroke : 41.2 mm

Thread take up lever stroke : 68 mm

Class of needle : DP X 17 # 16 (the standard specification)

Wiper system : Back to forward wiping system (the standard specification)

Left to right wiping system (t he optional specification)

*1

Presser foot lift

Presser foot stroke

Work holder lift

: 15 mm (18mm max.)

*2

: Variable from 4mm to 10mm ( 4m m is standard)

*2

: 25 mm

Hook : Large size shuttle hook

Bobbin case : With non racing spring

Bobbin : Large size aluminum bobbin

Thread trimmer system Horizontal engagement with fixed knife and movable knife

Lubrication system :

Manual oiling and replenishment with the oil braids from the oil

tanks

Lubrication oil : White machining oil

X-Y drive system : Stepping motor and timing belt drive

Intermittent or continuous feeding

Machine dimension : 1,200mm(W) x 565mm(L) x 1,220mm(H)

Weight : TOTAL 143Kg

Type of controller : PLK-E-CU-20

Steel stand : T-shape steel stand for the standing or the sitting operation

(2) Specification of main motor

Type of motor : XL- 554- 20

2

Cautio

From the library of Superior Sewing Machine & Supply LLC • www.supsew.com

3. INSTALLATION

The machine should be installed by the specialists who have enough experience for the

sewing machine installations.

All the necessary electric wiring should be done by electric engineers who are qualified for the

electric wiring.

If any damage or fault is found on the machine at the installation, please do not operate until it

is repaired.

Please do not operate the sewing machine with excessive modifications from the standard

specification

3-1 Preparation of the table

If the table is not MITSUBISHI original, the thickness of the table is required to have 40mm

more.

And please refer to the cut out t able dr awing for your own preparation.

The cut out drawing is shown on the last page of this technical manual as APPENDIX drawing.

3-2 Preparation for the steel stand

If the steel stand is not MITSUBISHI original, please refer to the assembling drawing for your

own preparation.

The assembling drawing is shown on the last page of t his t echnical manual as Ref.1 to Ref.3.

If the steel stand is MITSUBISHI original, please assemble the steel stand with the assembling

instructions enclosed in the packing.

3-3 Installation of the motor

If the motor is purchased without assembling to the table, the motor has to be installed

underneath the table.

Please install the motor with the instructions explained in the paragraph [Installation of the

Motor] on the other [CONTROL UNI T] technical manual.

3-4 Installation of the control box

If the control box is purchased without assembling to the table, the control box has to be

installed underneath the table.

Please install the control box with the instruction in the paragraph [Installation of the control

n

box] on the other

CONTROL UNIT technical manual.

3-5 Connection of the operation panel

Please connect the operation panel with the instructions of Operation Panel manual enclosed in

the packing.

3

From the library of Superior Sewing Machine & Supply LLC • www.supsew.com

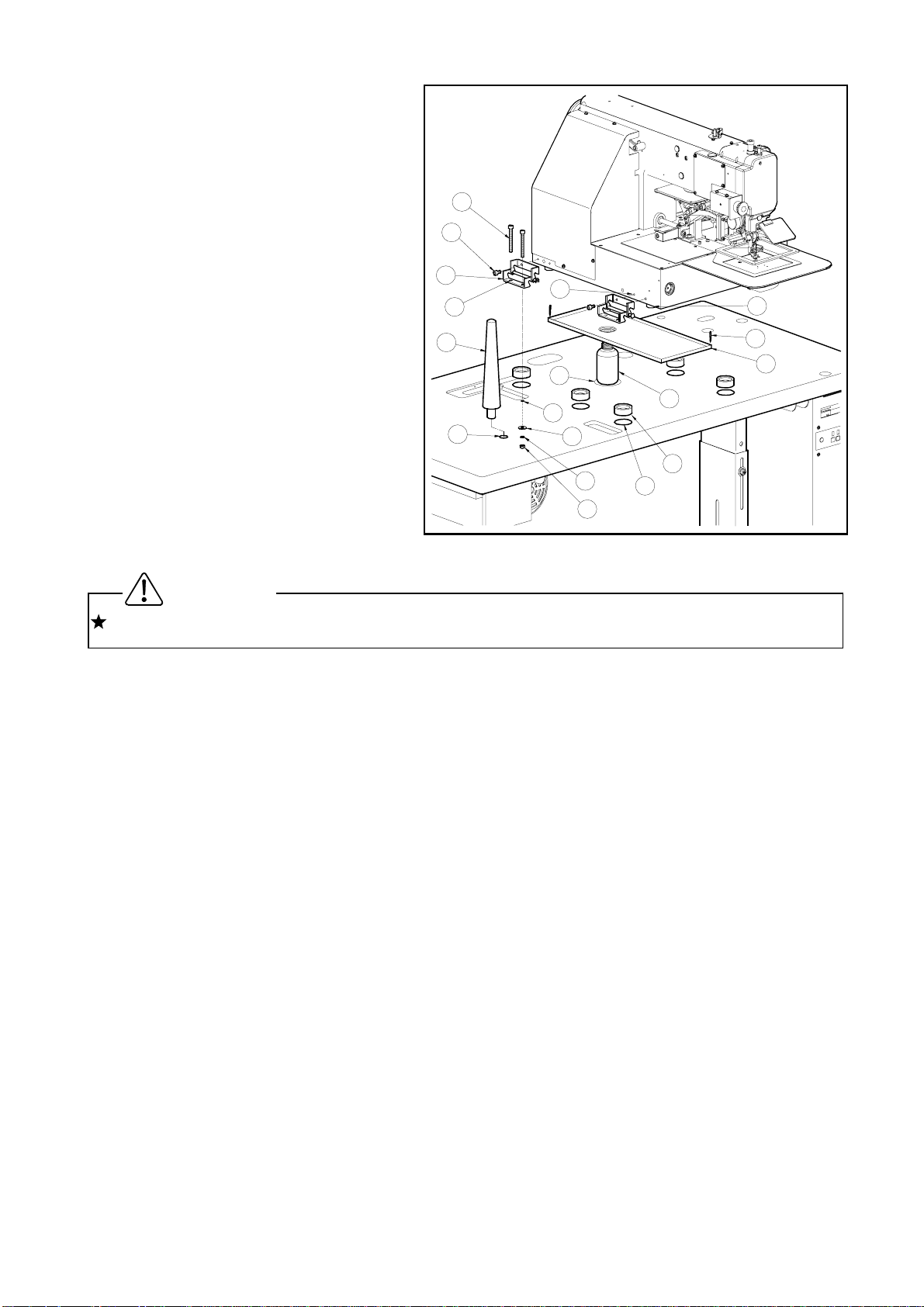

3-6 Installation of the power switch

If the power switch is purchased without assembling to the table, the power switch has to be

attached with the following procedure.

(1) Mount the power switch (NO.1) with the wood screw (NO.2) underneath the table as shown

on the figure.

(2) Fix the electric cords with the staples (NO.3) underneath the table.

(3) Hook up the connector (NO.4) of the power switch (NO.1) to the connector (NO.5) of the

control box (NO.9).

(4) Attach the power plug (NO.7) to another end of the power switch cord (NO.6).

3-7 Connection of the foot switch

Connect the foot switch (NO.8) t o t he cont rol box (NO.9)

The foot switch is enclosed in the accessory box.

5

4

3

1

2

7

6

8

4

9

From the library of Superior Sewing Machine & Supply LLC • www.supsew.com

3-8 Installation of the oil pan

(1) Assemble the oil pan (NO.1) and

oil bottle (NO.2), which are

enclosed in the accessory box.

(2) I nsert the oil bottle (NO.2) into the

tabletop cut-out hole (NO.3), which

14

11

has much shorter distance from

the bottle center to the fr ont.

(3) Install the oil pan (NO.1) parallel

with the table front edge.

(4) Fix the oil pan (NO.1) at its four

corners on the table top with four

staples (NO.4) en-closed in the

accessory box.

18

9

13

19

12

10

8

4

3

2

15

6

16

17

7

1

3-9 Installation of the sewing machine head

For the safety, please make sure t o carry the sewing machine head by more than two people.

(1) Make sure to hold the machine table with the caster stopper.

(2) Fit t he rubber cushion pads (NO.6) into the each hole (NO.7) on the tabletop. The rubber

Caution

cushion pads (NO.6) are enclosed in the accessory box.

(3) Put the sewing machine head on the table top and set the each leg (NO.8) to the each

rubber cushion pad (NO.6)

(4) Att ach two hinges (NO.9) temporarily, make the setting screw (NO.11) fastening with the

thread holes (NO.10) light, on the left side surface of the machine bed with the hexagonal

socket head set screws (NO.11).

(5) At this time, take notice that the E-shaped snap ring on the front side hinge must be come

to the backside, and E-shaped snap ring on the backside hinge must be come to the front.

(6) These parts are all enclosed in the accessory box.

(7) Fit the screw holes (NO.13) of the hinges (NO.9) to the bolt setting holes (NO.12) on the

table top then, pass the bolt (NO.14) through these holes and fasten the bolt (NO.14) to fix

the hinges (NO.9) with the flat washers (NO.15), the spring washers (NO.16) and the nuts

(NO.17).

(8) Fasten firmly hexagonal socket head set screws (NO.11), which set the hinges (NO.9)

temporarily at above procedure (4) then, fix the hinges (NO.9) perfect ly.

(9) Insert the headrest (NO.18) into t he hole ( NO .19) on the tabletop.

5

Cautio

From the library of Superior Sewing Machine & Supply LLC • www.supsew.com

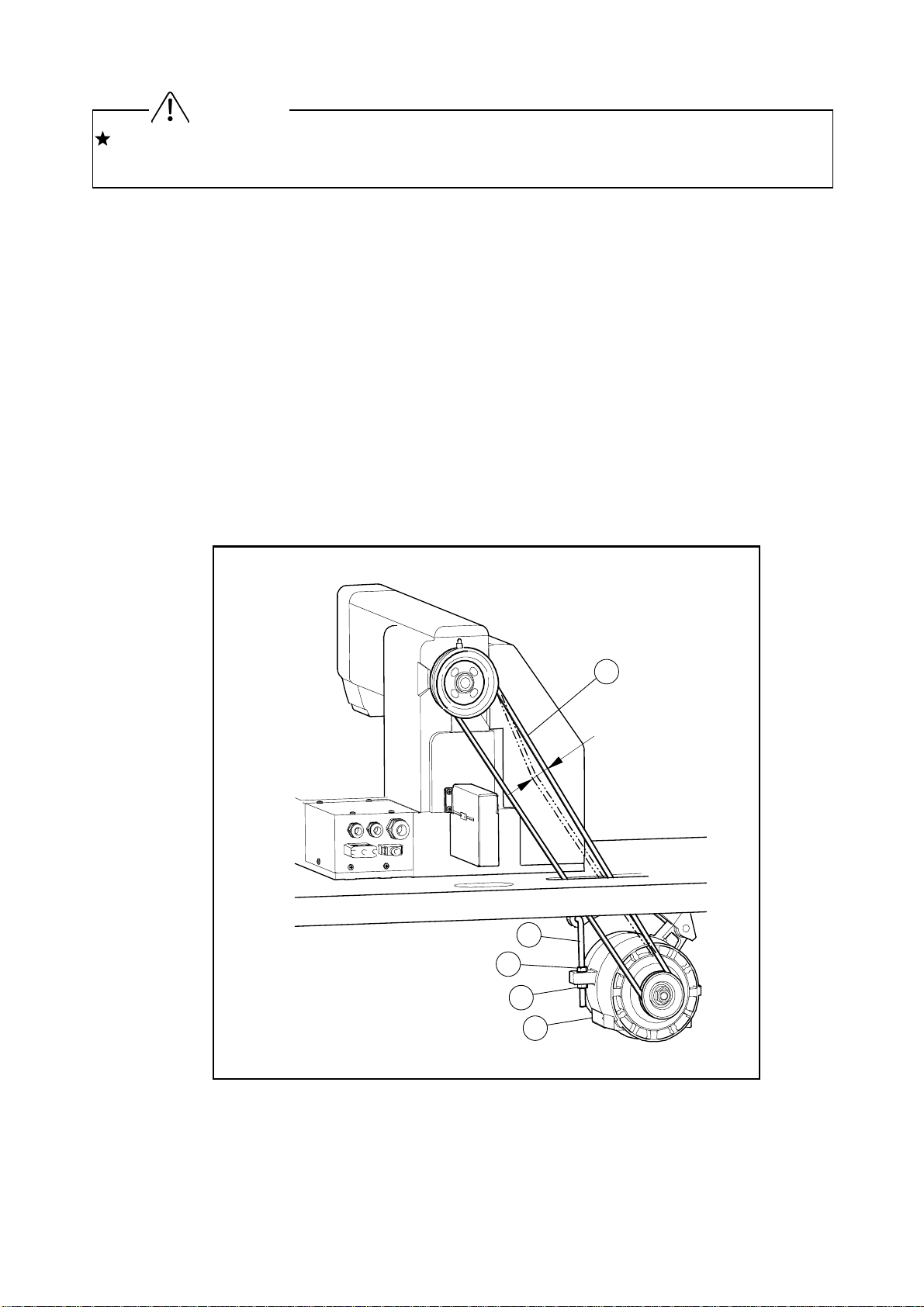

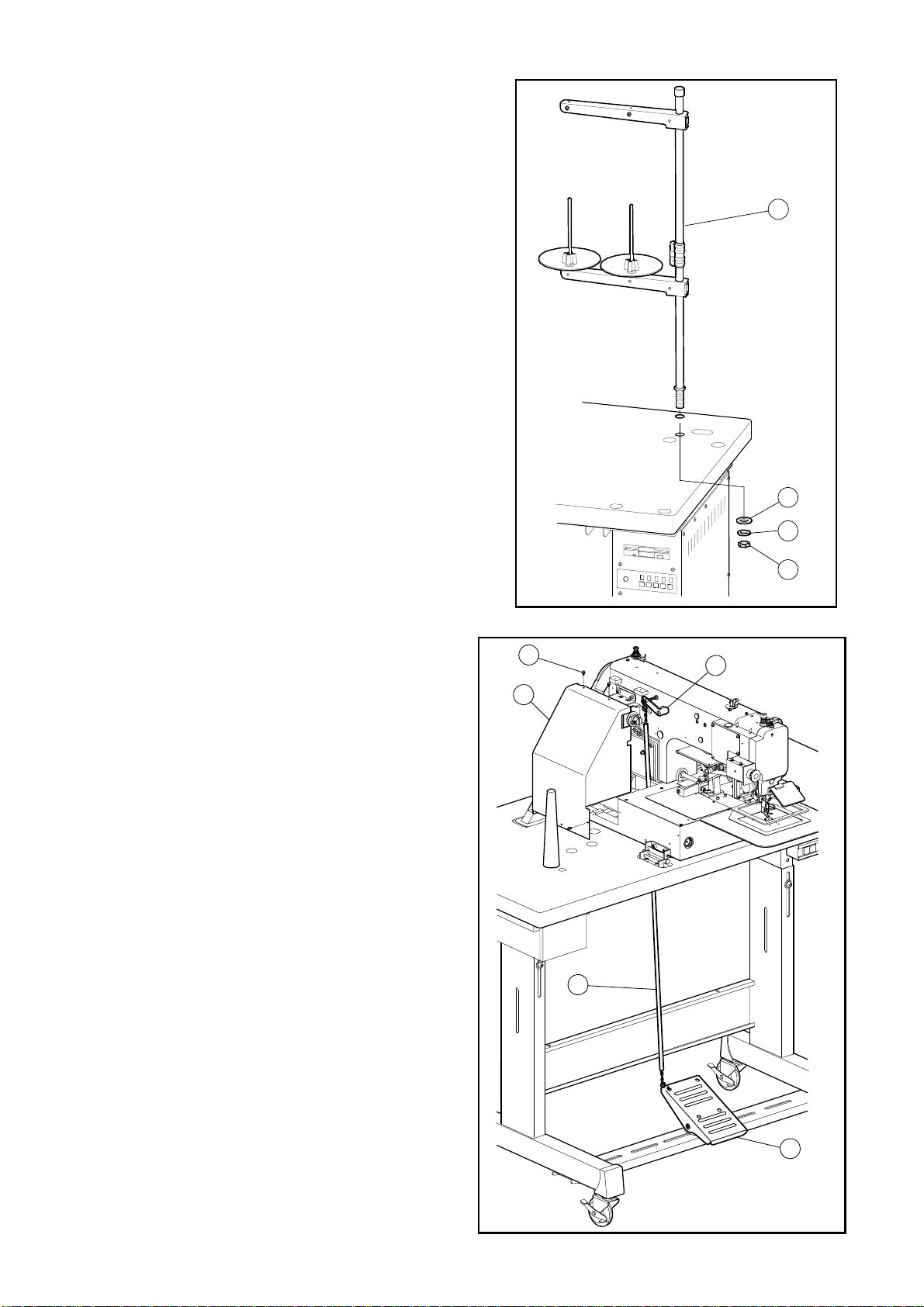

3-10 Putting across the V-belt

For the safety, when tilt or raise the sewing machine head, please make sure to hold the

sewing machine head with both hands by two people at least.

(1) Tilt the sewing machine head to the left, and hold it with the head r est.

(2) Put the V-belt (NO.4) across the sewing machine pulley and the motor pulley with passing it

through the slit on the tabletop.

(3) Raise the tilted sewing machine head to the original position.

(4) Push the center portion of V-belt by the f inger with the presser of about 1Kg.

If the V-belt tension is proper , it should be yielded about 10 mm.

If the V-belt tension is not pr oper, please adjust it as follows.

(5) Loosen two nut (No.2) on the motor .position adjust bolt (No.1).

(6) Fix the motor (No.5) position with putting the tension to the V belt by its weight and firstly,

tighten the upper nut (No.2) t hen secondly, t ighten the lower nut (No.2).

Please make sure to fasten t he nut s ( NO . 5) firmly after the adjust m ent .

(7) Put the motor pulley cover on the motor with the set screws.

n

10

4

mm

1

2

6

3

5

From the library of Superior Sewing Machine & Supply LLC • www.supsew.com

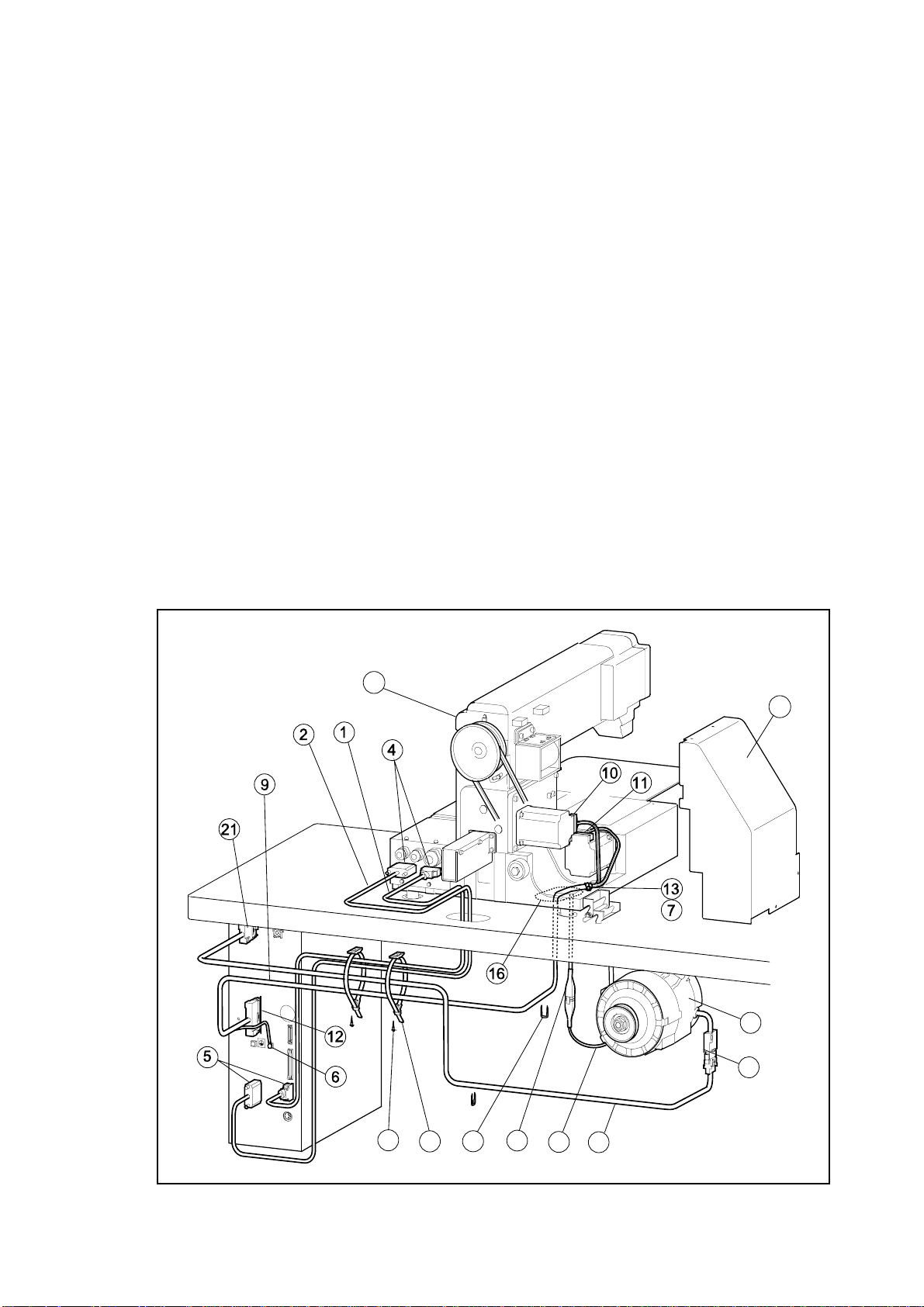

3-11 Connection of the electric cables

(1) Connect t he white color cable (NO.1) and the black color cable (NO.2) across the printed

circuit board unit connectors (NO.4) on the sewing machine head (NO.3) rear face and the

connectors (NO.5) on the control box. T hese cables ar e enclosed in t he accessor y box.

(2) Remove the stepping motor cover (NO.8) f r om sewing machine head ( NO . 3).

(3) Pass upward the cable (NO.9) which is attached the two connectors at the end, through the

cut-out hole (NO.16) on the table top then, connect it to the X-stepping motor connector

(No.11) and to the Y-stepping motor connector (No.10). At this time, fix this cable with the

nylon clip (NO.13) and setscrew (No.7) which are provided on the sewing machine head.

And also, connect the other end of the cable (NO.9) to the connector (NO.12) on the control

box. The cable (NO.9) is enclosed in the accessory box.

(4) Pass downward the another cable (NO.15) which is extended from the sewing machine

head through the cut-out hole (NO.16) on the table top then, connect it to the cable (NO.18)

extended from the motor (NO . 17)

(5) Connect the last cable (NO. 19) to the other extended cable (NO.20) from the motor then,

hook up the other end of the cable ( NO.19) to the connector (NO.21) on the control box.

(6) Attach the tow binder (NO.22) underneath the table with the wood screws (NO.23) then,

bundle and fix all the connected cables with the binders (NO.22) and the staples (NO.23).

The binders (NO.22), the wood screws (NO.23) and the stables (NO.24) are enclosed in

the accessory box.

3

8

17

20

23

15

2422

18

19

7

From the library of Superior Sewing Machine & Supply LLC • www.supsew.com

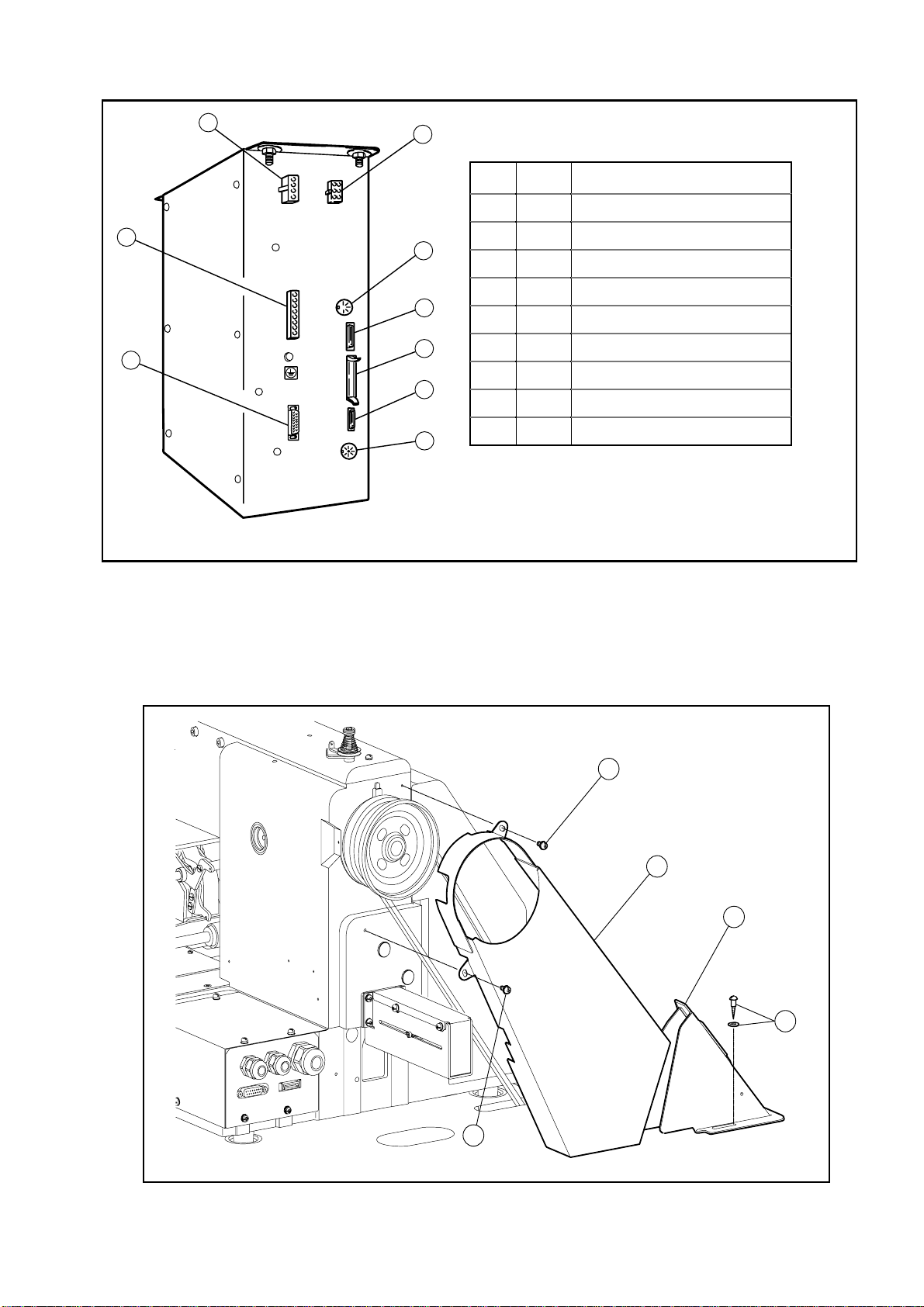

< Back side view of the Control box >

3

4

1

2

Fig Con Connect with

1 A Main motor cable

2 B Power supply cable

5

6

7

8

9

3 C Stepping motor cable

4 D Solenoid output cable

5 E RS-232C (optional use)

6 F O per at ion panel cable

7 G Extension I/O cable

8 H Input signal cable

9 I Foot switch cable

3-12 Installation of the belt cover

Put the large belt cover (NO.2) on t he sewing machine head with the set scr ews (NO. 1 & 4)

and small belt cover (NO.3) on the table top with the set screws (NO. 5)

All the necessary parts are enclosed in the accessory box.

4

2

3

5

1

8

From the library of Superior Sewing Machine & Supply LLC • www.supsew.com

3-13 Installation of the thread stand

(1) Assemble the thread stand with the

instructions enclosed in the packing.

(2) Fit the thread stand (NO.1) in the thread

stand hole on the tabletop.

(3) Fix the thread stand (NO.1) firmly from the

rear side of the table with tightening the nut

(NO.4) and the washers (NO.2, 3).

1

2

3

4

3-14 Functioning the work holder pedal

(1) Connect the chain (NO.1) across the

lever (NO.2) located at the left side of the

sewing machine head and the work

holder pedal mounted on the steel stand

bottom beam. The chain (NO.1) is

enclosed in the accessory box.

(2) Put the stepping motor cover (NO.4) back

on the sewing machine head with the

screw (NO.5) after the chain (NO.1)

connection.

5

2

4

1

9

3

Cautio

From the library of Superior Sewing Machine & Supply LLC • www.supsew.com

4. LUBRICATION

Please make sure to turn power switch OFF befor e oiling.

Please make sure to put some oil before starting the operation of the brand new machine or

NOTE Please use high quality white machining oil.

4-1 Filling the oil tank

Pour the oil through the oil hole (NO.1) to the oil tank (NO.2) on the machine arm. Move the

work holder by hand to the right end then, machine bed. Please fill with the oil over level mark

(NO.6) of the oil tank.

4-2 Oiling

Put some oil to red marked oil holes (NO . 7 ~ 13).

n

8

9

10

11

12

7

13

1

2

6

4

5

10

From the library of Superior Sewing Machine & Supply LLC • www.supsew.com

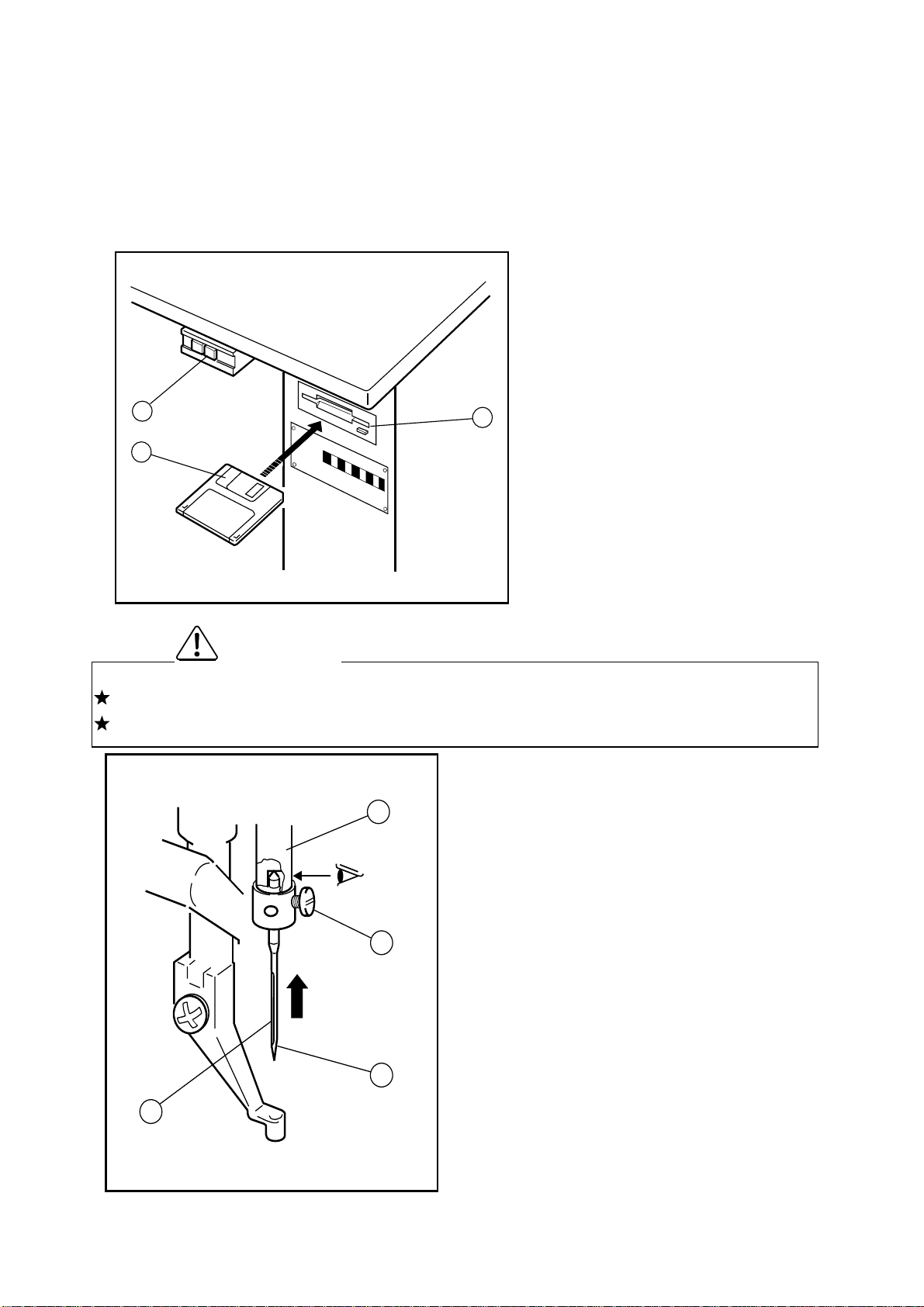

5. PROPER OPERATION

5-1 Loading the system software to the control box.

When the brand new machine is operated first time or when the control box is adjusted for the

repairing, the system software has to be loaded t o the control box.

For this loading, please take the following procedure.

(1) Insert the system floppy disc printed

[ F1 ] (NO.2) into the disc drive (NO.3)

of the control box.

O

F

F

O

N

(2) The system floppy discs are enclosed

in the accessory box.

1

(3) Turn the power switch (NO.1) ON.

3

(4) Load the system software with

2

5-2 Installation of the needle

Please make sure to turn the power switch OFF bef or e installing or replacing the needle.

Please pay attention for the fingers not to be wounded by the needlepoint.

Caution

(1) Loosen the needle set screw (NO.1) then,

insert the new needle (NO.2) until the

3

needle head is reached the end of the

following the instructions [Loading the

system software] on the technical

manual [

(5)

After loading the system software,

CONTROL UNIT].

keep the system floppy disks with in

care.

hole of the needle bar (NO.3).

(2) Fasten the setting screw (NO.1) with

facing the needle groove (NO.4) to the

1

front.

2

4

11

Loading...

Loading...