BC-5800

Auto Hematology Analyzer

Service Manual

Copyright

© 2008 Shenzhen Mindray Bio-medical Electronics Co., Ltd. All rights Reserved.

Intellectual Property Statement

SHENZHEN MINDRAY BIO-MEDICAL ELECTRONICS CO., LTD. (hereinafter called

Mindray) owns the intellectual property rights to this Mindray product and this manual. This

manual may refer to information protected by copyrights or patents and does not convey any

license under the patent rights of Mindray, nor the rights of others. Mindray does not assume

any liability arising out of any infringements of patents or other rights of third parties.

Mindray intends to maintain the contents of this manual as confidential information.

Disclosure of the information in this manual in any manner whatsoever without the written

permission of Mindray is strictly forbidden.

Release, amendment, reproduction, distribution, rent, adaption and translation of this manual

in any manner whatsoever without the written permission of Mindray is strictly forbidden.

, are the registered trademarks or trademarks owned by Mindray in China

and other countries. All other trademarks that appear in this manual are used only for editorial

purposes without the intention of improperly using them. They are the property of their

respective owners.

Responsibility on the Manufacturer Party

Contents of this manual are subject to changes without prior notice.

All information contained in this manual is believed to be correct. Mindray shall not be liable

for errors contained herein nor for incidental or consequential damages in connection with the

furnishing, performance, or use of this manual.

Mindray is responsible for safety, reliability and performance of this product only in the

condition that:

all installation operations, expansions, changes, modifications and repairs of this

product are conducted by Mindray authorized personnel;

the electrical installation of the relevant room complies with the applicable national

and local requirements;

the product is used in accordance with the instructions for use.

I

z

This equipment must be operated by skilled/trained medical professionals.

z

It is important for the hospital or organization that employs this equipment

to carry out a reasonable service/maintenance plan. Neglect of this may

result in machine breakdown or injury of human health.

z Be sure to operate the analyzer under the situation specified in this manual;

otherwise, the analyzer will not work normally and the analysis results will

be unreliable, which would damage the analyzer component s and cause

personal injury.

II

Warranty

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE.

Exemptions

Mindray's obligation or liability under this warranty does not include any transportation or

other charges or liability for direct, indirect or consequential damages or delay resulting from

the improper use or application of the product or the use of parts or accessories not approved

by Mindray or repairs by people other than Mindray authorized personnel.

This warranty shall not extend to:

any Mindray product which has been subjected to misuse, negligence or accident;

any Mindray product from which Mindray's original serial number tag or product

identification markings have been altered or removed;

any product of any other manufacturer.

Return Policy

Return Procedure

In the event that it becomes necessary to return this product or part of this product to Mindray,

the following procedure should be followed:

1. Obtain return authorization: Contact the Mindray Service Department and obtain a

Customer Service Authorization (Mindray) number. The Mindray number must

appear on the outside of the shipping container. Returned shipments will not be

accepted if the Mindray number is not clearly visible. Please provide the model

number, serial number, and a brief description of the reason for return;

2. Freight policy: The customer is responsible for freight charges when this product is

shipped to Mindray for service (this includes customs charges);

3. Return address: Please send the part(s) or equipment to the address offered by

Customer Service department.

III

Company Contact

Manufacturer: Shenzhen Mindray Bio-Medical Electronics Co., Ltd.

Address:

Phone:

Fax:

Mindray Building, Keji 12th Road South, Hi-tech Industrial Park,

Nanshan,ShenZhen 518057, P.R.China,

+86 755 26582479 26582888

+86 755 26582934 26582500

IV

Table of Contents

Copyright I

Warranty.............................................................................................................................III

Return Policy......................................................................................................................III

Table of Contents 1

1 Using This Manual 1-1

1.1 Introduction.......................................................................................................... 1-1

1.2 Who Should Read This Manual........................................................................... 1-2

1.3 How to Find Information ...................................................................................... 1-3

1.4 Conventions Used in This Manual....................................................................... 1-4

1.5 Special Terms Used in This Manual .................................................................... 1-5

1.6 Symbols............................................................................................................... 1-6

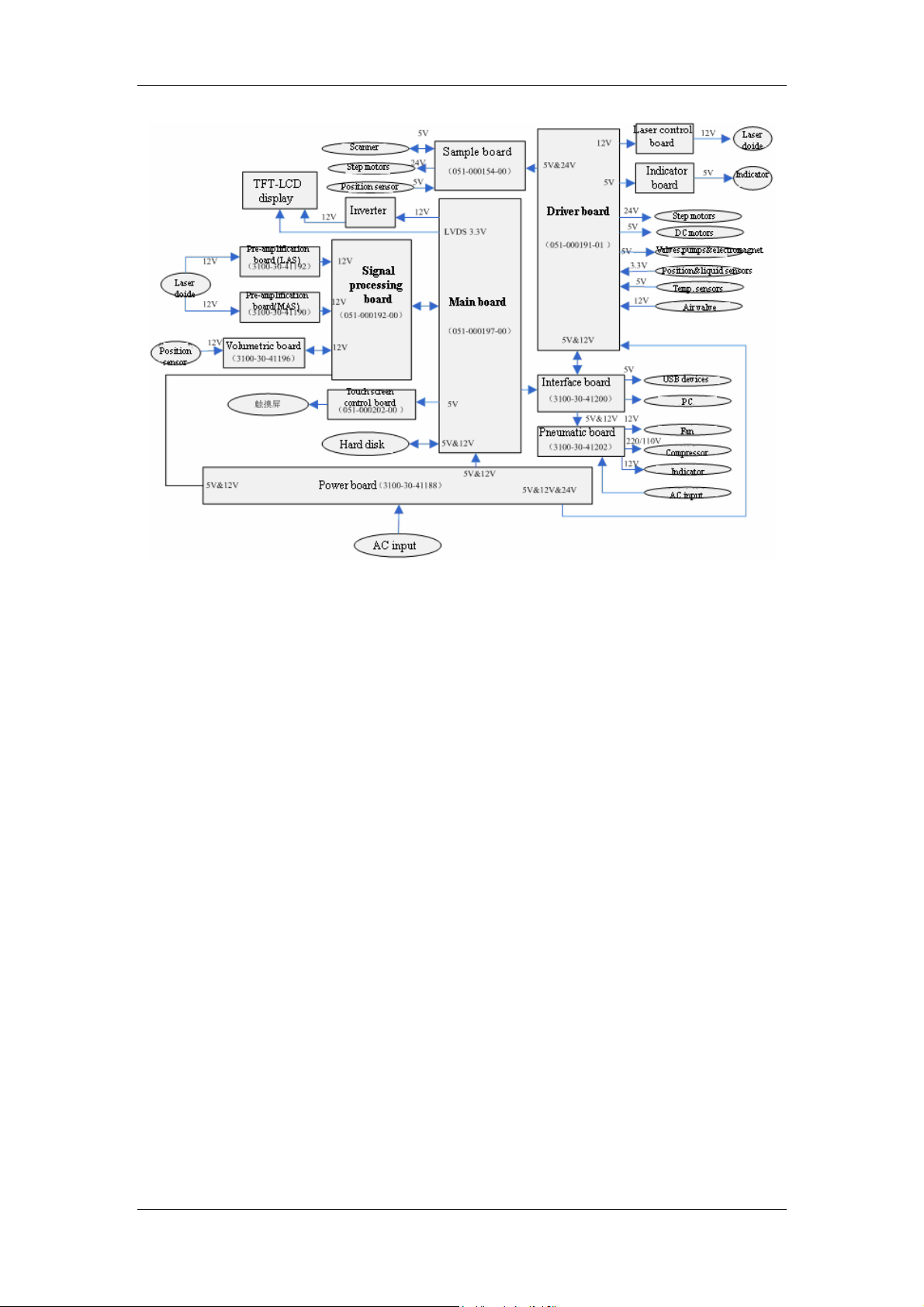

2 System Structure 2-1

2.1 System Overview................................................................................................. 2-1

2.2 Fluidic System ..................................................................................................... 2-2

2.3 Hardware System ................................................................................................ 2-3

2.4 Main Structure...................................................................................................... 2-4

2.5 Software Structure ............................................................................................. 2-12

3 Fluidic System 3-1

3.1 Introduction of Fluidic Parts................................................................................. 3-1

3.2 Introduction of Pneumatic Parts .......................................................................... 3-7

3.3 Fluidic System ..................................................................................................... 3-9

3.4 Basic Cycle Design Description......................................................................... 3-16

3.5 Sample Predilution Flowchart............................................................................ 3-25

4 Hardware System 4-1

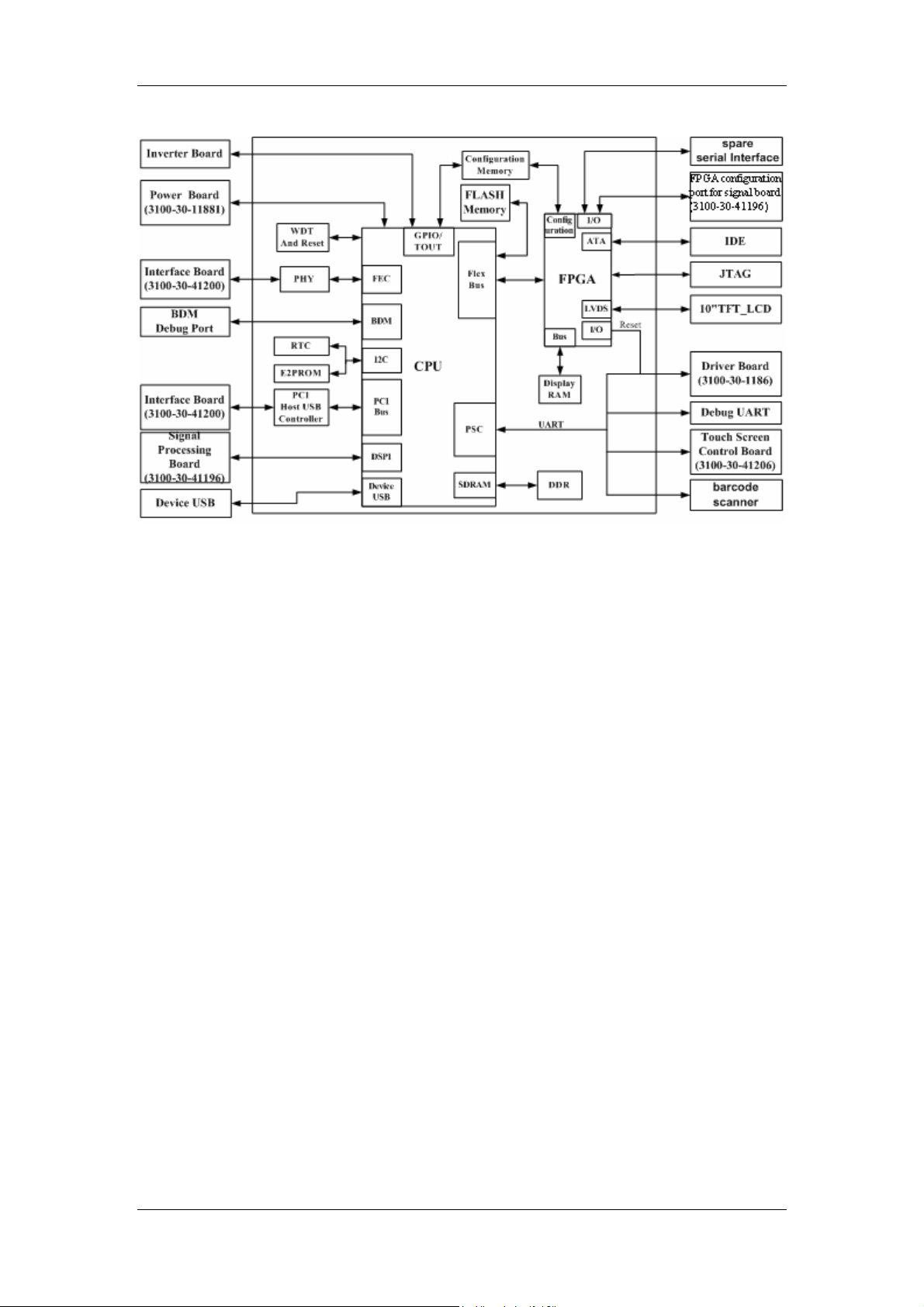

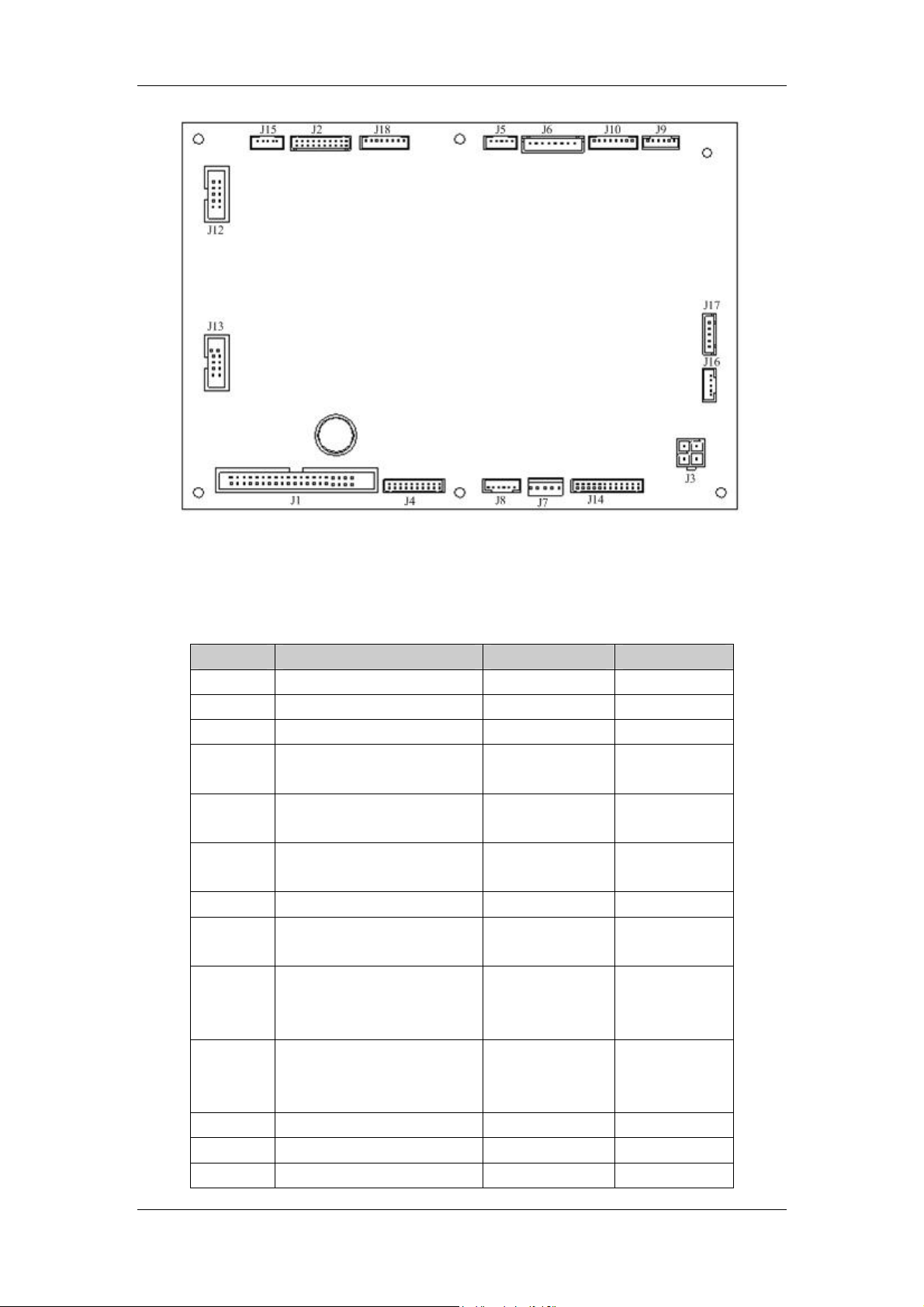

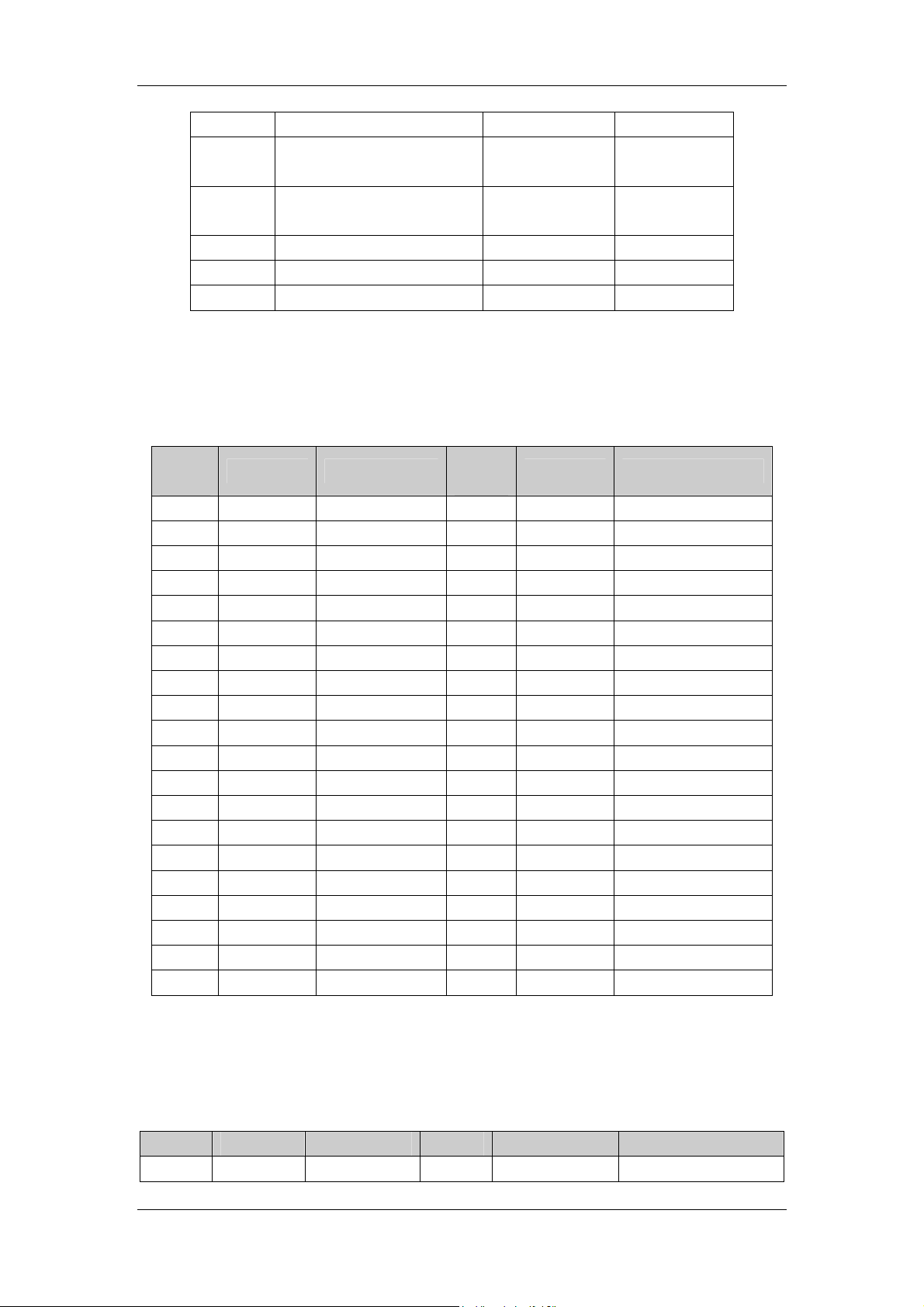

4.1 Main Board .......................................................................................................... 4-3

4.2 Signal Processing Board ................................................................................... 4-21

4.3 Driver Board....................................................................................................... 4-36

4.4 Power Board ...................................................................................................... 4-75

4.5 Interface Board .................................................................................................. 4-84

4.6 Indicator Board .................................................................................................. 4-90

4.7 Touchscreen Control Board ............................................................................... 4-93

4.8 Pneumatic Control Board .................................................................................. 4-97

4.9 Pre-amplification Board, Laser Control Board and Volumetric Board ............. 4-103

4.10 Sample Transport Board.................................................................................. 4-122

4.11 Sample Detecting Board.................................................................................. 4-137

4.12 Pressure Detecting Board ............................................................................... 4-148

1

Using This Manual

4.13 SATA and IDE Signal Conversion Board......................................................... 4-154

5 Servicing 5-1

5.1 General ................................................................................................................ 5-1

5.2 Disassembling the Panels ................................................................................... 5-2

5.3 Replacing the Power Supply Assembly ............................................................. 5-12

5.4 Replacing the Touchscreen Assembly............................................................... 5-16

5.5 Replacing the Fluidic Components.................................................................... 5-22

5.6 Replacing the RBC Assembly............................................................................ 5-56

5.7 Replacing the HGB Bath Assembly ................................................................... 5-66

5.8 Replacing the WBC Bath Assembly .................................................................. 5-70

5.9 Replacing the Reagent Preheating Assembly ................................................... 5-76

5.10 Replacing the Open Vial Sampling/SRV Assembly........................................... 5-78

5.11 Replacing the Sample Transmitting Assembly .................................................. 5-96

5.12 Replacing the Autosampler and Mixer Assemblies ......................................... 5-115

5.13 Replacing the Pneumatic Unit ......................................................................... 5-130

5.14 Replacing the Ambient Temperature Sensor................................................... 5-138

5.15 Replacing the Blood Sensor ............................................................................ 5-140

5.16 Replacing the Filtering Cartridge ..................................................................... 5-142

6 Optical System 6-1

6.1 Optical System Adjustment and Servicing .......................................................... 6-1

6.2 Removing and Installing Optical System Assemblies.......................................... 6-2

6.3 Adjustment......................................................................................................... 6-11

6.4 Common Failures of the Optical System ........................................................... 6-27

7 Troubleshooting 7-1

7.1 Error code and information.................................................................................. 7-1

7.2 Causes of Common Errors .................................................................................. 7-6

7.3 Function Sequence Codes and Information ...................................................... 7-14

7.4 Error analysis and processing ........................................................................... 7-16

8 Maintaining Your Analyzer 8-1

8.1 List of Parts That Need to Be Replaced Periodically .......................................... 8-1

8.2 Basic Maintenance from Service Engineer ......................................................... 8-1

9 Appendices A-1

2

1 Using This Manual

1.1 Introduction

The chapter explains how to use the BC-5800 service manual. This manual provides the

reference information and procedures needed in servicing the BC-5800. Before servicing the

BC-5800, read and understand the manual carefully to ensure the proper servicing of the

equipment and personnel safety.

This manual is to be used together with the operation manual of BC-5800. It does not contain

information and procedures already covered in the operation manual of BC-5800.

z Be sure to operate and service the analyzer strictly as instructed in this

manual and the operation manual.

1-1

Using This Manual

1.2 Who Should Read This Manual

To use this manual effectively, you need to have the following capacities:

Comprehensive knowledge of electric circuit and fluidic system;

Comprehensive knowledge of reagents;

Comprehensive knowledge of quality control;

Thorough understanding of troubleshooting;

The ability to operate the analyzer skillfully;

The ability to use basic mechanical tools and understand related terminology;

The ability to use a digital voltmeter and an oscilloscope masterly;

And the ability to read pneumatic/hydraulic schematics and understand related

terminology.

1-2

Using This Manual

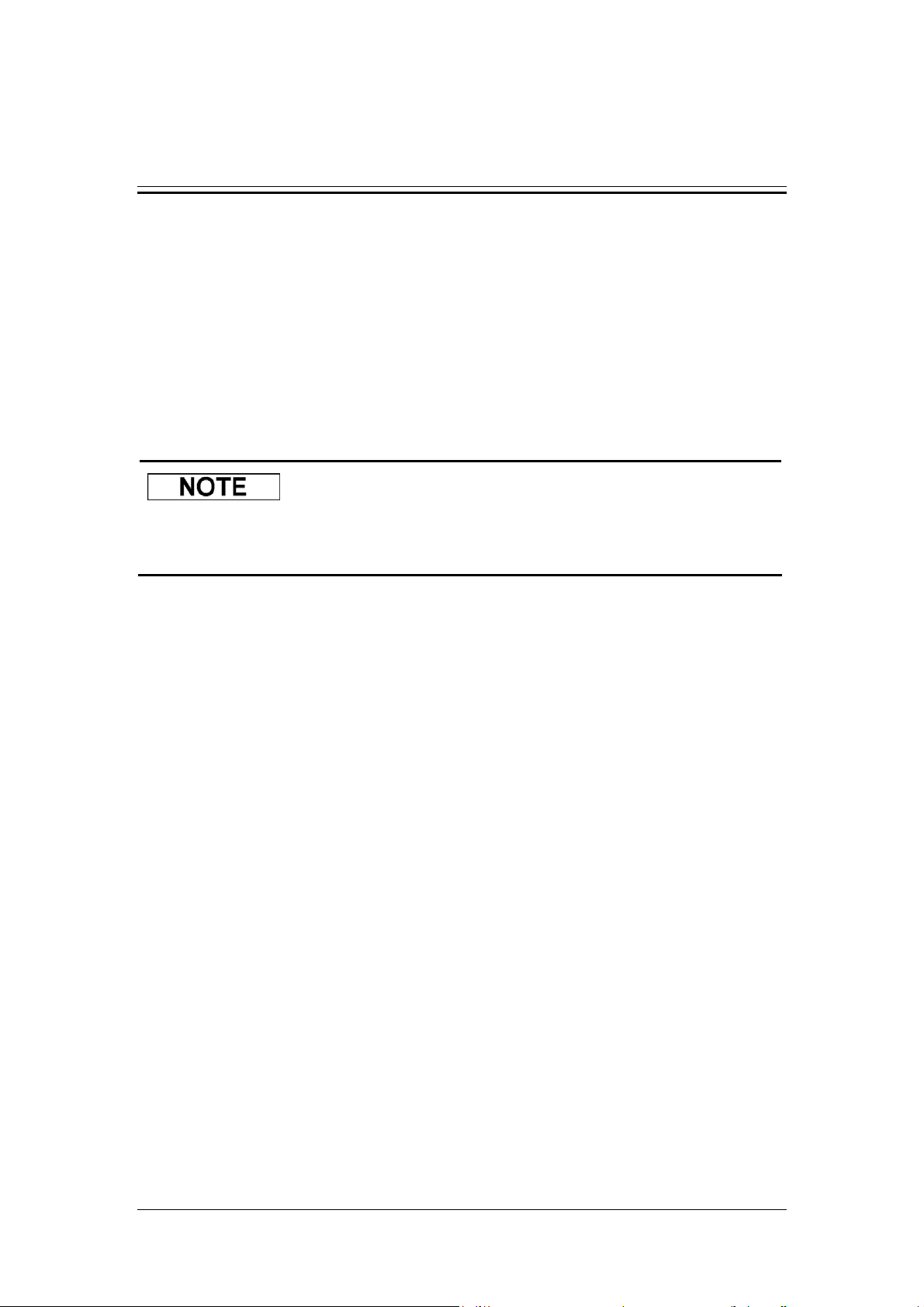

1.3 How to Find Information

This operation manual comprises 8 chapters and 5 appendices. Refer to the table below to find

the information you need.

If you want to … See …

learn about the system structure and the basic

principle of BC-5800

learn about the fluidic system

learn about the hardware system

learn about how to service the BC-5800

learn about the optical system of BC-5800 and its

maintenance methods

learn about how to troubleshoot the common errors

of the BC-5800

learn about how to maintain the BC-5800

learn about the main spare parts of the BC-5800

learn about the main wearing parts of the BC-5800

learn about the schematic diagram of the fluidic

system of the BC-5800

learn about the function of each valve and pump of

the BC-5800

learn about the tubing connection of the BC-5800

Chapter 2 System Structure

Chapter 3 Fluidic System

Chapter 4 Hardware System

Chapter 5 Servicing

Chapter 6 Optical System

Chapter 7 T roubleshooting

Chapter 8 Maintenance

Appendix A List of Spare parts

Appendix B List of Wearing Parts

Appendix C Fluidic Diagram

Appendix D Pump and Valve

Function T a ble

Appendix E Tubing

1-3

Using This Manual

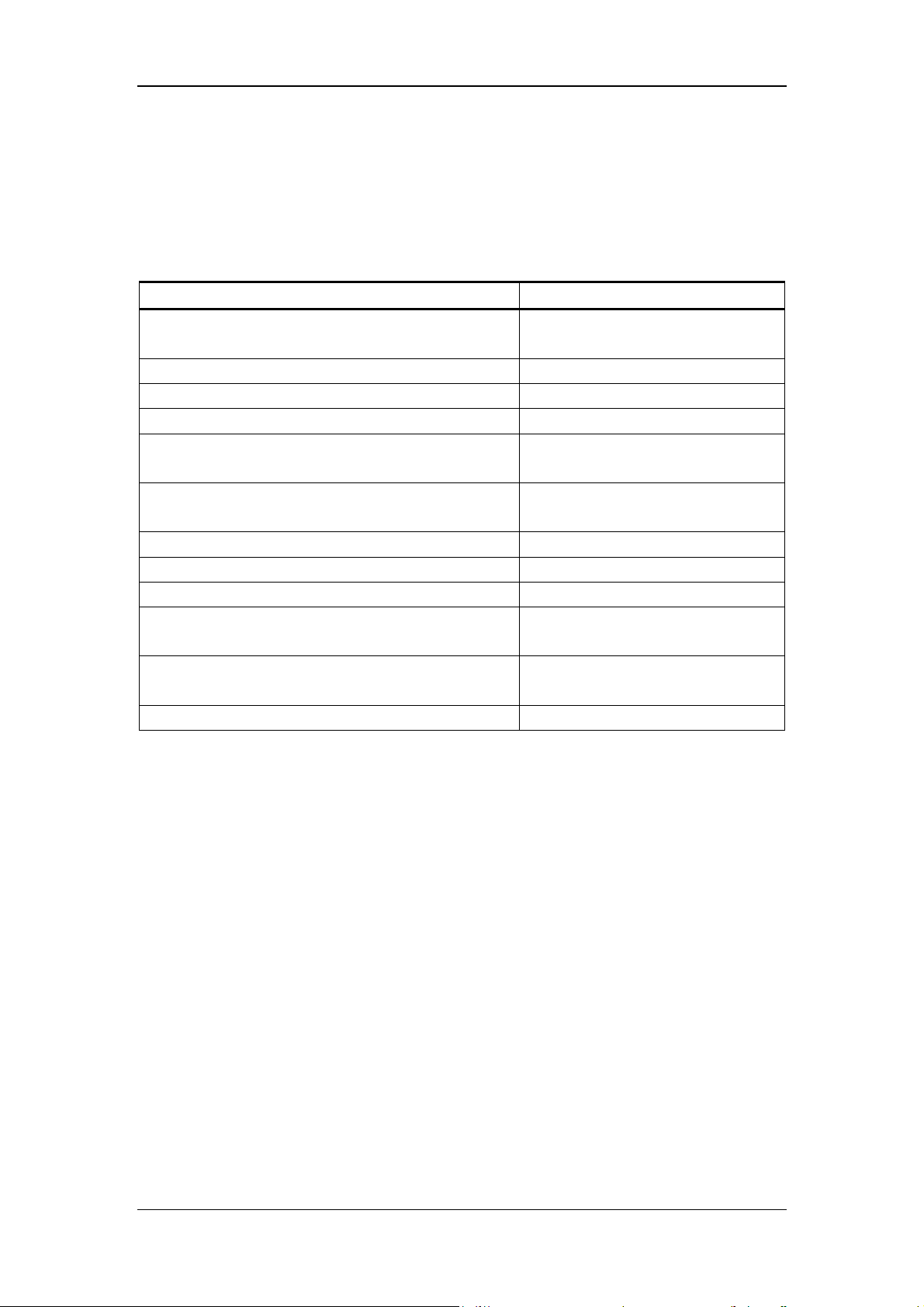

1.4 Conventions Used in This Manual

This manual uses certain typographical conventions to clarify meaning in the text:

Format Meaning

[XX] all capital letters enclosed in [ ] indicate a key name (either on

the pop-up keyboard or the external keyboard)

“XX” letters included in " " indicate text you can find on the screen

of BC-5800

XX italic letters indicate titles of the chapters that are referred to

XX

All illustrations in this manual are provided as examples only. They may not necessarily reflect

your analyzer setup or data displayed.

all-capitalized, bold and italic letters indicate a major operation

defined in Section 1.4

1-4

Using This Manual

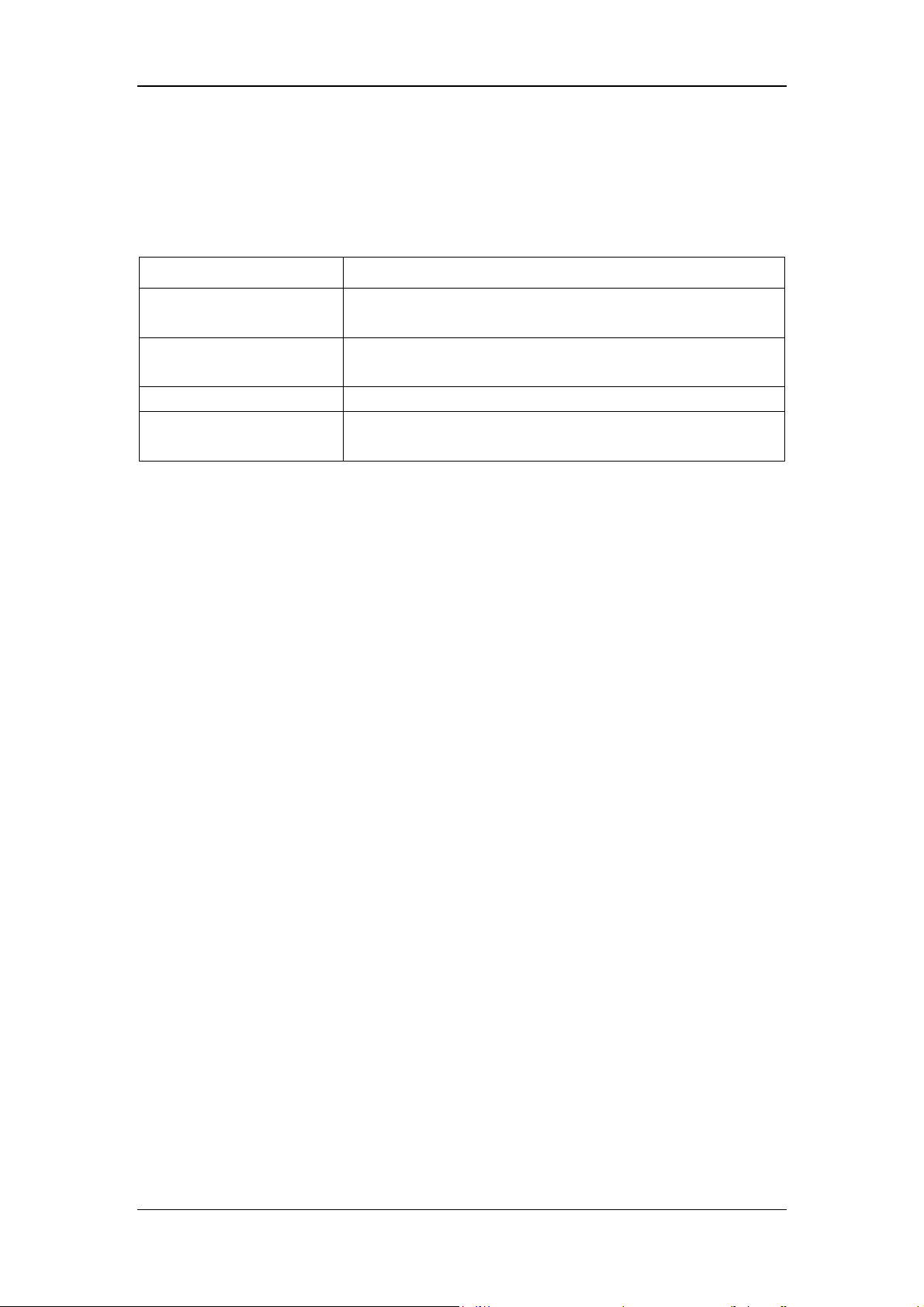

1.5 Special Terms Used in This Manual

When you read … It means …

CLICK

ENTER

DELETE

DRAG SCROLL BAR

SELECT from

“ ** “ pull-down list

to press the desired item lightly with your finger; or to left-CLICK

it with the mouse.

to CLICK the desired edit box and use the external keyboard or

the pop-up keyboard to enter the desired characters or digits; or

to scan the number by using the bar-code scanner.

to move the cursor to the character or digit that you want to delete

by clicking the left button of the mouse or using

[←][→][Home][End],

and then delete the character after the cursor by pressing [Del], or

delete the character before the cursor by pressing [BackSpace]

([←] on the upper right part of the soft keyboard).

to CLICK the arrow buttons at the ends of the scroll bar; or to

CLICK and hold the mouse button down while dragging the scroll

bar until the desired information is displayed; or to touch the scroll

bar and rest your finger there until the desired information is

displayed.

to CLICK the down arrow button of the desired box to display the

pull-down list, (and DRAG SCROLL BAR) to browse and then

CLICK the desired item; or to press the keys

([↑][↓][PageUp][PageDown]) to browse the current list and press

[ENTER] to select the desired item.

1-5

Using This Manual

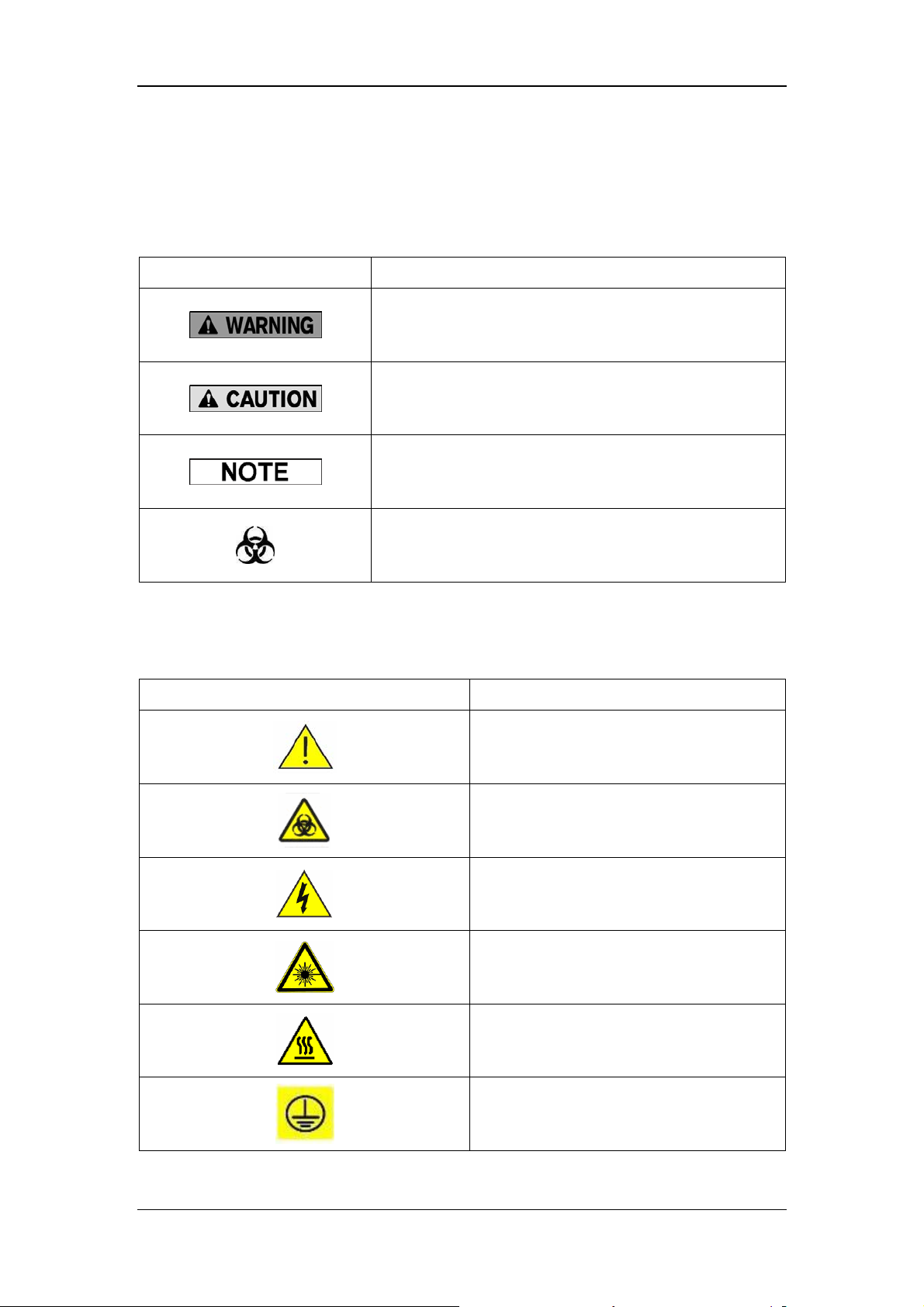

1.6 Symbols

You will find the following symbols in this manual.

When you see… Then…

read the statement below the symbol. The statement is

alerting you to an operating hazard that can cause

personnel injury.

read the statement below the symbol. The statement is

alerting you to a possibility of analyzer damage or

unreliable analysis results.

read the statement below the symbol. The statement is

alerting you to information that requires your attention.

read the statement below the symbol. The statement is

You may find the following symbols on the analyzer, reagents, controls or calibrators.

When you see… It means…

alerting you to a potentially biohazardous condition.

CAUTION, CONSULT ACCOMPANYING

DOCUMENTS.

BIOLOGICAL RISK

HIGH VOLTAGE

WARNING, LASER BEAM

WARNING, HOT SURFACE

PROTECTIVE EARTH (GROUND)

1-6

Using This Manual

EARTH (GROUND)

ALTERNATING CURRENT

FOR IN VITRO DIAGNOSTIC USE

TYPE B DEVICE

BATCH CODE

USE BY (YYYY-MM-DD)

SERIAL NUMBER

MEASUREMENT AUTHORIZATION

SYMBOL

DATE OF MANUFACTURE

MANUFACTURER

TEMPERATURE LIMITATION

CONSULT INSTRUCTIONS FOR USE

Be sure to observe the following precautions for the safety of patients, operators and yours

when you are servicing the analyzer.

1-7

Using This Manual

z It is important for the hospital or organization that employs this equipment

to carry out a reasonable service/maintenance plan. Neglect of this may

result in machine breakdown or harm to human health.

z Never use combustible gas (e.g. anesthetic) or combustible liquid (e.g.

ethanol) around the analyzer. Otherwise, the risk of explosion may exist.

z When servicing the analyzer, be sure to turn off the power. Servicing the

analyzer when it is on may bring risk of electric shock or damage to

electronic components.

z Connect the analyzer to a socket having sole fuse and protective switch. Do

not use the same fuse and protective switch with other equipment (e.g. life

supporting equipment). Otherwise, the equipment failure, over current or

impulse current that occurs at the startup moment may lead to tripping.

z To prevent personal injury during mainten ance, keep y our clothes, hairs and

hands from the moving parts, such as sample probe, clipper and piercer.

z Possible mechanical movement of the warned position may lead to personal

injury during the normal operation, removal and maintenance.

z Be sure to dispose of reagents, waste, samples, consumables, etc.

according to government regulations.

z The reagents are irritating to eyes, skin and mucosa. Wear proper personal

protective equipment (e.g. gloves, lab coat, etc.) and follow safe laboratory

procedures when handling them in the laboratory.

z If the reagents accidentally spill on your skin, wash them off with plenty of

water and if necessary, go see a doctor; if the reagents accidentally spill into

your eyes, wash them off with plenty of water and immediately go see a

doctor.

1-8

Using This Manual

z Improper maintenance may damage the analyzer. Maintain the analyzer

strictly as instructed by the service manual and inspect the analyzer

carefully after the maintenance.

z For problems not mentioned in the service manual, contact Mindray

customer service department for maintenance adv i ce.

z To prevent personal injury or damage to equipment components, remove

metal jewelry before maintaining or servicing electronic components of the

equipment.

z Electrostatic discharge may damage electronic components. If there is a

possibility of ESD damage with a procedure, then do that procedure at an

ESD workstation, or wear an antistatic wrist strap.

z This equipment must be operated by skilled/trained medical professionals.

z Samples, controls, calibrators and waste are potentially infectious. Wear

proper personal protective equipment (e.g. gloves, lab coat, etc.) and follow

safe laboratory procedures when handling them in the laboratory.

z All the analyzer components and surfaces are potentially infectious. Take

proper protective measures for operation or maintenance.

z The sample probe tip is sharp and may contain biohazardous materials.

Exercise caution to avoid contact with the probe when working around it.

1-9

2 System Structure

2.1 System Overview

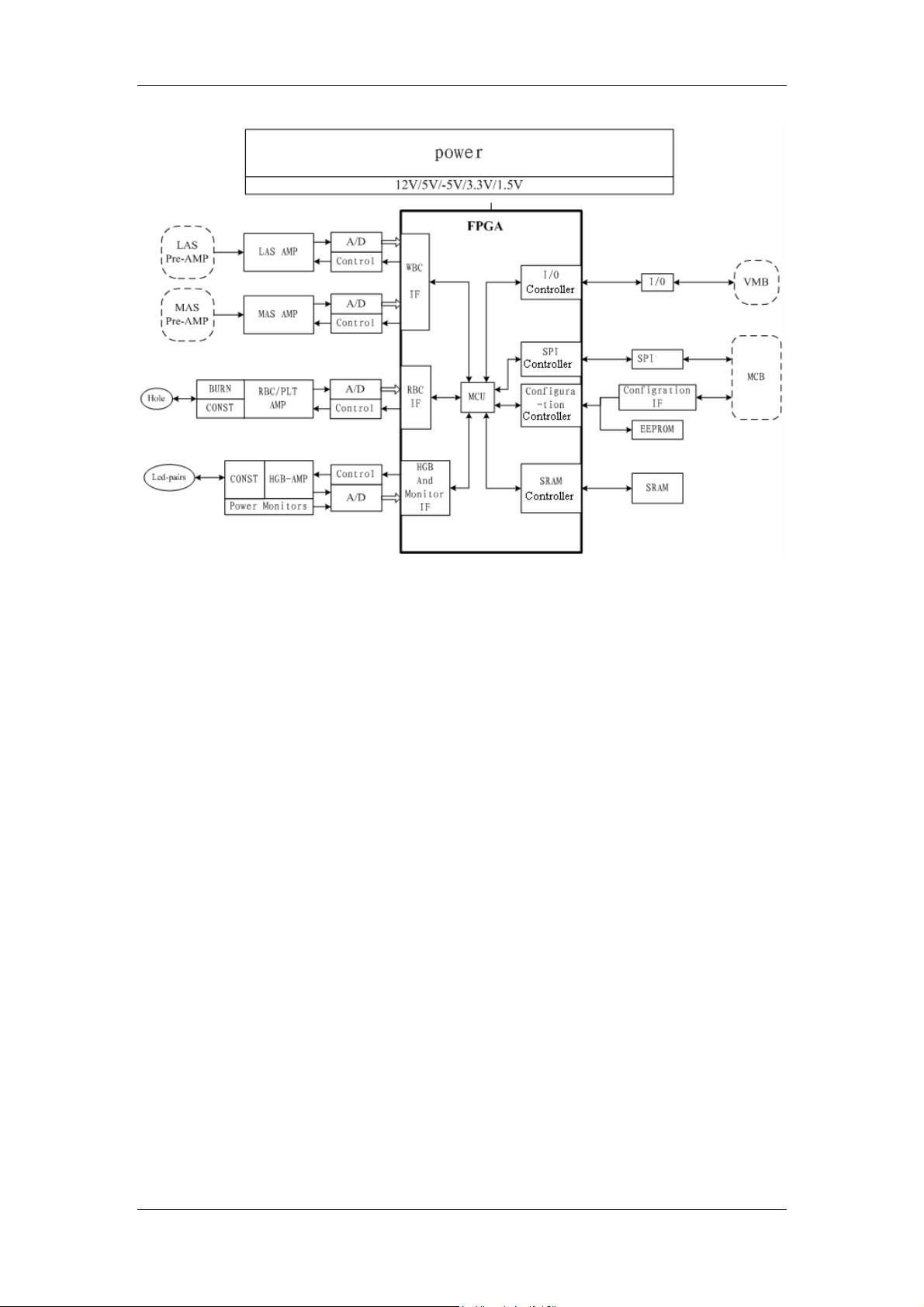

Hardware

Hardware is designed for signal gathering, the controlling and driving of motion components

and the processing and display of data. It is mainly composed of main board, power drive

board, signal processing board, power board, blood sensor board and pressure sensor

board.

Interfaces

BC-5800 offers many interfaces to facilitate data processing and selection of various

accessories. It provides 4 USB interfaces, 1 network interface, 1 pneumatic unit control

interface and 1 reserved interface. USB interfaces can be used to connect mouse, keyboard,

printer, scanner and USB, and to perform software upgrade. The network interface adopts

built-in network card, can perform networking function.

Software running environment

System software can be divided into boot software, operation software and application

software. The boot software and operation software are stored in the FLASH chip of the main

board, and the application software is stored in the hard disk. The boot software has two main

functions, one is to configure address space, and the other is to initialize system memory.

The operation system completes the resource initialization of CPU board and provides

operation system environment to the application software. The application software offers an

interactive operation interface.

Fluidic system

Fluidic system is the tubing structure of the analyzer where reagent, sample and air flow

through. All hydraulic parts are connected correspondingly, and they are controlled by

software and drive hardware according to the specified order to realize control over the

allocation and direction of media.

2-1

System Structure

2.2 Fluidic System

Please refer to Chapter 3 Fluidic System of this manual.

2-2

System Structure

2.3 Hardware System

Please refer to Chapter 5 Hardware System of this manual.

2-3

System Structure

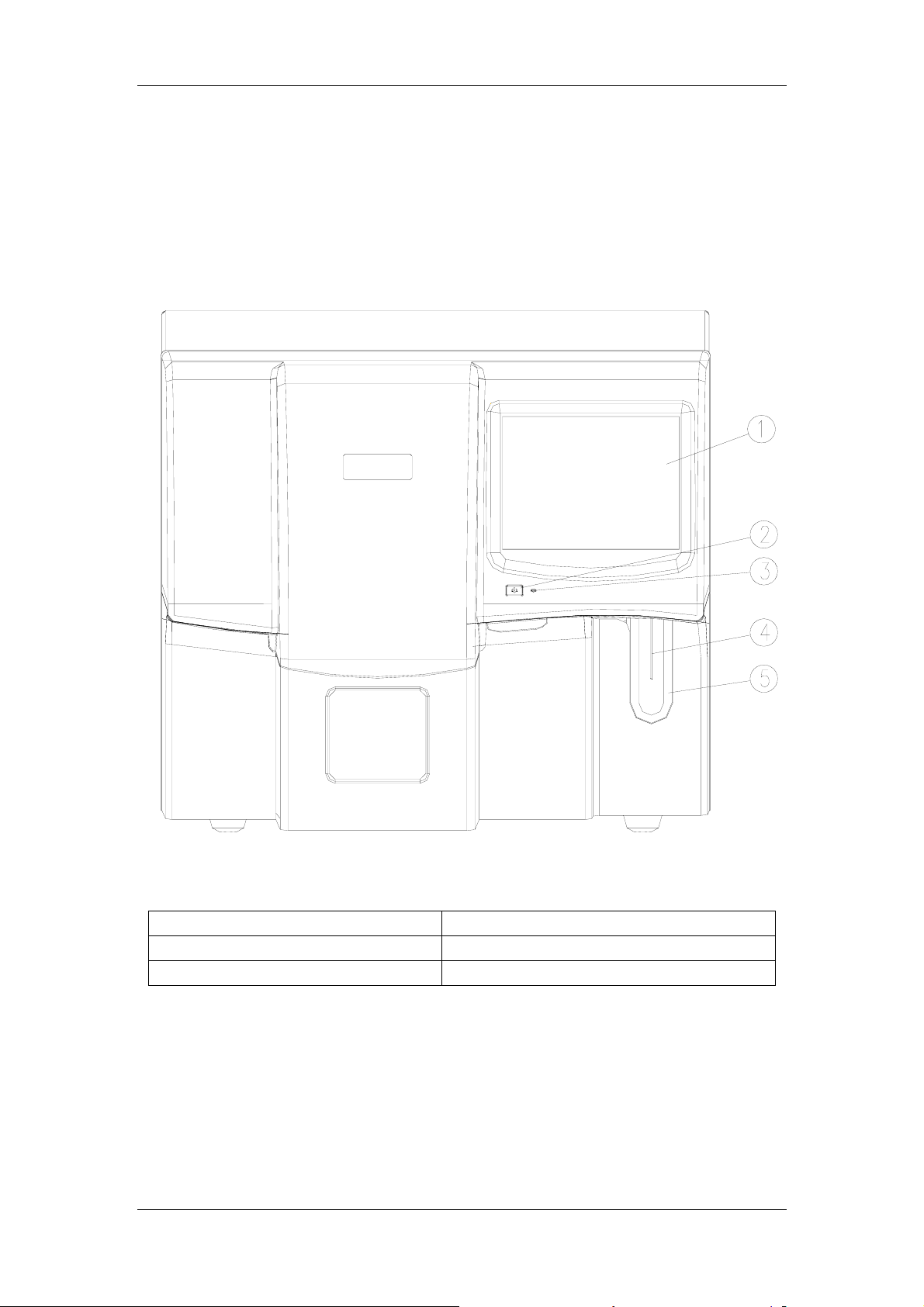

2.4 Main Structure

BC-5800 5-differential auto hematology analyzer consists of the main unit (analyzer),

pneumatic unit and accessories.

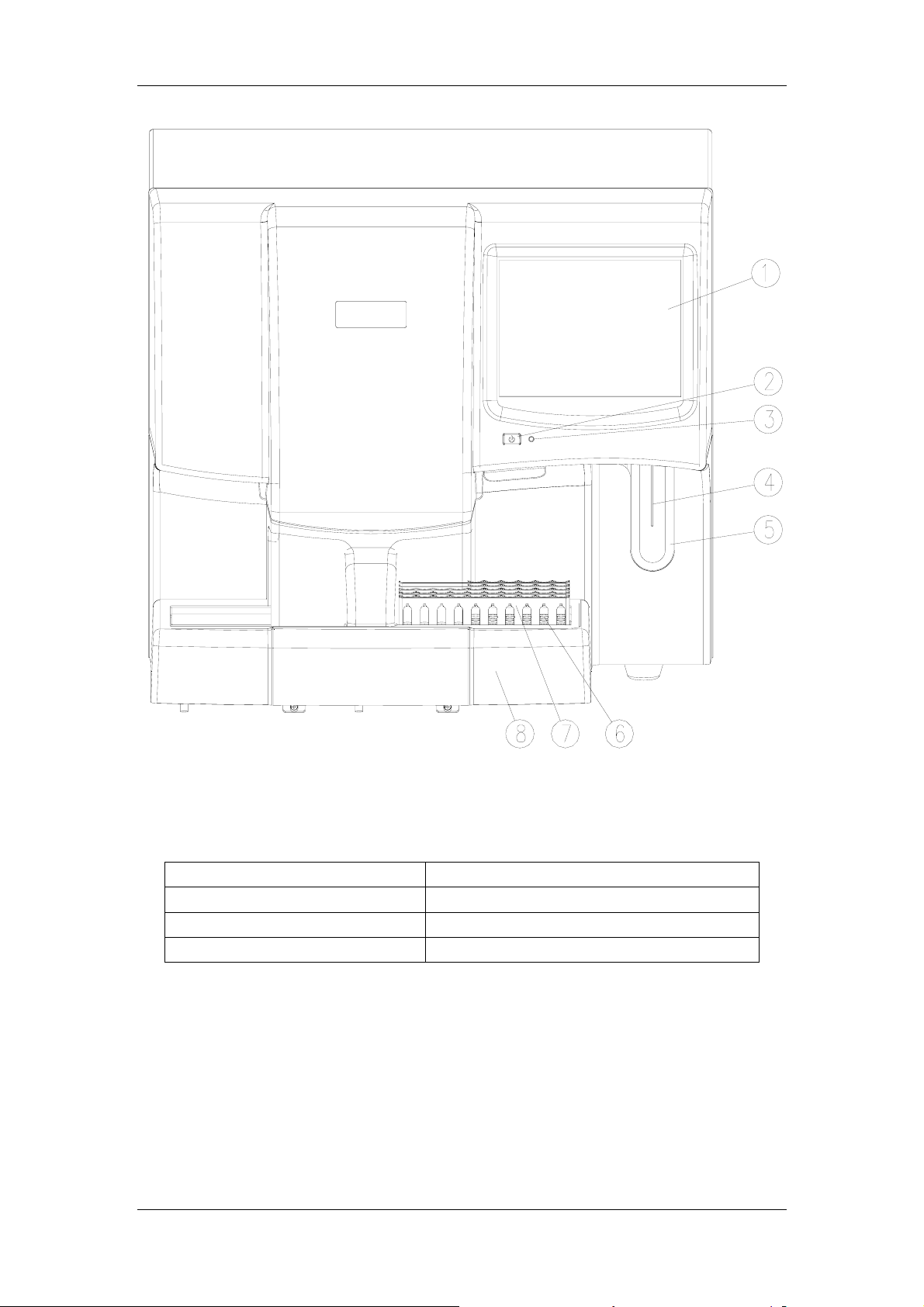

Figure 2-1 Front of the Analyzer

1----Touch screen 4----Sample probe

2----Power button 5----Aspirate key

3----Power indicator

2-4

System Structure

Figure 2-2 Front of the Analyzer (

1----Touch screen 5----Aspirate key

2----Power button 6----Sample tube

3----Power indicator 7----Tube rack

4----Sample probe 8----Autoloader

2-5

Autoloader Configured)

System Structure

1

2

21

20

19

18

17

16

15

14

10111213

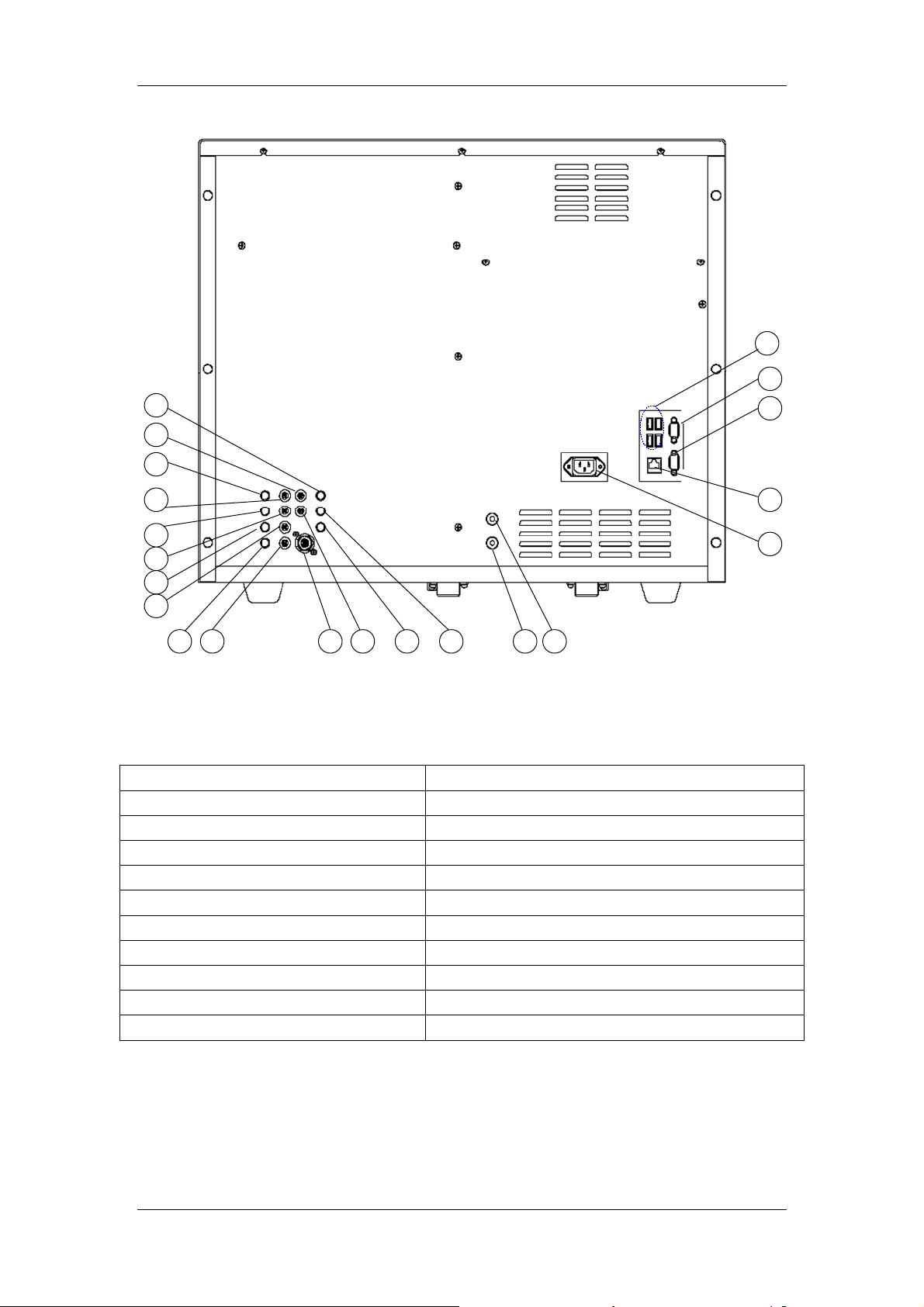

Figure 2-3 Back of the Analyzer

1----USB interface 12----M-58D diluent inlet

2----Reserved interface 13----M-58D diluent sensor BNC connector

3----Pneumatic unit control interface 14----M-58LBA lyse inlet

4----USB interface 15----M-58LBA lyse sensor BNC connector

5----Power input

6----Vacuum interface

7----Pressure interface

8----M-58 diluent sensor BNC connector

9----Waste sensor BNC connector 20----M-58LH lyse inlet

10----M-58 cleanser inlet 21----M-58LH lyse sensor BNC connector

11----Waste outlet

16----M-58LEO(Ⅱ) lyse inlet

17----M-58LEO(Ⅱ) lyse sensor BNC connector

18----M-58LEO(Ⅰ) lyse sensor BNC connector

19----M-58LEO(Ⅰ) lyse inlet

6789

3

4

5

2-6

System Structure

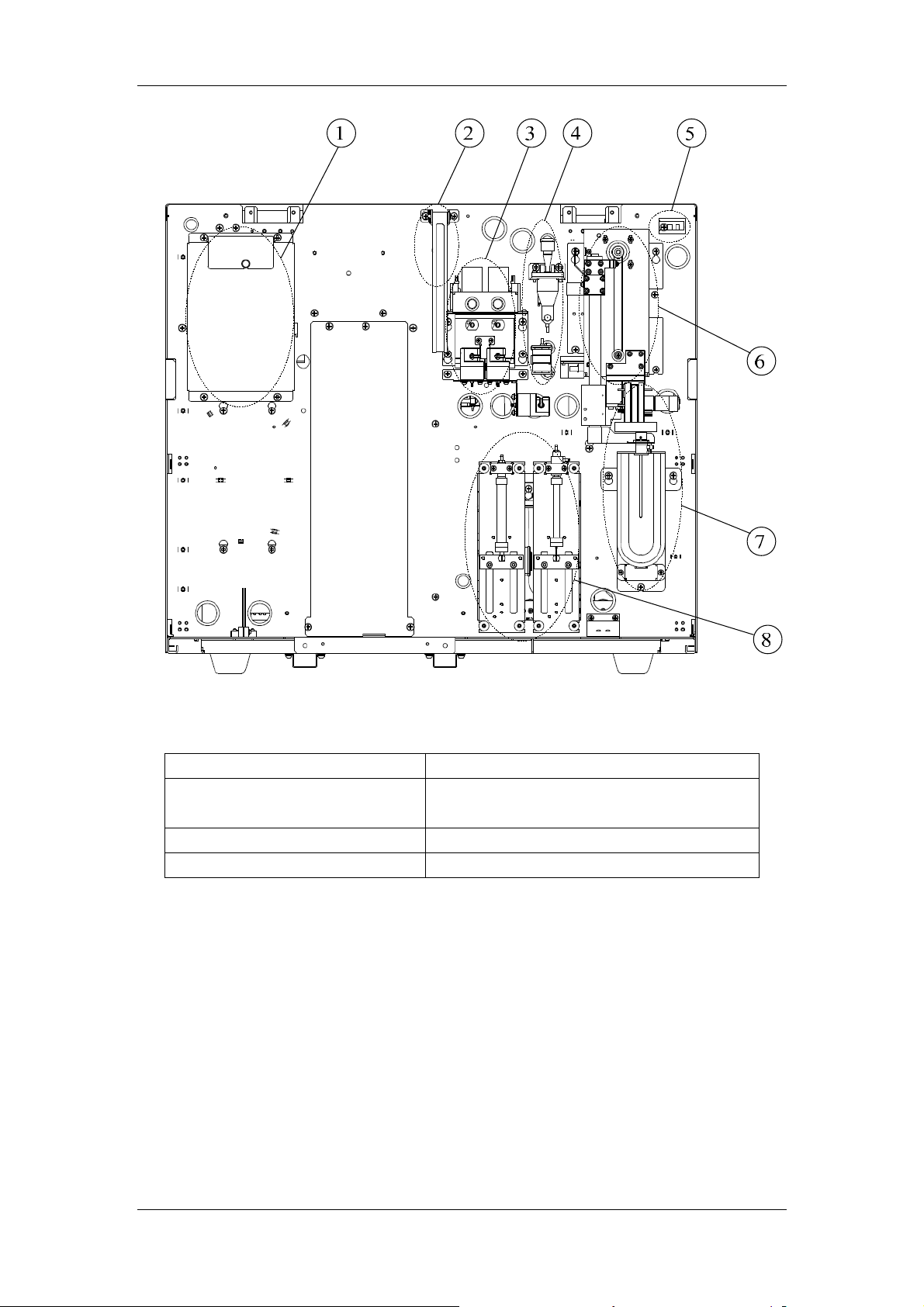

Figure 2-4 Front of the Analyzer (Front Cover Removed)

1----RBC & HGB bath unit 5----Cover photocoupler protecting unit

2----Cover support unit 6----Manual sampling and SRV(Sample

Rotator Valve) unit

3----WBC bath unit 7----START on/off unit

4----RBC premix bath unit 8----Syringes

2-7

System Structure

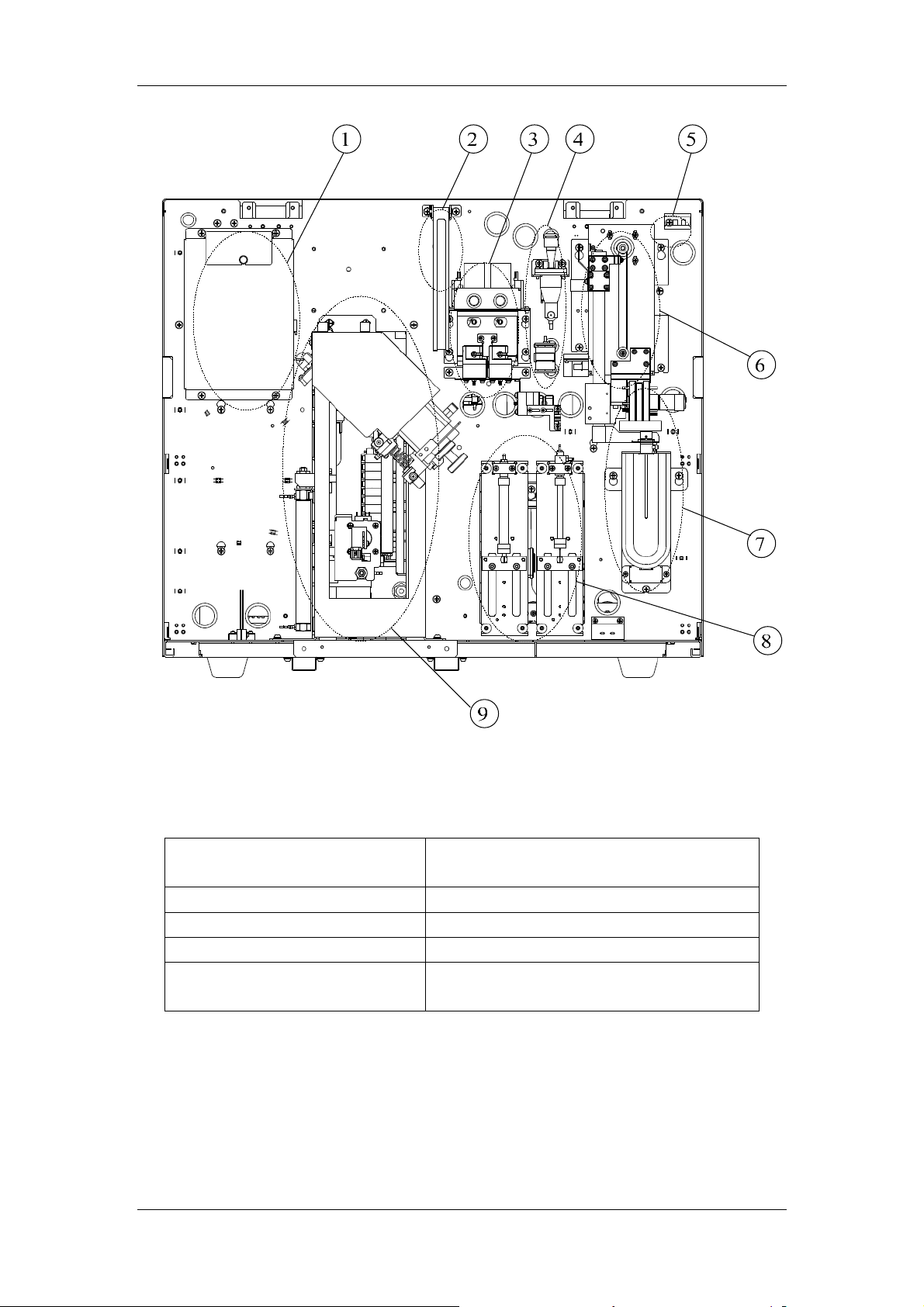

Figure 2-5 Front of the Analyzer (Front Cover Removed, Pierce & Mix Unit Configured)

1----RBC & HGB bath unit 6----Manual sampling and SRV(Sample

Rotator Valve) unit

2----Cover support unit 7----START on/off unit

3----WBC bath unit 8----Syringes

4----RBC premix bath unit 9----Pierce & mix unit

5----Cover photocoupler protecting

unit

2-8

System Structure

1

2

3

678

Figure 2-6 Inside Right of the Analyzer (Right Door Removed)

1----Optical system 5----Burkert valve unit

2----Valve & pump unit 6----Pinch valve unit

3----Cistern and waste chamber

unit

4----Waste five-way valve unit 8----Reagent preheating unit

7---- Waste chamber

4

5

2-9

System Structure

9 10 11 12

8

7

6

5

4

3

2

1

Figure 2-7 Inside Left of the Analyzer (Left Door Removed)

1----Power input 7----Pressure sensor board

2----Interface board 8----Fan

3----Filter 9----Hard disk unit

4----Air valve unit 10----Main board and signal board unit

5----Pressure regulator unit 11----PCB support bar unit

6----Power drive board unit 12----Volumetric unit

2-10

System Structure

Figure 2-8 Front of Pneumatic Unit

1----Relief valve 2----Power indicator

2-11

System Structure

2.5 Software Structure

Software system can be divided into boot software, operation software and application

software. Boot software is autoloaded by hardware; its code runs in FLASH to configure

address space and to initialize system memory. Operation system completes the resource

initialization of CPU board, loading application software and transferring the CPU control

authority to application software. The code of application software runs in SDRAM, it obtains

the resource data needed from external hard disk to provide functions like counting,

parameter setting, quality control, device maintenance, data management, assistance, help,

etc. The application software sends control command to corresponding fluidic units at the

specified time according to the fluidic unit control sequence in basic sequence.

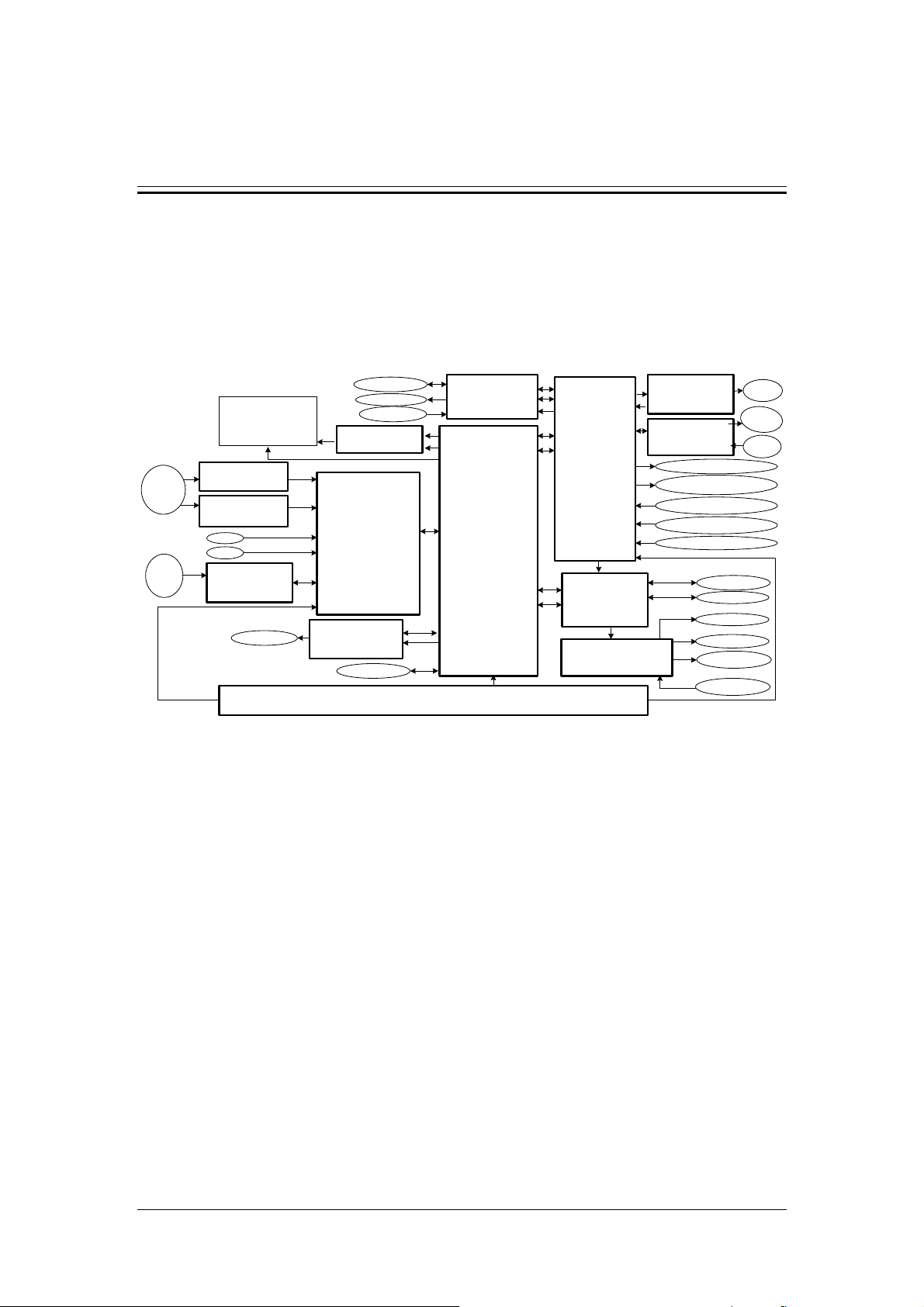

2.5.1 Menu Structure

1. Main screen

There are 8 function icons in the main screen menu. Operators can click on the function

icons in the main screen to enter into corresponding screens to perform all functions of the

analyzer. See Figure 2-9 fo r the submenu structure of the main screen.

Figure 2-9 Menu Structure of the Main Screen

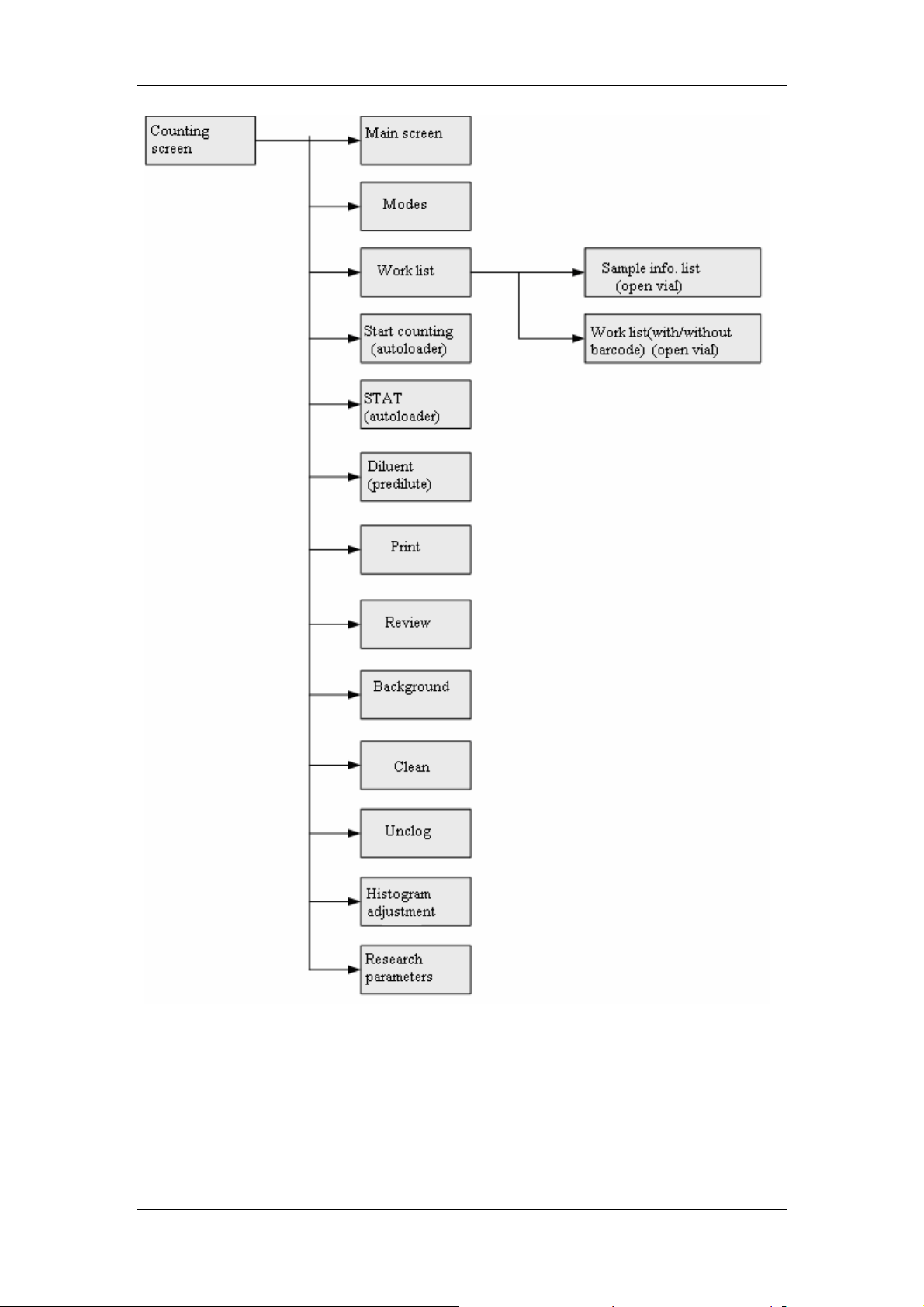

2. Counting screen

Counting screen comprises four parts: status region, measurement result and data region of

the current sample, data display region of the next sample and function button region.

Operators can click each function button in the counting screen to perform the functions of

the analyzer.

See Figure 2-10 for the menu structure of the counting screen:

2-12

System Structure

Figure 2-10 Menu Structure of the Counting Screen

3. Review screen

There are two modes of sample results review, table review mode and graph review mode.

When entering review screen from other screens, operators see the list review screen first.

See below for the menu structure of each screen:

Table review

2-13

System Structure

See Figure 2-11 for the menu structure of the table review menu:

Figure 2-11 Menu Structure of Table Review Mode

Graph review

See Figure 2-12 for the menu structure of the graph review mode:

2-14

System Structure

Figure 2-12 Menu Structure of Graph Review Mode

4. QC (Quality Control) screen

There are two QC programs: L-J QC and X-B QC. When switching to QC screen from other

screen, operators see L-J QC screen first.

L-J QC

See Figure 2-13 for the menu structure of L-J QC screen

2-15

System Structure

Figure 2-13 L-J QC Menu Structure

X-B QC

See Figure 2-14 for the menu structure of X-B QC screen

Figure 2-14 L-J QC Menu Structure

5. "Service" screen

"Service" screen includes "Maintenance", "Status", "Self-test", "Log", "Debug" and

"Initialization" screens. When switching to "Service" screen from other screens, operators

see the "Maintenance" screen first. See below for the menu structure of each screen:

2-16

System Structure

"Maintenance" screen

See Figure 2-15 for the menu structure of the "Maintenance" screen:

Figure 2-15 Menu Structure of the "Maintenance" Screen

"Status" screen

See Figure 2-16 for the menu structure of the "Status" screen:

2-17

System Structure

Service Main

Count

Maintain

Status

Self-test

Log

Init.

Debug

Figure 2-16 Menu Structure of the "Status" Screen

"Self-test" screen

See Figure 2-17 for the menu structure of the "Self-test" screen:

Version

Temp&Pres

Vol.&Cur.

Position

Func. Set

2-18

System Structure

Figure 2-17 Menu Structure of the "Self-test" Screen

"Log" screen

See Figure 2-18 for the menu structure of the "Log" screen:

2-19

System Structure

Figure 2-18 Menu Structure of the "Log" screen

"Debug" screen

See Figure 2-19 for the menu structure of the "Debug" screen:

2-20

System Structure

Figure 2-19 Menu Structure of the "Debug" Screen

"Initialization" screen

See Figure 2-20 for the menu structure of the "Initialization" screen:

2-21

System Structure

Service Main

Count

Maintain

Status

Self-test

Log

Init.

Debug

Set init.

Runs init.

Figure 2-20 Menu Structure of the "Initialization" Screen

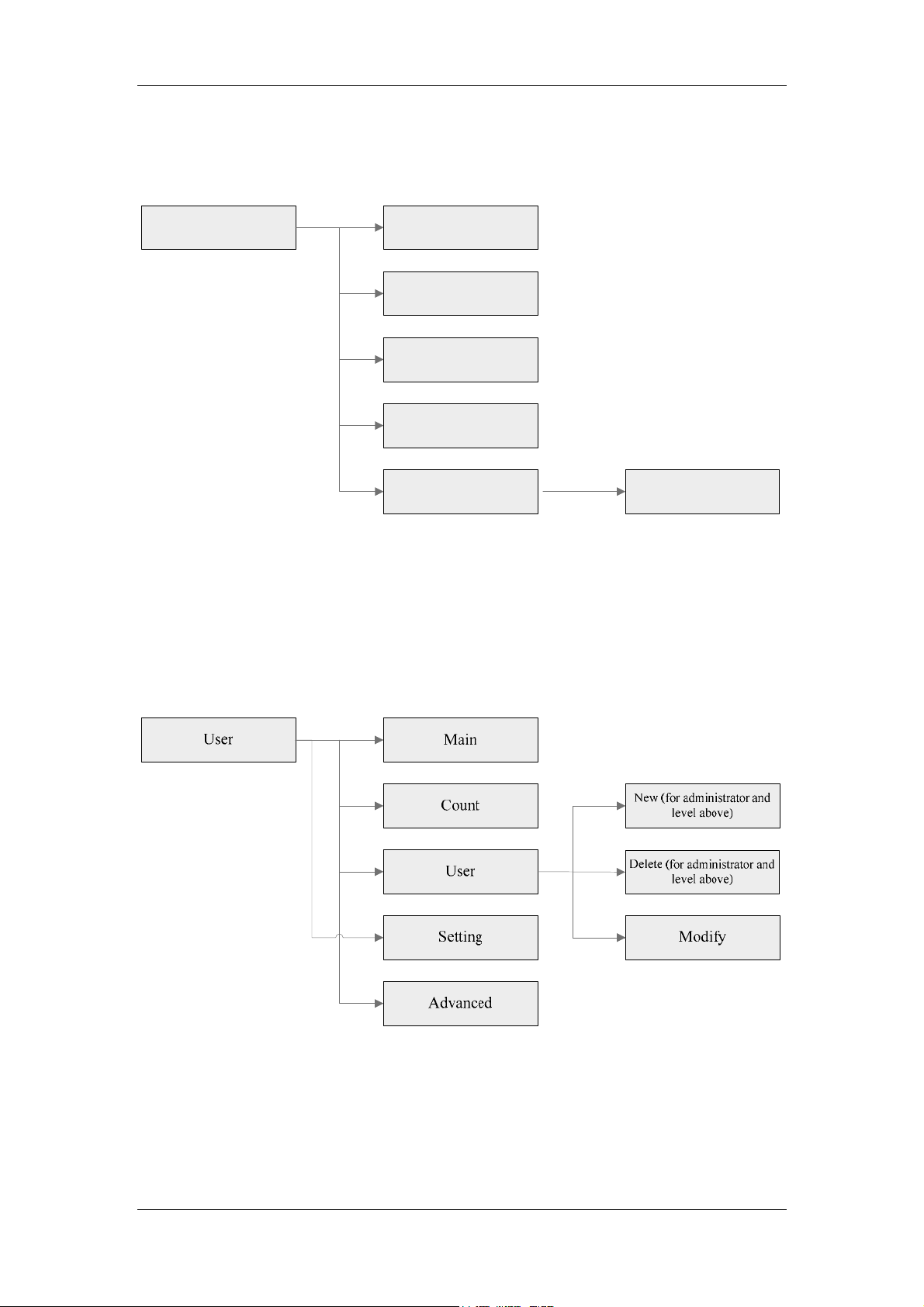

7. "Setup" screen

"Setup" screen includes "User", "Setting" and "Advance" screens. When switching to

"Setup" screen from other screen, operators see "Setting" screen first. See below for the

menu structure of each function screen:

Setting

See Figure 2-21 for the menu structure of the "Setting" screen:

2-22

System Structure

Figure 2-21 Menu Structure of "Setting" Screen

2-23

Advanced

System Structure

See Figure 2-22 for the menu structure of the "Advanced" screen:

Advanced Main

Count

User

Setting

Advanced

Figure 2-22 Menu Structure of "Advanced" Screen

Service

User Management

See Figure 2-23 for the menu structure of the "User" screen:

Figure 2-23 Menu Structure of the "User" Screen

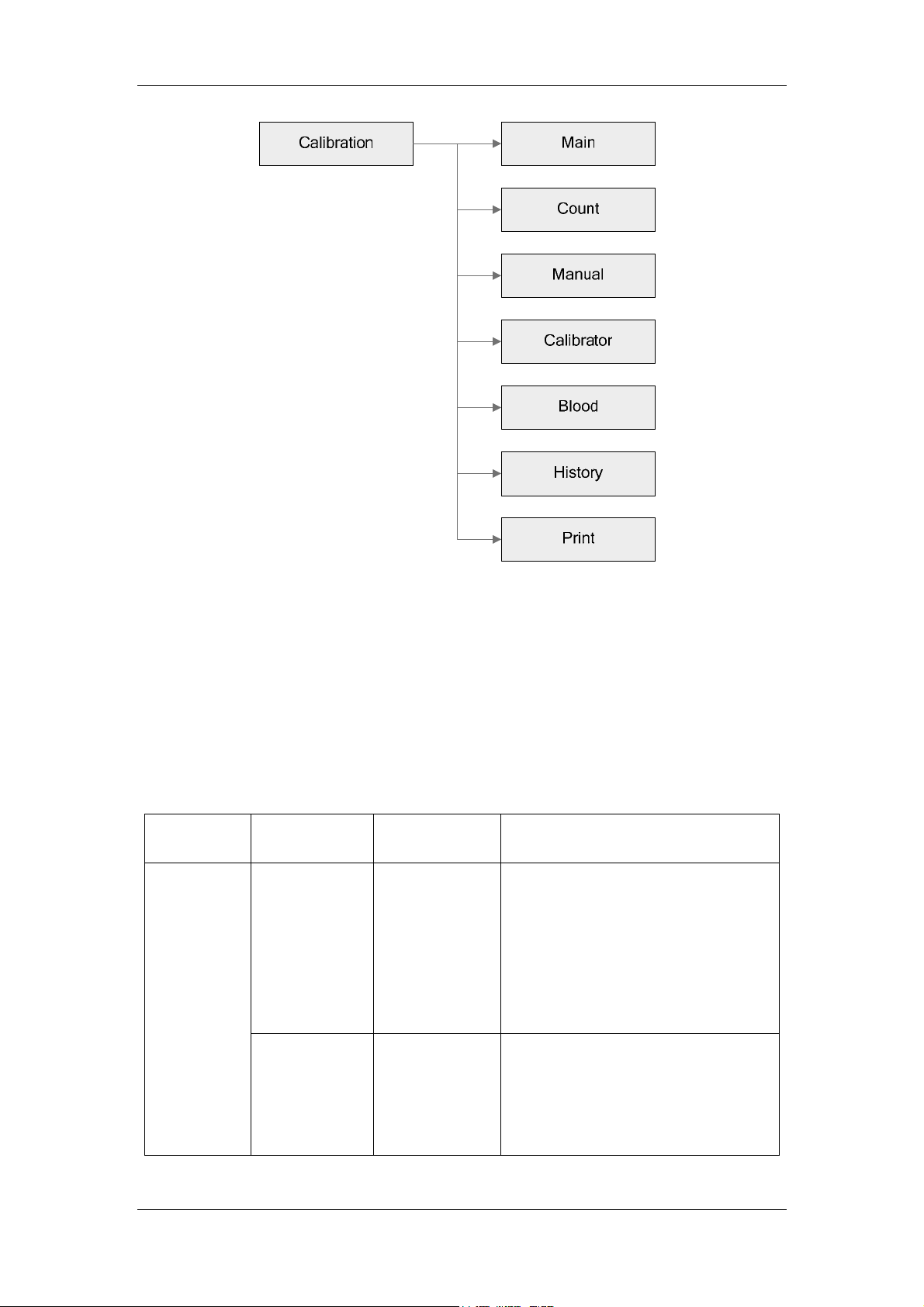

8. Calibration screen

2-24

System Structure

Figure 2-24 Menu Structure of the "Calibration" screen

2.5.2 Password

There are three levels of password: common user level, user administrator level and service

engineer level. The authorities of user administrator level cover all those of the common user

level, and the authorities of the service engineer level cover all those of the user administrator

level. See Table 2-1 for the permitted functions under each level of password.

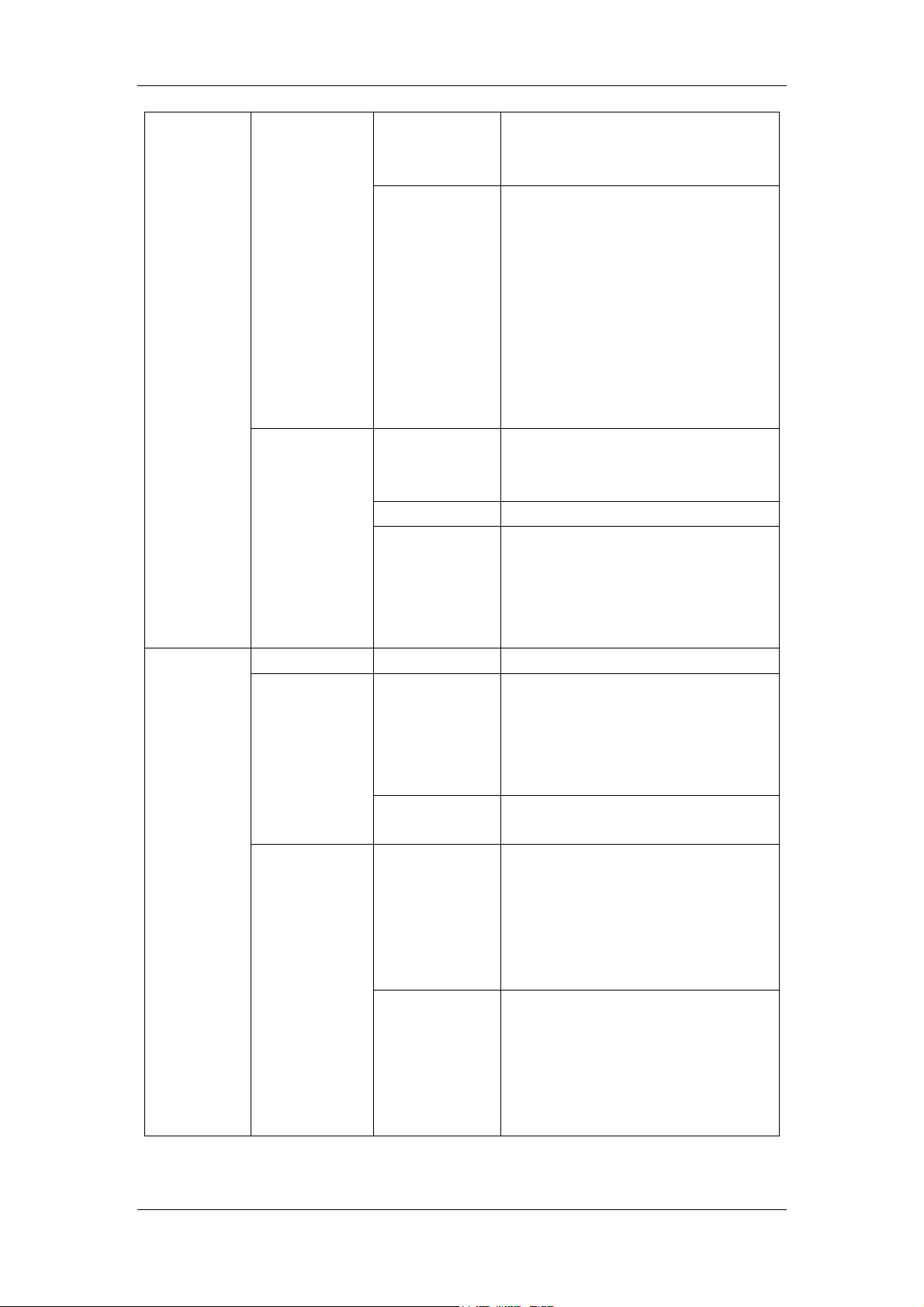

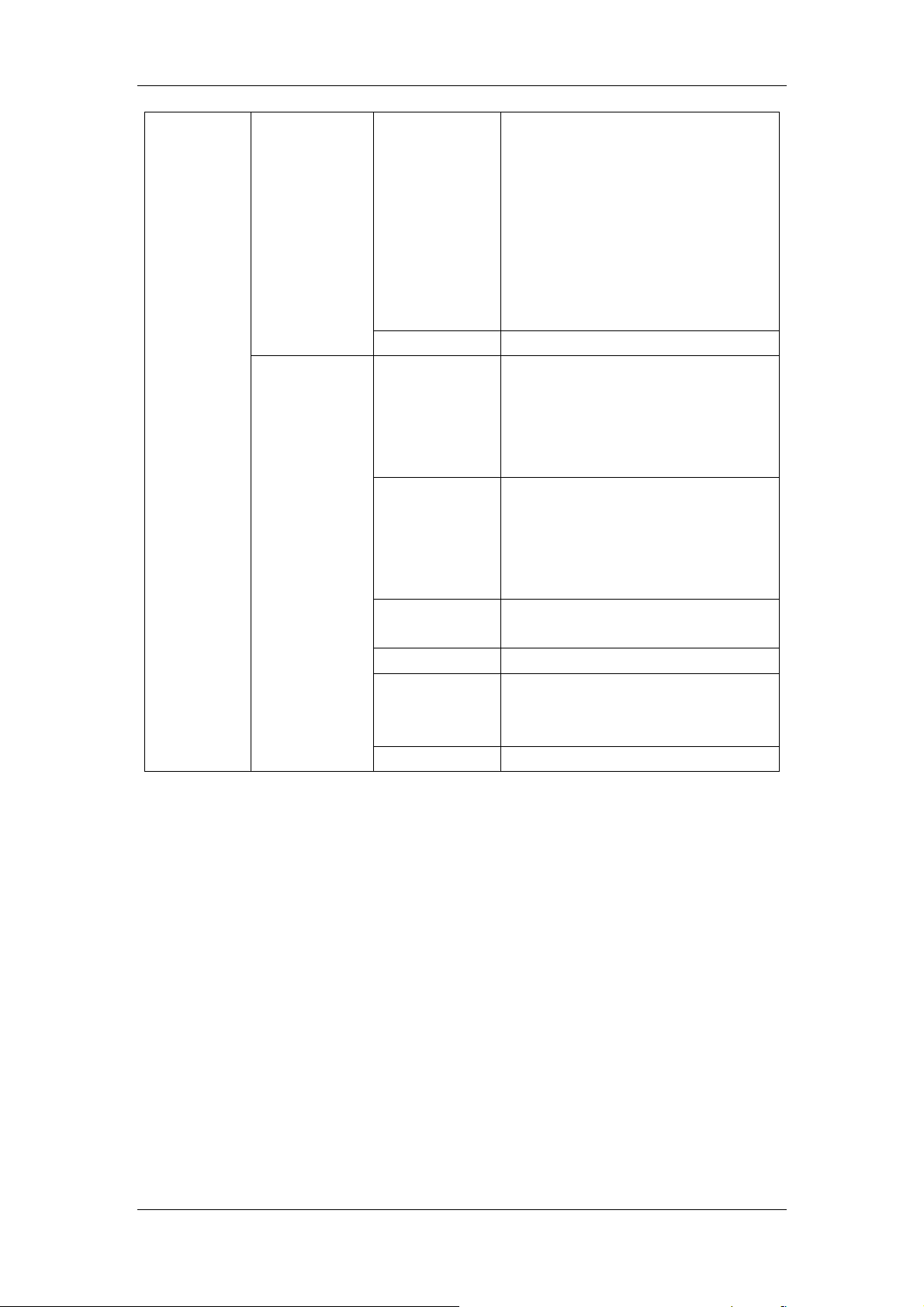

Table 2-1 Function Comparison Table of All Levels of Password

Password

level

Common

user

Module Screen Permitted Functions

Counting Counting Switching count mode, editing data of

the next sample, implementing count,

adding diluent, printing results of the

current sample, implementing

background count, unclogging,

cleaning, auto-sampling, STAT and

reviewing research parameters.

Review Table review Browsing sample records, editing

sample information (sample ID cannot

be altered), CV, and trend, selecting,

searching for and printing sample

data, switching

2-25

User

administrator

System Structure

Graph review Editing sample information, printing

sample data and research parameters

LJ QC setup, LJ QC count, LJ QC

LJ QC

graph and LJ QC table

XB QC setup and control, XB QC

QC

Calibration

Setup

XB QC

Manual

calibration

graph, XB QC table

Manual calibration result browsing

and printing

User User management(altering username,

password and operator's information)

Setting Setting date and time, assistance

settings and reagent expiration date.

Service

Self-test Mechanical self-test, valve self-test,

circuit self-test

Log

Includes "All", "Parameter Setup"

and "Others". Error information and

run sequence records cannot be

viewed in "All"

Status Version, temperature and pressure,

voltage and current, position and

photocoupler, and configuration

Maintenance Replacing/priming, cleaning,

maintaining, overall maintenance

Counting Counting Adjust histogram

Review

Table review 1 Delete sample data (set the deleting

authority for administrator in "Setup"

screen)

2 Modify sample ID

3 Check sample data

Graph review 1 Adjust histogram

2 Modify sample ID

3 Check sample data

Calibration

Manual

calibration

Modify open vial-whole blood, open

vial-predilute calibration parameters

and print

Calibrator Calibration under open vial-whole

blood and open vial-predilute mode

Fresh blood Calibration for fresh blood under open

vial-whole blood and open

vial-predilute mode

Calibration

history

Browsing and printing calibration

history

2-26

System Structure

Service

engineer

Setup

User 1 Add users

2 Delete users

3 Modify user information

Setting Print device parameters,

communication parameters, counting

report printing setup, autoloader stop

condition, gain setup (HGB setting),

reference range (general, man,

woman, child, neonate, user-defined),

counting parameter units, RBC count

time, department and sender ID

setup, tube barcode setup (autoloader

configured)

Service

Initialization Can initialize parameter units and

reference range, and print device

information

Self-test Can perform touch screen calibration

Log

Display "All", "Parameter Setup",

"Others" and "Error Information".

Run sequence records and log of

operations of service engineer level

cannot be viewed in "All".

Counting Counting

Review

Table review 1 Export data to USB (sample data

export, scattergram export)

2 View and print repeatability and

trend graph

3 Delete sample data

Graph review Display and print special information

of samples

Calibration

Modify calibration parameter under

open vial-whole blood and open

vial-predilute mode; modify the related

parameters under autoloader-whole

Manual

calibration

blood or closed tube-whole blood

mode

Modify calibration parameter under

open vial-whole blood and open

vial-predilute mode; modify the related

parameters under autoloader-whole

blood or closed tube-whole blood

Calibrator

mode

2-27

System Structure

Setup

Service

Advanced

setting\service

engineer

1 set auto-entry Flash mode

2 Languages

3 Device serial numbers

4 Volume setup for RBC volumetric

tube

5 Sample record deletion authority

setup

6、print bind reference range and its

flags

Gain Set the current value of all gains

Log

1 Display log type: "All", "Parameter

Setup", "Others", "Error

Information" and "Run Sequence".

All records can be viewed

2 Can export log with USB

Status 1 View version information of CD and

algorithm in version screen

2 View Temp. PID

(Kp,Ti,Td,T(S),SP(℃)) in temperature

& pressure screen

Self-test Temperature and pressure calibration

can be done in self-test screen

Initialization View runs initialization

Debug 1 Importing data with USB

2 Wipe block debug

3 Mix unit debug.

Maintenance Software upgrade (USB upgrade)

2-28

3 Fluidic System

3.1 Introduction of Fluidic Parts

3.1.1 Needles

Sample probe: connects to SRV (Sample Rotary Valve) for sample aspiration under

open vial mode.

Piercing needle: connects to piercing mechanism for sample aspiration under

autoloader mode.

Sample flow probe: connects to flow cell for the formation of sample flow in WBC

detection unit.

3.1.2 Probe Wipe

Probe wipe for sample probe: locates below SRV, its function is to wash the interior

and exterior of the sample probe.

Probe wipe for piercing needle: locates in piercing mechanism, its function is to

wash the interior and exterior of the piercing needle.

3.1.3 Pumps

Metering pump: metering part, aspirates fluid by negative pressure, and then

switches to negative pressure to drain fluid, providing reagent of a predetermined

amount for sample analysis. For specific models and function, please refer to

Appendix D3.

Syringes: aspirates and dispenses sample and reagent quantitatively. 1

2.5ml-syringe and 1 100ul-syringe. The first one is mainly used to aspirate sample

and diluent for cleaning open vial and piercing probe wipe; the latter one is mainly

used to push sample flow.

3.1.4 Valves

Fluidic valve: controls fluid or air flow direction.

Pinch valve: starts/stops the fluid flow. For the quantity and function, please refer to

Appendix D4.

3-1

Fluidic System

Check valve: controls the unidirectional flow of fluid or air. For the quantity and

function, please refer to Appendix D5. See Figure 3-1 for the direction of check

valve.

Figure 3-1 Check Valve

SRV: metering part, provides a pre-determined amount of sample for analysis. See

Figure 3-2 - Figure 3-4.

3-2

Figure 3-2 Open vial feeding position SRV fluidic status

3-3

Fluidic System

Figure 3-3 Autoloading position SRV fluidic status

3-4

Fluidic System

0

2

Figure 3-4 SRV tube interfaces

Serial

Hole position

No.

1. HGB6ul (open vial) 13.

2. RBC6ul (open vial) 14.

3. 15.

DIFF20ul (open vial)

4.

5. 17.

BASO 20ul (open vial)

6.

7. HGB6ul (autoloading) 19.

8. RBC6ul (autoloading) 20.

9. 21. Open vial positioning hole

DIFF20ul (autoloading)

1

11 23. Peripheral cleaning channel

BASO 20ul (autoloading)

1

Serial

number

RBC sample (first dilution) 62.5ul

16.

18.

22. Piercing positioning hole

24. /

RBC sample (first dilution) 62.5ul

Hole position

(open vial)

(autoloading)

3.1.5 Cisterns and Waste Cisterns

DIL cistern: diluent cistern, for sample diluting and cleaning.

FCM cistern: sheath fluid (diluent) cistern, for WBC detection and cleaning.

Cleanser cistern: cleanser cistern, for cleanser maintenance.

WC1 waste cistern: waste cistern, gathering waste of WC2, WC3 and other

channels.

WC2 waste cistern: waste cistern, gathering waste of WBC unit.

WC3 waste cistern: waste cistern, providing stable negative pressure during RBC

counting and gathering waste of RBC unit.

3-5

Fluidic System

3.1.6 Baths

WBC bath: includes DIFF bath and BASO bath; DIFF bath is for the reaction of WBC

4-differential sample,

BASO bath is for the reaction of sample testing basophils.

Flow cell: it is the part facilitating WBC testing; sheath fluid forms here.

RBC premix bath: RBC channel, it is for the first dilution of sample in RBC channel.

RBC bath: RBC/PLT detection unit where the test on RBC/PLT completes.

HGB bath: HGB detection unit where the HGB test completes.

Volume tube: controls the volume of RBC/PLT testing sample.

3-6

Fluidic System

3.2 Introduction of Pneumatic Parts

3.2.1 Pneumatic System

Pneumatic system provides pressure to support the normal operation of the analyzer.

Pneumatic unit provides pressure and vacuum to the analyzer at the same time; the pressure

is regulated to 0.25MPa within the pneumatic unit and then starts output. After the analyzer

receives the pressure and vacuum from the pneumatic unit, a drying filter filtrates and dries the

pressure, and then regulates it to 0.07MPa and 0.16MPa; the vacuum is also regulated to

–0.04MPa.

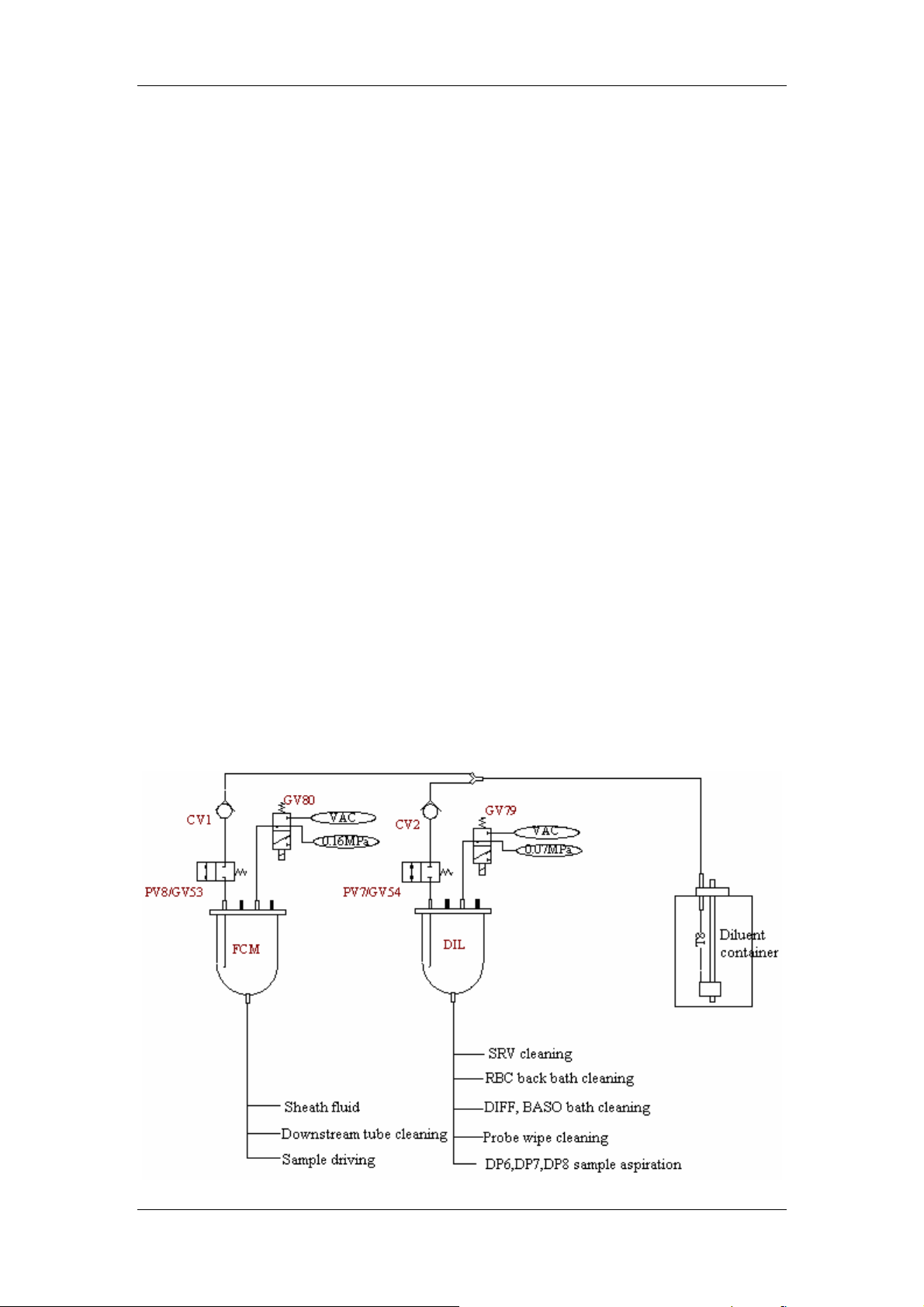

See the following Figure 3-5 for the pneumatic system.

Figure 3-5 Pneumatic system

3.2.2 The Functions of Air Pressure

See the following Table 3-1 for the functions of air pressure.

Table 3-1 Illustration on using pressure

Type Name Function

Pressure

0.25MPa Driving cylinder and pinch valve.

0.16MPa Forming sheath fluid.

0.07MPa Draining waste;

3-7

Fluidic System

Draining reagent for metering pump, DIL cistern and cleanser

cistern.

Vacuum

-0.085MPa

-0.04MPa

Aspirating reagent for metering pumps and cisterns.

WC1 cistern aspirates waste.

3.2.3 Valves

Air valve: controls the directional flow of air.

Pressure regulator: regulates pressure coming out directly from the pneumatic unit to

meet requirement on all kinds of pressure.

3.2.4 Filters

Pressure filter: filtrates and dries the air with pressure coming directly out from the

pneumatic unit.

Small filter: connects to FCM cistern, filters small impurities in diluent coming out

from FCM cistern.

Figure 3-6 Small filter

3-8

Fluidic System

3.3 Fluidic System

3.3.1 Reagent Volume Required

Sample analysis for a single sample each time

The analysis modes include open vial whole blood, autoloading whole blood and

predilute mode, each mode is divided into CBC+5DIFF and CBC, so there are

altogether 6 modes.

CBC+5DIFF mode

Reagents Name

M-58 diluent M-58D diluent 58mL 60ml 58ml

M-58LEO(I) lyse 1.56mL 1.56mL 1.56mL

M-58 lyse

M-580LEO(II) lyse 0.32mL 0.32mL 0.32mL

M-58LBA lyse 1.56mL 1.56mL 1.56mL

M-58LH lyse 1.0mL 1.0mL 1.0mL

Open vial

whole blood

Autoloading

whole

blood

CBC mode

Reagents Name

M-58 diluent M-58D diluent 48mL 50ml 48mL

M-58LEO(I) lyse - - -

M-58 lyse

M-58LEO(II) lyse - - -

M-58LBA lyse 1.56mL 1.56mL 1.56mL

M-58LH lyse 1.0mL 1.0mL 1.0mL

Open vial

whole blood

Autoloading

whole

blood

Predilute

Predilute

Normal startup function

Reagent volume required:

Reagents Name

M-58 diluent M-58D diluent 216ml

M-58 lyse

Cleanser for

hospital use

Reagent volume required

when starting up normally

M-58LEO(I) lyse 5.2ml

M-58LEO(II) lyse 1.28ml

M-58LBA lyse 5.2ml

M-58LH lyse 4.0ml

M-58 cleanser

3-9

-

Fluidic System

Startup after emptying(prepare to ship)

Reagent volume required

Reagents Name

M-58 diluent M-58D diluent 674ml

M-58LEO(I) lyse 13.52ml

M-58LEO(II) lyse 8.96ml

M-58 lyse

M-58LBA lyse 15.6ml

M-58LH lyse 9ml

Cleanser for

hospital use

M-58 cleanser 142ml

Reagent volume

Notes

required when starting

up after

emptying(prepare to

ship)

Volume consumed is

414ml, 260ml reagent

is stored in tubing and

cisterns

Volume consumed is

8.22ml, 5.3ml reagent

is stored in tubes

Volume consumed is

5.58ml, 3.38ml

reagent is stored in

tubes

Volume consumed is

12.3ml, 3.3ml reagent

is stored in tubes

Volume consumed is

5.8ml, 3.2ml reagent

is stored in tubes

Volume consumed is

25ml, 117ml reagent is

stored in tubes and

cisterns

Shutdown function

Reagent volume required:

Reagents Name

M-58 diluent M-58D diluent 11ml

M-58 lyse

Cleanser for

hospital use

M-58LEO(I) lyse -

M-58LEO(II) lyse -

M-58LBA lyse -

M-58LH lyse -

M-58 cleanser

3-10

Reagent volume

required when shutting

down normally

49ml

Fluidic System

3.3.2 Fluidic System Drawing

Figure 3-7 Fluidic system

3.3.3 WBC Channel

BASO Channel

Reagents used:

LBA lyse: lyses RBC, PLT and turns WBC (excluding basophils) into naked nucleus cells;

Diluent: cleaning, and providing sheath fluid

Detection principle: flow cytometry and semi-conductive laser scatter technology

Detection parameters: WBC, BASO# and BASO%

Diagram information: WBC scattergram

Dilution ratio: 1:52

Metering volume: 50.9µl

Function description: the sample is diluted in the bath to the ratio of 1:52, and then

the dilution moves to the flow cell. Meanwhile sheath fluid is started and stabilized.

After that, the dilution moves to the measuring segment of the flow cell. Sample

syringe pushes the dilution, which is surrounded by the sheath fluid, through the flow

cell for optical measurement at a stable speed within certain amount of time. Then

clean the measurement tube to restore its original status.

3-11

Fluidic System

DIFF Channel

Reagents used:

LEO(I) and LEO(II): lyses RBC and performs dissimilation treatment to various types of WBC;

Diluent: cleaning, and providing sheath fluid

Detection principle: flow cytometry and semi-conductive laser scatter technology

Detection parameters: MONO#, MONO%, LYMPH#, LYMPH %, NEUT#, NEUT%,

EOS# and EOS%

Diagram information: DIFF scattergram

Dilution ratio: 1:68

Metering volume: 61.7µl

Function description: the sample is diluted in the bath to the ratio of 1:68, and then

the dilution moves to the flow cell. Meanwhile sheath fluid is started and stabilized.

After that, the dilution moves to the measuring segment of the flow cell. Sample

syringe drives the dilution, which is surrounded by the sheath fluid, through the flow

cell for optical measurement at a stable speed within certain amount of time. Then

clean the measurement tube to restore its original status.

Fluidic Disposition of WBC Channel

Aspirating and metering sample and reagent: aspirate sample into SRV with whole

blood aspirating syringe, and then DP1 aspirates the pre-determined amount of

reagent and dispense the reagent into DIFF bath. DP2 and DP3 both aspirate certain

amount of reagent and then dispense the DIFF and BASO samples into DIFF and

BASO baths.

Mix: mix the sample with reagent by jet flow produced when dispensing the sample

and by using the mixing bar in DIFF and BASO bath.

Clean: clean the bath with fluid in DIL cistern through energizing fluidic valve SV17

and pinch valve PV11 and PV12.

Waste drainage: drain the waste with WC1 vacuum by energizing SV30 and SV31.

3.3.4 RBC/PLT Channel

RBC/PLT Channel

Reagents used:

Diluent: diluting and cleaning, providing conductive environment and isovolumetric treatment

to cells

Detection principle: aperture impedance method

3-12

Fluidic System

Detection parameters: RBC and PLT

Diagram information: RBC histogram and PLT histogram

Dilution ratio: 1:18000

Metering volume: 300µl

The function of RBC channel is to count RBC and PLT in blood sample, the method adopted is

impedance method. During the detection, blood sample needs to be diluted to the ratio of

1:18000, which is hard to achieve with a single dilution, so the second dilution needs to be

conducted. First dilute the sample to the ratio of 1:433 and dispense it in to the premix bath;

and then aspirate the 1:433 sample back into the SRV and redilute it to the ratio of 1:41.6,

finally dispense it into RBC bath to form the 1:18000 sample.

RBC/PLT Channel Disposition

Aspirating and metering of sample and reagent: First dispense the sample that is

measured by SRV through 2.6ml metering pump DP8 and SV22 into RBC premix

bath, aspirate the sample that is diluted for the fist time with 1ml metering pump, and

then dispense the diluted sample into RBC counting bath through metering pump

DP8, SV22 and SV05.

Mix: bubble mix and jet flow mix;

Clean: add diluent into the RBC counting bath through DP8, SV22 and SV05 to clean

the bath; add diluent in to the premix bath through DP6 and SV23 to clean the bath;

Waste draining: RBC premix bath drains waste by WC1 vacuum and SV29; RBC

counting bath drains waste by WC1 vacuum and SV36;

3.3.5 HGB Channel

HGB Channel

Reagents used:

Diluent: to dilute and clean

HGB lyse: to lyse RBC and mix with HGB

Detection principle: colorimetric method

Detection parameter: HGB

Dilution ratio: 1:500

The detection principle of HGB channel is colorimetric method, HGB concentration is

obtained by comparing the intensity of light passing through the sample with blank

reference reading.

HGB Channel Disposition

Aspirating and metering sample and reagent: dispense the sample in SRV into HGB

3-13

Fluidic System

bath through DP7 and SV19, meanwhile dispense certain amount of lyse into the

bath through DP5 and SV28;

Mix: bubble mix and jet flow mix;

Clean: dispense diluent into the HGB bath through DP7 and SV19 to clean the bath;

Waste draining: drains waste by WC1 vacuum and SV35;

3.3.6 Fluid Feeding and Draining Channel

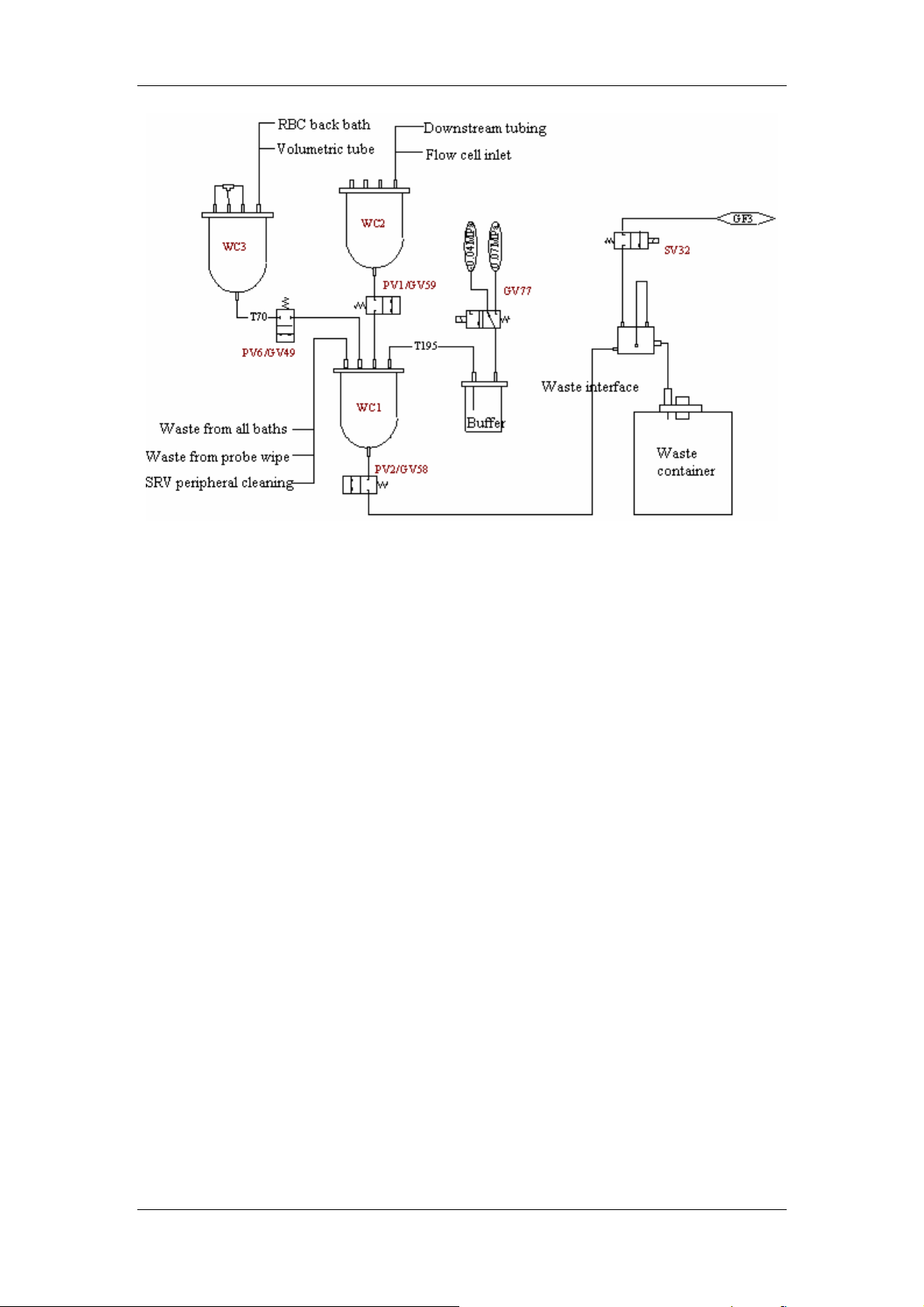

Fluid feeding and draining channel includes DIL cistern, FCM cistern, waste cistern WC1, WC2

and WC3. See Figure 3-8 for the fluidic system connection. DIl and FCM cistern units both

have a three-way valve and a pneumatic pinch valve apart from the cistern. The three-way air

valve switches pressure for the cistern. Under pressure (DIL cistern: 0.07Mpa, FCM cistern

0.16Mpa), the cistern feeds fluid to the fluidic system and provides pressure as a driving force;

under vacuum, the three-way air valve helps to energize the pinch valve, the cistern is then

filled with fluid (from the diluent container). WC2 is an open container with air pressure; its

outlet is connected to WC1 through pneumatic pinch valve PV1. Energize PV1, waste in WC2

flows to WC1. WC3 is a closed container; its outlet is connected to WC1 through pneumatic

pinch valve PV6. Energize PV6, waste in WC3 flows to WC1, meanwhile WC3 stores vacuum

for RBC counting, and RBC bath and volumetric tube cleaning.WC1 also has a three-way air

valve and a pneumatic pinch valve. The energizing/de-energizing of the air valve switches the

pressure of WC1 between pressure (0.07Mpa) and vacuum (

can gather waste in all channels; under pressure, it helps to energize PV2 to drain waste into

waste container. The inlet of waste pump is connected to the waste draining outlets of all

channels; its outlet is connected to waste container.

The corresponding channels of each cistern, waste cistern and waste pump are marked in

Figure 3-8.

–0.04Mpa). Under vacuum, WC1

3-14

Fluidic System

Figure 3-8 The fluidic connection chart of cistern and waste channels

3.3.7 Sampling and Blood Dispensing Channel

Sampling and blood dispensing modules include: SRV and its controlling cylinder, peripheral

cleaning channel, probe wipe and whole blood aspirating syringe. The function of blood

dispensing and sampling channel is to aspirate certain amount of sample into SRV, complete

sample metering through the rotation of SRV, and then dispense certain amount of sample into

corresponding baths by metering pumps. The function of peripheral cleaning channel is to

clean the sample that is spilled out when SRV is rotating and avoid sample from leakage.

Probe wipe cleans the interior and exterior of sample probe.

3.3.8 Shutdown Cleanser Cleaning Disposition

Cleanser cleaning drive: the cleaning drive is the pressure of 0.07MPa in the

cleanser cistern and whole blood aspirating syringe, each is for a different cleaning

area. 0.07MPa pressure cleans all baths and flow cell; the syringe cleans SRV and

sample probe;

Cleanser cleaning procedure: energize fluid valve SV13 and the cleanser control

valves of all baths, dispense certain amount of cleanser into the baths by pressure to

clean them.

3-15

Fluidic System

3.4 Basic Cycle Design Description

3.4.1 Open Vial Whole Blood Measurement Cycle

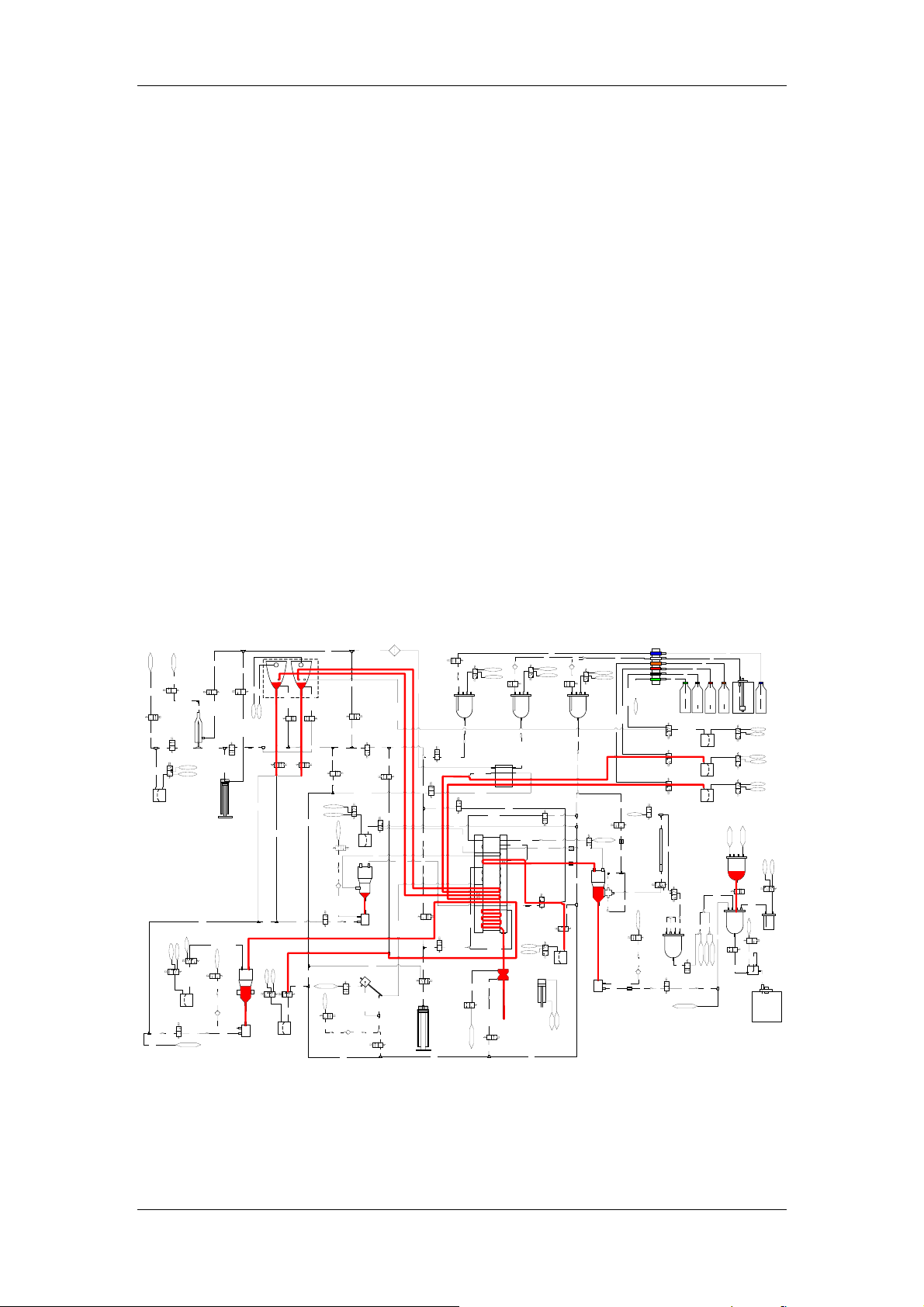

0-11s, see the red lines in Figure 3-9

SRV is at the working position, that is SRV bar stays at the upper position.

During 0-3.6s, aspirate the sample to SRV from manual sample flow probe through

whole blood syringe SV09 and SV10;

Start probe wipe to clean the exterior of the open vial sample probe;

Empty RBC premix bath, RBC bath, HGB bath, DIFF and BASO bath;

Add 2ml diluent to HGB bath through DP7 and SV19, wait for 3.5s until the dilution

becomes stable, measure background voltage and then empty HGB bath;

Dispense diluent into RBC bath through DP8, SV22 and SV5 to clean the bath and

then empty it;

Dispense LEO I lyse and LBA lyse into DIFF bath and BASO bath respectively to

clean the baths, then empty them;

Empty waste cistern.

J27-T351-J104

2

2

C

W

T185

SV8

T184

T182

C2

T183

DP4

1.5mL

C24

T214 T212

C25

T186

T43

C12

T47

J25-T42-J26

T128

LF1

T38-J105

5

9

J

1

SV1

3

T

6

2

1

9

P

P

J

-

6

5

1

1

2

2

T

T

2

2

J

C11

3

5

T154

T155

1

T

1

2

J

SV11

SV12

GV76

SV23

T78

DP6

1mL

T80

预混池

隔离室

T141

穿

刺

9

P

6

2

1

T

2

7

J

T127

T123

SV20

T122

C34

C13

T158

6

5

1

T

1

6

1

T

C15

7

5

1

T

4

6

1

T

C16

5

6

J81-T95

1

T

C17

6

6

1

T

4

SV16

7

J

7

6

1

T

3

T148-P4-P3

7

J

C35

T144

C19

T136

T143

针

SV9

T142

J71-T125

C33

T124

C32

GV78

SV15

4

1

VAC

T

0.07MPa

C36

5

1

T

PV8/GV53

M-50

T160

C14

SV13

J23-T159-J24

SV18

T162

SV10

C18

E

G

L

N

I

m

R

5

.

Y

2

S

_

P

T121

T39-J30

J75-T145-J76

T40-J34-T35

T77

PV4/GV56

C39

SV14

T79-J80

J79-T137

J31-T41

J33-T33

J32-T41

G2

G1

K

D2

D1

F2

F1

B1

A2

7

4

1

T

8

7

J

C66

T100

液

废

4

V

P

12

8

T73-J57

L M

H

分血阀

J77-T146

T99

C42

J69-T98-J70

SV21

7

9

T

C43

预加热池组

1

2

C

T44

W

T181

SV6

J1-T180-J2

T179

流动室

SV7

J3-T178-J4

VAC

0.07 MPa

GV75

H

a

L

P

M

7

SV28

VAC

0

.

0

GV70

J91-T140-J92

DP5

1mL

SV35

T213

WC1-废液

T45

SV3

SV2

C1

J7-T49-J8

J11-T48-J12

C3

T175

J5-T177-J6

C4

PV10/GV52

J9-T176-J10

E

G

L

N

I

µ

0

R

0

Y

1

S

_

S

T204

J93-T139-P5-J94

0.07MPa

HGB池

0

1

GV65

2

T

C27

T209

T205-J88-T206-J87-T207

CV6

J89-T208-J90

T211

C26

隔离室

1

0

2

2

0

T

2

T

板

板

前

前

C6C5C7

J13-T174-J14

T200

T203

0.07MPa

GV73

BASO

C22C23

J86-T138-P6

VAC

DIFF

3

7

1

T

2

7

1

T

9

4

1

T

T135

3

3

1

T

C29

C8

J19-T151-J20

T150

C9

VAC

0.07MPa

GV66

C20

CV5

SV29

T119

P

V

废

5

-

液

0.07MPa

GV68

T130

T129

C30 C31

T152

C10

SV17

0

.

0

7

M

P

a

7

1

1

T

T116

T112-J83-T113-J82-T114

J84-T115-J85

T118

C21

封闭进样拭子

PV5/GV55

CV4

T131

T46

T218

0

7

1

T

9

6

1

T

PV11/GV51PV12/GV50

8

7

9

9

1

1

T

T

J17-T168-J18J15-T171-J16

SV31

SV30

T199

T120

C28

T132

SV19

T134

DP7

2mL

T13

C45

T19

T20

GV80

CV1

T22

FCM

T36

C38

T38-J28-T37-J29

34

56

7

T163

SV24

T74-J58

I1

T88-J59

I2

T90-P7

E1

C40

T87-J60

E2

T89-P8

T86

B2

A1

T93

T94-J64

C

C130

SV5

GV74

0.07MPa

VAC

开放采

样拭子

采样针

分血阀运动气缸

T96

0.16MPa

GV79

VAC

CV2

T23

PV7/GV54

DIL

T50

C47

T51

T33-J35

T35-J36

C48

T71

T72

C49

T76

C50

C51

T75

T91-J98

T92-J97

1

8

T

C41

T85

C52

2

8

3

8

T

T

SV22

T84

DP8

2.6mL

GV60

GV61

PV3/GV57

RBC池

隔离室

VAC

0.07MPa

PV3-废液

T103-J67-T102-J68-T101

SV34

T55

C56

T56

T58

C58

J65-T104-J66

T107

M-50

T18

M-50D

LBA

LEO(I)

LEO(II)

LH

J43-T29-J44

J41-T28-J42

H

L

J39-T27-J40

J37-T26-J38

SV33

T52

T61

OPEN

T62

3

5

T

体积计量管

T54

C57

T60

SV37

T59

T64

T57

0.07MPa

GV67

T106

C53

5

0

1

T

CV3

8

9

0

0

1

1

T

T

C54

SV36

T2

T3

T4

T5

T6

T12

J45-T11-J46

J47-T10-J48

LH试剂桶

LEO(II)试剂桶

J51-T30-J52

SV25

DP1

LEO(II)

0.32mL

J53-T32-J54

SV26

DP2

LEO(I)

0.52mL

J55-T34-J56

SV27

DP3

0.52mL

LBA

C59

T63

SV38

5

6

T

C64

C60

C61

7

9

8

6

6

6

T188

6

6

T

T

T187

T

T

C62 C63

WC3

液

液

废

废

-

4

5

V

V

P

P

T70

PV6/GV49

T110

T111

C55

WC1-废液

T1

7

T8

T

试剂桶

0

J49-T9-J50

5

稀释液桶

-

LBA试剂桶

PV2/GV58

C65

M

0.07MPa

VAC

GV69

0.07MPa

VAC

GV71

0.07MPa

VAC

GV72

WC2-2

WC2-1

WC2

0.07MPa

-0.04MPa

GV77

PV1/GV59

T191

T195

WC1

缓冲池

3

F

G

SV32

8

4

3

T

T193

T192

T194

废液接口

废液桶

LEO(I)试剂桶

T189

T190

液

废

3

V

P

Figure 3-9 Aspiration fluidic status under open vial whole blood mode

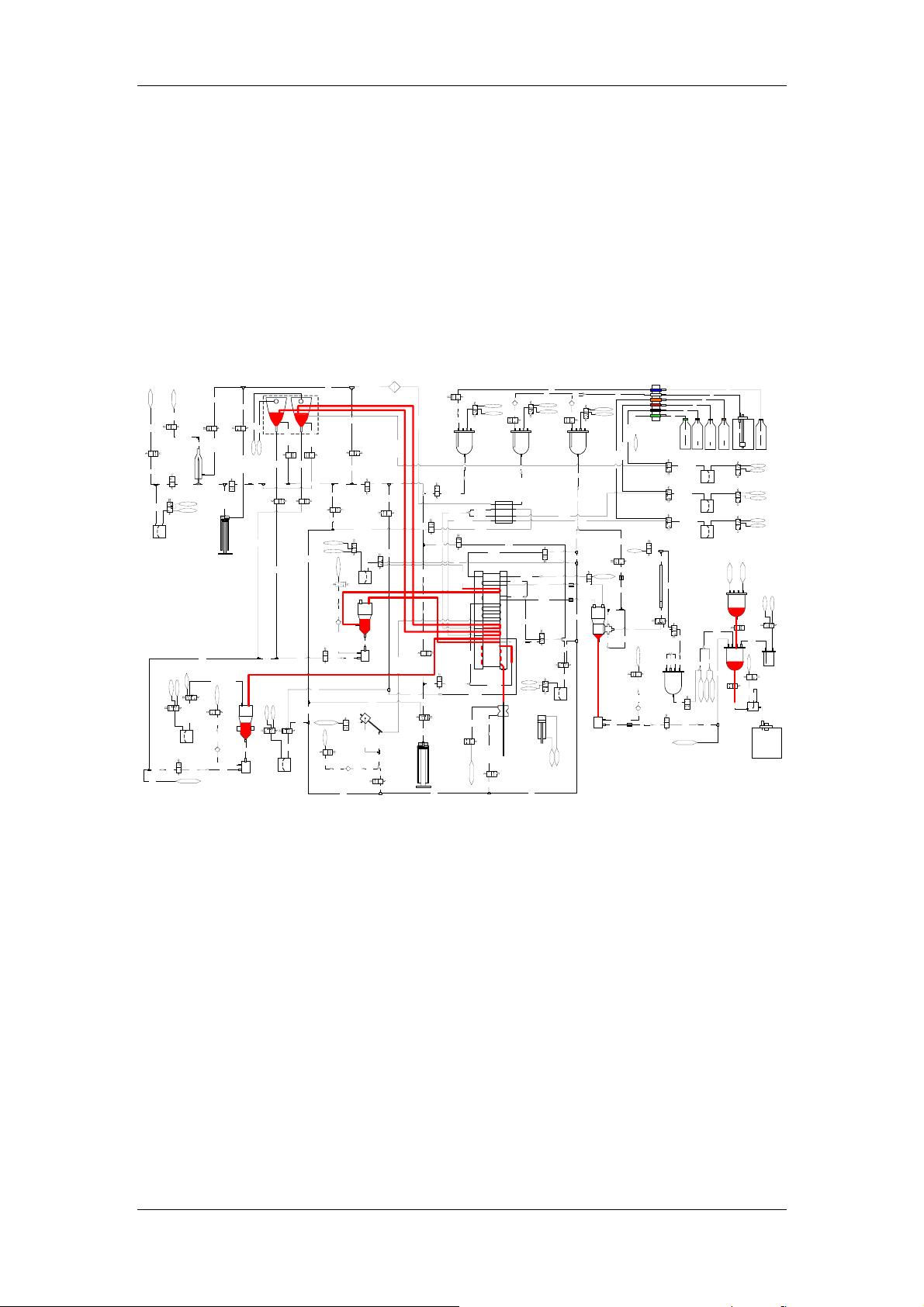

11-18s, see the red lines in Figure 3-10

3-16

Fluidic System

SRV switches to the lower position, that is the SRV bar is at the lower position; That

means the SRV has obtained samples of 4 portions needed for the measurement;

Dispense RBC sample into premix bath through DP8 and SV22 to dilute it for the first

time, and then aspirate the diluted sample back into aspiration channel through DP6;

Dispense HGB sample into HGB bath through DP7 and SV19, meanwhile add lyse

into HGB bath through DP5 and SV28 to mix with the sample;

Dispense DIFF sample into DIFF bath through DP2 and SV26;

Dispense BASO sample into BASO bath through DP3 and SV27;

Other operations: fill up FCM cistern, empty WC2 waste cistern.

J27-T351-J104

2

2

C

W

5

8

1

T

SV8

T184

T182

C2

3

8

1

T

DP4

1.5mL

C24

T214 T212

C25

T186

T43

C12

7

4

T

J25-T42-J26

T128

LF1

5

0

1

J

8

3

T

5

9

J

1

SV1

3

T

6

2

1

9

P

P

J

-

6

5

1

1

2

2

T

T

2

2

J

C11

3

5

T154

T155

1

T

1

2

J

SV11

SV12

GV76

SV23

T78

DP6

1mL

T80

预混池

隔离室

T141

穿

刺

9

P

6

2

1

T

2

7

J

T127

T123

SV20

T122

C34

C13

T158

6

5

1

T

1

6

1

T

C15

7

5

1

T

4

6

1

T

C16

5

6

J81-T95

1

T

C17

6

6

1

T

4

3

SV16

7

P

J

-

-

4

7

P

6

1

8

4

T

-

1

3

T

7

J

C35

T144

C19

T136

3

4

1

T

针

SV9

2

4

1

T

5

2

1

T

1

7

J

C33

4

2

1

T

C32

GV78

SV15

4

1

VAC

T

0.07MPa

C36

5

1

T

PV8/GV53

M-50

T160

C14

SV13

J23-T159-J24

SV18

T162

SV10

C18

E

G

L

N

I

m

R

5

.

Y

2

S

_

P

T121

T39-J30

J75-T145-J76

T40-J34-T35

T77

PV4/GV56

C39

SV14

0

8

J

9

7

T

J79-T137

J31-T41

J33-T33

J32-T41

G2

G1

K

D2

D1

F2

F1

B1

A2

7

4

1

T

8

7

J

C66

0

0

1

T

液

废

4

V

P

12

8

T73-J57

L M

H

分血阀

J77-T146

9

9

T

C42

0

7

J

8

9

T

9

6

J

SV21

7

9

T

C43

预加热池组

1

2

4

C

4

T

W

1

8

1

T

SV6

J1-T180-J2

T179

流动室

SV7

J3-T178-J4

VAC

0.07 MPa

GV75

H

a

L

P

C

M

A

7

SV28

V

0

.

0

2

9

J

0

4

1

T

-

GV70

1

9

J

DP5

1mL

SV35

T213

WC1-废液

5

4

T

SV3

SV2

C1

8

J

9

4

T

7

J

2

1

J

8

4

T

1

1

J

C3

T175

J5-T177-J6

C4

0

1

J

PV10/GV52

6

7

1

T

9

J

E

G

L

N

I

µ

0

R

0

Y

1

S

_

S

T204

J93-T139-P5-J94

a

P

M

7

0

.

0

HGB池

0

1

GV65

2

T

C27

9

0

2

T

T205-J88-T206-J87-T207

CV6

J89-T208-J90

T211

C26

隔离室

1

0

2

2

0

T

2

T

板

板

前

前

4

1

J

-

C6C5C7

4

7

1

T

3

1

J

0

0

2

T

T203

a

P

M

7

0

.

0

GV73

BASO

C22C23

J86-T138-P6

C

A

V

DIFF

0

7

1

T

9

6

1

T

PV11/GV51PV12/GV50

8

7

9

9

1

1

T

T

J17-T168-J18J15-T171-J16

SV31

SV30

9

9

1

T

T120

C28

T132

SV19

4

3

1

T

DP7

2mL

3

7

1

T

2

7

1

T

9

4

1

T

T135

3

3

1

T

C29

C8

J19-T151-J20

T150

C9

VAC

0.07MPa

GV66

C20

CV5

SV29

T119

P

V

废

5

-

液

a

P

M

7

0

.

0

GV68

0

3

1

T

T129

C30 C31

T152

C10

SV17

0

.

0

7

M

P

a

7

1

1

T

6

1

1

T

5

8

J

5

1

1

T112-J83-T113-J82-T114

T

4

8

J

T118

C21

封闭进样拭子

PV5/GV55

CV4

T131

6

4

T

T218

T13

C45

T19

T20

GV80

CV1

2

2

T

FCM

T36

C38

9

2

J

7

3

T

8

2

J

8

3

T

34

56

7

T163

SV24

T74-J58

I1

T88-J59

I2

T90-P7

E1

C40

T87-J60

E2

T89-P8

6

8

T

B2

A1

T93

T94-J64

C

C130

SV5

GV74

0.07MPa

VAC

开放采

样拭子

缸

气

动

运

针

阀

样

血

采

分

T96

0.16MPa

GV79

VAC

CV2

3

2

T

PV7/GV54

DIL

T50

C47

T51

T33-J35

T35-J36

C48

T71

T72

C49

T76

C50

C51

T75

T91-J98

T92-J97

1

8

T

C41

T85

C52

2

8

3

8

T

T

SV22

4

8

T

DP8

2.6mL

0

1

6

6

V

V

G

G

PV3/GV57

RBC池

隔离室

VAC

0.07MPa

PV3-废液

1

0

1

T

8

6

J

2

0

1

T

7

6

J

3

0

1

T

SV34

T55

C56

6

5

T

8

5

T

C58

J65-T104-J66

T107

M-50

T18

M-50D

LBA

LEO(I)

LEO(II)

LH

4

4

J

9

2

2

4

T

J

-

-

3

8

4

2

J

T

1

4

J

H

0

L

4

J

7

2

8

T

3

-

J

9

3

6

J

2

T

-

7

3

J

2

SV33

5

T

T61

OPEN

2

6

T

3

5

T

管

量

计

积

4

5

体

T

C57

T60

SV37

T59

T64

7

5

T

a

P

M

7

0

.

0

6

GV67

0

1

T

C53

5

0

1

T

CV3

8

9

0

0

1

1

T

T

C54

SV36

T2

T3

T4

T5

T6

6

8

4

4

桶

J

J

-

-

剂

1

2

0

桶

1

1

1

试

T

T

T

)

剂

-

-

I

5

I

7

(

试

4

4

J

J

O

H

E

L

L

J51-T30-J52

SV25

DP1

LEO(II)

0.32mL

J53-T32-J54

SV26

DP2

LEO(I)

0.52mL

J55-T34-J56

SV27

DP3

0.52mL

LBA

C59

3

6

T

SV38

5

6

T

C64

C60

C61

7

9

8

6

6

6

T188

6

6

T

T

T187

T

T

C62 C63

WC3

液

液

废

废

-

4

5

V

V

P

P

T70

PV6/GV49

T110

T111

C55

WC1-废液

T1

0

5

桶

J

桶

8

-

桶

桶

9

7

T

剂

剂

试

)

I

(

O

E

L

T189

T190

液

废

3

V

P

T

9

4

J

PV2/GV58

C65

剂

液

T

试

试

释

A

0

5

稀

B

-

L

M

0.07MPa

VAC

GV69

0.07MPa

VAC

GV71

0.07MPa

VAC

GV72

2

1

-

2

2

C

C

W

W

a

a

P

P

M

M

WC2

4

7

0

0

.

.

0

0

-

GV77

PV1/GV59

1

9

1

T

T195

WC1

缓冲池

3

F

G

SV32

8

4

3

3

T

9

1

T

2

9

1

T

4

9

1

T

废液接口

废液桶

Figure 3-10 Drainage fluidic status under open v i al whole blood mode

18-23s, see the red lines in Figure 3-11

SRV switches to the upper position;

Deliver the diluted sample (first dilution) that is measured by SRV to RBC bath

through DP8, SV22 and SV5;

Wait until the HGB sample turns stable, preparing measurement;

Deliver the sample in DIFF bath to the inlet of the flow cell through DP4, SV7, PV10

and PV11, start sheath fluid through SV3;

3-17

2

2

C

W

5

8

1

T

SV8

T184

T182

C2

3

8

1

T

DP4

1.5mL

C24

T214 T212

C25

T186

Fluidic System

J27-T351-J104

T43

C12

7

4

T

J25-T42-J26

T128

LF1

5

0

1

J

8

3

T

5

9

J

1

SV1

3

T

6

2

1

9

P

P

J

-

6

5

1

1

2

2

T

T

2

2

J

C11

3

5

T154

T155

1

T

1

2

J

SV11

SV12

GV76

SV23

T78

DP6

1mL

T80

预混池

隔离室

T141

穿

刺

9

P

6

2

1

T

2

7

J

T127

T123

SV20

T122

C34

C13

T158

6

5

1

T

1

6

1

T

C15

7

5

1

T

4

6

1

T

C16

5

6

J81-T95

1

T

C17

6

6

1

T

4

3

SV16

7

P

J

-

-

4

7

P

6

1

8

T

4

-

1

3

T

7

J

C35

T144

C19

T136

3

4

1

T

针

SV9

2

4

1

T

5

2

1

T

1

7

J

C33

4

2

1

T

C32

GV78

SV15

4

1

VAC

T

0.07MPa

C36

5

1

T

PV8/GV53

M-50

T160

C14

SV13

J23-T159-J24

SV18

T162

SV10

C18

E

G

L

N

I

m

R

5

.

Y

2

S

_

P

T121

T39-J30

J75-T145-J76

T40-J34-T35

T77

PV4/GV56

C39

SV14

0

8

J

9

7

T

J79-T137

J31-T41

J33-T33

J32-T41

G2

G1

K

D2

D1

F2

F1

B1

A2

7

4

1

T

8

7

J

C66

0

0

1

T

液

废

4

V

P

12

8

T73-J57

L M

H

分血阀

J77-T146

9

9

T

C42

0

7

J

8

9

T

9

6

J

SV21

7

9

T

C43

预加热池组

1

2

4

C

4

T

W

1

8

1

T

SV6

J1-T180-J2

T179

流动室

SV7

J3-T178-J4

VAC

0.07 MPa

GV75

H

a

L

P

C

M

A

7

SV28

0

V

.

0

2

9

J

0

4

1

T

-

GV70

1

9

J

DP5

1mL

SV35

T213

WC1-废液

5

4

T

SV3

SV2

C1

8

J

9

4

T

7

J

2

1

J

8

4

T

1

1

J

C3

T175

J5-T177-J6

C4

0

1

J

PV10/GV52

6

7

1

T

9

J

E

G

L

N

I

µ

0

R

0

Y

1

S

_

S

T204