SV600

Ventilator

Operator’s Manual

© 2017-2018 Shenzhen Mindray Bio-Medical Electronics Co., Ltd. All rights Reserved.

For this Operator’s Manual, the issue date is December, 2018.

I

Intellectual Property Statement

SHENZHEN MINDRAY BIO-MEDICAL ELECTRONICS CO., LTD. (hereinafter called

Mindray) owns the intellectual property rights to this Mindray product and this manual. This

manual may refer to information protected by copyright or patents and does not convey any

license under the patent rights or copyright of Mindray, or of others.

Mindray intends to maintain the contents of this manual as confidential information.

Disclosure of the information in this manual in any manner whatsoever without the written

permission of Mindray is strictly forbidden. Release, amendment, reproduction, distribution,

rental, adaptation, translation or any other derivative work of this manual in any manner

whatsoever without the written permission of Mindray is strictly forbidden.

, and are the trademarks, registered or otherwise, of

Mindray in China and other countries. All other trademarks that appear in this manual are

used only for informational or editorial purposes. They are the property of their respective

owners.

II

Responsibility on the Manufacturer

Party

Contents of this manual are subject to change without prior notice.

All information contained in this manual is believed to be correct. Mindray shall not be liable

for errors contained herein or for incidental or consequential damages in connection with the

furnishing, performance, or use of this manual.

Mindray is responsible for the effects on safety, reliability and performance of this product,

only if:

all installation operations, expansions, changes, modifications and repairs of this product

are conducted by Mindray authorized personnel;

the electrical installation of the relevant room complies with the applicable national and

local requirements; and

the product is used in accordance with the instructions for use.

WARNING

It is important for the hospital or organization that employs this equipment to

carry out a reasonable service/maintenance plan. Neglect of this may result in

machine breakdown or personal injury.

NOTE

This equipment must be operated by skilled/trained clinical professionals.

III

Warranty

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE.

Exemptions

Mindray's obligation or liability under this warranty does not include any transportation or

other charges or liability for direct, indirect or consequential damages or delay resulting from

the improper use or application of the product or the use of parts or accessories not approved

by Mindray or repairs by people other than Mindray authorized personnel.

This warranty shall not extend to:

Malfunction or damage caused by improper use or man-made failure.

Malfunction or damage caused by unstable or out-of-range power input.

Malfunction or damage caused by force majeure such as fire and earthquake.

Malfunction or damage caused by improper operation or repair by unqualified or

unauthorized service people.

Malfunction of the instrument or part whose serial number is not legible enough.

Others not caused by instrument or part itself.

IV

Customer Service Department

Manufacturer: Shenzhen Mindray Bio-Medical Electronics Co., Ltd.

Address: Mindray Building, Keji 12th Road South, High-tech industrial

park, Nanshan, Shenzhen 518057, P.R. China

Website: www.mindray.com

E-mail Address: service@mindray.com

Tel: +86 755 81888998

Fax: +86 755 26582680

EC-Representative: Shanghai International Holding Corp. GmbH (Europe)

Address: Eiffestraβe 80, 20537 Hamburg, GERMANY

Tel: 0049-40-2513175

Fax: 0049-40-255726

V

Preface

Manual Purpose

This manual contains the instructions necessary to operate the product safely and in

accordance with its function and intended use. Observance of this manual is a prerequisite for

proper product performance and correct operation and ensures patient and operator safety.

This manual is based on the maximum configuration and therefore some contents may not

apply to your product. If you have any question, please contact us.

This manual is an integral part of the product. It should always be kept close to the equipment

so that it can be obtained conveniently when needed.

Intended Audience

This manual is geared for clinical professionals who are expected to have a working

knowledge of medical procedures, practices and terminology as required for monitoring of

critically ill patients.

Illustrations

All illustrations in this manual serve as examples only. They may not necessarily reflect the

setup or data displayed on your ventilator.

Conventions

Italic text is used in this manual to quote the referenced chapters or sections.

[ ] is used to enclose screen texts.

→ is used to indicate operational procedures.

Password

A password is required to access different menus within the ventilator.

System menu: 1234

VI

Table of Contents

1 Safety ................................................................................................................................. 1-1

1.1 Safety Information .......................................................................................................... 1-1

1.1.1 DANGER ........................................................................................................... 1-2

1.1.2 WARNING ......................................................................................................... 1-2

1.1.3 CAUTION .......................................................................................................... 1-6

1.1.4 NOTE ................................................................................................................. 1-8

1.2 Equipment Symbols ........................................................................................................ 1-8

2 The Basics ......................................................................................................................... 2-1

2.1 System Description ......................................................................................................... 2-1

2.1.1 Intended Use....................................................................................................... 2-1

2.1.2 Contraindications ............................................................................................... 2-1

2.1.3 Components ....................................................................................................... 2-1

2.2 Equipment Appearance ................................................................................................... 2-2

2.2.1 Front View .......................................................................................................... 2-2

2.2.2 Rear View ........................................................................................................... 2-4

2.2.3 Air Compressor .................................................................................................. 2-6

3 Installations and Connections ......................................................................................... 3-1

3.1 Connect the Power Supply .............................................................................................. 3-1

3.2 Connect the Pipeline Supply ........................................................................................... 3-2

3.3 Install the Gas Cylinder ................................................................................................... 3-4

3.4 Install the Support Arm ................................................................................................... 3-5

3.5 Install the Patient Tubing ................................................................................................ 3-7

3.5.1 Install Adult/Pediatric Tubing ............................................................................ 3-8

3.5.2 Install Neonate Tubing ....................................................................................... 3-9

3.6 Install the Humidifier ..................................................................................................... 3-11

3.6.1 Install the Humidifier onto the Ventilator .......................................................... 3-11

3.6.2 Install the Humidifier onto the Pendant ........................................................... 3-13

3.7 Install the Nebulizer ...................................................................................................... 3-14

3.7.1 Install Pneumatic Nebulizer ............................................................................. 3-15

3.7.2 Install Electronic Nebulizer .............................................................................. 3-16

3.8 Install the Oxygen Sensor ............................................................................................. 3-17

3.8.1 O

3.8.2 Paramagnetic O

3.9 Install Module ............................................................................................................... 3-19

Cell .............................................................................................................. 3-17

2

Sensor ................................................................................... 3-18

2

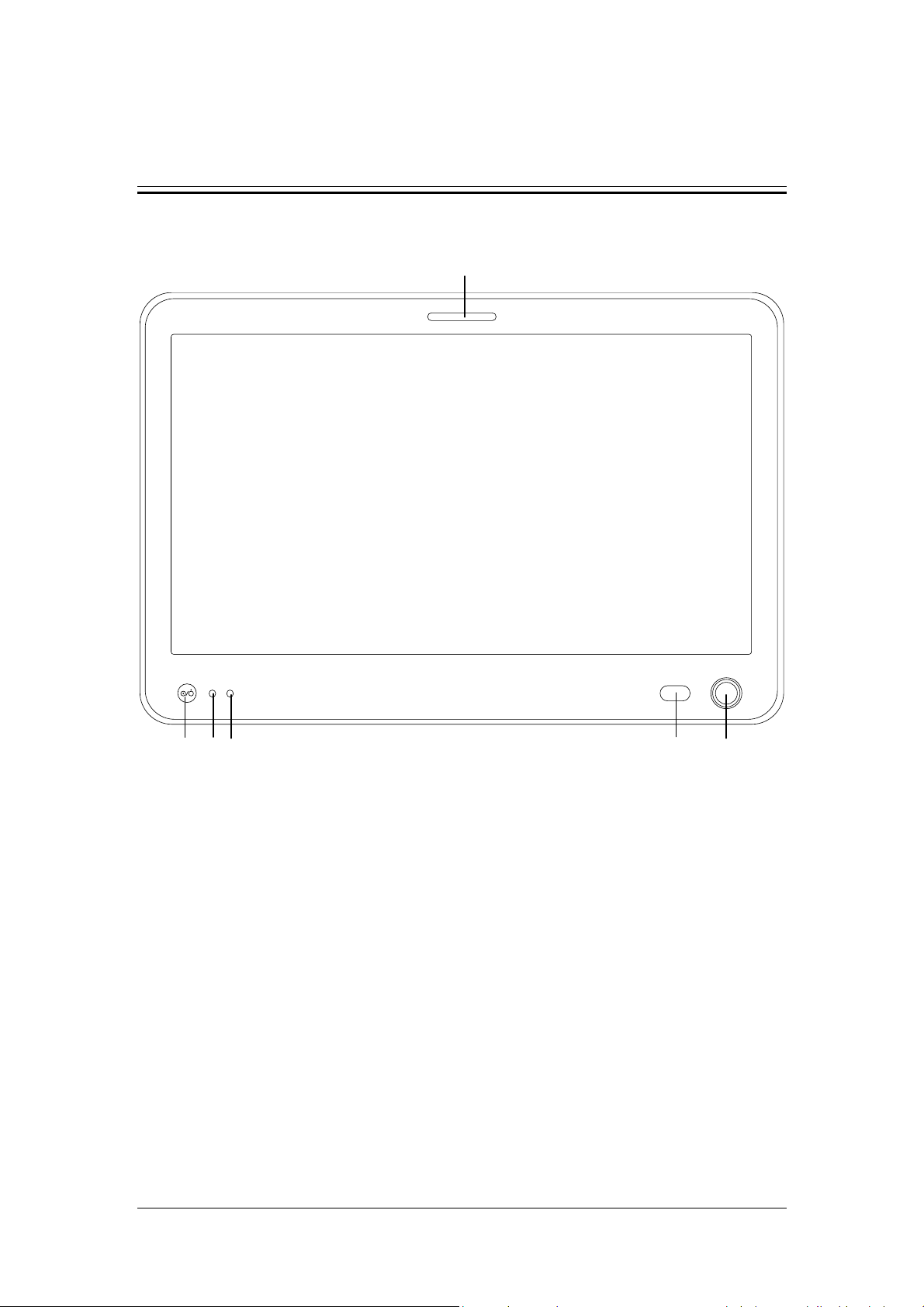

4 User Interface ................................................................................................................... 4-1

4.1 Display Controls ............................................................................................................. 4-1

4.2 Waveforms Screen ........................................................................................................... 4-5

1

4.2.1 Graphic trend ...................................................................................................... 4-6

4.2.2 PulmoSight ......................................................................................................... 4-6

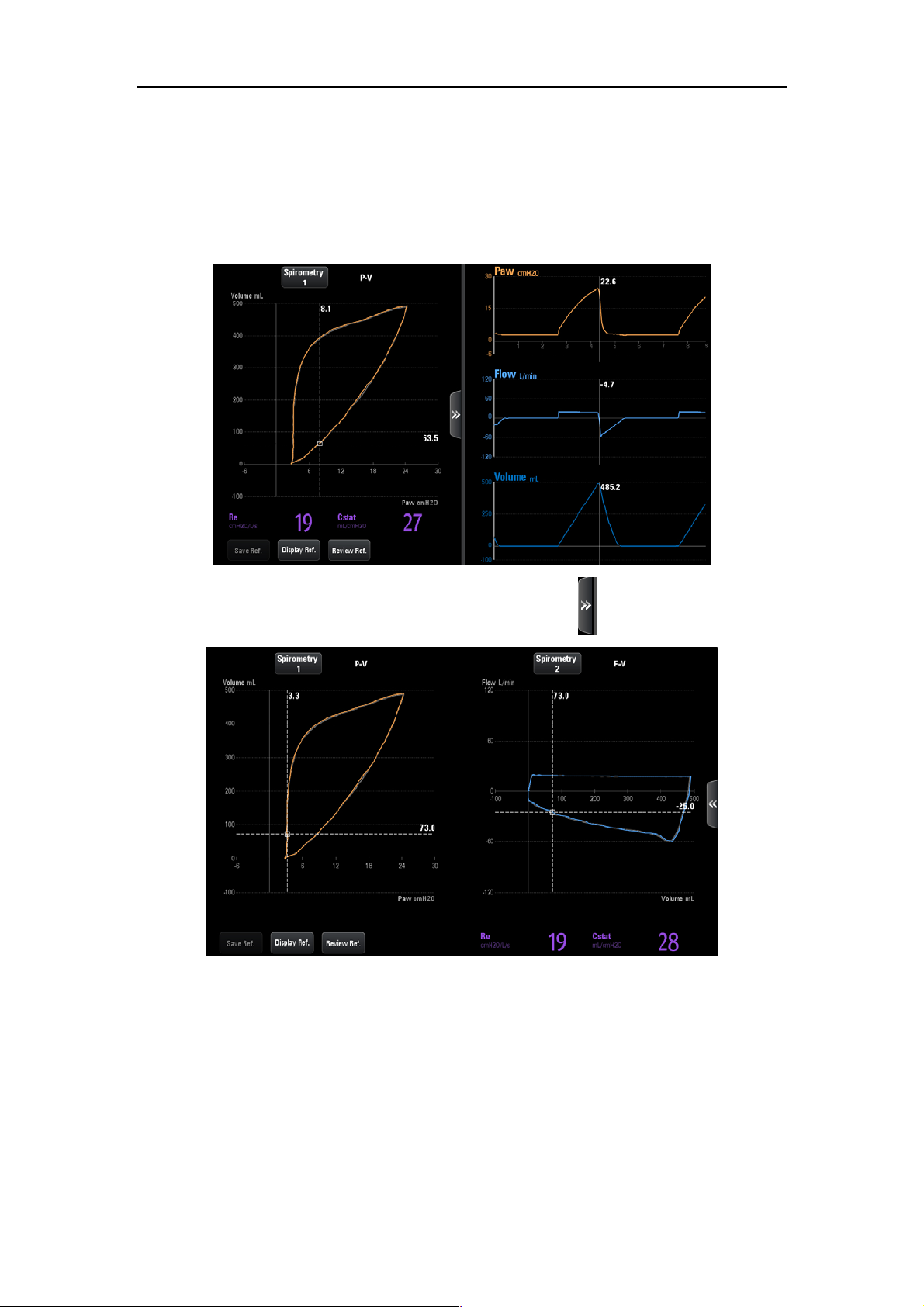

4.3 Spirometry Screen ........................................................................................................... 4-7

4.4 Measured Values Screen ................................................................................................ 4-10

4.5 Big Numeric Interface ................................................................................................... 4-10

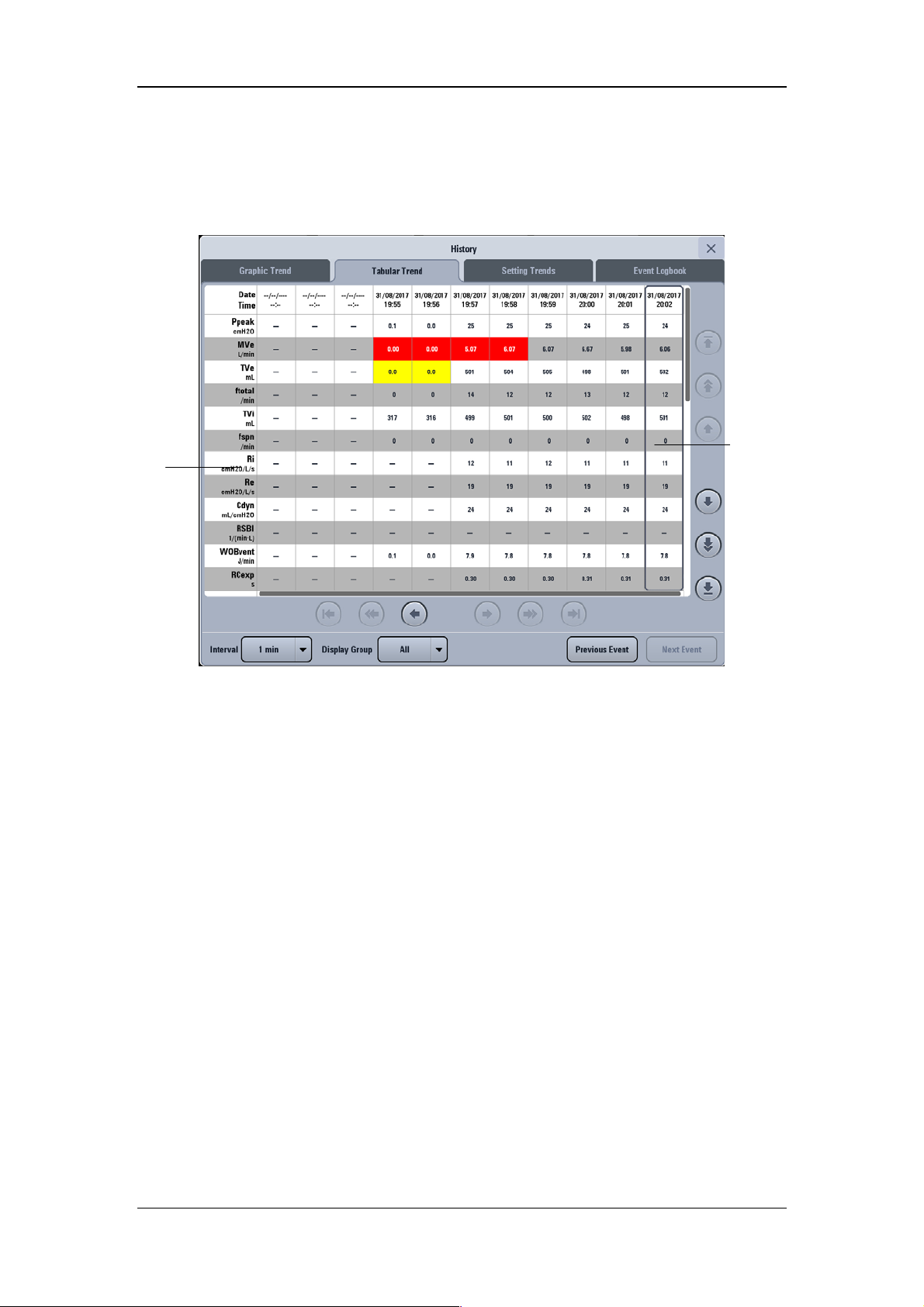

4.6 History ............................................................................................................................ 4-11

4.6.1 Graphic Trend.................................................................................................... 4-11

4.6.2 Tabular Trend ................................................................................................... 4-13

4.6.3 Setting Trends................................................................................................... 4-14

4.6.4 Event Logbook ................................................................................................. 4-15

4.7 Freeze ............................................................................................................................ 4-16

4.7.1 Enter Freeze Status ........................................................................................... 4-16

4.7.2 View Frozen Waveforms .................................................................................. 4-16

4.7.3 View Frozen Loop ............................................................................................ 4-17

4.7.4 Exit Freeze Status ............................................................................................. 4-17

4.8 Screen Capture .............................................................................................................. 4-18

4.9 Lock Screen ................................................................................................................... 4-18

5 System Settings ................................................................................................................. 5-1

5.1 Date & Time Settings ...................................................................................................... 5-1

5.2 Export to USB ................................................................................................................. 5-1

5.2.1 Export Screen ..................................................................................................... 5-1

5.2.2 Export Data ........................................................................................................ 5-1

5.2.3 Transfer Settings ................................................................................................. 5-2

5.3 Basic Settings .................................................................................................................. 5-3

5.3.1 Set Flow/Tpause(%) ........................................................................................... 5-3

5.3.2 Set Tinsp/I:E ....................................................................................................... 5-3

5.3.3 Set IBW/Height .................................................................................................. 5-3

5.3.4 Set TV/IBW ....................................................................................................... 5-4

5.3.5 Setup DuoLevel .................................................................................................. 5-4

5.3.6 Set Invasive Apnea Mode ................................................................................... 5-4

5.3.7 Set O

% increment during O2↑ period ............................................................ 5-4

2

5.3.8 Set Oxygen Sensor Monitoring .......................................................................... 5-5

5.4 Screen Settings ................................................................................................................ 5-6

5.4.1 Adjust Screen Brightness ................................................................................... 5-6

5.4.2 Adjust Key Volume ............................................................................................ 5-6

5.4.3 Screen Setup ....................................................................................................... 5-6

5.4.4 Color Settings ..................................................................................................... 5-7

5.5 System Settings ............................................................................................................... 5-8

5.5.1 Set Language ...................................................................................................... 5-8

5.5.2 Set Unit .............................................................................................................. 5-8

5.5.3 Set Minimum Alarm Volume ............................................................................. 5-8

5.5.4 Default Settings .................................................................................................. 5-9

5.5.5 Set Nurse Call .................................................................................................. 5-10

2

5.5.6 Set Network ...................................................................................................... 5-10

5.5.7 View System Information ................................................................................. 5-10

5.6 Set Tool Shortcut Key .................................................................................................... 5-11

5.7 Set Gas Supply ............................................................................................................... 5-11

5.8 Factory Service Settings ................................................................................................. 5-11

6 Start Ventilation ................................................................................................................ 6-1

6.1 Turn on the System ......................................................................................................... 6-1

6.2 System Check .................................................................................................................. 6-1

6.3 Circuit Test ...................................................................................................................... 6-3

6.4 Select Patient ................................................................................................................... 6-5

6.4.1 Set Patient Information on the Ventilator ........................................................... 6-5

6.4.2 Getting Patient Information from the ADT Server ............................................. 6-5

6.5 Ventilation Type .............................................................................................................. 6-6

6.5.1 Invasive Ventilation ............................................................................................ 6-6

6.5.2 Non-Invasive Ventilation (NIV) ......................................................................... 6-7

6.5.3 Set Ventilation Type ........................................................................................... 6-7

6.6 Ventilation Mode ............................................................................................................. 6-8

6.6.1 Ventilation Mode and Parameter Setup .............................................................. 6-8

6.6.2 V-A/C ............................................................................................................... 6-10

6.6.3 P-A/C ................................................................................................................ 6-11

6.6.4 V-SIMV ............................................................................................................ 6-12

6.6.5 P-SIMV ............................................................................................................ 6-13

6.6.6 CPAP/PSV ........................................................................................................ 6-14

6.6.7 PSV-S/T ............................................................................................................ 6-16

6.6.8 PRVC ................................................................................................................ 6-17

6.6.9 PRVC-SIMV .................................................................................................... 6-18

6.6.10 DuoLevel ........................................................................................................ 6-20

6.6.11 APRV .............................................................................................................. 6-21

6.6.12 VS ................................................................................................................... 6-22

6.6.13 AMV ............................................................................................................... 6-23

6.6.14 CPRV .............................................................................................................. 6-25

6.6.15 nCPAP ............................................................................................................ 6-26

6.6.16 Apnea Ventilation ........................................................................................... 6-27

6.7 Other Ventilation Settings ............................................................................................. 6-28

6.7.1 Sigh .................................................................................................................. 6-28

6.7.2 Leak Compensation .......................................................................................... 6-29

6.7.3 Automatic Tube Resistance Compensation (ATRC) ........................................ 6-31

6.7.4 IntelliCycle ....................................................................................................... 6-32

6.8 Alarm settings ............................................................................................................... 6-32

6.9 Start Ventilation ............................................................................................................. 6-32

6.10 Ventilation Parameters................................................................................................. 6-33

6.11 Enter Standby Status ................................................................................................... 6-37

6.12 Turn the System off ..................................................................................................... 6-37

3

7 Neonatal Ventilation ......................................................................................................... 7-1

7.1 Safety Information .......................................................................................................... 7-1

7.2 Connecting Patient Tubing to the Flow Sensor ............................................................... 7-2

7.3 Circuit Test ...................................................................................................................... 7-2

7.4 Start Ventilation ............................................................................................................... 7-2

7.5 Backup Ventilation .......................................................................................................... 7-3

7.6 Set the Monitoring Switch .............................................................................................. 7-3

7.7 Neonatal Flow Sensor Zeroing ........................................................................................ 7-3

8 CO

Monitoring ................................................................................................................ 8-1

2

8.1 Introduction ..................................................................................................................... 8-1

8.2 CO2 Module .................................................................................................................... 8-4

8.3 Sidestream CO

Module .................................................................................................. 8-5

2

8.3.1 Preparation for Measurement ............................................................................. 8-5

8.3.2 Make CO

Settings ............................................................................................. 8-6

2

8.3.3 Measurement Limitations ................................................................................... 8-8

8.3.4 Troubleshooting .................................................................................................. 8-8

8.3.5 Zero the Sensor .................................................................................................. 8-8

8.3.6 Calibrate the Sensor ........................................................................................... 8-8

8.4 Mainstream CO

module ................................................................................................. 8-9

2

8.4.1 Preparation for Measurement ............................................................................. 8-9

8.4.2 Make CO

Settings ........................................................................................... 8-10

2

8.4.3 Measurement Limitations .................................................................................. 8-11

8.4.4 Zero the Sensor ................................................................................................. 8-11

8.4.5 Calibrate the Sensor ......................................................................................... 8-12

9 SpO2 Monitoring .............................................................................................................. 9-1

9.1 Introduction ..................................................................................................................... 9-1

9.2 Safety Information .......................................................................................................... 9-2

9.3 Applying the Sensor ........................................................................................................ 9-3

9.4 Make SpO

9.4.1 Set SpO

Settings ........................................................................................................ 9-3

2

Monitoring .......................................................................................... 9-3

2

9.4.2 Set Sensitivity..................................................................................................... 9-3

9.4.3 Beat Volume ....................................................................................................... 9-3

9.4.4 Set CO

Waveform ............................................................................................. 9-3

2

9.5 Measurement Limitations ................................................................................................ 9-4

10 Special Functions .......................................................................................................... 10-1

10.1 Manual Breath ............................................................................................................. 10-1

10.2 Expiration Hold ........................................................................................................... 10-1

10.3 Inspiration Hold .......................................................................................................... 10-2

10.4 Nebulizer ..................................................................................................................... 10-2

10.4.1 Pneumatic Nebulizer ...................................................................................... 10-3

10.4.2 Electronic Nebulizer ....................................................................................... 10-3

4

10.5 O2↑(Oxygen Enrichment) .......................................................................................... 10-4

10.6 Suction ........................................................................................................................ 10-5

10.7 P0.1 ............................................................................................................................. 10-6

10.8 PEEPi .......................................................................................................................... 10-6

10.9 NIF .............................................................................................................................. 10-7

10.10 Calculation of Alveolar Ventilation ........................................................................... 10-7

10.11 P-V Tool .................................................................................................................... 10-8

10.12 Recruitment Tool(SI) ......................................................................................... 10-10

10.12.1 History ......................................................................................................... 10-11

10.13 Weaning Tools .......................................................................................................... 10-11

10.13.1 Help Information Viewing.......................................................................... 10-12

10.13.2 Spontaneous Breathing Trial (SBT) ........................................................... 10-12

10.13.3 History ........................................................................................................ 10-13

10.14 O

Therapy .............................................................................................................. 10-14

2

10.14.1 Preparing for O

10.14.2 Switching on O

10.14.3 O

Therapy Timing/Timer .......................................................................... 10-18

2

10.14.4 Switching off O

Therapy ........................................................................... 10-14

2

Therapy ........................................................................... 10-17

2

Therapy ........................................................................... 10-18

2

11 Alarms ............................................................................................................................ 11-1

11.1 Introduction .................................................................................................................. 11-1

11.2 Alarm Categories .......................................................................................................... 11-2

11.3 Alarm Priority Levels ................................................................................................... 11-2

11.4 Alarm Signals ............................................................................................................... 11-2

11.4.1 Alarm Lamp ..................................................................................................... 11-3

11.4.2 Audible Alarm ................................................................................................. 11-3

11.4.3 Alarm Messages .............................................................................................. 11-3

11.4.4 Flashing Alarm Numeric ................................................................................. 11-3

11.4.5 Alarm Status Symbol ....................................................................................... 11-4

11.5 Alarm Volume Settings ................................................................................................. 11-4

11.6 Set Alarm Limits .......................................................................................................... 11-5

11.6.1 Auto Alarm Limits ........................................................................................... 11-5

11.7 AUDIO PAUSED ......................................................................................................... 11-6

11.7.1 Set AUDIO PAUSED ...................................................................................... 11-6

11.7.2 Terminate AUDIO PAUSED ........................................................................... 11-6

11.8 Current Alarm ............................................................................................................... 11-7

11.9 Alarm Chain ................................................................................................................. 11-8

11.10 Recent Alarm .............................................................................................................. 11-8

11.11 ALARM OFF ............................................................................................................. 11-9

11.12 Alarm Tests ............................................................................................................... 11-10

11.12.1 Battery in Use .............................................................................................. 11-10

11.12.2 Loss of Power .............................................................................................. 11-10

11.12.3 Paw Too High .............................................................................................. 11-10

11.12.4 Paw Too Low ............................................................................................... 11-11

5

11.12.5 TVe Too Low ............................................................................................... 11-11

11.12.6 TVe Too High .............................................................................................. 11-11

11.12.7 MV Too Low ............................................................................................... 11-11

11.12.8 Air Supply Pressure Low ............................................................................. 11-11

11.12.9 O

Supply Pressure Low .............................................................................. 11-12

2

11.12.10 PEEP Too Low .......................................................................................... 11-12

11.12.11 Airway Obstructed ..................................................................................... 11-12

11.12.12 FiO

11.12.13 FiO

11.12.14 EtCO

11.12.15 EtCO

11.12.16 SpO

11.12.17 SpO

11.12.18 SpO

Too High ........................................................................................... 11-12

2

Too Low ............................................................................................ 11-13

2

Too High ........................................................................................ 11-13

2

Too Low ......................................................................................... 11-13

2

Too High .......................................................................................... 11-13

2

Too Low ........................................................................................... 11-14

2

Desat ................................................................................................ 11-14

2

11.12.19 PR Too High .............................................................................................. 11-14

11.12.20 PR Too LOW ............................................................................................. 11-14

11.13 Nurse Call ................................................................................................................. 11-15

11.14 When an Alarm Occurs ............................................................................................ 11-16

12 Cleaning and Disinfection ............................................................................................ 12-1

12.1 Methods for Cleaning and Disinfection ...................................................................... 12-2

12.2 Disassemble the Ventilator’s Cleanable and Disinfectable Parts ................................ 12-5

12.2.1 Expiration Valve Assembly and Membrane ................................................... 12-5

12.2.2 Inspiration safety valve assembly .................................................................. 12-7

12.2.3 HEPA Filter Components and Air Intake Dust Filter ................................... 12-10

12.2.4 Back air supply cooling fan dust filter ......................................................... 12-12

12.2.5 Main Unit Air Outlet Dust Filter .................................................................. 12-13

12.2.6 Patient Tubing .............................................................................................. 12-14

12.2.7 Humidifier .................................................................................................... 12-16

12.2.8 Nebulizer ...................................................................................................... 12-19

12.2.9 Mainstream CO

Module ............................................................................. 12-22

2

13 Maintenance ................................................................................................................. 13-1

13.1 Repair Policy ............................................................................................................... 13-1

13.2 Maintenance Schedule ................................................................................................ 13-2

13.3 View Preventive Maintenance Items ........................................................................... 13-4

13.4 Pressure and Flow Zeroing .......................................................................................... 13-5

13.5 Neonatal Flow Sensor Zeroing .................................................................................... 13-5

13.6 Flow Calibration ......................................................................................................... 13-6

13.7 O

13.8 CO

% Calibration .......................................................................................................... 13-7

2

Calibration ........................................................................................................... 13-8

2

13.8.1 Sidestream CO

13.8.2 Mainstream CO

Module ................................................................................. 13-8

2

Module ............................................................................... 13-9

2

13.9 Touch Screen Calibration ............................................................................................ 13-9

6

13.10 Battery Maintenance ................................................................................................. 13-9

13.10.1 Battery Guidelines ....................................................................................... 13-11

13.10.2 Battery Performance Conditioning .............................................................. 13-11

13.10.3 Battery Performance Checking .................................................................. 13-12

13.10.4 Battery Storage ........................................................................................... 13-12

13.10.5 Battery Recycling ....................................................................................... 13-13

13.11 Electrical Safety Inspection ..................................................................................... 13-13

13.12 Water Build-up in the Flow Sensor ......................................................................... 13-15

13.12.1 Prevent Water Build-up .............................................................................. 13-15

13.12.2 Clear Water Build-up .................................................................................. 13-15

14 Accessories .................................................................................................................... 14-1

A Theory of Operation ....................................................................................................... A-1

A.1 Pneumatic Circuit Principle .......................................................................................... A-1

A.1.1 Pneumatic Circuit Diagram .............................................................................. A-1

A.1.2 Parts List ........................................................................................................... A-2

A.1.3 Definition of Symbols ...................................................................................... A-3

A.1.4 Pneumatic System Overview ............................................................................ A-4

A.2 Electrical System ........................................................................................................... A-7

A.2.1 Electrical System Structure Diagram ............................................................... A-7

A.2.2 Parts List ........................................................................................................... A-8

B Product Specifications ..................................................................................................... B-1

B.1 Safety Specifications ...................................................................................................... B-1

B.2 Environmental Specifications ......................................................................................... B-2

B.3 Power Requirements ....................................................................................................... B-3

B.4 Physical Specifications ................................................................................................... B-4

B.5 Pneumatic System Specifications ................................................................................... B-5

B.6 Ventilator Specifications ................................................................................................. B-7

B.7 Ventilator Accuracy ...................................................................................................... B-10

B.8 Alarm ............................................................................................................................ B-12

B.8.1 Settable Alarms ................................................................................................ B-12

B.8.2 Internal Alarms ................................................................................................ B-13

B.9 Special Function ........................................................................................................... B-13

B.10 CO

B.11 SpO

Module Specifications ........................................................................................ B-14

2

B.10.1 Sidestream CO

B.10.2 Mainstream CO

Module Specifications ....................................................................................... B-16

2

Module ................................................................................ B-14

2

Module ............................................................................... B-15

2

B.12 Air Compressor Specification ..................................................................................... B-18

B.13 Backup Air Supply ..................................................................................................... B-18

C EMC ................................................................................................................................ C-1

7

D Alarm Messages .............................................................................................................. D-1

D.1 Physiological Alarm Messages ...................................................................................... D-1

D.1.1 Ventilator Parameters ....................................................................................... D-1

D.1.2 CO

D.1.3 SpO

Module...................................................................................................... D-2

2

Module .................................................................................................... D-3

2

D.2 Technical Alarm Messages ............................................................................................ D-4

D.2.1 Power Board ..................................................................................................... D-4

D.2.2 Main Control Board ......................................................................................... D-5

D.2.3 Monitor Board .................................................................................................. D-5

D.2.4 CO

D.2.5 SpO

Module...................................................................................................... D-9

2

Module .................................................................................................. D-10

2

D.2.6 Neo. Module .................................................................................................... D-11

E Factory Defaults .............................................................................................................. E-1

E.1 Ventilation Parameters .................................................................................................... E-1

E.2 Setup ............................................................................................................................... E-2

E.3 SystemSettings ................................................................................................................ E-3

E.4 Alarms ............................................................................................................................. E-3

E.5 History ............................................................................................................................ E-4

E.6 Special Functions ............................................................................................................ E-4

E.7 O

Therapy ...................................................................................................................... E-5

2

E.8 CO

E.9 SpO

Module .................................................................................................................... E-6

2

Module .................................................................................................................. E-6

2

E.10 Other ............................................................................................................................. E-6

F Symbols and Abbreviations ............................................................................................. F-1

F.1 Unit .................................................................................................................................. F-1

F.2 Symbols ........................................................................................................................... F-2

F.3 Abbreviations .................................................................................................................. F-2

8

1 Safety

1.1 Safety Information

DANGER

Indicates an imminent hazard that, if not avoided, will result in death or serious

injury.

WARNING

Indicates a potential hazard or unsafe practice that, if not avoided, could result in

death or serious injury.

CAUTION

Indicates a potential hazard or unsafe practice that, if not avoided, could result in

minor personal injury and/or product/property damage.

NOTE

Provides application tips or other useful information to ensure that you get the

most from your product.

1-1

1.1.1 DANGER

There are no dangers that refer to the product in general.

1.1.2 WARNING

WARNING

The ventilator must only be operated and used by authorized medical personnel

well trained in the use of this product. Any unauthorized or untrained personnel

should not perform any operations. It must be operated strictly following the

Operator’s Manual.

Before putting the system into operation, the operator must verify that the

equipment, connecting cables and accessories are in correct working order and

operating condition.

To avoid the risk of electric shock, this equipment must be connected to a properly

installed power outlet with protective earth contacts only. If the installation does

not provide for a protective earth conductor, disconnect it from the power line. In

this case, lithium ion batteries should be used temporarily to supply power to the

equipment.

Use external power source (AC power) before the batteries are depleted.

To avoid explosion hazard, do not use the equipment in the presence of flammable

anesthetic agent, vapors or liquids. When O

any fire sources.

Do not place the ventilator adjacent to any barrier, which can prevent cold air

from flowing, resulting in equipment overheat.

Do not open the case of the equipment, as you may suffer an electric shock. All

servicing and future upgrades must be carried out by the personnel trained and

authorized by us only.

Users should set alarm volume and alarm limits based on patients’ actual

condition. Do not rely exclusively on the audible alarm system for patient

monitoring. Adjustment of alarm volume to a low level may result in a hazard to

the patient. Always keep the patient under close surveillance.

The physiological parameters and alarm messages displayed on the screen of the

equipment are for doctor’s reference only and cannot be directly used as the basis

for clinical treatment.

To dispose of the package material, observe the applicable waste control

regulations. And keep the package material out of children’s reach.

is used, keep the ventilator away from

2

All staff should be aware that disassembling or cleaning some parts of the

ventilator can cause risk of infection.

1-2

WARNING

Maintenance menu can only be accessed when the equipment is disconnected from

the patient.

Positive pressure ventilation may be accompanied by some side effects such as

barotrauma, hypoventilation, hyperventilation, etc.

Using high frequency electrosurgery equipment, defibrillators, or short-wave

treatment equipment in the vicinity of the ventilator may interfere with its

operation and pose a risk of patient injury.

Do not use antistatic or conductive masks or patient tubing. They can cause burns

if they are used near high frequency electrosurgery equipment.

Do not use the ventilator in a hyperbaric chamber.

If the equipment internal monitoring system malfunctions, an alternative plan

must be available to ensure adequate level of monitoring. The operator of the

ventilator must be responsible for patient’s proper ventilation and safety under all

circumstances.

As required by the relevant rules and regulations, oxygen concentration should be

monitored when the equipment is used on the patient. If your ventilator is not

configured with such monitoring function or this function is turned off, use a

monitor which complies with the requirements of ISO 80601-2-55 for oxygen

concentration monitoring.

All analog or digital products connected to this system must be certified to the

specified IEC standards (such as IEC 60950 for data processing equipment and

IEC 60601-1 for medical electrical equipment). All configurations shall comply

with the valid version of IEC 60601-1. The personnel who are responsible for

connecting the optional equipment to the I/O signal port shall be responsible for

medical system configuration and system compliance with IEC 60601-1 as well.

Do not touch the patient when connecting the peripheral equipment via the I/O

signal ports or replacing the O

cell, to prevent patient leakage current from

2

exceeding the requirements specified by the standard.

This equipment is not suitable for use in an MRI environment.

When the ventilator’s gas supply input system fails or has faults, please contact us

immediately for service by specified personnel.

The ventilator shall not be used with helium or mixtures with Helium.

Do not move the ventilator before removing the support arm from it, in order to

avoid the ventilator getting tilted during the movement.

The oxygen and air gas mixer of the ventilator is without grease and thus no

de-grease process is needed. Do not use lubricants that contain oil or grease, and

rubber hose assembly should not be contaminated with grease. Lubricants will

burn or explode when exposed to high O

concentrations.

2

1-3

WARNING

The maximum pressure of hose is 1.4MPa@21℃ and please check whether gas

supply pressure meets hose requirements before usage.

Hose connectors adopt standardized gas terminal connector with gas nature.

Different types of gas and gas with different pressures shall not be exchanged with

each other.

Hose may be aging quickly by long-term exposure to acidity, alkalinity or

ultraviolet rays.

Don’t cascade two or more hose assemblies together.

The ventilator arm could bear 1kg maximally and don’t hang over 1kg goods.

After the ventilator is installed or the main control board is replaced, the altitude

must be reset. After resetting the altitude value, please perform flow calibration

(factory).

When disconnecting fast connectors, please operate by two hands to prevent

potential injury caused by sudden pressure release.

Do not block the air intake on the side of the ventilator.

To prevent interrupted operation of the ventilator due to electromagnetic

interference, avoid using the ventilator adjacent to or stack with other device. If

adjacent or stacked use is necessary, verify the ventilator’s normal operation in the

configuration in which it will be used.

To prevent possible personal injury and equipment damage, ensure that the

ventilator is secured to the trolley or placed on the safe and smooth surface.

To prevent possible equipment damage, avoid tipping over the ventilator when

crossing thresholds.

To prevent possible equipment damage, push the brake down when parking the

ventilator.

Avoid the use of polluted air. When the equipment uses air as gas source for

ventilation, if the air is polluted, harmful substance may enter the patient tubing.

To prevent patient injury caused by equipment malfunction, when the alarm

[Technical Error**] occurs, remove the equipment immediately, record failure

code, and contact the Customer Service Department.

To prevent possible ventilator malfunction, do not spill liquid onto the ventilator.

Backup air supply could cause gas to be heated. To reduce the temperature of gas

inside the tubing and prevent patient injury accordingly, ensure that the length of

patient tubing from the humidifier to Y piece is greater than 1.2m.

The internal electrical power source is to be used temporarily if the integrity of the

protective earth conductor or the protective grounding system in the installation is

in doubt.

1-4

WARNING

Nebulization or humidification can increase the resistance of breathing system

filters, and that you need to monitor the filter frequently for increased resistance

and blockage.

The ventilation accuracy can be affected by the gas added by use of a nebulizer.

The ventilator shall not be used with nitric oxide.

Check if the alarm limit settings are appropriate before taking measurement.

When operating the unit with the power supply unit, always connect the unit to an

easily accessible outlet so that it can be unplugged quickly in the event of a

malfunction.

No modification of this equipment is allowed.

Stop using the ventilator and contact us immediately when the buzzer sounds.

Please place cables of neonatal flow sensor correctly, to avoid patients from

becoming entangled or unplanned extubation.

System leakage, such as leakage caused by an uncuffed endotracheal tube, may

influence airflow readings, including airflow parameters, pressure, dead space, and

CO

production.

2

When ventilator is connected to patient, do not remove or replace fuse, or perform

any other maintenance tasks. Such tasks must be performed when the patient is not

using the ventilator.

Please ensure that the AC power cord is disconnected before removing or replacing

the fuse.

HAZARD can exist if different ALARM PRESETS are used for the same or

similar equipment in any single area. Please read the manual and confirm the

correct alarm pre-settings for the ventilator before using it.

1-5

1.1.3 CAUTION

CAUTION

The ventilator must be inspected and serviced regularly by trained service

personnel.

To ensure patient safety, always prepare resuscitator for use.

Always have a special person attend and monitor the operation of the equipment

once the ventilator is connected to the patient.

During the operation of the ventilator, do not disassemble the inspiration safety

valve and expiration valve unless in standby status.

To ensure patient safety, use only parts and accessories specified in this manual.

At the end of its service life, the equipment, as well as its accessories, must be

disposed of in compliance with the guidelines regulating the disposal of such

products.

Magnetic and electrical fields are capable of interfering with the proper

performance of the equipment. For this reason, ensure that all external devices

operated in the vicinity of the equipment comply with the relevant EMC

requirements. Mobile phone, X-ray equipment or MRI devices are a possible

source of interference as they may emit higher levels of electromagnetic radiation.

This system operates correctly at the electrical interference levels identified in this

manual. Higher levels can cause nuisance alarms that may stop mechanical

ventilation. Pay attention to false alarms caused by high-intensity electrical fields.

Before connecting the equipment to the power line, check that the voltage and

frequency ratings of the power line are the same as those indicated on the

equipment’s label or specified in this manual.

Always install or carry the equipment properly to avoid damage caused by

dropping down, impact, strong vibration or other mechanical force.

Check whether the repetitive patient tubing is damaged or leaked before usage. If

so, don’t use such tubing.

To electrically isolate the ventilator circuits from all poles of the supply mains

simultaneously, disconnect the mains plug.

To minimize the risk of fire, do not use supply hose assembly that is worn or

contaminated with combustible materials like grease or oil.

It is the clinician’s responsibility to ensure that all ventilator settings are

appropriate.

To prevent possible patient injury, ensure the ventilator is set up for appropriate

patient type with the appropriate patient tubing. Ensure that the System Check or

1-6

CAUTION

tubing check is performed before each patient.

Perform Flow Sensor Calibration before the first use, or when the measured values

have deviations.

To prevent possible patient injury, ensure the ventilation parameters are set up

properly before ventilating the patient.

To ensure the accuracy of oxygen monitoring, replace an exhausted O

cell as soon

2

as possible or use an external monitor that complies with ISO 80601-2-55.

A fan failure could result in oxygen enrichment inside the ventilator and a

subsequent fire hazard.

To reduce the risk of explosion, do not force the chemical O

cell open or place it

2

close to a source of heat.

When ventilating with a mask, avoid high airway pressures. High pressures may

cause gastric distension.

Peak pressures exceeding 33 cmH

O may increase the risk of gastric insufflation

2

when the ventilation type is non-invasive. When ventilating with such pressures,

consider using an invasive mode.

To reduce the risk of fire, use only tube systems approved for medical purposes

and for use with oxygen between the oxygen source and ventilator.

To reduce the risk of fire, ensure adequate ventilation at the rear of the ventilator.

To reduce the risk of fire, switch off the oxygen source when the ventilator is not in

a ventilating mode.

Avoid putting the ventilator in the storage environment of more than 50℃ for a

long time. Such environment may damage or shorten the battery lives of internal

battery and O

cell.

2

Use the original packing materials to ship the ventilator.

To prevent fire hazard, use only specified fuses or fuses with the same type, rated

voltage, and rated current as the existing fuses. When it is necessary to replace

fuses, contact the Customer Service Department.

The ventilator is suitable for use within the PATIENT ENVIRONMENT.

Additional MULTIPLE SOCKET- OUTLET or extension cord shall not be

connected to the system.

Before moving the ventilator, ensure that the casters and brakes can work

properly, and the main unit is locked on the trolley.

Please use dry and clean medical compressed air and oxygen as gas supply. Water

in gas supply can cause equipment malfunction.

1-7

1.1.4 NOTE

NOTE

Put the ventilator and its accessories in a location where you can easily see the

screen and access the operating controls.

Keep this manual close to the equipment so that it can be obtained conveniently

when needed.

The software was developed in compliance with IEC 62304. The possibility of

hazards arising from software errors is minimized.

This manual describes all features and options. Your equipment may not have all

of them.

When the oxygen supply is insufficient, the ventilator will automatically switch to

air supply. When the air supply is insufficient, the ventilator will automatically

switch to oxygen supply.

The ventilator is equipped with barometric pressure sensors, and has the function

of barometric pressure compensation.

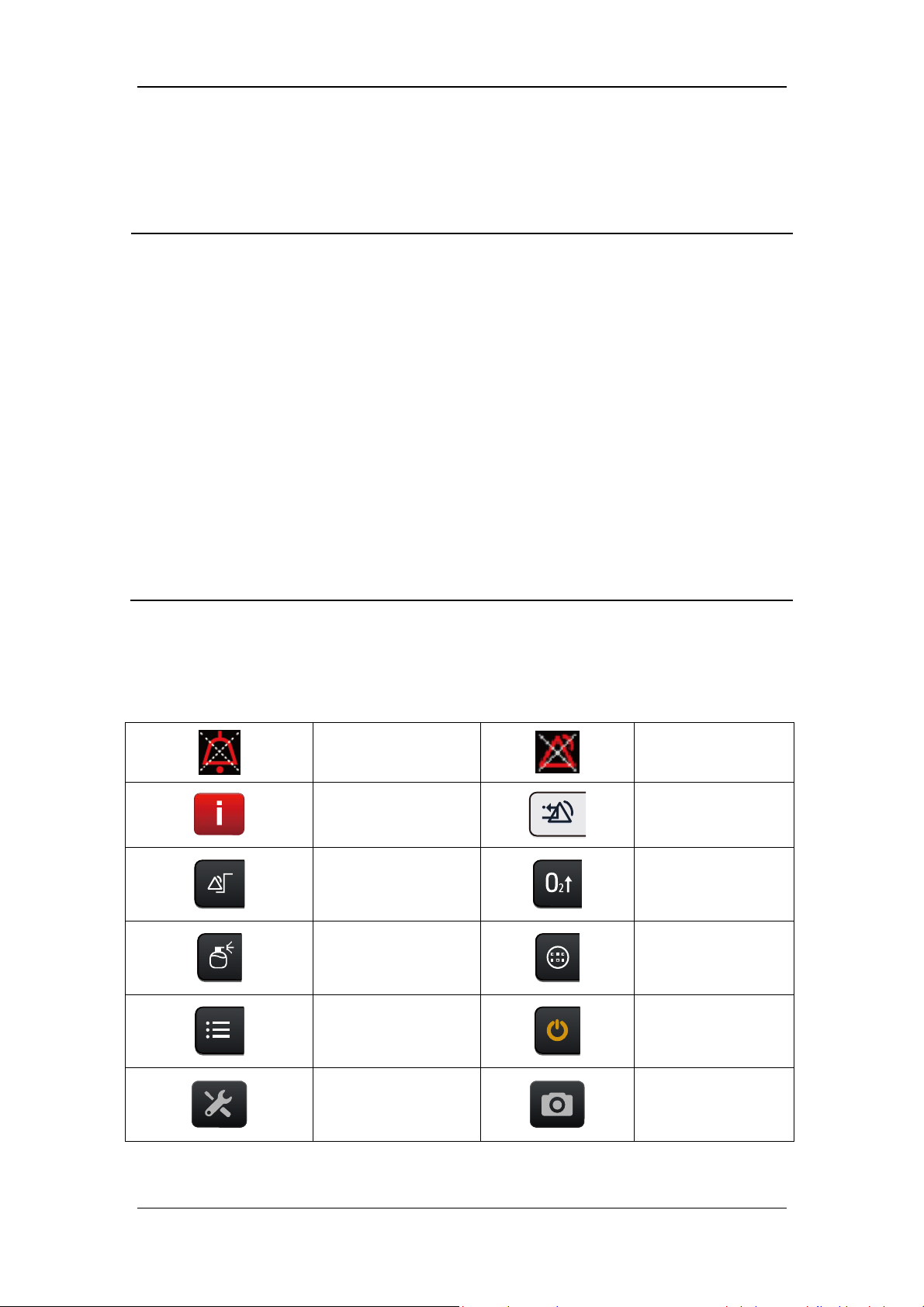

1.2 Equipment Symbols

AUDIO PAUSED

Recent Alarm

Alarm settings

Nebulizer

ALARM OFF

Clear alarm

O2↑key

Tools key

Setup

Preventive

maintenance

Standby key

Screen Capture

1-8

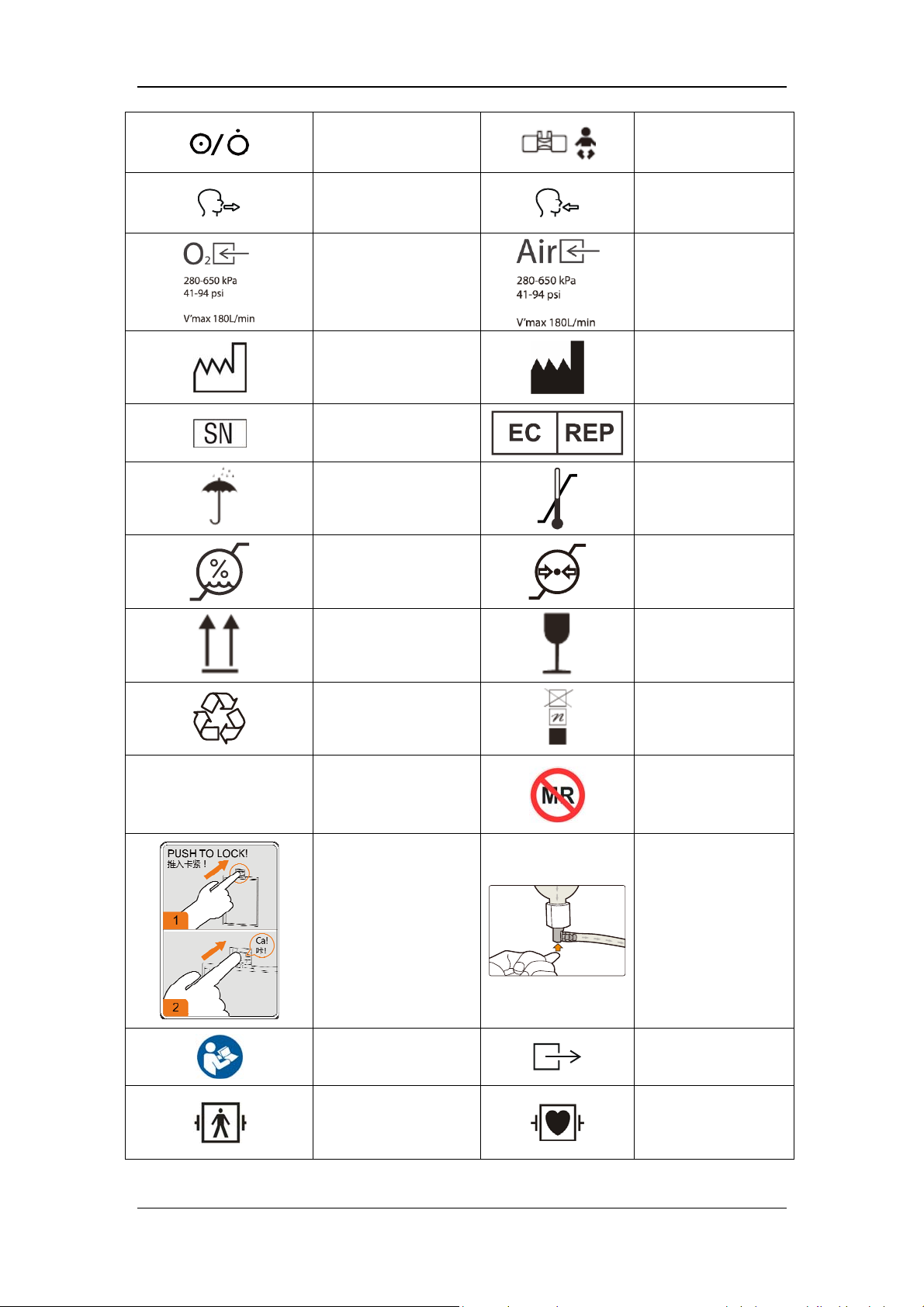

History

Freeze

Inspiratory trigger

icon

Adult (male)

Pediatric (male)

Backup Air Supply

Invasive Ventilation

Non-Invasive

Ventilation

Adult (female)

Pediatric (female)

Adjust screen

Neonate

brightness/volume to

night mode

Adjust screen

Start O2 therapy timer

brightness/volume to

day mode

Stop O2 therapy timer

Caution

Fuse

Battery LED

RS-232 connector

USB connector

Display connector

Oxygen sensor

connector

Reset O2 therapy

timer

Equipotentiality

Protective earth

ground

AC power

VGA output

connector

Network connector

Nurse call connector

Pneumatic nebulizer

connector

Lock

Unlock

1-9

Power switch

Expiration connector

Oxygen supply

connector

Date of manufacture

Serial number

Keep dry

Humidity limitation

Neonatal flow sensor

connector

Inspiration connector

Air supply connector

Manufacturer

European community

representative

Temperature

limitation

Atmospheric pressure

limitation

IP21

This way up

Recyclable

Degree of protection

against harmful

ingress of water

Fragile, handle with

care

Stacking limit by

number

Not suitable for use

in an MRI

environment

High Efficiency

Particle Air (HEPA)

Water trap indicator

installation instruction

Refer to the operator's

manual

Defibrillation-proof

BF application part

Ventilator gas outlet

DEFIBRILLATION-

PROOF TYPE CF

APPLIED PART

1-10

Reset the paramagnetic oxygen sensor (NOTE: This operation can be

performed only by the Customer Service Department or authorized

personnel.)

The following definition of the WEEE label applies to EU member

states only.

This symbol indicates that this product should not be treated as

household waste. By ensuring that this product is disposed of

correctly, you will help prevent bringing potential negative

consequences to the environment and human health. For more detailed

information with regard to returning and recycling this product, please

consult the distributor from whom you purchased it.

* For system products, this label may be attached to the main unit

only.

The product bears CE mark indicating its conformity with the

provisions of the Council Directive 93/42/EEC concerning medical

devices and fulfills the essential requirements of Annex I of this

directive.

Unified circulation mark indicates that products marked them passed

all specified in the technical regulations of the Customs Union of the

procedure for the assessment (confirmation) of conformity and

complies with the requirements applicable to all the products technical

regulations of the Customs Union.

1-11

FOR YOUR NOTES

1-12

2 The Basics

2.1 System Description

2.1.1 Intended Use

This product is intended to be used in intensive care situations within a professional

healthcare facility, or during transport within a professional healthcare facility. This product

is intended to provide ventilation assistance and breathing support for adult, paediatric and

neonate patients. The product should be operated by properly-trained and authorized medical

personnel. This equipment is not suitable for use in an MRI environment.

2.1.2 Contraindications

There are no absolute contraindications for this product. For some special diseases, however,

some necessary treatments shall be taken for ventilator mechanical ventilation, or special

ventilation modes shall be adopted to prevent possible patient injury.

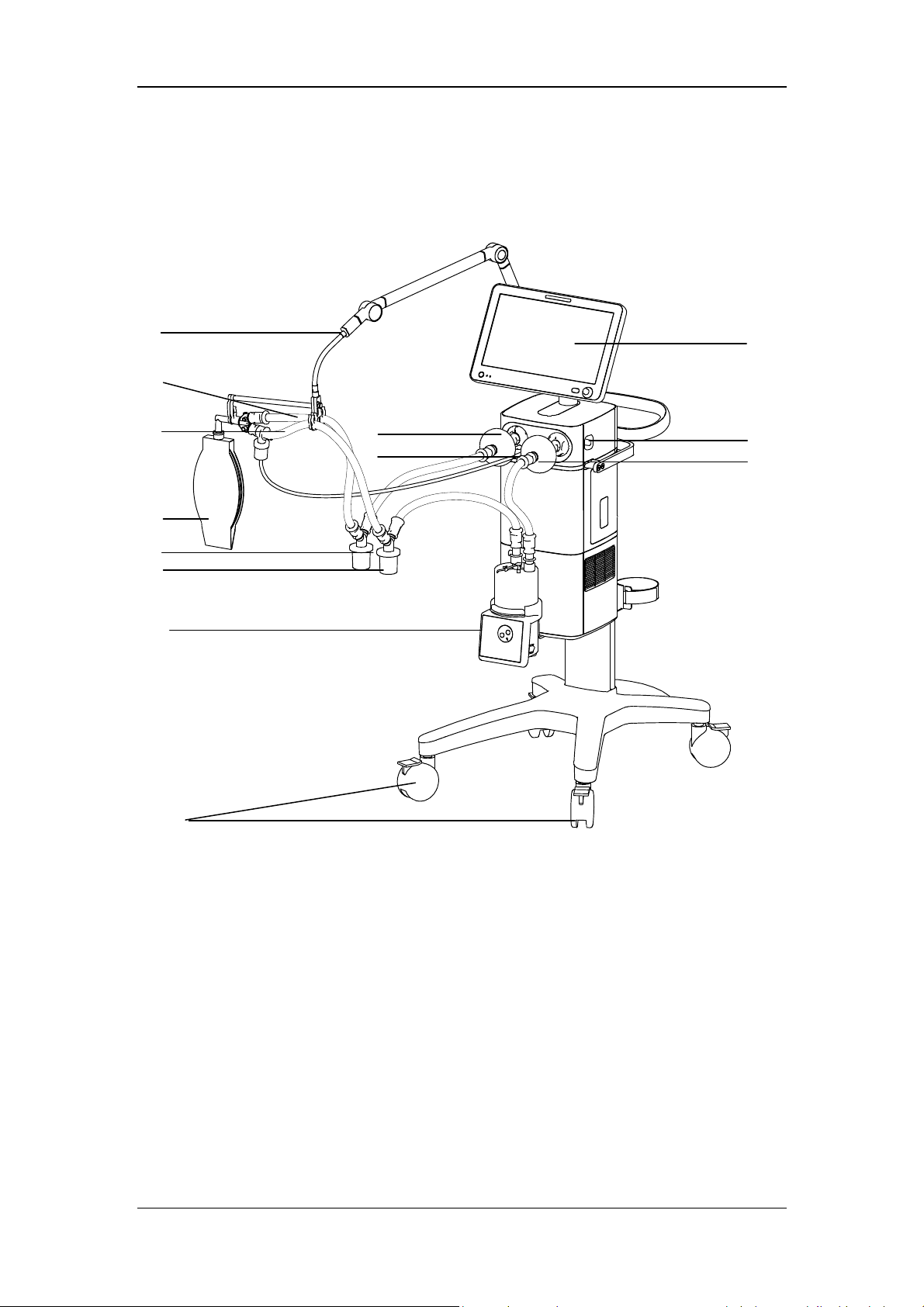

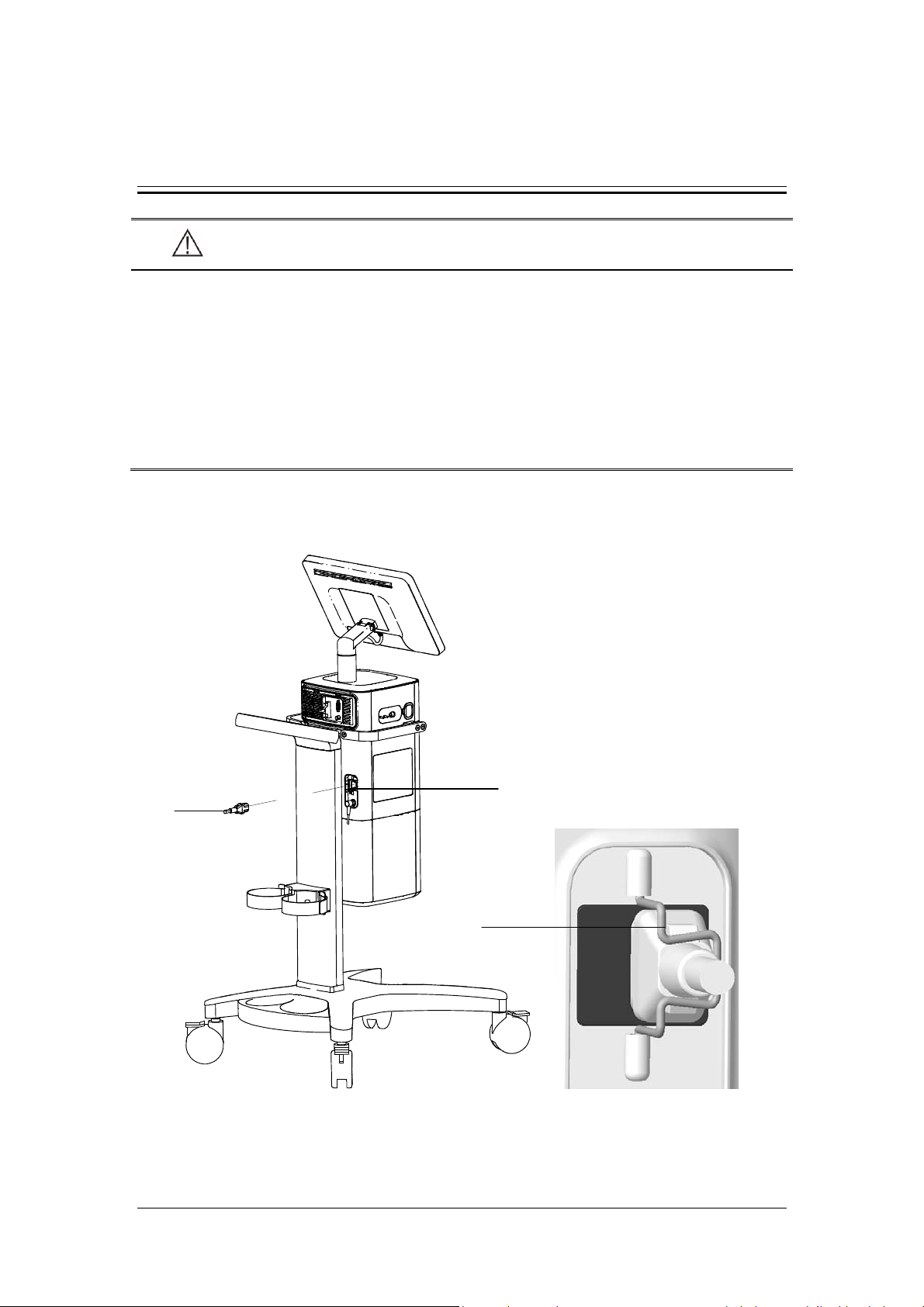

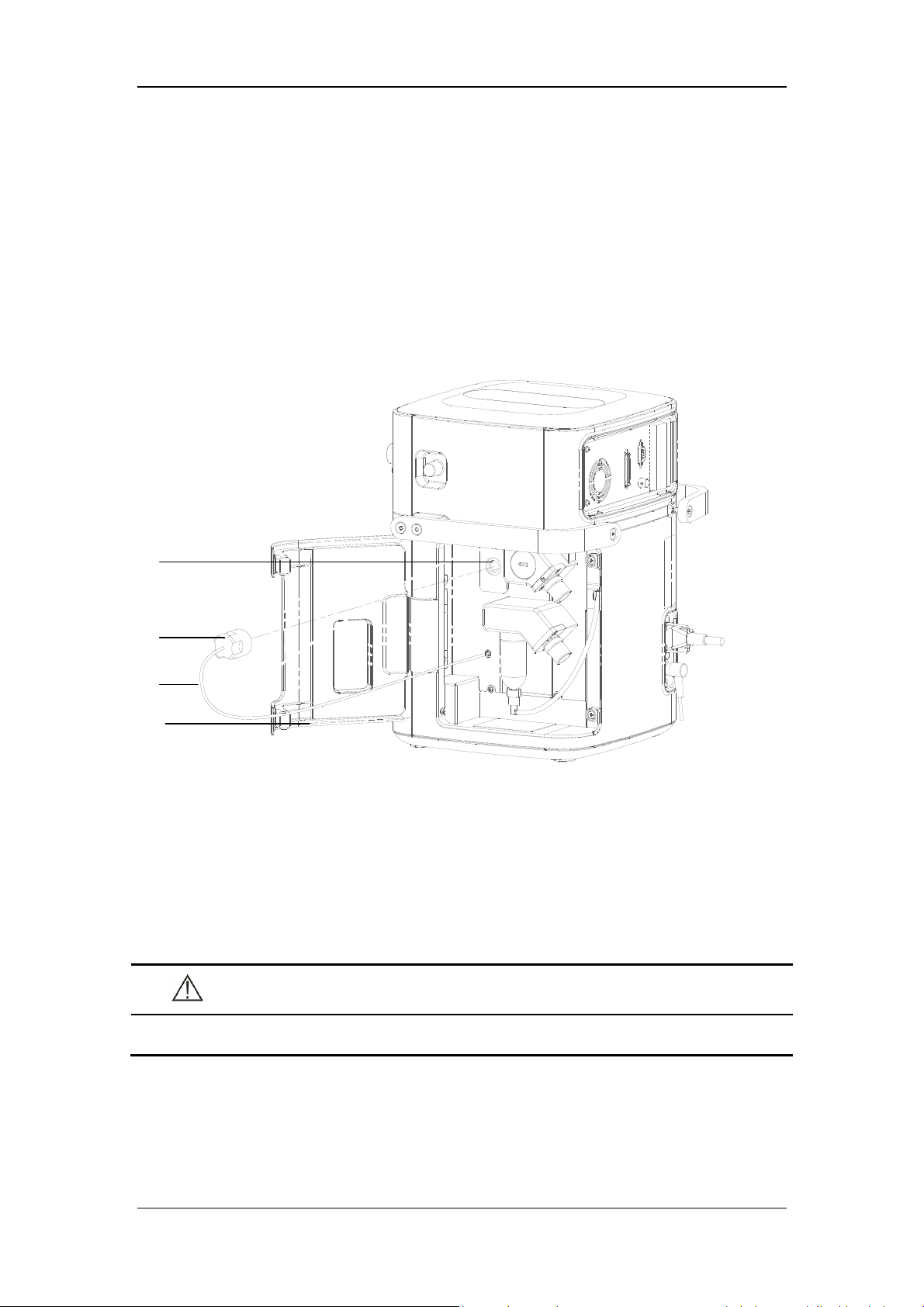

2.1.3 Components

The ventilator consists of a main unit (including pneumatic circuit, electronic system,

mechanical structure, display, CO

(model: C3), trolley, and support arm.

The ventilator is suitable for use within the PATIENT ENVIRONMENT. Connect the patient

to the ventilator via the patient breathing circuit. The applied part of the ventilator is

breathing masks.

module, SpO2 module), backup air supply, air compressor

2

2-1

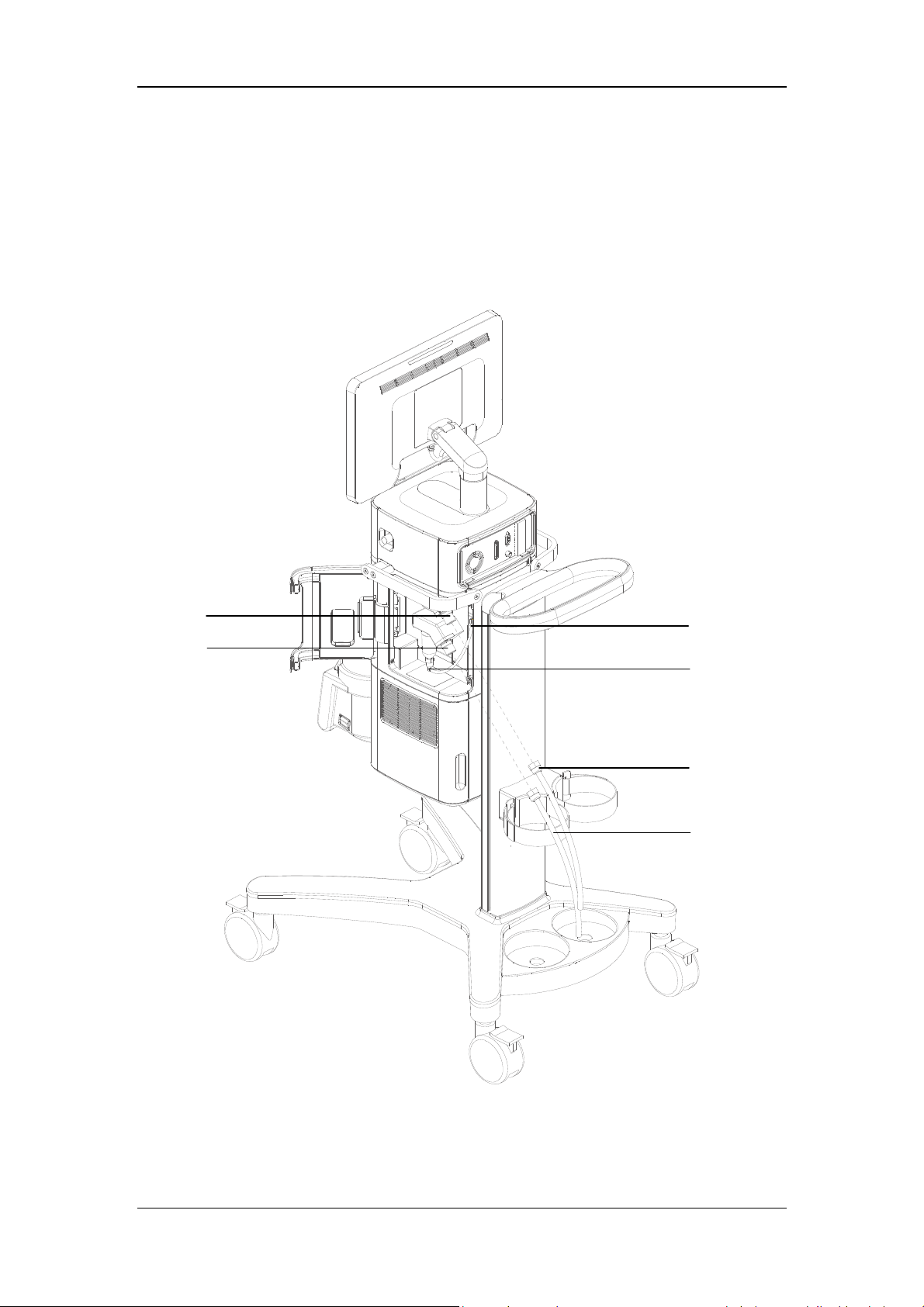

2.2 Equipment Appearance

2.2.1 Front View

8

7

6

5

4

3

2

11

12

9

13

10

1

2-2

1. Caster and brake

The ventilator has four casters and all casters have brakes.

2. Humidifier

3. Inspiratory water trap

Collects condensed water in the inspiratory tube.

4 Expiratory water trap

Collects condensed water in the expiratory tube.

5. Test lung

6. Inspiratory tube

7. Expiratory tube

8 Support arm

Supports and hangs the patient tubing.

9. Display

10. Inspiratory filter

11. Expiratory filter

12 Nebulizer connector

To connect pneumatic nebulizer.

13. Leak test plug

For System Check or Flow Calibration.

2-3

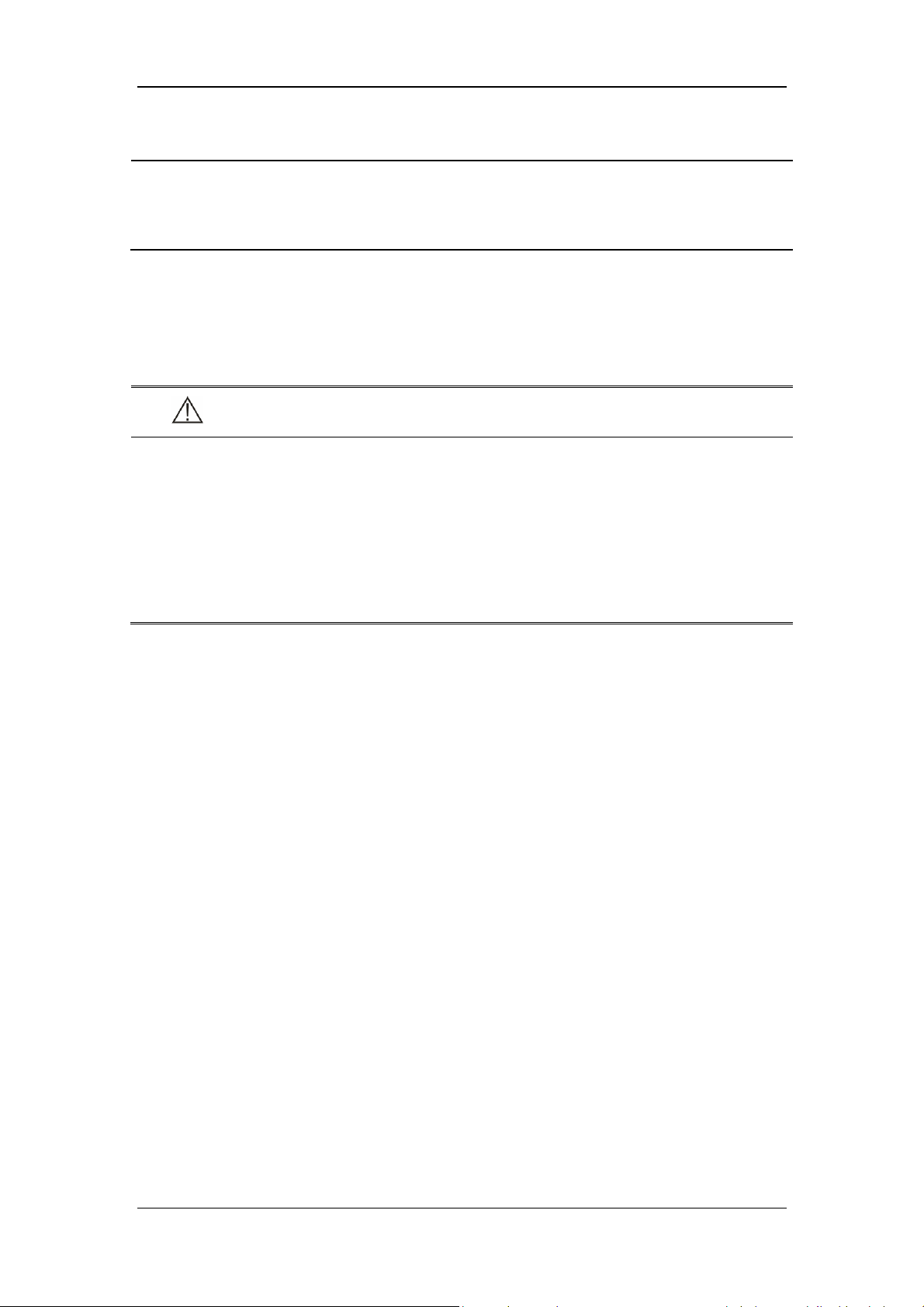

2.2.2 Rear View

5

4

3

2

1

6

7

8

9

10

1. Cylinder retaining clip

For retaining the gas cylinder.

2. Trolley rear handle

3. Nurse call connector

Connects to the hospital’s nurse call system and outputs nurse call signals when an

alarm occurs.

4. Main unit and display connector

5. RS-232 connector

Connects to the external calibration device for calibrating pressure. An external medical

device can be connected via this connector to communicate with the ventilator.

2-4

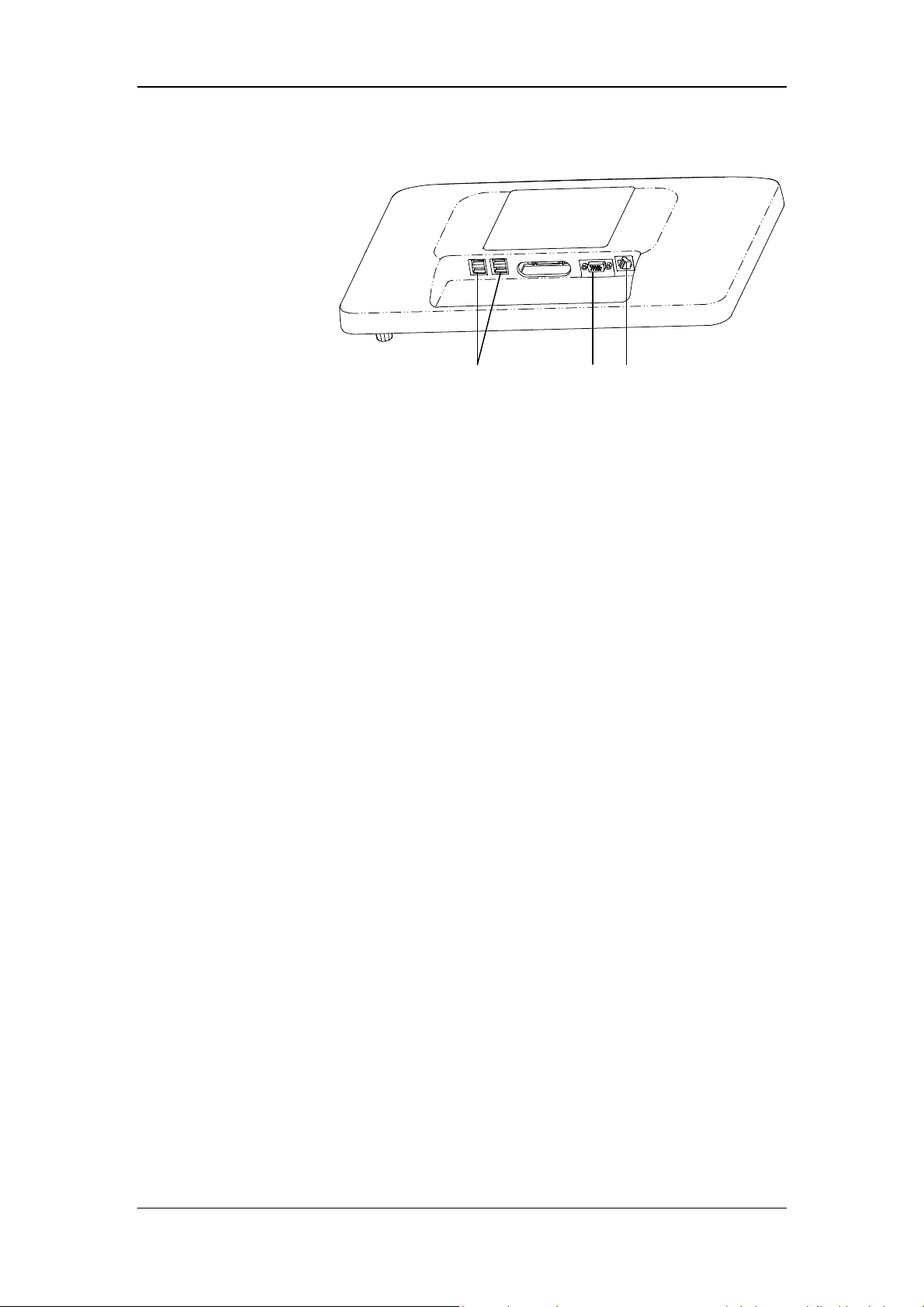

6. Display

A

B

C

A. USB connector

Conducts ventilator software upgrade, configuration information and history data (such

as patient data, alarm log) export, configuration transfer between machines of the same

type via USB device. The device can also be connected to the electronic nebulizer via

USB.

B. VGA connector

Outputs VGA video signals with the same contents to the primary display and connects

to the external display (supporting display with resolution of 1920*1080).

C. Network connector

A connector which supports connection with a PC to perform software upgrade and

connection with external medical and information device.

7. Neonatal flow sensor connector

Connects neonatal flow sensor.

8. Module slot

Inserts and identifies CO

9. AC power receptacle

10. Equipotential stud / lug

module and SpO2 module mentioned in this manual.

2

2-5

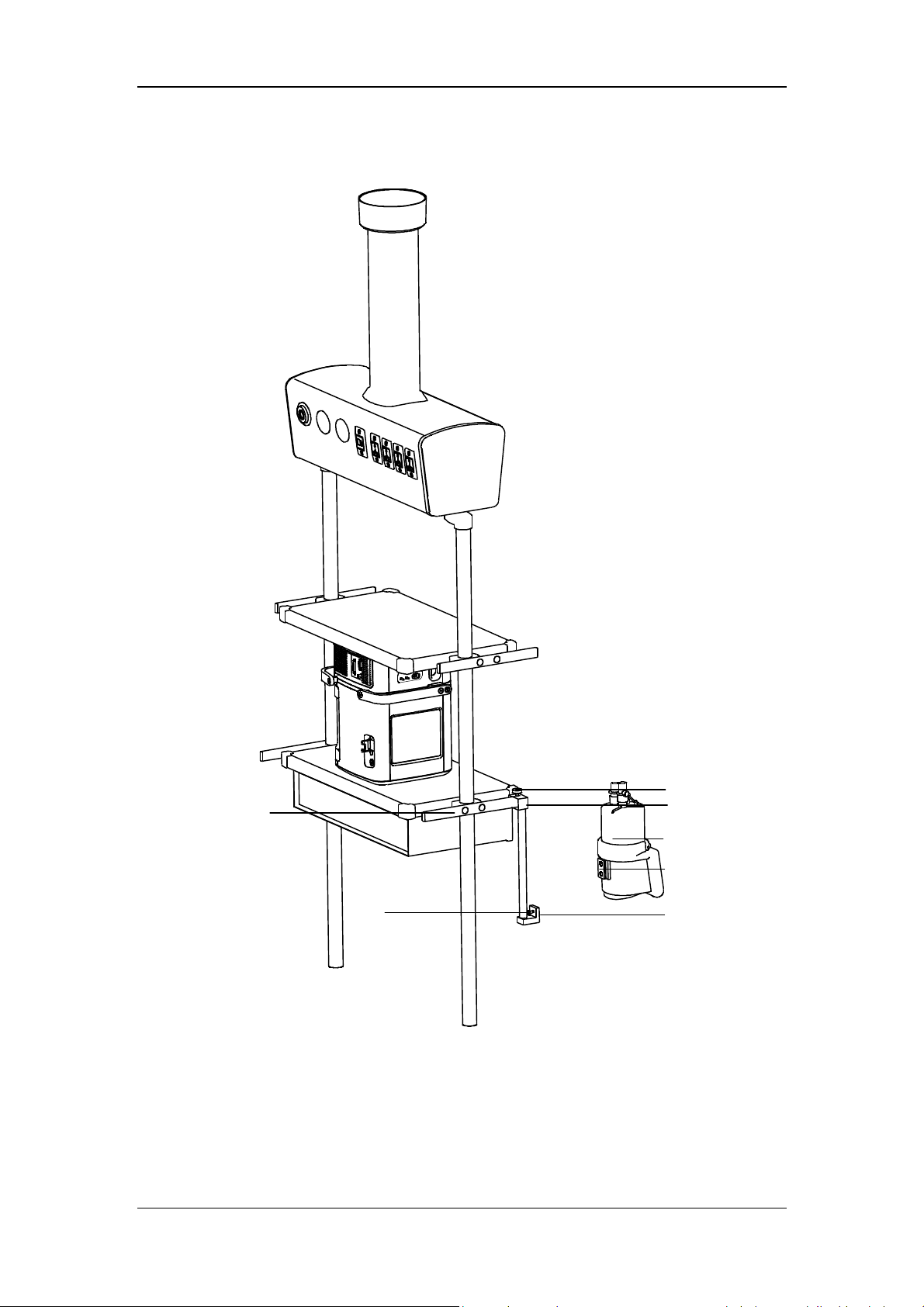

2.2.3 Air Compressor

The air compressor has two types of configurations: standby and non-standby.

In case of standby configuration, the compressor starts to deliver compressed air to the

ventilator or anesthesia machine automatically if the hospital central pipeline gas supply

stops supplying gas. The compressor stops delivering compressed air automatically when the

central pipeline gas supply returns to normal.

In case of non-standby configuration, central pipeline gas supply inlet is not available and

only compressed air outlet is available.

4

1

3

2

1. Power indicator

The power indicator is lit when the compressor is connected to power supply and the

power switch is turned on.

2. Status indicator (standby configuration)

The status indicator is lit when the central pipeline gas supply is applied.

3. Warning indicator

The warning indicator is lit when some failures occur to the compressor (e.g. internal

temperature abnormally high, semiconductor refrigeration failure, solenoid valve failure,

or fan failure). In this case, the compressor may shut off at any time and stop delivering

gas.

4. Pressure gauge

The pressure gauge indicates the air pressure at the compressed air outlet.

5. Air intake vent (with dust filter)

6. Power switch

5

6

7

8

Turn on or turn off the air compressor.

7. Mains power inlet (with fixing pressure plate)

2-6

8. Hourmeter

The hourmeter indicates the accumulated running time of the compressor (not including

the accumulated running time when the central pipeline gas supply is applied).

9. Compressed air outlet

10. Central pipeline gas supply inlet (standby configuration)

NOTE

Burn-in is required for the compressor before delivery. The reading indicated by

the compressor hourmeter shall be less than 150 hours at the time of delivery.

2-7

FOR YOUR NOTES

2-8

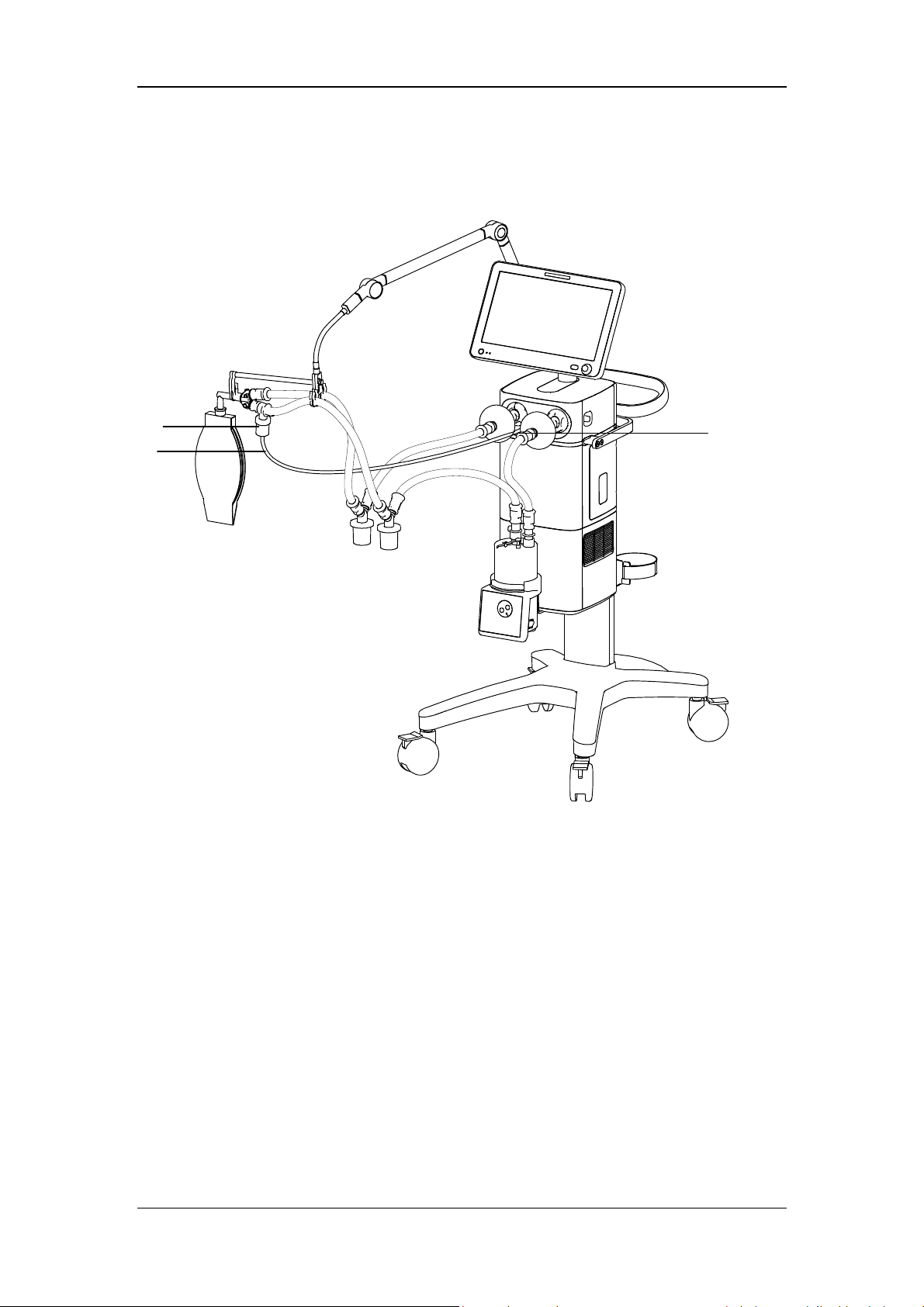

3 Installations and Connections

WARNING

Do not use antistatic or conductive masks or patient tubing. They can cause burns if

they are used near high frequency electrosurgery equipment.

To ensure optimum performance of the ventilator, re-do System Check each time

when accessories or components like patient tubing, humidifier, and filter are

replaced.

Adding accessories or other components to the breathing system of the ventilator

can increase system inspiratory and expiratory resistance.

3.1 Connect the Power Supply

A

B

C

A. AC power receptacle B. AC power cord C. Anti-unplugging hook of power

3-1

1. Turn the anti-unplugging hook of power to the right-hand side.

2. Insert the AC power cord into the AC power receptacle.

3. Put back anti-unplugging hook of power to clamp the power cord in place.

3.2 Connect the Pipeline Supply

A

B

C

D

E

F

A. Oxygen supply inlet B. Air supply inlet

C. Drainage tube and slot

D. Pushrod of water trap and drainage valve at air supply inlet

E. O

supply hose F. Air supply hose

2

3-2

This ventilator provides O

and air supply connectors. Supply hoses are marked in different

2

colors. The connector of each hose should not be exchanged with each other. Gas supply

hoses and the ventilator are connected as follows.

1. Check whether the sealing ring on the gas supply hose connection is in good condition

before connecting the gas supply hose. If the sealing ring is damaged, do not use the

hose. Replace the sealing ring to prevent leakage.

2. Align the hose connector with and insert it into the inlet of the O

supply or air supply

2

on the back of the ventilator.

3. Ensure that the gas supply hose is properly connected to the gas supply inlet. Tighten the

hose nut.

During use, the operator can check the water volume in the water trap through the transparent

observation window on the side door of the machine. If the water level is close to the filter

element, please take out the drain pipe from the slot and press the drainage valve pushrod of

water collection cup up to drain the water. Please place a container under the water trap to

catch the water, so that the water will not splash on the machine. Pushrod of drainage valve

will automatically re-place to its original position after drainage and then re-place the

drainage tube to the slot. Please contact your service personnel if any crack and leakage is

found on water trap.

NOTE

When draining the water, please use a container to catch the water, so that the

water will not splash on the machine.

If drainage in the ventilation status, please prevent water splash and use a container

to prevent water from directly spraying to the battery bottom.

WARNING

Inspect the oxygen supply connector carefully and ensure that there is no leakage.

If there is significant gas leakage, oxygen concentration in the surrounding

environment will exceed normal oxygen concentration in the atmosphere, resulting

in a potentially dangerous oxygen-enriched environment.

Place the supply hose carefully, avoiding exposure to the environment in which

possible damage to the supply hose is easily caused by cut or heating.

The compressed gas must be dry, and free from dust and oil. Gas pressure must be

280 kPa to 650 kPa. Otherwise, the correct functioning of the device is not assured.

3-3

3.3 Install the Gas Cylinder

CAUTION

Ensure that the gas cylinder is equipped with pressure-reducing valve.

A

B

C

A. Gas cylinder B. Cylinder fixing buckle C. Trolley base

1. Place the gas cylinder onto the trolley base.

2. Fix the gas cylinder via cylinder fixing buckle.

3-4

3.4 Install the Support Arm

F

G

E

D

C

B

A. Fixing block knob B. Fixing block C. Tube hook

D. Support arm joint E. Support bar F. Support arm joint

G. Support arm joint

A

3-5

1. Loosen the fixing block knob. Place the fixing block onto the handle at the rear of the

ventilator.

2. Tighten the fixing block knob.

WARNING

To prevent possible patient injury due to accidental extubation, check the support

arm joints and the connection security as necessary.

3. Adjust the support arm.

Support arm joint F or G: to adjust the upward-bending angle of the support arm, only

lift up the support bar to the desired position without the need to push the blue unlocking

key

bar, and then push and hold the blue key

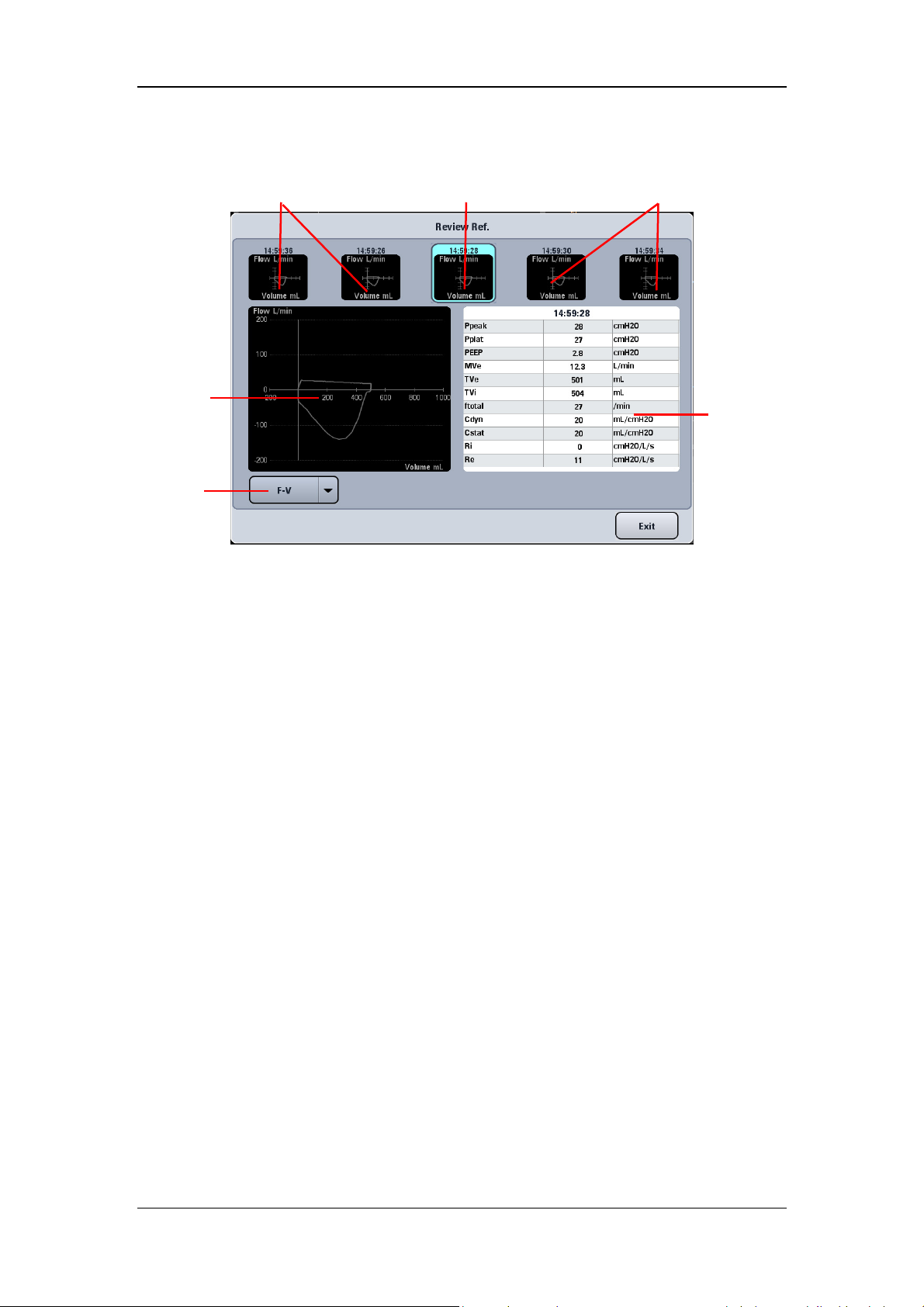

hold the support bar and press it downward with the other hand. Release the blue

unlocking key

joint F or G can be adjusted for up to 130º.

Support arm joint D: swivel upward or downward to the desired position.

Hold the bottom of support arm or the support bar beside support arm joint G and swivel

it to the left, or to the right, with force to rotate the support arm to the desired position.

4. Place the patient tubing onto the tube hook.

. To adjust the downward-bending angle of the support arm, lift up the support

on support arm joint with one hand, and

after adjusting the support bar to the desired position. Support arm

3-6

NOTE

Operate support arm joint F or G with both hands as shown below. Operating with

a single hand will bring some risks.

The maximum weight of the support arm is 1 kg.

Please install the support arm according to the instruction on the handle of the

ventilator.

3.5 Install the Patient Tubing

WARNING

To minimize the risk of bacterial contamination or physical damage, remove and

install the bacterial filter with care.

To prevent patient or ventilator contamination, always use a bacteria filter between

the ventilator and the patient inspiratory limb.

CAUTION

The use of an expiratory filter may lead to a significant increase in expiratory

resistance. Excessive expiratory resistance may compromise ventilation and

increase patient’s work of breathing and intrinsic PEEP.

The patient tubing shall comply with the requirements of ISO 5367.

The bacteria filters shall comply with the requirements of ISO 23328-1 and ISO

23328-2.

The Heat & Moisture Exchange (HME) shall comply with the requirements of ISO

9360-1 and ISO 9360-2.

3-7