Disassembling Guide for

Ex-55/65

International Customer Service Department

Mindray CO. Ltd.

2008.09 (Ver 1.1)

- 1 -

Content

Warning........................................................................................................................- 3 -

Note..............................................................................................................................- 3 -

1 Tools..........................................................................................................................- 4 -

2 Preparations for Disassembly.................................................................................- 4 -

3 Circuit System Disassembly...................................................................................- 6 -

3.1 Remove the Top Panel............................................................................................- 6 -

3.2 Remove the CPU board..........................................................................................- 7 -

3.3 Remove the Button Board ...................................................................................... - 8 -

3.4 Remove the Monitor Board....................................................................................- 8 -

3.5 Remove the Net Board...........................................................................................- 9 -

3.6 Remove the CIS interface board............................................................................- 9 -

3.7 Remove the Built-in Batteries..............................................................................- 10 -

3.8 Remove the Speaker............................................................................................. - 11 -

3.9 Remove the Three-way Valve .............................................................................. - 11 -

3.10 Remove the Power Board...................................................................................- 12 -

4 Pneumatic System Disassembly ..........................................................................- 14 -

4.1 Remove the Upper Rear Panel............................................................................. - 14 -

4.2 Remove the Front Panel.......................................................................................- 15 -

4.3 Remove the Display Assembly ............................................................................- 15 -

4.4 Remove the High Voltage Inverter.......................................................................- 17 -

4.5 Remove the System Switch..................................................................................- 17 -

4.6 Remove the Flow Meter control board. ............................................................... - 18 -

4.7 Remove the Alarm Light......................................................................................- 19 -

4.8 Remove the Encoder Board ................................................................................. - 20 -

4.9 Remove the O2 Flush Button...............................................................................- 20 -

4.10 Remove the Pipeline or Cylinder Pressure Gauges............................................- 21 -

4.11 Remove the Flow Meter.....................................................................................- 22 -

4.12 Remove the Needle Valves.................................................................................- 22 -

4.13 Remove the Module Socket Communication Board (NIOS).............................- 23 -

4.14 Remove the Pipeline Gas Supply Inlet Assembly..............................................- 23 -

4.15 Disassemble the Pipeline Gas Supply Inlet Assembly....................................... - 24 -

4.16 Remove the ACGO Switch ................................................................................- 25 -

4.17 Remove the Breathing Valve Assembly............................................................. - 25 -

4.18 Remove the O2-N2O block valve......................................................................- 26 -

5 Electrical and Pneumatic Diagrams .....................................................................- 27 -

5.1 Electrical Connections .........................................................................................- 27 -

5.2 Pneumatic Connections........................................................................................ - 28 -

5.3 Modular Connections...........................................................................................- 29 -

- 2 -

Warning

To help prevent fires, only use lubricants approved for anesthesia or O2 equipment.

Do not use lubricants that contain oil or grease. They burn or explode in high O2

concentrations.

Obey infection control and safety procedures. Used equipment may contain blood and

body fluids.

Movable parts and removable components may present a pinch or a crush hazard. Use

care when moving or replacing system parts and components.

Use care when disassembling the parts with sharp edges to avoid cuts.

Pay attention to the screws during the disassembly to prevent screws from falling into the

inside of the equipment. Failure to do so may cause short circuit.

Make sure to bleed gas pressure before disassembling pneumatic fittings to avoid

personal injury caused by high pressure gas.

Note

When re-assembling, inspect all parts for deterioration. Replace them if necessary. Use

appropriate screws and parts.

After repairs are completed or parts replaced, you are required to perform the checkout

procedure. Please refer to Service Manual PART 4 “Checkout and Test”.

- 3 -

1 Tools

During disassembling and replacing, the following tools may be required:

Inner hexagon wrench

Electric screwdriver

Diagonal pliers

Flathead screwdriver

Drawer spacing fixer

M4 sleeve screwdriver

Flow meter positioning fixture

Adjustable wrench

Tweezers

2 Preparations for Disassembly

Before disassembly,

1. Make sure:

The anesthesia machine is stopped.

Bleed the gas pressure from the anesthesia machine as described below.

Disconnect the AC power supply.

Disconnect all pipeline and cylinder gas supplies.

Prepare the tools required for disassembly.

Maneuver the anesthesia machine to an appropriate location and then step the four caster

brakes to fix the machine.

- 4 -

2. Bleeding Gas Pressure

Make sure to bleed the gas pressure from the anesthesia machine before disassembling

pneumatic fittings to avoid personal injury or equipment damage. Bleed gas pressure as

follows:

1. Set the system switch to ON.

2. Close other cylinder valves and disconnect pipeline gas supplies. Do not disconnect the

O2 pipeline. If pipeline O2 is not available, connect O2 cylinder and open the O2 cylinder

valve.

3. Turn the flow controls for all gases (except O2) to the minimum flow.

4. Ensure that all cylinder and pipeline pressure gauges read zero.

5. Disconnect the O2 pipeline supply (or close the O2 cylinder valve). Press the O2 flush

button to bleed O2 from the system.

6. Set the system switch to OFF.

- 5 -

3 Circuit System Disassembly

3.1 Remove the Top Panel

1 Pry up the eight screws covers and unscrew the eight screws exposed.

2 Lift the top panel followed by disconnecting the cable marked in the picture.

- 6 -

3. Then you can see the circuit part.

3.2 Remove the CPU board

★Please first finish Part 3.1, then:

Disconnect all the cables and remove the four screws and then take out the CPU board.

- 7 -

3.3 Remove the Button Board

★Please first finish Part 3.1, then:

Disconnect all the cables and remove the four screws and then take out the button board.

3.4 Remove the Monitor Board

★Please first finish Part 3.1, then:

Disconnect all the cables and tubes from the monitor board. Then unscrew the four

screws marked in the picture to remove the monitor board.

- 8 -

3.5 Remove the Net Board

★Please first finish Part 3.1, then:

Disconnect the cable from the CPU board to the net board and remove the two screws

then take out the net board.

3.6 Remove the CIS interface board

★Please first finish Part 3.1, then:

Disconnect the cable from the CPU board to the net board and remove the three screws

then take out the CIS interface board.

- 9 -

3.7 Remove the Built-in Batteries

★Please first finish Part 3.1, then:

Unscrew the six screws (marked in the picture) and the two nuts on the battery assembly.

Disconnect the cable to take out the battery box.

- 10 -

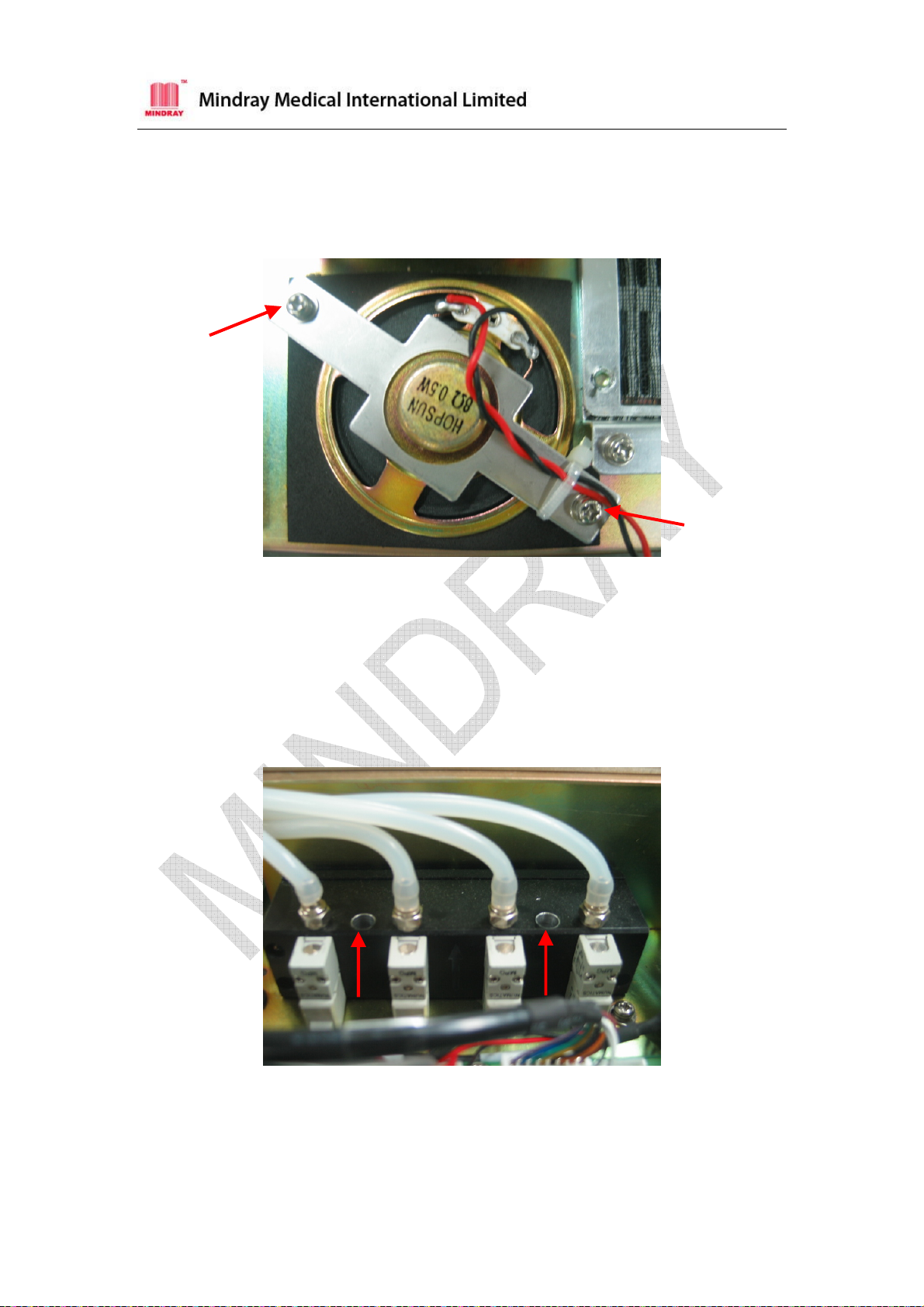

3.8 Remove the Speaker

★Please first finish Part 3.1, then:

Disconnect the cables from the speaker. Unscrew the two screws to remove the speaker.

3.9 Remove the Three-way Valve

★Please first finish Part 3.1, then:

Disconnect the cables and tubes from the three-way valve. Then unscrew the two screws

marked in the picture to remove the three-way valve.

- 11 -

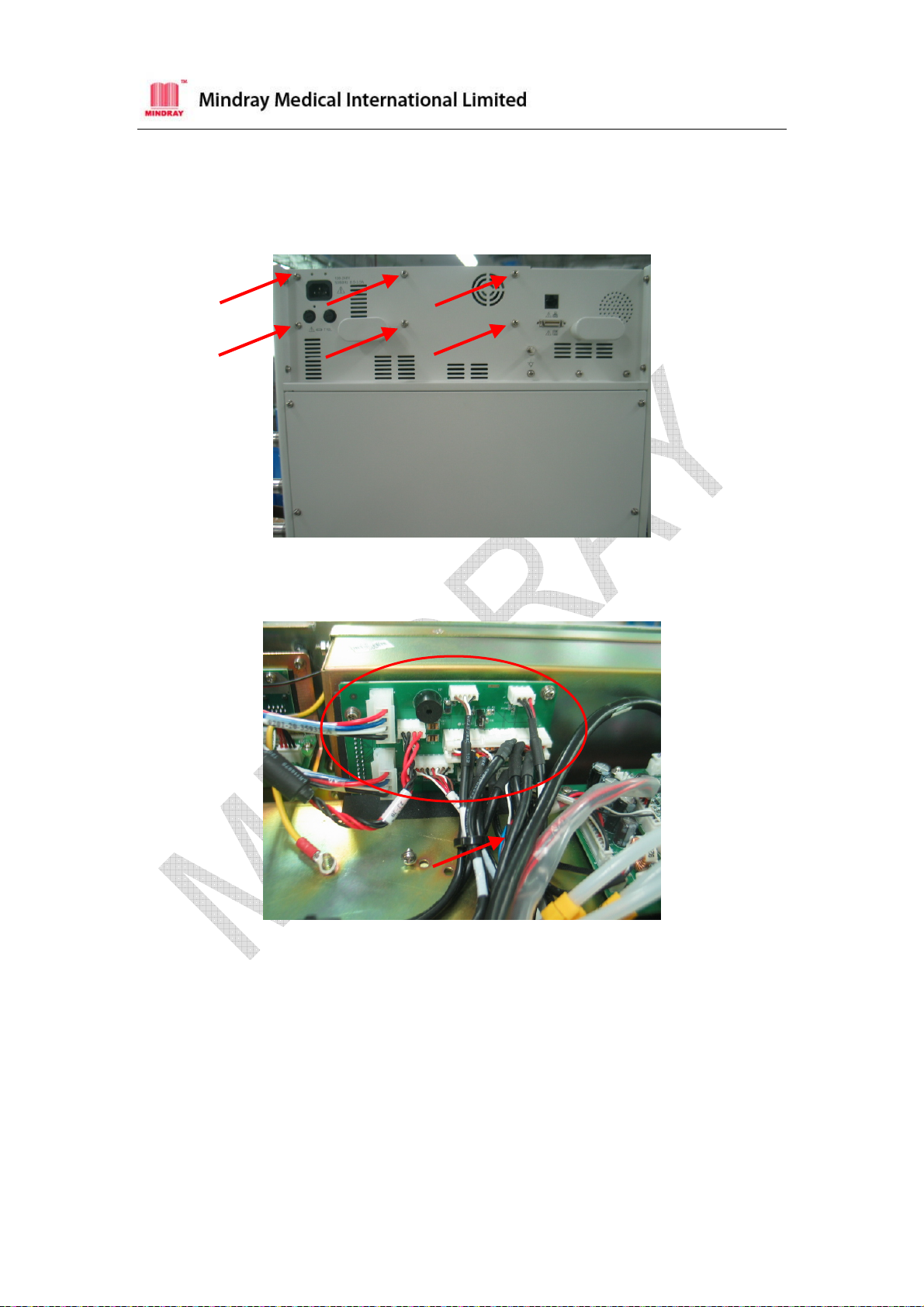

3.10 Remove the Power Board

★Please first finish Part 3.1, then:

1 Unscrew the six screws as shown below.

2 Take out the power box after disconnecting the cables from the power conversion

board marked in the picture.

- 12 -

3 Disconnect the five screws on the power conversion board marked in the picture.

4 Unscrew the four screws on both sides of the power box to open the power box.

5 Unscrew the four screws marked in the picture to remove the power board.

- 13 -

4 Pneumatic System Disassembly

4.1 Remove the Upper Rear Panel

1 Unscrew the six screws to remove the upper rear panel as shown below.

2 Then you can see the Pneumatic System as below.

- 14 -

4.2 Remove the Front Panel

★Please first finish Part 3.1, Part 4.1, then:

Unscrew the two screws and then disconnect the pipes connecting from the front panel to

system switch, O2 flush button, flow meter, needle valves, pressure gauges, and carefully

take the panel out.

4.3 Remove the Display Assembly

★Please first finish Part 3.1, Part 4.1, Part 4.2, then:

1 Disconnect all the related cables and unscrew the ten screws shown in the picture.

- 15 -

2 Unscrew the two screws marked in the picture and take off the button board

communication cable.

3 Turn over the assembly. Disconnect the cables and unscrew the four screws marked

in the picture to remove the display.

- 16 -

4.4 Remove the High Voltage Inverter

★Please first finish Part 3.1, Part 4.1, Part 4.2, Part 4.3, then:

Unscrew the two screws and remove the high voltage inverter

4.5 Remove the System Switch

★Please first finish Part 3.1, Part 4.1, Part 4.2, then:

1 Unscrew the two screws as shown below.

- 17 -

2 Unscrew the other two screws on the other side to remove the system switch

assembly.

4.6 Remove the Flow Meter control board.

★Please first finish Part 3.1, Part 4.1, Part 4.2, Part 4.3, then:

1 Disconnect all the pipes marked in the picture.

2 Unscrew the four screws marked in the picture to remove the electronic flow meter

control board.

- 18 -

4.7 Remove the Alarm Light

★Please first finish Part 3.1, Part 4.1, Part 4.2, Part 4.3, then:

Unscrew the three screws and remove the alarm light

- 19 -

4.8 Remove the Encoder Board

★Please first finish Part 3.1, Part 4.1, Part 4.2, Part 4.3, then:

Pull out the encoder cover and then rotate the nut to remove the Encoder board.

4.9 Remove the O2 Flush Button

★Please first finish Part 3.1, Part 4.1, Part 4.2, then:

Disconnect the gas pipes and cables on the O2 flush button assembly. Then unscrew the

four screws to remove the O2 flush button assembly.

- 20 -

4.10 Remove the Pipeline or Cylinder Pressure Gauges

Each pipeline or cylinder pressure gauge can be removed alone in the same way. The

following takes AIR cylinder pressure gauge for an example.

★Please first finish Part 3.1, Part 4.1, Part 4.2, then:

1 Find the AIR cylinder pressure gauge by referring to the gauge label in the front of the

anaesthesia machine.

2 Disconnect the gas pipes from the AIR pressure gauge. Then unscrew the two

screws marked in the picture to take out the pressure gauge.

- 21 -

4.11 Remove the Flow Meter

★Please first finish Part 3.1, Part 4.1, Part 4.2, then:

Unscrew the six screws marked in the picture to remove the total flow meter.

4.12 Remove the Needle Valves

★Please first finish Part 3.1, Part 4.1, Part 4.2, then:

Unscrew the seven screws with an inner hexagon wrench and then you can take out the

needle valves.

- 22 -

4.13 Remove the Module Socket Communication Board (NIOS)

★Please first finish Part 4.1, then:

Unscrew the five screws and disconnect all the cables, take out the module socket

communication board. (The NIOS module)

4.14 Remove the Pipeline Gas Supply Inlet Assembly

★Please first finish Part 4.1, then:

Disconnect the gas pipes on the pipeline gas supply inlet assembly. Unscrew the four

screws marked in the pictures to remove the pipeline gas supply inlet assembly.

- 23 -

4.15 Disassemble the Pipeline Gas Supply Inlet Assembly

★Please first finish Part 4.1, Part 4.14, then:

1 Unscrew the four screws on the gas pipe tail fitting to remove the tail fitting.

Gas pipe connector Gas pipe support Gas pipe tail fitting

2 Replace the seal on the gas pipe tail fitting and the filter on the gas pipe connector.

Seal

Filter

- 24 -

4.16 Remove the ACGO Switch

★Please first finish Part 4.1, then:

Disconnect the gas pipes and cables on the ACGO switch assembly. Then unscrew the

three screws to remove the ACGO switch assembly.

4.17 Remove the Breathing Valve Assembly

★Please first finish Part 4.1, then:

1 Disconnect the cables and pipes from the breathing valve assembly. Then unscrew

the three screws marked in the picture.

- 25 -

2 Pull the breathing valve assembly as the direction shown in the picture to take it out.

4.18 Remove the O2-N2O block valve

★Please first finish Part 4.1, then:

Unscrew the two screws and take the O2-N2O block valve out.

- 26 -

5 Electrical and Pneumatic Diagrams

5.1 Electrical Connections

- 27 -

5.2 Pneumatic Connections

Pneumatic Connection (configured with O2, N2O and AIR supplies, high-pressure

cylinders and auxiliary O2 supply)

- 28 -

5.3 Modular Connections

- 29 -

Loading...

Loading...