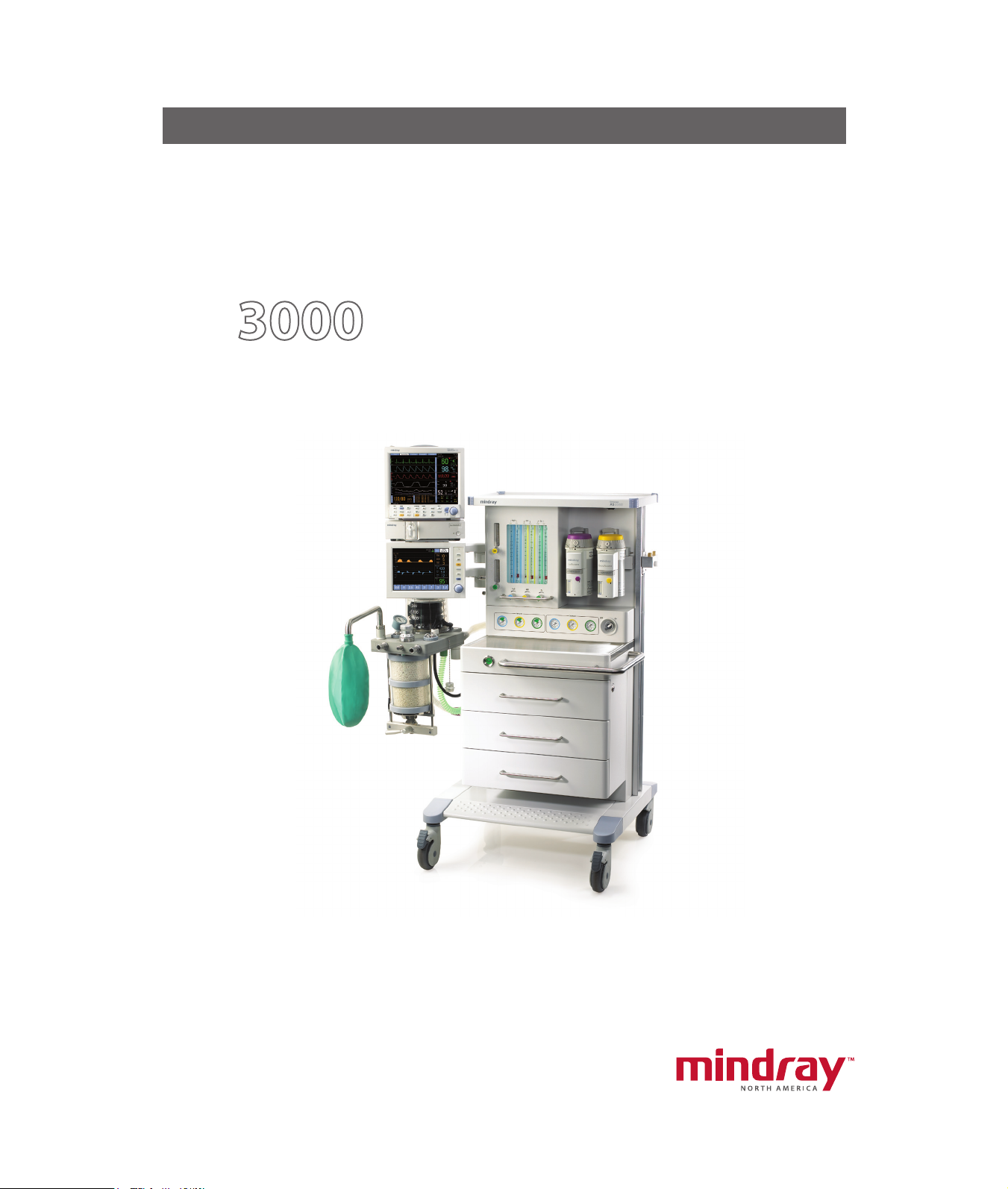

Mindray AS3000 Service Manual

AS

™

Datascope

Service Manual

ANESTHESIA DELIVERY SYSTEM

AS

™

Datascope

Service Manual

ANESTHESIA DELIVERY SYSTEM

AS3000™ is a U.S. trademark of Mindray DS USA, Inc.

Copyright © Mindray DS USA, Inc., 2008. All rights reserved. Contents of this publication may not be reproduced in any

form without permission of Mindray DS USA, Inc.

®

Krytox

is a U.S. registered trademark of E. I. du Pont de Nemours and Company

Selectatec

Glyptal

®

®

is a U.S. registered trademark of Glyptal, Inc.

Dräger Vapor

is a U.S. trademark of Datex Ohmeda

®

and plug-in system S-2000 are registered trademarks of Dräger Medical.

AS3000™ Service Manual 0070-10-0683

Table of Contents

Foreword.......................................................................................................................................................vii

Warnings, Cautions and Notes ........................................................................................................................vii

Warnings ......................................................................................................................................................vii

Cautions .......................................................................................................................................................viii

Notes ............................................................................................................................................................ ix

Theory of Operation .....................................................................................................1 - 1

Introduction................................................................................................................................................ 1 - 1

Microprocessor-controlled Ventilator.............................................................................................................. 1 - 2

Components............................................................................................................................................... 1 - 3

Front View .......................................................................................................................................... 1 - 3

Side View........................................................................................................................................... 1 - 5

Rear View........................................................................................................................................... 1 - 7

Other components (not identified in graphics) ......................................................................................... 1 - 8

Breathing System................................................................................................................................. 1 - 9

The Ventilator Unit ............................................................................................................................... 1 - 9

Adjustable Alarms ............................................................................................................................. 1 - 10

Compliance Compensation................................................................................................................. 1 - 10

Electrical Supply ....................................................................................................................................... 1 - 11

Electrical components......................................................................................................................... 1 - 11

Ventilator Control and Drive....................................................................................................................... 1 - 12

BDU (Basic Digital Unit)...................................................................................................................... 1 - 12

Amplifier Board ........................................................................................................................ 1 - 14

Drive Gas Pressure Sensor Board ................................................................................................ 1 - 19

PAW Pressure Sensor Board....................................................................................................... 1 - 20

Breathing System Heater ............................................................................................................ 1 - 21

Sensor Board............................................................................................................................ 1 - 23

Power Management........................................................................................................................... 1 - 26

Battery ............................................................................................................................................. 1 - 28

Power Supply.................................................................................................................................... 1 - 28

Anesthesia System Components .................................................................................................................. 1 - 29

Auxiliary Outlets................................................................................................................................ 1 - 29

Absorber Heater Wire Board .............................................................................................................. 1 - 29

Work Light Board .............................................................................................................................. 1 - 29

Ventilator UI ............................................................................................................................................. 1 - 31

Keyboard Board................................................................................................................................ 1 - 31

Display............................................................................................................................................. 1 - 34

Communication Interface / RS232 Isolate Board ...................................................................................1 - 35

Fuses ............................................................................................................................................... 1 - 35

Ventilator Pneumatic - O

Ventilator pneumatic drive .................................................................................................................. 1 - 36

Drive Pressure-High pressure regulator ................................................................................................. 1 - 36

Gas Box Assembly............................................................................................................................. 1 - 36

Tube color coding.............................................................................................................................. 1 - 36

The Breathing System ................................................................................................................................ 1 - 37

CMV mode, inspiration ...................................................................................................................... 1 - 37

CMV mode, expiration....................................................................................................................... 1 - 37

Manual mode, inspiration................................................................................................................... 1 - 38

Manual mode, expiration ................................................................................................................... 1 - 38

Pneumatic PEEP ................................................................................................................................. 1 - 39

Ventilator in Standby.......................................................................................................................... 1 - 39

Breathing System Components ............................................................................................................ 1 - 39

Ventilation Bellows System.......................................................................................................... 1 - 39

Drive Gas ........................................................................................................... 1 - 36

2

AS3000™ Service Manual 0070-10-0683 i

Table of Contents

Manual Breathing Bag............................................................................................................... 1 - 39

Absorber .......................................................................................................................... 1 - 39

CO

2

Inspiratory and Expiratory Valves................................................................................................ 1 - 39

APL (Airway Pressure Limiting) valve ............................................................................................ 1 - 39

Installation Guide .........................................................................................................2 - 1

Delivery of The New Anesthesia Machine ...................................................................................................... 2 - 1

Assembly ................................................................................................................................................... 2 - 2

Unpacking.......................................................................................................................................... 2 - 2

Breathing System and Breathing System Accessories ................................................................................ 2 - 2

Attaching the Mounting Arms and User Interface............................................................................. 2 - 3

Breathing System Connections ...................................................................................................... 2 - 3

Anesthesia System Connections..................................................................................................... 2 - 3

Tank Wrench and Pre-operation Checklist............................................................................................... 2 - 4

Patient Suction Regulator and Arm......................................................................................................... 2 - 4

Suction Canister Bracket....................................................................................................................... 2 - 4

Utility Tray, Monitor Mounting Arm with Utility Hook(s)............................................................................. 2 - 4

Vaporizers.......................................................................................................................................... 2 - 4

High Pressure Hoses ............................................................................................................................ 2 - 5

Emergency Cylinder(s) ......................................................................................................................... 2 - 5

Breathing Circuit, CO

Absorbent, and Liquid Vaporizer Agent ................................................................ 2 - 5

2

Monitoring Products - Mounting and Electrical Connection........................................................................2 - 6

Agent Monitor Waste Gas Scavenging .................................................................................................. 2 - 6

Oxygen Sensor Calibration .................................................................................................................. 2 - 6

Installation Checkout Procedure .................................................................................................................... 2 - 8

Repair Information ....................................................................................................... 3 - 1

Introduction................................................................................................................................................ 3 - 1

Warnings and Cautions............................................................................................................................... 3 - 2

Warnings ........................................................................................................................................... 3 - 2

Cautions............................................................................................................................................. 3 - 2

Troubleshooting Guidelines .......................................................................................................................... 3 - 2

Special Tools Required ................................................................................................................................ 3 - 3

Troubleshooting Chart ................................................................................................................................. 3 - 4

Common Symptoms and Corrective Actions for Field Service Technicians ................................................... 3 - 4

Leak Troubleshooting................................................................................................................................. 3 - 11

Test Pneumatics ........................................................................................................................................ 3 - 12

Leak Test - Manual Ventilation Test....................................................................................................... 3 - 12

Safety Valve Test ............................................................................................................................... 3 - 13

Leak Test - Automatic Ventilation Test.................................................................................................... 3 - 14

Compliance Test................................................................................................................................ 3 - 15

Pneumatic Hose and Wiring Diagrams ........................................................................................................ 3 - 16

Pneumatic Hose Labeling.................................................................................................................... 3 - 16

Sampling Pipeline Module Interface Labeling ........................................................................................ 3 - 17

Electrical Cable Labeling .................................................................................................................... 3 - 18

Replacement Parts and Accessories ...............................................................................4 - 1

Introduction................................................................................................................................................ 4 - 1

Available Replacement Parts and Sub-Assemblies ........................................................................................... 4 - 1

Exchange Program .............................................................................................................................. 4 - 1

Replacement Parts Pricing Information .................................................................................................... 4 - 1

Ordering Information ........................................................................................................................... 4 - 2

Isometric Drawings...................................................................................................................................... 4 - 3

Chassis .............................................................................................................................................. 4 - 3

Chassis Parts List ......................................................................................................................... 4 - 5

ii 0070-10-0683 AS3000™ Service Manual

Table of Contents

Breathing System................................................................................................................................. 4 - 6

Breathing System Parts List.......................................................................................................... 4 - 11

Electric Box....................................................................................................................................... 4 - 12

Electric Box Parts List.................................................................................................................. 4 - 12

Gas Circuit Box................................................................................................................................. 4 - 13

Gas Circuit Box Parts List............................................................................................................ 4 - 13

User Interface.................................................................................................................................... 4 - 14

User Interface Parts List............................................................................................................... 4 - 15

Flowmeter......................................................................................................................................... 4 - 16

Flowmeter Parts List.................................................................................................................... 4 - 16

Calibration ...................................................................................................................5 - 1

Introduction................................................................................................................................................ 5 - 1

Calibration Warnings, Precautions, and Notes............................................................................................... 5 - 2

Warnings ........................................................................................................................................... 5 - 2

Cautions............................................................................................................................................. 5 - 2

Notes................................................................................................................................................. 5 - 3

General Guidelines..................................................................................................................................... 5 - 4

Test Equipment and Special Tools Required.................................................................................................... 5 - 4

Calibration Procedures ................................................................................................................................ 5 - 4

Oxygen Sensor Calibration .................................................................................................................. 5 - 4

Proportional Valve Regulator Calibration ................................................................................................ 5 - 6

Flow Sensor Calibration ....................................................................................................................... 5 - 7

Flow Valve Calibration......................................................................................................................... 5 - 9

Paw Sensor....................................................................................................................................... 5 - 10

PEEP Valve ....................................................................................................................................... 5 - 11

Flow Meter ....................................................................................................................................... 5 - 12

Leakage detection.............................................................................................................................. 5 - 13

Startup leakage detection........................................................................................................... 5 - 13

APL Valve leakage detection....................................................................................................... 5 - 13

Safety Valve leakage detection ................................................................................................... 5 - 13

Breathing System leakage detection............................................................................................. 5 - 13

Compliance detection ........................................................................................................................ 5 - 13

Periodic Maintenance.................................................................................................... 6 - 1

Maintenance Schedule ................................................................................................................................ 6 - 1

Periodic Maintenance Consumable Parts Kits.................................................................................................. 6 - 1

Periodic Maintenance Schedule of Service Activities........................................................................................ 6 - 2

Visual Inspection Checklist ........................................................................................................................... 6 - 2

Replacement of Consumable Parts................................................................................................................. 6 - 3

Check Valve Cleaning................................................................................................................................. 6 - 4

Tools and Materials ............................................................................................................................. 6 - 4

Cleaning Procedure ............................................................................................................................. 6 - 5

Battery Maintenance and Replacement ........................................................................................................ 6 - 13

Battery Maintenance .......................................................................................................................... 6 - 13

Battery Replacement .......................................................................................................................... 6 - 13

Functional Tests ........................................................................................................................................ 6 - 13

Test Equipment and Special Tools Required........................................................................................... 6 - 13

Pressure Regulator Checks .................................................................................................................. 6 - 14

Proportional Valve Regulator ...................................................................................................... 6 - 14

Gas Delivery System Tests................................................................................................................... 6 - 14

Flush Verification ................................................................................................................. 6 - 14

O

2

O Ratio System ............................................................................................................... 6 - 15

O

2:N2

Start-Up Tests .................................................................................................................................... 6 - 15

AS3000™ Service Manual 0070-10-0683 iii

Table of Contents

System Self Test......................................................................................................................... 6 - 15

Leak/Safety Valve Test............................................................................................................... 6 - 15

Leak Test .................................................................................................................................. 6 - 17

Compliance Test ....................................................................................................................... 6 - 20

Manual Leak Test ...................................................................................................................... 6 - 21

Oxygen Sensor Calibration ........................................................................................................ 6 - 22

Pneumatic Leak Tests.......................................................................................................................... 6 - 24

O Cylinder Leak Test ............................................................................................................. 6 - 24

N

2

Cylinder Leak Test................................................................................................................ 6 - 24

O

2

AIR Cylinder Leak Test ............................................................................................................... 6 - 24

Line Supply Check Valves Test .................................................................................................... 6 - 24

O Line Pressure Leak Test ....................................................................................................... 6 - 25

N

2

Line Pressure Leak Test.......................................................................................................... 6 - 25

O

2

AIR Line Pressure Leak Test ......................................................................................................... 6 - 25

Cylinder Supply Check Valves Test .............................................................................................. 6 - 25

Breathing System Checks.................................................................................................................... 6 - 26

Waste Gas Scavenger Test (if available) ...................................................................................... 6 - 26

Internal Gas Connections Test ..................................................................................................... 6 - 26

Drive Gas Pressure Loss Alarm, N

O Cutoff Test ........................................................................... 6 - 26

2

Performance Verification .................................................................................................................... 6 - 27

Standby Mode Ventilation Test.................................................................................................... 6 - 27

Manual Mode Ventilation Test .................................................................................................... 6 - 27

APNEA Alarm Test .................................................................................................................... 6 - 27

Alarm MUTE Test....................................................................................................................... 6 - 27

CMV Adult Ventilation Mode Test................................................................................................ 6 - 28

CMV Child Ventilation Mode Test................................................................................................ 6 - 29

Airway Disconnect Alarm Test..................................................................................................... 6 - 29

PCV Adult Ventilation Mode Test ................................................................................................. 6 - 30

Pressure Support (PS) Ventilation Mode Test.................................................................................. 6 - 31

Alarms and Failsafe Functions ............................................................................................................. 6 - 32

Set Up ..................................................................................................................................... 6 - 32

Low FiO

High FiO

Alarm Test.................................................................................................................. 6 - 32

2

Alarm Test ................................................................................................................ 6 - 33

2

Peak Pressure Alarms Test .......................................................................................................... 6 - 33

Minute Volume Alarm Test.......................................................................................................... 6 - 34

Miscellaneous Tests............................................................................................................................ 6 - 34

Test the Line Voltage Alarm ........................................................................................................ 6 - 34

Wheel Brakes Test..................................................................................................................... 6 - 34

Work Light Test ......................................................................................................................... 6 - 34

Auxiliary Flowmeter................................................................................................................... 6 - 35

Patient Suction Regulator (if available) ......................................................................................... 6 - 35

Vaporizers........................................................................................................................................ 6 - 35

Vaporizer Interlock Test.............................................................................................................. 6 - 35

Vaporizer Accuracy Test ............................................................................................................ 6 - 36

Vaporizer Leak Test ................................................................................................................... 6 - 36

Dräger Vapor 2000 Operating Instructions ARRB-F001 ................................................................. 6 - 37

Electrical Tests................................................................................................................................... 6 - 38

Convenience AC Outlets Test...................................................................................................... 6 - 38

Electrical Safety Inspection Test ................................................................................................... 6 - 38

AS3000 Installation Checklist ............................................................................................................. 6 - 38

Cleaning.................................................................................................................................................. 6 - 39

Cleaning and Disinfecting the AS3000 ................................................................................................ 6 - 39

iv 0070-10-0683 AS3000™ Service Manual

Table of Contents

Cleaning and Sterilizing the Breathing System and Components.............................................................. 6 - 39

Preoperative Checklist ............................................................................................................................... 6 - 39

Phone Numbers and How To Get Assistance................................................................................................ 6 - 47

Warranty ..................................................................................................................... 7 - 1

Warranty Statements................................................................................................................................... 7 - 1

Disclaimers ................................................................................................................................................ 7 - 2

Product Improvements .......................................................................................................................... 7 - 2

Manufacturer’s Responsibility ....................................................................................................................... 7 - 2

AS3000™ Service Manual 0070-10-0683 v

Table of Contents

This page intentionally left blank.

vi 0070-10-0683 AS3000™ Service Manual

Foreword Introduction

Foreword

This Service Manual is intended as a guide for technically qualified personnel performing

repair and calibration procedures.

Warnings, Cautions and Notes

Please read and adhere to all warnings, cautions and notes listed here and in the

appropriate areas throughout this manual.

A WARNING is provided to alert the user to potential serious outcomes (death, injury, or

serious adverse events) to the patient or the user.

A CAUTION is provided to alert the user to use special care necessary for the safe and

effective use of the device. They may include actions to be taken to avoid effects on patients

or users that may not be potentially life threatening or result in serious injury, but about which

the user should be aware. Cautions are also provided to alert the user to adverse effects on

this device of use or misuse and the care necessary to avoid such effects.

A NOTE is provided when additional general information is applicable.

Warnings

WARNING: Whenever using anesthetic gases, nitrous oxide, oxygen, or

WARNING: For continued protection against fire hazard, replace all

WARNING: In order to prevent an electric shock, the machine

WARNING: Remove all accessory equipment from the shelf before

WARNING: Possible explosion hazard. Do not operate machine near

WARNING: The use of anti-static or electrically conductive respiration

any hospital gas always follow the appropriate agent

evacuation/collection procedures. Use the hospital gas

evacuation system.

fuses with the specified type and rating.

(protection class I) may only be connected to a correctly

grounded mains connection (socket outlet with grounding

contact).

moving the anesthesia machine over bumps or on any

inclined surface. Heavy top loading can cause the machine

to tip over causing injury.

flammable anesthetic agents or other flammable

substances. Do not use flammable anesthetic agents (i.e.,

ether or cyclopropane.)

tubes, when utilizing high frequency electric surgery

equipment, may cause burns and is therefore not

recommended in any application of this machine.

WARNING: Possible electric shock hazard. The machine may only be

opened by authorized service personnel.

AS3000™ Service Manual 0070-10-0683 vii

Introduction Cautions

WARNING: Compressed gasses are considered Dangerous Goods/

WARNING: Avoid exposure to respiratory gases by always directing

Hazardous Materials per I.A.T.A. and D.O.T. regulations. It is

a violation of federal and international law to offer any

package or over pack of dangerous goods for

transportation without the package being appropriately

identified, packed, marked, classified, labeled and

documented according to D.O.T. and I.A.T.A. regulations.

Please refer to the applicable I.A.T.A. Dangerous Goods

Regulations and /or the Code of Federal Regulations 49

(Transportation, Parts 171-180) for further information.

the fresh gas flow from the fresh gas outlet to the waste gas

scavenger.

Cautions

CAUTION: This device uses high pressure compressed gas. When

attaching or disconnecting backup gas cylinders, always

turn the cylinder valves slowly. Use the AS3000 flow meters

to bleed down the pressure, watching the cylinder gauge

indicate the depleting cylinder pressure, before

disconnecting the cylinder from the yoke. Always open and

close cylinder valves fully.

CAUTION: This device operates using compressed gas at high

pressures from the hospital central supply. When connecting

gas supply lines attach the hose connection to the machine

before connecting the quick disconnect fitting to the hospital

source. Disconnect the supply hose from the hospital source

connection prior to disconnecting it from the AS3000 gas

connection fittings.

CAUTION: Refer to the “Periodic Maintenance Schedule of Service

Activities” on page 6-2, in the Periodic Maintenance section

for assistance when performing scheduled periodic

maintenance.

CAUTION: Do not leave gas cylinder valves open if the pipeline supply

is in use and the system master switch is turned to 'ON'. If

used simultaneously, cylinder supplies could be depleted,

leaving an insufficient reserve supply in the event of

pipeline failure.

CAUTION: Use cleaning agent sparingly. Excess fluid could enter the

machine, causing damage.

CAUTION: This machine must only be operated by trained, skilled

medical staff.

CAUTION: Perform the electrical safety inspection as the last step after

completing a repair or after routine maintenance. Perform

this inspection with all covers, panels, and screws installed.

CAUTION: After changing the CO

CAUTION: Only Selectatec

CAUTION: After each exchange of a vaporizer, carry out a system Leak

test.

™

System may be used with the AS3000 unit.

test.

absorbent, carry out a system leak

2

compatible vaporizers with Interlock-

viii 0070-10-0683 AS3000™ Service Manual

Notes Introduction

CAUTION: The bellows dome cannot be autoclaved.

CAUTION: Do not clean the machine while it is on and/or plugged in.

CAUTION: Pressing “Quit” at any time during the procedure will cancel

the session's settings and reload the previously-stored

calibration coefficients.

CAUTION: Depleted soda lime changes color. Replace the soda lime if

approximately 2/3 of the absorber content is discolored.

absorbent can be safely changed without stopping

CO

2

mechanical ventilation.

Notes

NOTE: Unauthorized servicing may void the remainder of the

warranty. Check with the factory or with a local authorized

distributor to determine the warranty status of a particular

instrument.

AS3000™ Service Manual 0070-10-0683 ix

Introduction Notes

This page intentionally left blank.

x 0070-10-0683 AS3000™ Service Manual

1.0

Theory of Operation

1.1 Introduction

The AS3000 is a continuous flow anesthesia system which offers manual or automatic

ventilation, easily adjustable fresh gas delivery, anesthetic agent delivery, ventilation

monitoring, convenient ergonomics, and state-of-the-art safety systems. The components of the

AS3000 Anesthesia System are described this chapter.

AS3000™ Service Manual 0070-10-0683 1 - 1

Microprocessor-controlled Ventilator Theory of Operation

Gas Inlet

Block

N20

AIR

O2

Breathing

System

Ventilator

Pressure

Switch

Pressure

Regulator

Pressure

Regulator

Pressure

Regulator

Ratio•

Controller

N20•

Cuttoff

Flow

Tubes

Cylinder

Cylinder

Cylinder

Inlet Filter

Inlet Filter

Inlet Filter

O2

Flow

Meter

O2

Outlet

AIR•

Flow

Meter

Patient

Vaporizer

O2

Flush

Pressure

Regulator

Proportional

Valve

Solenoid

Valve

Fresh Gas

PEEP

Valve

Exhaust

Valve

APLValve

AGSS

Electronic

Control

Reversing

Valve

O2 Sensor

Insp.Valve

Absorber

Canister

Exp.Valve

Breathing Bag

OOO

P

P

P

P

P

P

P

Exp. Flow

Sensor

Insp. Flow

Sensor

Fresh Gas

Flow Sensor

V

Bellows

Vaporizer

1.2 Microprocessor-controlled Ventilator

The Microprocessor-controlled ventilator, with its dedicated Breathing System, allows timecontrolled, pressure limited, constant volume ventilation for all patient groups within a tidal

volume range of 40 mL (4 kg infant) to 1400 mL (large adult).

Time-controlled, pressure limited, and compliance compensated constant volume ventilation

is provided through the Controlled Mandatory Ventilation (CMV) mode. The CMV mode

delivers a viable ventilation method for complicated lung conditions. The ventilator also

provides time-controlled, volume dependant ventilation, targeting a set (adjustable) target

pressure provided through the Pressure Controlled Ventilation (PCV) mode. Automatic and

comprehensive system startup tests and alarm management systems ensure controlled

ventilation conditions in every mode of operation.

The durable and ergonomically designed user interface and Navigator

™

Knob enables easy

operation. The display provides the selected ventilation modes (CMV, PCV, PS and SIMV)

and the following values: Tidal Volume, Peak Pressure, Mean Pressure, FiO

, Breath Rate, I:E

2

Ratio, PEEP, Plateau Pressure, Alarm limits, and real-time Airway Pressure and flow

waveform.

1 - 2 0070-10-0683 AS3000™ Service Manual

FIGURE 1-1 The AS3000 Pneumatic System

Theory of Operation Components

4

5

6

7

8

9

2

1

10

11

3

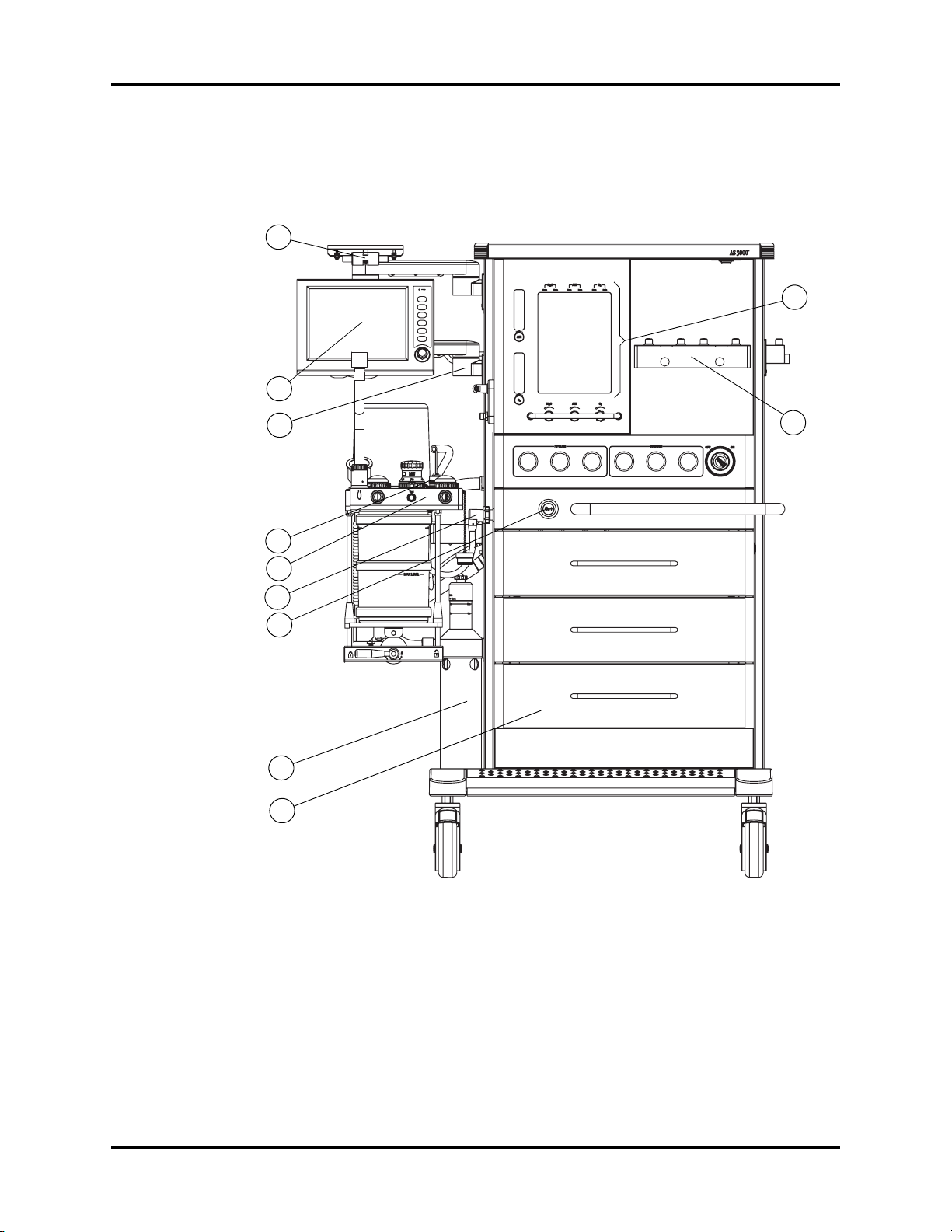

1.3 Components

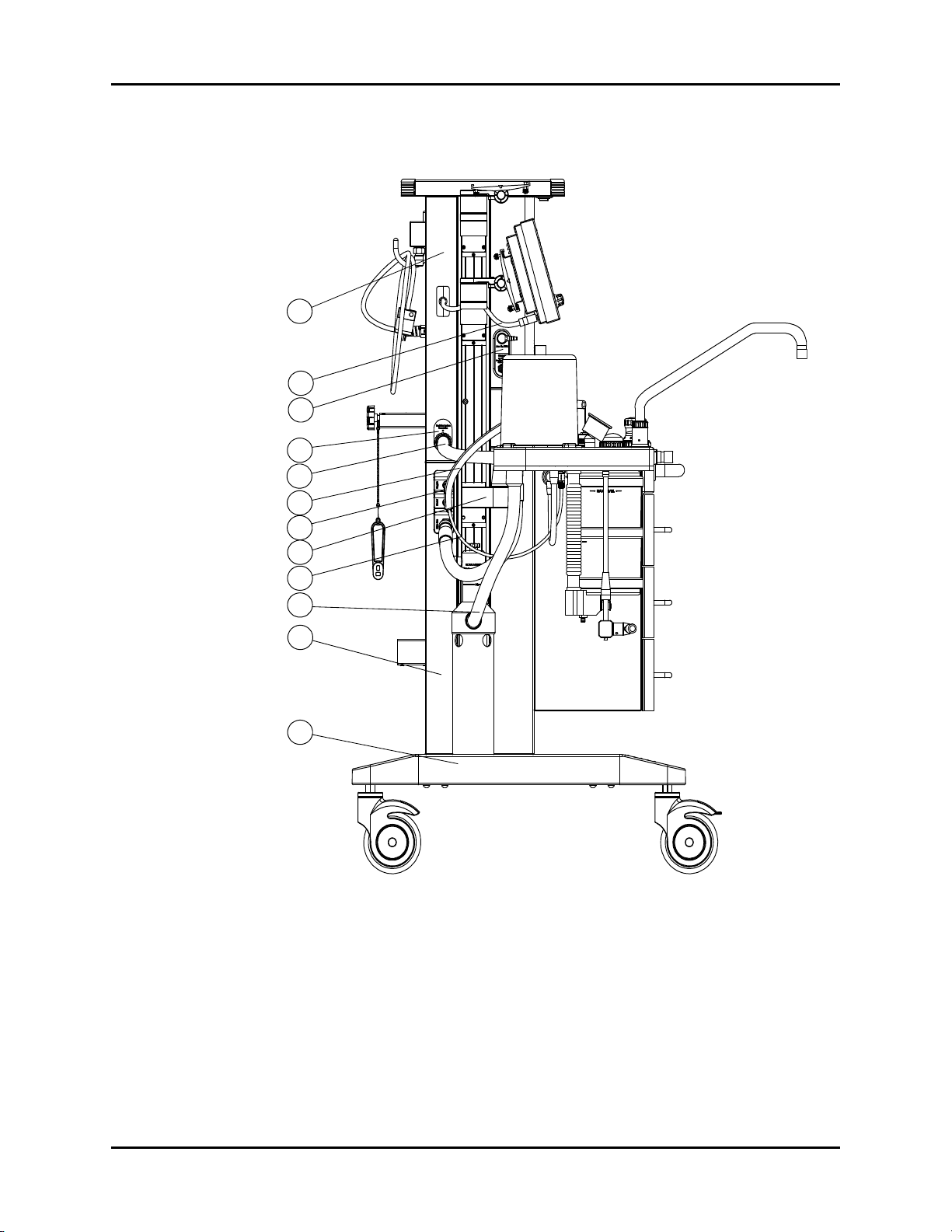

1.3.1 Front View

FIGURE 1-2 AS3000 Front View

1. Monitor Arm

The Monitor Arm provides support for a bedside monitor. It can easily rotate for more

convenient viewing.

2. User Interface

The display of the user Interface provides waveforms, numeric data and menu tabs. The keys

and Navigator Knob enable the user to power up the system, silence alarms, access menu

AS3000™ Service Manual 0070-10-0683 1 - 3

tabs, and switch between manual and mechanic ventilation.

Components Theory of Operation

3. UI Arm

The UI Arm provides support for the user interface assembly. It can easily rotate for more

convenient viewing.

4. Oxygen Sensor

The Oxygen Sensor monitors the oxygen concentration of the inspired gas of the Breathing

System.

5. Breathing System

The Breathing System’s main function is to store anesthetic gas, oxygen, and air; vent exhaust

gas; and absorb carbon dioxide. It connects directly to the respiratory passage to help

complete the breathing process.

6. CGO (Common Gas Outlet) Subassembly

Mixed gas composed of O

, AIR, N2O, and anesthetic agent connects to the patient's

2

Breathing System via a flexible tube from the CGO Subassembly.

7. O2 Flush Valve

The O2 Flush Valve is located on the front of the AS3000. The supplied gas does not pass

the flowmeter and vaporizer. It is directly sent to the fresh gas outlet. Press this button to

supply gas (35 - 50 L/min). Release this switch to automatically close the gas supply.

8. AGSS (Anesthetic Gas Scavenging System)

The AGSS (Anesthetic Gas Scavenging System) reclaims exhausted gas generated during

anesthesia.

9. Drawer Subassembly

The AS3000 has three drawers for storage, which can be locked and fixed through the

uppermost drawer lock.

10. Vaporizer Mounting Manifold

The Vaporizer Mounting Manifold provides support for up to two Selectatec

®

compatible

anesthetic vaporizers.

11. Flowmeter

The Flowmeter displays gas flow values for N2O, O2, AIR, Auxiliary O2, and Auxiliary AIR.

It consists of coarse and fine flow tubes used to accurately measure gas flow with additional

flow tubes to measure auxiliary O

and AIR gas flow.

2

Flow tube measurement values:

GAS FINE FLOW TUBE

O 0 - 1 L/min 1 - 12 L/min 1 - 10 L/min N/A

N

2

O

2

0 - 1 L/min 1 - 10 L/min 1 - 10 L/min 0 - 15 L/min

COARSE FLOW TUBE

-01 UNITS -02 UNITS AUXILIARY FLOW TUBE

AIR 0 - 1 L/min 1 - 15 L/min 1 - 12 L/min 0 - 15 L/min

1 - 4 0070-10-0683 AS3000™ Service Manual

Theory of Operation Components

12

13

14

15

16

17

18

19

20

21

22

23

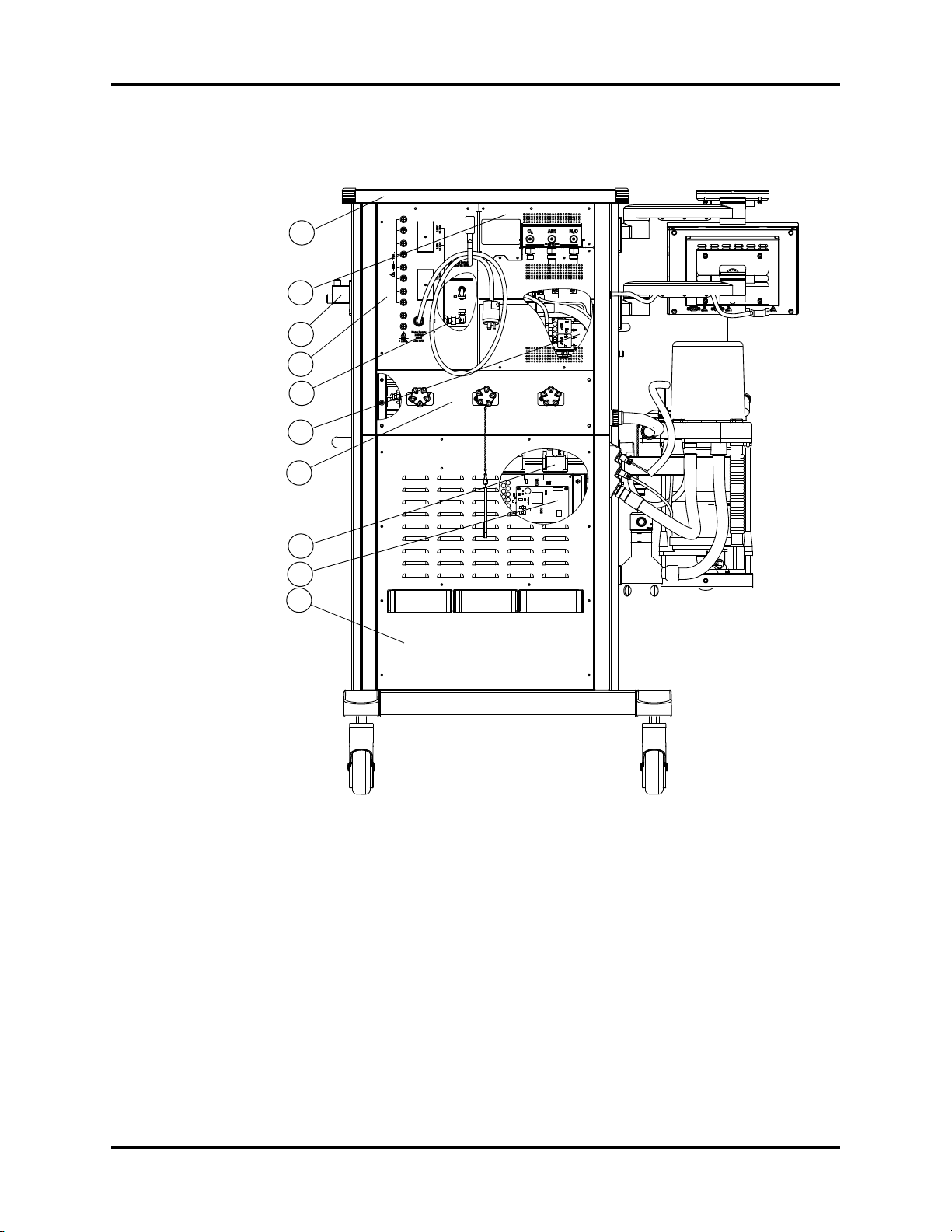

1.3.2 Side View

FIGURE 1-3 AS3000 Side View

12. Upper Mainframe Subassembly

The Upper Mainframe Subassembly provides support for the pressure gauges, the Flowmeter,

the gas box assembly, the mains supply assembly, and the YOKE assembly.

13. User Interface Cable

The User Interface Cable provides signal transmission between the User Interface and the

main unit.

AS3000™ Service Manual 0070-10-0683 1 - 5

Components Theory of Operation

14. Auxiliary Gas Outlet Assembly

The Auxiliary Gas Outlet Assembly provides the patient with auxiliary oxygen and air mixtures

(of different concentrations). It also contains an O

connection for use with other equipment.

2

15. Breathing System Interface

The Breathing System Interface provides a connection interface for gas signal acquisition

between the Breathing System and gas circuit.

16. Breathing System Pneumatic Hose

The Breathing System Pneumatic Hose provides multiple connections including: PEEP control,

Auto/Manual control, and four pressure sampling connections between the Breathing System

and mainframe.

17. O

Sensor Cable

2

The O2 Sensor Cable provides a connection between the oxygen sensor component in the Breathing

System and the oxygen concentration signal acquisition port on outlet module of the mainframe.

18. Breathing System Interface

The Breathing System Interface provides the main unit with an interface for connection with

drive gas, heating system and the oxygen concentration sensor of the Breathing System.

19. The Breathing System Support Arm

The Breathing System Support Arm provides connection between the Breathing System and

the mainframe, in order to support the Breathing System.

20. Heater Wire

The Heater Wire provides connection to the heating system of the Breathing System. By

heating the Breathing System during anesthesia, accumulation of water in the Breathing

System is minimized. It also provides comfortable gas to the patient.

21. AGSS Transfer Hose

The AGSS Transfer Hose provides pipeline connection between the exhaust gas outlet of the

Breathing System and the AGSS evacuation system.

22. Lower Mainframe Assembly

The Lower Mainframe Assembly provides support for the drawer subassembly, outlet module,

CGO subassembly, O

flush valve and the electric box. Together with the Upper Mainframe

2

Subassembly and Base Assembly, forms the mainframe of the machine.

23. Base Assembly

The Base Assembly provides support to the whole machine. The four casters provide

movement for the machine in any direction. The front casters have a locking function.

1 - 6 0070-10-0683 AS3000™ Service Manual

Theory of Operation Components

24

25

26

27

28

29

30

31

32

33

1.3.3 Rear View

FIGURE 1-4 AS3000 Rear View

24. Top Shelf Assembly

The Top shelf Assembly includes the work light and its switch. It also serves as a storage

area.

25. Gas Input Assembly

The Gas Input Assembly allows gas in the pipeline and backup gas cylinder to enter the

AS3000 for regulation. The Pressure regulator reduces pressure to 36 psi (250 kPa). The

O

operated valve can open allowing N2O to enter the flowmeter only when O2 pressure is

2

above 7.3 psi (50 kPa). Otherwise, N2O cannot enter the gas circuit. The pressure switch

generates a signal when the input pressure is below 29 psi (200 kPa), and the system will

provide an audible alarm.

AS3000™ Service Manual 0070-10-0683 1 - 7

Components Theory of Operation

26. Vaporizer Storage Mount

The Vaporizer Storage Mount provides the AS3000 with auxiliary placement for a

vaporizer.

27. Mains Supply Assembly

The Mains Supply Assembly attaches the AS3000 to an external AC wall outlet. It also

supplies power throughout the unit.

28. Electronic Flowmeter Assembly

The Electronic Flowmeter Assembly provides fresh gas flow measurement for the AS3000.

29. Gas Box Assembly

The Gas Box Assembly provides drive gas to the Breathing System and includes a safety

valve to insure that pressure stays below 85 cmH

O. It also contains the PEEP valve, and the

2

differential pressure sensors.

30. YOKE Assembly

The YOKE Assembly provides connection for three backup gas cylinders. The pressure

regulator for the backup gas cylinder reduces the pressure of a high pressure gas cylinder

down to 43.5 psi (300 kPa).

31. AMP Cables

The AMP Cables provide signal transmission between the electric box and gas circuit box.

32. Electric Box Assembly

The Electric Box Assembly provides, and distributes power to the AS3000.

33. Rear Panel Assembly

The Rear Panel Assembly protects, and provides heat dissipation for the electric box and

auxiliary support for the backup gas cylinder.

1.3.4 Other components (not identified in graphics)

34. Inspiratory and Expiratory Valves

The Inspiratory and Expiratory Valves are unidirectional valves that allow air to flow in only

one direction.

35. Absorber Canister

The AS3000 uses two Absorber Canisters which can contain 1500 mL of soda lime each.

They can be used for 6 - 8 hours each if full. Water generated from the reaction with CO

drained from a valve on the lower side of the canister.

36. APL (Airway Pressure Limiting) Valve

The APL Valve is used for limiting maximum airway pressure during manual ventilation. The

adjustable range of the APL is 0 - 70 cmH

O.

2

is

2

1 - 8 0070-10-0683 AS3000™ Service Manual

Theory of Operation Components

37. Bellows Assembly

The AS3000 employs ascending ventilation bellows, in which mixed gas is stored. Drive

gas supplied by the ventilator forces the bellows to descend sending mixed gas into the

inspiratory passage of patient's airway. If a patient's airway suffers from gas leakage, the

bellows will collapse, informing the operator of a possible problem. A tidal volume scale is

provided on the transparent dome, through which a patient's tidal volume can be estimated.

38. Pressure-relief Valve

The Pressure-relief Valve is located at the base of the bellows. When end-expiration airway

pressure reaches 1 - 3 cmH

expelled.

39. Exhaust Gas Outlet

The Exhaust Gas Outlet is located on the lower part of the Breathing System. It is connected

to the AGSS or via the AGSS transfer tube.

40. Absorber Heating System

The Breathing System is heated to body temperature to avoid humidified gases condensing

within the Breathing System thus improving airway climatization for the patient's re-breathing

of respiratory gases.

O, the pressure-relief valve opens and redundant gas is

2

1.3.5 Breathing System

The Breathing System is integrated into a compact aluminum block. This block is heated to

body temperature to prevent condensing of humidified gases within the Breathing System,

thus improving airway climatization for the patient's re-breathing of respiratory gases. The

heated Breathing System contains: an inspiratory valve with O

measurement, expiratory valve, APL Valve, breathing bag connection, and internal

inspiratory and expiratory flow sensors.

1.3.6 The Ventilator Unit

The AS3000 ventilator offers multiple ventilation modes: Controlled Mandatory Ventilation

with volume control (CMV), Pressure Control Ventilation (PCV), Synchronized Intermittent

Mandatory Ventilation (SIMV), and Pressure Support (PS) ventilation. Electronic PEEP is

available in all ventilation modes. User control over inspiratory flow (SLOPE) is possible in

PCV, SIMV, and PS modes. Automatic fresh gas compensation limits the effect of user

changes in fresh gas flow rate on the patient. The traditional bellows system is driven by

oxygen and makes patient disconnections clearly visible.

adapter for FiO2

2

AS3000™ Service Manual 0070-10-0683 1 - 9

Components Theory of Operation

1.3.7 Adjustable Alarms

Minimum and maximum alarm limits can be set for Peak Pressure, Mean Pressure and FiO2.

Minimum alarm limits can be set for Tidal Volume and Minute Volume. Exceeding the peak

pressure alarm limit automatically halts the inspiratory phase preventing airway pressure

from exceeding the high alarm setting. In the CMV mode, when reaching this pressure limit,

a “High Airway Pressure” alarm is displayed, and inspiration is discontinued. The next

inspiration occurs at the regular time interval, preventing increase of the respiratory rate. The

result is a decreased tidal volume (T Vol.) and minute volume (M Vol.). During pressure

limitation, the ventilator displays the alarm message until the condition is corrected.

1.3.8 Compliance Compensation

Compliance compensation automatically corrects for the expansion of the circuit in CMV

ventilation mode. System compliance is measured by the ventilator to maintain the set tidal

volume (±15%). The compliance test may be bypassed at machine power up. When

bypassing the compliance test, the default settings are used.

1 - 10 0070-10-0683 AS3000™ Service Manual

Theory of Operation Electrical Supply

Ventilator UI

Ventilator Control and Drive

Anesthesia

10.4” TFT-LCD

PC104

Backlight Inverter

Amplifier for

audio alarm

Communication

and Interface

Keypad

Knob

BDU

Amplifier

PWR MNG

DC/DC

BAT

PS

AC/DC

SW

Work L ight

FM Back Light

AC Heater

Ctrl &

Protect

Aux Mains

Outlet

Inlet

Filter

Power Supply

Pwr

DA

Cable

Switch

Switch

Internal Signals

Val. Exp. PEEP

Flow Insp.

FM Flow Sensor

Cal. Valve

Manual/Mech Val.

P. V a l. In sp.

Gas Source Pressure

FiO2 Sensor

Airway Pressure

Probe Flow

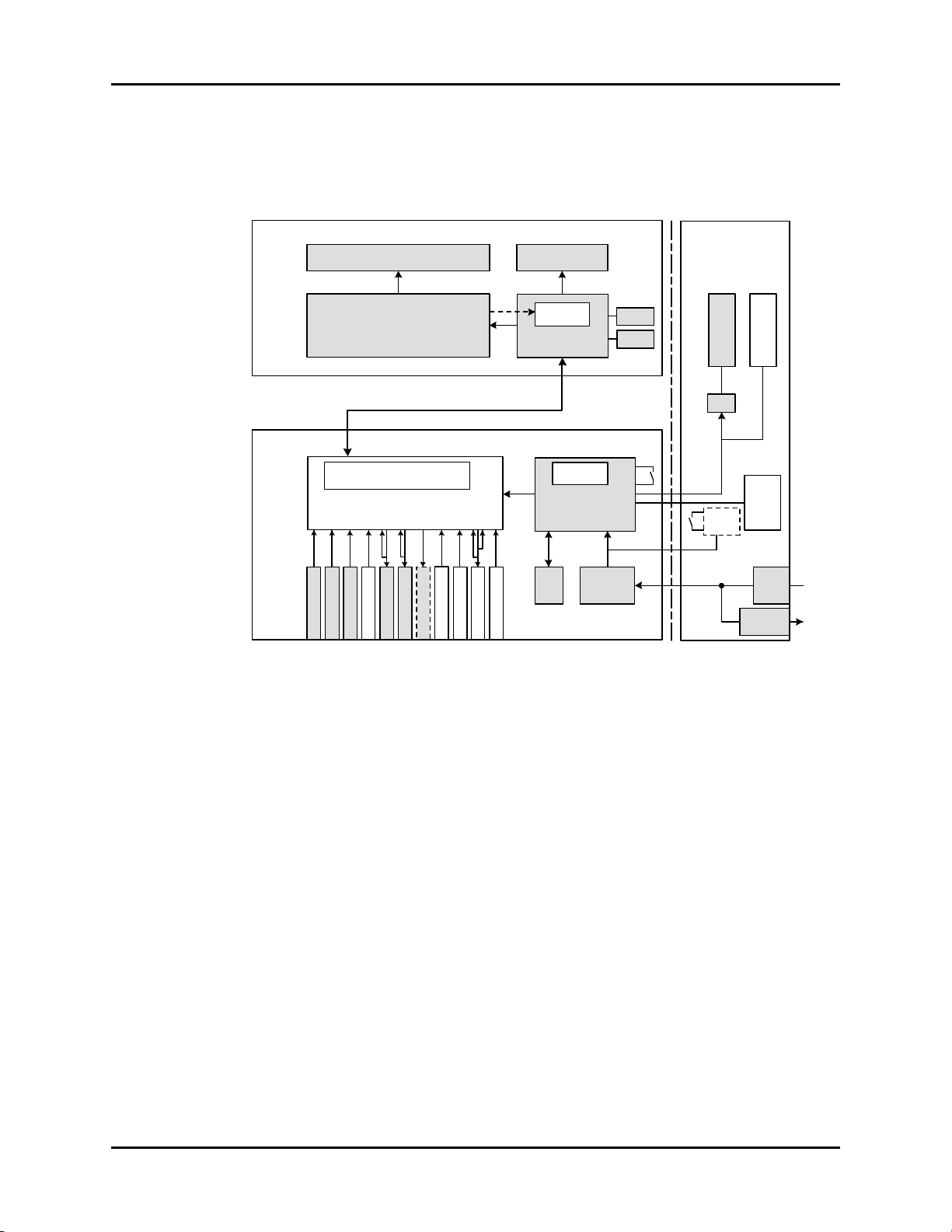

1.4 Electrical Supply

1.4.1 Electrical components

FIGURE 1-5 Electrical Components Overview

AS3000™ Service Manual 0070-10-0683 1 - 11

Ventilator Control and Drive Theory of Operation

1.5 Ventilator Control and Drive

1.5.1 BDU (Basic Digital Unit)

The BDU serves as the active ventilator control. The BDU controls the actions of the PEEP,

calibration, and proportional valves, and reads the signal flow, and pressure sensors and

valves

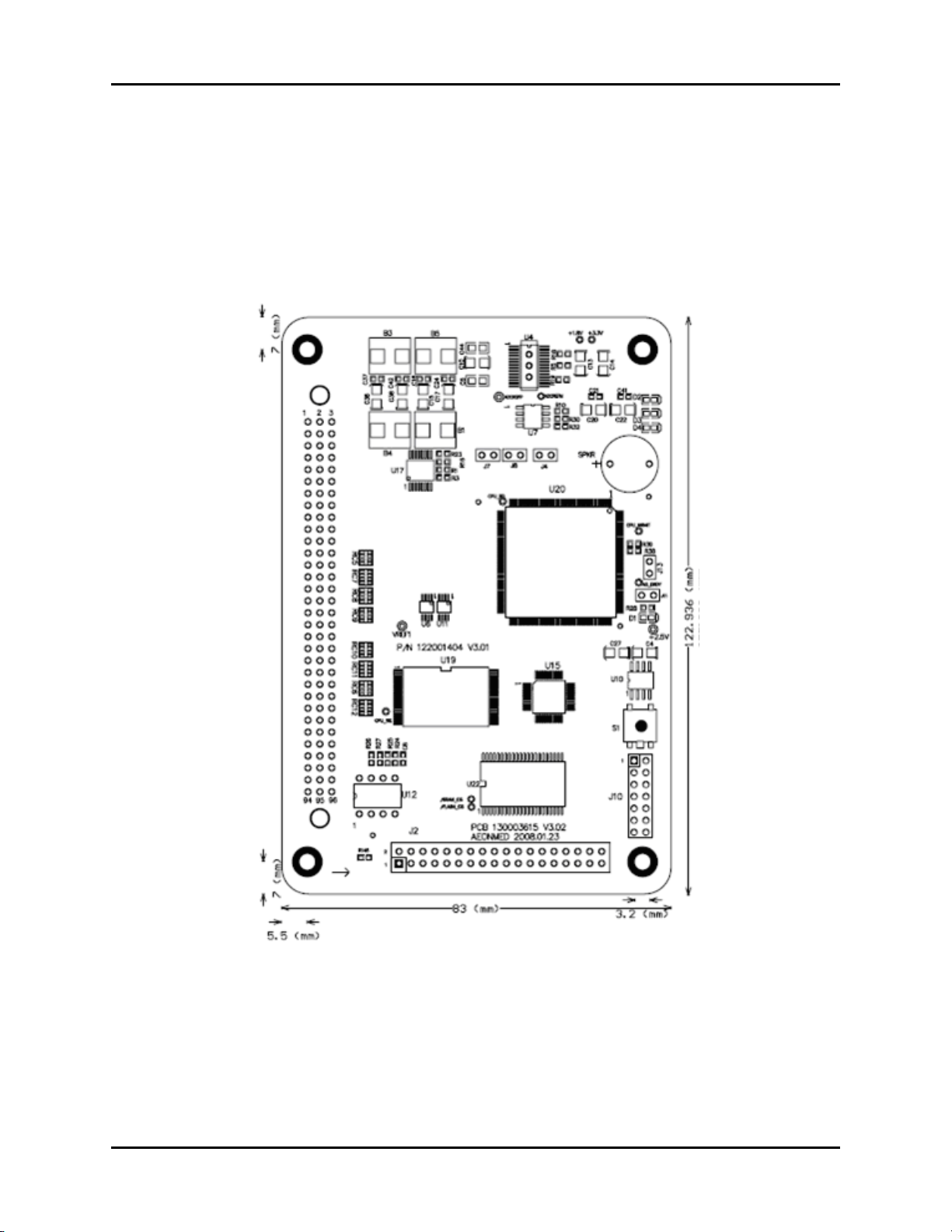

FIGURE 1-6 BDU Control Board, Top View

1 - 12 0070-10-0683 AS3000™ Service Manual

Theory of Operation Ventilator Control and Drive

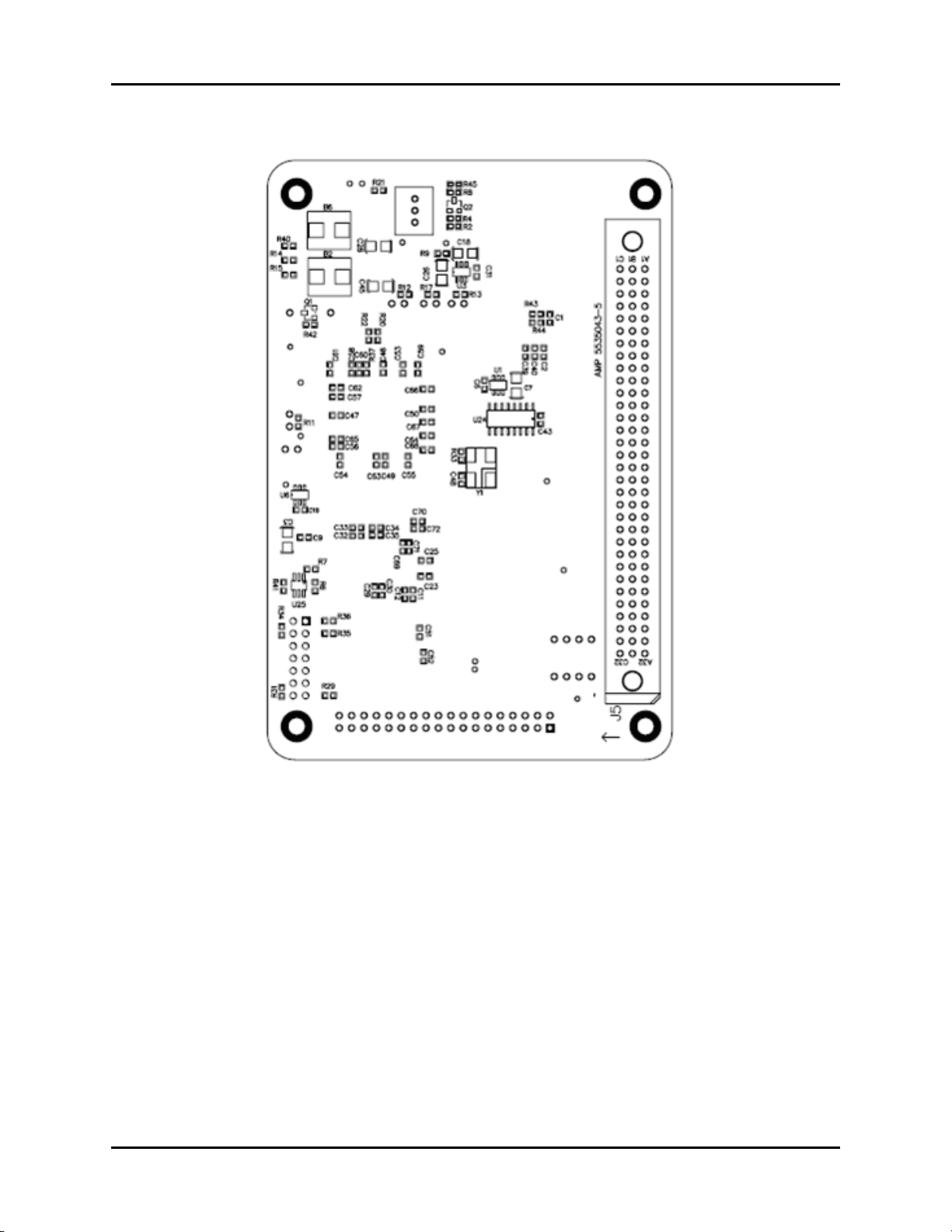

FIGURE 1-7 BDU Control Board, Bottom View

AS3000™ Service Manual 0070-10-0683 1 - 13

Ventilator Control and Drive Theory of Operation

1.5.1.1 Amplifier Board

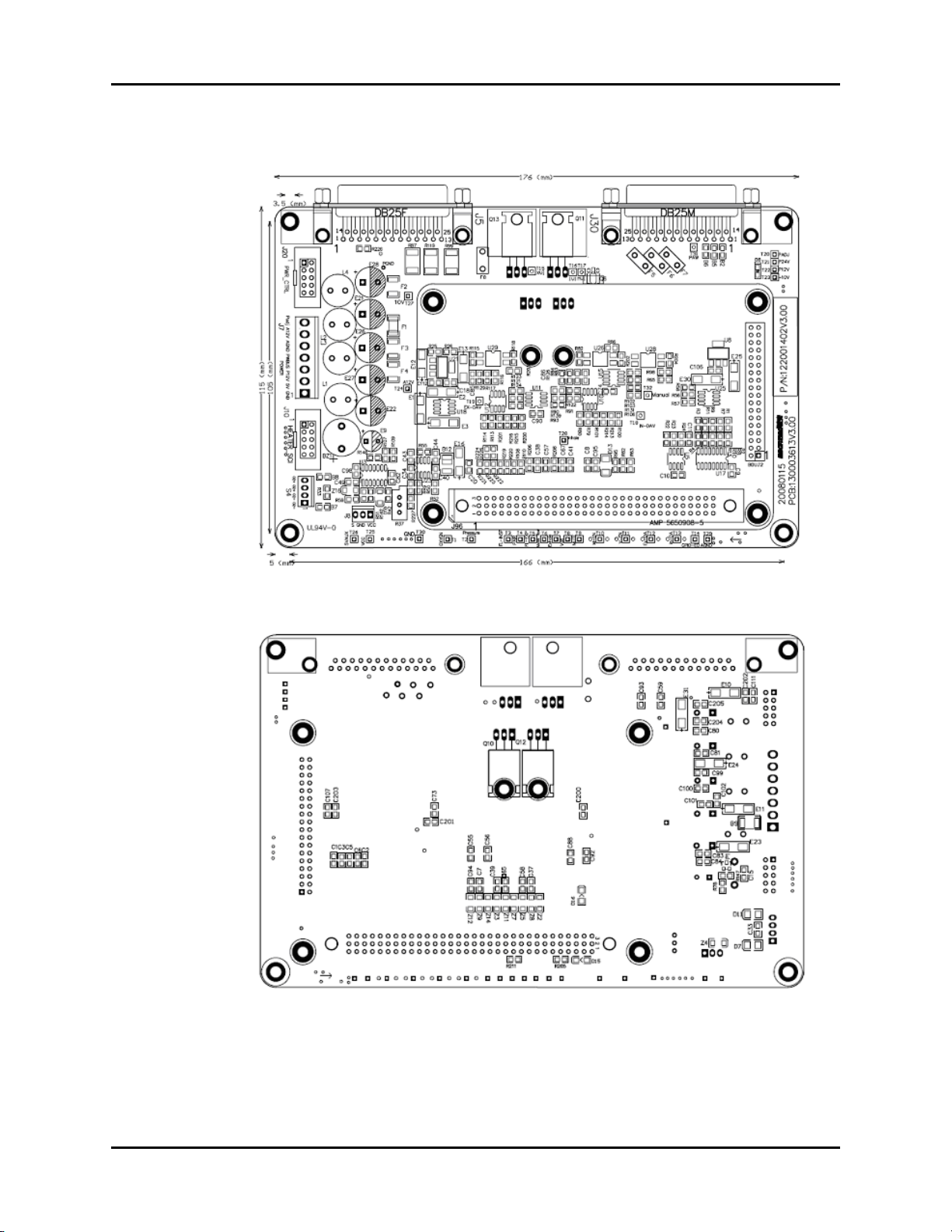

FIGURE 1-8 Amplifier Board, Top View

FIGURE 1-9 Amplifier Board, Bottom View

1 - 14 0070-10-0683 AS3000™ Service Manual

Theory of Operation Ventilator Control and Drive

O2 Sensor Input, S4

PIN NAME FUNCTION

1. O

2. O

3. O

4. O

-O

2

-O

2

+O

2

+O

2

Sensor Input -

2

Sensor Input -

2

Sensor Input +

2

Sensor Input +

2

DC Power Input, J7

PIN NAME FUNCTION

1. GND Power Ground

2. +5V Controller Logic Power

3. P12V Power 12V

4. PWBUS Power Bus 24V

5. GND Analog Ground

6. A12V Analog 12V

7. 5V/4.8V Power 5V/4.8V

Power Control, J20

PIN NAME FUNCTION

1. GND Ground

2. /PWON Power On Enable, Low active

3. PWEN Power On Enable, High active

4. 5VAUX 5V Auxiliary

5. DC_M AC/DC Monitor signal

6. PWBUS Power bus

7. BAT_M Battery Monitor signal

8. APE Auxiliary Power Enable

9. CHAR_SIGNAL Charge Status, No connection

10. /MUTE Mute, No connection

Signals and Power to Keyboard, J5

PIN NAME FUNCTION

1. ENPW Power Enable, High active

2. /PWON / Power on Enable, Low active

3. 5VAUX 5V Auxiliary

4. APE Auxiliary Power Enable

5. GND Ground

6. TTLRX TTL Receive

7. 232ARX RS232A Receive

8. 232BRX RS232B Receive

9. GND Ground

AS3000™ Service Manual 0070-10-0683 1 - 15

Ventilator Control and Drive Theory of Operation

Signals and Power to Keyboard, J5 (Continued)

PIN NAME FUNCTION

10. PWBUS PowerBus

11. PWBUS PowerBus

12. PWBUS PowerBus

13. GND Ground

14. GND Ground

15. DC24V DC24V monitor

16. BATV+ Battery monitor

17. /MUTE No connection

18. GND Ground

19. TTLTX TTL Transmit

20. 232ATX RS232A Transmit

21. 232BTX RS232B Transmit

22. GND Ground

23. PWBUS PowerBus

24. PWBUS PowerBus

25. GND Ground

Signals and Power to Sensor Board, J30

PIN NAME FUNCTION

1. A+12V Analogue +12V

2. FL_INS Import flow

3. FL_EXP Export flow

4. FM_FL Flowmeter flow

5. Pair Pressure of air

6. Paw Pressure inside air way

7. Pgas Pressure gas supply status

8. GND Ground

9. AGND Analog Ground

10. AGND Analog Ground

11. P24V Power 24V

12. P24V Power 24V

13. P24V Power 24V

14. P12V Power 12V

15. P12V Power 12

16. P5V Power 5V

17. P5V Power 5V

18. Inhale Inspire Valve

19. Man Manual/AUTO Valve

20. Exhale Expire Valve

21. Exhale Expire Valve

22. AGND Analog Ground

1 - 16 0070-10-0683 AS3000™ Service Manual

Theory of Operation Ventilator Control and Drive

Signals and Power to Sensor Board, J30 (Continued)

PIN NAME FUNCTION

23. AGND Analog Ground

24. AGND Analog Ground

25. AGND Analog Ground

Bus to BDU, J96

PIN NAME FUNCTION

1 - 3 5V 5V Power

4 - 6 GND Ground

Test Point Definition

DESIGNATOR NAME FUNCTION RANGE

T1 FIO

T2 Pgas Pressure switch of gas supply,

T3 FL_INSP Inspire Flow signal 0.20-0.30V (0 flow)

T4 Pair Absolute Pressure of air way 1.7-2.1V (atmospheric

T5 FL_EXP Expire flow signal 0.20-0.30V (0 flow)

T6 Fm_fl Flow of flowmeter 0.25-0.51V (flowmeter off)

T7 AD-Exhale PEEP valve, current feedback Level depends on PEEP

T8 Volt Internal power inspect

T9 MUTE Not used

T10 M-EN Manual/Auto mode select

T11 V-EN Valves enable Input Global valve enable signal.

T12 EX-DA Exhale DA output

T13 In-DA Inhale DA output

T14 GS_ST gas supply status, high active

T15 XVI unamplified version of T7

T16 IVI unamplified version of T28

T17 MVI Manual-Valve current feedback

T18 IVG Proportional valve drive signal,

T19 XVG PEEP valve drive signal - drives

T20 PADJ Power 4.8V 4.8V

T21 P24V Power 24V 24V

T22 P12V Power 12V 12V

ADC input of O2 Sensor 0.25-0.51V (In AIR)

2

low active

pressure)

setting and vent mode. No

activity may indicate open

connection from driver to

valve (ie. bad cable)

Must be active for valves to

operate.

Level depends on machine

drives T16 and T28

T15 and T7

settings.

Level depends on PEEP

setting and vend mode.

AS3000™ Service Manual 0070-10-0683 1 - 17

Loading...

Loading...