Service Manual

V

V

V

Patient Monitors

Mindray® is a registered trademark of Shenzhen Mindray Bio-Medical Electronics Co., Ltd.

Filte rLine

Microstream

Nellcor

Oxiband

Durasensor

OxiMax

Oxisensor

Max-Fast

miniMediCO

LNCS

LNOP

Masimo SET

®

is a U.S. registered trademark of Oridion Medical Ltd.

®

is a U.S. registered trademark of Oridion Medical Ltd.

™

is a U.S. trademark of Nellcor Puritan Bennett Inc.

®

is a U.S. registered trademark of Nellcor Puritan Bennett Inc.

®

is a U.S. registered trademark of Nellcor Puritan Bennett Inc.

™

is a U.S. trademark of Nellcor Puritan Bennett Inc.

®

is a U.S. registered trademark of Nellcor Puritan Bennett Inc.

™

is a trademark of Nellcor Puritan Bennett Inc.

®

is a trademark or registered trademark of Oridion Medical Ltd.

2

®

is a U.S. registered trademark of Masimo Corp.

®

is a U.S. registered trademark of Masimo Corp.

®

is a U.S. registered trademark of Masimo Corp.

Panorama™ is a U.S. trademark of Mindray, Inc.

Hypervisor is a registered trademark of Shenzhen Mindray Bio-Medical Electronics Co., Ltd.

Copyright © Mindray DS USA, Inc., 2011. All rights reserved. Contents of this publication may not be reproduced in any

form without permission of Mindray DS USA, Inc.

046-001131-00 V Series Service Manual

Tab le of C on ten ts

Foreword .................................................................................................................................................................................................................................v

How to Use This Guide .......................................................................................................................................................................................................v

Passwords................................................................................................................................................................................................................................v

Warnings, Cautions and Notes........................................................................................................................................................................................v

Theory of Operation ...................................................................................................................................................1 - 1

Introduction .............................................................................................................................................................................................................................1 - 1

Connectors for Peripheral Devices and Indicators .....................................................................................................................................................1 - 2

Connectors for Peripheral Devices........................................................................................................................................................................1 - 2

Indicators........................................................................................................................................................................................................................1 - 8

Main Unit ...................................................................................................................................................................................................................................1 - 10

Input System .................................................................................................................................................................................................................1 - 11

Output System..............................................................................................................................................................................................................1 - 11

Processing and Communications System..........................................................................................................................................................1 - 12

Power Management System ...................................................................................................................................................................................1 - 12

Equipment Interface System...................................................................................................................................................................................1 - 14

Interface Requirements.............................................................................................................................................................................................1 - 15

Parameter Module ......................................................................................................................................................................................................1 - 15

Repair Information .....................................................................................................................................................2 - 1

Introduction .............................................................................................................................................................................................................................2 - 1

Safety Precautions..................................................................................................................................................................................................................2 - 1

Troubleshooting Guidelines...............................................................................................................................................................................................2 - 2

Special Tools Required .........................................................................................................................................................................................................2 - 2

Disassembly Instructions.....................................................................................................................................................................................................2 - 3

Disassembling V 12 (12.1" Monitor)......................................................................................................................................................................2 - 4

Removal of the Battery Door...................................................................................................................................................................................2 - 5

Removal of the Front Housing................................................................................................................................................................................2 - 6

Removal of the Back Housing .................................................................................................................................................................................2 - 11

Disassembling V 21 (21.3" Monitor)......................................................................................................................................................................2 - 19

Disassembling V Dock ...............................................................................................................................................................................................2 - 34

Disassembling V Hub .................................................................................................................................................................................................2 - 38

Disassembling VPS Module .....................................................................................................................................................................................2 - 41

Disassembling CO

Disassembling 1X Module........................................................................................................................................................................................2 - 54

Disassembling Recoder Module ............................................................................................................................................................................2 - 58

Disassembling 12-Lead ECG Module ...................................................................................................................................................................2 - 61

Cable Wiring Diagrams.........................................................................................................................................................................................................2 - 63

Nurse Call Cable (3 Pin Circular to Unterminated) ..........................................................................................................................................2 - 63

Defib Synch Cable.......................................................................................................................................................................................................2 - 64

Serial Port to Serial Port Cable................................................................................................................................................................................2 - 64

ECG Shielded Lead Wires..........................................................................................................................................................................................2 - 65

3/5 Lead ECG Leadset ....................................................................................................................................................................................2 - 65

6-Lead ECG Leadset ........................................................................................................................................................................................2 - 69

Extension Lead ECG Leadset .......................................................................................................................................................................2 - 71

ECG Cable ESIS and Non ESIS..................................................................................................................................................................................2 - 73

3/5-Lead ECG Cable ........................................................................................................................................................................................2 - 73

6-Lead ECG Cable ............................................................................................................................................................................................2 - 74

Neonatal ECG Cable ........................................................................................................................................................................................2 - 76

IBP Cable.........................................................................................................................................................................................................................2 - 77

Temperature Cable.....................................................................................................................................................................................................2 - 78

IABP SYNC Cable..........................................................................................................................................................................................................2 - 81

Service Diagnostics Cable ........................................................................................................................................................................................2 - 81

Powered USB Cable ....................................................................................................................................................................................................2 - 82

Module.....................................................................................................................................................................................2 - 51

2

V Series Service Manual 046-001131-00 i

Table of Contents

Troubleshooting.....................................................................................................................................................................................................................2 - 83

ECG Troubleshooting.................................................................................................................................................................................................2 - 83

Temperature Troubleshooting...............................................................................................................................................................................2 - 85

Resp Troubleshooting ...............................................................................................................................................................................................2 - 85

IBP Troubleshooting...................................................................................................................................................................................................2 - 86

NIBP Troubleshooting................................................................................................................................................................................................2 - 87

Troubleshooting...............................................................................................................................................................................................2 - 88

SpO

2

Power Supply Troubleshooting .............................................................................................................................................................................2 - 89

Power On/Off Troubleshooting..............................................................................................................................................................................2 - 90

Display Failure Troubleshooting............................................................................................................................................................................2 - 91

V Hub Failure Troubleshooting ..............................................................................................................................................................................2 - 92

V Hub - External V Hub Troubleshooting ................................................................................................................................................2 - 92

Integral V Hub Troubleshooting ................................................................................................................................................................2 - 93

Alarm Troubleshooting.............................................................................................................................................................................................2 - 94

Recorder Troubleshooting.......................................................................................................................................................................................2 - 94

Interface Failure Troubleshooting.........................................................................................................................................................................2 - 95

USB Troubleshooting.................................................................................................................................................................................................2 - 95

Network-Related Problem Troubleshooting.....................................................................................................................................................2 - 96

Software Upgrade Troubleshooting.....................................................................................................................................................................2 - 97

Block Diagrams ...........................................................................................................................................................3 - 1

Introduction .............................................................................................................................................................................................................................3 - 1

Block Diagram..........................................................................................................................................................................................................................3 - 2

Isometric Drawings and Parts List.............................................................................................................................4 - 1

Introduction .............................................................................................................................................................................................................................4 - 1

V Dock Assembly (P/N 0998-00-1801-01)......................................................................................................................................................................4 - 1

AC-DC Power Module (P/N 801-DA6K-00032-00)............................................................................................................................................4 - 4

Subassembly, 12.1" Monitor (P/N 0998-00-1800-101)..............................................................................................................................................4 - 5

Subassembly, Back, 12.1" Monitor (P/N 0997-00-0607-01)..........................................................................................................................4 - 6

Subassembly, Chassis, 12.1" Monitor (P/N 801-DA6K-00023-00)...............................................................................................................4 - 8

Subassembly, Front, 12.1" Monitor (P/N 801-DA6K-00117-00)..................................................................................................................4 - 9

Subassembly, 21.3" Monitor (P/N 0998-00-1800-201)..............................................................................................................................................4 - 10

Subassembly, Back, 21.3" Monitor (P/N 0997-00-0614-01)..........................................................................................................................4 - 11

Subassembly, Chassis, 21.3" Monitor (P/N 801-DA6K-00024-00)...............................................................................................................4 - 12

Subassembly, Front, 21.3" Monitor (P/N 801-DA6K-00118-00)..................................................................................................................4 - 13

V Hub Assembly (P/N 0998-00-1803-01)........................................................................................................................................................................4 - 14

Assembly, Masimo VPS Module (P/N 0998-00-1802-0101A)..................................................................................................................................4 - 15

Subassembly, Valve, Pneumatic (P/N 801-DA6K-00066-00)........................................................................................................................4 - 16

Subassembly, VPS Front End (P/N 0997-00-0611-01) ....................................................................................................................................4 - 1

Subassembly, Front, 3X Module (P/N 0997-00-0612-03)..............................................................................................................................4 - 18

Assembly, Nellcor VPS Module (P/N 0998-00-1802-0102A)....................................................................................................................................4 -

Assembly, Recorder, Module (P/N 0998-00-1802-0202A).......................................................................................................................................4 - 2

Assembly, CO

Module (P/N 0998-00-1802-0301A)..................................................................................................................................................4 - 21

2

Assembly, Temperature Module (P/N 0998-00-1802-0501A)................................................................................................................................4 - 2

Assembly, IBP Module (P/N 0998-00-1802-0401A)....................................................................................................................................................4 - 2

Subassembly, Cardiac Output (C.O.) Module (P/N 0998-00-1802-0701A).........................................................................................................4 - 2

Assembly, VDI, Module (P/N 0998-00-1802-0801A) ..................................................................................................................................................4 - 2

Subassembly, Module, ECG, 12 Lead (P/N 0998-00-1804-01/0998-00-1804-02) ............................................................................................4 - 26

Diagnostics and Calibration.......................................................................................................................................5 - 1

Introduction .............................................................................................................................................................................................................................5 - 1

Warnings and Guidelines ....................................................................................................................................................................................................5 - 1

System Setup ...........................................................................................................................................................................................................................5 - 2

Introduction...................................................................................................................................................................................................................5 - 2

7

19

0

2

3

4

5

ii 046-001131-00 V Series Service Manual

Tab le of C on ten ts

System Dialog...............................................................................................................................................................................................................5 - 2

Navigating to the System Dialog ...............................................................................................................................................................5 - 2

Configuring the General Tab .......................................................................................................................................................................5 - 3

Configuring the Quick Functions Tab ......................................................................................................................................................5 - 3

Configuring the Alarms Tab .........................................................................................................................................................................5 - 5

Configuring the Printer Tab .........................................................................................................................................................................5 - 7

Configuring the Network Tab .....................................................................................................................................................................5 - 8

Configuring the System Tab ........................................................................................................................................................................5 - 9

Changing Password ........................................................................................................................................................................................5 - 12

Changing Password to Access Service Menu ........................................................................................................................................5 - 14

Configuration Management....................................................................................................................................................................................5 - 14

System Information Page....................................................................................................................................................................................................5 - 15

NIBP Calibration......................................................................................................................................................................................................................5 - 16

®

Microstream

Microstream

CO2 Calibration ..........................................................................................................................................................................................5 - 18

®

CO2 Leakage Test ......................................................................................................................................................................................5 - 19

Touchscreen Calibration......................................................................................................................................................................................................5 - 20

Verification................................................................................................................................................................................................................................5 - 21

Initial Setup....................................................................................................................................................................................................................5 - 21

V 12 Monitor Only ............................................................................................................................................................................................5 - 21

V 12 Monitor with V Hub ...............................................................................................................................................................................5 - 21

First Turn On ......................................................................................................................................................................................................5 - 21

ECG Tests ........................................................................................................................................................................................................................5 - 22

Initialization .......................................................................................................................................................................................................5 - 22

Leads Off .............................................................................................................................................................................................................5 - 22

Pacer Detect ......................................................................................................................................................................................................5 - 22

Heart Rate ...........................................................................................................................................................................................................5 - 22

Alarms ..................................................................................................................................................................................................................5 - 22

IBP 1 and IBP 2 Verification ......................................................................................................................................................................................5 - 23

Temperature Verification..........................................................................................................................................................................................5 - 23

Verification .........................................................................................................................................................................................................5 - 23

SpO

2

NIBP Verification ..........................................................................................................................................................................................................5 - 24

RESP Verification..........................................................................................................................................................................................................5 - 24

C.O. Verification ..........................................................................................................................................................................................................5 - 24

Operation Verification ......................................................................................................................................................................................5 - 25

CO

2

Battery Operation Verification................................................................................................................................................................................5 - 25

Network Print Test.......................................................................................................................................................................................................5 - 26

VDI Test ...........................................................................................................................................................................................................................5 - 26

Recorder Test ................................................................................................................................................................................................................5 - 26

Electrical Safety Tests.................................................................................................................................................................................................5 - 27

Protective Earth Resistance ..........................................................................................................................................................................5 - 28

Earth Leakage Test ..........................................................................................................................................................................................5 - 29

Patient Leakage Current ...............................................................................................................................................................................5 - 30

Mains on Applied Part Leakage ..................................................................................................................................................................5 - 32

Patient Auxiliary Current ...............................................................................................................................................................................5 - 33

Maintenance ...............................................................................................................................................................6 - 1

User Maintenance Introduction........................................................................................................................................................................................6 - 1

Maintenance Schedule.........................................................................................................................................................................................................6 - 2

Mechanical/Physical/Visual Inspection...............................................................................................................................................................6 - 3

Perform NIBP Verification and Calibration .........................................................................................................................................................6 - 3

Perform CO

Perform ECG Verification ..........................................................................................................................................................................................6 - 3

Perform RESP Verification.........................................................................................................................................................................................6 - 3

Verification and Calibration...........................................................................................................................................................6 - 3

2

V Series Service Manual 046-001131-00 iii

Table of Contents

Perform IBP Verification ............................................................................................................................................................................................6 - 3

Perform SpO

Verification ........................................................................................................................................................................................6 - 3

2

Perform Temperature Verification ........................................................................................................................................................................6 - 3

Perform C.O. Verification ..........................................................................................................................................................................................6 - 4

Perform VDI Verification............................................................................................................................................................................................6 - 4

Perform Recorder Verification ................................................................................................................................................................................6 - 4

Perform Electrical Safety Tests................................................................................................................................................................................6 - 4

Perform Touchscreen Calibration..........................................................................................................................................................................6 - 4

Perform Battery Verification....................................................................................................................................................................................6 - 4

Perform Network Print Test .....................................................................................................................................................................................6 - 4

Care and Cleaning of the Monitor....................................................................................................................................................................................6 - 5

Decontamination of the Monitor .....................................................................................................................................................................................6 - 6

Care and Cleaning of SpO

Sensors.................................................................................................................................................................................6 - 6

2

Care and Cleaning of Reusable Temperature Probes ...............................................................................................................................................6 - 7

Cleaning CO

Sensors, Adapters and Sampling Components...............................................................................................................................6 - 7

2

Sterilization and Cleaning of Cuffs...................................................................................................................................................................................6 - 7

Reusable Cuffs with Bladders..................................................................................................................................................................................6 - 7

Disposable Blood Pressure Cuffs ...........................................................................................................................................................................6 - 8

Care and Cleaning of ECG Cables and Lead wires......................................................................................................................................................6 - 8

Battery Replacement and Maintenance.........................................................................................................................................................................6 - 9

Battery Replacement..................................................................................................................................................................................................6 - 9

Battery Maintenance..................................................................................................................................................................................................6 - 9

Serial Number of Li-ion Battery ..............................................................................................................................................................................6 - 9

Specification for Internal Battery Replacement (P/N 801-DA6K-00026-00)...........................................................................................6 - 10

Specification for Coin Battery on Carrier Board................................................................................................................................................6 - 10

Local Recorder Maintenance..............................................................................................................................................................................................6 - 10

Cleaning the Local Recorder Printhead...............................................................................................................................................................6 - 10

Local Recorder Paper Replacement......................................................................................................................................................................6 - 10

Care and Storage of Thermal Chart Paper..........................................................................................................................................................6 - 11

Installation Guide .......................................................................................................................................................7 - 1

Installing V Dock.....................................................................................................................................................................................................................7 - 1

Mounting V Dock to a Wall Mount...................................................................................................................................................................................7 - 2

Mounting V Dock to a Rolling Stand ..............................................................................................................................................................................7 - 5

Installing 12.1” Monitor/21.3” Monitor to V Dock.......................................................................................................................................................7 - 6

Installing V Hub.......................................................................................................................................................................................................................7 - 8

Warranty......................................................................................................................................................................8 - 1

Warranty Statements ............................................................................................................................................................................................................8 - 1

Phone Numbers and How To Get Assistance...............................................................................................................................................................8 - 2

Manufacturer's Responsibility ...........................................................................................................................................................................................8 - 2

iv 046-001131-00 V Series Service Manual

Foreword Introduction

Foreword

The V Series Service Manual is intended as a guide for technically qualified personnel during

repair and calibration procedures.

Unauthorized servicing may void the remainder of the warranty. Check with the factory or with a

local authorized representative to determine the warranty status of a particular instrument.

The V 12/V 21 operates on line voltages. Therefore, an electric shock hazard may exist when the

instrument covers are removed. Repair and calibration procedures should only be performed by

qualified personnel who proceed with care and follow proper servicing techniques. Warnings are

given in various chapters, as well as in other appropriate locations.

How to Use This Guide

This guide is divided into eight sections. Navigate through the table of contents at the left of the

screen to select the desired topic. Links to other relevant sections are also provided within the

individual topics. In addition, scrolling through the topics with the page up and page down keys

is also possible.

Passwords

A password may be required to access different modes within the monitor. The default

passwords are listed below:

Service Mode: SERVICE

System Setup: SYSTEM

Warnings, Cautions and Notes

Read and adhere to all of the warnings and cautions listed throughout this manual.

A WAR NIN G is provided to alert the user to potentially serious outcomes (death, injury or serious

adverse events) to the patient or the user.

A CAUTION is provided to alert the user that special care should be taken for the safe and

effective use of the device. They will include actions to be taken to avoid effects on patients or

users that will not be potentially life threatening or result in serious injury, but about which the

user should be aware.

A NOTE is provided when additional general information is available.

V Series Service Manual 046-001131-00 v

Introduction Warn ings, Cautions and No tes

This page intentionally left blank.

vi 046-001131-00 V Series Service Manual

1.0

Theory of Operation

1.1 Introduction

The V 12/V 21 is a modular patient monitoring system. The system architecture allows users to

customize, by removal or addition of modules, monitored parameters based on a patient’s

monitoring need or acuity level. The modular design simplifies the addition of monitoring

additional parameters with the addition of parameter modules.

The V 12/V 21 focuses on the philosophy of “ Ease of Use” while incorporating traditionally

highly complex monitoring parameters. The user interface minimizes menu layers and excessive

user interaction to simplify patient care. The V 12/V 21 maximizes the amount of viewable data

through the use of a portrait display orientation.

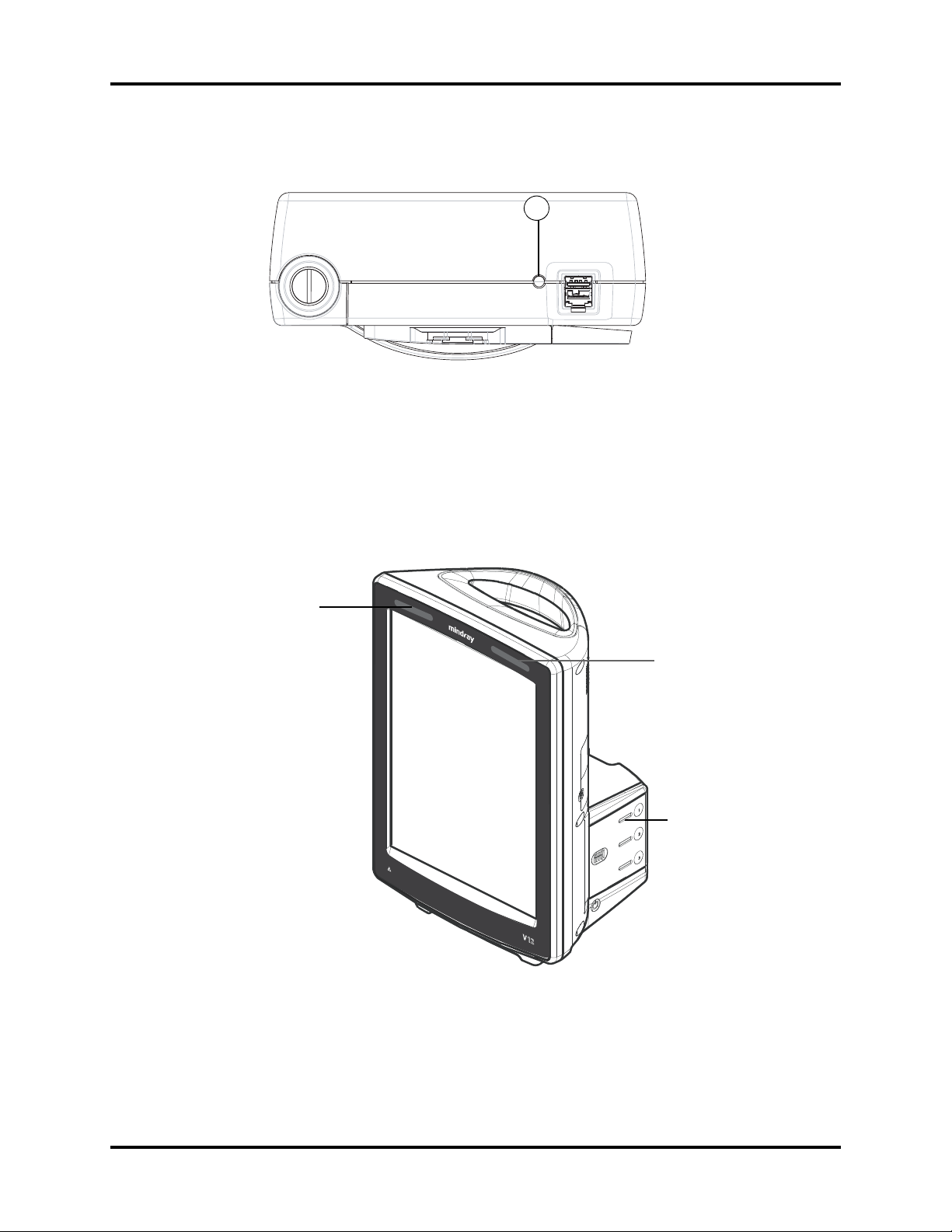

Tou c h pa d

FIGURE 1-1 Example V 12/V 21 Patient Monitor

V Series Service Manual 046-001131-00 1 - 1

Connectors for Peripheral Devices and Indicators Theory of Operation

1.2 Connectors for Peripheral Devices and Indicators

This section describes all the connectors for peripheral devices and indicators.

1.2.1 Connectors for Peripheral Devices

V 12 and V 21

V 12 and V 21 refer to the 12.1" monitor and 21.3" monitor respectively.

3

2

4

5

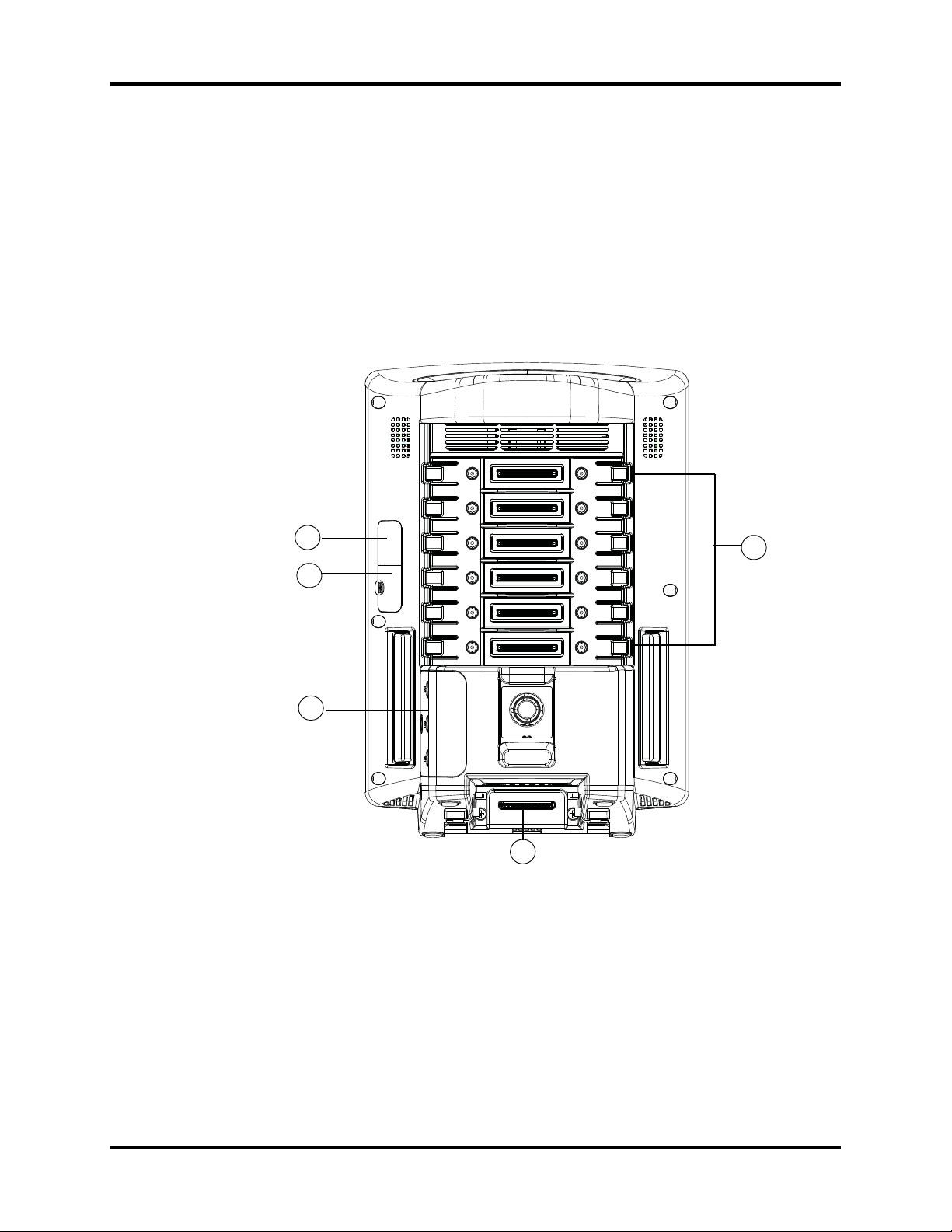

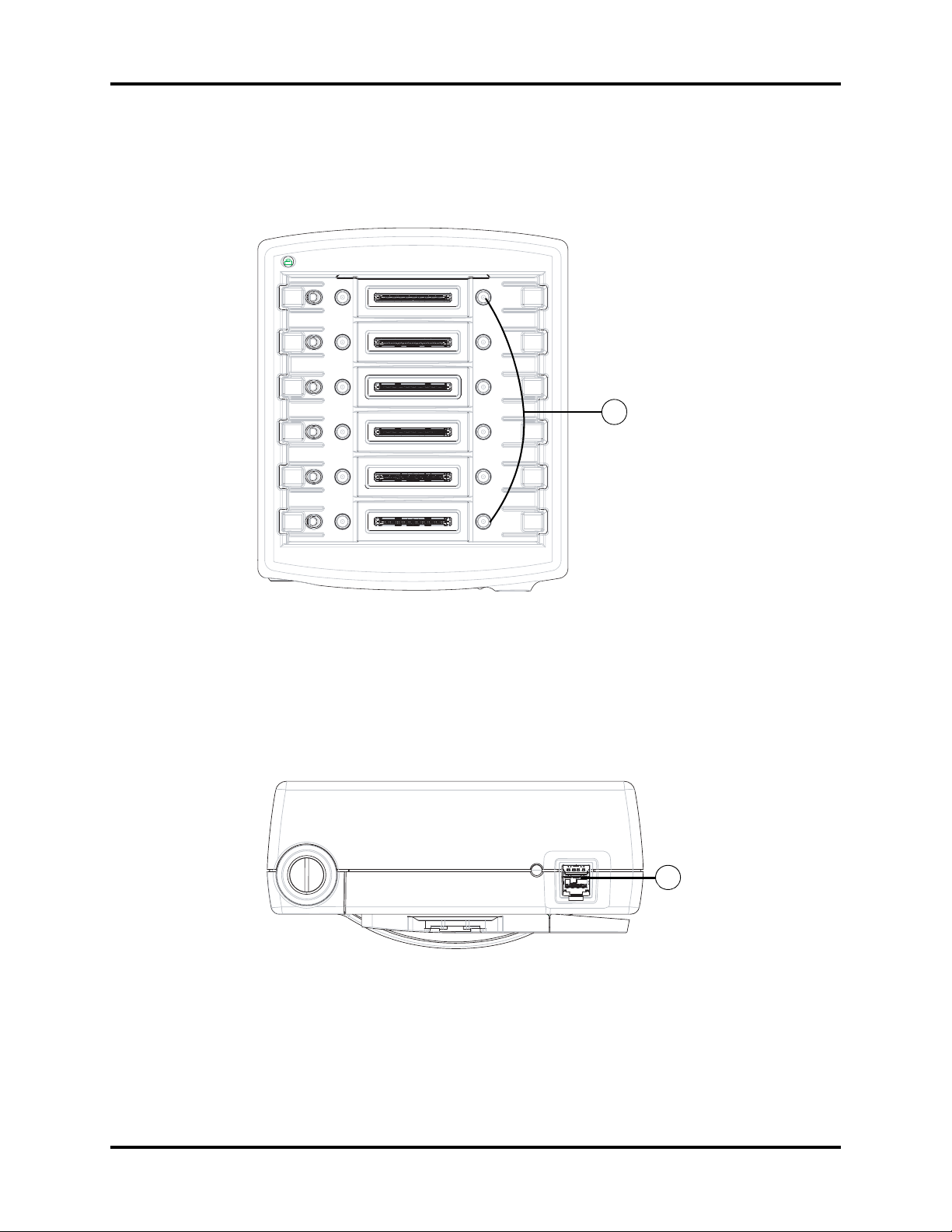

FIGURE 1-2 Example V 12 Rear View

1. Integrated module bays (for V 12 only) : Provides six module bays for modules and can

accommodate any combination of one, two or three bay wide modules that total six or less

bays.

2. V Hub connector: Connects V Hub via a PUSB cable.

3. RS-232 debug port: Connects a PC and is used for debug.

4. Battery connector (for V 12 only): Contains 3 battery connectors for removable batteries.

5. V Dock connector: Provides quick connection and release with components during

stationary operation.

1

1 - 2 046-001131-00 V Series Service Manual

Theory of Operation Connectors for Peripheral Devices and Indicators

33 6

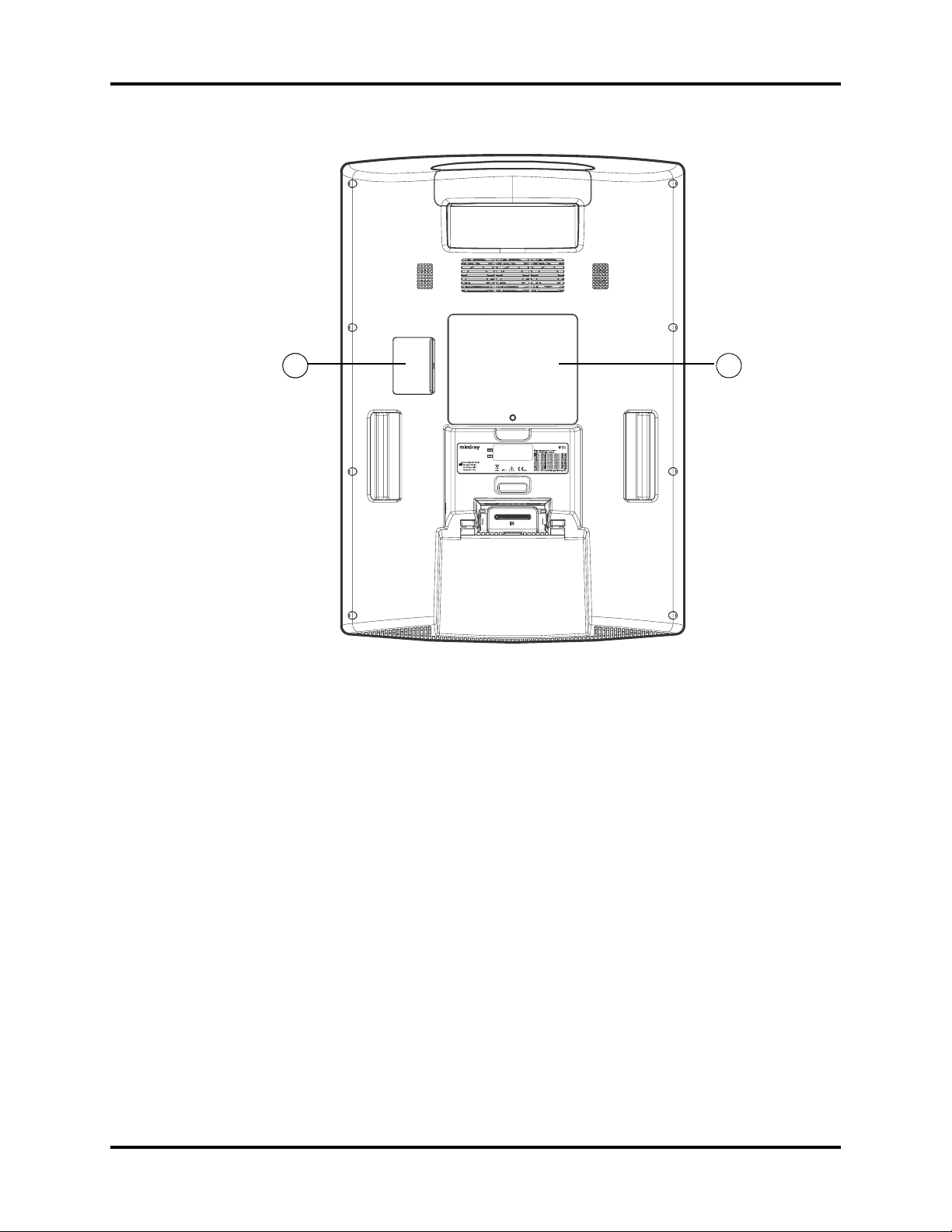

FIGURE 1-3 Example V 21 Rear View

3. RS-232 debug port: Connects a PC and is used for debug.

6. SATA connector (for V 21 only): Connects SATA driver (optional).

V Series Service Manual 046-001131-00 1 - 3

Connectors for Peripheral Devices and Indicators Theory of Operation

V Dock Physical Views

Front View

1

FIGURE 1-4 Example V Dock Front View

1. V Dock connector: Interfaces to a V 12 or V 21 monitor which allows for power and data

communication.

1 - 4 046-001131-00 V Series Service Manual

Theory of Operation Connectors for Peripheral Devices and Indicators

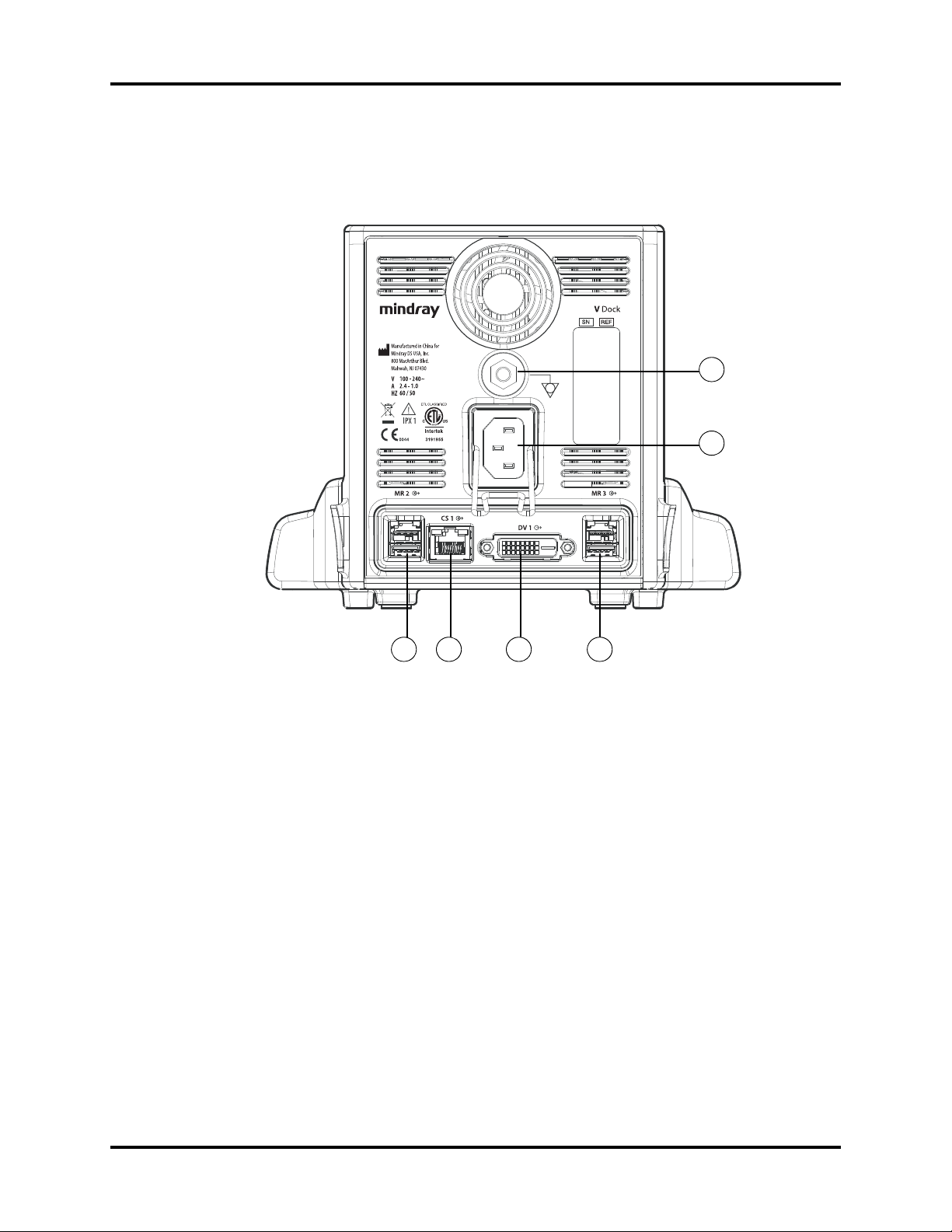

Rear View

1

2

3 4 35

FIGURE 1-5 Example V Dock Rear View

1. Equipotential lug: Connects the equipotential lug of other equipment when the monitor is

used with other equipment, eliminating the potential difference between them.

2. AC receptacle: Connects an AC power source (100-240 VAC, 50/60 Hz).

3. V Hub connector (3): Connects V Hub via PUSB cables.

4. Digital video interface (DVI) connector: Connects a second display via a DVI cable.

5. Central station (CS) connector: A RJ45 connector, through which a network or PC can be

connected.

V Series Service Manual 046-001131-00 1 - 5

Connectors for Peripheral Devices and Indicators Theory of Operation

Right Side View

2 1

FIGURE 1-6 Example V Dock Right Side View

1. V Hub connector (3): Connects V Hub via PUSB cables.

2. Standard USB connector or serial bus (3): Connects external USB devices.

Left Side View

2

1

FIGURE 1-7 Example V Dock Left Side View

1. Standard USB connector or serial bus (3): Connects external USB devices.

2. Nurse call: Connects nurse call relay.

1 - 6 046-001131-00 V Series Service Manual

Theory of Operation Connectors for Peripheral Devices and Indicators

V Hub Physical View

Front View

1

FIGURE 1-8 Example V Hub Front View

1. Integrated module bay (6): Accommodates any combination of one, two, or three bay wide

modules that totals six or less bays. It allows for power and data communication to modules.

Bottom View

1

FIGURE 1-9 Example V Hub Bottom View

1. V Hub connector: Allows for power and data communication to the monitor or V Dock.

V Series Service Manual 046-001131-00 1 - 7

Connectors for Peripheral Devices and Indicators Theory of Operation

1.2.2 Indicators

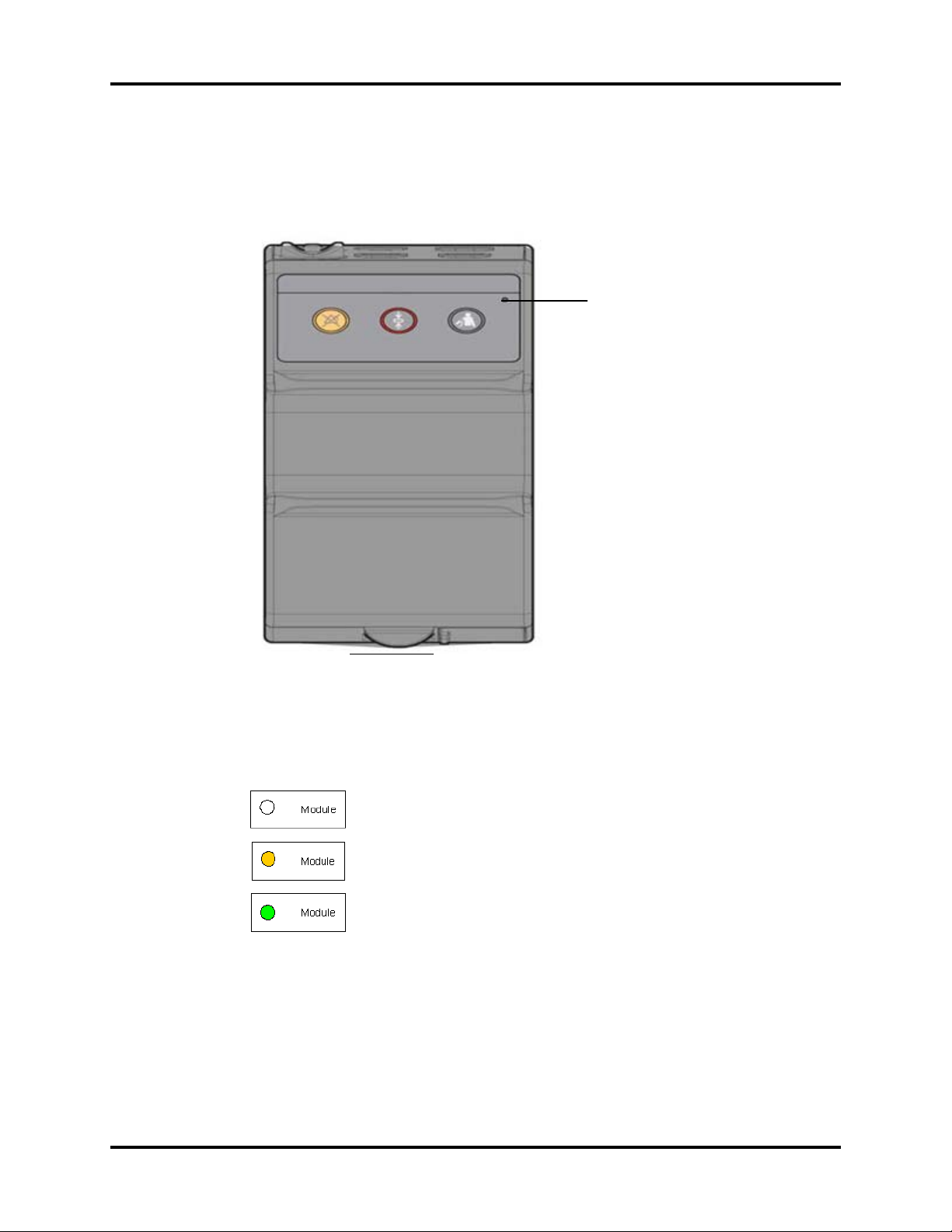

Module Indicator

Each module has one indicator. The status indicator is a single bi-color LED (green/amber).

Indicator

FIGURE 1-10 Example VPS Front View

The status indicator shows three kinds of status levels.

Indicates unconnected and no power.

Indicates USB power and no communication. When a module is connected, the amber LED illuminates to indicate that USB power is available

to the module, but there is no communication.

Indicates fully functional and proper communication. Once the V Hub

communicates and is identified, the LED turns green.

1 - 8 046-001131-00 V Series Service Manual

Theory of Operation Connectors for Peripheral Devices and Indicators

V Hub Indicator

1

FIGURE 1-11 Example V Hub Indicator

1. Indicates the 12 Volt and 5 Volt power status of V Hub. When the V Hub indicator is off, it

indicates power source disconnection. When the V Hub indicator is lit in yellow, 5V is normal

but 12V is abnormal. When the V Hub indicator is lit in green, 12V is normal.

Battery Indicator

Battery indicators (for V 12 only) show the capacity and the charging status of each battery.

Alarm Indicator

Alarm Indicator

Battery Indicator

FIGURE 1-12 Example Battery Indicator

Alarm Indicator

Alarm indicators show the status of the patient monitor or patient. See FIGURE 1-12.

V Series Service Manual 046-001131-00 1 - 9

Main Unit Theory of Operation

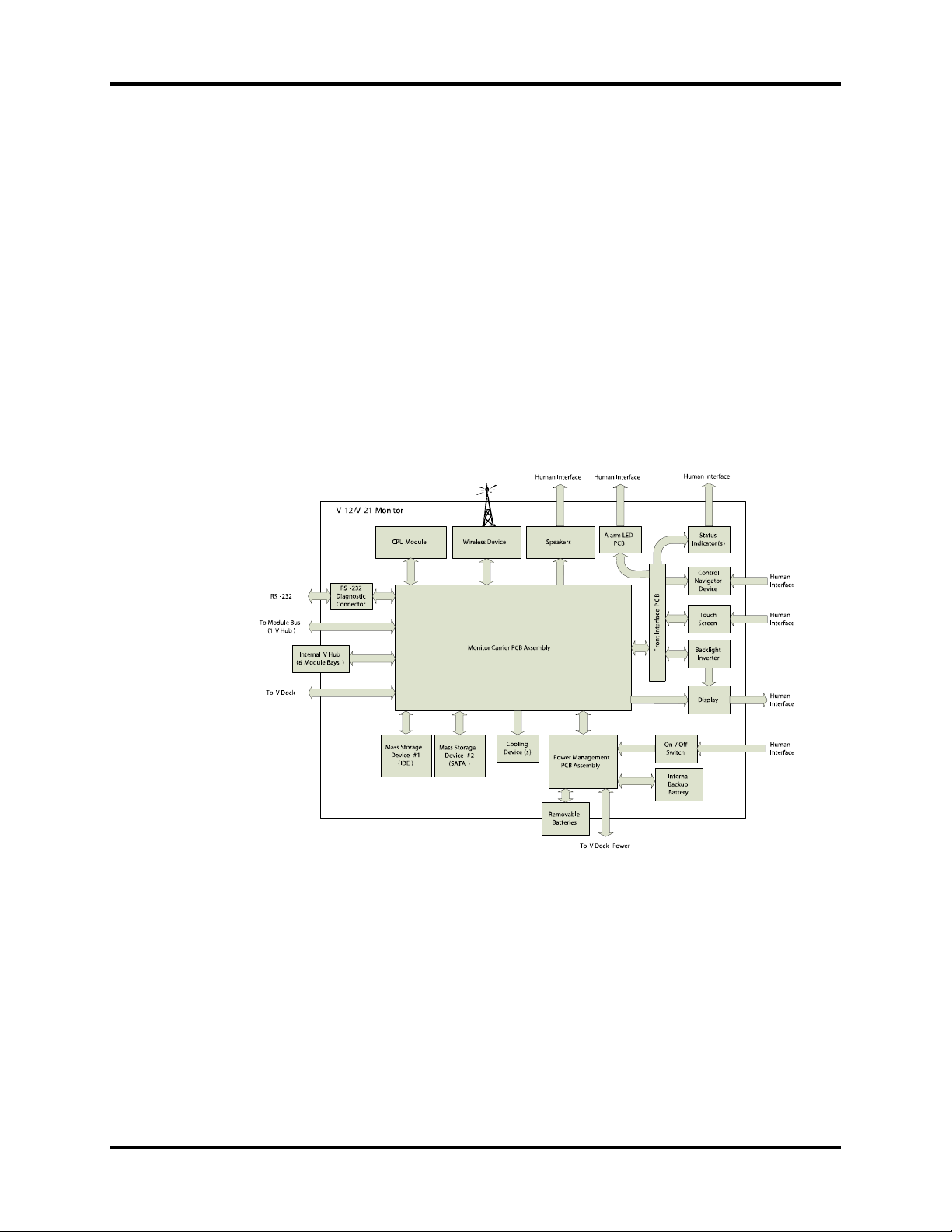

1.3 Main Unit

The patient monitor consists of :

• Input system: Touchscreen, touch pad, power button, keyboard/mouse

• Output system: LCD panel, alarm lamp, speaker, AC and battery status LEDs, recorder

• Processing and communications system: CPU module, monitor carrier board

• Power management system: Li-Ion battery, internal backup battery, battery interface board,

AC-DC power board, power management board (PMB)

• Power interface system: Monitor carrier board, V Dock

• Equipment interface system: Monitor carrier board, V Dock , V Hub

In addition, the patient monitor can also utilize a USB storage device, USB mouse, USB keyboard,

etc.

FIGURE 1-13 illustrates the architecture of V 12/V 21 patient monitor.

FIGURE 1-13 Electrical Architecture of V 12/V 21

1 - 10 046-001131-00 V Series Service Manual

Theory of Operation Main Unit

1.3.1 Input System

Touchscreen

The touchscreen is operable with or without gloves and provides a recalibration function.

Touc h Pad

The touch pad is only for the V 21 and located at the lower part of the monitor's front panel.

Power Button

The power button is located at the lower right part of V 12/V 21. Pressing it will power the

monitor on or off. The power button's status is detected by the power management board.

Keyboard / Mouse

USB keyboard and mouse is supported.

1.3.2 Output System

LCD Panel

The V 21 display uses a 21.3" LCD screen with a resolution of 1600x1200. V 12 display uses a 12.1"

LCD screen with a resolution of 768x1024. The LCD panel gets signals from the main board and

gets power from the inverter board, which is driven by the main board through the front

interface connector board.

Alarm Lamp

The monitor has two groups of alarm lamps on the alarm LED board, which is on the front panel.

The monitor I/O microprocessor passes the control signal to the LED driver TLC59116 via I2C bus.

Speaker

The speakers provide sound for alarms, heart beats, etc. They are driven by the COM Express

Module and the monitor I/O carrier board.

AC and Battery Status LEDs

The AC and battery status LEDs, located on V Dock (docking station), are controlled by the AC-DC

power board and PMB respectively. The PMB monitors battery status and passes the control

signal to V Dock via connectors.

Recorder

The Recorder module is used to print locally to a thermal recorder. The recorder gets power and

data from the V Hub through the non-Isolated module host communications board. The keypad/

LED is for indication and operation.

V Series Service Manual 046-001131-00 1 - 11

Main Unit Theory of Operation

1.3.3 Processing and Communications System

The processing and communication system mainly consists of two boards: CPU module and

monitor I/O carrier board.

CPU Module

The CPU module is a standard COM Express board, which is the heart of the patient monitor, and

implements a series of tasks including display processing, system control, data storage, and

processing, input and output system. The CPU module contains CPU, north-bridge, south-bridge,

DDR2 RAM, real-time clock, EEPROM, etc. It interfaces to the carrier board only, which then

provides interfaces to all other external devices.

Monitor Carrier Board

The monitor I/O carrier board is the CPU module's carrier board and will be described in detail in

section1.3.5 Equipment Interface System on Page 1-14 and Page 1-15.

1.3.4 Power Management System

Li-Ion Battery

• Three removable li-ion batteries are available. The battery compartment door is located at

the lower right of the patient monitor. The battery power is introduced to the power module

via the battery interface board and then processed and distributed to V 12 via the power

management board.

Internal Backup Battery

• The monitor uses one single-cell li-ion backup battery (P/N: 022-000006-00 SANYO

UR18650W high rate li-ion battery 3.7V 1500mAh). The battery is fixed to the battery

interface board.

Battery Interface Board

• The battery interface board serves as an interface between the batteries and the power

management board.

AC-DC Power Board

• The AC-DC power board converts input from AC power, and generates one regulated DC

output of voltage 15V. The output is turned on/off via connection or disconnection of the AC

power cord. The power supply provides an indication of AC presence.

• The Power Pin Board acts as a conduit for 12V and 15V to pass between the power supply and

mid and high acuity versions of the V Series patient monitor.

1 - 12 046-001131-00 V Series Service Manual

Theory of Operation Main Unit

Power Management Board (PMB)

This board is responsible for power management and performs the following functions:

• Auto-selects available power source (DS-DC, removable li-ion battery packs or internal li-ion

backup battery).

• Provides three regulated DC output voltages: 12V, 5V and 3.3V.

• Detects the power switch status to turn on/off the outputs.

• Monitors the system status (PS_ON) to hold the power or to turn it off.

• Provides over-voltage, over-current and short-circuit protection for all outputs.

• Monitors the input voltage and current provided to, and the output voltage and current draw

from each DC/DC converter output.

• Monitors the temperature of the PMB.

• Provides means to charge the three removable li-ion battery packs and the internal backup

battery and provides a CHRGR_ACTIVE output signal.

• Provides a UART interface to communicate with monitor I/O board and passes the PMB

information to monitor at a regular interval.

V Series Service Manual 046-001131-00 1 - 13

Main Unit Theory of Operation

1.3.5 Equipment Interface System

Monitor Carrier Board

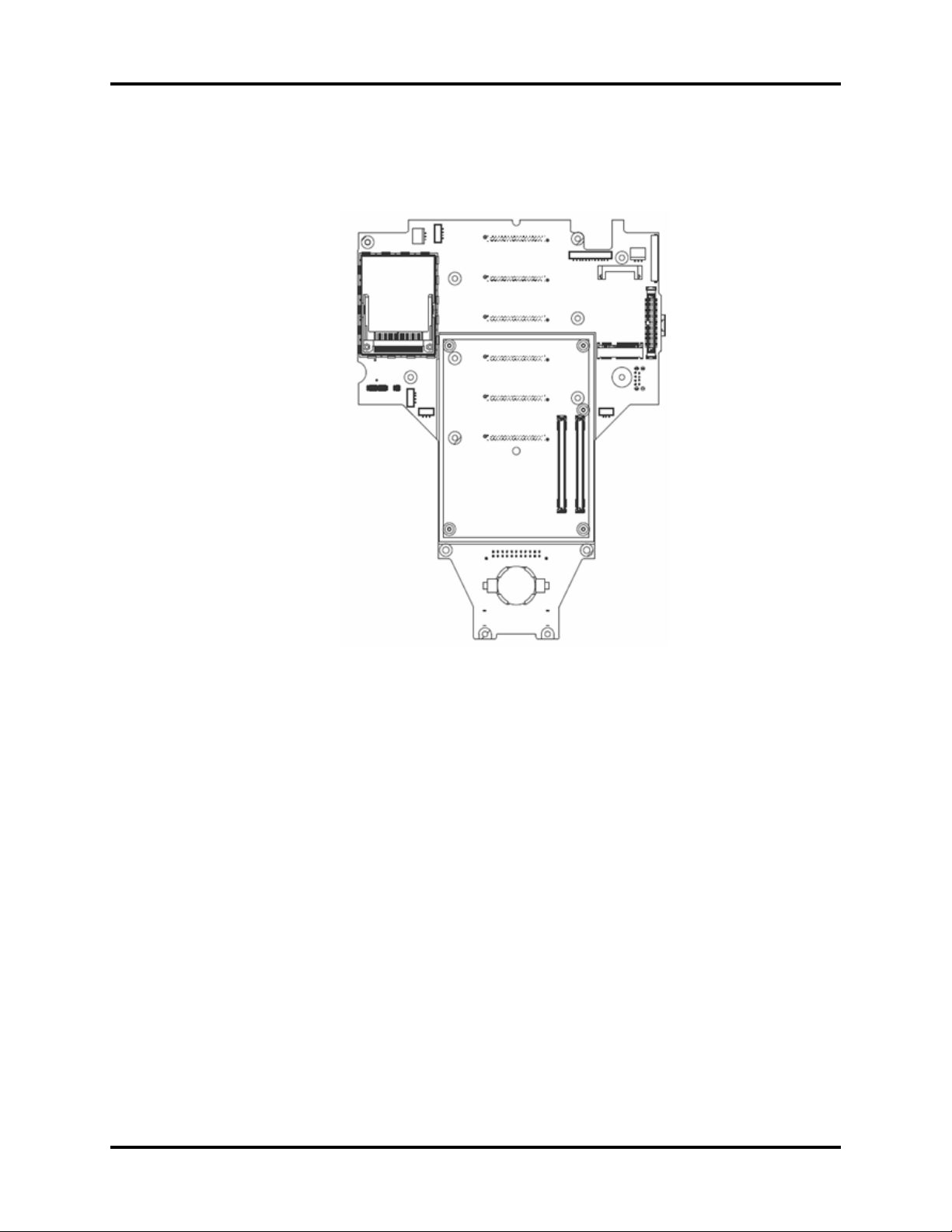

FIGURE 1-14 Monitor Carrier Board

The monitor carrier board implements the following tasks:

• Provides interfaces for CF, SATA, WiFi, LVDS display and so on.

• Communicates with PMB through UART and provides a debug serial port.

• Communicates with the CPU module through USB.

• Interfaces with I2C devices such as EEPROMs, the CPU module, alarm led drivers and Port

Expander.

• Monitors temperatures, detects fan status and controls fan speed.

• Detects dock presence and implements power control.

• Controls backlight and display brightness.

• Detects V Hub status and implements power control.

V Dock

V Dock (docking station) mounts to a fixed location and provides electrical connections for

network, power, USB, nurse call, display, and V Series module bus devices.

1 - 14 046-001131-00 V Series Service Manual

Theory of Operation Main Unit

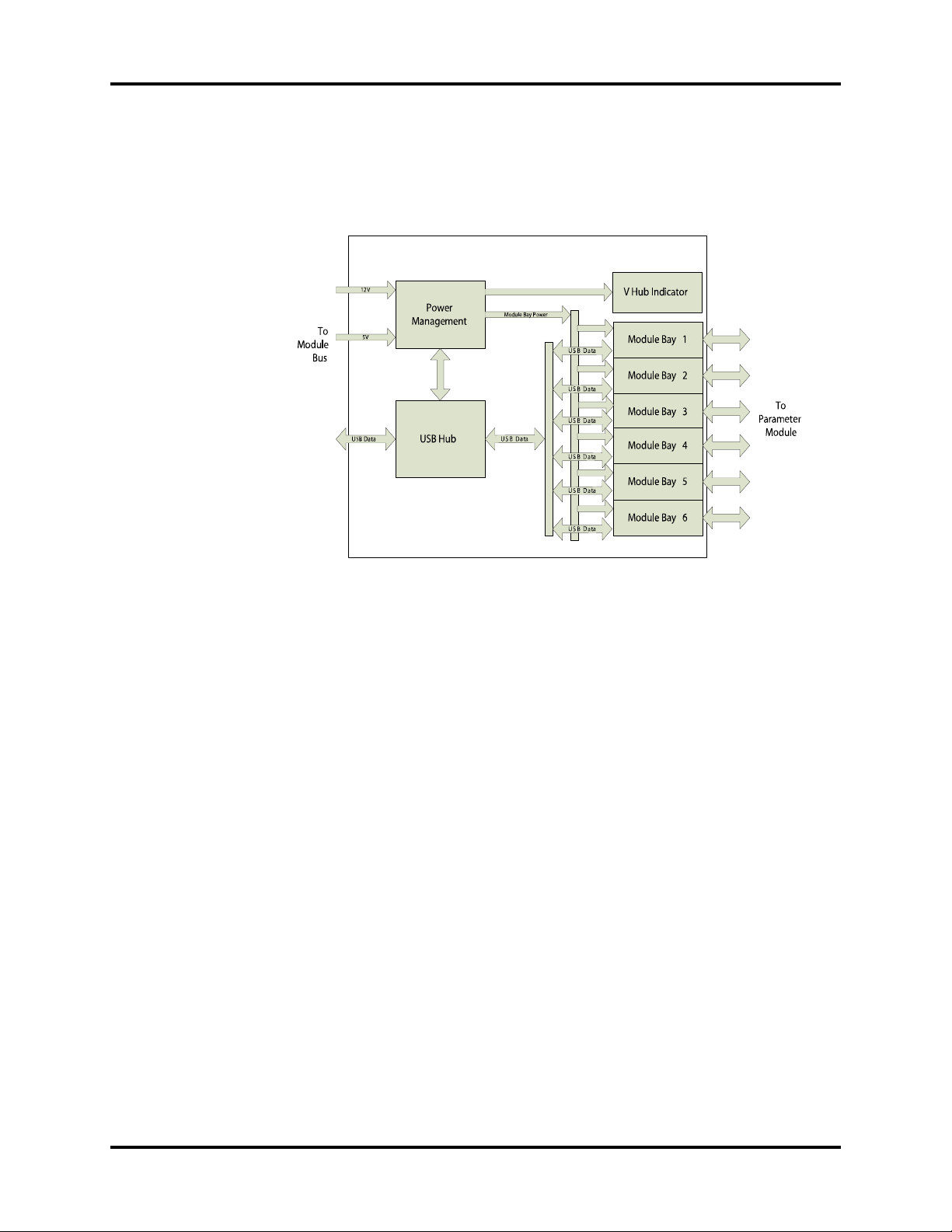

V Hub

V Hub provides the electrical interface between V 12/V 21 patient monitor and parameter

modules. It is used to extend the module bus to six module bays.

FIGURE 1-15 Electrical Architecture of V Hub

1.3.6 Interface Requirements

V Series Patient Monitor provides wired or wireless network interface to communicate with

Panorama, Hypervisor, etc. Wireless card is in V 12/V 21 and wired network connector is on the

docking station.

1.3.7 Parameter Module

Parameter modules include VPS, Recorder, VDI, CO2, C.O., IBP, TEMP,12L ECG/EKG, NIBP, SpO2.

Each parameter module consists of four parts: host communication board, keypad/LED,

parameter board and instrument/patient connector board.

The NI-HCB or HCB is the interface between module bus and the parameter board, playing a role

of power supply, data communication and processing. Parameter serves as the main source of

patient parameter data. Instruments or sensors are connected to parameter modules via the

instrument/patient connector board. Keypad/LED is for indication and operation.

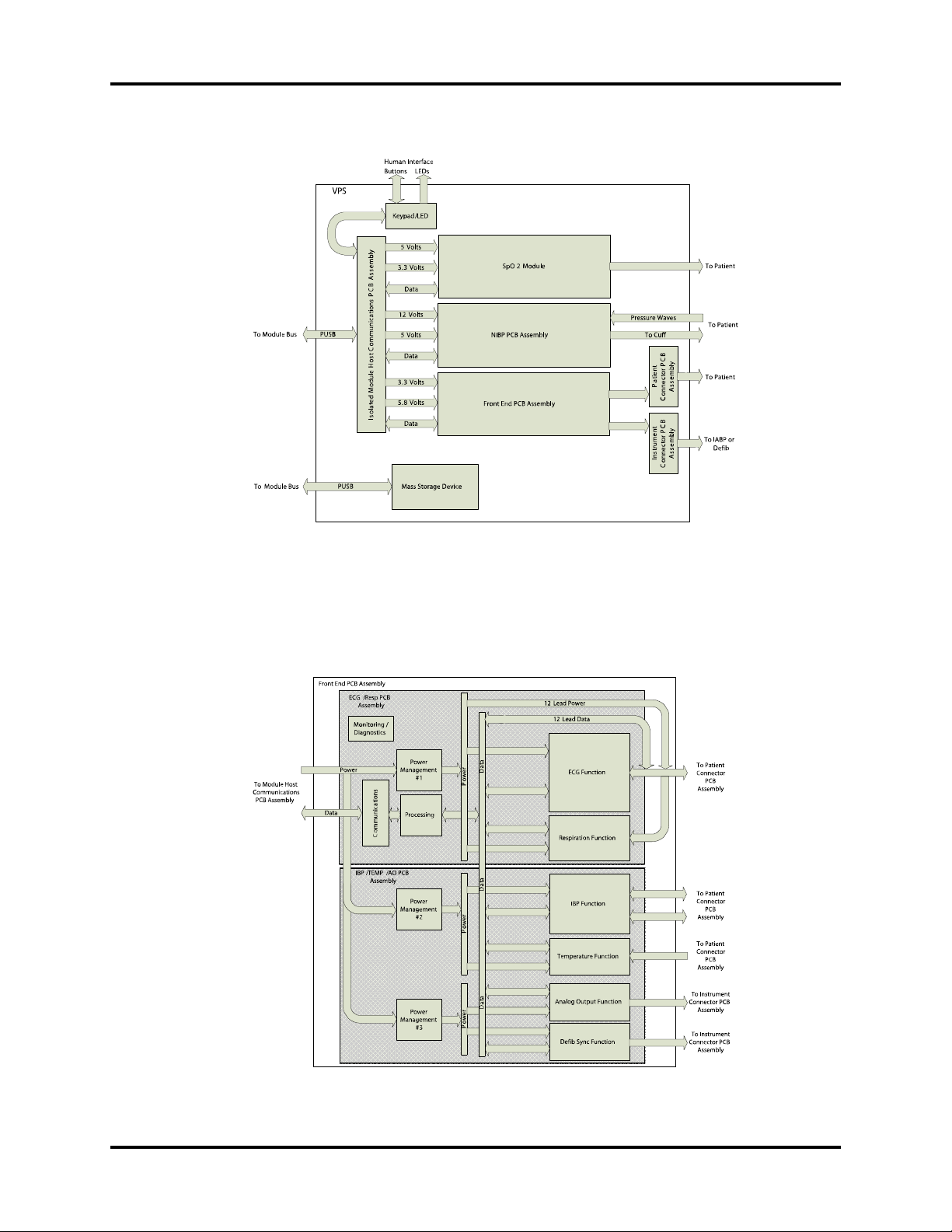

VPS (V Patient Server)

The VPS is a collection of the most commonly measured parameters, including 3/5/6 Lead ECG,

Respiration, Invasive Blood Pressure (2 channels), Temperature, SpO

Defibrillator Sync.

Otherwise the VPS also provides mass storage to store all patients' historical data and specific

configuration data. It is a 3X module.

, Analog Output (2), and a

2

FIGURE 1-16 shows the electrical architecture of VPS.

V Series Service Manual 046-001131-00 1 - 15

Main Unit Theory of Operation

FIGURE 1-16 Electrical Architecture of VPS

The Front End serves as the main source of patient parameter data. It contains the primary

functions of ECG, Respiration, IBP, and Temperature.

FIGURE 1-17 shows the electrical

architecture of front end module.

FIGURE 1-17 Electrical Architecture of Front End Module

1 - 16 046-001131-00 V Series Service Manual

Theory of Operation Main Unit

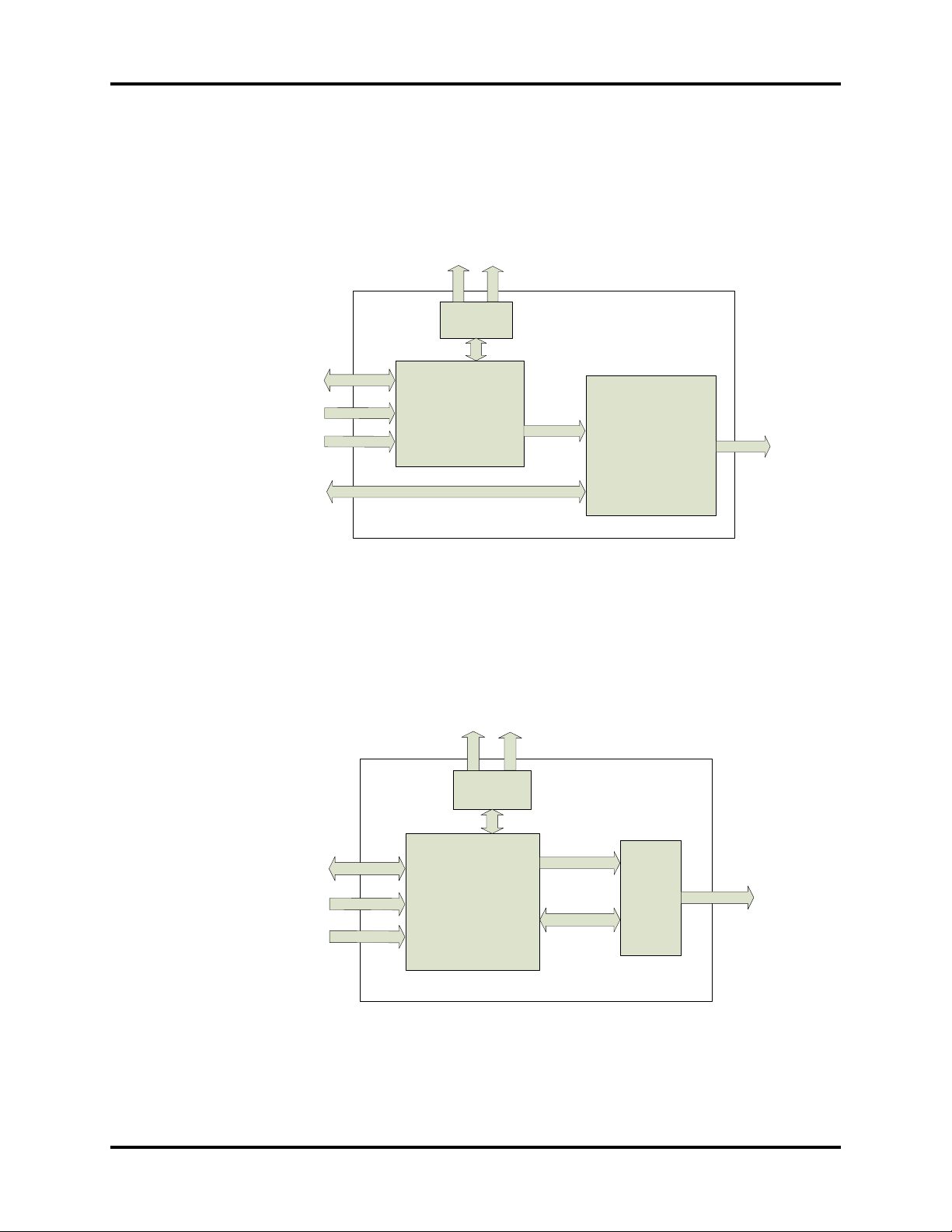

Recorder Module

The Recorder module prints to an internal thermal recorder. FIGURE 1-18 shows the electrical

architecture of recorder module.

Human Interface

Buttons

LEDs

To Module Bus

To Module Bus

Recorder Module

USB Data

V

2

1

o

s

t

l

V

5

o

s

t

l

Key Pad/LED

Non-Isolated Module Host

Communications PCB

Assembly

USB Data

Power

OEM Recorder

FIGURE 1-18 Electrical Architecture of Recorder Module

VDI Module

The VDI module acquires data from other medical devices supported by V series. It is a 1X

module.

FIGURE 1-19 shows the electrical architecture of VDI module.

Human Interface

Buttons

LEDs

Paper

Output

To Module Bus

VDI Module

USB Data

V

2

1

t

l

o

s

t

V

5

l

o

s

Key Pad/LED

Non-Isolated Module

Host Communications

PCB Assembly

Power

RS232 Data

Panel

Connector

PCB

assembly

Other

Devices

FIGURE 1-19 Electrical Architecture of VDI Module

V Series Service Manual 046-001131-00 1 - 17

Main Unit Theory of Operation

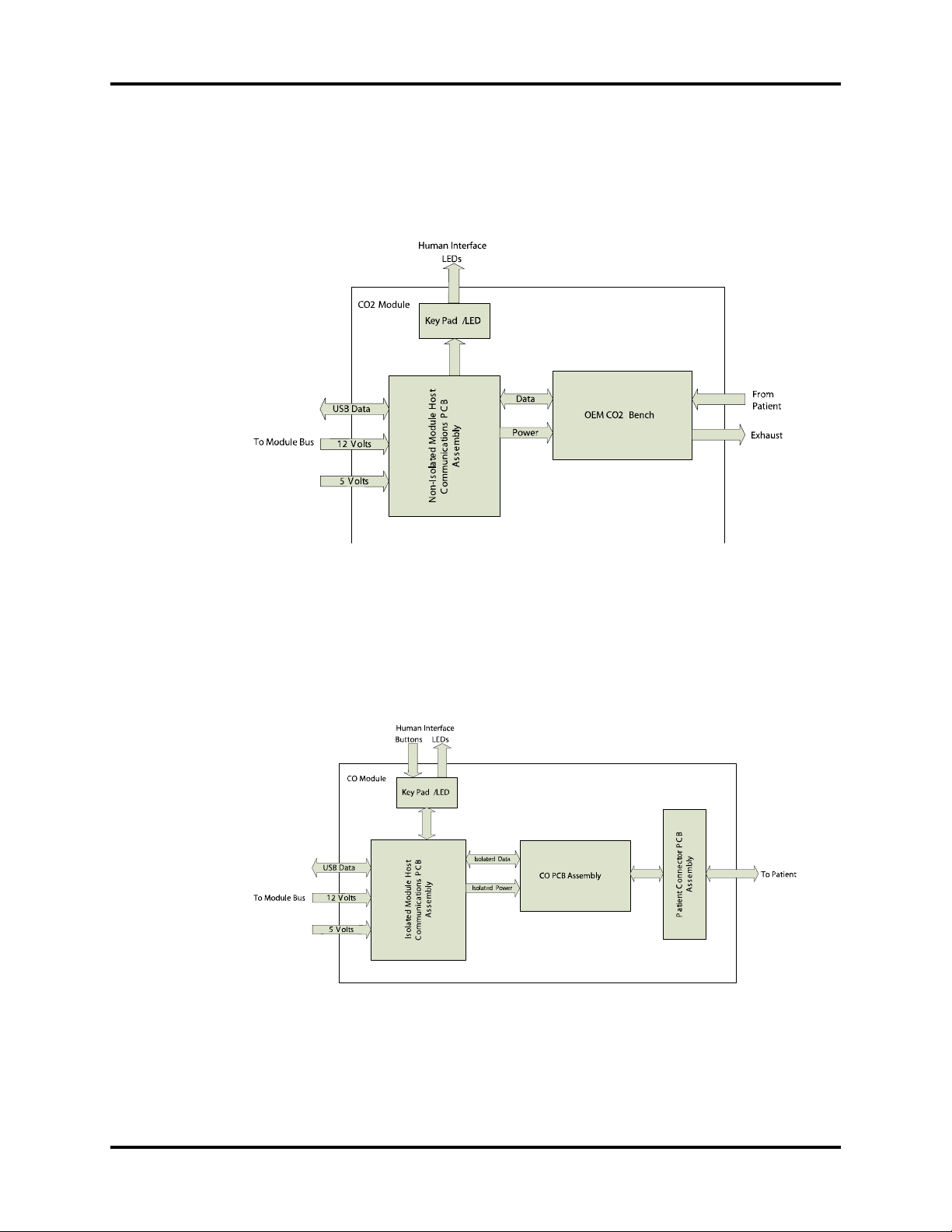

CO2 Module

The CO2 module measures the percentage of CO2 inspired and expired air from breathing. It is a

2X module.

FIGURE 1-20 shows the electrical architecture of CO2 module.

FIGURE 1-20 Electrical Architecture of CO2 Module

C.O. Module

The cardiac output module measures thermodilution cardiac output. It is a 1X module. FIGURE 1-

21 shows the electrical architecture of C.O. module.

FIGURE 1-21 Electrical Architecture of C.O. Module

1 - 18 046-001131-00 V Series Service Manual

Theory of Operation Main Unit

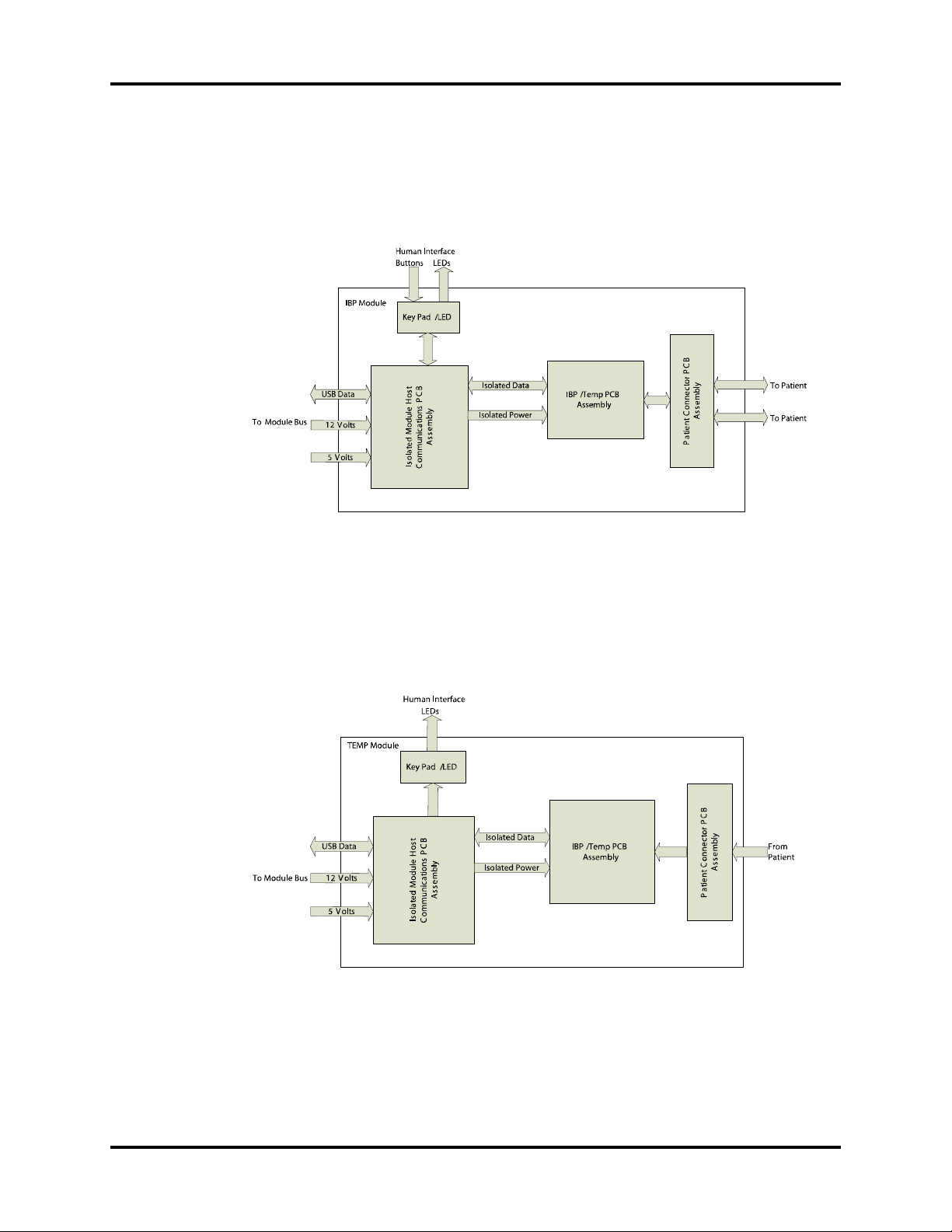

IBP Module

The IBP module measures the invasive blood pressure. It is a 1X module. FIGURE 1-22 shows the

electrical architecture of IBP module.

FIGURE 1-22 Electrical Architecture of IBP Module

TEMP Module

The Temp module measures temperature. It is a 1X module. FIGURE 1-23 shows the electrical

architecture of TEMP module.

FIGURE 1-23 Electrical Architecture of TEMP Module

V Series Service Manual 046-001131-00 1 - 19

Main Unit Theory of Operation

12L ECG/EKG Module

The12L ECG/EKG module monitors 12 lead ECG and Respiration including ST and arrhythmia

analysis through the VPS module.

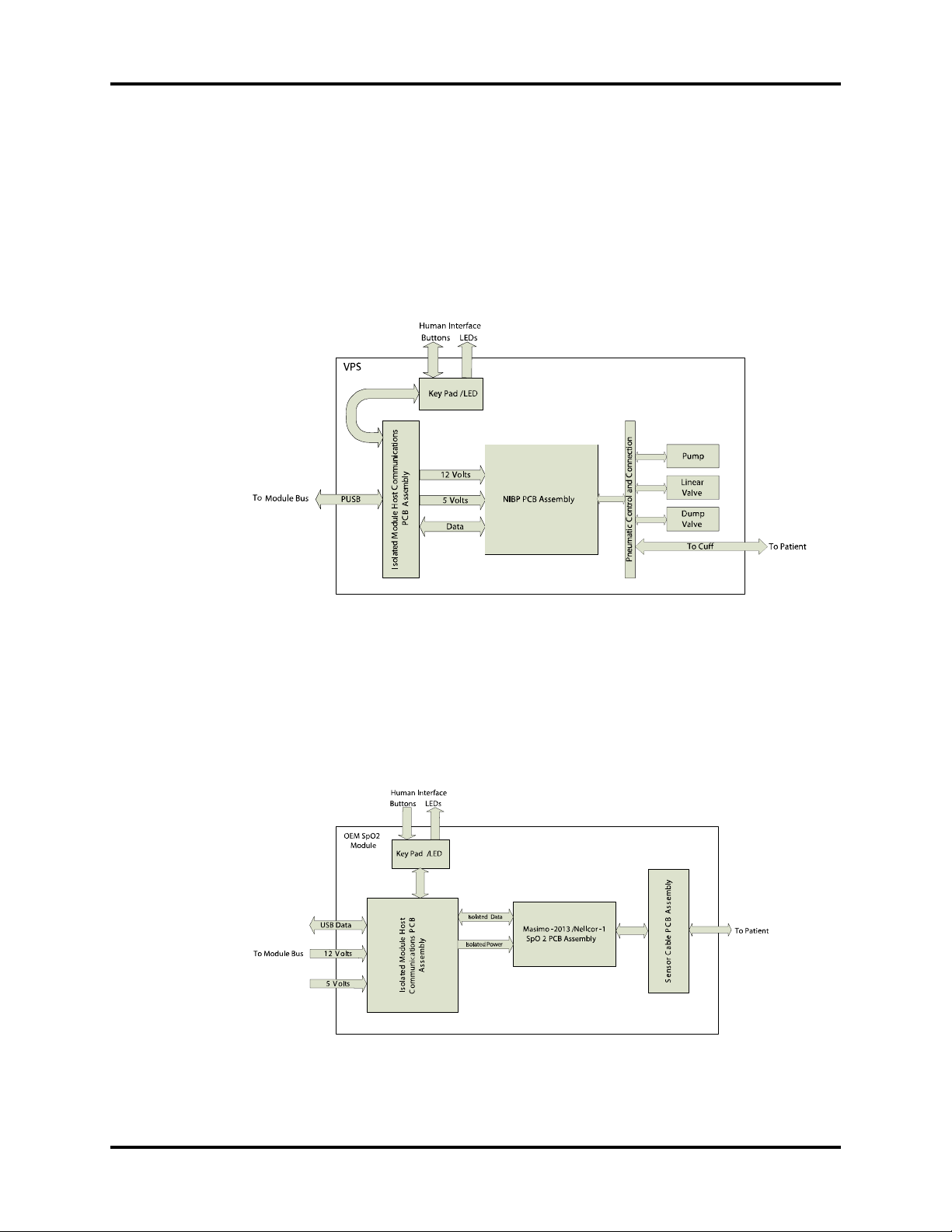

NIBP Module

The NIBP module measures non-invasive blood pressure. FIGURE 1-24 shows the electrical

architecture of NIBP module.

FIGURE 1-24 Electrical Architecture of NIBP Module

OEM SpO2 Module

There are two types of SpO2 modules: Masimo-2013 SpO2 and Nellcor-1 SpO2 module. Host

communication board, keypad/LED and patient connector board are also needed to work with

the OEM SpO

board. FIGURE 1-25 shows the electrical architecture of OEM SpO2 module.

2

FIGURE 1-25 Electrical Architecture of OEM SpO2 Module

1 - 20 046-001131-00 V Series Service Manual

2.0

Repair Information

2.1 Introduction

This chapter provides the necessary technical information to perform repairs on the instrument.

The most important prerequisites for effective troubleshooting are a thorough understanding of

the instrument functions as well as understanding the theory of operation.

2.2 Safety Precautions

In the event the instrument covers are removed, observe the following warnings and guidelines.

1. Do not short component leads together.

2. The instrument covers must not be removed by other than qualified technical personnel

who have received supplementary instructions regarding maintenance of medical

equipment or has equivalent experience in this area.

WARNING: Internal Electrical Shock Hazard -This unit does not contain any user-

serviceable parts. Do not remove instrument covers. Refer servicing to

qualified personnel.

WARNING: Whenever the monitor is opened for calibration or repair, a risk

(leakage) current safety check and a verification of basic functions of all

parameters should be performed before the monitor is returned

clinical use. See ‘‘Verification’’ on page 5-21 for details.

V Series Service Manual 046-001131-00 2 - 1

Troubleshooting Guidelines Repair Information

2.3 Troubleshooting Guidelines

1. Identify the problem

Due to the wide variety of potential symptoms certain problems may be more subtle than

others. One approach to troubleshooting is to set up the instrument as described in Chapter

5.0. Following the guidelines of the tests will help determine the problem if one exists.

2. Avoid shorting component leads

During repair procedures, it can become tempting to make a series of quick measurements.

Always turn the power off before connecting and disconnecting the test Leads and probes.

The accidental shorting of Leads can easily stress the components and cause a second fail

ure ( aside from the safety risk ).

3. Use the proper equipment

The equipment listed below is suggested to fulfill a wide range of troubleshooting requirements. It is imperative to use the designated equipment in order to ensure proper results of

any and all test procedures.

4. Clean up the repair area

After any repair, especially after any soldering or desoldering, clean off the repair area with

alcohol and a stiff brush. This will remove any residual solder flux, in turn allowing the instrument to return to its original appearance.

-

2.4 Special Tools Required

•DVM

• Digital mercury manometer - 0 to 300 mmHg

• Safety analyzer

• Patient simulator

• NIBP test chamber / Dummy cuff (P/N 0138-00-0001-01 (700 cc) or -03 (500 cc))

• CAT-5 crossover cable

• USB cable 2.0

• USB memory stick or USB hard drive 2.0 specified in the Operator's Manual

• Desktop PC or notebook PC

• Microsoft XP/Vista/Windows 7 operating system

• Intel Pentium CPU, above 500MHz

• Above 128M memory

• At least one net card

• At least one USB port

2 - 2 046-001131-00 V Series Service Manual

Repair Information Disassembly Instructions

2.5 Disassembly Instructions

This section describes the disassembly procedures for the patient monitor and its components.

Tools Required

• Screwdrivers

• Flat-bladed screwdrivers

• Sharp nose pliers

• 3-mm inner hexagon wrench

• ESD mat and wrist strap

• Antistatic glove

Preparation for Disassembly

1. Power down the V 12/V 21.

2. Remove the line cord from V Dock.

3. Remove all cable assemblies connecting to V 12/V 21, V Hub, and modules.

4. Remove all the modules from V 12/V 21 and V Hub.

5. Remove any batteries installed.

6. Perform all work on a properly grounded ESD workstation.

V Series Service Manual 046-001131-00 2 - 3

Disassembly Instructions Repair Information

2.5.1 Disassembling V 12 (12.1" Monitor)

Removal of the Diagnostics Access Cover

1. Open the module bus access and loosen the captive screw.

2. Remove the diagnostics access cover.

Diagnostics

Access Cover

Module Bus

Access

Captive Screw

2 - 4 046-001131-00 V Series Service Manual

Repair Information Disassembly Instructions

Removal of the Small Fan and Cable Assembly

1. Open the battery compartment door and use a flat-bladed screwdriver to push out the small

fan cover from the hole of the first battery door.

Small Fan Cover

2. Disconnect the small fan and cable assembly from the fan connecting cable.

NOTE: When reassembling the small fan, ensure that the fan is installed in the

proper direction.

2.5.2 Removal of the Battery Door

Open the battery door and remove it.

Small Fan

V Series Service Manual 046-001131-00 2 - 5

Disassembly Instructions Repair Information

2.5.3 Removal of the Front Housing

1. Place the monitor face down on a protective surface.

2. Use a small flat-bladed screwdriver to remove the 6-screw-hole covers.

2 - 6 046-001131-00 V Series Service Manual

Repair Information Disassembly Instructions

3. Remove the 6 M4X10 screws and loosen 2 captive screws from the rear of the monitor. Turn

the rear housing over to the top side of the front housing as indicated by the long arrow

shown in the first picture below.

Captive

Screws

Turn Ove r in

This Direction

Back

Housing

Assembly

Front

Housing

Assembly

V Series Service Manual 046-001131-00 2 - 7

Disassembly Instructions Repair Information

4. Remove the display cable from J13 of the carrier PCBA. Unlatch the sockets and remove the

front interface cable from J14 of the carrier PCBA and JP2 of the front Interface PCBA.

Removal of the Alarm LED PCBA / CCFL Inverter PCBA /Front Interface PCBA

1. Remove the alarm LED cable from J1. Remove the CCFL inverter cable from JP6.

2. Remove the touchscreen cable from J4. Remove the 2 MX6 screws that secure the front

interface PCBA.

Front In terface

PCBA

2 - 8 046-001131-00 V Series Service Manual

Repair Information Disassembly Instructions

3. Remove the alarm LED cable from J1. Remove the 2 M3X6 screws that secure the alarm LED

PCBA.

Alarm LED PCBA

4. Remove the LCD cable from CN2. Remove the CCFL inverter cable from CN1. Remove the 2

M3X6 screws that secure the CCFL inverter.

CCFL Inverter

PCBA

V Series Service Manual 046-001131-00 2 - 9

Disassembly Instructions Repair Information

Removal of the LCD/Display Cable /Touchscreen

1. Remove the 8 M3X6 screws. First pull the LCD subassembly out from the bracket. Then lift

the subassembly up and place the LCD face up.

2. Remove the display cable from the LCD. Remove the 4 M3X6 screws and separate the LCD

from the display mounting frame. Remove the touchscreen from the front housing.

Tou c h sc r ee n

LCD S ubassembly

2 - 10 046-001131-00 V Series Service Manual

Repair Information Disassembly Instructions

2.5.4 Removal of the Back Housing

Lie down the back housing and use an underlay to secure it.

Removal of the CF Solid State Drive

1. Open the CF Shield cover with sharp nose pliers clamping the tips of the cover.

CF Shield Cover

V Series Service Manual 046-001131-00 2 - 11

Disassembly Instructions Repair Information

2. Remove the CF solid state drive from the carrier PCBA by pushing it up forward.

CF Solid State Drive

Removal of the Wireless Transceiver/Antenna and Cable Assembly

1. Remove the 2 antenna and cables from the wireless transceiver.

2. Remove the 2 M3X6 screws that secure the fan mounting bracket. Then pull out the antenna

and cables.

Antenna and

Cable

Assembly

2 - 12 046-001131-00 V Series Service Manual

Repair Information Disassembly Instructions

3. Unfold the clips (two places) and remove the wireless transceiver.

Wireles s

Tra nsc ei ver

Removal of the Triple Fans and Cable Assembly

Remove the cable from the carrier PCBA J30. Remove the fans and gasket from the back housing.

Then remove the fans from the gasket.

Gasket

Trip le Fan

NOTE: When reassembling the fans, make the side of the fans with marks (the

figure on the left) face the symmetric holes of gaskets and the other

side (the figure on the right) face the dissymmetric holes. Ensure that

the side with marks face outside when assembling the fan to the back

housing.

Face outside Face inside

V Series Service Manual 046-001131-00 2 - 13

Disassembly Instructions Repair Information

Removal of the Speaker and Cable Assembly

Remove the speaker cable assembly from J9 and J12 of the carrier PCBA. Remove the 2 M3X6

screws and 2 speaker mounting brackets.

Speaker

Removal of the Handle

Remove the 2 M3X16 socket-head screws with 3-mm inner hexagon wrench. Separate the handle

from the back housing.

2 - 14 046-001131-00 V Series Service Manual

Repair Information Disassembly Instructions

Removal of the Carrier Board and CPU Subassembly

1. Remove the thermistor and cable assembly from J20 of the carrier board PCBA. Remove the

5 M3X6 pan head screws that secure the carrier PCBA. Remove the 6 M3X12 screws that

secure the heat-sink.

2. Hold the back of the heat-sink and pull the assembly out carefully.

Carrier Board and

CPU Subassembly

NOTE: EMI clip is assembled at the sixth rib on the heat-sink for V 12 only.

V Series Service Manual 046-001131-00 2 - 15

Disassembly Instructions Repair Information

Removal of the Fan Control PCBA

Remove the fan control PCBA from the back housing assembly. Remove the carrier board

connecting cable from J1. Remove the fan connecting cable from J2.

Fan Co ntrol PCBA

Removal of the Power Management PCBA

1. Remove the 4 M3X30 screws that secure the power management PCBA.

Power Management

PCBA

2. Separate the power management PCBA from the back housing assembly by pushing its

heat-sink to the right.

Push in This

Direction

2 - 16 046-001131-00 V Series Service Manual

Repair Information Disassembly Instructions

3. Slant the power management module toward 1 marked in the figure below and remove it.

4. Remove the pushbutton switch and cable from J3.

1

Removal of the Chassis Subassembly

1. Remove the 2 M4X10 screws and the thermistor and cable assembly.

Thermistor

and Cable

Assembly

2. Remove the captive screw in the bottom of the chassis and pull out the chassis assembly.

V Series Service Manual 046-001131-00 2 - 17

Disassembly Instructions Repair Information

3. Remove the 6 M3X6 screws to separate the li-ion battery pack PCBA.

Chassis Subassembly

Li-ion Battery Pack PCBA

Removal of the Pushbutton Switch and Cable Assembly

If the pushbutton switch and cable assembly in your unit is the one as shown below, loosen the

nut with sharp nose pliers

Pushbutton Switch and

Cable

and pull out the pushbutton switch and cable assembly carefully.

If the pushbutton switch and cable assembly in your unit is the one as shown below, loosen the

screw and remove the p

Pushbutton Switch and Cable

ushbutton switch and cable assembly.

Screw

2 - 18 046-001131-00 V Series Service Manual

Repair Information Disassembly Instructions

2.5.5 Disassembling V 21 (21.3" Monitor)

Removal of the Front Housing

1. Place the monitor face down on a protective surface.

2. Use a small flat-bladed screwdriver to remove the 8 screw hole covers.

Screw Hole Cover

3. Remove the 8 M4X10 screws from the rear of the monitor. Turn the rear housing over to the

left side of the front housing.

CAUTION: Do not tilt the rear housing for more than 45 degrees to prevent any

possible damage to the front interface cable inside the monitor.

Unlatch the sockets and remove the front interface cable from J14 of the carrier PCBA and JP2 of

the front interface PCBA.

V Series Service Manual 046-001131-00 2 - 19

Disassembly Instructions Repair Information

4. Remove the double-coated tape that secures the display cable. Remove the display cable

from J13 and J24 of the carrier PCBA. Remove the display cable from the socket of the LCD.

Double Coated Tape

Removal of the Front Interface PCBA / CCFL Inverter PCBA / Alarm LED PCBA / Front Plate/

To uc h pa d

1. Remove the alarm LED cable from J1.

2. Remove the touchpad cable from Jp10.

3. Remove the AC present cable from J3.

4. Remove the touchscreen cable from J4.

5. Remove the CCFL inverter cable from JP5.

6. Remove the 2 M3X6 screws that secure the front interface PCBA.

7. Remove the LCD cable from the CCFL inverter PCBA (6 places).

8. Remove the CCFL inverter cable from CN. Remove the 4 M3X6 screws that secure the CCFL

inverter PCBA.

2 - 20 046-001131-00 V Series Service Manual

Repair Information Disassembly Instructions

9. Remove the alarm LED cable from J1. Remove the 3 M3X6 screws that secure the alarm LED

PCBA.

10. Remove the 3 M3X6 screws that secure the front plate (shown in the picture above) and

turn the front plate around to separate the reclosable fastener.

Reclosable Fastener

Front Pl ate

NOTE: One EMI clip is assembled on the front plate.

11. Remove the 4 M3X6 screws that secure the touchpad mounting frame.

12. Remove the touchpad mounting frame.

V Series Service Manual 046-001131-00 2 - 21

Disassembly Instructions Repair Information

Tou c h pa d

Tou ch p ad

Mounting

Frame

Removal of the LCD/Touchscreen

1. Remove the 14 M3X6 screws that secure the LCD subassembly.

2. Lift the subassembly up and pull out the touchscreen cable carefully and place the LCD face

up. Separate the touchscreen from the front housing.

LCD S ubass embly

3. Remove the 2 M3X6 screws that secure the top bracket to the LCD.

4. Remove the 2 M3X6 screws that secure the bottom bracket to the LCD.

2 - 22 046-001131-00 V Series Service Manual

Repair Information Disassembly Instructions

Top Br ack et

Bottom Bracket

Removal of the Back Housing