Mitsubishi PLK-B1008H Manual

MITSUBISHI

Industrial Sewing Machine

TECHNICAL MANUAL MECHANICAL VERSION

Electronic Pattern Sewing Machine

Model PLK-B1008H

From the library of: Superior Sewing Machine & Supply LLCA 180E463P01

' |

|

|

|

|

2. SPECIFICATION |

|

|

|

|

(1) Specification of mechanism |

|

|

|

|

Sewing area |

X-Direction(lefl/right) |

Y- Direction (fore/backward) |

||

|

100mm |

|

80mm |

|

Maximum sewing speed |

700spm |

|

|

|

Sewing speed |

1o steps variable from 200 to 700 stitch/min |

|||

Stitch length |

0.1 to |

12.7 mm |

|

|

|

(Adjustable from 0.1 mm to 12.7mm by 0.1 mm resolution.) |

|||

Stitch type |

Single needle lock stitch |

|

|

|

Class of needle |

Schmitz 794 #230 |

|

|

|

Needle bar stroke |

56.6 mm |

|

|

|

Threaj take up leverstroke |

94mm |

|

|

|

Stepping foot lift |

16mm |

|

|

|

Work holder lift |

20mm (25max.) |

|

|

|

Thickness of material |

Max 10mm |

|

|

|

Hook |

Barrel shuttle hook |

|

|

|

Bobbin |

Large size Steel bobbin |

|

|

|

Thread trimmer system |

Electric heat cut system |

|

|

|

|

Amount of heating time is selectable by selecting setting table |

|||

|

Voltage |

IN: AC 210/230V |

OUT: AC 1V |

|

Pre heating |

available by using Function Code 4 |

|||

Thread |

#8~#00 (Synthetic) |

|

|

|

Lubrication system |

Manual oiling |

|

|

|

Lubrication oil |

White machining oil |

|

|

|

X-Y drive system |

Stepping motor and timing belt drive |

|||

|

Intermittent or continuous feeding |

|||

Machine dimension |

HEAD 41 OW x 780L x 540H TOTAL 1200W x 780L x 1320L |

|||

Weight |

HEAD 92Kg TOTAL 172Kg |

|

||

Type of controller |

PLK-B-CU-20 |

|

|

|

(2) Specification of main motor |

|

|

|

|

Type of motor |

: XL-554-20 |

|

|

|

From the library of: Superior Sewing Machine & Supply LLC

3-6 Installation of the power switch

If the power switch is purchased without assembling to the table, the power switch has to be attached with the following procedure.

(1} fvlount the power switch (NO.<D) with the wood screw (NO.@} underneath the table as shown on the figure.

(2} |

Fix the electric cords with the staples (NO.®) underneath the table. |

(3} Hook up the oonnector (NO.O) of the power switch (NO.<D) to the oonnector (N0.6) of the cable (NO.®}. |

|

(4} |

Hook up the connector (NO.O) of the cable (NO.®) to the connector of the control box (NO.®). |

(5} |

Connect the terminal (NO.O} to the terminal adapter on the transformer (NO.®). |

|

Two terminal has been prepared on this transformer (for 21 OV and for 230V). Detail of wiring are |

|

informed in APPENDIX on this manual. |

(6} |

Connect the other terminal (N0.0) to the terminal adapter PORT No.5 of the relay socket (NO.®). |

|

Detail of wiring are informed in APPENDIX on this manual. |

|

These terminal adapter are located inside of the motor cover of machine head. |

(7} |

Attach the power plug (N0.0) to the another end of the power switch cord (NO.®). All the |

necessary parts are enclosed in the accessory box.

For detail description, please refer to APPENDIX 1 and 2 Wiring diagram.

From the library of: Superior Sewing Machine & Supply LLC

4. LUBRICATION

,----&Caution

*Please make sure to turn power switch OFF before oiling.

*Please make sure to put some oil before starting the operation of the brand new machine or when the sewing machine is resumed the operation after along interval.

INOTE! Please use high quality white machining oil.

Put some oil to red marked oil holes and other part as described below arrow sign.

0

I=

Lubrication position |

|

|

|

|

1. Presser foot mechanism |

2. Rock shaft bushing |

3. Crank rod |

4. Thread take up cam |

|

5. Thread take up shaft |

6. Arm shaft bushing left |

7. Foot lifting eccentric |

||

8. Arm shaft bushing middle |

9. Connecting rod |

10. Arm shaft bushing right |

||

11. Hook shaft bushing left |

12. hook shaft bushing right, Rock shaft bushing |

|||

13. Hook |

From the library of: Superior Sewing Machine & Supply LLC |

|||

|

driver |

|

|

|

5-5 Setting the bobbin

5-5-1 Taking out the bobbin

(1)Turn the hand wheel by hand until the needle bar comes down to the lower point of its stroke so that case retaining spring (NO.®) in the shuttle body comes to recess part (NO.CD) in the cover of the shuttle race body.

INOTE I When "Down Angle of the needle bar" has been set, the hand wheel is rotated

automatically by pressing INEEDLE UP/DNI Key on the teaching panel. The method to

set the down angle is shown in TECHNICAL MANUAL <Teaching panel> 2.9.(5) "Down angle setting mode".

(2) When the case retaining spring (NO.®) is pressed, the bobbin case (NO.®) will be opened and the bobbin (NO.®) will pop out the case.

5-5-2 Taking out the bobbin

(1)After pulling out thread approximately 1Dcm from bobbin (NO.®), put the bobbin into bobbin case (NO.GJ).

(2)Pass the thread through the threading groove (NO.®) in the bobbin case.

At this time, with pulling the thread, check that the rotation of the bobbin (NO.®) is same as arrow of below figure.

(3)Pass the thread through thread slit (NO.®) and pull it then, the thread can be passed under the thread tension spring (NO.<V) and pulled out.

(4)Push the bobbin case into the original position and turn back the hand wheel to up position.

5

From the library of: Superior Sewing Machine & Supply LLC

6-2. The ,teaching operation

Detail descriptions for pattern input are mentioned in TECHNICAL MANUAL <Teaching Panel>.

As for the input method of PLK-61 008H, it is necessary to operate the peculiarity compared with other PLK machines. Peculiar point is

STOP code [USTP] just after TRIM code is required for thermal trimming sequence.

&Caution -------------------- ,

*If STOP code is not put just after TRIM code, the X-Y table and needle will move during thermal trimming procedure and cause to damage the machine.

There are two ways to put STOP code in the pattern data (setting in the teaching mode and addition in

the modification mode).

6-2-1. Setting of STOP code in the teaching mode

(1)Turn the pattern input key ON

(2)Input pattern data as usual until just before the point where RETURN key is ON.

(3)Turn CODE key ON at the point.

Display on teaching panel

1.CODE 2.CODE NUBMER -- -~

3.EXTENDED CODE |

1E |

|

- |

~----------- ---- |

·-·. ----- |

(4)Turn 1 key and ENTER key ON

(5)Turn 1 key and ENTER key ON

(6)Turn CODE key ON again

(7)Turn 2 key and ENTER key ON

(8)Turn RETURN key ON

(9)Turn END key ON

6-2-2. Addition of STOP code in the modification mode

(1)Read the pattern data

(2)Put MODIFY key ON

(3)Put JOG+ key ON until point just after TRIM code.

(4)Put FUNCTION key ON

(5)Put 3 key and ENTER key ON

(6)Put 2 key and ENTER key ON

1.TRIM |

2.USTP |

|

|

|

||

3.FUN1 |

4.2HP |

|

|

|

||

|

|

|

|

|

|

|

1.CODE |

2.CODE NUBMER |

|

|

|

||

3.EXTENDED CODE |

1E |

|||||

|

|

|

|

|

||

1.TRIM |

2.USTP |

1E I |

||||

3.FUN1 |

4.2HP |

|||||

|

|

|

|

|

|

|

1.STITCH 2.SPEED 3.CODE 4.MOVE(B)

1.DELTE CODE 2.ADD CODE

(7) Put ENTER key ON |

|

|

|

|

- |

·-~~~ |

||

|

|

1.CODE |

|

|

||||

|

|

2.CODE NUBMER |

||||||

|

|

3.EXTENDED CODE |

1E |

|||||

(8) |

Put 1 key and ENTER key 0 N |

|

|

|

|

--~ |

||

1.TRIM |

2.USTP- |

|||||||

|

|

~=~=:4=.2--HP __ |

~ |

|||||

(9) |

Put 2 key and ENTER key ON |

USTP CODE |

2i._YN I |

|||||

(1 0) Put 1 key and ENTER key ON |

ADDITION? |

|

|

|||||

(11) Put MODIFYFrom thekey ONlibrary of: Superior Sewing Machine & Supply LLC

6-3. Pre-heating control

To secure the trimming, it is available to use pre-heating by input Function Code No.4 (FN4) in the pattern data. Relationship between FN4 and pre-heating behavior is described as below.

Stitch |

Fu_4 |

Trjrn |

ex.1) Pattern data ooooooooooowooooooooooooooo Heater oN

ex.2) Pattern data ooJ1'l't\'oooooo~ooooooooo@iooot5iO

Heater

ON

When FN4 code is input once, pre-heater is continue to on until trim code is appeared.(ex.1) When FN4 code is input twice, pre-heater is on at first code and off at second code. Usually FN4 is better to put only 1 time.

6-4. The thermal trimming operation

There are 3 operation switches for thermal trimming operation.

|

The switch <D is Manual/ Test mode conversion switch. |

|

|

||||||

|

The switch ® |

is Enable I Disable lower thermal thread trimming device switch. |

|||||||

|

The switch @ is Enable I Disable upper thermal thread trimming device switch. |

||||||||

|

INOTEI Switch 2 and 3 does not wqrk unt[[_J!ower lLWitg_~_.9lL1!nd on again |

||||||||

|

for safety reason. |

|

|

|

|

|

|

||

6-4-1. Thermal thread trimming device switch (NO.®and |

®) |

|

|

|

|||||

|

The Iower and upper th ermaI th read tnmm1ng. dev1ce |

|

|

|

|

|

|||

|

|

{Rear) |

|||||||

|

switch work as like below table. |

|

|

|

|||||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

Low or thread |

Upper thread |

|

|

Lower |

Upper |

Device action |

|

|

|

|||

|

|

|

|

ON |

ON |

||||

|

(NO.C?l) |

(NO.®) |

|

|

|

||||

|

|

|

|

|

lglOFF |

IB'~~'"''"",. |

|||

|

ON |

ON |

Both trimmers work |

|

|

|

|||

|

OFF |

ON |

Do not work either |

|

|

|

|||

|

ON |

OFF |

Lower trimmer works |

|

|

|

|

|

|

|

|

|

|

|

|

|

OFF |

||

|

OFF |

OFF |

Do not work either |

|

|

|

|||

From the library of: Superior Sewing Machine &{Front)Supply LLC

'

7. STANDARD ADJUSTMENT |

|

.----& Caution -------------------- |

, |

*Please make sure to turn the power switch OFF before adjust the sewing machine.

*If the adjustment is required under the power switch is ON, keep the start foot switch away from the foot.

*Be careful not to be wounded by the needle or the inner hook point.

*Please make sure to put the safety guards (Eye guard, Belt guard, Link cover and finger guard etc.) back on the original location after the sewing machine adjustment.

7-1 Adjustment of the shuttle

(1 )Turn the power switch OFF.

(2)Turn the shuttle (NO.!D) counterclockwise until it will go no further.

(3)Put shuttle (NO.!D) to come contact with the driver race (NO.a>) by NO.O point.

(4)Check a distance (N0.6) between the blade point of the shuttle (NO.!D) and the end face of the shuttle race. Proper distance is 1mm. If distance is not proper, refer to following adjustment.

(5)Turn the shuttle (NO. !D) until at the point described in (1).

(6) Loosen the bolt (NO.®).

(?)Align the blade point of the shuttle (N0.6) by turning the shuttle by hand.

(B) After adjustment has been completed, tighten screw (NO.®) firmly.

3

1

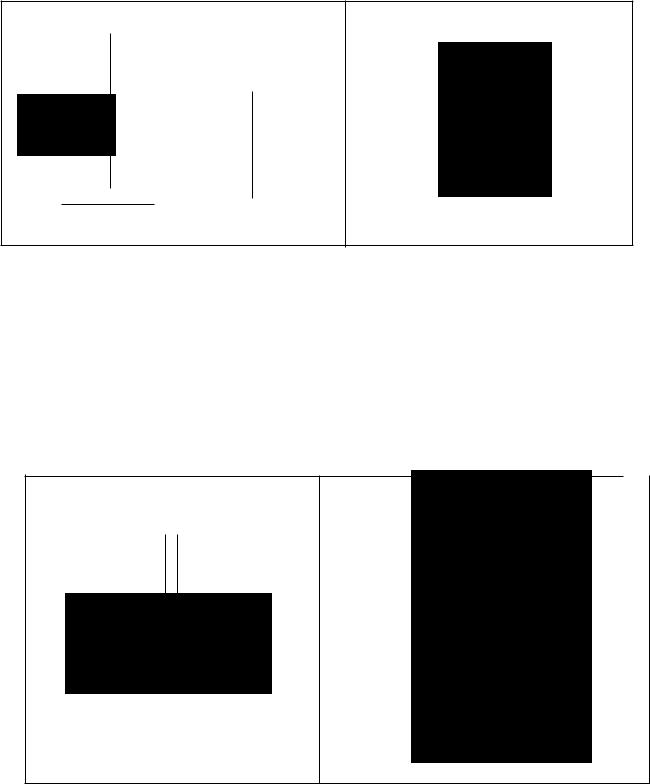

7-2 Adjustment of the position between the needle and the shuttle

(1)Turn the hand wheel to make the needle bar ascend 5 mm from its lowest position.

(2)At this time, blade point (NO.a>) should be aligned with the center of the needle (NO.!D).

And the distance from the upper surface of the throat plate to the lower end of the needle bar

shouldFrombe 26the.5 mmlibrary. of: Superior Sewing Machine & Supply LLC

To adjust the position of the needle and shuttle, referring following procedure_

'

(1) Remove the cover of the arm top.

(2) Loosen screw (NO.Ql)

(3) Loosen screw (NO.®). and adjust so that marker dot (NO.O) engraved on the eccentric cam of the vertical rod is aligned with marker line (N0.6) engraved on the main shaft.

(4) Then, tighten screw (NO.®)

(5) Turn the hand wheel counterclockwise, and check the lifting amount of the needle bar_

(6) After the adjustment, securely tighten screws (NO. Gil and ®).

/ |

|

t\ |

0 |

||

Loading...

Loading...